Surface Coatings of Reinforcement Phases in Magnesium Matrix Composites: A Review

Abstract

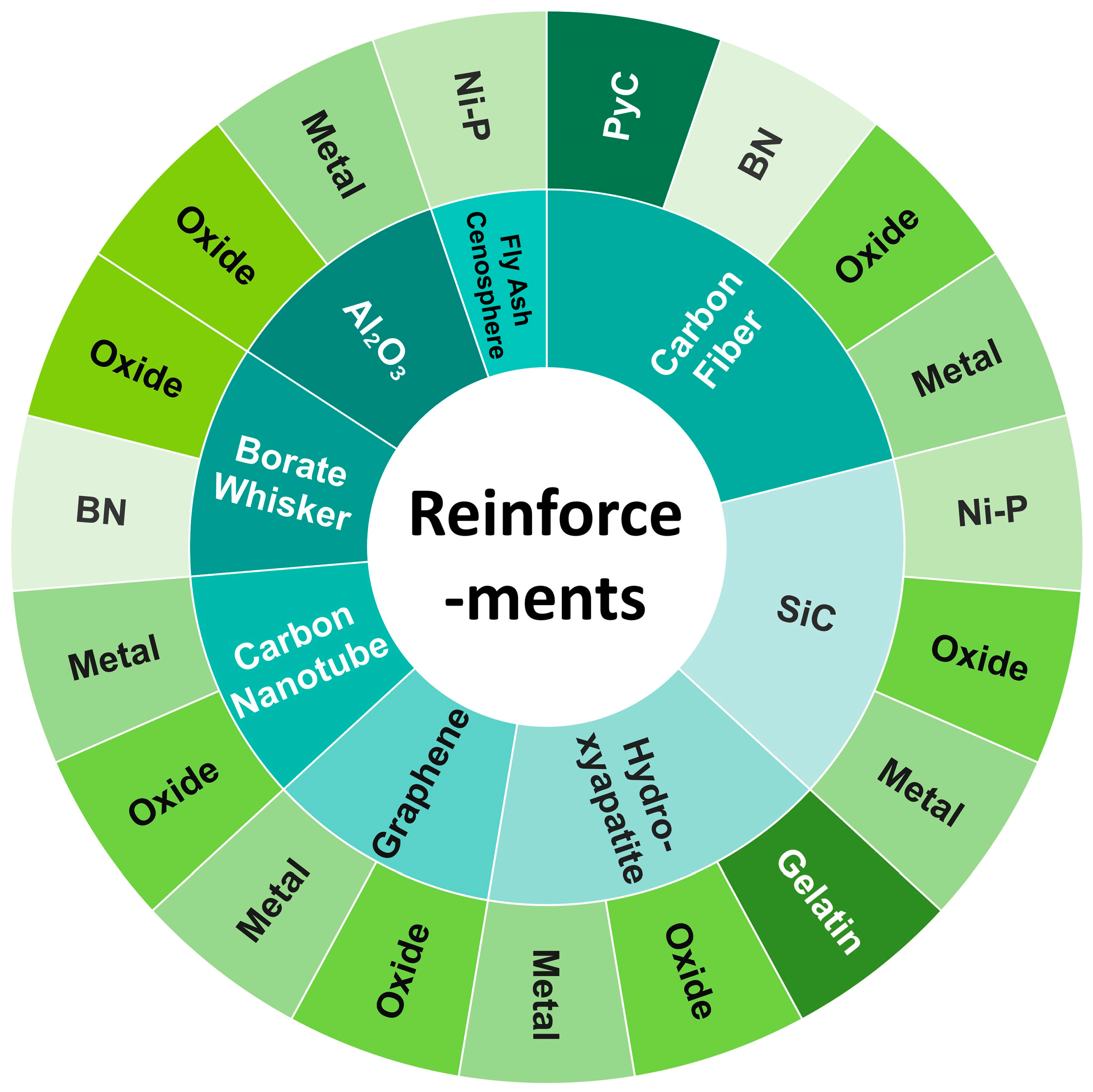

:1. Introduction

2. Carbon-Reinforced MMCs

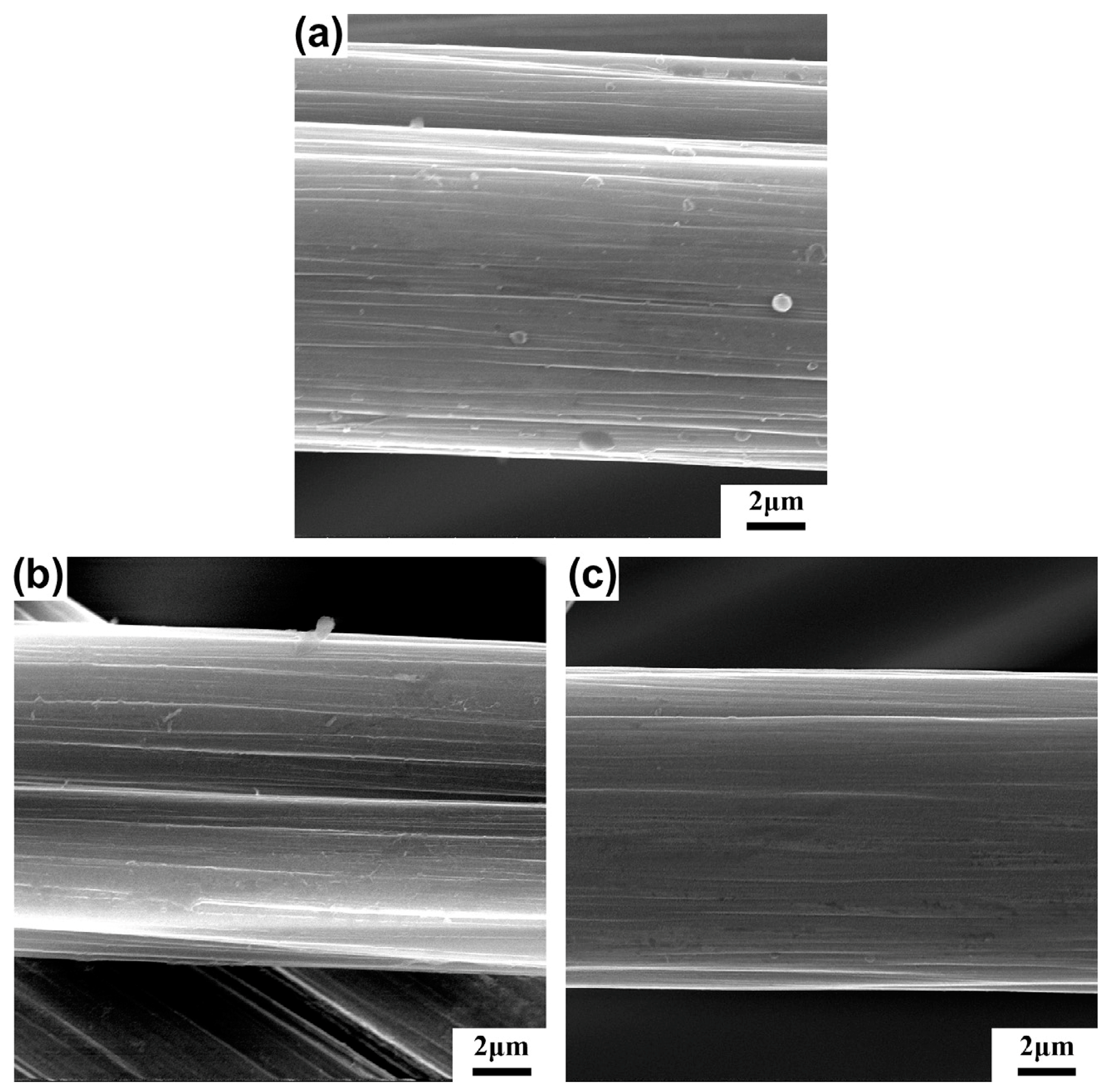

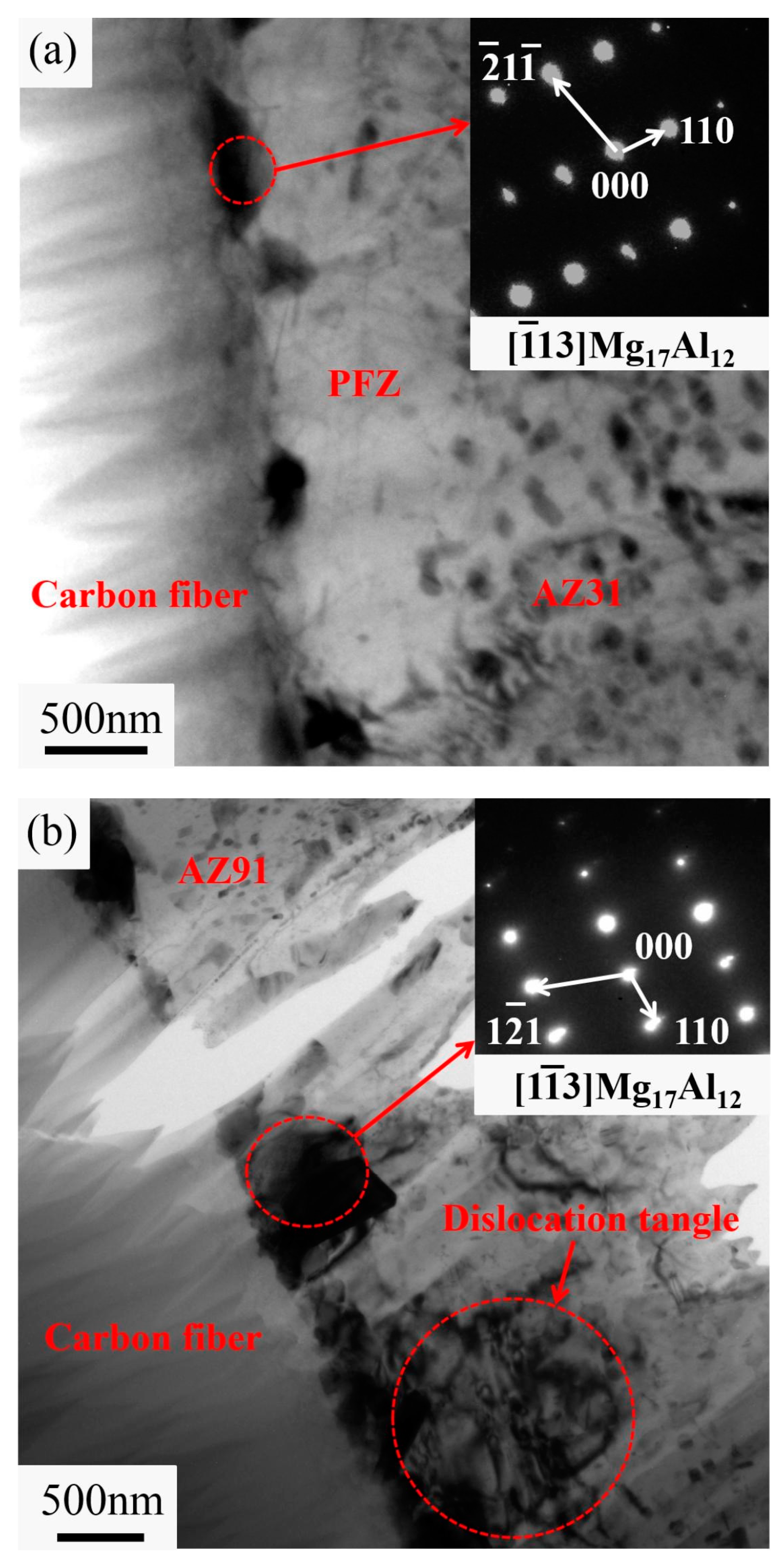

2.1. Carbon Fiber

2.1.1. Oxide Coatings

2.1.2. Pyrolytic Carbon Coatings

2.1.3. Metal Coatings

2.1.4. Other Coatings

