Effect of Polydopamine Coating of Cellulose Nanocrystals on Performance of PCL/PLA Bio-Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nanocomposite Preparation

2.3. DFT Modeling of Stabilization Energy between Constituents

2.4. Characterization of Blends Structure

2.5. Testing

3. Results and Discussion

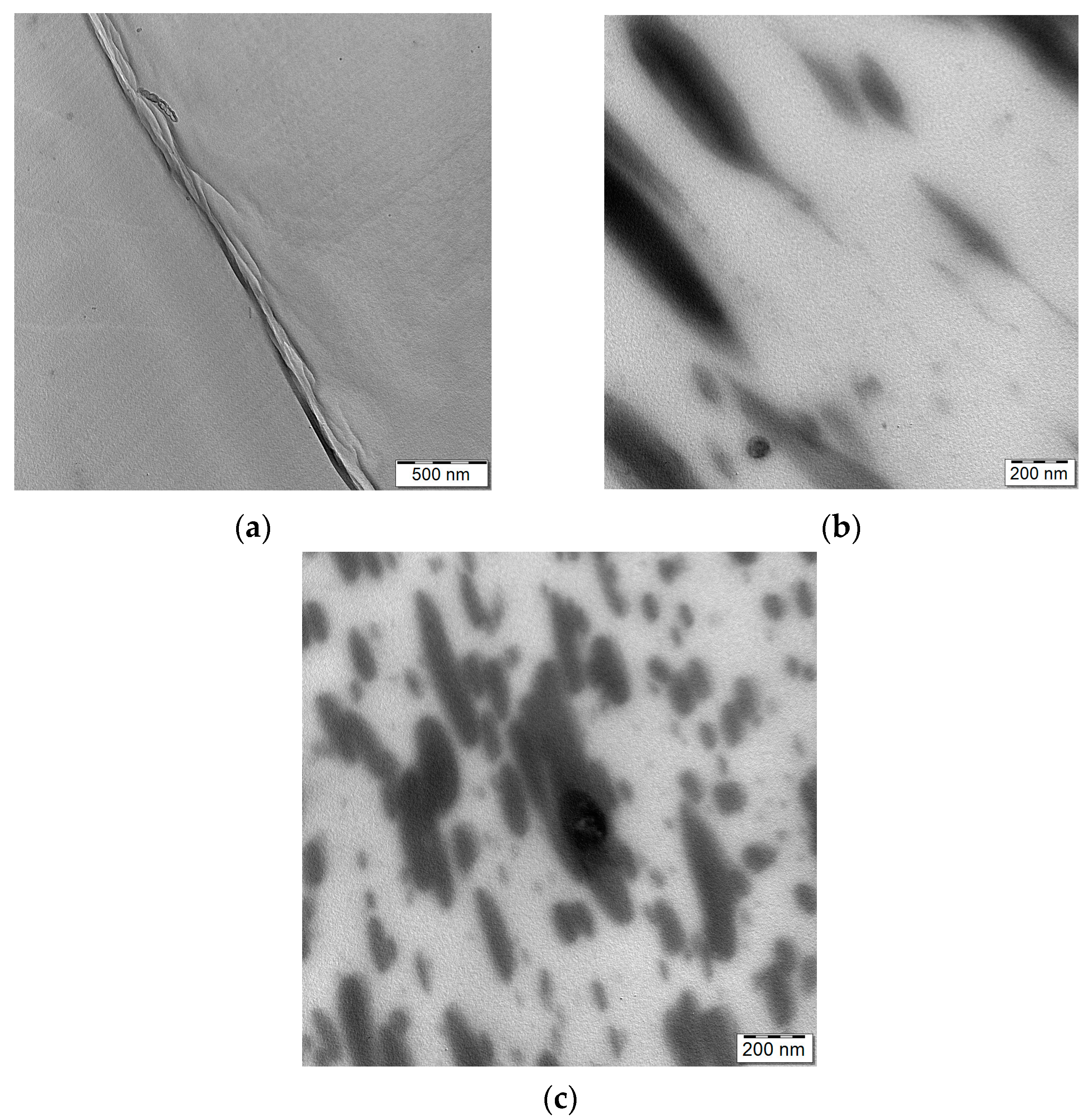

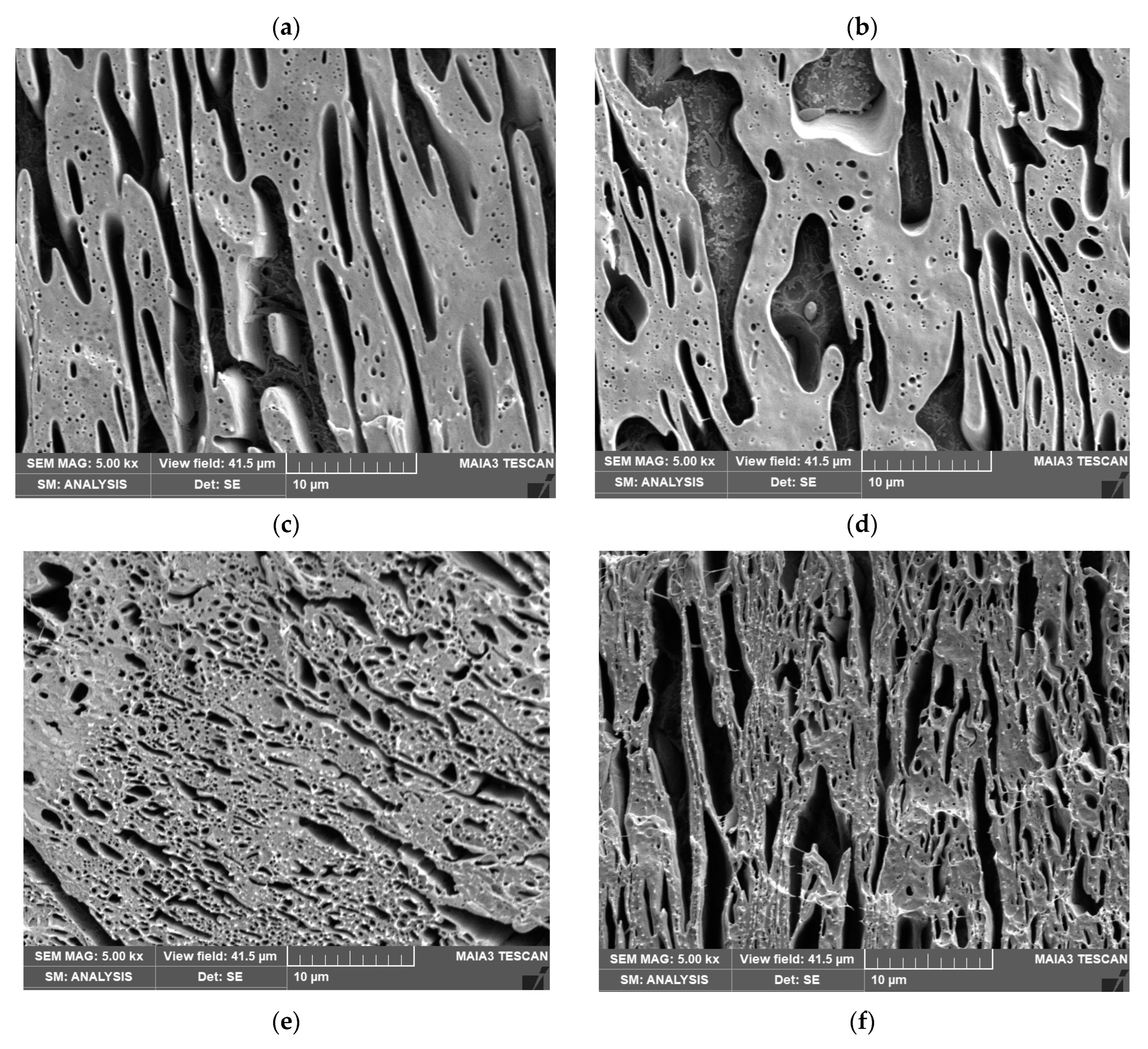

3.1. CNC and Polydopamine-Coated CNC Localization

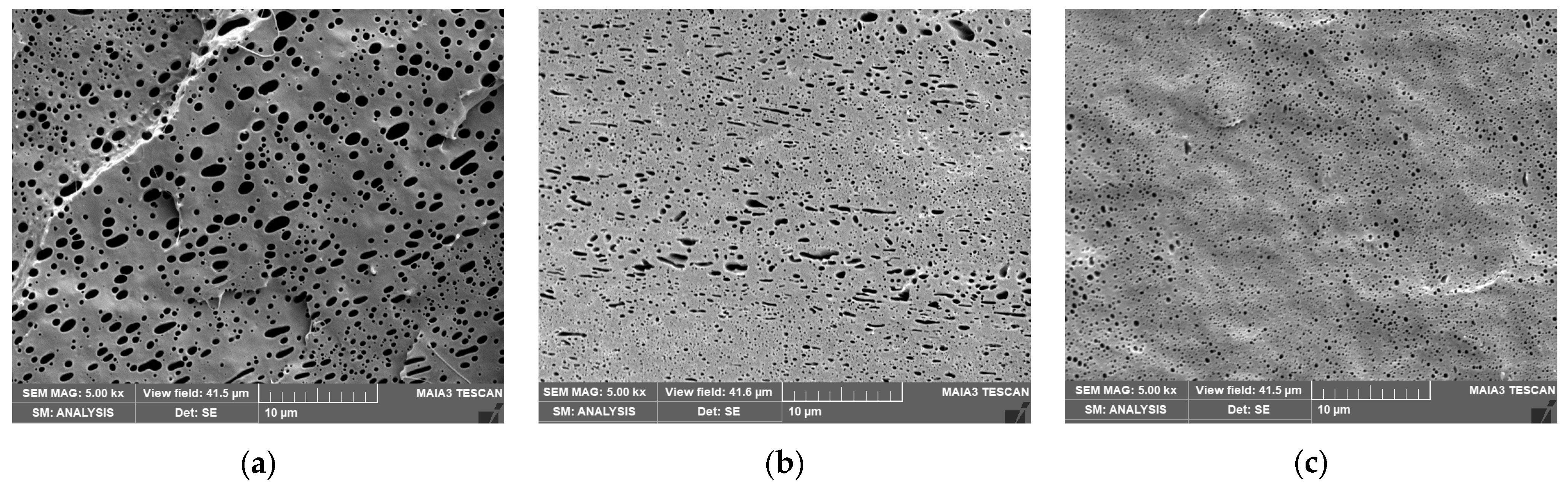

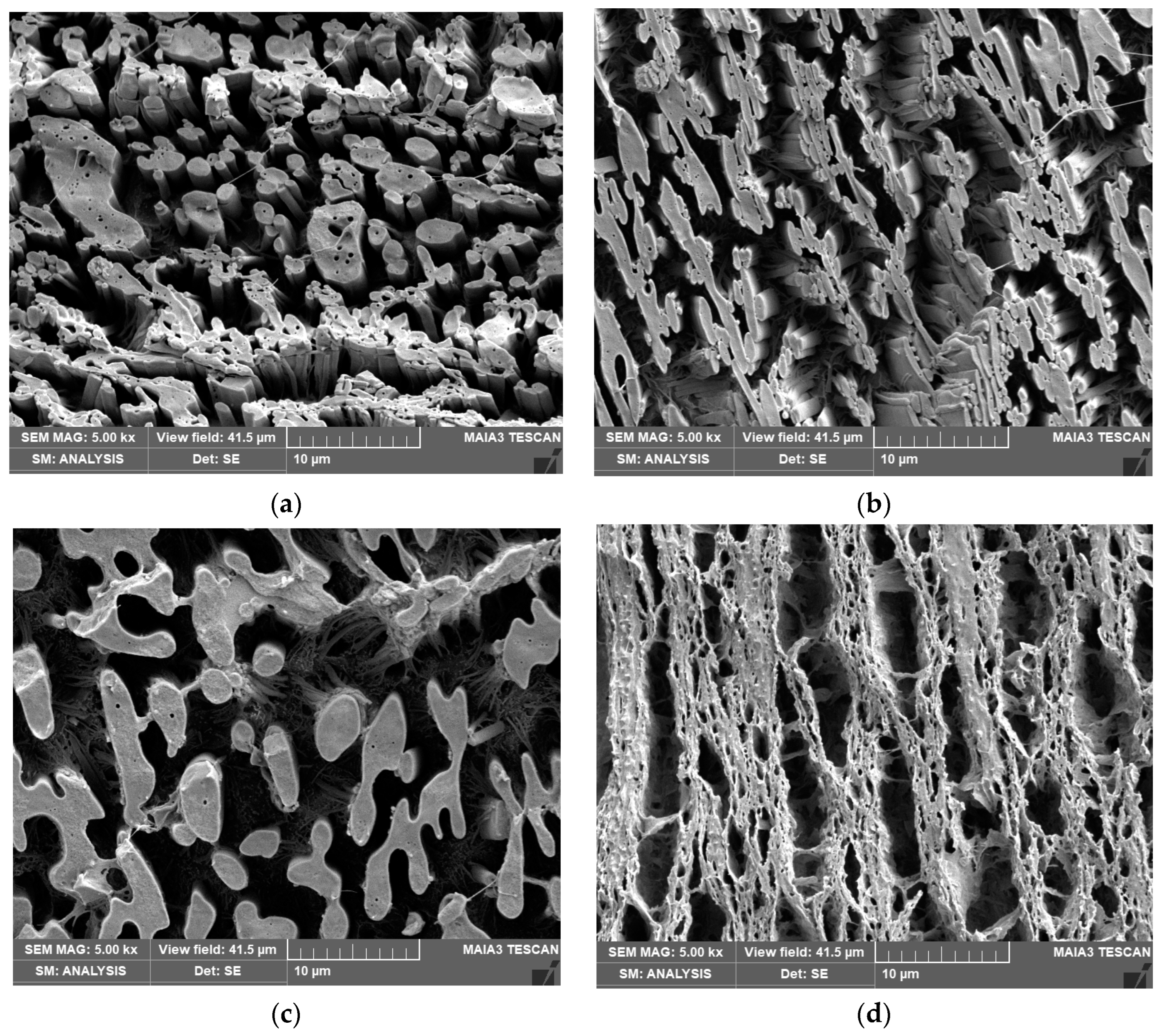

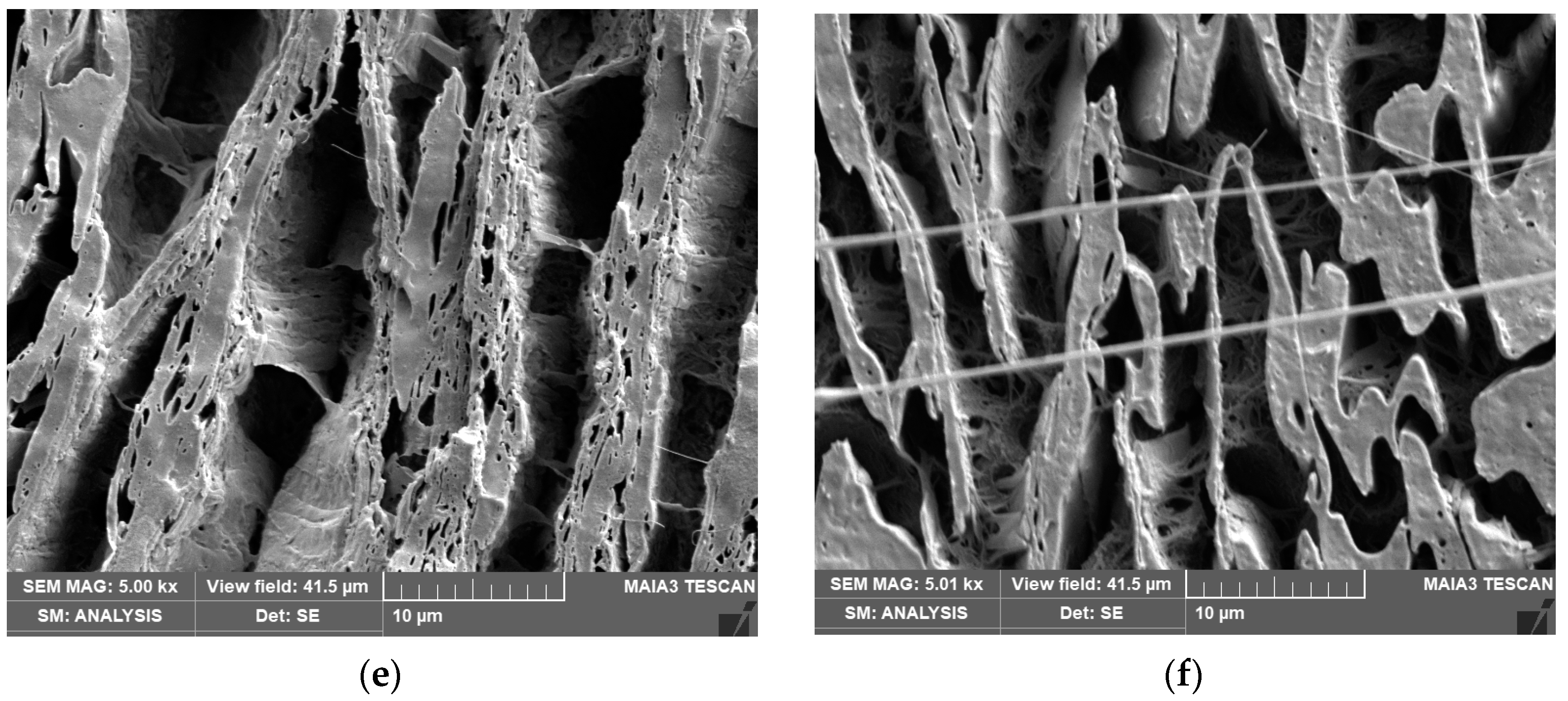

3.2. Structure of Blends and Related Nanocomposites

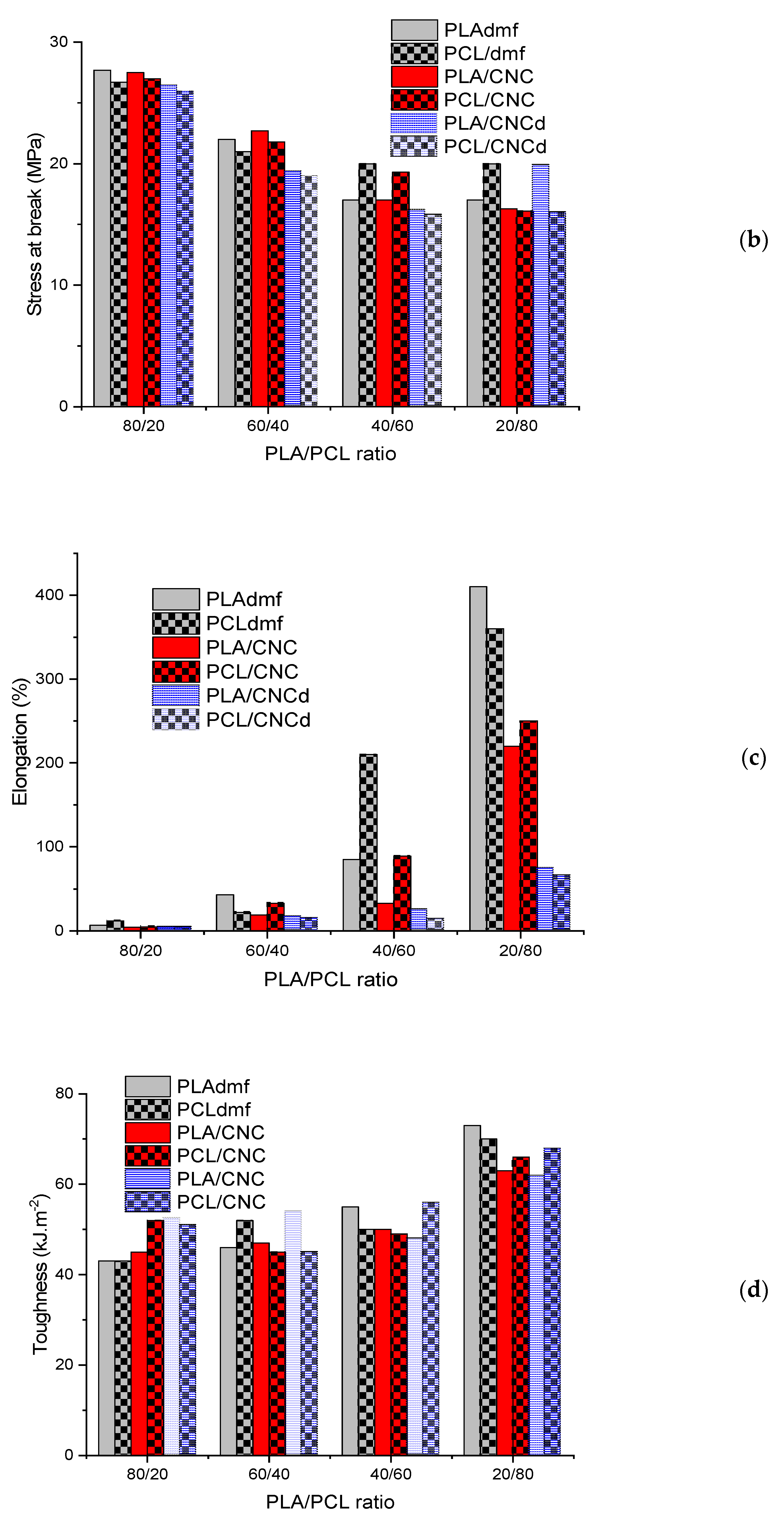

