Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite

Abstract

:1. Introduction

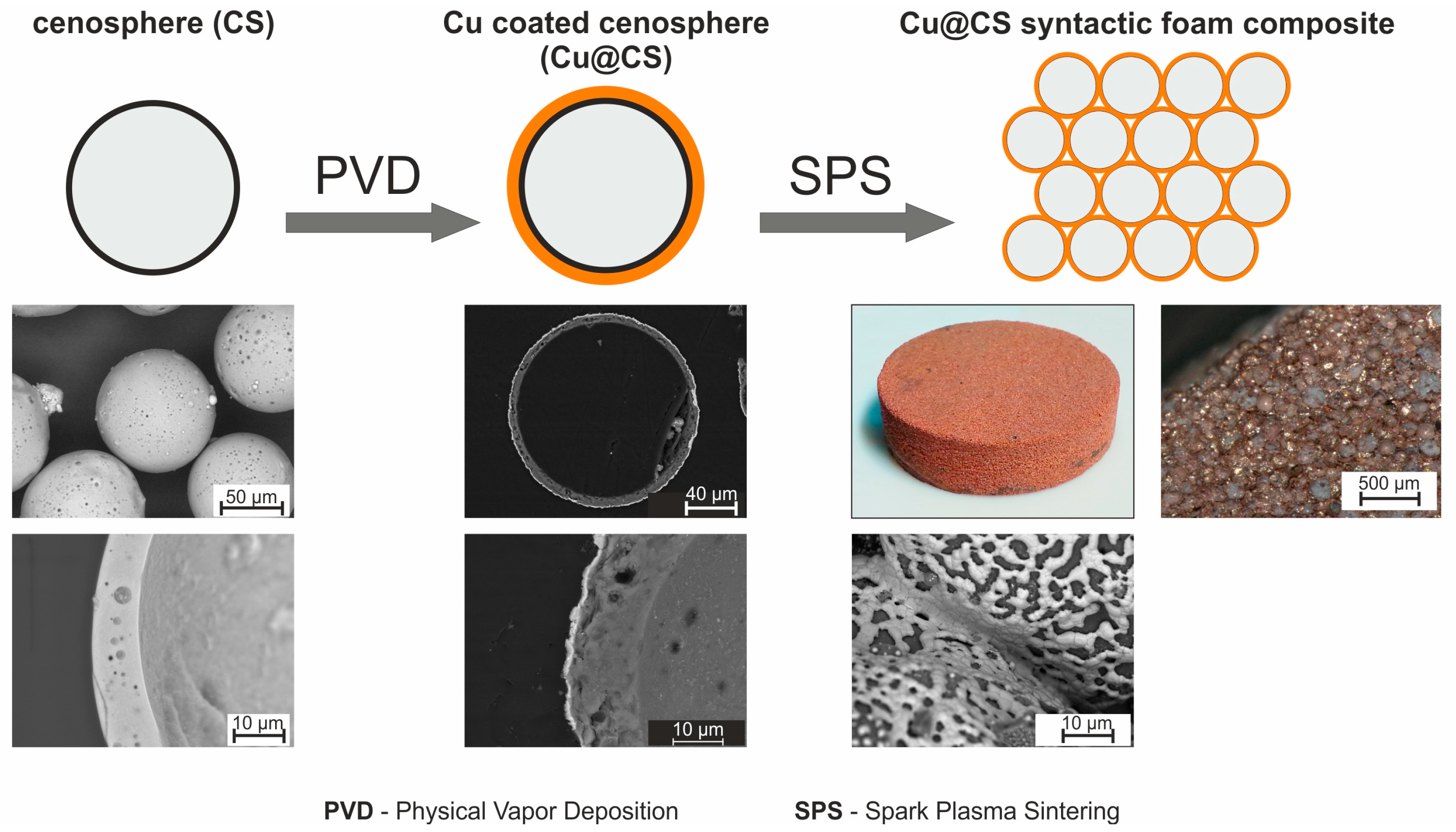

2. Materials and Methods

3. Results and Discussion

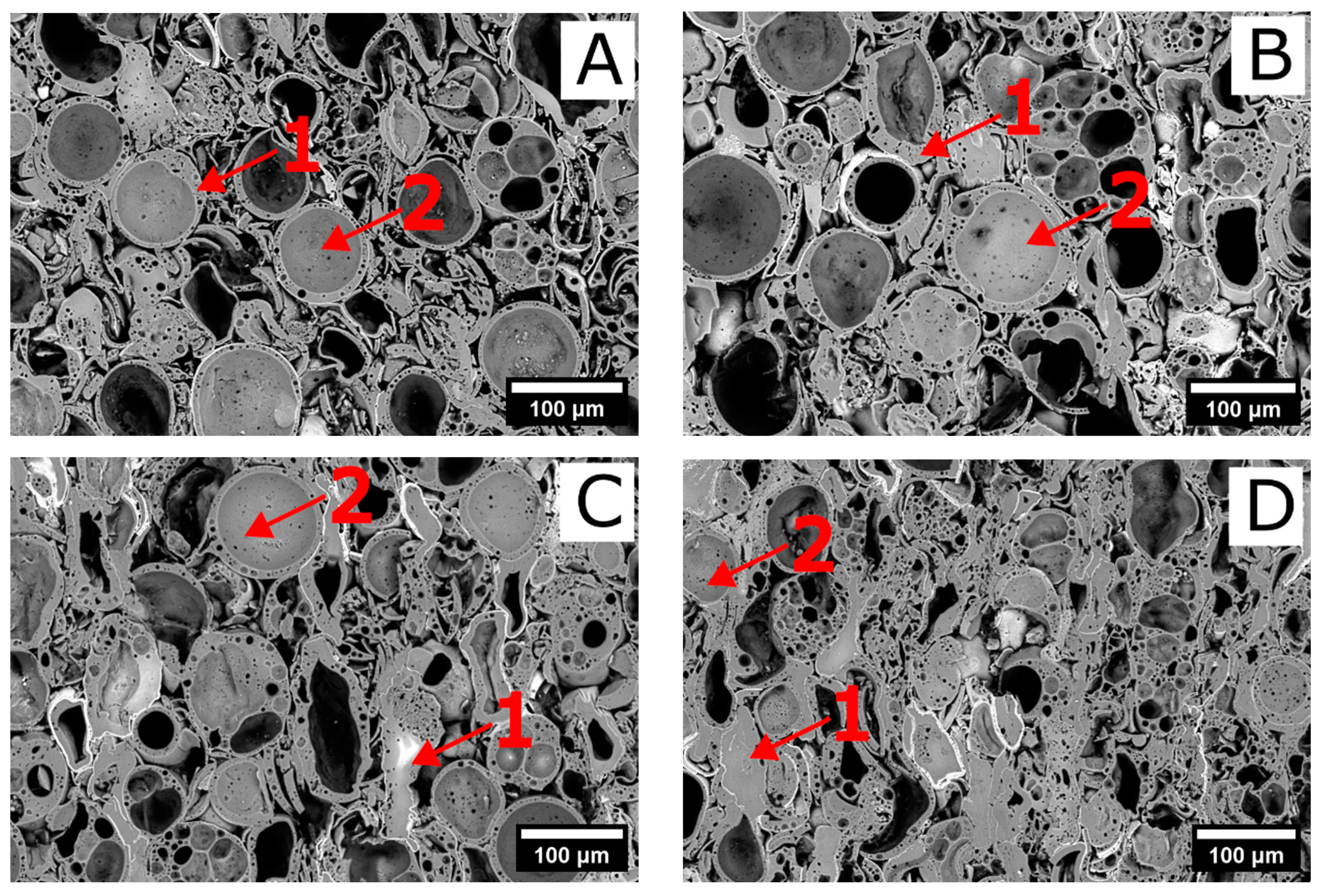

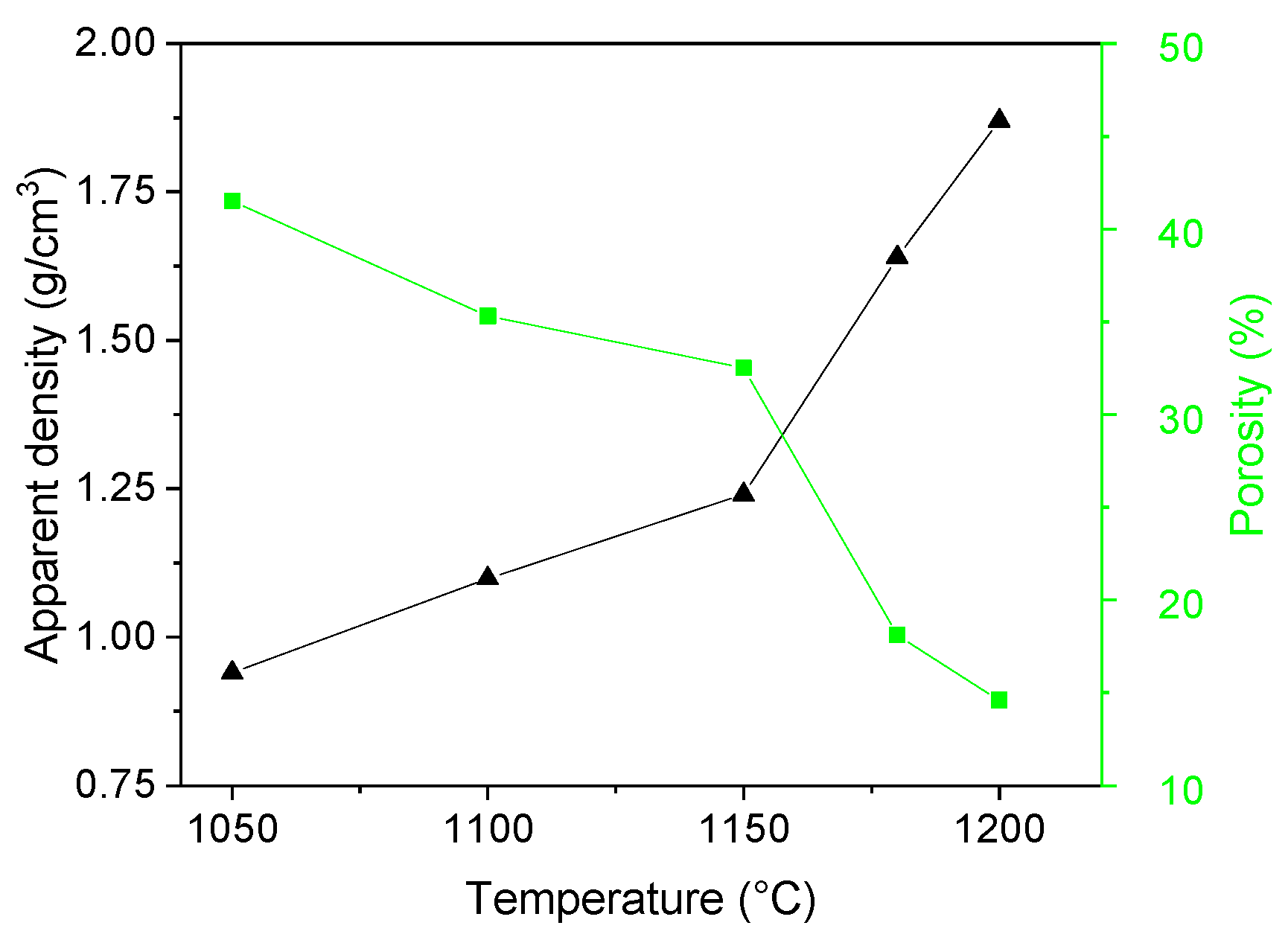

