Experimental Investigation of Surface Roughness and Material Removal Rate in Wire EDM of Stainless Steel 304

Abstract

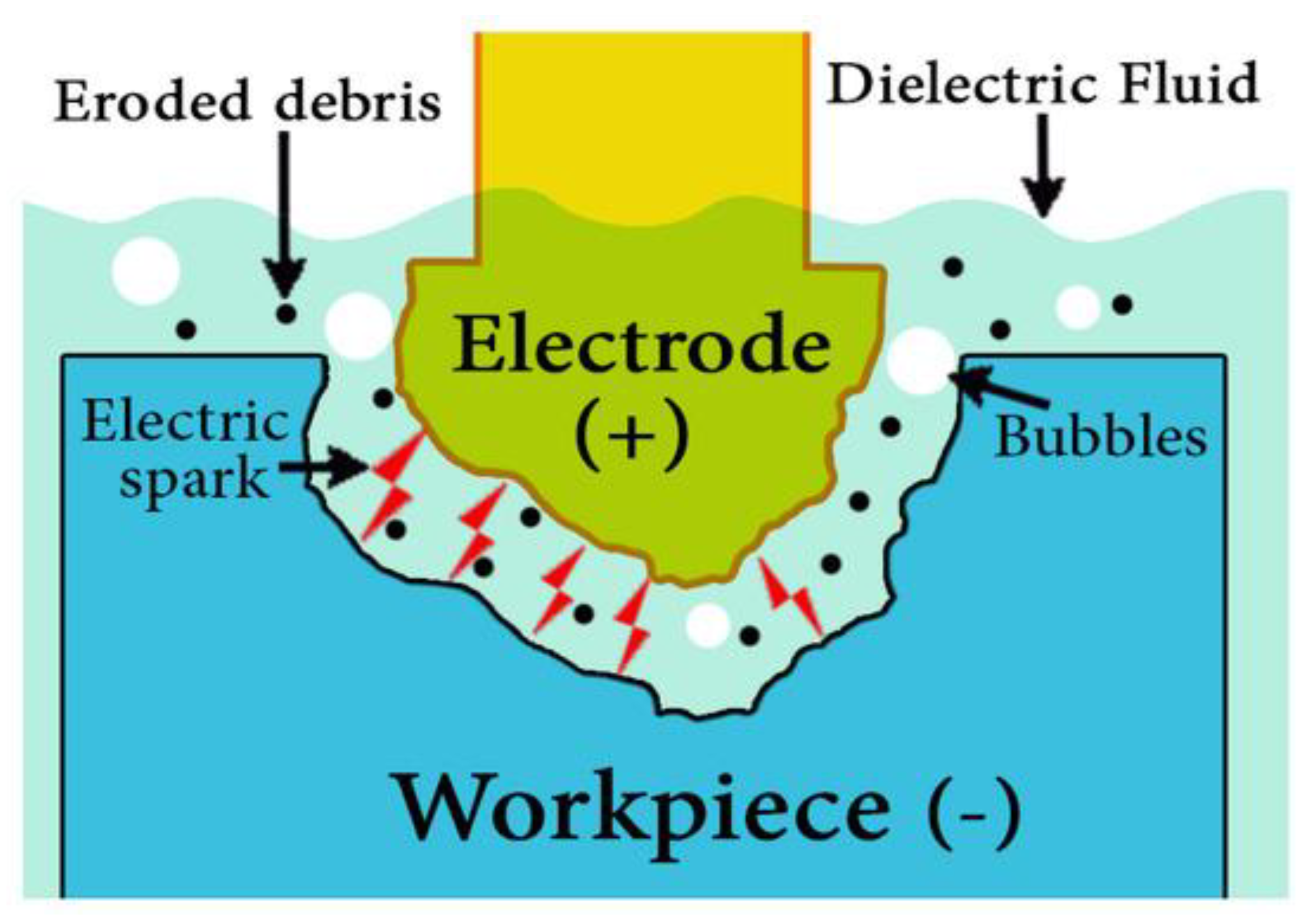