3.3. Mechanical Properties

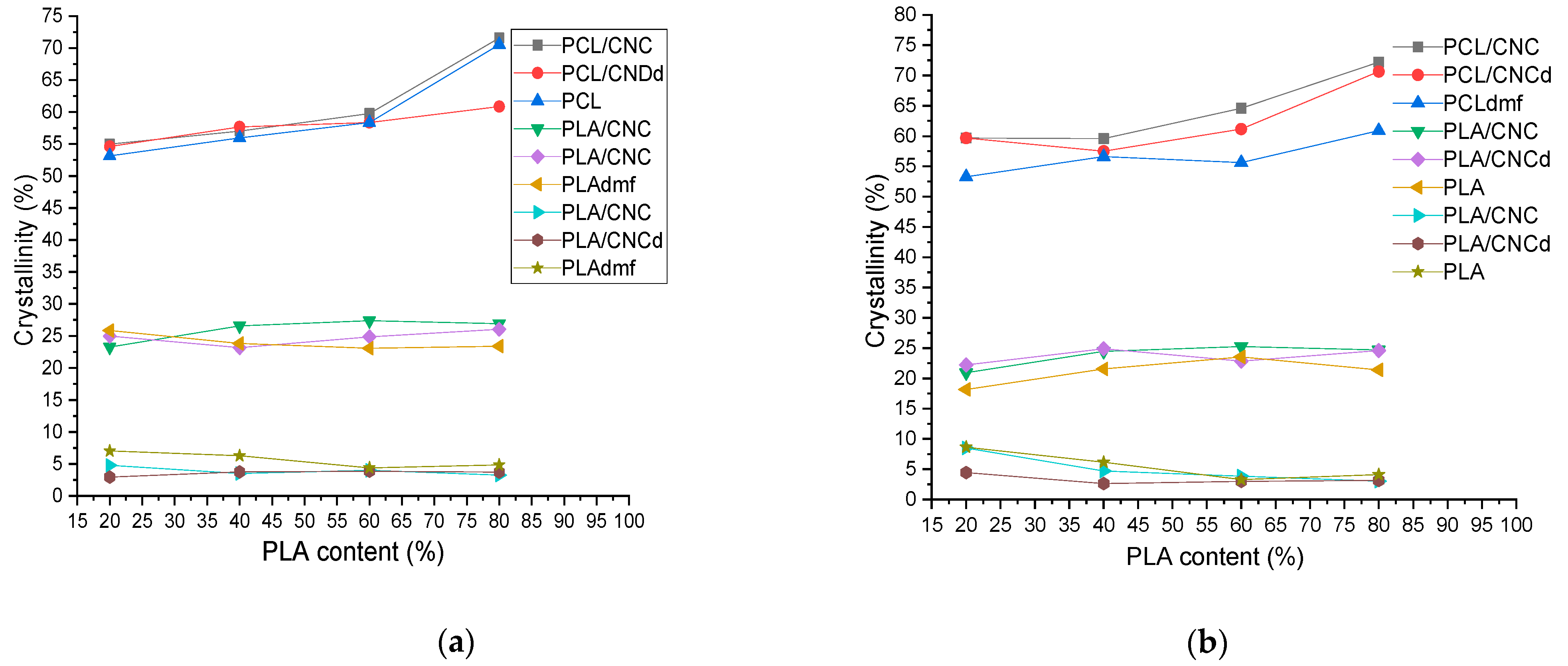

3.4. Crystallinity of Blends and Nanocomposites

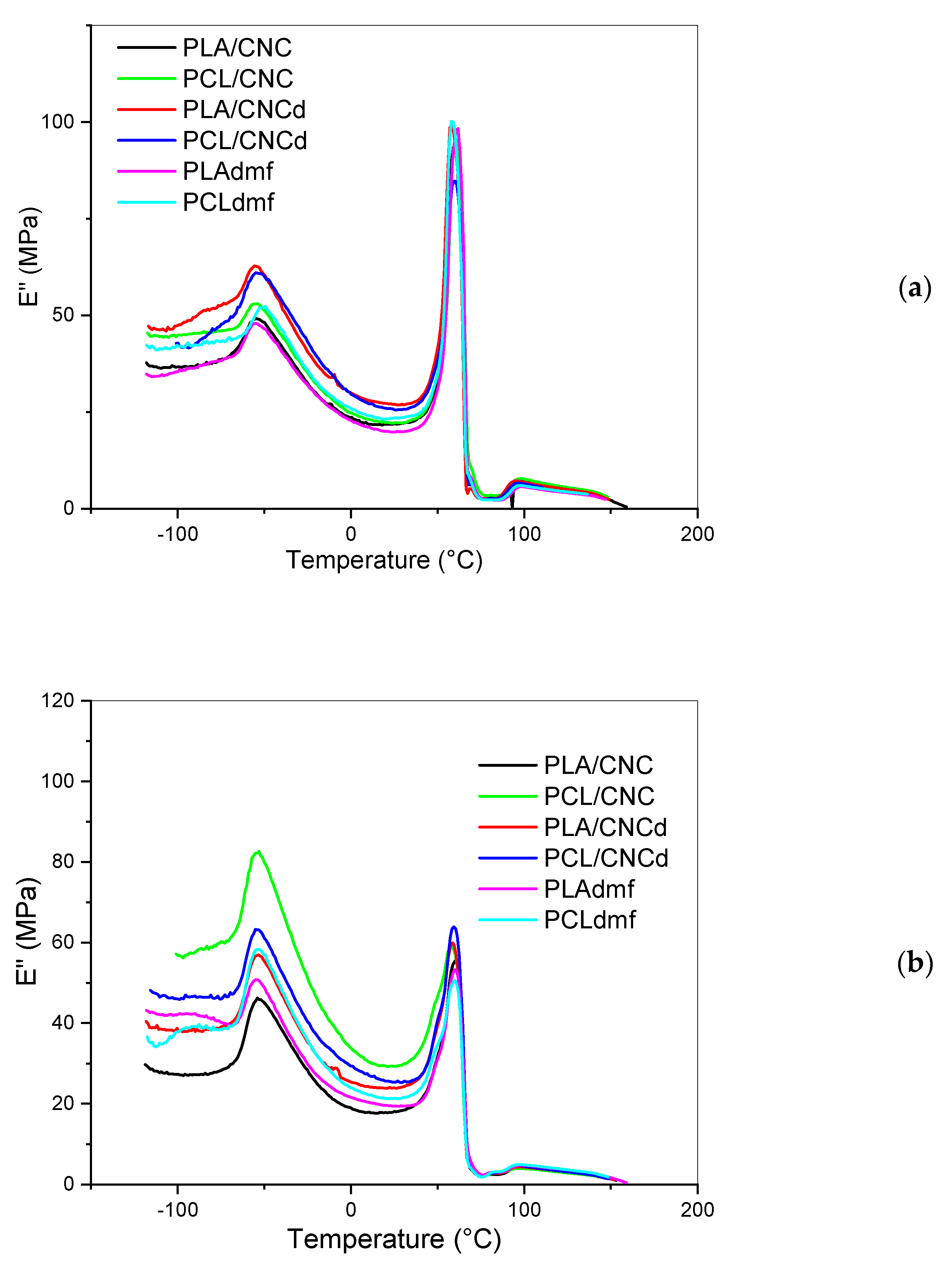

3.5. Dynamic Mechanical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.-M. Structuration, Selective Dispersion and Compatibilizing Effect of (nano)fillers in Polymer Blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Gelfer, M.Y.; Song, H.H.; Liu, L.; Hsiao, B.S.; Chu, B.; Rafailovich, M.; Si, M.; Zaitsev, V. Effects of organoclays on morphology and thermal and rheological properties of polystyrene and poly(methyl methacrylate) blends. J. Polym. Sci. Part B—Polym. Phys. Part B 2003, 41, 44–54. [Google Scholar] [CrossRef]