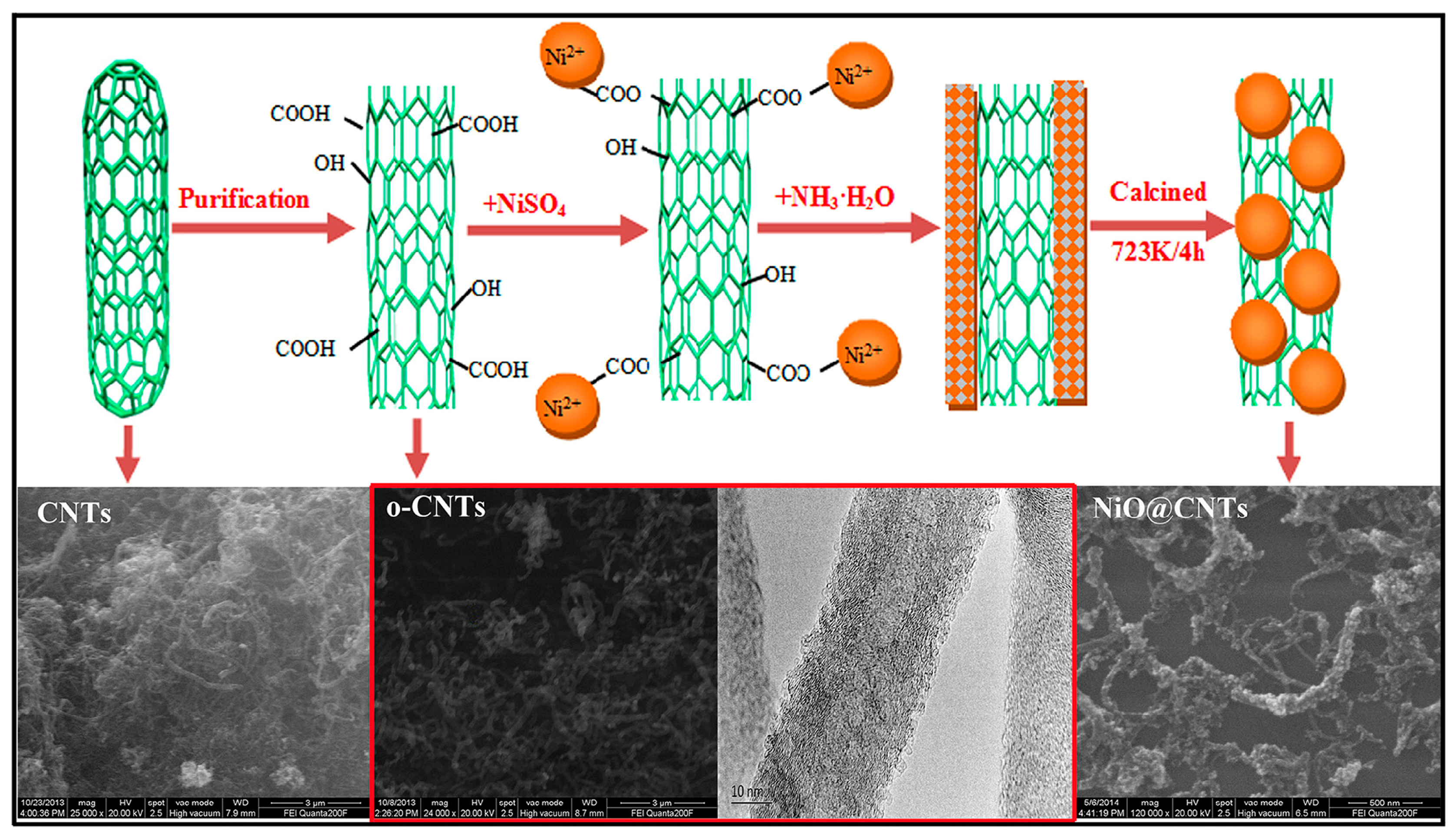

2.2. Carbon Nanotubes

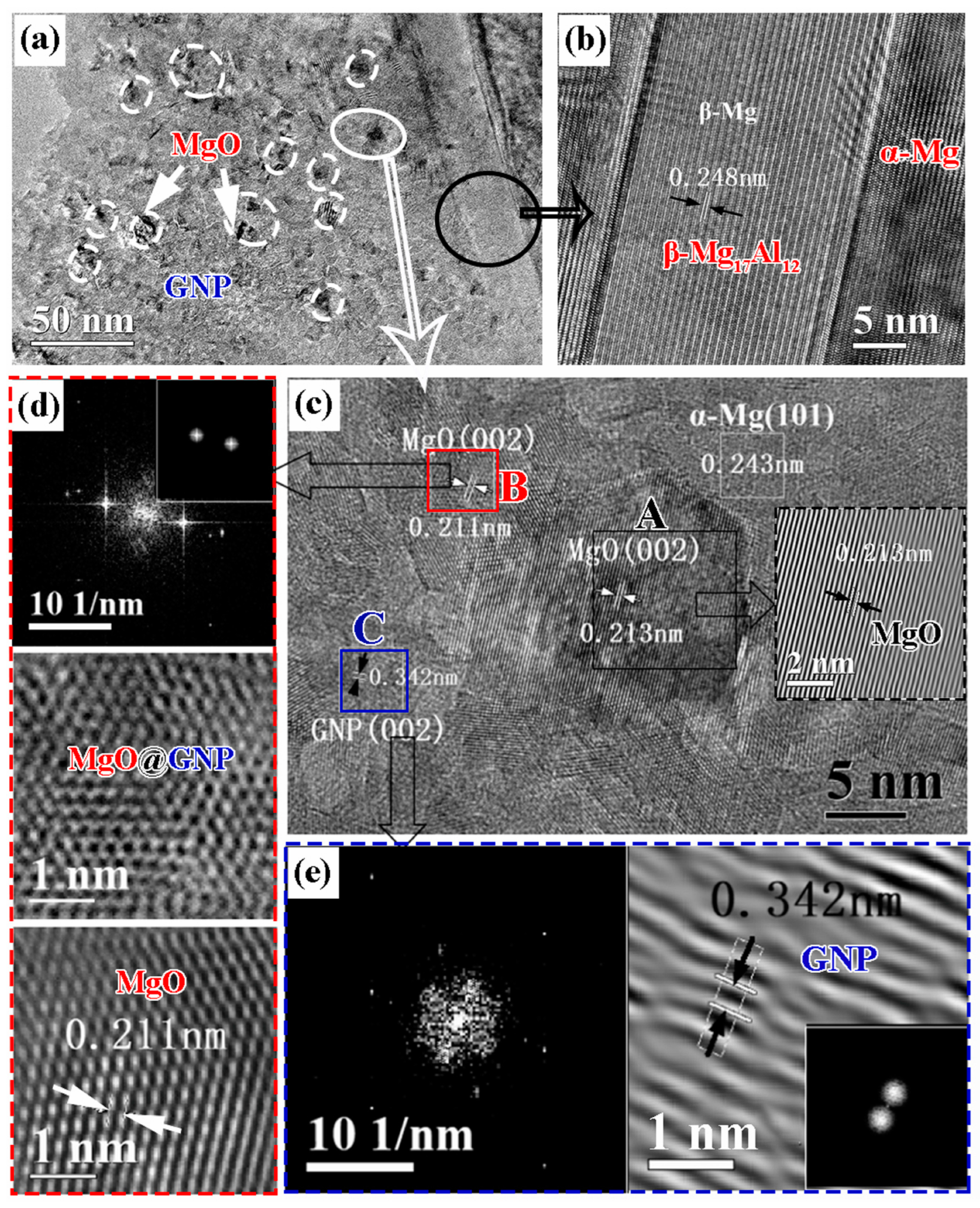

2.3. Graphene

2.4. Other Carbon Reinforcements

3. Ceramic-Reinforced MMCs

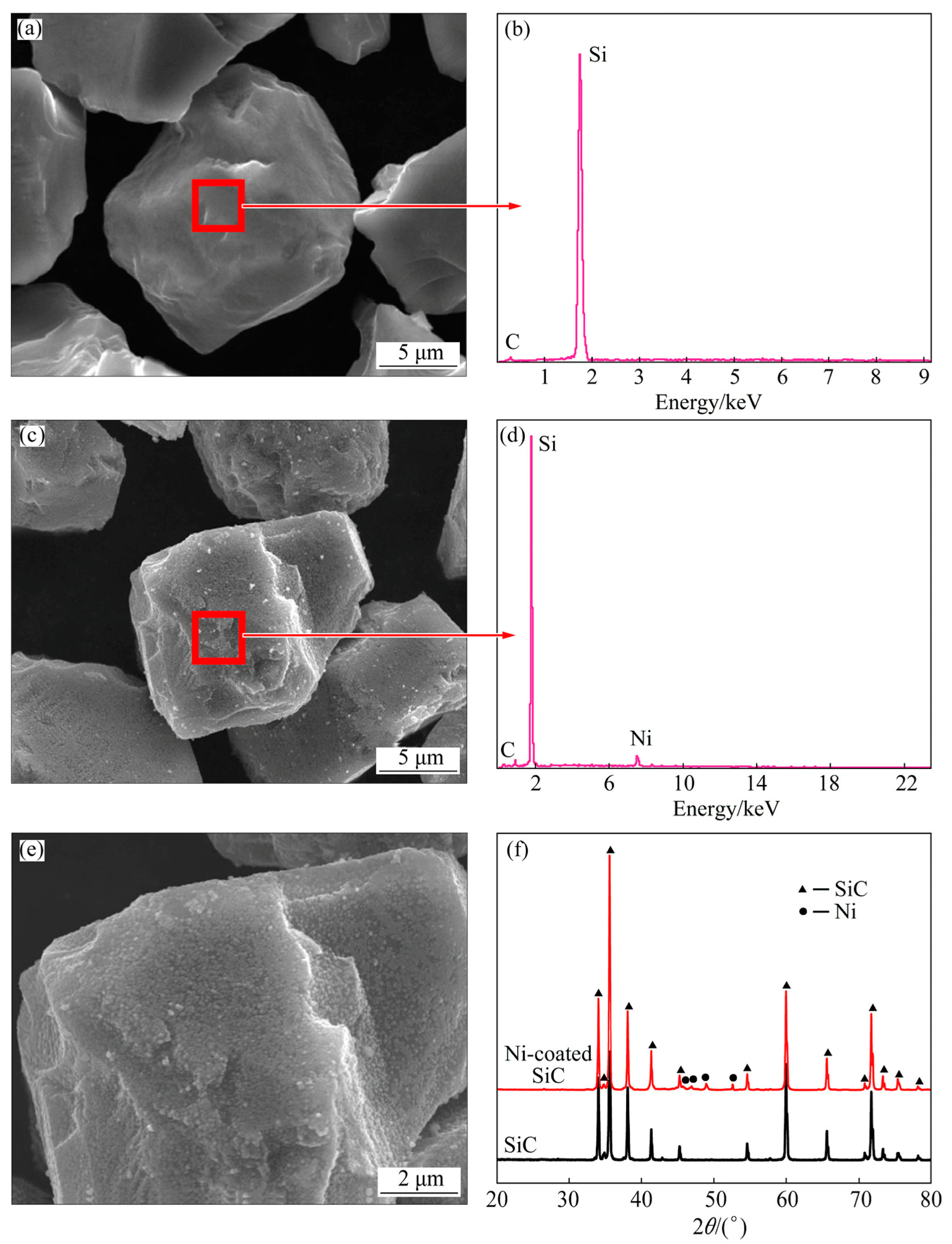

3.1. SiC Particle

3.2. Al2O3 Particle

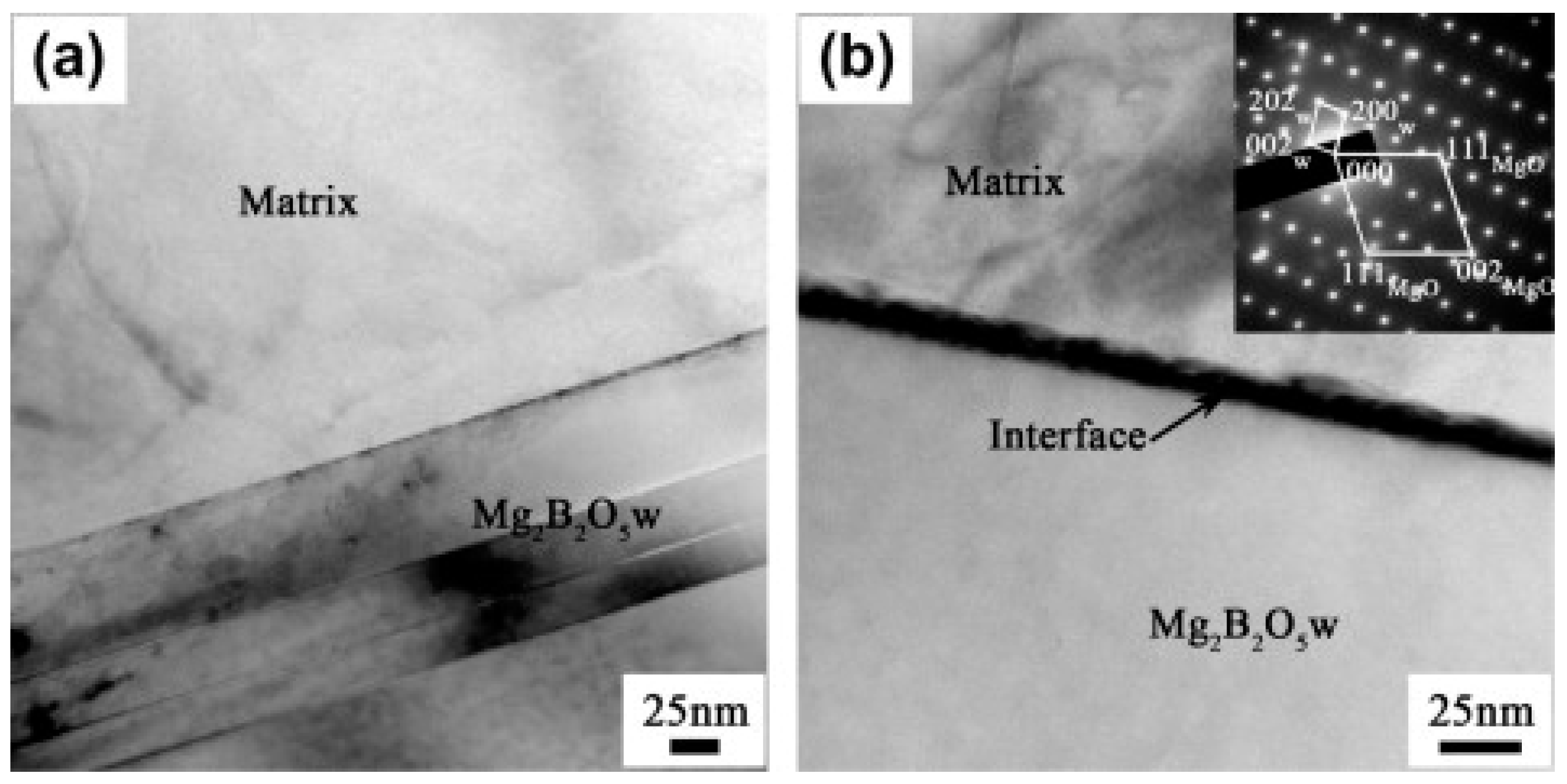

3.3. Whisker

3.4. Hydroxyapatite

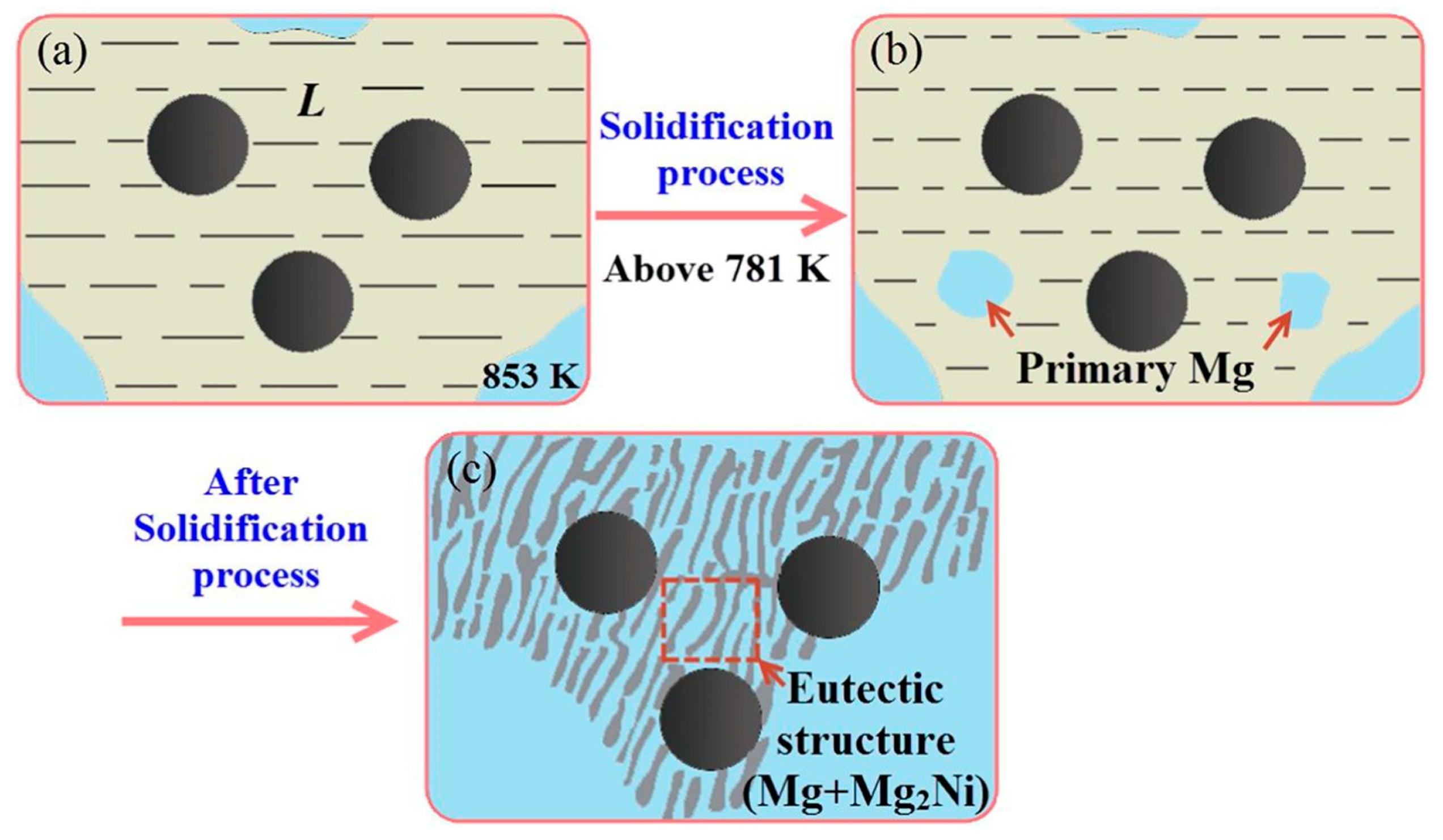

3.5. Fly Ash Cenospheres

4. Discussion

4.1. The Effect of Coatings

4.2. Future Recommendations

- New types of coatings and reinforcements need to be explored. This can be studied from the angle of economy or high performance. In addition, new applications of coatings at the micro-scale and nano-scale can be developed, such as preventing the oxidation of the metal powder during processing [119].