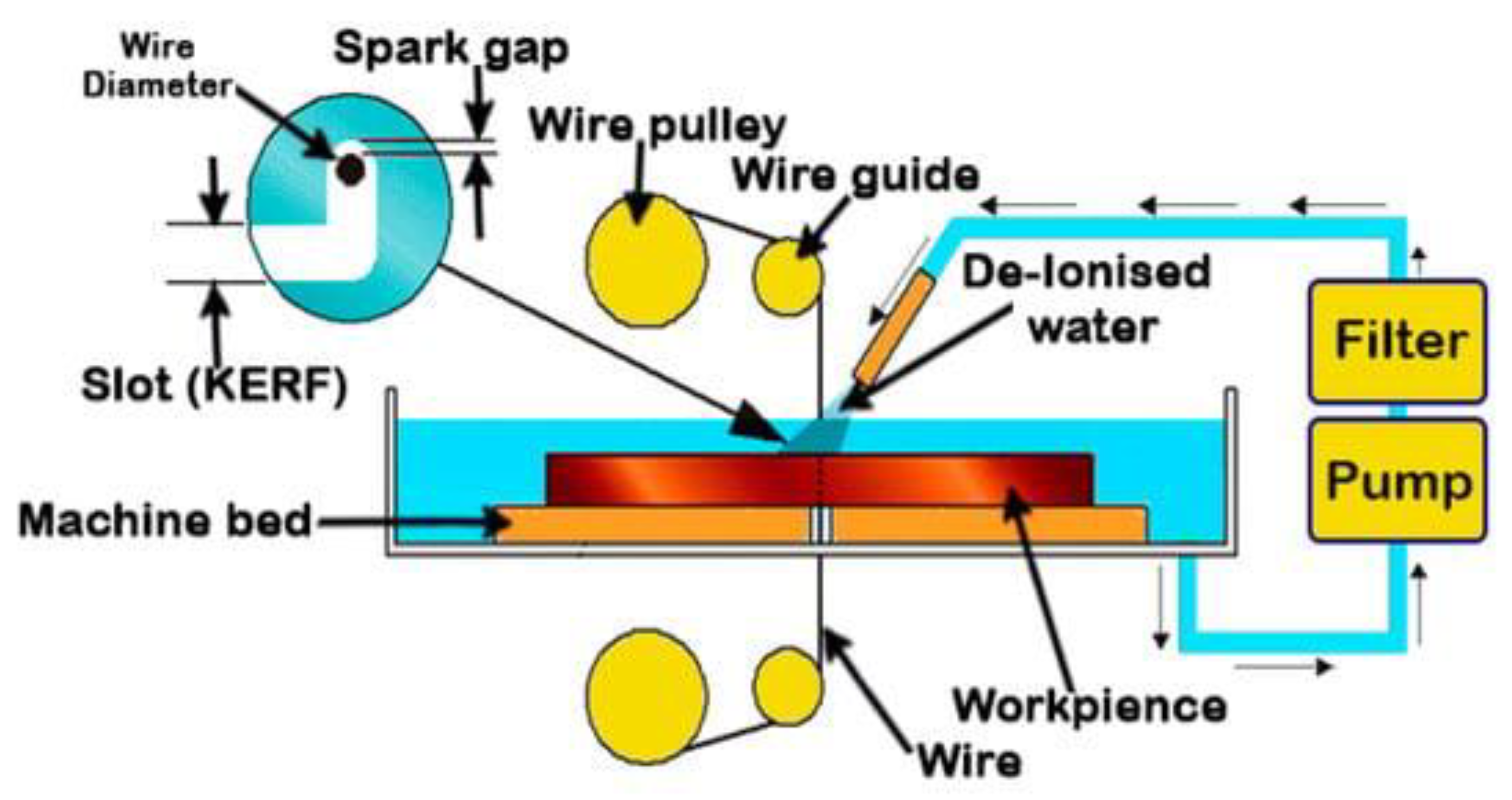

:1. Introduction

2. Materials and Methods

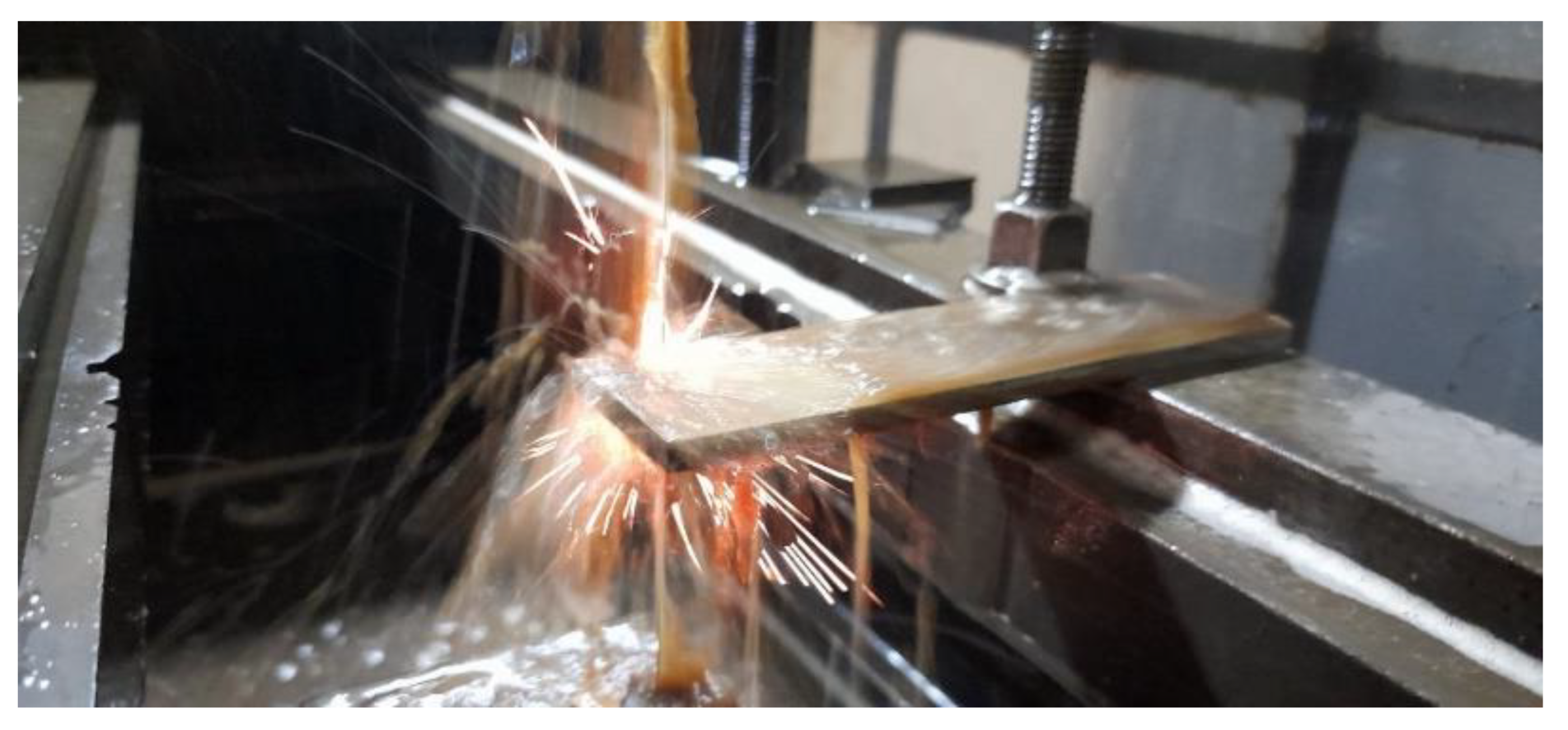

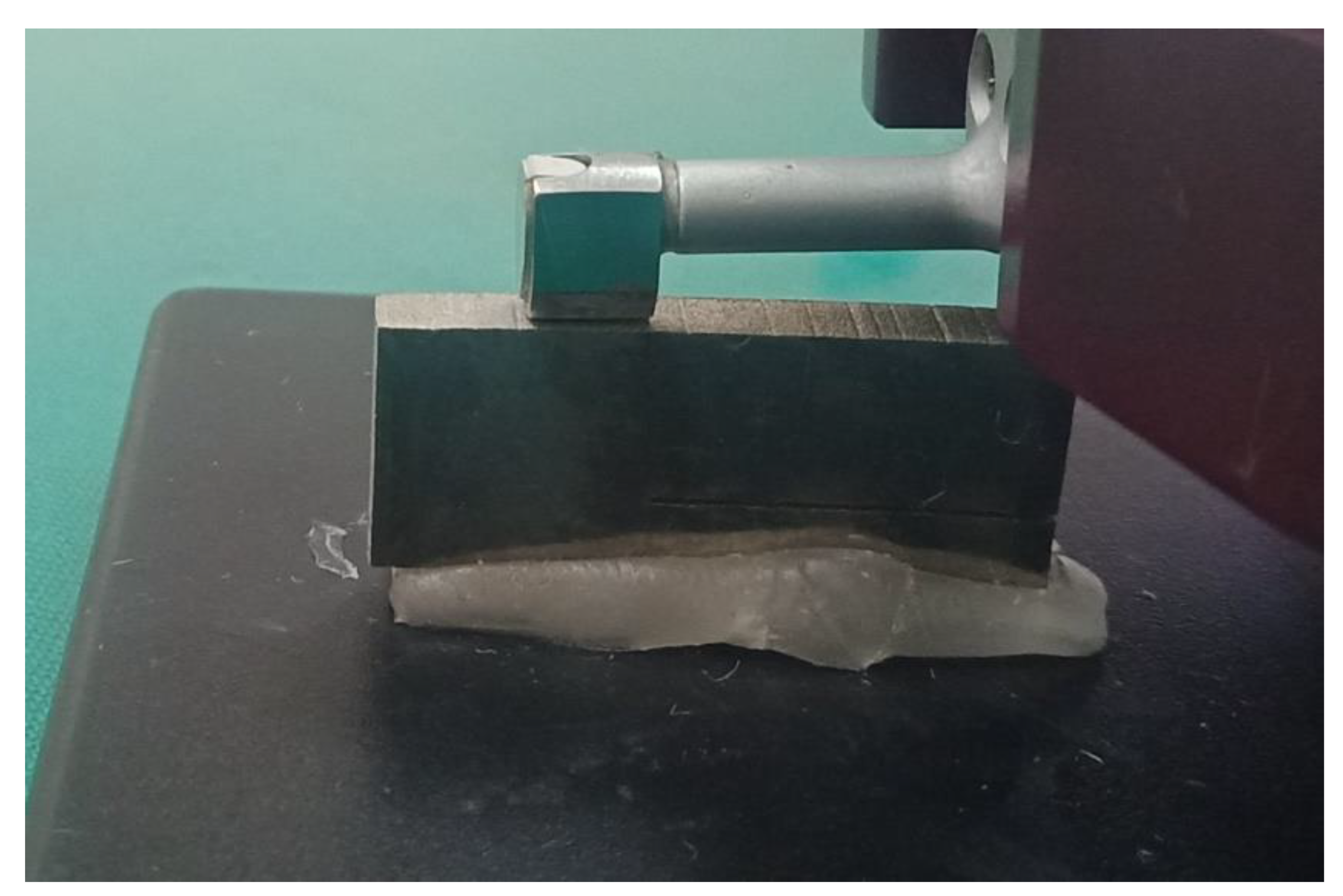

