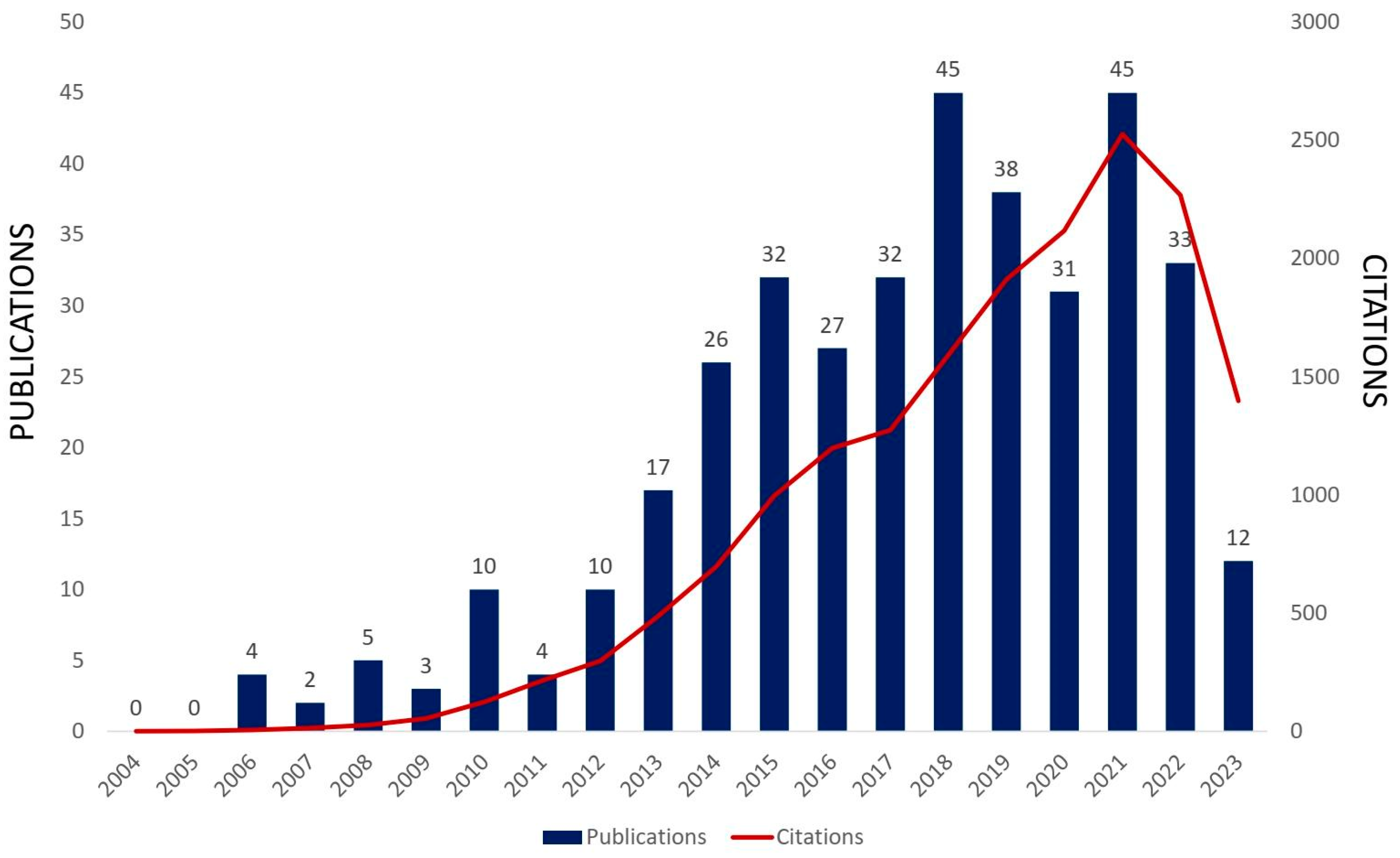

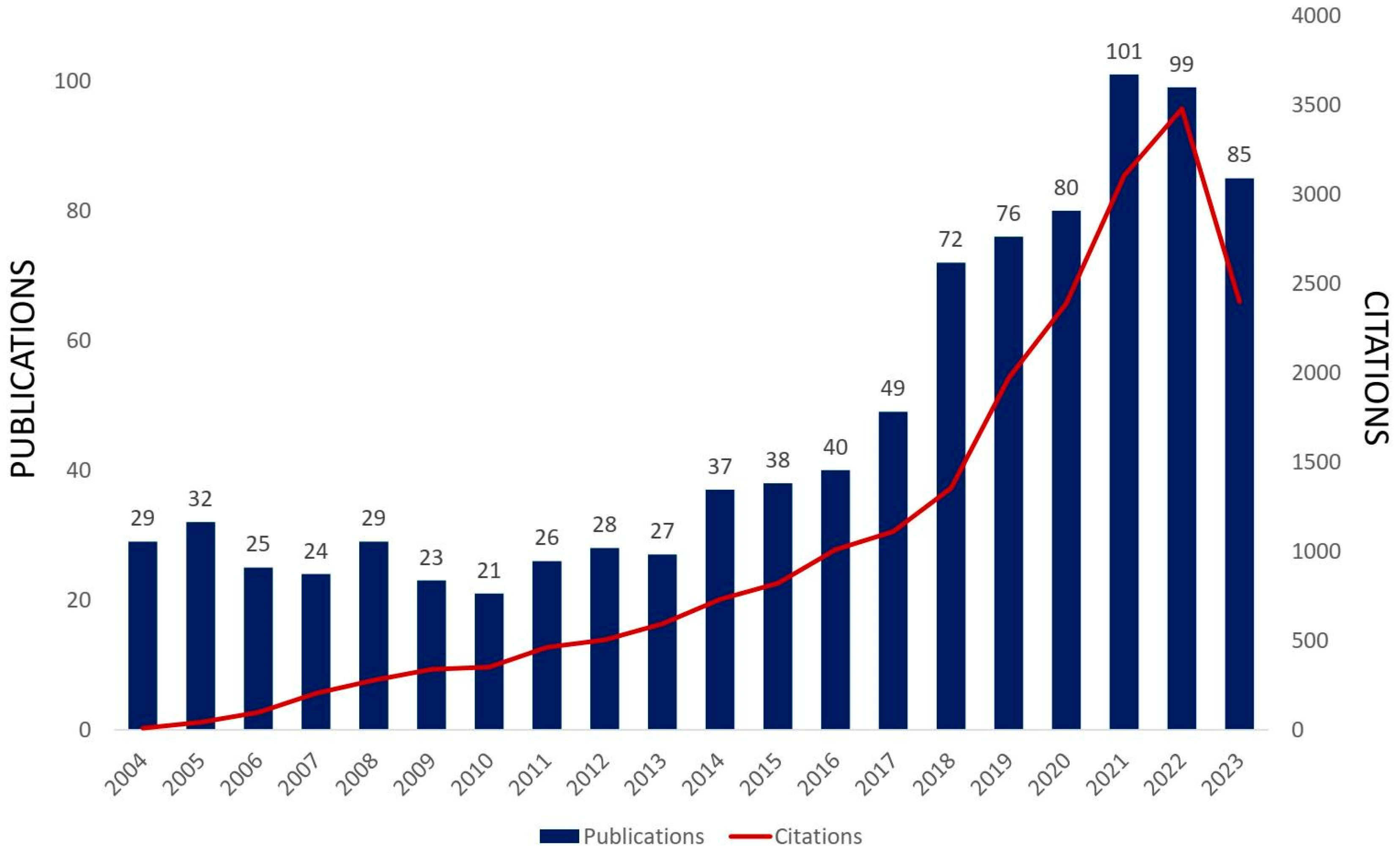

A Brief Review of MoO3 and MoO3-Based Materials and Recent Technological Applications in Gas Sensors, Lithium-Ion Batteries, Adsorption, and Photocatalysis