- Furthermore, more detailed and nano-scale studies of the interface structure are needed, and precise structure-function relationships need to be established. The interfaces between the reinforcements and coatings and the interfaces between the coatings and the matrix both need to be further investigated.

- The durability of coatings needs to be further studied. Due to the activity and erodibility of Mg, it is critical to make the strengthening effect of the composites and coatings last longer. Whether there is coating degradation and its impact on the properties of composites are worthy of study.

- In addition to coating treatments, there are many surface modification methods for reinforcements, such as surface grafting [12,152]. There are few studies on the comparison between different coatings, different reinforcements, and different surface modification methods. Only by making sufficient comparisons can we give practical suggestions for future application selection.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khatkar, S.K. Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics. Rev. Adv. Mater. Sci. 2023, 62, 20220294. [Google Scholar] [CrossRef]

- Ye, H.Z.; Liu, X.Y. Review of recent studies in magnesium matrix composites. J. Mater. Sci. 2004, 39, 6153–6171. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, X.; Chen, J.; Peng, X.; Chen, D.; Pan, F. Research advances in magnesium and magnesium alloys worldwide in 2020. J. Magnes. Alloys 2021, 9, 705–747. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Berto, F. Functionalized carbon nanotube-encapsulated magnesium-based nanocomposites with outstanding mechanical and biological properties as load-bearing bone implants. Mater. Des. 2022, 213, 110354. [Google Scholar] [CrossRef]

- Shi, H.; Xu, C.; Hu, X.; Gan, W.; Wu, K.; Wang, X. Improving the Young’s modulus of Mg via alloying and compositing—A short review. J. Magnes. Alloys 2022, 10, 2009–2024. [Google Scholar] [CrossRef]

- Nie, Y.; Dai, J.; Li, X.; Zhang, X. Recent developments on corrosion behaviors of Mg alloys with stacking fault or long period stacking ordered structures. J. Magnes. Alloys 2021, 9, 1123–1146. [Google Scholar] [CrossRef]

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, B.; Wang, Q.; Yang, H.; Yuan, M.; Huang, G.; Zhang, D.; Pan, F. Influence of Ce content on the microstructures and tensile properties of Mg-1Gd-0.5Zn alloys. Mater. Sci. Eng. A 2021, 823, 141675. [Google Scholar] [CrossRef]

- Ma, R.; Lv, S.; Xie, Z.; Yang, Q.; Yan, Z.; Meng, F.; Qiu, X. Achieving high strength-ductility in a wrought Mg–9Gd–3Y–0.5Zr alloy by modifying with minor La addition. J. Alloys Compd. 2021, 884, 161062. [Google Scholar] [CrossRef]

- Lei, B.; Jiang, B.; Yang, H.; Dong, Z.; Wang, Q.; Yuan, M.; Huang, G.; Song, J.; Zhang, D.; Pan, F. Effect of Nd addition on the microstructure and mechanical properties of extruded Mg-Gd-Zr alloy. Mater. Sci. Eng. A 2021, 816, 141320. [Google Scholar] [CrossRef]

- Guan, H.; Xiao, H.; Ouyang, S.; Tang, A.; Chen, X.; Tan, J.; Feng, B.; She, J.; Zheng, K.; Pan, F. A review of the design, processes, and properties of Mg-based composites. Nanotechnol. Rev. 2022, 11, 712–730. [Google Scholar] [CrossRef]

- Zhou, J.; Zhong, K.; Zhao, C.; Meng, H.; Qi, L. Effect of carbon nanotubes grown temperature on the fracture behavior of carbon fiber reinforced magnesium matrix composites: Interlaminar shear strength and tensile strength. Ceram. Int. 2021, 47, 6597–6607. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhao, R.; Bai, P.; Du, W.; Guan, R.; Tie, D.; Naik, N.; Huang, M.; Guo, Z. AZ91 alloy nanocomposites reinforced with Mg-coated graphene: Phases distribution, interfacial microstructure, and property analysis. J. Alloys Compd. 2022, 902, 163484. [Google Scholar] [CrossRef]

- Gu, J.H.; Zhang, X.N.; Qiu, Y.F.; Gu, M.Y. Damping behaviors of magnesium matrix composites reinforced with Cu-coated and uncoated SiC particulates. Compos. Sci. Technol. 2005, 65, 1736–1742. [Google Scholar] [CrossRef]

- Li, H.; Fan, J.; Geng, X.; Li, B.; Liang, C.; Wang, H.; Li, Y.; Qiao, Z.; Kang, J. Alumina powder assisted carbon nanotubes reinforced Mg matrix composites. Mater. Des. 2014, 60, 637–642. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, B.; Zhao, D.; Lü, H.; Zhai, T.; Liu, F. Microstructure and mechanical properties of AlN particles in situ reinforced Mg matrix composites. Mater. Sci. Eng. A 2016, 674, 158–163. [Google Scholar] [CrossRef]

- Kevorkijan, V.; Davor Škapin, S. Mg/B4C Composites with a High Volume Fraction of Fine Ceramic Reinforcement. Mater. Manuf. Process. 2009, 24, 1337–1340. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of a novel magnesium/nickel composite with improved mechanical properties. J. Alloys Compd. 2002, 335, L10–L15. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Hu, X.; Wu, K. Effects of hot extrusion on microstructure and mechanical properties of Mg matrix composite reinforced with deformable TC4 particles. J. Magnes. Alloys 2020, 8, 421–430. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantaş, K.; Der, O.; Yalçın, B.; Şimşir, E.; Aamir, M. Microstructural and Mechanical Behavior Investigations of Nb-Reinforced Mg-Sn-Al-Zn-Mn Matrix Magnesium Composites. Metals 2023, 13, 1097. [Google Scholar] [CrossRef]

- Qian, X.; Yang, H.; Hu, C.; Zeng, Y.; Huang, Y.; Shang, X.; Wan, Y.; Jiang, B.; Feng, Q. Effect of potential difference between nano-Al2O3 whisker and Mg matrix on the dispersion of Mg composites. Int. J. Miner. Metall. Mater. 2023, 30, 104–111. [Google Scholar] [CrossRef]

- Xue, Y.; Li, H.; Qi, L.; Yang, L.; Wang, J.; Ma, Y. Interfacial microstructure and strengthening mechanisms of Cf/Mg composite with double-layer interface. Ceram. Int. 2021, 47, 31149–31159. [Google Scholar] [CrossRef]

- Li, S.; Qi, L.; Zhang, T.; Zhou, J.; Li, H. Microstructure and tensile behavior of 2D-Cf/AZ91D composites fabricated by liquid-solid extrusion and vacuum pressure infiltration. J. Mater. Sci. Technol. 2017, 33, 541–546. [Google Scholar] [CrossRef]

- Guo, Y.; Fu, H.; Ma, K.; Liu, J.; Zhang, Y.; Xiang, C.; Zhang, Q. Experimental and simulation investigation on thermal and mechanical properties for the hollow sphere reinforced AZ31 magnesium matrix composite. Mech. Adv. Mater. Struct. 2022, 29, 7051–7062. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, Y. Research progress in interfacial regulation of magnesium matrix composites. J. Mater. Eng. 2023, 51, 1–15. [Google Scholar]

- Fan, T.; Liu, Y.; Yang, K.; Song, J.; Zhang, D. Recent Progress on Interfacial Structure Optimization and Their Influencing Mechanism of Carbon Reinforced Metal Matrix Composites. Acta Metall. Sin. 2019, 55, 16–32. [Google Scholar]

- Qi, L.; Liu, J.; Guan, J.; Zhou, J.; Li, H. Tensile properties and damage behaviors of Csf/Mg composite at elevated temperature and containing a small fraction of liquid. Compos. Sci. Technol. 2012, 72, 1774–1780. [Google Scholar] [CrossRef]

- Ren, F.; Wu, S.; Shi, W. Interface Characteristics and Damping Performance of Ni-coated Short Carbon Fiber Reinforced AZ91D Magnesium Matrix Composites. J. Mater. Res. 2017, 31, 74–80. [Google Scholar]

- Radha, R.; Sreekanth, D. Electroless tin coated hydroxyapatite reinforced Mg-Sn alloy composite for enhanced bio corrosion resistance and bioactivity. Compos. Commun. 2020, 21, 100372. [Google Scholar] [CrossRef]

- Li, S.; Qi, L.; Zhang, T.; Zhou, J.; Li, H. Interfacial microstructure and tensile properties of carbon fiber reinforced Mg-Al-RE matrix composites. J. Alloys Compd. 2016, 663, 686–692. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Li, Z.; Ding, Y.; Zhao, X.; Zhang, X.; Wang, H.; Liu, C.; Guo, X. Strengthening Ni-Coated CNT/Mg Composites by Optimizing the CNT Content. Nanomaterials 2022, 12, 4446. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Dai, D.; Xiong, G.; Lan, S.; Zhang, C. Composite Nanocoatings of Biomedical Magnesium Alloy Implants: Advantages, Mechanisms, and Design Strategies. Adv. Sci. 2023, 10, e2300658. [Google Scholar] [CrossRef] [PubMed]

- Gnedenkov, A.S.; Sinebryukhov, S.L.; Filonina, V.S.; Ustinov, A.Y.; Gnedenkov, S.V. Hybrid Coatings for Active Protection against Corrosion of Mg and Its Alloys. Polymers 2023, 15, 3035. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Kong, D.; Huang, J.; Wang, M.; Yamaguchi, T.; Wang, H. Achieving the lightweight wear-resistant TiC reinforced AlFeCrCo medium-entropy alloy coating on Mg alloy via resistance seam processing. Scr. Mater. 2022, 210, 114429. [Google Scholar] [CrossRef]