2.1. Materials and Experimental Setup

2.2. Experimental Procedure and Characterization

2.3. Regression Modelling

− 0.12767 Vn Cn − 0.0766 fn (Poff)n + 0.15747 fn (Pon)n + 0.11649 fn Cn

3. Results and Discussion

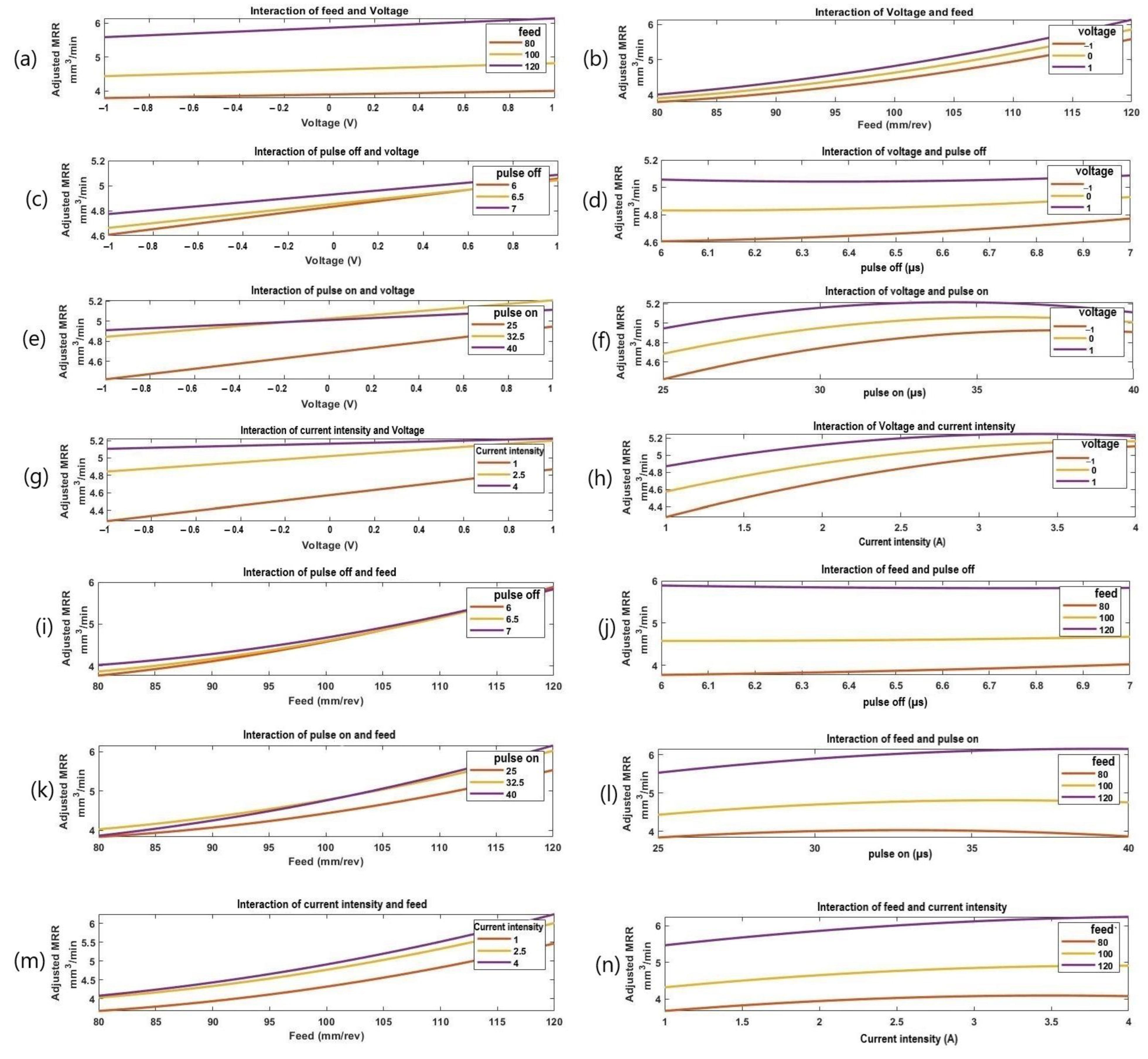

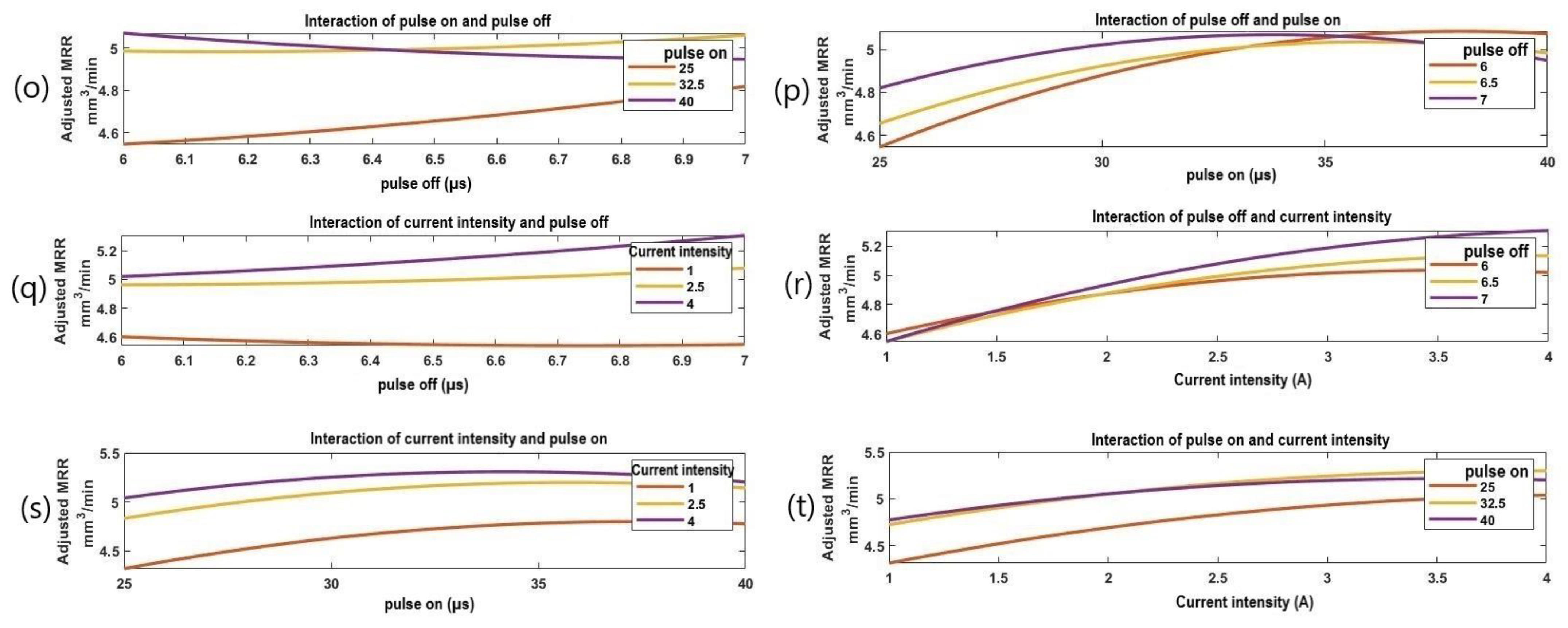

3.1. Material Removal Rate