Abstract

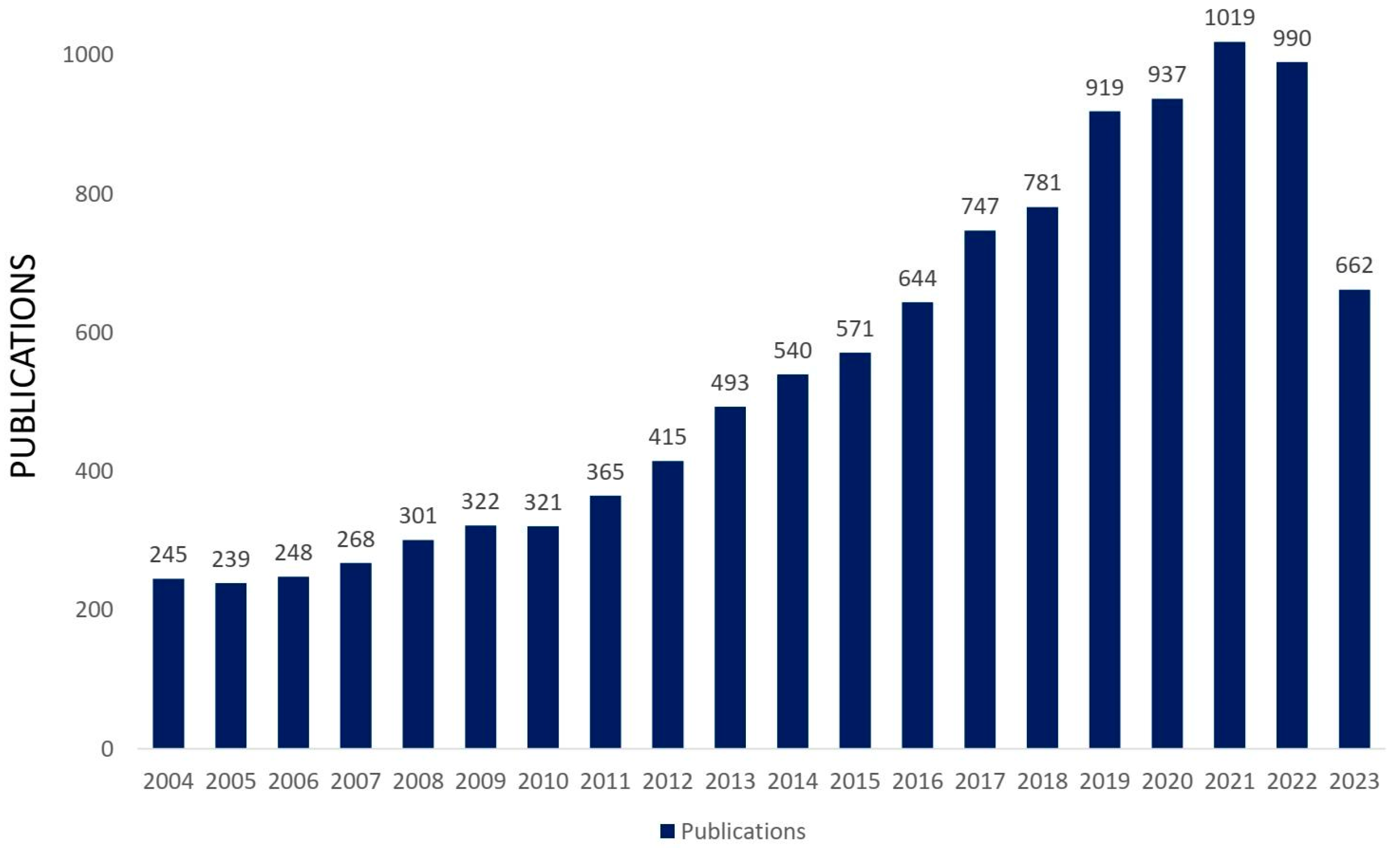

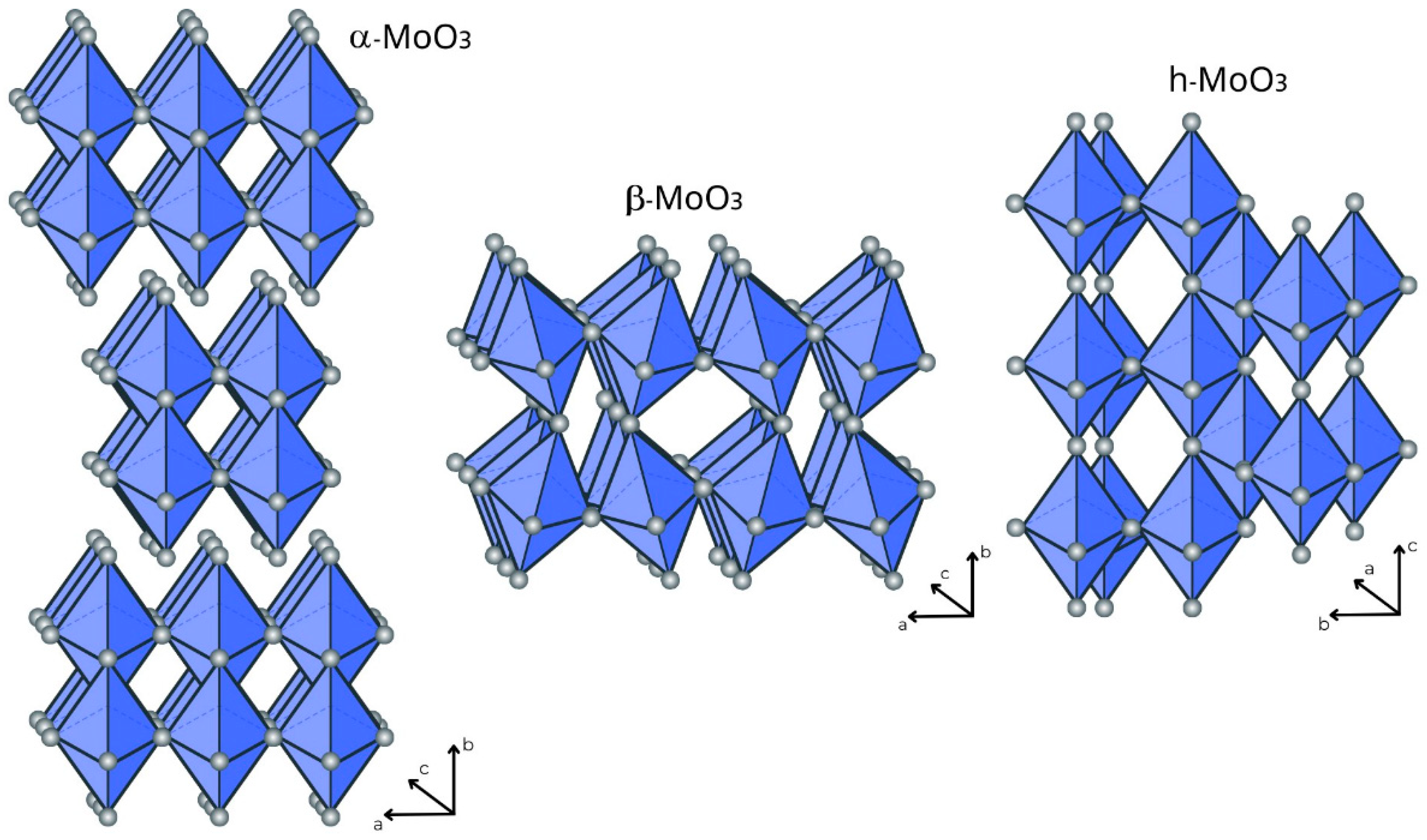

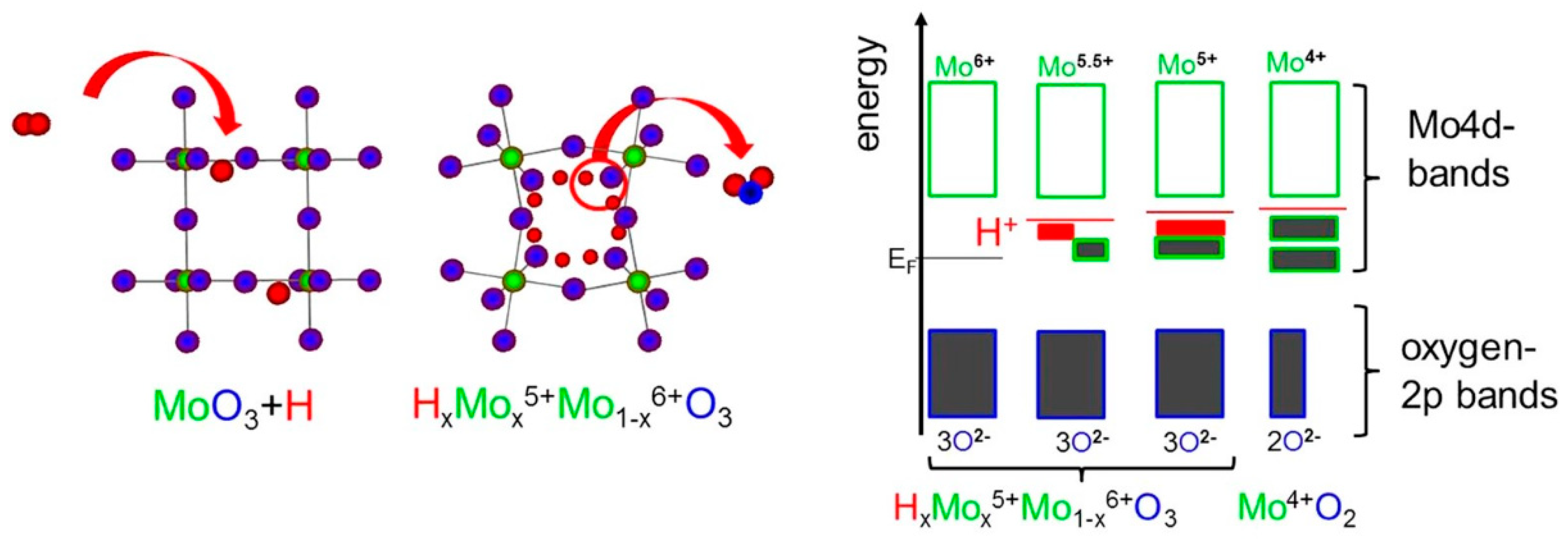

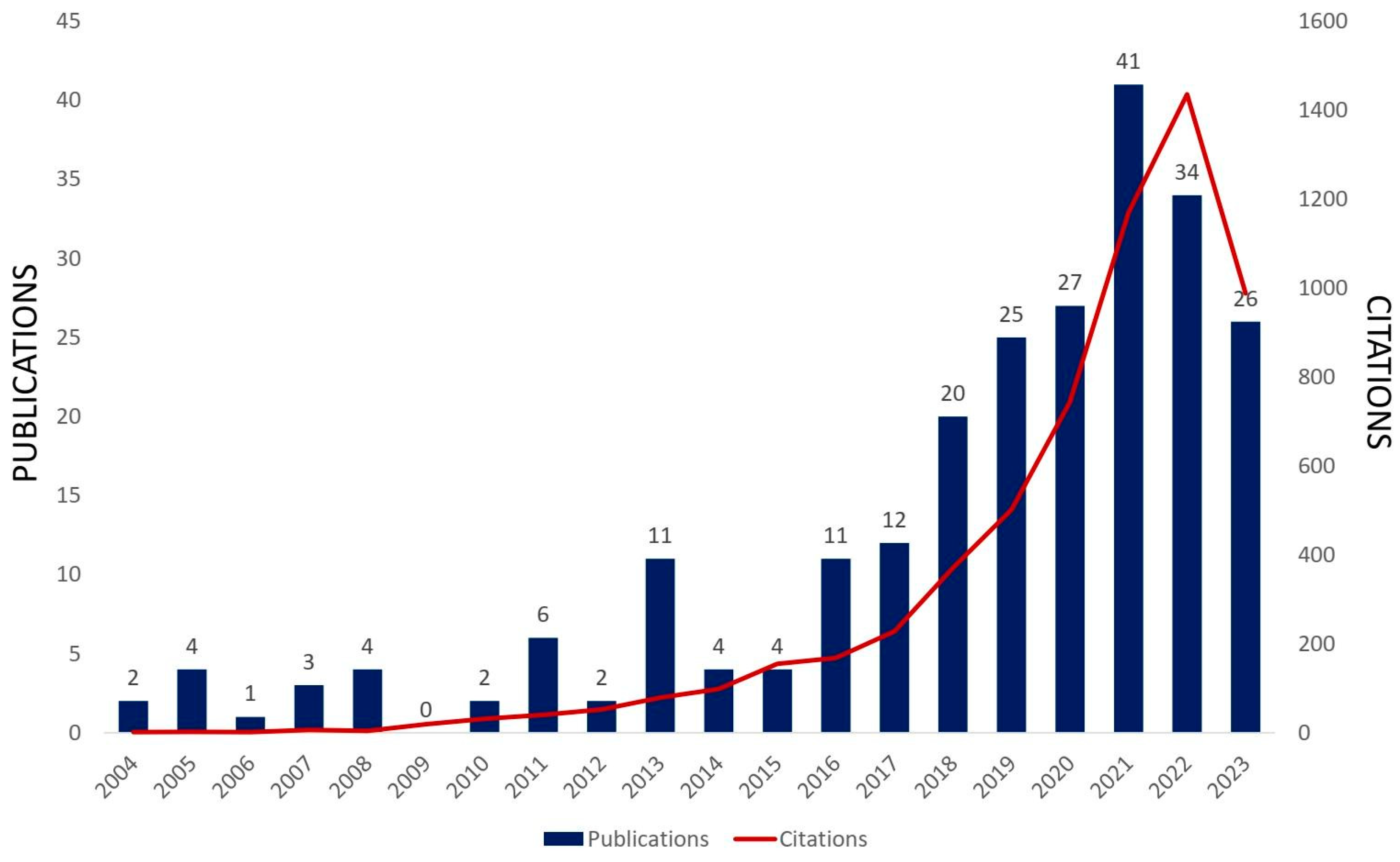

:1. Introduction

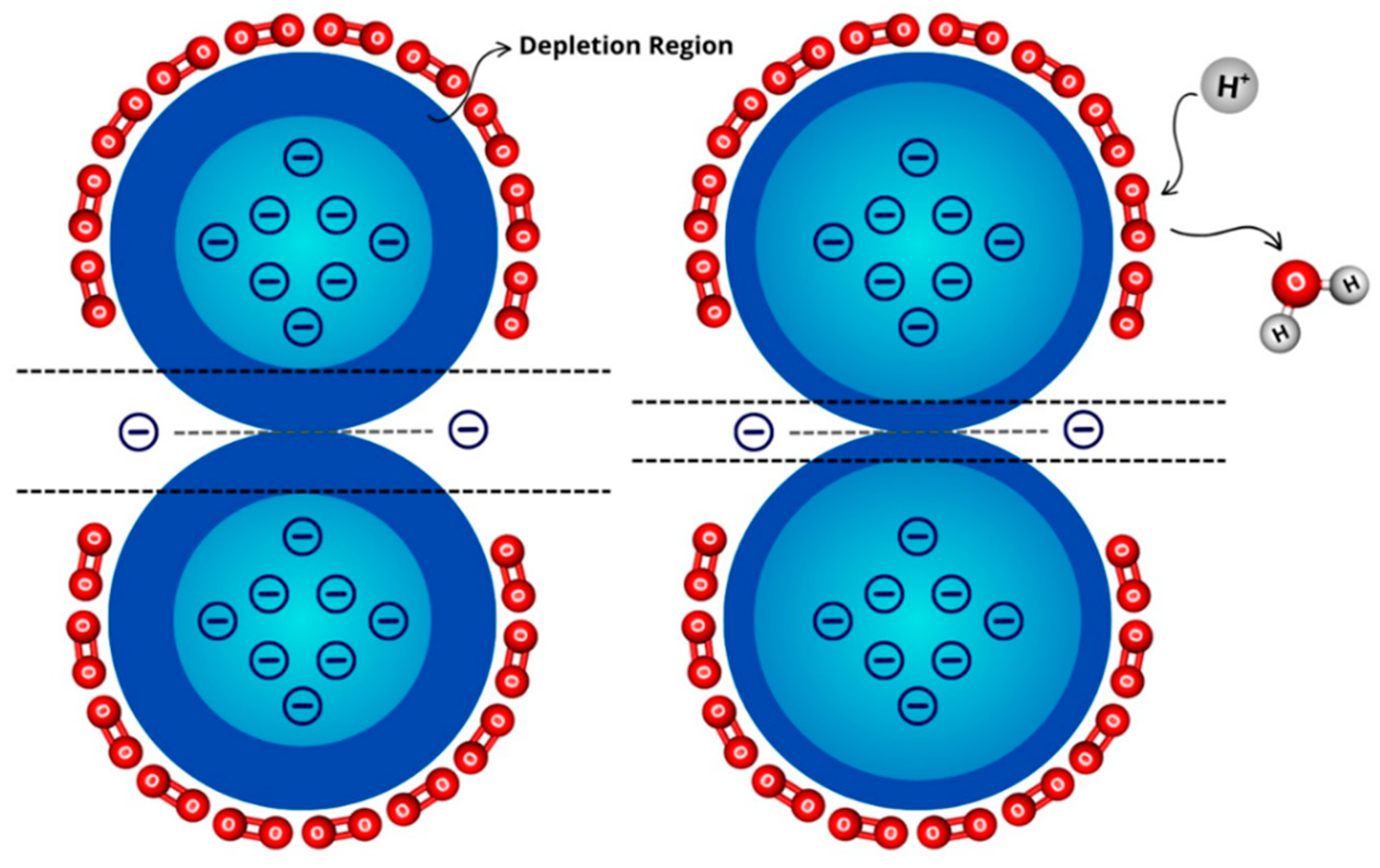

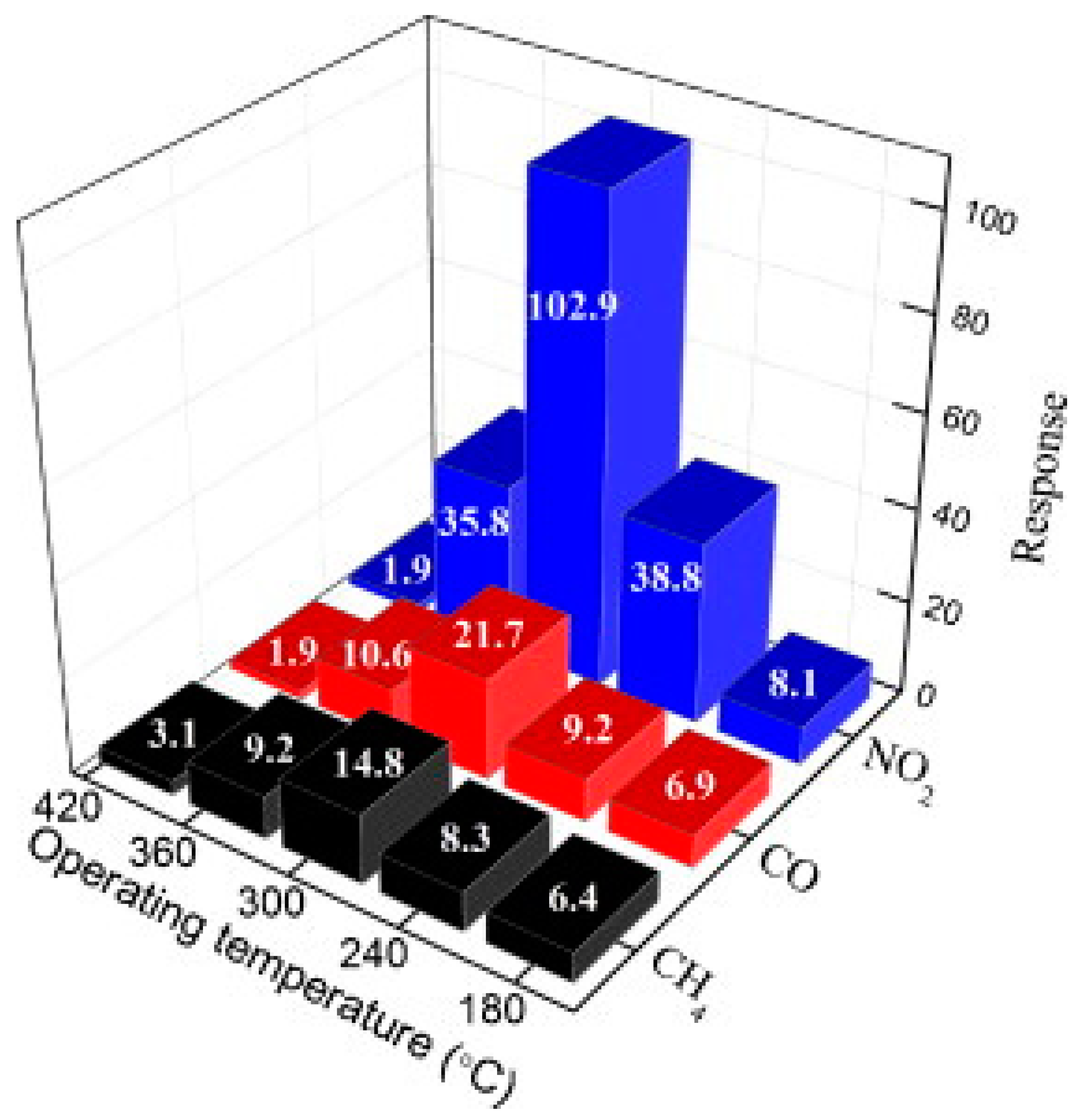

2. Air Pollution and Gas Sensing Applications

| Material | Morphology | Synthesis Method | Working Temp. (°C) | Gas (Conc.) | Optimal Sens. (%) | Optimal Temp. (°C) | Reference |

|---|---|---|---|---|---|---|---|

| α-MoO3 | Thin Films | Pulsed laser deposition | 100 and 200 | NO2 (10 ppm) | 25 | 100 | [31] |

| α-MoO3 | Nanobelts | Hydrothermal | (250–400) | C2H6O (800 ppm) | 173 | 300 | [35] |

| α-MoO3 | Nanobelts | Hydrothermal | (100–400) | 1-butylamine (100 ppm) | ~90 | 340 | [37] |

| α-MoO3 | Nanorods | Hydrothermal | (100–350) | Triethylamine (100 ppm) | ~115 | 200 | [38] |

| α-MoO3 | Nanoflowers/nanosheets | In situ oxidation | (100–350) | H2S (10 ppm) | ~38 | 250 | [40] |

| α-MoO3 | Large-sized | Vapor-phase transport | (50–125) | NO2 (10 ppb) | 2.3 | 100 | [42] |

| α-MoO3 | Hierarchical microflower | Thiourea-assisted hydrothermal | (120–380) | CO (50 ppm) | 8.02 | 260 | [43] |

| α-MoO3 | Nanoparticles | Thermal evaporation | (150–250) | CO2 (150 ppm) | 15 | 250 | [44] |

| α-MoO3 | Hierarchical nanofiber-assembled | Hydrothermal | (50–350) | C2H6O (400 ppm) | 24 | 300 | [45] |

| α-MoO3 | Hierarchical nanosheet-assembled | Hydrothermal | (50–350) | C2H6O (400 ppm) | 32 | 300 | [45] |

| α-MoO3 | Nanorods | Thermal evaporation under vacuum | RT a | NH3 (100 ppm) | 886 | RT a | [47] |

| α-MoO3 | Porous nanosheets | Solvothermal | 50, 90, 133, 172, and 217 | Trimethylamine (10 ppm) | 51.47 | 133 | [48] |

| α-MoO3 | Nanorods | Hydrothermal | (100–350) | Triethylamine (100 ppm) | 153.36 | 200 | [50] |