- Qi, L.; Li, S.; Zhang, T.; Zhou, J.; Li, H. An analysis of the factors affecting strengthening in carbon fiber reinforced magnesium composites. Compos. Struct. 2019, 209, 328–336. [Google Scholar] [CrossRef]

- Ma, Y.; Guo, L.; Qi, L.; Sun, J.; Wang, J.; Cao, Y. Growth mechanism and thermal behavior of electroless Cu plating on short carbon fibers. Surf. Coat. Technol. 2021, 419, 127294. [Google Scholar] [CrossRef]

- Qi, X.; Qin, C.; Zhong, W.; Au, C.; Ye, X.; Du, Y. Large-Scale Synthesis of Carbon Nanomaterials by Catalytic Chemical Vapor Deposition: A Review of the Effects of Synthesis Parameters and Magnetic Properties. Materials 2010, 3, 4142–4174. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Li, J. Carbon nanotube in different shapes. Mater. Today 2009, 12, 12–18. [Google Scholar] [CrossRef]

- Kathyayini, H.; Nagaraju, N.; Fonseca, A.; Nagy, J.B. Catalytic activity of Fe, Co and Fe/Co supported on Ca and Mg oxides, hydroxides and carbonates in the synthesis of carbon nanotubes. J. Mol. Catal. A Chem. 2004, 223, 129–136. [Google Scholar] [CrossRef]

- Jo, I.; Cho, S.; Kim, H.; Jung, B.M.; Lee, S.K.; Lee, S.B. Titanium dioxide coated carbon nanofibers as a promising reinforcement in aluminum matrix composites fabricated by liquid pressing process. Scr. Mater. 2016, 112, 87–91. [Google Scholar] [CrossRef]

- Kwon, H.; Lee, G.G.; Kim, S.G.; Lee, B.W.; Seo, W.C.; Leparoux, M. Mechanical properties of nanodiamond and multi-walled carbon nanotubes dual-reinforced aluminum matrix composite materials. Mater. Sci. Eng. A 2015, 632, 72–77. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Karbalaei Akbari, M.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part. A 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Chand, S. Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Feldhoff, A.; Pippel, E.; Woltersdorf, J. Carbon-fibre reinforced magnesium alloys: Nanostructure and chemistry of interlayers and their effect on mechanical properties. J. Microsc. 1999, 196, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhu, R.; Huang, P.; Wang, X. Interfacial shear strength and fracture toughness between single carbon fiber and TiO2 matrix under microbond test. J. Adhes. 2021, 97, 821–839. [Google Scholar] [CrossRef]

- Wang, C.; Ji, X.; Roy, A.; Silberschmidt, V.V.; Chen, Z. Shear strength and fracture toughness of carbon fibre/epoxy interface: Effect of surface treatment. Mater. Des. 2015, 85, 800–807. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Lee, H.C.; Kim, S.S. The effect of post-processing of carbon fibers on the mechanical properties of epoxy-based composites. Compos. Part. B 2013, 45, 172–177. [Google Scholar] [CrossRef]

- Feldhoff, A.; Pippel, E.; Woltersdorf, J. TiN coatings in C/Mg-Al composites: Microstructure, nanochemistry and function. Philos. Mag. A 2000, 80, 659–672. [Google Scholar] [CrossRef]

- Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Interfacial reaction and nanostructures in Mg matrix composites reinforced with carbon fibers modified by sol–gel method. Compos. Sci. Technol. 2013, 87, 69–76. [Google Scholar] [CrossRef]

- Li, K.; Pei, Z.; Gong, J.; Shi, N.; Sun, C. Fabrication of SiO2 coating on carbon fibre and its application in Mg-based composite. Acta Metall. Sin. 2007, 43, 1282–1286. [Google Scholar]

- Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Evolution of interfacial nanostructures and stress states in Mg matrix composites reinforced with coated continuous carbon fibers. Compos. Sci. Technol. 2012, 72, 152–158. [Google Scholar] [CrossRef]

- Kleine, A.; Hemptenmacher, J.; Dudek, H.J.; Kainer, K.U.; Krüger, G. Interface formation in carbon fibre reinforced magnesium alloys (AZ91). J. Mater. Sci. Lett. 1995, 14, 358–360. [Google Scholar] [CrossRef]

- Wang, W.G.; Zhang, J.F.; Zan, Y.N.; Liu, Z.Y.; Wang, D.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Failure mechanism of nano-structural interfacial layer in Mg matrix composites reinforced with Cf. Compos. Part. A 2022, 154, 106780. [Google Scholar] [CrossRef]

- Pei, Z.L.; Li, K.; Gong, J.; Shi, N.L.; Elangovan, E.; Sun, C. Micro-structural and tensile strength analyses on the magnesium matrix composites reinforced with coated carbon fiber. J. Mater. Sci. 2009, 44, 4124–4131. [Google Scholar] [CrossRef]

- Li, K.; Shi, N.; Gong, J.; Sun, C. Interfacial Interaction in Coated Carbon Fibre. Reinforced Aluminous Mg-based Composites. J. Mater. Sci. Technol. 2008, 24, 936–940. [Google Scholar]

- Xia, C.J.; Wang, M.L.; Wang, H.W.; Zhou, C. The Effect of Aluminum Content on TiO2 Coated Carbon Fiber Reinforced Magnesium Alloy Composites. Appl. Mech. Mater. 2014, 488, 30–35. [Google Scholar]

- Cho, S.; Jo, I.; Jung, B.M.; Lee, E.; Choi, J.R.; Lee, S.-K.; Lee, S.-B. Interfacial analysis of TiO2 coated carbon nanofibers and Mg-Al alloy matrix fabricated using a liquid pressing process. Scr. Mater. 2017, 136, 50–54. [Google Scholar] [CrossRef]

- Dorner-Reisel, A.; Nishida, Y.; Klemm, V.; Nestler, K.; Marx, G.; Müller, E. Investigation of interfacial interaction between uncoated and coated carbon fibres and the magnesium alloy AZ91. Anal. Bioanal. Chem. 2002, 374, 635–638. [Google Scholar]

- Li, S.; Qi, L.; Zhang, T.; Zhou, J.; Li, H. Interfacial failure behavior of PyC-Cf/AZ91D composite fabricated by LSEVI. J. Mater. Sci. Technol. 2018, 34, 1602–1608. [Google Scholar] [CrossRef]

- Zhang, T.; Qi, L.; Li, S.; Wei, X.; Ju, L. Effect of PyC coating on mechanical properties of Cf/AZ91D composites. Surf. Eng. 2018, 34, 852–860. [Google Scholar] [CrossRef]

- Li, S.; Qi, L.; Zhou, J.; Zhang, T.; Dong, K. Failure Behaviors of 2D-Cf/Mg Composites Fabricated by Liquid-Solid Extrusion Following Vacuum Pressure Infiltration. Solid. State Phenom. 2016, 256, 216–221. [Google Scholar] [CrossRef]

- Gu, J.H.; Zhang, X.N.; Gu, M.Y. The damping capacity of AZ91 magnesium matrix composites reinforced with the coated carbon fiber fabric. Mater. Trans. 2004, 45, 1743–1747. [Google Scholar] [CrossRef]

- Li, S.; Qi, L.; Zhang, T.; Ju, L.; Li, H. Interfacial microstructure and mechanical properties of Cf/AZ91D composites with TiO2 and PyC fiber coatings. Micron 2017, 101, 170–176. [Google Scholar] [CrossRef]

- Valente, M.; Marini, D.; Genova, V.; Quitadamo, A.; Marra, F.; Pulci, G. Lightweight metallic matrix composites: Development of new composites material reinforced with carbon structures. J. Appl. Biomater. Funct. Mater. 2019, 17, 2280800019840294. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, Y.; Wang, W.; Liu, S.; Zhang, J.; Fu, Y.; Wang, T.; Li, T. Effects of interfacial diffusion induced infiltration process on the microstructure evolution and interfacial enhancement of CF/ Mg composites. J. Mater. Process. Technol. 2021, 294, 117143. [Google Scholar] [CrossRef]

- Hou, L.G.; Wu, R.Z.; Wang, X.D.; Zhang, J.H.; Zhang, M.L.; Dong, A.P.; Sun, B.D. Microstructure, mechanical properties and thermal conductivity of the short carbon fiber reinforced magnesium matrix composites. J. Alloys Compd. 2017, 695, 2820–2826. [Google Scholar] [CrossRef]

- Ren, F.-Z.; Gao, J.-C.; Li, W.; Zhang, M.; Tan, Z. Effect of interface properties on the mechanical performance of carbon fiber/Mg composites fabricated by powder metallurgy. New Carbon. Mater. 2011, 26, 278–286. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, M.; Lu, C.; Lu, X. Fabrication of Palladium-Free Nickel-Coated Carbon Fiber Reinforced Magnesium Alloy Composites by Powder Metallurgy Hot Extrusion and Their Microstructure. Rare Met. Mater. Eng. 2012, 41, 743–747. [Google Scholar]

- Yao, Y.; Xu, Z.; Sugio, K.; Choi, Y.; Matsugi, K.; Kang, S.; Fu, R.; Sasaki, G. Fabrication of Vapor-Grown Carbon Fiber-Reinforced Magnesium-Calcium Alloy Composites by Compo-Casting Process. Mater. Trans. 2017, 58, 673–678. [Google Scholar] [CrossRef]

- Lu, P.; Xia, C.; Wang, H.; Liu, D. Study on Zinc-coated Cf/Mg Composite. Hot Work. Technol. 2009, 38, 122–124+127. [Google Scholar]

- Reischer, F.; Pippel, E.; Woltersdorf, J.; Stöckel, S.; Marx, G. Carbon fibre-reinforced magnesium: Improvement of bending strength by nanodesign of boron nitride interlayers. Mater. Chem. Phys. 2007, 104, 83–87. [Google Scholar] [CrossRef]

- Honma, T.; Nagai, K.; Katou, A.; Arai, K.; Suganuma, M.; Karnado, S. Synthesis of high-strength magnesium alloy composites reinforced with Si-coated carbon nanofibres. Scr. Mater. 2009, 60, 451–454. [Google Scholar] [CrossRef]