- Pawar, S.P.; Suryasarathi, B. Peculiar morphological transitions induced by nanoparticles in polymeric blends: Retarded relaxation or altered interfacial tension. Phys. Chem. Chem. Phys. 2015, 17, 14470–14478. [Google Scholar] [CrossRef] [PubMed]

- Chow, W.S.; Ishak, Z.A.M. Polyamide Blend-Based Nanocomposites: A Review. Express Polym. Lett. 2015, 9, 211–232. [Google Scholar] [CrossRef]

- Kelnar, I.; Kratochvíl, J.; Fortelný, I.; Kaprálková, L.; Zhigunov, A.; Kotrisová, M.; Khunová, V.; Nevoralová, M. Influence of clay-nanofiller geometry on the structure and properties of poly(lactic acid)/thermoplastic polyurethane nanocomposites. RSC Adv. 2019, 6, 30755–30762. [Google Scholar] [CrossRef]

- Li, J.; Wu, D. Nucleation roles of cellulose nanocrystals and chitin nanocrystals in poly(ε-caprolactone) nanocomposites. Int. J. Biol. Macromol. 2022, 205, 587–594. [Google Scholar] [CrossRef]

- Nofar, M. Chapter 9—PLA blend nanocomposites. In Multiphase Polylactide Blends; Nofar, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 311–355. [Google Scholar]

- Li, T.T.; Zhang, H.; Huang, S.Y.; Pei, X.; Lin, Q.; Tian, S.; Ma, Z.; Lin, J.H. Preparation and property evaluations of PCL/PLA composite films. J. Polym. Res. 2021, 28, 156. [Google Scholar] [CrossRef]