| α-MoO3 | Nanorods | Hydrothermal | 250 | Triethylamine (50 ppm) | 73.46 | 250 | [51] |

| α-MoO3 | Nanowires | Hydrothermal | (200–320) | Triethylamine (500 ppm) | ~4150 | 280 | [61] |

| h-MoO3 | Nanosheets | Dispersion | RT a | NH3 (0.3 ppm) | 3.78 | RT a | [39] |

| α-MoO3−x | Thin films | Chemical vapor deposition | (160–270) | NO2 (10 ppm) | 56 | 250 | [56] |

| α-MoO3−x | Thin films | Chemical vapor deposition | (160–270) | H2S (10 ppm) | 18 | 250 | [56] |

| Pt-α- MoO3 | Nanoparticles | Dispersion | (170–300) | H2 (500 ppm) | 18 | 260 | [36] |

| Au-α-MoO3 | Nanoparticles/Nanobelts | Hydrothermal | (100–400) | 1-butylamine (100 ppm) | ~300 | 240 | [37] |

| Zn-MoO3 | Hierarchical microflower | Thiourea-assisted hydrothermal | (120–380) | CO (50 ppm) | 31.23 | 240 | [43] |

| Au-MoO3 | Nanoparticles/nanobelts | Hydrothermal + Dispersion | (180–300) | Trimethylamine (50 ppm) | 70 | 280 | [49] |

| Pt-MoO3 | Nanobelts | Hydrothermal + Dispersion | RT a | HCHO (200 ppm) | 39.3 | RT a | [52] |

| Au-MoO3 | Nanoparticles/hollow spheres | Surfactant-modified approach | (217–330) | Toluene (100 ppm) | 17.5 | 250 | [59] |

| Au-MoO3 | Nanoparticles/hollow spheres | Surfactant-modified approach | (217–330) | Xylene (100 ppm) | 22.1 | 250 | [59] |

| Cr2O3-α-MoO3 | Nanorods | Hydrothermal | (100–350) | Triethylamine (100 ppm) | 150.25 | 200 | [38] |

| α-MoO3-ZnO | Nanoparticles/nanobelts | Hydrothermal | (100–300) | C2H6O (400 ppm) | 19 | 250 | [46] |

| α-MoO3-SnS | Nanotubes | Hydrothermal | 250 | Triethylamine (50 ppm) | 36.06 | 250 | [51] |

| NiO-α-MoO3 | Core-shell nanorods | Hydrothermal + Dispersion | (150–350) | (100 ppm) | 34.91 | 250 | [60] |

| h-BN-α-MoO3 | Nanowires/2D material | High-temperature pyrolysis | (200–320) | Triethylamine (500 ppm) | 8616 | 260 | [61] |