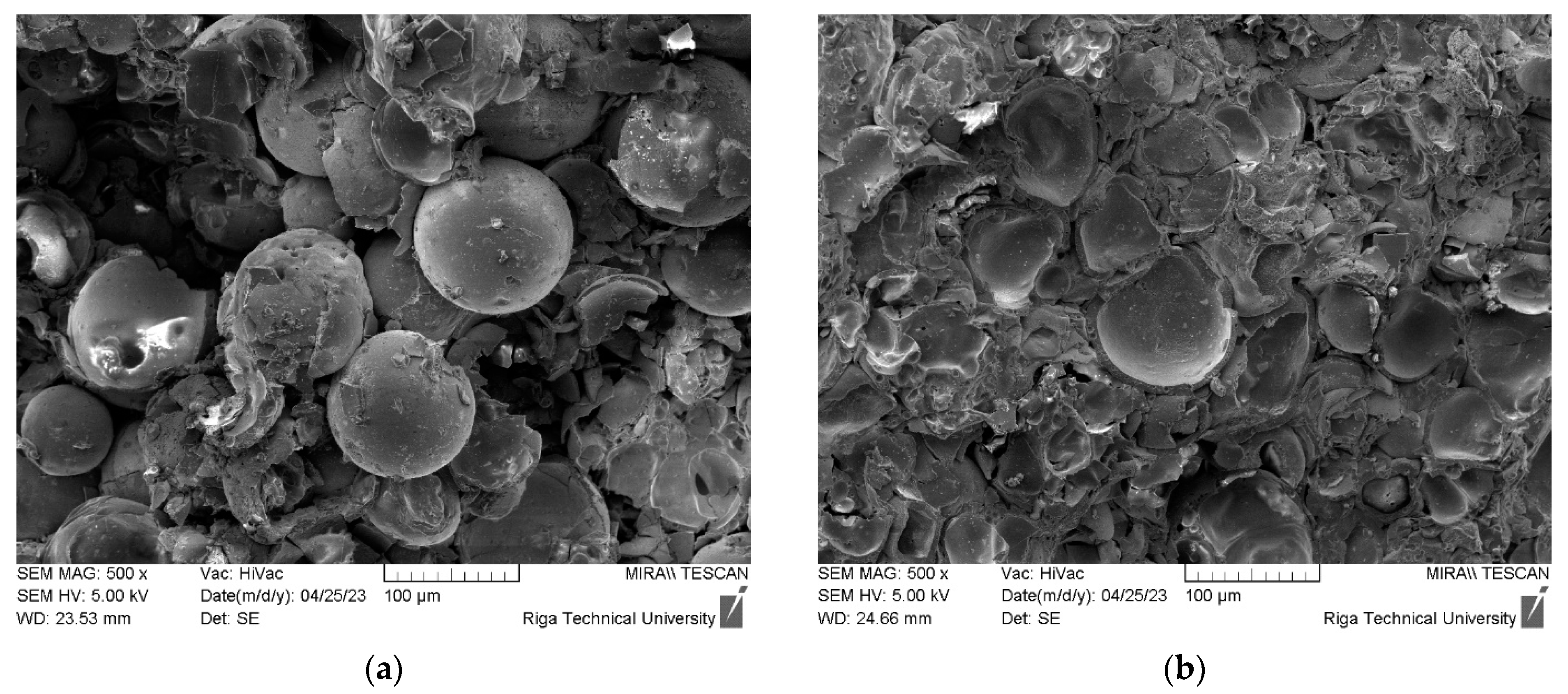

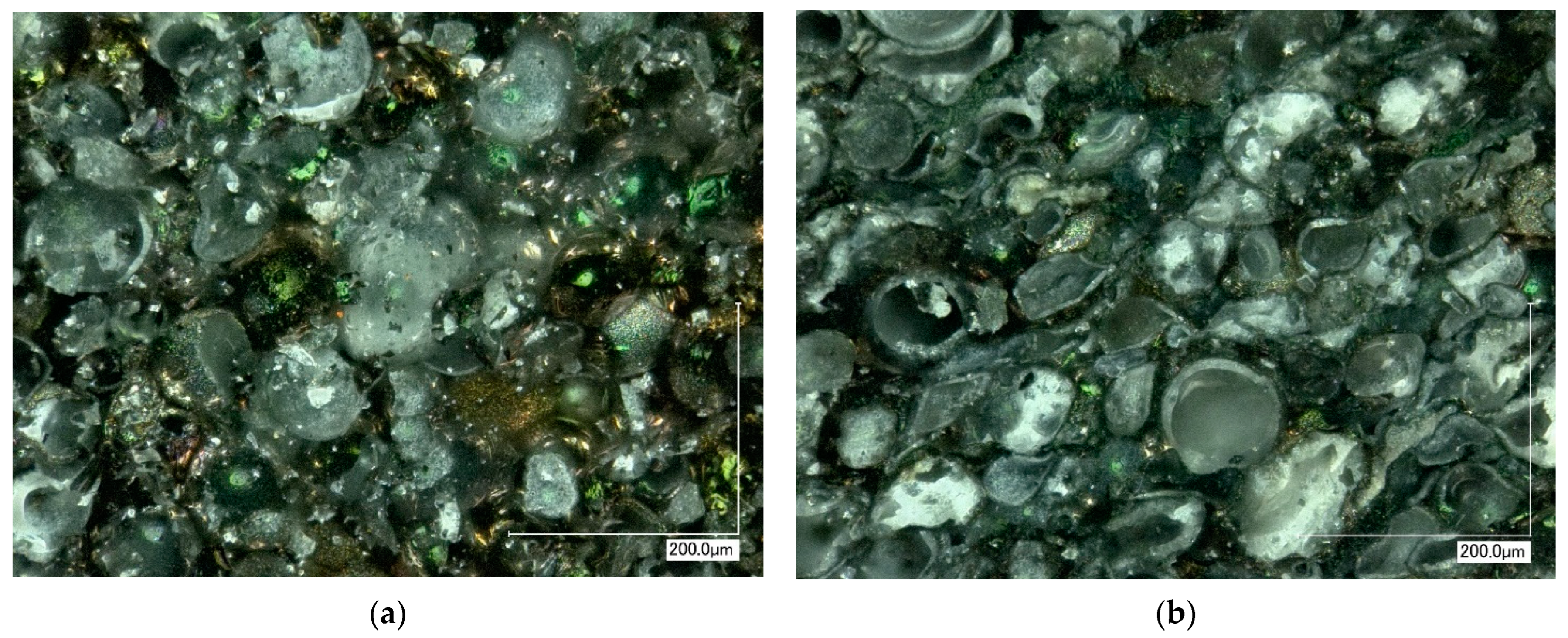

3.1. Microstructure of the Samples

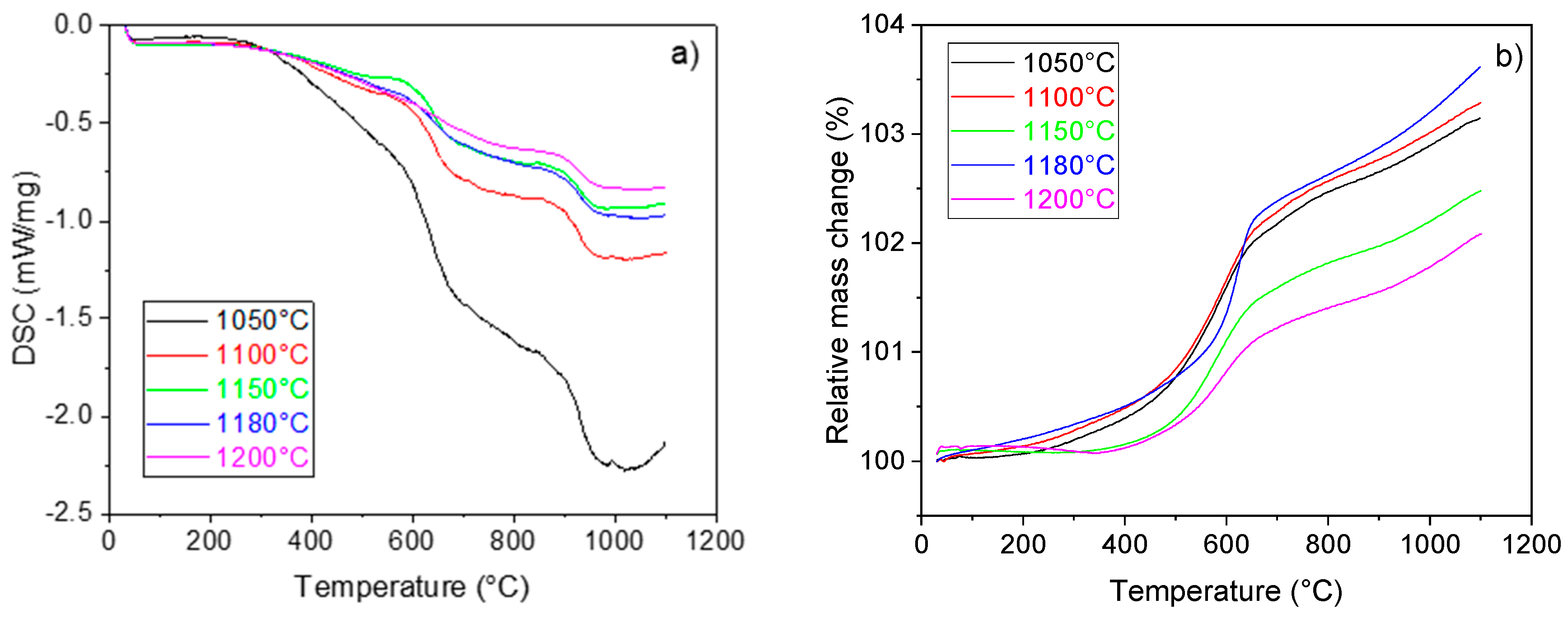

3.2. Thermal Analyses

3.3. Thermal Diffusivity

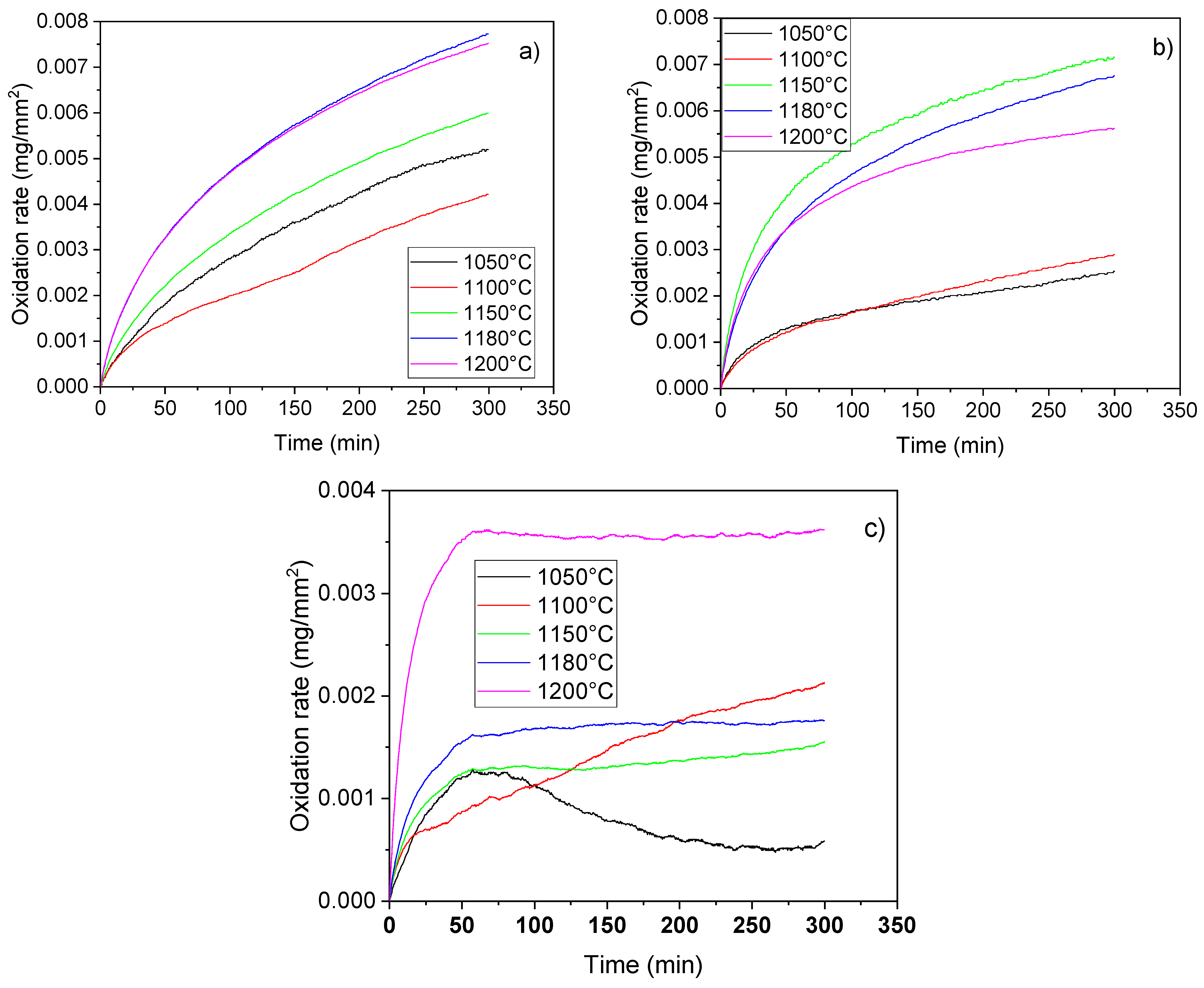

3.4. Oxidation Resistance

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.-D. Introduction to Composite Materials. In Composite and Nanocomposite Materials—From Knowledge to Industrial Applications; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar] [CrossRef]

- Mavhungu, S.; Akinlabi, E.; Onitiri, M.; Varachia, F. Aluminum Matrix Composites for Industrial Use: Advances and Trends. Procedia Manuf. 2017, 7, 178–182. [Google Scholar] [CrossRef]

- Afolabi, L.O.; Ariff, Z.M.; Hashim, S.F.S.; Alomayri, T.; Mahzan, S.; Kamarudin, K.-A.; Muhammad, I.D. Syntactic foams formulations, production techniques, and industry applications: A review. J. Mater. Res. Technol. 2020, 9, 10698–10718. [Google Scholar] [CrossRef]