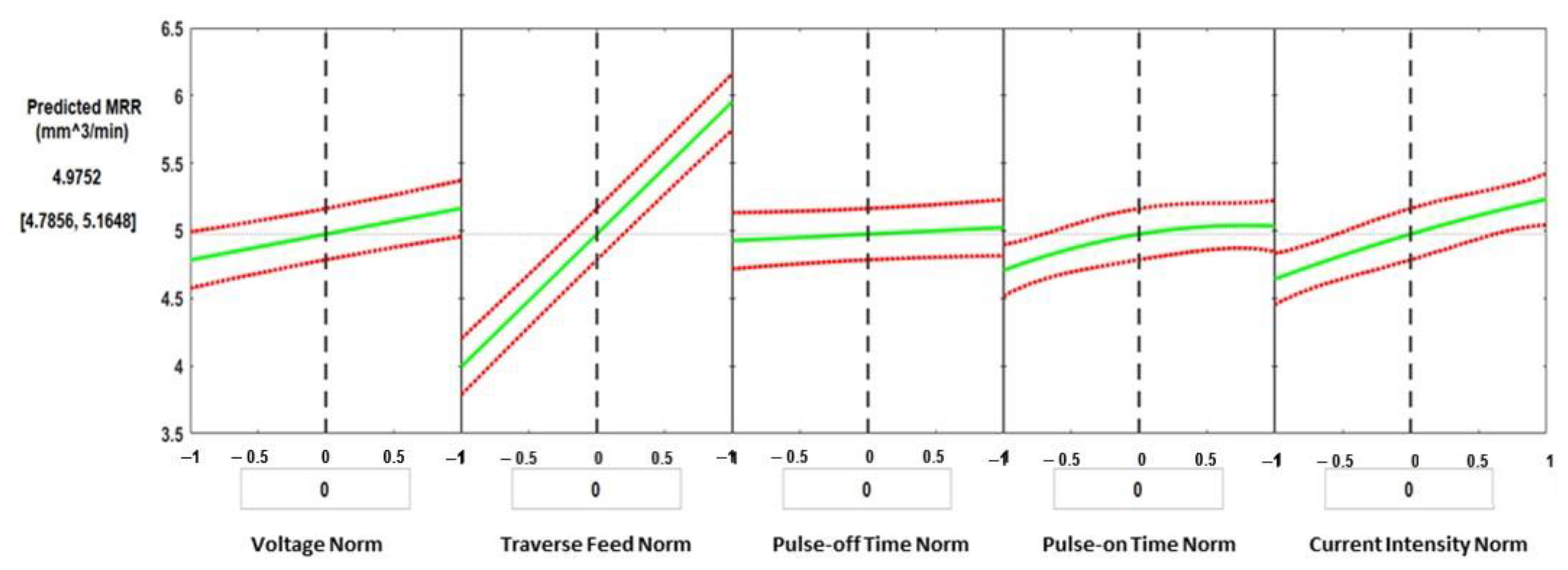

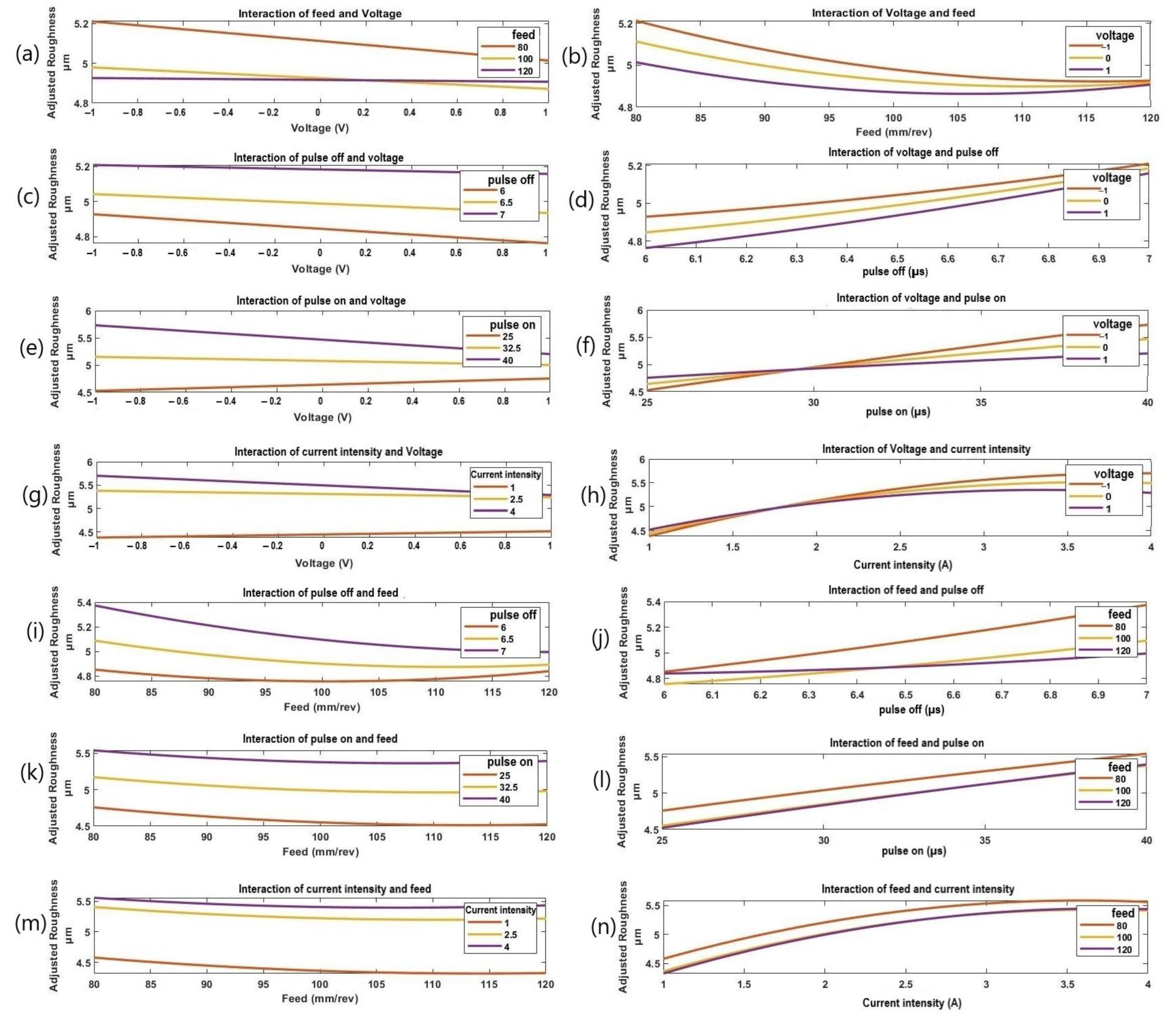

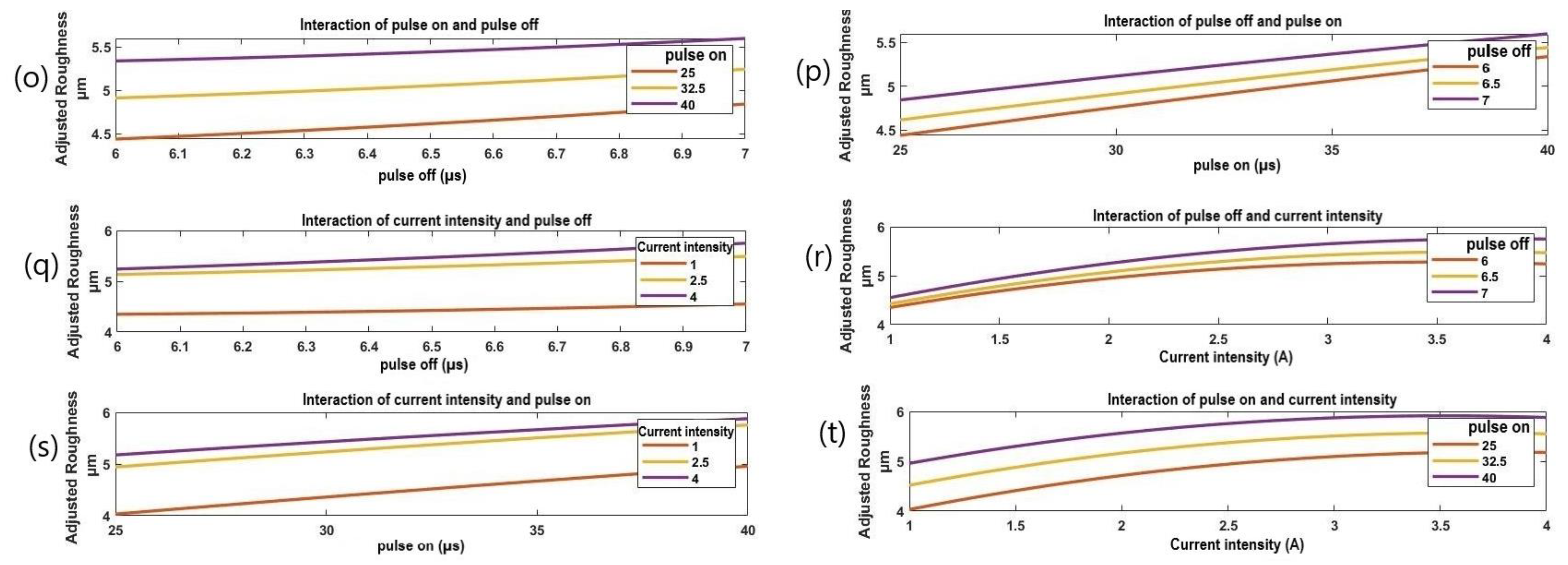

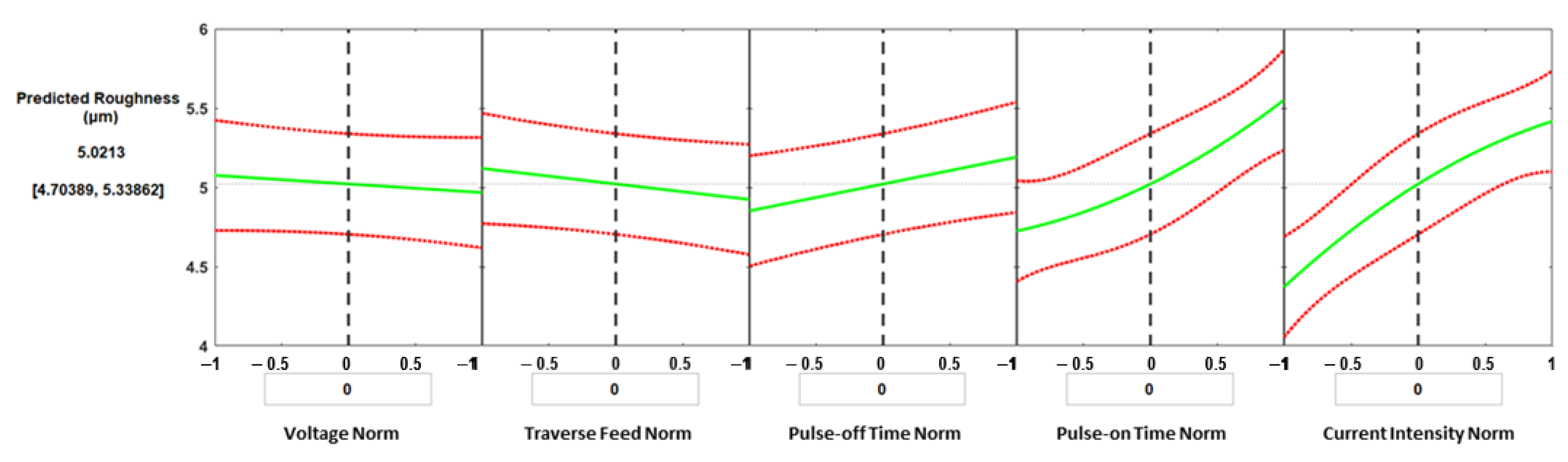

3.2. Surface Roughness

4. Conclusions

- For the WEDM of stainless steel 304, an increase in MRR was observed with increasing applied voltage, feed, pulse-on time, and current intensity.