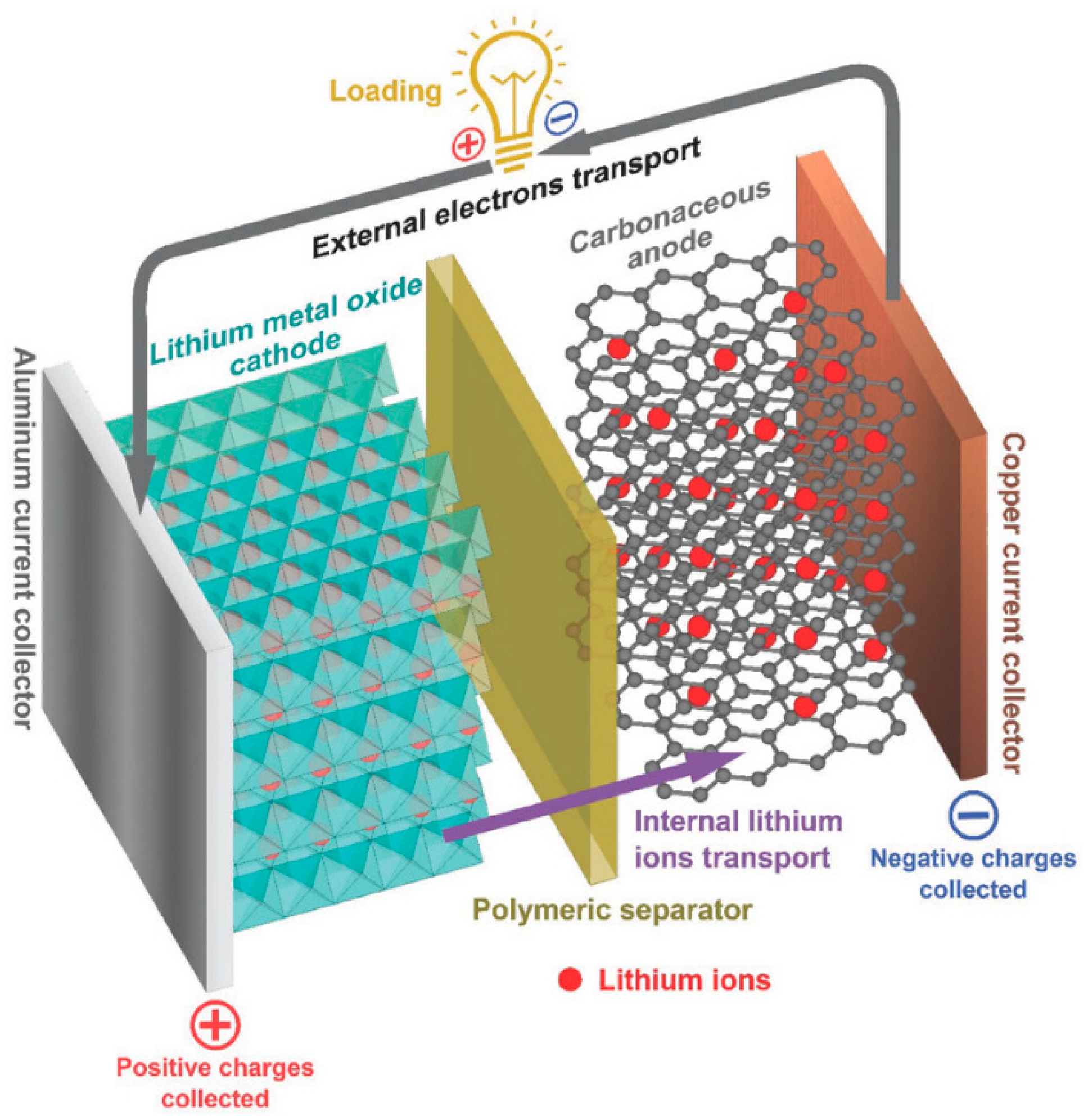

3. Lithium-Ion Batteries

| Material | Morphology | Synthesis Method | Current Density (mA·g−1) | Li Ion Capacity (mA·h.g−1) a | Cycles | Initial Coulombic Efficiency (ICE) (%) | Reference |

|---|---|---|---|---|---|---|---|

| α-MoO3 | Sheets | Thermal plasma | 3000 | 700 | 200 | 70 | [75] |

| α-MoO3 | Nanobelts | Hydrothermal | 100 | 787 | 100 | 70.6 | [77] |

| α-MoO3−x | Nanobelts | Mechanical grinding | 500 | 820 | 200 | UD b | [78] |

| N-α-MoO3−x | Nanoflowers | NR c | 100 | 1261 | 450 | 81.2 | [76] |

| Carbon-α-MoO3 | Nanoparticles/Nanofibers | Electrospinning | 500 | 801.1 | 200 | ~98 | [4] |

| Carbon-α-MoO3-MoO2 | Nanoribbons/Nanoparticles | Solid-phase | 100 | 840 | 100 | 52 | [24] |

| CNT-α-MoO3 | Nanofibers/Nanoplates | Electrospinning | 1000 | 972 | 100 | 62.7 | [62] |

| α-MoO3-SnS2 | Nanorods/Nanosheets | Hydrothermal | 60 | 568.2 | 100 | 92.7 | [79] |

| Carbon-MoO2 | Nanoplate-like | CO2 oxidation | 50 | 323 | 300 | UD b | [80] |

| α-MoO3-TiO2 | Nanobelts | Hydrothermal | 400 | 935.8 | 400 | 73 | [81] |

| α-MoO3-NiO | Flower-like microspheres | Hydrothermal + Coverage | 100 | 944 | 100 | 81 | [82] |

| Carbon-α-MoO3-SnO2 | Nanoflakes | Chemical Vapor Deposition + Dispersion | 200 | 1020.5 | 200 | 62.8 | [83] |

| α-MoO3-RGO | Nanoparticles | Ultrasonication | 500 | 568 | 100 | UD b | [84] |

| CNT-SiO2-α-MoO3 | Cactus-like | Self-assembly and in situ carbonization | 1000 | 700 | 500 | 99.8 | [85] |

| Fe2O3-TeO2-MoO3 | Nanoparticles | Molten | 1000 | 463.2 | 800 | 47.4 | [86] |

| Carbon-SnO2-MoO3 | Nanoparticles/Nanosheets | Hydrothermal | 200 | 1338.3 | 300 | 70 | [87] |

| h-MoO3-Grafene | Microrods | Scalable precipitation | 2000 | 665 | 300 | 63 | [88] |

| h-MoO3-GO | Microrods | Scalable precipitation | 1000 | 789 | 100 | 65 | [88] |

| SnO2-MoO3-Graphene | Nano-grain/Sheet-like | Hydrothermal | 200 | 1522.5 | 250 | 72.2 | [89] |

| SnO2-MoO3-CNT | Nanoparticles/Nanotubes | Hydrothermal | 200 | 1372.2 | 280 | 80.9 | [90] |

| Carbon-α-MoO3 | Nanoparticles | Solution combustion | 100 | 668 | 200 | UD b | [91] |

| α-MoO3-Fe2O3 | Micro-octahedrons | Thermolysis | 200 | 1218 | 350 | 81.9 | [92] |

| α-MoO3-MoO2-g-C3N4 | Nanosheets | Hydrothermal + Freeze-Drying | 500 | 992 | 100 | 72 | [93] |

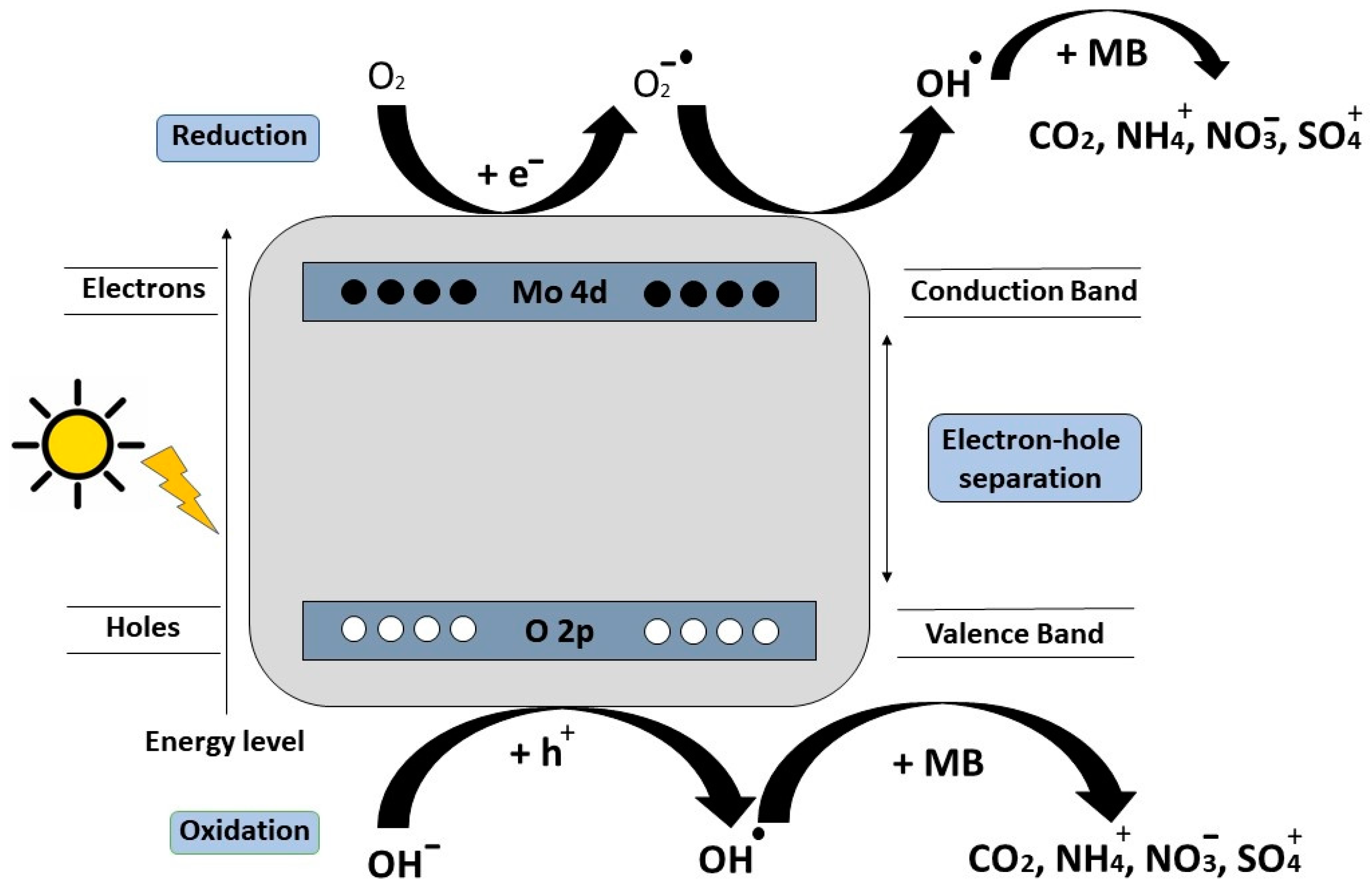

4. Water Pollution Treatment: Adsorption and Photocatalysis

| Material | Morphology | Synthesis Method | Adsorbent Nature | Target | Lamp/Power | Time (min) | Removal Efficiency (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| α-MoO3 | Nanoparticles | Hydrothermal | Cationic dye | MB | LED (12 W) | 90 | 99 | [128] |

| α-MoO3 | Plate-like | Pechini-based | Cationic dye | RhB | 160 W | 15 | 93.3 | [129] |

| α-MoO3 | Nanorods | Hydrothermal | Cationic dye | MB | Xenon (300 W) | 120 | 98 | [130] |

| α-MoO3 | Nanorods | Hydrothermal | Cationic dye | RhB | Xenon (300 W) | 120 | 90 | [130] |

| α-MoO3 | Microfibers | Hydrothermal | Cationic dye | MB | Halogen (150 W) | 120 | 90 | [131] |

| g-C3N4-tourmaline-α-MoO3−x | Nanosheets | Hydrothermal | Cationic dye | RhB | Xenon (300 W) | 40 | ~100 | [58] |

| g-C3N4-α-MoO3 | Nanosheets/Nanoparticles | Mixing/Annealing | Cationic dye | RhB | Xenon (300 W) | 24 | 100 | [112] |

| α-MoO3-Cu2S | Nanoparticles/Hexagonal rods | Hydrothermal | Cationic dye | MB | Metal-halide (200 W) | 120 | 98 | [116] |

| α-MoO3-SiO2 | Monoliths | Sol–Gel/Wet impregnation | Cationic dye | RhB | CFL/(45 W) | 150 | 88.6 | [118] |

| α-MoO3-NiO | Nanobelts/Nanoparticles | Hydrothermal | Cationic dye | MB | Xenon (500 W) | 120 | 96.5 | [120] |

| α-MoO3 | Nanoparticles | Hydrothermal | Anionic dye | Eosin Yellow | LED (12 W) | 90 | 94 | [128] |

| α-MoO3 | Nanorods | Hydrothermal | Anionic Dye | Alizarin | Xenon (300 W) | 120 | 74 | [130] |

| Ag-α-MoO3-TiO2 | Spherical particles | Hydrothermal | Anionic dye | MO | UV light (100 W) | 330 | 75.8 | [132] |

| g-C3N4-α-MoO3 | Nanosheets/Nanoparticles | Mixing/Annealing | Anionic dye | MO | Xenon (300 W) | 40 | 82.3 | [112] |

| α-MoO3-WO3 | Nanorods | Hydrothermal | Metal ion | Cr6+ | Tungsten (150 mW/cm−2) | 25 | 97.6 | [110] |

| α-MoO3@ZIF-8 | Nanowires/nanoparticles | Hydrothermal | Metal ion | Cr6+ | Sun 2000 | 40 | 100 | [133] |

| MWCNT-α-MoO3 | Nanotubes/Nanoparticles | Hydrothermal | Metal ion | Cr6+ | Xenon (300 W) | 30 | 100 | [134] |

| α-MoO3-Fe2O3 | Nanorods | Hydrothermal | Drug | Tetracycline | UD a | 90 | 96.5 | [111] |

| α-MoO3-SiO2 | Monoliths | Sol-Gel/Wet impregnation | Drug | Metronidazole | CFL/(45 W) | 180 | 67.4 | [118] |

| PPy-α-MoO3 | Spherical like Particles/Platelike | In situ polymerization | Drug | Acetaminophen | Xenon (500 W) | 180 | 93.4 | [121] |

| g-C3N4-α-MoO3 | Particles | Impregnation and calcination | Herbicide | 2,4-dichlorophenol | Natural sunlight | 300 | 99 | [119] |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- de Castro, I.A.; Datta, R.S.; Ou, J.Z.; Castellanos-Gomez, A.; Sriram, S.; Daeneke, T.; Kalantar-Zadeh, K. Molybdenum Oxides—From Fundamentals to Functionality. Adv. Mater. 2017, 29, 1701619–1701649. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, S.; Hassanzadeh-Tabrizi, S.A. MoO3 fibers and belts: Molten salt synthesis, characterization and optical properties. Ceram. Int. 2015, 41, 10839–10843. [Google Scholar] [CrossRef]