- Botlhoko, O.J.; Ramontja, J.; Ray, S.S. A new insight into morphological, thermal, and mechanical properties of melt-processed polylactide/poly (ε-caprolactone) blends. Polym. Degrad. Stabil. 2018, 154, 84–95. [Google Scholar] [CrossRef]

- Urquijo, J.; Guerrica-Echevarría, G.; Eguiazábal, J.I. Melt processed PLA/PCL blends: Effect of processing method on phase structure, morphology, and mechanical properties. J. Appl. Polym. Sci. 2015, 132, 42641. [Google Scholar] [CrossRef]

- Yu, Z.; Yin, J.; Yan, S.; Xie, Y.; Ma, J.; Chen, X. Biodegradable poly(l-lactide)/poly(ɛ-caprolactone)-modified montmorillonite nanocomposites: Preparation and characterization. Polymer 2007, 48, 6439–6447. [Google Scholar] [CrossRef]

- Agwuncha, S.C.; Ray, S.S.; Jayaramudu, J.; Khoathane, C.; Sadiku, R. Influence of Boehmite Nanoparticle Loading on the Mechanical, Thermal, and Rheological Properties of Biodegradable Polylactide/Poly(ϵ-caprolactone) Blends. Macromol. Mater. Eng. 2015, 300, 31–47. [Google Scholar] [CrossRef]

- Zhu, B.; Bai, T.; Wang, P.; Wang, Y.; Liu, C.; Shen, C. Selective dispersion of carbon nanotubes and nanoclay in biodegradable poly (ε-caprolactone)/poly (lactic acid) blends with improved toughness, strength and thermal stability. Int. J. Biol. Macromol. 2020, 153, 1272–1280. [Google Scholar] [CrossRef] [PubMed]