- Ahonen, M.; Koppel, T. Mobile learning and health-risk management of pulsed microwave technologies. In Proceedings of the 11th International Conference on Mobile and Contextual Learning 2012, Helsinki, Finland, 16–18 October 2012; CEUR Workshop Proceedings. pp. 134–139. [Google Scholar]

- Koppel, T.; Tint, P. Reducing exposure to extremely low frequency electromagnetic fields from portable computers. Agron. Res. 2014, 12, 863–874. [Google Scholar]

- Yahyaei, H.; Mohseni, M. Nanocomposites Based EMI Shielding Materials. In Advanced Materials for Electromagnetic Shielding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 263–288. [Google Scholar] [CrossRef]

- Ray, B.; Parmar, S.; Datar, S. Flexible and Transparent EMI Shielding Materials. In Advanced Materials for Electromagnetic Shielding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 167–175. [Google Scholar] [CrossRef]

- Dhar, S.; Rogers, A.; Abdala, C. Breaking away: Violation of distortion emission phase-frequency invariance at low frequencies. J. Acoust. Soc. Am. 2011, 129, 3115–3122. [Google Scholar] [CrossRef] [PubMed]

- Teli, M.D.; Valia, S.P. Graphene and CNT Based EMI Shielding Materials. In Advanced Materials for Electromagnetic Shielding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 241–261. [Google Scholar] [CrossRef]

- Surendran, A.; Ajitha, A.R.; Thomas, S.; Geethamma, V.G.; Aswathi, M.K. Advanced Carbon Based Foam Materials for EMI Shielding. In Advanced Materials for Electromagnetic Shielding; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 305–325. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Group, S.I. Electromagnetic Shielding Effectiveness of Cementitious Composites. Constr. Build. Mater. 2020, 285, 122842. [Google Scholar] [CrossRef]

- Amonette, J.E.; Matyáš, J. Functionalized silica aerogels for gas-phase purification, sensing, and catalysis: A review. Microporous Mesoporous Mater. 2017, 250, 100–119. [Google Scholar] [CrossRef]

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Pavel, S.; Ladislav, M.; Radimir, V.; Jiri, J.; Rene, C. The Modified Cement Composite Materials for Electromagnetic Shielding and Stress Detections. In ICONS 2015: The Tenth International Conference on Systems; IARIA: Barcelona, Spain, 2015; pp. 83–86. [Google Scholar]

- Moglie, F.; Micheli, D.; Laurenzi, S.; Marchetti, M.; Primiani, V.M. Electromagnetic shielding performance of carbon foams. Carbon 2012, 50, 1972–1980. [Google Scholar] [CrossRef]

- Letellier, M.; Macutkevic, J.; Kuzhir, P.; Banys, J.; Fierro, V.; Celzard, A. Electromagnetic properties of model vitreous carbon foams. Carbon 2017, 122, 217–227. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Pei, X.; Zhang, Y.; Yi, D.; Zhai, W.; Zhang, L.; Wei, X.; Zheng, W. Ultrathin carbon foams for effective electromagnetic interference shielding. Carbon 2016, 100, 375–385. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Ai, S.; Hou, B.; Zhang, J.; Liang, X.; Zhou, Q.; Liu, H.; Cui, S. Porous SiC/melamine-derived carbon foam frameworks with excellent electromagnetic wave absorbing capacity. J. Adv. Ceram. 2019, 8, 479–488. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Yan, Q.; Zheng, W.-G.; He, Z.; Yu, Z.-Z. Tough Graphene−Polymer Microcellular Foams for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Yan, D.-X.; Ren, P.-G.; Pang, H.; Fu, Q.; Yang, M.-B.; Li, Z.-M. Efficient electromagnetic interference shielding of lightweight graphene/polystyrene composite. J. Mater. Chem. 2012, 22, 18772–18774. [Google Scholar] [CrossRef]

- Arjmand, M.; Apperley, T.; Okoniewski, M.; Sundararaj, U. Comparative study of electromagnetic interference shielding properties of injection molded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon 2012, 50, 5126–5134. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L.; Lawrence, R.W. A Comparative Study of EMI Shielding Properties of Carbon Nanofiber and Multi-Walled Carbon Nanotube Filled Polymer Composites. J. Nanosci. Nanotechnol. 2005, 5, 927–931. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Shishkin, A.; Koppel, T.; Gupta, N. A review of porous lightweight composite materials for electromagnetic interference shielding. Compos. Part B Eng. 2018, 149, 188–197. [Google Scholar] [CrossRef]

- Pokhrel, A.; Seo, D.N.; Lee, S.T.; Kim, I.J. Processing of Porous Ceramics by Direct Foaming: A Review. J. Korean Ceram. Soc. 2013, 50, 93–102. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Wadley, H.N.G. Metal Foams: A Design Guide, 1st ed.; Butterworth Heinemann: Woburn, MA, USA, 2000; Available online: http://www.sciencedirect.com/science/article/pii/B9780750672191500064 (accessed on 7 May 2016).

- Colombo, P. Ceramic foams: Fabrication, properties and applications. Key Eng. Mater. 2001, 206 Pt 3, 1913–1918. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-0034769221&partnerID=40&md5=d3500b975b3cf77f7ab00f3a1584c037 (accessed on 8 November 2023).