- Kim, M.R.; Ahn, S.J.; Jang, D.J. Fabrication and characterization of MoO3 clusters-coated TiO2 nanotubes showing charge-transferred photoluminescence. Eur. Phys. J. D 2009, 52, 75–78. [Google Scholar] [CrossRef]

- Zhao, X.; Jia, W.; Wu, X.; Lv, Y.; Qiu, J.; Guo, J.; Wang, X.; Jia, D.; Yan, J.; Wu, D. Ultrafine MoO3 anchored in coal-based carbon nanofibers as anode for advanced lithium-ion batteries. Carbon 2020, 156, 445–452. [Google Scholar] [CrossRef]

- Nadimicherla, R.; Zha, R.; Wei, L.; Guo, X. Single crystalline flowerlike α-MoO3 nanorods and their application as anode material for lithium-ion batteries. J. Alloys Compd. 2016, 687, 79–86. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, S.; Bawankule, P.; Gupta, A.; Kumar, R.; Kumar, P.; Tiwari, A. Selective wavelength optical filters from mixed polymorph and binary integration of MoO3 multilayer structures. Opt. Mater. 2021, 111, 110709–110718. [Google Scholar] [CrossRef]

- Ijeh, R.O.; Nwanya, A.C.; Nkele, A.C.; Madiba, I.G.; Bashir, A.K.H.; Ekwealor, A.B.C.; Osuji, R.U.; Maaza, M.; Ezema, F. Optical, electrical and magnetic properties of copper doped electrodeposited MoO3 thin films. Ceram. Int. 2020, 46, 10820–10828. [Google Scholar] [CrossRef]

- Koçak, S.; Ertaş, F.N.; Dursun, Z. Electrochemical deposition and behavior of mixed-valent molybdenum oxide film at glassy carbon and ITO electrodes. Appl. Surf. Sci. 2013, 265, 205–213. [Google Scholar] [CrossRef]

- Soultati, A.; Kostis, I.; Argitis, P.; Dimotikali, D.; Kennou, S.; Gardelis, S.; Speliotis, T.; Kontos, A.G.; Davazoglou, D.; Vasilopoulou, M. Dehydration of molybdenum oxide hole extraction layers via microwave annealing for the improvement of efficiency and lifetime in organic solar cells. J. Mater. Chem. C 2016, 4, 7683–7694. [Google Scholar] [CrossRef]

- Vasilopoulou, M.; Soultati, A.; Argitis, P.; Stergiopoulos, T.; Davazoglou, D. Fast recovery of the high work function of tungsten and molybdenum oxides via microwave exposure for efficient organic photovoltaics. J. Phys. Chem. Lett. 2014, 5, 1871–1879. [Google Scholar] [CrossRef]

- Vasilopoulou, M.; Douvas, A.M.; Georgiadou, D.G.; Palilis, L.C.; Kennou, S.; Sygellou, L.; Soultati, A.; Kostis, I.; Papadimitropoulos, G.; Davazoglou, D.; et al. The influence of hydrogenation and oxygen vacancies on molybdenum oxides work function and gap states for application in organic optoelectronics. J. Am. Chem. Soc. 2012, 134, 16178–16187. [Google Scholar] [CrossRef]

- Chithambararaj, A.; Bose, A.C. Hydrothermal synthesis of hexagonal and orthorhombic MoO3 nanoparticles. J. Alloys Compd. 2011, 509, 8105–8110. [Google Scholar] [CrossRef]

- Kolawole, F.O.; Ramirez, M.A.; Kolawole, S.K.; Varela, L.B.; Tschiptschin, A.P. Deposition and characterization of molybdenum oxide (MoO3) nanoparticles incorporated diamond-like carbon coatings using pulsed-DC PECVD. Mater. Lett. 2020, 278, 128420. [Google Scholar] [CrossRef]

- Lemos, R.M.J.; Balboni, R.D.C.; Cholant, C.M.; Azevedo, C.F.; Pawlicka, A.; Gündel, A.; Flores, W.H.; Avellaneda, C.O. Molybdenum doping effect on sol-gel Nb2O5: Li+ thin films: Investigation of structural, optical and electrochromic properties. Mater. Sci. Semicond. Process. 2021, 134, 105995. [Google Scholar] [CrossRef]

- Anjaneyulu, R.B.; Mohan, B.S.; Naidu, G.P.; Muralikrishna, R. Visible light enhanced photocatalytic degradation of methylene blue by ternary nanocomposite, MoO3/Fe2O3/rGO. J. Asian Ceram. Soc. 2018, 6, 183–195. [Google Scholar] [CrossRef]

- Sreedhara, M.B.; Matte, H.S.; Govindaraj, A.; Rao, C.N. Synthesis, characterization, and properties of few-layer MoO3. Chem. Asian J. 2013, 8, 2430–2435. [Google Scholar] [CrossRef] [PubMed]

- Koike, K.; Wada, R.; Yagi, S.; Harada, Y.; Sasa, S.; Yano, M. Characteristics of MoO3 films grown by molecular beam epitaxy. Jpn. J. Appl. Phys. 2014, 53, 05FJ02. [Google Scholar] [CrossRef]

- Han, Y.; Rheem, Y.; Lee, K.-H.; Kim, H.; Myung, N.V. Synthesis and characterization of orthorhombic-MoO3 nanofibers with controlled morphology and diameter. J. Ind. Eng. Chem. 2018, 65, 231–238. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J.; Zong, S.; Wang, X.; Chen, K.; Liu, L.; Fang, Y. Fabrication of graphitic carbon Nitride/Nonstoichiometric molybdenum oxide nanorod composite with the nonmetal plasma enhanced photocatalytic hydrogen evolution activity. J. Colloid Interface Sci. 2022, 606, 848–859. [Google Scholar] [CrossRef]

- Di Yao, D.; Field, M.R.; O’Mullane, A.P.; Kalantar-Zadeh, K.; Ou, J.Z. Electrochromic properties of TiO2 nanotubes coated with electrodeposited MoO3. Nanoscale 2013, 5, 10353–10359. [Google Scholar] [CrossRef]

- Samsuri, A.; Latif, M.N.; Shamsuddin, M.R.; Salleh, F.; Abu Tahari, M.N.; Tengku Saharuddin, T.S.; Dzakaria, N.; Yarmo, M.A. Studies on influence of hydrogen and carbon monoxide concentration on reduction progression behavior of molybdenum oxide catalyst. Int. J. Hydrogen Energy 2021, 46, 24831–24844. [Google Scholar] [CrossRef]

- Taghipour, E.; Tahmasebi, N. One-step hydrothermal synthesis of MoO3/MoO2 composite for efficient removal of methylene blue from aqueous solutions. Mater. Today Commun. 2021, 26, 102012–102020. [Google Scholar] [CrossRef]

- Chen, C.Z.; Li, Y.; Tang, X.D. Evidence of oxygen vacancy and possible intermediate gap state in layered α-MoO3 single-crystal nanobelts. Phys. B Condens. 2016, 481, 192–196. [Google Scholar] [CrossRef]

- Borgschulte, A.; Sambalova, O.; Delmelle, R.; Jenatsch, S.; Hany, R.; Nüesch, F. Hydrogen reduction of molybdenum oxide at room temperature. Sci. Rep. 2017, 7, 40761–40769. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Gattorno, G.; Martínez-Hernández, A.; Aleman-Vázquez, L.O.; Torres-García, E. Structural and thermal study of carbon-modified molybdenum sub-oxide catalysts. Appl. Catal. A Gen. 2007, 321, 117–124. [Google Scholar] [CrossRef]

- Dang, J.; Zhang, G.-H.; Chou, K.-C.; Reddy, R.G.; He, Y.; Sun, Y. Kinetics and mechanism of hydrogen reduction of MoO3 to MoO2. Int. J. Refract. Met. Hard Mater. 2013, 41, 216–223. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, G.-H.; Chou, K.-C. Mechanism and kinetic study of hydrogen reduction of ultra-fine spherical MoO3 to MoO2. Int. J. Refract. Hard Met. 2016, 54, 342–350. [Google Scholar] [CrossRef]

- Zhu, Y.; Yao, Y.; Luo, Z.; Pan, C.; Yang, J.; Fang, Y.; Deng, H.; Liu, C.; Tan, Q.; Liu, F.; et al. Nanostructured MoO3 for efficient energy and environmental catalysis. Molecules 2020, 25, 18. [Google Scholar] [CrossRef]

- Ren, H.; Sun, S.; Cui, J.; Li, X. Synthesis, functional modifications, and diversified applications of molybdenum oxides micro-/nanocrystals: A review Cryst. Growth Des. 2018, 18, 6326–6369. [Google Scholar] [CrossRef]

- Malik, R.; Joshi, N.; Tomer, V.K. Advances in the designs and mechanisms of MoO3 nanostructures for gas sensors: A holistic review. Mater. Adv. 2021, 2, 4190–4227. [Google Scholar] [CrossRef]

- Bisht, P.; Kumar, A.; Jensen, I.T.; Ahmad, M.; Belle, B.D.; Mehta, B.R. Enhanced gas sensing response for 2D α-MoO3 layers: Thickness-dependent changes in defect concentration, surface oxygen adsorption, and metal-metal oxide contact. Sens. Actuators B Chem. 2021, 341, 129953–129963. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Peng, S.; Xu, L.; Zeng, W. Volatile Organic Compounds Gas Sensors Based on Molybdenum Oxides: A Mini Review. Front. Chem. 2020, 8, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Bhat, S.; John, A.; Panda, P.K. A review on metal-oxide based p-n and n-n heterostructure nanomaterials for gas sensing applications. Sens. Int. 2021, 2, 100085–100103. [Google Scholar]

- Boboriko, N.E.; Dzichenka, Y.U. Molecular dynamics simulation as a tool for prediction of the properties of TiO2 and TiO2:MoO3 based chemical gas sensors. J. Alloys Compd. 2021, 855, 157490–157501. [Google Scholar] [CrossRef]

- Mo, Y.; Tan, Z.; Sun, L.; Lu, Y.; Liu, X. Ethanol-sensing properties of α-MoO3 nanobelts synthesized by hydrothermal method. J. Alloys Compd. 2020, 812, 152166–152170. [Google Scholar] [CrossRef]

- Farzi-kahkesh, S.; Fattah, A.; Rahmani, M.B. Synthesis and optimum temperature determination of highly sensitive MoO3-based heterojunction Schottky sensor for hydrogen detection. Microelectron. Eng. 2021, 235, 111453–111459. [Google Scholar] [CrossRef]