- Kelnar, I.; Kratochvíl, J.; Kaprálková, L.; Zhigunov, A.; Nevoralová, M. Graphite Nanoplatelets-Modified PLA/PCL: Effect of Blend Ratio and Nanofiller Localization on Structure and Properties. J. Mech. Behav. Biomed. Mater. 2017, 71, 271–278. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Zhang, Y.; Zhang, M.; Yu, W. Selective Localization of Multiwalled Carbon Nanotubes in Poly(ε-caprolactone)/Polylactide Blend. Biomacromolecules 2009, 10, 417–424. [Google Scholar] [CrossRef]

- Wang, B.; Ye, X.; Wang, B.; Li, X.; Xiao, S.; Liu, H. Reactive graphene as highly efficient compatibilizer for cocontinuous poly(lactic acid)/poly(ε-caprolactone) blends toward robust biodegradable nanocomposites. Compos. Sci. Technol. 2022, 221, 109326. [Google Scholar] [CrossRef]

- Kelnar, I.; Kratochvíl, J.; Fortelný, I.; Kaprálková, L.; Zhigunov, A.; Khunová, V.; Nevoralová, M. Effect of halloysite on structure and properties of melt-drawn PCL/PLA microfibrillar composites. Express Polym. Lett. 2016, 10, 381–393. [Google Scholar] [CrossRef]

- Kelnar, I.; Kratochvíl, J.; Fortelný, I.; Kaprálková, L.; Zhigunov, A.; Nevoralová, M. Effect of Graphite Nanoplatelets on Melt Drawing and Properties of PCL/PLA Microfibrillar Composites. Polym. Compos. 2018, 39, 3147–3156. [Google Scholar] [CrossRef]

- Motloung, M.P.; Ojijo, V.; Bandyopadhyay, J.; Ray, S.S. Morphological characteristics and thermal, rheological, and mechanical properties of cellulose nanocrystals-containing biodegradable poly(lactic acid)/poly(ε-caprolactone) blend composites. J. Appl. Polym. Sci. 2019, 137, 48665. [Google Scholar] [CrossRef]

- Jadhav, H.; Jadhav, A.; Takkalkar, P.; Hossain, N.; Nizammudin, S.; Zahoor, M.; Jamal, M.; Mubarak, M.N.; Griffin, G.; Kao, N. Potential of polylactide based nanocomposites-nanopolysaccharide filler for reinforcement purpose: A comprehensive review. J. Polym. Res. 2020, 27, 330. [Google Scholar] [CrossRef]

- Chomachayi, M.D.; Jalali-arani, A.; Martínez Urreaga, J. The effect of silk fibroin nanoparticles on the morphology, rheology, dynamic mechanical properties, and toughness of poly(lactic acid)/poly(ε-caprolactone) nanocomposite. J. Appl. Polym. Sci. 2020, 137, 49232. [Google Scholar] [CrossRef]

- Sessini, V.; Navarro-Baena, I.; Arrieta, M.P.; Dominici, F.; López, D.; Torre, L.; Kenny, J.M.; Dubois, P.; Raquez, J.-M.; Peponi, L. Effect of the addition of polyester-grafted-cellulose nanocrystals on the shape memory properties of biodegradable PLA/PCL nanocomposites. Polym. Degrad. Stab. 2018, 152, 126–138. [Google Scholar] [CrossRef]

- Goffin, A.-L.; Habibi, Y.; Raquez, J.-M.; Dubois, P. Polyester-grafted cellulose nanowhiskers: A new approach for tuning the microstructure of immiscible polyester blends. ACS App. Mater. Interfaces 2012, 4, 3364–3371. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Li, J.; Wang, B.; Liu, J.; Chen, P.; Miao, M.; Gu, Q. Chitin nanocrystals grafted with poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and their effects on thermal behavior of PHBV. Carbohydr. Polym. 2012, 87, 784–789. [Google Scholar] [CrossRef]

- Habib, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519–1542. [Google Scholar] [CrossRef] [PubMed]

- Ray, S.S.; Okamoto, K. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar]

- Liu, S.; Chen, Y.; Liu, C.; Gan, L.; Ma, X.; Huang, J. Polydopamine-coated cellulose nanocrystals as an active ingredient in poly(vinyl alcohol) films towards intensifying packaging application potential. Cellulose 2019, 26, 9599–9612. [Google Scholar] [CrossRef]

- Li, L.; Bao, R.-Y.; Gao, T.; Liu, Z.-Y.; Xie, B.-N.; Yang, M.-B.; Yang, W. Dopamine-induced functionalization of cellulose nanocrystals with polyethylene glycol towards poly(L-lactic acid) bionanocomposites for green packaging. Carbohydr. Polym. 2019, 203, 275–284. [Google Scholar] [CrossRef]

- Samyn, P. Polydopamine and Cellulose: Two Biomaterials with Excellent Compatibility and Applicability. Polym. Rev. 2021, 61, 814–865. [Google Scholar] [CrossRef]

- Phua, S.L.; Yang, L.; Toh, C.L.; Guoqiangm, D.; Lau, S.K.; Dasari, A.; Lu, X. Simultaneous enhancements of UV resistance and mechanical properties of polypropylene by incorporation of dopamine-modified clay. ACS Appl. Mater. Interfaces 2013, 5, 1302–1309. [Google Scholar] [CrossRef]

- Grimme, S.; Antony, J.; Ehrlich, S.; Krieg, H. A Consistent and Accurate Ab Initio Parametrization of Density Functional Dispersion Correction (DFT-D) for the 94 Elements H-Pu. J. Chem. Phys. 2010, 132, 154104. [Google Scholar] [CrossRef]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Petersson, G.A.; Nakatsuji, X.; et al. Gaussian 16, Revision A.03; Gaussian Inc.: Wallingford, CT, USA, 2016. [Google Scholar]