- Hou, J.; Du, W.; Wang, Z.; Li, S.; Liu, K.; Du, X. Combination of enhanced thermal conductivity and strength of MWCNTs reinforced Mg-6Zn matrix composite. J. Alloys Compd. 2020, 838, 155573. [Google Scholar] [CrossRef]

- Chen, B.; Kondoh, K.; Umeda, J.; Li, S.; Jia, L.; Li, J. Interfacial in-situ Al2O3 nanoparticles enhance load transfer in carbon nanotube (CNT)-reinforced aluminum matrix composites. J. Alloys Compd. 2019, 789, 25–29. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J.; Takahashi, M.; Kondoh, K. Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests. Compos. Sci. Technol. 2015, 113, 1–8. [Google Scholar] [CrossRef]

- Zhang, D.; Shen, P.; Shi, L.; Jiang, Q. Wetting of B4C, TiC and graphite substrates by molten Mg. Mater. Chem. Phys. 2011, 130, 665–671. [Google Scholar] [CrossRef]

- Han, G.; Du, W.; Ye, X.; Liu, K.; Du, X.; Wang, Z.; Li, S. Compelling mechanical properties of carbon nanotubes reinforced pure magnesium composite by effective interface bonding of Mg2Ni. J. Alloys Compd. 2017, 727, 963–969. [Google Scholar] [CrossRef]

- Liang, J.; Li, H.; Qi, L.; Tian, W.; Li, X.; Zhou, J.; Wang, D.; Wei, J. Influence of Ni-CNTs additions on the microstructure and mechanical properties of extruded Mg-9Al alloy. Mater. Sci. Eng. A 2016, 678, 101–109. [Google Scholar] [CrossRef]

- Nai, M.H.; Wei, J.; Gupta, M. Interface tailoring to enhance mechanical properties of carbon nanotube reinforced magnesium composites. Mater. Des. 2014, 60, 490–495. [Google Scholar] [CrossRef]

- Nasiri, S.; Yang, G.; Spiecker, E.; Li, Q. An Improved Approach to Manufacture Carbon Nanotube Reinforced Magnesium AZ91 Composites with Increased Strength and Ductility. Metals 2022, 12, 834. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Ding, Y.; Jiao, S.; Zhang, Y.; Shi, Z.; Hu, J.; Wang, X.; Li, Z.; Wang, H.; Guo, X. Influence of Soft Phase and Carbon Nanotube Content on the Properties of Hierarchical AZ61 Matrix Composite with Isolated Soft Phase. Nanomaterials 2022, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Jiang, G.; Song, S.; Li, J.; Liu, L. Molecular dynamics simulation of enhanced interfacial cohesive behavior of Ni-coated MWCNT/Mg composites. Compos. Interfaces 2022, 29, 97–110. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Sansoz, F.; Shen, M. Molecular dynamics simulation on temperature and stain rate-dependent tensile response and failure behavior of Ni-coated CNT/Mg composites. Appl. Phys. A Mater. Sci. Process. 2018, 124, 506. [Google Scholar] [CrossRef]

- Zhou, X.; Song, S.; Li, L.; Zhang, R. Molecular dynamics simulation for mechanical properties of magnesium matrix composites reinforced with nickel-coated single-walled carbon nanotubes. J. Compos. Mater. 2016, 50, 191–200. [Google Scholar] [CrossRef]

- Ding, Y.; Shi, Z.; Li, Z.; Jiao, S.; Hu, J.; Wang, X.; Zhang, Y.; Wang, H.; Guo, X. Effect of CNT Content on Microstructure and Properties of CNTs/Refined-AZ61 Magnesium Matrix Composites. Nanomaterials 2022, 12, 2432. [Google Scholar] [CrossRef] [PubMed]

- Habibi, M.K.; Hamouda, A.M.S.; Gupta, M. Enhancing tensile and compressive strength of magnesium using ball milled Al plus CNT reinforcement. Compos. Sci. Technol. 2012, 72, 290–298. [Google Scholar] [CrossRef]

- Kondoh, K.; Fukuda, H.; Umeda, J.; Imai, H.; Fugetsu, B.; Endo, M. Microstructural and mechanical analysis of carbon nanotube reinforced magnesium alloy powder composites. Mater. Sci. Eng. A 2010, 527, 4103–4108. [Google Scholar] [CrossRef]

- Najafi, A. Development of high oxidation resistant coating of nanostructured MgO on carbon nanotubes via simple precipitation technique in Mg/CO gas system. Ceram. Int. 2016, 42, 18573–18578. [Google Scholar] [CrossRef]

- Yu, Q.-H.; Huang, H.-Q.; Wang, W.-C.; Zhou, G.-H.; Luo, L.; Zeng, X.-S.; Liu, Y. Achieving high stability of MgO/carbon nanotube interface via the co-deposition technique. J. Alloys Compd. 2020, 824, 153889. [Google Scholar]

- Li, N.; Yan, H.; Wu, Q.; Cao, Z. Fabrication of Carbon Nanotubes and Rare Earth Pr Reinforced AZ91 Composites by Powder Metallurgy. Chin. J. Mech. Eng. 2021, 34, 26. [Google Scholar] [CrossRef]

- Yuan, Q.-H.; Zeng, X.-S.; Liu, Y.; Luo, L.; Wu, J.-B.; Wang, Y.-C.; Zhou, G.-H. Microstructure and mechanical properties of AZ91 alloy reinforced by carbon nanotubes coated with MgO. Carbon 2016, 96, 843–855. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, G.; Liao, L.; Yan, X.; Peng, L.; Ma, G.; Yang, C.; Wang, Q. Microstructures and mechanical properties of Mg-based composites reinforced with different nano-carbon materials. Chin. J. Nonferrous Met. 2021, 31, 30–41. [Google Scholar]

- Yuan, Q.; Zeng, X.; Wang, Y.; Luo, L.; Ding, Y.; Li, D.; Liu, Y. Microstructure and mechanical properties of Mg-4.0Zn alloy reinforced by NiO-coated CNTs. J. Mater. Sci. Technol. 2017, 33, 452–460. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Keshavarz, M.; Kehtari, M.; Ramakrishna, S.; Berto, F. MgO-incorporated carbon nanotubes-reinforced Mg-based composites to improve mechanical, corrosion, and biological properties targeting biomedical applications. J. Mater. Res. Technol. 2022, 20, 976–990. [Google Scholar] [CrossRef]

- Zhao, R.; Zhao, Z.; Bai, P.; Du, W.; Tie, D.; Zhang, Z.; Wang, L.; Wang, Y. Research on tribological behavior of graphene with in-situ MgO nanoparticles reinforced AZ91 alloy composite. Compos. Commun. 2022, 30, 101086. [Google Scholar] [CrossRef]

- Wu, L.; Wu, R.; Hou, L.; Zhang, J.; Zhang, M. Microstructure, mechanical properties and wear performance of AZ31 matrix composites reinforced by graphene nanoplatelets(GNPs). J. Alloys Compd. 2018, 750, 530–536. [Google Scholar] [CrossRef]

- Sun, X.; Li, C.; Dai, X.; Zhao, L.; Li, B.; Wang, H.; Liang, C.; Li, H.; Fan, J. Microstructures and properties of graphene-nanoplatelet-reinforced magnesium-matrix composites fabricated by an in situ reaction process. J. Alloys Compd. 2020, 835, 155125. [Google Scholar] [CrossRef]

- Ye, J.; Chen, X.; Li, J.; Liu, C.; Wu, B.; Pan, F. Microstructure and compressive properties of Mg-9Al composite reinforced with Ni-coated graphene nanosheets. Vacuum 2020, 181, 109629. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X. Mechanical Properties and Strengthening Mechanism of Graphene Nanoplatelets Reinforced Magnesium Matrix Composites. Acta Metall. Sin. 2020, 56, 240–248. [Google Scholar]

- Zhao, R.; Pei, J.; Du, W.; Zhao, Z.; Zhang, L.; Gao, J.; Bai, P.; Tie, D. Fabrication of magnesium-coated graphene and its effect on the microstructure of reinforced AZ91 magnesium-matrix composites. Adv. Compos. Hybrid Mater. 2022, 5, 504–512. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, Y.; Wang, L.-D.; Zhu, Y.-P.; Wang, X.-J.; Sheng, J.; Yang, Z.-Y.; Shi, H.-L.; Shi, Z.-D.; Fei, W.-D. Achieving high strength and ductility in graphene/magnesium composite via an in-situ reaction wetting process. Carbon 2018, 139, 954–963. [Google Scholar] [CrossRef]

- Shuai, C.; Wang, B.; Bin, S.; Peng, S.; Gao, C. TiO2-Induced In Situ Reaction in Graphene Oxide-Reinforced AZ61 Biocomposites to Enhance the Interfacial Bonding. ACS Appl. Mater. Interfaces 2020, 12, 23464–23473. [Google Scholar] [CrossRef] [PubMed]

- Shuai, C.; Wang, B.; Bin, S.; Peng, S.; Gao, C. Interfacial strengthening by reduced graphene oxide coated with MgO in biodegradable Mg composites. Mater. Des. 2020, 191, 108612. [Google Scholar] [CrossRef]

- Li, X.; Shi, H.; Wang, X.; Hu, X.; Xu, C.; Shao, W.; Lu, Z.; Xiang, S. Achieving high strength and modulus in graphene reinforced Mg matrix composites via an in-situ process. Mater. Sci. Eng. A 2022, 852, 143713. [Google Scholar] [CrossRef]

- Li, J.; Peng, R.; Ru, J.; Wu, J.; Zhou, K.; Yan, Y.; Xu, X.; Zhou, Y. Effects of Chromium Carbide Coatings on Microstructure and Thermal Conductivity of Mg/Diamond Composites Prepared by Squeeze Casting. Materials 2022, 15, 1284. [Google Scholar] [CrossRef]

- Molina-Jorda, J.M. Nano- and micro-/meso-scale engineered magnesium/diamond composites: Novel materials for emerging challenges in thermal management. Acta Mater. 2015, 96, 101–110. [Google Scholar] [CrossRef]

- Olszowka-Myalska, A.; Myalski, J.; Botor-Probierz, A. Microstructural Characteristics of an AZ91 Matrix-Glassy Carbon Particle Composite. Adv. Eng. Mater. 2010, 12, 609–616. [Google Scholar] [CrossRef]