- Fu, H.; Wu, Z.; Yang, X.; He, P.; An, X.; Xiong, S.; Han, D. Ultra-high sensitivity and selectivity of Au nanoparticles modified MoO3 nanobelts towards 1-butylamine. Appl. Surf. Sci. 2021, 542, 148721–148731. [Google Scholar] [CrossRef]

- Li, W.; He, S.; Feng, L.; Yang, W. Cr-doped α-MoO3 nanorods for the fast detection of triethylamine using a pulse-heating strategy. Mater. Lett. 2019, 250, 143–146. [Google Scholar] [CrossRef]

- Sakhuja, N.; Jha, R.; Bhat, N. Facile green synthesis of 2D hexagonal MoO3 for selective detection of ammonia at room temperature. Mater. Sci. Eng. B. 2021, 271, 115249–115259. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Hu, X.; Wu, Q.; Xiong, W.; Qin, Z.; Xie, C.; Zeng, D. Exposed Mo atoms induced by micropores enhanced H2S sensing of MoO3 nanoflowers. J. Hazard. Mater. 2022, 429, 128270–128278. [Google Scholar] [CrossRef]

- Bai, S.; Chen, S.; Chen, L.; Zhang, K.; Luo, R.; Li, D.; Liu, C.C. Ultrasonic synthesis of MoO3 nanorods and their gas sensing properties. Sens. Actuators B Chem. 2012, 174, 51–58. [Google Scholar] [CrossRef]

- Li, W.; Ou, Q.; Wang, X.; Xing, K.; Tesfamichael, T.; Motta, N.; Qi, D.-C. Large-sized α-MoO3 layered single crystals for superior NO2 gas sensing. Appl. Surf. Sci. 2022, 586, 152793–152804. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Wei, Z.; Xu, L.; Zeng, W. Experimental and theoretical studies of Zn-doped MoO3 hierarchical microflower with excellent sensing performances to carbon monoxide. Ceram. Int. 2020, 46, 29222–29232. [Google Scholar] [CrossRef]

- Thomas, T.; Kumar, Y.; Ramos Ramón, J.A.; Agarwal, V.; Guzmán, S.S.; Reshmi, R.; Pushpan, S.; Loredo, S.L.; Sanal, K.C. Porous silicon/α-MoO3 nanohybrid based fast and highly sensitive CO2 gas sensors. Vacuum 2021, 184, 109983–109993. [Google Scholar] [CrossRef]

- Ji, H.; Zeng, W.; Li, Y. New insight into the gas-sensing properties of nanofiber-assembled and nanosheet-assembled hierarchical MoO3 structures. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 114, 113646–113652. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Fu, H.; Xu, L.; Jin, H.; Zhang, X.; Wang, L.; Yu, K. Synthesis of 1D α-MoO3/0D ZnO heterostructure nanobelts with enhanced gas sensing properties. J. Alloys Compd. 2019, 788, 248–256. [Google Scholar] [CrossRef]

- Thomas, T.; Jayababu, N.; Shruthi, J.; Mathew, A.; Cerdán-Pasarán, A.; Hernández-Magallanes, J.A.; Sanal, K.C.R.; Reshmi, R. Room temperature ammonia sensing of α-MoO3 nanorods grown on glass substrates. Thin Solid Film. 2021, 722, 138575–138584. [Google Scholar] [CrossRef]

- Shen, S.; Zhang, X.; Cheng, X.; Xu, Y.; Gao, S.; Zhao, H.; Zhou, X.; Huo, L. Oxygen-Vacancy-Enriched Porous α-MoO3 Nanosheets for Trimethylamine Sensing. ACS Appl. Nano Mater. 2019, 2, 8016–8026. [Google Scholar] [CrossRef]

- Zhang, J.; Song, P.; Li, Z.; Zhang, S.; Yang, Z.; Wang, Q. Enhanced trimethylamine sensing performance of single-crystal MoO3 nanobelts decorated with Au nanoparticles. J. Alloys Compd. 2016, 685, 1024–1033. [Google Scholar] [CrossRef]

- He, S.; Li, W.; Feng, L.; Yang, W. Rational interaction between the aimed gas and oxide surfaces enabling high-performance sensor: The case of acidic α-MoO3 nanorods for selective detection of triethylamine. J. Alloys Compd. 2019, 783, 574–582. [Google Scholar] [CrossRef]

- Ma, Y.T.; Ma, S.Y.; Tang, J.; Wu, Z.G.; Shi, J.; Zhao, Y.; Wang, Y.; Pei, S.T. Constructed heterostructured SnS@MoO3 hollow nanotubes and detected sensing properties towards TEA. Vacuum 2021, 184, 109939–109943. [Google Scholar] [CrossRef]

- Fu, X.; Yang, P.; Xiao, X.; Zhou, D.; Huang, R.; Zhang, X.; Cao, F.; Xiong, J.; Hu, Y.; Tu, Y.; et al. Ultra-fast and highly selective room-temperature formaldehyde gas sensing of Pt-decorated MoO3 nanobelts. J. Alloys Compd. 2019, 797, 666–675. [Google Scholar] [CrossRef]

- Yu, H.; Wang, C.; Meng, F.-Y.; Liang, J.-G.; Kashan, H.S.; Adhikari, K.K.; Wang, L.; Kim, E.-S.; Kim, N.-Y. Design and analysis of ultrafast and high-sensitivity microwave transduction humidity sensor based on belt-shaped MoO3 nanomaterial. Sens. Actuators B Chem. 2020, 304, 127138–127147. [Google Scholar] [CrossRef]

- Mohamed Azharudeen, A.; Karthiga, R.; Rajarajan, M.; Suganthi, A. Selective enhancement of non-enzymatic glucose sensor by used PVP modified on α-MoO3 nanomaterials. Microchem. J. 2020, 157, 105006–105014. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, J.; Gao, F.; Tu, X.; Qian, Y.; Yu, Y.; Lu, L.; Wang, W. Development of a new electrochemical sensing platform based on MoO3-polypyrrole nanowires/MWCNTs composite and its application to luteolin detection. Synth. Met. 2020, 271, 116620–116627. [Google Scholar] [CrossRef]

- Rahman, F.; Zavabeti, A.; Rahman, M.A.; Arash, A.; Mazumder, A.; Walia, S.; Sriram, S.; Bhaskaran, M.; Balendhran, S. Dual Selective Gas Sensing Characteristics of 2D alpha-MoO3−x via a Facile Transfer Process. ACS Appl. Mater. Interfaces 2019, 11, 40189–40195. [Google Scholar] [CrossRef]

- Guo, J.; Li, H.; Ma, Q.; Zhang, Q.; Wang, Y.; Wang, X. Surface oxygen vacancies actuated MoO3/CuMoO4 self-assembled microspheres for highly selective triethylamine detection. Sens. Actuators B Chem. 2022, 369, 132256–132266. [Google Scholar] [CrossRef]

- Zheng, F.; Dong, F.; Lv, Z.; Li, H.; Zhou, L.; Chen, Y.; Huo, T.; Luo, X. A novel g-C3N4/tourmaline composites equipped with plasmonic MoO3−x to boost photocatalytic activity. Colloids Interface Sci. Commun. 2021, 43, 100434–100443. [Google Scholar] [CrossRef]

- Sui, L.-L.; Zhang, X.-F.; Cheng, X.; Wang, P.; Xu, Y.-M.; Gao, S.; Zhao, H.; Huo, L.-H. Au-loaded hierarchical MoO3 hollow spheres with enhanced gas sensing performance for the detection of BTX (benzene, toluene and xylene) and the sensing mechanism. ACS Appl. Mater. Interfaces 2017, 9, 1661–1670. [Google Scholar] [CrossRef]

- Yang, W.; Fang, B.; Xiao, X.; Meng, H.; Liu, S. Hierarchical core-shell heterostructures of α-MoO3 nanorods@NiO nanosheets for significant detection of ethyl acetate vapor. Sens. Actuators B Chem. 2022, 358, 131457–131466. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, H.; Cao, J.; Wang, Y. Ultrahigh sensitive and selective triethylamine sensor based on h-BN modified MoO3 nanowires. Adv Powder Technol. 2022, 33, 103432–103443. [Google Scholar] [CrossRef]

- Oh, S.H.; Park, S.M.; Kang, D.-W.; Kang, Y.C.; Cho, J.S. Fibrous network of highly integrated carbon nanotubes/MoO3 composite bundles anchored with MoO3 nanoplates for superior lithium ion battery anodes. J. Ind. Eng. Chem. 2020, 83, 438–448. [Google Scholar] [CrossRef]

- Lee, H.-J.; Shim, H.-W.; Kim, J.-C.; Kim, D.-W. Mo-MoO3-graphene nanocomposites as anode materials for lithium-ion batteries: Scalable, facile preparation and characterization. Electrochim. Acta 2017, 251, 81–90. [Google Scholar] [CrossRef]

- Deng, L.; Wei, T.; Liu, J.; Zhan, L.; Chen, W.; Cao, J. Recent developments of carbon-based anode materials for flexible lithium-ion batteries. Crystals 2022, 12, 1279. [Google Scholar] [CrossRef]

- Pavlovskii, A.A.; Pushnitsa, K.; Kosenko, A.; Novikov, P.; Popovich, A.A. Organic Anode Materials for Lithium-Ion Batteries: Recent Progress and Challenges. Materials 2022, 16, 177. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Peng, J.; Zhang, Y.; Cui, Y.; An, L.; Chen, P.; Zhang, F. Lithium vanadium oxide/graphene composite as a promising anode for lithium-ion batteries. Nanomaterials 2022, 13, 43. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Liang, D.; Zhao, H. Enhanced electrochemical Performance Promoted by Tin in silica Anode materials for Stable and High-capacity Lithium-ion Batteries. Materials 2021, 14, 1071. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Hong, L. Micro- and Nano-Structured Vanadium Pentoxide (V2O5) for Electrodes of Lithium-Ion Batteries. Adv. Energy Mater. 2017, 7, 1602545–1602577. [Google Scholar] [CrossRef]

- Cui, Y.; Pu, Y.; Hao, Y.; Zhuang, Q. Electrochemical behavior of α-MoO3 nanobelts as cathode material for Lithium ions batteries Russ. J. Electrochem. 2015, 51, 119–124. [Google Scholar]

- Wang, X.J.; Nesper, R.; Villevieille, C.; Novák, P. Ammonolyzed MoO3 nanobelts as novel cathode material of rechargeable Li-Ion batteries. Adv. Energy Mater. 2013, 3, 606–614. [Google Scholar] [CrossRef]

- Opra, D.P.; Gnedenkov, S.V.; Sokolov, A.A.; Podgorbunsky, A.B.; Laptash, N.M.; Sinebryukhov, S.L. Fluorine substituted molybdenum oxide as cathode material for Li-ion battery. Mater. Lett. 2015, 160, 175–178. [Google Scholar] [CrossRef]

- Hashem, A.M.; Groult, H.; Mauger, A.; Zaghib, K.; Julien, C.M. Electrochemical properties of nanofibers a-MoO3 as cathode materials for Li batteries. J. Power Sources 2012, 219, 126–132. [Google Scholar] [CrossRef]

- Vincent, R.C.; Cheetham, A.K.; Seshadri, R. Structure and lithium insertion in oxides of molybdenum. APL Mater. 2023, 11, 010902–010912. [Google Scholar] [CrossRef]

- Ramana, C.; Mauger, A.; Julien, C.M. Growth, characterization and performance of bulk and nanoengineered molybdenum oxides for electrochemical energy storage and conversion. Prog. Cryst. Growth Charact. Mater. 2021, 67, 100533–100594. [Google Scholar] [CrossRef]

- Du, Y.; He, J.; Hou, G.; Yuan, F. α-MoO3 sheets with high exposed plane reinforced by thermal plasma for stable Li-ion storage. Electrochim. Acta 2020, 334, 135593–135602. [Google Scholar] [CrossRef]