- Thiyagarajan, R.; Kumar, M.S. A Review on Closed Cell Metal Matrix Syntactic Foams: A Green Initiative towards Eco-Sustainability. Mater. Manuf. Process. 2021, 36, 1333–1351. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Effects of hollow fly-ash particles on the properties of magnesium matrix syntactic foams: A review. Mater. Perform. Charact. 2016, 5, 116–131. [Google Scholar] [CrossRef]

- Yousaf, Z.; Smith, M.; Potluri, P.; Parnell, W. Compression properties of polymeric syntactic foam composites under cyclic loading. Compos. Part B Eng. 2020, 186, 107764. [Google Scholar] [CrossRef]

- Valencia-Villegas, J.P.; Mesa, A.M.G.; Arbeláez-Pérez, O.F. Properties of modified concrete with crumb rubber: Effect of the incorporation of hollow glass microspheres. Rev. Fac. Ing. Univ. Antioq. 2020, 98, 59–68. [Google Scholar] [CrossRef]

- Bai, C.; Shao, J.; Li, X.; Zhang, Z.; Qiao, Y.; Hao, J.; Li, H.; Zheng, T.; Colombo, P. Fabrication and properties of slag-based geopolymer syntactic foams containing hollow glass microspheres. Mater. Lett. 2022, 308, 131158. [Google Scholar] [CrossRef]

- Xia, B.; Wang, Z.; Gou, L.; Zhang, M.; Guo, M. Porous mullite ceramics with enhanced compressive strength from fly ash-based ceramic microspheres: Facile synthesis, structure, and performance. Ceram. Int. 2022, 48, 10472–10479. [Google Scholar] [CrossRef]

- Lin, J.-H.; Hsu, P.-Y.; Huang, C.-H.; Lai, M.-F.; Shiu, B.-C.; Lou, C.-W. Functional Hollow Ceramic Microsphere/Flexible Polyurethane Foam Composites with a Cell Structure: Mechanical Property and Sound Absorptivity. Polymers 2022, 14, 913. [Google Scholar] [CrossRef] [PubMed]

- He, S.; Carolan, D.; Fergusson, A.; Taylor, A.C. Investigating the transfer of toughness from rubber modified bulk epoxy polymers to syntactic foams. Compos. Part B Eng. 2022, 245, 110209. [Google Scholar] [CrossRef]

- Abedin, R.; Feng, X.; Pojman, J.; Ibekwe, S.; Mensah, P.; Warner, I.; Li, G. A Thermoset Shape Memory Polymer-Based Syntactic Foam with Flame Retardancy and 3D Printability. ACS Appl. Polym. Mater. 2022, 4, 1183–1195. [Google Scholar] [CrossRef]

- Al-Sahlani, K.; Taherishargh, M.; Kisi, E.; Fiedler, T. Controlled Shrinkage of Expanded Glass Particles in Metal Syntactic Foams. Materials 2017, 10, 1073. [Google Scholar] [CrossRef]

- Movahedi, N.; Fiedler, T.; Taşdemirci, A.; Murch, G.E.; Belova, I.V.; Güden, M. Impact loading of functionally graded metal syntactic foams. Mater. Sci. Eng. A 2022, 839, 142831. [Google Scholar] [CrossRef]

- Movahedi, N.; Murch, G.E.; Belova, I.V.; Fiedler, T. Functionally graded metal syntactic foam: Fabrication and mechanical properties. Mater. Des. 2019, 168, 107652. [Google Scholar] [CrossRef]

- Arunachalam, K.P.; Avudaiappan, S.; Flores, E.I.S.; Parra, P.F. Experimental Study on the Mechanical Properties and Microstructures of Cenosphere Concrete. Materials 2023, 16, 3518. [Google Scholar] [CrossRef] [PubMed]

- Tanirbergenova, S.K.; Dinistanova, B.K.; Zhylybayeva, N.K.; Tugelbayeva, D.A.; Moldazhanova, G.M.; Aitugan, A.; Taju, K.; Nazhipkyzy, M. Synthesis of Cenospheres from Ash and Their Application. J. Compos. Sci. 2023, 7, 276. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Lu, Z.; Sun, M.; Li, Z. Fiber-reinforced cementitious composites incorporating glass cenospheres—Mechanical properties and microstructure. Constr. Build. Mater. 2017, 154, 529–538. [Google Scholar] [CrossRef]

- Ren, S.; Tao, X.; Xu, X.; Guo, A.; Liu, J.; Fan, J.; Ge, J.; Fang, D.; Liang, J. Preparation and characteristic of the fly ash cenospheres/mullite composite for high-temperature application. Fuel 2018, 233, 336–345. [Google Scholar] [CrossRef]

- Shao, Y.; Jia, D.; Liu, B. Characterization of porous silicon nitride ceramics by pressureless sintering using fly ash cenosphere as a pore-forming agent. J. Eur. Ceram. Soc. 2009, 29, 1529–1534. [Google Scholar] [CrossRef]

- John, B.; Nair, C.P.R. Thermosetting polymer based syntactic foams: An overview. In Handbook of Thermoset Plastics; Elsevier: Amsterdam, The Netherlands, 2022; pp. 801–832. [Google Scholar] [CrossRef]

- Krella, A. Resistance of PVD Coatings to Erosive and Wear Processes: A Review. Coatings 2020, 10, 921. [Google Scholar] [CrossRef]

- Schmid, G.; Eisenmenger-Sittner, C.; Hell, J.; Horkel, M.; Keding, M.; Mahr, H. Optimization of a container design for depositing uniform metal coatings on glass microspheres by magnetron sputtering. Surf. Coat. Technol. 2010, 205, 1929–1936. [Google Scholar] [CrossRef]