- Zhou, D.; Qiu, F.; Wang, H.; Jiang, Q. Manufacture of Nano-Sized Particle-Reinforced Metal Matrix Composites: A Review. Acta Metall. Sin. (Engl. Lett.) 2014, 27, 798–805. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, Y.; Tan, J.; Chen, Y.; Chen, Y.; Li, J.; Chen, X.; Zheng, K.; Pan, F. Large strain hardening of magnesium containing in situ nanoparticles. Nanotechnol. Rev. 2021, 10, 1018–1030. [Google Scholar] [CrossRef]

- Guo, S.-Q.; Wang, R.-C.; Peng, C.-Q.; Cai, Z.-Y.; Dong, C.-G. Microstructures and mechanical properties of Ni-coated SiC particles reinforced AZ61 alloy composites. Trans. Nonferrous Met. Soc. China 2019, 29, 1854–1863. [Google Scholar] [CrossRef]

- Inem, B.; Pollard, G. Interface structure and fractography of a magnesium-alloy, metal-matrix composite reinforced with SiC particles. J. Mater. Sci. 1993, 28, 4427–4434. [Google Scholar] [CrossRef]

- Hao, X.; Hao, W.; Geng, G.; Ma, T.; Wang, C.; Zhao, F.; Song, H.; Li, Y. Effects of High-Density Pulse Currents on the Solidification Structures of Cu-SiCp/AZ91D Composites. Adv. Mater. Sci. Eng. 2019, 2019, 1684580. [Google Scholar] [CrossRef]

- Muraliraja, R.; Pradeepkumar, K.; Mohanraj, P.; Kumar, T.V.; Dhanasekaran, C.; Chandrasekaran, M.; Ragavanantham, S.; Shaisundaram, V.S. The Effects of Electroless Ni-P Coated SiC on the Properties of Magnesium Composite. Mater. Perform. Charact. 2022, 11, 223–235. [Google Scholar] [CrossRef]

- Chen, Z.; Li, S.; Wang, Y.; Li, W.; Wei, C.; Kong, W.; Jia, X.; Pei, Q.; Zhang, W. Electrochemical Deposition of Magnesium on SiC Fibers from the LiCl-KCl-MgCl2 Molten Salt. J. Electrochem. Soc. 2016, 163, D522–D525. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater. Sci. Eng. A 2005, 392, 163–168. [Google Scholar] [CrossRef]

- Kumar, D.S.; Suman, K.N.S.; Sasanka, C.T.; Ravindra, K.; Poddar, P.; Siva, S.B.V. Microstructure, mechanical response and fractography of AZ91E/Al2O3 (p) nano composite fabricated by semi solid stir casting method. J. Magnes. Alloys 2017, 5, 48–55. [Google Scholar]

- Paramsothy, M.; Chan, J.; Kwok, R.; Gupta, M. Al2O3 Nanoparticle Addition to Commercial Magnesium Alloys: Multiple Beneficial Effects. Nanomaterials 2012, 2, 147–162. [Google Scholar] [CrossRef]

- Ercetin, A.; Pimenov, D.Y. Microstructure, Mechanical, and Corrosion Behavior of Al2O3 Reinforced Mg2Zn Matrix Magnesium Composites. Materials 2021, 14, 4819. [Google Scholar] [CrossRef]

- Kumar, D.S.; Suman, K.N.S.; Poddar, P. A study on the impact and fatigue failure of AZ91E-Ni coated alumina composites. Can. Metall. Q. 2020, 59, 316–323. [Google Scholar] [CrossRef]

- Kumar, D.S.; Suman, K.N.S.; Poddar, P. Effect of particle morphology of Ni on the mechanical behavior of AZ91E-Ni coated nano Al2O3 composites. Mater. Res. Express 2017, 4, 066505. [Google Scholar] [CrossRef]

- Zheng, M.; Wu, K.; Liang, H.; Kamado, S.; Kojima, Y. Microstructure and mechanical properties of aluminum borate whisker-reinforced magnesium matrix composites. Mater. Lett. 2002, 57, 558–564. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; Weng, W.; Zhang, Y.; Wang, M.; Wang, H. Characteristic and mechanical properties of magnesium matrix composites reinforced with Mg2B2O5w and B4Cp. Mater. Des. 2012, 37, 533–536. [Google Scholar] [CrossRef]

- Han, L.; Jin, P.; Chen, S.; Wang, J. Interfacial Structure of CuO-Coated Mg2B2O5 Whisker Reinforced Magnesium Matrix Composite. Rare Met. Mater. Eng. 2013, 42, 1221–1225. [Google Scholar]

- Li, J.; Xia, C.; Zhang, Y.; Wang, M.; Wang, H. Effects of TiO2 coating on microstructure and mechanical properties of magnesium matrix composite reinforced with Mg2B2O5w. Mater. Des. 2012, 39, 334–337. [Google Scholar] [CrossRef]

- Jin, P.; Han, L.; Chen, S.; Wang, J.; Zhu, Y. Microstructure and tensile properties of ZnO-coated magnesium borate whisker reinforced AZ31B composite. Mater. Sci. Eng. A 2012, 554, 48–52. [Google Scholar] [CrossRef]

- Mo, Z.; Liang, C.; Lin, J.; Wang, H.; Xu, X.; Hu, L.; Fan, Y.; Zhang, X.; Xue, Y.; Tang, C. Synthesis of uniform BN-coated aluminum borate nanowhiskers and their applications in reinforced magnesium matrix composites. Mater. Chem. Phys. 2012, 132, 347–353. [Google Scholar] [CrossRef]

- Sasaki, G.; Wang, W.G.; Hasegawa, Y.; Choi, Y.B.; Fuyama, N.; Matsugi, K.; Yanagisawa, O. Surface treatment of Al18B4O33 whisker and development of Al18B4O33/ZK60 magnesium alloy matrix composite. J. Mater. Process. Technol. 2007, 187, 429–432. [Google Scholar] [CrossRef]

- Zheng, M.Y.; Wu, K.; Liang, M.; Kamado, S.; Kojima, Y. The effect of thermal exposure on the interface and mechanical properties of Al18B4O33w/AZ91 magnesium matrix composite. Mater. Sci. Eng. A 2004, 372, 66–74. [Google Scholar] [CrossRef]

- Zheng, M.; Wu, K.; Yao, C. Effect of interfacial reaction on mechanical behavior of SiCw/AZ91 magnesium matrix composites. Mater. Sci. Eng. A 2001, 318, 50–56. [Google Scholar] [CrossRef]

- Sasaki, G.; Yoshida, M.; Pan, J.; Fuyama, N.; Fujii, T.; Fukunaga, H. Mechanical properties and microstructure of magnesium alloys composites fabricated by casting. Mater. Sci. Forum 2000, 350, 215–220. [Google Scholar] [CrossRef]

- Chen, S.H.; Jin, P.P.; Schumacher, G.; Wanderka, N. Microstructure and interface characterization of a cast Mg2B2O5 whisker reinforced AZ91D magnesium alloy composite. Compos. Sci. Technol. 2010, 70, 123–129. [Google Scholar] [CrossRef]

- Witte, F.; Kaese, V.; Haferkamp, H.; Switzer, E.; Meyer-Lindenberg, A.; Wirth, C.J.; Windhagen, H. In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 2005, 26, 3557–3563. [Google Scholar] [CrossRef]

- Kwon, S.-H.; Jun, Y.-K.; Hong, S.-H.; Kim, H.-E. Synthesis and dissolution behavior of β-TCP and HA/β-TCP composite powders. J. Eur. Ceram. Soc. 2003, 23, 1039–1045. [Google Scholar] [CrossRef]

- Chen, M.; Tan, J.; Lian, Y.; Liu, D. Preparation of Gelatin coated hydroxyapatite nanorods and the stability of its aqueous colloidal. Appl. Surf. Sci. 2008, 254, 2730–2735. [Google Scholar] [CrossRef]

- Ye, X.; Chen, M.; Yang, M.; Wei, J.; Liu, D. In vitro corrosion resistance and cytocompatibility of nano-hydroxyapatite reinforced Mg–Zn–Zr composites. J. Mater. Sci. Mater. Med. 2010, 21, 1321–1328. [Google Scholar] [CrossRef]

- Wang, X.; Chen, M.; You, C.; Liu, D.; Wei, J. Effects of Nanohydroxyapatite Addition on Properties of Mg-Zn-Zr Alloy for Biodegradable Intravascular Stents. Rare Met. Mater. Eng. 2010, 39, 2211–2216. [Google Scholar]

- Sun, J.e.; Chen, M.; Cao, G.; Bi, Y.; Liu, D.; Wei, J. The effect of nano-hydroxyapatite on the microstructure and properties of Mg-3Zn-0.5Zr alloy. J. Compos. Mater. 2014, 48, 825–834. [Google Scholar] [CrossRef]

- Zheng, H.; Chen, M.; Li, Z.; You, C.; Liu, D. Effects of MgO Modified HA Nanoparticles on the Microstructure and Properties of Mg-Zn-Zr/m-HA Composites. Acta Metall. Sin. 2017, 53, 1364–1376. [Google Scholar]

- Zheng, H.R.; Li, Z.; You, C.; Liu, D.B.; Chen, M.F. Effects of MgO modified beta-TCP nanoparticles on the microstructure and properties of beta-TCP/Mg-Zn-Zr composites. Bioact. Mater. 2017, 2, 1–9. [Google Scholar]

- Kutchko, B.G.; Kim, A.G. Fly ash characterization by SEM–EDS. Fuel 2006, 85, 2537–2544. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Menendez, R.; Diaz-Somoano, M.; Martinez-Tarazona, M.R. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 2. Characterization of ceramic cenosphere and salt concentrates. Fuel 2004, 83, 585–603. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Menendez, R.; Alvarez, D.; Diaz-Somoano, M.; Martinez-Tarazona, M.R. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 1. Characterization of feed coals and fly ashes. Fuel 2003, 82, 1793–1811. [Google Scholar] [CrossRef]

- Yu, S.R.; Huang, Z.Q. Dry Sliding Wear Behavior of Fly Ash Cenosphere/AZ91D Mg Alloy Composites. J. Mater. Eng. Perform. 2014, 23, 3480–3488. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Ginsztler, J. Compressive characteristics of metal matrix syntactic foams. Compos. Part. A 2012, 43, 553–561. [Google Scholar] [CrossRef]