- Hou, X.; Ruan, M.; Zhou, L.; Wu, J.; Meng, B.; Huang, W.; Zhong, K.; Yang, K.; Fang, Z.; Xie, K. Superior lithium storage performance in MoO3 by synergistic effects: Oxygen vacancies and nanostructures. J. Energy Chem. 2023, 78, 91–101. [Google Scholar] [CrossRef]

- Cao, L.; He, J.; Li, J.; Yan, J.; Huang, J.; Qi, Y.; Feng, L. Surface tiny grain-dependent enhanced rate performance of MoO3 nanobelts with pseudocapacitance contribution for lithium-ion battery anode. J. Power Sources 2018, 392, 87–93. [Google Scholar] [CrossRef]

- Paste, R.; Abbas, S.A.; Singh, A.; Lin, H.-C.; Chu, C.W. Oxygen-Enriched α-MoO3–x nanobelts suppress lithium dendrite formation in stable lithium-metal batteries. J. Power Sources 2021, 507, 230306–230316. [Google Scholar] [CrossRef]

- Chen, X.; Huang, Y.; Zhang, K. a-MoO3 nanorods coated with SnS2 nano sheets core-shell composite as high-performance anode materials of lithium ion batteries. Electrochim. Acta 2016, 222, 956–964. [Google Scholar] [CrossRef]

- Byeon, A.; Hatter, C.; Park, J.H.; Ahn, C.W.; Gogotsi, Y.; Lee, J.W. Molybdenum oxide/carbon composites derived from the CO2 oxidation of Mo2CTx (MXene) for lithium ion battery anodes. Electrochim. Acta 2017, 258, 979–987. [Google Scholar] [CrossRef]

- Cheng, X.; Li, Y.; Sang, L.; Ma, J.; Shi, H.; Liu, X.; Lu, J.; Zhang, Y. Boosting the electrochemical performance of MoO3 anode for long-life lithium ion batteries: Dominated by an ultrathin TiO2 passivation layer. Electrochim. Acta 2018, 269, 241–249. [Google Scholar] [CrossRef]

- Teng, Y.; Zhao, H.; Zhang, Z.; Li, Y.; Liu, H. Self-assembly of flower-like MoO3-NiO microspheres with carbon coating as high-performance anode material for lithium-ion batteries. Mater. Lett. 2019, 246, 141–143. [Google Scholar] [CrossRef]

- Wang, H.; Xie, S.; Yao, T.; Wang, J.; She, Y.; Shi, J.-W.; Shan, G.; Zhang, Q.; Han, X.; Leung, M.K. Casting amorphorized SnO2/MoO3 hybrid into foam-like carbon nanoflakes towards high-performance pseudocapacitive lithium storage. J. Colloid Interface Sci. 2019, 547, 299–308. [Google Scholar] [CrossRef] [PubMed]

- Naresh, N.; Jena, P.; Satyanarayana, N. Compounds, Facile synthesis of MoO3/rGO nanocomposite as anode materials for high performance lithium-ion battery applications. J. Alloys Compd. 2019, 810, 151920–151928. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Z.; Liu, B.; Wang, S.; Xiong, C. Fabrication of cactus-like CNT/SiO2/MoO3 ternary composites for superior lithium storage. Energy 2021, 217, 119386–119393. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Wu, J. Fe2O3–TeO2–MoO3 semiconductor glass-ceramics as anode materials for high specific capacity lithium ion batteries. Mater. Chem. Phys. 2021, 258, 123894–123903. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, K.; Ke, J.; Guo, Z.; Deng, X.; Bai, C.; Sun, Y.; Wang, Q.; Yang, B.; Dong, H.; et al. Synthesis of ternary SnO2–MoO3–C composite with nanosheet structure as high-capacity, high-rate and long-lifetime anode for lithium-ion batteries. Ceram. Int. 2021, 47, 9303–9309. [Google Scholar] [CrossRef]

- Almodóvar, P.; López, M.L.; Ramírez-Castellanos, J.; Nappini, S.; Magnano, E.; González-Calbet, J.M.; Díaz-Guerra, C. Synthesis, characterization and electrochemical assessment of hexagonal molybdenum trioxide (h-MoO3) micro-composites with graphite, graphene and graphene oxide for lithium ion batteries. Electrochim. Acta 2021, 365, 137355–137367. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, M.; Ke, J.; Feng, Y.; Li, W.; Xiong, D.; He, M. Synthesis and electrochemical performances of ternary nanocomposite SnO2@ MoO3@ graphene as high-performance anode material for lithium-ion batteries. Chem. Phys. Lett. 2021, 770, 138408–138417. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, M.; Ke, J.; Li, W.; Feng, Y.; Xiong, D.; He, M. SnO2-MoO3 nanoparticles anchored in carbon nanotubes as a large-capacity, high-rate, and long-lifetime anode for lithium-ion batteries. Ceram. Int. 2021, 47, 27022–27031. [Google Scholar] [CrossRef]

- Shahsank, M.; Naik, H.B.; Sumedha, H.; Nagaraju, G. Implementing an in-situ carbon formation of MoO3 nanoparticles for high performance lithium-ion battery. Ceram. Int. 2021, 47, 10261–10267. [Google Scholar] [CrossRef]

- Chen, Y.; Zong, W.; Chen, H.; Li, Z.; Pang, H.; Yuan, A.; Yang, H.; Shen, X. Cyanide-metal framework derived porous MoO3-Fe2O3 hybrid micro-octahedrons as superior anode for lithium-ion batteries. Chem. Eng. J. 2021, 426, 130347–130354. [Google Scholar] [CrossRef]

- Zhang, P.; Cai, B.; Feng, Y.; Pan, H.; Yao, J. Constructing MoO3@ MoO2 heterojunction on g-C3N4 nanosheets with advanced Li-ion storage ability. J. Alloys Compd. 2021, 875, 160077–160084. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, X.; Zhang, X.; Xu, Y.; Gao, S.; Zhao, H.; Huo, L. High efficient and selective removal of Pb2+ through formation of lead molybdate on α-MoO3 porous nanosheets array. J. Colloid Interface Sci. 2017, 491, 80–88. [Google Scholar] [CrossRef] [PubMed]

- Sulejmanović, J.; Kovač, N.; Memić, M.; Šabanović, E.; Begić, S.; Sher, F.; Engineering, E. Selective removal of lead ions from aqueous solutions using SiO2–MoO3: Isotherm, kinetics and thermodynamic studies. Case Stud. Chem. Environ. Eng. 2021, 3, 100083–100087. [Google Scholar] [CrossRef]

- Chen, J.; Liao, Y.; Wan, X.; Tie, S.; Zhang, B.; Lan, S.; Gao, X. A high performance MoO3@ MoS2 porous nanorods for adsorption and photodegradation of dye. J. Solid State Chem. 2020, 291, 121652–121662. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, J.; Qin, Z.; Huang, R.; Wang, Y.; Tong, S. Construction of MoS2 nanoarrays and MoO3 nanobelts: Two efficient adsorbents for removal of Pb (II), Au (III) and Methylene Blue. J. Environ. Sci. 2022, 111, 38–50. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, R. Physics, Efficient adsorption of methylene blue on hybrid structural phase of MoO3 nanostructures. Mater. Chem. Phys. 2022, 275, 125211–125225. [Google Scholar] [CrossRef]

- Ren, P.; Ren, X.; Xu, J.; Li, H.; Zheng, Y.; Hong, Y.; Lin, Y.; Zhou, Y.; Chen, Y.; Zhang, W. Excellent adsorption property and mechanism of oxygen vacancies-assisted hexagonal MoO3 nanosheets for methylene blue and rhodamine b dyes. Appl. Surf. Sci. 2022, 597, 153699–153709. [Google Scholar] [CrossRef]

- Ma, Y.; Jia, Y.; Jiao, Z.; Wang, L.; Yang, M.; Bi, Y.; Qi, Y. Facile synthesize α-MoO3 nanobelts with high adsorption property. Mater. Lett. 2015, 157, 53–56. [Google Scholar] [CrossRef]

- Kedves, E.-Z.; Bárdos, E.; Gyulavári, T.; Pap, Z.; Hernadi, K.; Baia, L. Dependence of cationic dyes’ adsorption upon α-MoO3 structural properties. Appl. Surf. Sci. 2022, 573, 151584–151596. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Q.; Luo, J.; Chen, H.; Cai, W.; Su, X. Hydrothermal fabrication of TiO2-MoO3 nanocomposites with superior performance for water treatment. Nano-Struct. Nano-Objects 2018, 13, 93–99. [Google Scholar] [CrossRef]

- Muthukumar, P.; Sowmiya, E.; Arunkumar, G.; Pannipara, M.; Al-Sehemi, A.G.; Anthony, S.P. Highly enhanced dye adsorption of MoO3 nanoplates fabricated by hydrothermal-calcination approach in presence of chitosan and thiourea. Chemosphere 2022, 291, 132926–132936. [Google Scholar] [CrossRef]

- Heiba, H.F.; Taha, A.A.; Mostafa, A.R.; Mohamed, L.A.; Fahmy, M.A. Preparation and characterization of novel mesoporous chitin blended MoO3-montmorillonite nanocomposite for Cu (II) and Pb (II) immobilization. Int. J. Biol. Macromol. 2020, 152, 554–566. [Google Scholar] [CrossRef]

- Allam, E.A.; El-Sharkawy, R.M.; Gizawy, M.; Mahmoud, M.E. Physics, Assembly of CeO2–MoO3–SiO2 (CH2) 3-(Alginate)2 As A novel nanocomposite for removal of MnII/CrVI and 56Mn/51Cr radionuclides from water. Mater. Chem. Phys. 2021, 262, 124278–124293. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, D.; Xu, Y.; Liu, X.; Materials, M. Adsorption of thiophene compounds on MoO3/γ-Al2O3 catalysts with different mesopore sizes. Microporous Mesoporous Mater. 2017, 238, 46–55. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, H.; Zhang, Z.; Dang, T.; Zhang, W.; Wang, J.; Lu, Y.; Liu, S. Keggin-type polycationic AlO4Al12 (OH)24 (H2O) 127+ intercalated MoO3 composites for methyl orange adsorption. Chin. Chem. Lett. 2022, 33, 2617–2620. [Google Scholar] [CrossRef]

- Huang, J.; Ye, M.; Qu, Y.; Chu, L.; Chen, R.; He, Q.; Xu, D. Pb (II) removal from aqueous media by EDTA-modified mesoporous silica SBA-15. J. Colloid Interface Sci. 2012, 385, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Huang, L.; Xu, J.; Xu, H.; Xu, Y.; Xia, J.; Li, H. Visible-light-induced blue MoO3–C3N4 composite with enhanced photocatalytic activity. Mater. Res. Bull. 2015, 70, 500–505. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Balakumar, V.; Jones, B.F.; Muthuraj, V. Physics, A structural unique 1D-MoO3@ 3D-WO3 nanohybrid for stable and reusable photocatalytic conversion of hexavalent chromium in aqueous medium. Mater. Chem. Phys. 2021, 267, 124688–124699. [Google Scholar] [CrossRef]

- Xiao, J.; Lv, J.; Lu, Q. Building Fe2O3/MoO3 nanorod heterojunction enables better tetracycline photocatalysis. Mater. Lett. 2022, 311, 131580–131584. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Chen, X.; Zang, J. MoO3/g-C3N4 heterostructure for degradation of organic pollutants under visible light irradiation: High efficiency, general degradation and Z-scheme degradation mechanism. Ceram. Int. 2021, 47, 33697–33708. [Google Scholar] [CrossRef]

- Agarwal, P.; Paramasivam, I.; Shrestha, N.K.; Schmuki, P. MoO3 in self-organized TiO2 nanotubes for enhanced photocatalytic activity. Chem. Asian J. 2010, 5, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Li, Y.; Zhou, Y.; Li, W.; Ji, S.; Yao, H.; Cao, X.; Jin, P. Interfacial-charge-transfer-induced photochromism of MoO3@ TiO2 crystalline-core amorphous-shell nanorods. Sol. Energy Mater. Sol. Cells 2017, 160, 116–125. [Google Scholar] [CrossRef]