- The results show that the feed is the most significant parameter on MRR, which agrees with the ANOVA results with a p-value of 9.72 × 10−29. Applied current intensity and voltage came second and third as the most significant parameters, with p-values of 6.02 × 10−7 and 3.77 × 10−5, respectively.

- Pulse-on time was found to have a higher impact on MRR at higher feed levels than lower feeds, whereas pulse-off time has less of an impact at high feeds than low feeds.

- For all feed levels, MRR increases slightly with an increase in current intensity; MRR also increases with the increase in the pulse-off time for various pulse-on time levels.

- The results of the effect of the five parameters on obtainable surface roughness show that the current intensity is the most significant parameter, which agrees with the ANOVA results with p-value of 1.89 × 10−7. Applied pulse-on time and pulse-off time came second and third significant parameters with p-values of 1.602 × 10−5 and 0.0204, respectively.

- Ra slightly increases as current intensity and pulse-on time increase from 25 to 29 µs and from 1 to 1.75 A, respectively, followed by a decrease in the surface roughness with the increase in current intensity and pulse-on time from 29 to 40 µs and 1.75 to 4 A, respectively.

- There is trade-off between the effect of the process parameters on both responses, material removal rate, and surface roughness, which indicates the challenge to optimize both responses simultaneously. This clearly demonstrates the need for a reliable multi-objective optimization technique to obtain sets of working conditions for both high MRR and low surface roughness together.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dobrzański, L.A. Significance of materials science for the future development of societies. J. Mater. Process. Technol. 2006, 175, 133–148. [Google Scholar] [CrossRef]

- Verma, A.; Chauhan, S.S.; Dwivedi, S.P. Review paper on thermal expansion and tribological behavior of composite materials. Mater. Today: Proc. 2022. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, J.; Kuriyagawa, T. Manufacturing technologies toward extreme precision. Int. J. Extreme Manuf. 2019, 1, 22001. [Google Scholar] [CrossRef] [Green Version]

- Material Removal Process. 2020. Available online: https://www.sciencedirect.com/topics/engineering/material-removal-process (accessed on 20 September 2019).

- Sinha, A.K. Defects and Distortion in Heat-Treated Parts. Metallography 1991, 4, 601–619. [Google Scholar]

- Malakizadi, A.; Mallipeddi, D.; Dadbakhsh, S.; M’Saoubi, R.; Krajnik, P. Post-processing of additively manufactured metallic alloys—A review. Int. J. Mach. Tools Manuf. 2022, 179, 103908. [Google Scholar] [CrossRef]

- Goiogana, M.; Elkaseer, A. Self-Flushing in EDM Drilling of Ti6Al4V Using Rotating Shaped Electrodes. Materials 2019, 12, 989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pramanik, A. Developments in the non-traditional machining of particle reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2014, 86, 44–61. [Google Scholar] [CrossRef] [Green Version]

- Alting, L.; Boothroyd, G. Nontraditional Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2020; pp. 363–416. [Google Scholar] [CrossRef]

- Madic, M.; Radovanovic, M. Ranking of some most commonly used nontraditional machining processes using rov and critic methods. UPB Sci. Bull. Ser. D Mech. Eng. 2015, 77, 193–204. [Google Scholar]

- La Monaca, A.; Murray, J.W.; Liao, Z.; Speidel, A.; Robles-Linares, J.A.; Axinte, D.A.; Hardy, M.C.; Clare, A.T. Surface integrity in metal machining—Part II: Functional performance. Int. J. Mach. Tools Manuf. 2021, 164, 103718. [Google Scholar] [CrossRef]

- Farooq, M.U.; Ali, M.A.; He, Y.; Khan, A.M.; Pruncu, C.I.; Kashif, M.; Ahmed, N.; Asif, N. Curved profiles machining of Ti6Al4V alloy through WEDM: Investigations on geometrical errors. J. Mater. Res. Technol. 2020, 9, 16186–16201. [Google Scholar] [CrossRef]

- Thomas, D.S.; Gilbert, S.W. Costs and cost effectiveness of additive manufacturing: A literature review and discussion. Addit. Manuf. Costs 2015, 1–96. [Google Scholar] [CrossRef]

- Equbal, A.; Sood, A.K. Electrical Discharge Machining: An Overview on Various Areas of Research. Manuf. Ind. Eng. 2014, 13, 1–2. [Google Scholar] [CrossRef] [Green Version]

- Papenberg, N.P.; Gneiger, S.; Weißensteiner, I.; Uggowitzer, P.J.; Pogatscher, S. Mg-Alloys for Forging Applications—A Review. Materials 2020, 13, 985. [Google Scholar] [CrossRef] [Green Version]

- Abu Qudeiri, J.E.; Saleh, A.; Ziout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Advanced Electric Discharge Machining of Stainless Steels: Assessment of the State of the Art, Gaps and Future Prospect. Materials 2019, 12, 907. [Google Scholar] [CrossRef] [Green Version]

- Rashid, A.; Jahan, M.P. Chapter 2 - Microfabrication by electrical discharge machining-based hybrid processes. In Micro and Nano Technologies, Micro Electro-Fabrication; Saleh, T., Ali, M.S.M., Takahata, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 33–62. ISBN 9780128200490. [Google Scholar] [CrossRef]

- Assarzadeh, S.; Ghoreishi, M. Electro-thermal-based finite element simulation and experimental validation of material removal in static gap single-spark die-sinking electro-discharge machining process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 231, 28–47. [Google Scholar] [CrossRef]

- Abu Qudeiri, J.E.; Zaiout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Principles and Characteristics of Different EDM Processes in Machining Tool and Die Steels. Appl. Sci. 2020, 10, 2082. [Google Scholar] [CrossRef] [Green Version]