- Sharma, R.K.; Reddy, G. Effect of substrate temperature on the characteristics of α-MoO3 hierarchical 3D microspheres prepared by facile PVD process. J. Alloys Compd. 2014, 598, 177–183. [Google Scholar] [CrossRef]

- Schwinger, L.; Lehmann, S.; Zielbauer, L.; Scharfe, B.; Gerdes, T. Aluminum Coated Micro Glass Spheres to Increase the Infrared Reflectance. Coatings 2019, 9, 187. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Mineralogy of combustion wastes from coal-fired power stations. Fuel Process. Technol. 1996, 47, 261–280. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Kasar, A.K.; Gupta, N.; Rohatgi, P.K.; Menezes, P.L. A Brief Review of Fly Ash as Reinforcement for Composites with Improved Mechanical and Tribological Properties. JOM 2020, 72, 2340–2351. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Antonowicz, M.; Paszenda, Z.K. Cenospheres and their application advantages in biomedical engineering—A systematic review. Rev. Adv. Mater. Sci. 2020, 59, 115–130. [Google Scholar] [CrossRef]

- Shishkin, A.; Hussainova, I.; Kozlov, V.; Lisnanskis, M.; Leroy, P.; Lehmhus, D. Metal-Coated Cenospheres Obtained via Magnetron Sputter Coating: A New Precursor for Syntactic Foams. JOM 2018, 70, 1319–1325. [Google Scholar] [CrossRef]

- Shishkin, A.; Drozdova, M.; Kozlov, V.; Hussainova, I.; Lehmhus, D. Vibration-Assisted Sputter Coating of Cenospheres: A New Approach for Realizing Cu-Based Metal Matrix Syntactic Foams. Metals 2017, 7, 16. [Google Scholar] [CrossRef]

- Shishkin, A.; Abramovskis, V.; Zalite, I.; Singh, A.K.; Mezinskis, G.; Popov, V.; Ozolins, J. Physical, Thermal, and Chemical Properties of Fly Ash Cenospheres Obtained from Different Sources. Materials 2023, 16, 2035. [Google Scholar] [CrossRef]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Hill, R.J.; Howard, C.J. Quantitative phase analysis from neutron powder diffraction data using the Rietveld method. J. Appl. Crystallogr. 1987, 20, 467–474. [Google Scholar] [CrossRef]

- Ma, K.; Zhang, R.; Sun, J.; Liu, C. Oxidation Mechanism of Biomedical Titanium Alloy Surface and Experiment. Int. J. Corros. 2020, 2020, 1678615. [Google Scholar] [CrossRef]

| Phase ID | Sintering Temperature, °C | ||||

|---|---|---|---|---|---|

| 1050 | 1100 | 1150 | 1180 | 1200 | |

| Mullite | 47 | 50 | 43 | 47 | 51 |

| TiO | 4 | 3 | 3 | 3 | 3 |

| Quartz | 3 | 2 | 1 | 2 | 2 |

| Ti2O3 | 1 | <1 | 2 | 3 | 4 |

| Rutile | - | - | <1 | - | - |

| Cristobalite | - | - | <1 | 2 | 2 |

| Amorphous | 45 | 44 | 50 | 43 | 38 |

| Element | Sample ID | |||||||

|---|---|---|---|---|---|---|---|---|

| 1050 | 1100 | 1150 | 1180 | |||||

| 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | |

| O | 50 | 47 | 50 | 51 | 50 | 50 | 49 | 52 |

| Al | 18 | 22 | 23 | 21 | 18 | 25 | 14 | 20 |

| Si | 28 | 25 | 24 | 23 | 25 | 23 | 28 | 23 |

| Ti | 2 | 4 | 1 | 4 | 2 | 1 | 2 | 2 |

| K | <1 | <1 | <1 | <1 | <1 | - | 1 | <1 |

| Na | <1 | <1 | - | - | <1 | <1 | 2 | <1 |

| Ca | <1 | - | - | - | 2 | - | <1 | 2 |

| Mg | - | - | - | - | - | - | <1 | - |

| Fe | - | <1 | <1 | - | <1 | - | 2 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abramovskis, V.; Drunka, R.; Csáki, Š.; Lukáč, F.; Veverka, J.; Illkova, K.; Gavrilovs, P.; Shishkin, A. Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite. Materials 2023, 16, 7523. https://doi.org/10.3390/ma16247523

Abramovskis V, Drunka R, Csáki Š, Lukáč F, Veverka J, Illkova K, Gavrilovs P, Shishkin A. Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite. Materials. 2023; 16(24):7523. https://doi.org/10.3390/ma16247523

Chicago/Turabian StyleAbramovskis, Vitalijs, Reinis Drunka, Štefan Csáki, František Lukáč, Jakub Veverka, Ksenia Illkova, Pavels Gavrilovs, and Andrei Shishkin. 2023. "Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite" Materials 16, no. 24: 7523. https://doi.org/10.3390/ma16247523

APA StyleAbramovskis, V., Drunka, R., Csáki, Š., Lukáč, F., Veverka, J., Illkova, K., Gavrilovs, P., & Shishkin, A. (2023). Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite. Materials, 16(24), 7523. https://doi.org/10.3390/ma16247523