- Luong, D.D.; Gupta, N.; Rohatgi, P.K. The high strain rate compressive response of Mg-Al alloy/fly Ash cenosphere composites. JOM 2011, 63, 48–52. [Google Scholar] [CrossRef]

- Vogiatzis, C.A.; Skolianos, S.M. On the sintering mechanisms and microstructure of aluminium–ceramic cenospheres syntactic foams produced by powder metallurgy route. Compos. Part. A 2016, 82, 8–19. [Google Scholar] [CrossRef]

- Huang, Z.; Yu, S.; Liu, J.; Zhu, X. Microstructure and mechanical properties of in situ Mg2Si/AZ91D composites through incorporating fly ash cenospheres. Mater. Des. 2011, 32, 4714–4719. [Google Scholar] [CrossRef]

- Braszczynska-Malik, K.N.; Kamieniak, J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 2017, 128, 209–216. [Google Scholar] [CrossRef]

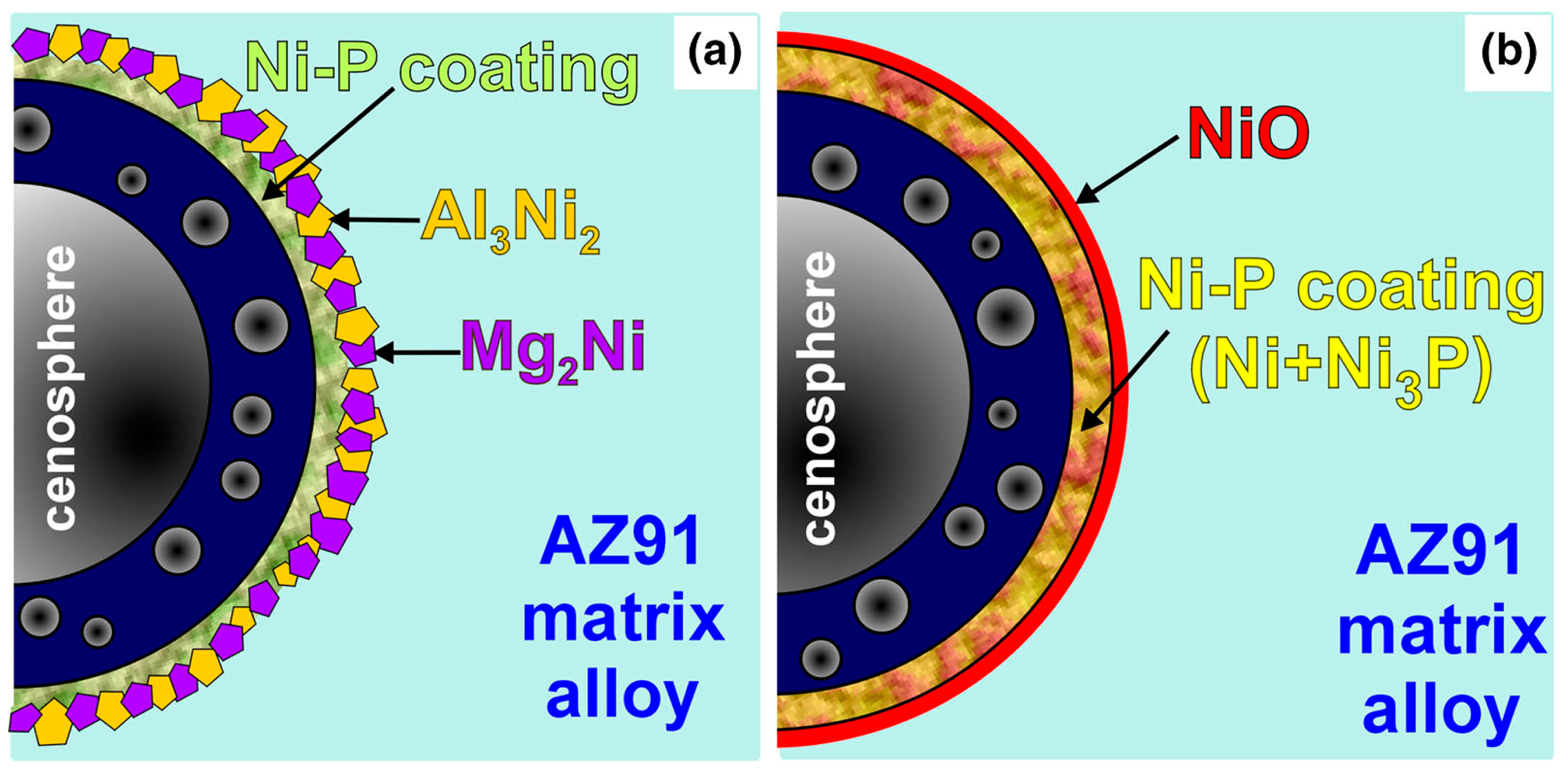

- Braszczynska-Malik, K.N.; Kamieniak, J. The Role of Ni-P Coating Structure on Fly Ash Cenospheres in the Formation of Magnesium Matrix Composites. Metall. Mater. Trans. A 2017, 48, 5649–5657. [Google Scholar] [CrossRef]

- Braszczynska-Malik, K.N.; Kamieniak, J. Analysis of interface between components in AZ91 magnesium alloy foam composite with Ni-P coated fly ash cenospheres. J. Alloys Compd. 2017, 720, 352–359. [Google Scholar] [CrossRef]

- Zhang, T.; Qi, L.; Fu, J.; Chao, X.; Li, W.; Li, H. Microstructure and thermal expansion behavior of a novel Cf -SiCNWs/AZ91D composite with dual interface. Ceram. Int. 2019, 45, 12563–12569. [Google Scholar] [CrossRef]

| Reference | Fraction of Reinforcements | Matrix | Reinforcement | Coatings | Tensile Strength of Matrix (MPa) | Tensile Strength of Uncoated Reinforcement/Matrix (MPa) | Tensile Strength of Coated Reinforcement/Matrix (MPa) |

|---|---|---|---|---|---|---|---|

| [30] | - | AE44 | CF | PyC | 185 | - | 412 |

| [35] | 45 vol% | AZ31 | CF | PyC | - | 256 | 426 |

| [35] | 45 vol% | AZ91 | CF | PyC | - | 227 | 401 |

| [60] | 45 vol% | AZ91D | CF | PyC | - | 308 | 416 |

| [59] | - | AZ91D | CF | PyC | 180 | 220 | 400 |

| [63] | 45 vol% | AZ91D | CF | PyC | 180 | 235 | 400 |

| [63] | 45 vol% | AZ91D | CF | TiO2 | 180 | 235 | 333 |

| [57] | 10 vol% | AZ91 | CF | TiO2 | 153 | - | 306 |

| [49] | 45 vol% | Mg | CF | TiO2 | 30 | - | 980 |

| [49] | 45 vol% | Mg | CF | Al2O3 | 30 | - | 550 |

| [51] | 45 vol% | Mg | CF | ZrO2 | 30 | - | 1080 |

| [69] | 0.5 wt% | Mg-Al-Ca | CF | Ni | 141 | - | 161.8 |

| [68] | 4 | Mg | CF | Ni | 90 | - | 167 |

| [67] | 5.5 vol% | Mg | CF | Ni | 213.78 | 187.35 | 241.82 |

| [72] | 7.5 wt% | AZ91D | CF | Si | 336.8 | - | 470 |

| [93] | 3 wt% | AZ91 | CNT | MgO | 215 | 301 | 331 |

| [92] | 3 wt% | AZ91 | CNT | MgO | 168 | 250 | 284 |

| [91] | 1 wt% | AZ91-Pr | CNT | TiO2 | 261.32 | 258.47 | 389.67 |

| [94] | 1 wt% | Mg-0.4Zn | CNT | NiO | 159 | 176 | 212 |

| [77] | 2 wt% | Mg | CNT | Ni | - | 205.9 | 304.5 |

| [78] | 1 wt% | AZ91D | CNT | Ni | 321 | - | 382 |

| [79] | 0.3 wt% | Mg | CNT | Ni | 171 | 163 | 237 |

| [87] | 0.3 wt% | Mg | CNT | Al | 153 | - | 227 |

| [105] | 0.35 vol% | Mg-6Zn | Graphene | MgO | 235.71 | - | 330 |

| [102] | 0.3 vol% | Mg-6Zn | Graphene | ZnO | 269 | - | 316 |

| [140] | 1 wt% | Mg-Zn3-0.8Zr | HA | MgO | 306 | 317.53 | 346.11 |

| [139] | 1 wt% | Mg-Zn3-0.8Zr | HA | MgO | 306 | 320 | 325 |

| [138] | 1 wt% | Mg-3Zn-0.5Zr | HA | Gelatin | - | 275 | 285 |

| [137] | 1 wt% | Mg-Zn3-0.8Zr | HA | Gelatin | - | 315 | 325 |

| [111] | 9 vol% | AZ61 | SiC particle | Ni | 272.8 | 320 | 336 |

| [121] | 2 wt% | AZ91E | Al2O3 particle | Ni | 162.77 | - | 221.09 |

| [124] | 36 vol% | AZ31B | Mg2B2O5 whisker | CuO | - | 181 | 249 |

| [126] | 36 vol% | AZ31B | Mg2B2O5 whisker | ZnO | - | 181 | 305 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Chen, B. Surface Coatings of Reinforcement Phases in Magnesium Matrix Composites: A Review. Materials 2023, 16, 7560. https://doi.org/10.3390/ma16247560

Wu S, Chen B. Surface Coatings of Reinforcement Phases in Magnesium Matrix Composites: A Review. Materials. 2023; 16(24):7560. https://doi.org/10.3390/ma16247560

Chicago/Turabian StyleWu, Shiyi, and Bin Chen. 2023. "Surface Coatings of Reinforcement Phases in Magnesium Matrix Composites: A Review" Materials 16, no. 24: 7560. https://doi.org/10.3390/ma16247560

APA StyleWu, S., & Chen, B. (2023). Surface Coatings of Reinforcement Phases in Magnesium Matrix Composites: A Review. Materials, 16(24), 7560. https://doi.org/10.3390/ma16247560