- Prathipati, R.; Dora, S.P.; Chanamala, R. Wear behavior of wire electric discharge machined surface of 316L stainless steel. SN Appl. Sci. 2020, 2, 412. [Google Scholar] [CrossRef] [Green Version]

- Gowthaman, P.; Gowthaman, J.; Nagasundaram, N. A study of machining characteristics of AISI 4340 alloy steel by wire electrical discharge machining process. Mater. Today Proc. 2020, 27, 565–570. [Google Scholar] [CrossRef]

- Chaudhary, T.; Siddiquee, A.N.; Chanda, A.K. Effect of wire tension on different output responses during wire electric discharge machining on AISI 304 stainless steel. Def. Technol. 2018, 15, 541–544. [Google Scholar] [CrossRef]

- Johny, A.; Thiagarajan, C. Investigation of surface integrity and it’s optimization on pure titanium using molybdenum wire by reciprocated travelling WEDM—A review. Mater. Today: Proc. 2020, 33, 2581–2584. [Google Scholar] [CrossRef]

- Sen, R.; Paul, S.; Choudhuri, B. Investigation on wire electrical discharge machining of AISI 304 stainless steel. Mater. Today: Proc. 2022, 62, 1210–1214. [Google Scholar] [CrossRef]

- Van Sy, L. Multi-Objective Optimization of Processing Parameters in WEDM with Stainless Steel-304 for Die-Angular Cutting. J. Mech. Eng. 2021, 71, 141–150. [Google Scholar] [CrossRef]

- Kalyanakumar, S.; Prabhu, L.; Saravanan, M.; Imthiyas, A. Experimental investigation of MRR, RA of 304 stainless steel using WEDM. IOP Conf. Series: Mater. Sci. Eng. 2020, 993, 12035. [Google Scholar] [CrossRef]

- Mathew, B.; Babu, J. Multiple Process Parameter Optimization of WEDM on AISI304 Using Taguchi Grey Relational Analysis. Procedia Mater. Sci. 2014, 5, 1613–1622. [Google Scholar] [CrossRef] [Green Version]

- Lingadurai, K.; Nagasivamuni, B.; Kamatchi, M.M.; Palavesam, J. Selection of Wire Electrical Discharge Machining Process Parameters on Stainless Steel AISI Grade-304 using Design of Experiments Approach. J. Inst. Eng. Ser. C 2012, 93, 163–170. [Google Scholar] [CrossRef]

- Vinothkumar, H.; Balakrishnan, M.; Gulanthaivel, K.; Logeshwaran, R.; Mohanraj, R. Investigation on effects of flux assisted GTAW welding process on mechanical, metallurgical characteristics of dissimilar metals SS 304 and SS 316 L. Mater. Today Proc. 2020, 33, 3191–3196. [Google Scholar] [CrossRef]

- AZO. Grade 304 Stainless Steel: Properties, Fabrication and Applications. AZO Mater. Handb. 2015, 1–12. [Google Scholar]

- Zaman, U.K.U.; Khan, U.A.; Aziz, S.; Baqai, A.A.; Butt, S.U.; Hussain, D.; Siadat, A.; Jung, D.W. Optimization of Wire Electric Discharge Machining (WEDM) Process Parameters for AISI 1045 Medium Carbon Steel Using Taguchi Design of Experiments. Materials 2022, 15, 7846. [Google Scholar] [CrossRef]

- Shather, S.K.; Hammood, S.A.; Hussain, N.A.-H.A.; Hasson, N.H. Effect of Wire Diameter, Feeding Rate, Pulse (on/off) Time on Surface Roughness and Metal Removal Rate for Cr-Mo Steel (SCM425H) During Wire Electrical Discharge Machine (WEDM) Cutting Operation. Eng. Technol. J. 2020, 38, 854–860. [Google Scholar] [CrossRef]

| Grad | Mn | C | S | P | Si | Ni | N | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Stainless Steel 304 | 2.00 | 0.08 | 0.03 | 0.045 | 0.75 | 8 | 0.10 | 18–20 | Balance |

| Property | Value |

|---|---|

| Density | 8.00 g/cm3 |

| Melting Point | 1450 °C |

| Modulus of Elasticity | 193 GPa |

| Electrical Resistivity | 0.072 ×10−6 Ω.m |

| Thermal Conductivity | 16.2 W/m.K at 100 °C |

| Thermal Expansion | 17.2 × 10−6/K at 100 °C |

| WEDM Condition (Unit) | Levels |

|---|---|

| Voltage, V (V) | High, Low |

| Traverse feed, f (mm/min) | 80, 120 |

| Pulse-on time, Pon (µs) | 25, 30, 40 |

| Pulse-off time, Poff (µs) | 6, 7 |

| Current intensity, C (A) | 1, 2, 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naeim, N.; AbouEleaz, M.A.; Elkaseer, A. Experimental Investigation of Surface Roughness and Material Removal Rate in Wire EDM of Stainless Steel 304. Materials 2023, 16, 1022. https://doi.org/10.3390/ma16031022

Naeim N, AbouEleaz MA, Elkaseer A. Experimental Investigation of Surface Roughness and Material Removal Rate in Wire EDM of Stainless Steel 304. Materials. 2023; 16(3):1022. https://doi.org/10.3390/ma16031022

Chicago/Turabian StyleNaeim, Noha, Mona A. AbouEleaz, and Ahmed Elkaseer. 2023. "Experimental Investigation of Surface Roughness and Material Removal Rate in Wire EDM of Stainless Steel 304" Materials 16, no. 3: 1022. https://doi.org/10.3390/ma16031022

APA StyleNaeim, N., AbouEleaz, M. A., & Elkaseer, A. (2023). Experimental Investigation of Surface Roughness and Material Removal Rate in Wire EDM of Stainless Steel 304. Materials, 16(3), 1022. https://doi.org/10.3390/ma16031022