- Arfaoui, A.; Mhamdi, A.; Besrour, N.; Touihri, S.; Ouzari, H.; Alrowaili, Z.; Amlouk, M. Investigations into the physical properties of SnO2/MoO3 and SnO2/WO3 bi-layered structures along with photocatalytic and antibacterial applications. Thin Solid Film. 2018, 648, 12–20. [Google Scholar] [CrossRef]

- Patil, S.B.; Kishore, B.; Manjunath, K.; Reddy, V.; Nagaraju, G. One step hydrothermal synthesis of novel Cu2S-MoO3 nanocomposite for lithium ion battery and photocatalytic applications. Int. J. Hydrogen Energy 2018, 43, 4003–4014. [Google Scholar] [CrossRef]

- Zhu, J.-M.; Hosseini, M.; Fakhri, A.; Rad, S.S.; Hadadi, T.; Nobakht, N.; Biology, P.B. Highly efficient of molybdenum trioxide-cadmium titanate nanocomposites for ultraviolet light photocatalytic and antimicrobial application: Influence of reactive oxygen species. J. Photochem. Photobiol. B Biol. 2019, 191, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Basu, S. Visible-light-driven efficient photocatalytic abatement of recalcitrant pollutants by centimeter-length MoO3/SiO2 monoliths with long service life. Appl. Mater. Today 2021, 23, 101033–101045. [Google Scholar] [CrossRef]

- Alenazi, D.A.K.; Aslam, M.; Chandrasekaran, S.; Soomro, M.T.; Ali, S.; Danish, E.Y.; Ismail, I.; Hameed, A. Facile fabrication of MoO3/g-C3N4 pn junction for boosted photocatalytic elimination of 2,4-D under natural sunlight exposure. J. Environ. Chem. Eng. 2021, 9, 106322. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Liu, Z.; Yang, D.; Zhang, M.; Gao, L.; Zhou, Y.; Lu, C. Facile synthesis of Z-scheme NiO/α-MoO3 pn heterojunction for improved photocatalytic activity towards degradation of methylene blue. Arab. J. Chem. 2022, 15, 103513–103525. [Google Scholar] [CrossRef]

- Srinithi, S.; Balakumar, V.; Chen, S.-M. In-situ fabrication of polypyrrole composite with MoO3: An effective interfacial charge transfers and electrode materials for degradation and determination of acetaminophen. Chemosphere 2022, 291, 132977–132987. [Google Scholar] [CrossRef]

- Paul, M.; Dhanasekar, M.; Bhat, S.V. Silver doped h-MoO3 nanorods for sonophotocatalytic degradation of organic pollutants in ambient sunlight. Appl. Surf. Sci. 2017, 418, 113–118. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, Y.; Zhang, J.; Chen, K.; Huang, C.; Chen, H.; Qiu, X. Plasmonic MoO3−x nanosheets with tunable oxygen vacancies as efficient visible light responsive photocatalyst. Appl. Surf. Sci. 2019, 490, 395–402. [Google Scholar] [CrossRef]

- Li, J.; Xu, X.; Huang, B.; Lou, Z.; Li, B. Light-induced in situ formation of a nonmetallic plasmonic MoS2/MoO3–x heterostructure with efficient charge transfer for CO2 reduction and SERS detection. ACS Appl. Mater. Interfaces 2021, 13, 10047–10053. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Wang, Z.; Rao, Y.; Zhao, Y.; Cao, J.; Ho, K.-F.; Zhai, Y.; Xiong, M.; Li, J.; Huang, Y. Oxygen vacancy mediated α-MoO3 bactericidal nanocatalyst in the dark: Surface structure dependent superoxide generation and antibacterial mechanisms. J. Hazard. Mater. 2023, 443, 130275–130285. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.-Y.; Niu, C.-G.; Huang, D.-W.; Guo, H.; Feng, H.-P.; Li, L.; Liu, H.-Y.; Fan, Q.-Q.; Qin, M.-Z. Appropriate oxygen vacancies and Mo-N bond synergistically modulate charge transfer dynamics of MoO3−x/S-CN for superior photocatalytic disinfection: Unveiling synergistic effects and disinfection mechanism. J. Hazard. Mater. 2023, 445, 130481–130496. [Google Scholar] [CrossRef]

- Wang, K.-L.; Zhao, H.-M.; Li, Y.; Sun, T.; Xue, B. Highly dispersed molybdenum-embedded polymeric carbon nitride with enhanced photocatalytic activity for degradation of dyes and antibiotics. Appl. Surf. Sci. 2020, 528, 146931–146938. [Google Scholar] [CrossRef]

- Sharma, P.K.; Raghubanshi, A.; Shah, K. Examining dye degradation and antibacterial properties of organically induced α-MoO3 nanoparticles, their uptake and phytotoxicity in rice seedlings. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100315–100325. [Google Scholar]

- Sales, H.B.; Menezes, R.R.; Neves, G.A.; Souza, J.J.d.; Ferreira, J.M.; Chantelle, L.; Menezes de Oliveira, A.L.; Lira, H.L. Development of sustainable heterogeneous catalysts for the photocatalytic treatment of effluents. Sustainability 2020, 12, 7393. [Google Scholar] [CrossRef]

- Hussain, M.K.; Khalid, N.R. Surfactant-assisted synthesis of MoO3 nanorods and its application in photocatalytic degradation of different dyes in aqueous environment. J. Mol. Liq. 2022, 346, 117871–117882. [Google Scholar] [CrossRef]

- Dewangan, K.; Singh, D.; Satpute, N.; Singh, R.; Jaiswal, A.; Shrivas, K.; Bahadur, I. Hydrothermally grown α-MoO3 microfibers for photocatalytic degradation of methylene blue dye. J. Mol. Liq. 2022, 349, 118202–118212. [Google Scholar] [CrossRef]

- Kader, S.; Al-Mamun, M.R.; Suhan, M.B.K.; Shuchi, S.B.; Islam, M.S. Innovation, Enhanced photodegradation of methyl orange dye under UV irradiation using MoO3 and Ag doped TiO2 photocatalysts. Environ. Technol. Innov. 2022, 27, 102476–102491. [Google Scholar] [CrossRef]

- Zhang, Y.; Park, S.-J. Facile construction of MoO3@ ZIF-8 core-shell nanorods for efficient photoreduction of aqueous Cr (VI). Appl. Catal. B 2019, 240, 92–101. [Google Scholar] [CrossRef]

- Al-Namshah, K.; Mohamed, R. Decoration of MoO3 nanoparticles by MWCNTs driven visible light for the reduction of Cr (VI). Ceram. Int. 2020, 46, 6914–6919. [Google Scholar] [CrossRef]

| Adsorbent | Morphology | Synthesis Method | Adsorbent Nature | Target | qm (mg·g−1) | Reference |

|---|---|---|---|---|---|---|

| α-MoO3 | Nanobelts | Solvothermal | Cationic dye | MB | 1408 | [97] |

| α-MoO3 | Nanobelts | Hydrothermal | Cationic dye | MB | UD a | [100] |

| α-MoO3 | Platelet-like crystals | Calcination | Cationic dye | RhB | 26.56 | [101] |

| α-MoO3 | Platelet-like crystals | Calcination | Cationic dye | MB | 152.7 | [101] |

| α-MoO3 | Platelet-like crystals | Calcination | Cationic dye | CV | 199.4 | [101] |

| α-MoO3 | Platelet-like crystals | Calcination | Cationic dye | MG | 53.05 | [101] |

| α-MoO3 | Micro/nanoplates | Hydrothermal | Cationic dye | RhB | UD a | [103] |

| α-MoO3 | Micro/nanoplates | Hydrothermal | Cationic dye | MB | UD a | [103] |

| h-MoO3 | Nanosheets | Hydrothermal | Cationic dye | RhB | 1242 | [99] |

| h-MoO3 | Nanosheets | Hydrothermal | Cationic dye | MB | 1433 | [99] |

| α-MoO3/h-MoO3 | Nanoparticles | Internal combustion | Cationic dye | MB | 141.2 | [98] |

| α-MoO3-MoO2 | Nanoparticles | Hydrothermal | Cationic dye | MB | 1250 | [22] |

| α-MoO3-MoS2 | Porous core-shell nanorods | Hydrothermal | Cationic dye | RhB | 326.83 | [96] |

| α-MoO3-TiO2 | Nanoparticles | Hydrothermal | Cationic dye | RhB | 169 | [102] |

| α-MoO3-TiO2 | Nanoparticles | Hydrothermal | Cationic dye | MB | 180 | [102] |

| α-MoO3 | Micro/nanoplates | Hydrothermal | Anionic dye | Eosin yellow | UD a | [103] |

| Al13-MoO3 | Flake-like | Polycationic Encapsulation | Anionic dye | MO | 357.2 | [107] |

| α-MoO3 | Porous nanosheet array | Hydrothermal | Metal ion | Pb2+ | 1450 | [94] |

| α-MoO3 | Nanobelts | Solvothermal | Metal ion | Pb2+ | 684.93 | [97] |

| SiO2-α-MoO3 | UD a | Thermal decomposition | Metal ion | Pb2+ | 222.2 | [95] |

| α-MoO3-TiO2 | Nanoparticles | Hydrothermal | Metal ion | Cr3+ | 59 | [102] |

| Chitin-MoO3-Montmorillonite | Nanorods | Blending | Metal ion | Cu2+ | 19.03 | [104] |

| Chitin-MoO3-Montmorillonite | Nanorods | Blending | Metal ion | Pb2+ | 15.92 | [104] |

| CeO2–MoO3–SiO2(CH2)3-(Alginate)2 | Nanoparticle | Combustion/microwave irradiation | Metal ion | Mn2+ | 122.06 | [105] |

| CeO2–MoO3–SiO2(CH2)3-(Alginate)2 | Nanoparticle | Combustion/microwave irradiation | Metal ion | Cr6+ | 151.96 | [105] |

| MoO3/γ-Al2O3 | Nanoparticles/Nanorods | Cation-anion double hydrolysis/Impregnation | Aromatic sulfur compound | Dibenzothiophene | UD a | [106] |

| MoO3/γ-Al2O3 | Nanoparticles/Nanorods | Cation-anion double hydrolysis/Impregnation | Aromatic sulfur compound | Thiophene | UD a | [106] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva Júnior, M.G.; Arzuza, L.C.C.; Sales, H.B.; Farias, R.M.d.C.; Neves, G.d.A.; Lira, H.d.L.; Menezes, R.R. A Brief Review of MoO3 and MoO3-Based Materials and Recent Technological Applications in Gas Sensors, Lithium-Ion Batteries, Adsorption, and Photocatalysis. Materials 2023, 16, 7657. https://doi.org/10.3390/ma16247657

da Silva Júnior MG, Arzuza LCC, Sales HB, Farias RMdC, Neves GdA, Lira HdL, Menezes RR. A Brief Review of MoO3 and MoO3-Based Materials and Recent Technological Applications in Gas Sensors, Lithium-Ion Batteries, Adsorption, and Photocatalysis. Materials. 2023; 16(24):7657. https://doi.org/10.3390/ma16247657

Chicago/Turabian Styleda Silva Júnior, Mário Gomes, Luis Carlos Costa Arzuza, Herbet Bezerra Sales, Rosiane Maria da Costa Farias, Gelmires de Araújo Neves, Hélio de Lucena Lira, and Romualdo Rodrigues Menezes. 2023. "A Brief Review of MoO3 and MoO3-Based Materials and Recent Technological Applications in Gas Sensors, Lithium-Ion Batteries, Adsorption, and Photocatalysis" Materials 16, no. 24: 7657. https://doi.org/10.3390/ma16247657

APA Styleda Silva Júnior, M. G., Arzuza, L. C. C., Sales, H. B., Farias, R. M. d. C., Neves, G. d. A., Lira, H. d. L., & Menezes, R. R. (2023). A Brief Review of MoO3 and MoO3-Based Materials and Recent Technological Applications in Gas Sensors, Lithium-Ion Batteries, Adsorption, and Photocatalysis. Materials, 16(24), 7657. https://doi.org/10.3390/ma16247657