- Boys, S.F.; Bernardi, F. The Calculation of Small Molecular Interactions by the Differences of Separate Total Energies. Some Procedures with Reduced Errors. Mol. Phys. 1970, 19, 553–566. [Google Scholar] [CrossRef]

- Ostafińska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Kelnar, I.; Kaprálková, L.; Krejčíková, S.; Zhigunov, A.; Dybal, J.; Pavlovec, L.; Janata, M. Formation of Graphene Oxide-Based Ordered Structures in Epoxy: Effect of Grafted Polymer Chains. Polym. Plast. Tech. Mat. 2021, 60, 1084–1097. [Google Scholar] [CrossRef]

- Nofar, M.; Salehiyan, R.; Ray, S.S. Influence of nanoparticles and their selective localization on the structure and properties of polylactide-based blend nanocomposites. Compos. B Eng. 2021, 215, 108845. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, H.; Tong, L.; Fang, Z. “Cutting effect” of organoclay platelets in compatibilizing immiscible polypropylene/polystyrene blends. J. Zhejiang Univ. Sci. A 2008, 9, 1614–1620. [Google Scholar] [CrossRef]

- Rotrekl, J.; Matějka, L.; Kaprálková, L.; Zhigunov, A.; Hromádková, J.; Kelnar, I. Epoxy/PCL nanocomposites: Effect of layered silicate on structure and behavior. Express Polym. Lett. 2012, 6, 975–986. [Google Scholar] [CrossRef]

- Kerner, E.H. The elastic and thermo-elastic properties of composite media. Proc. Phys. Soc. B 1956, 69, 808–813. [Google Scholar] [CrossRef]

- Ishida, H.; Chaisuwan, T. Mechanical property improvement of carbon fiber reinforced polybenzoxazinone by rubber interlayer. Polym. Compos. 2003, 24, 597–607. [Google Scholar] [CrossRef]

- Huitric, J.; Ville, J.; Mederic, P.; Aubry, T. Solid-state mechanical properties of PE/PA blends filled with organoclay or compatibilized by a graft co-polymer: A comparative study. Polym. Test. 2018, 70, 208–214. [Google Scholar] [CrossRef]

- Mistretta, M.; Ceraulo, M.; La Mantia, F.; Morreale, M. Compatibilization of polyethylene/polyamide 6 blend nanocomposite films. Polym. Compos. 2015, 36, 992–998. [Google Scholar] [CrossRef]

- Bucknall, C.B. Deformation Mechanisms in Rubber-Toughened Polymers. In Polymer Blends; Paul, D.R., Bucknall, C.B., Eds.; John Wiley & Sons: New York, NY, USA, 2000; pp. 83–118. [Google Scholar]

- Bartczak, Z.; Argon, A.S.; Cohen, R.E.; Kowalewski, T. The morphology and orientation of polyethylene in films of sub-micron thickness crystallized in contact with calcite and rubber substrates. Polymer 1999, 40, 2367–2380. [Google Scholar] [CrossRef]

- Kelnar, I.; Stephan, M.; Jakisch, L.; Fortelný, I. Reactive blending of nylon 6 and modified poly(styrene-co-maleic anhydride); influence of poly(styrene-co-maleic anhydride) modification by fatty amine onto blend properties. J. Appl. Polym. Sci. 1997, 66, 555–562. [Google Scholar] [CrossRef]

- Kelnar, I.; Zhigunov, A.; Kaprálková, L.; Fortelný, I.; Krejčíková, S.; Dybal, J.; Janata, M.; Brus, J.; Kobera, L.; Štengl, V. Ductile/brittle PA6/PS system: Effect of carbon nanoplatelets-modified interface on performance. J. Appl. Polym. Sci. 2020, 137, 49100. [Google Scholar] [CrossRef]

- Davies, W.E.A. The theory of elastic composite materials. J. Phys. D—Appl. Phys. 1971, 4, 1325. [Google Scholar] [CrossRef]

- Michell, R.M.; Müller, A.J. Confined crystallization of polymeric materials. Prog. Polym. Sci. 2016, 54–55, 183–213. [Google Scholar] [CrossRef]

- Moll, J.; Kumar, S.K. Glass Transitions in Highly Attractive Highly Filled Polymer Nanocomposites. Macromolecules 2012, 45, 1131–1135. [Google Scholar] [CrossRef]

- Eklind, H.; Maurer, F.H.J. Micromechanical transitions in compatibilized polymer blends. Polymer 1996, 37, 2641–2651. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of miscibility on mechanical and thermal properties of poly (lactic acid)/polycaprolactone blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

| Blend Ratio | PLA/PCL | PLA/PCL/CNC | PLA/PCL/CNCd | |||

|---|---|---|---|---|---|---|

| PLAdmf | PCLdmf | PLA/CNC | PCL/CNC | PLA/CNCd | PCL/CNCd | |

| 80/20 PCL Size (µm) | 0.51 | 0.57 | 0.39 | 0.34 | 0.27 | 0.27 |

| 20/80 PLA Size (µm) | 0.6 | 0.55 | 0.38 | 0.33 | 0.24 | 0.25 |

| Composition | E (MPa) | Stress at Break (MPa) | Break Strain (%) | Toughness (kJ/m2) | Tg (°C) |

|---|---|---|---|---|---|

| PLAdmf | 2629 ± 261 | 48.4 ± 4.9 | 8.1 ± 3.6 | 12.9 ± 1.8 | 60.74 |

| PLA + 2% CNC | 2894 ± 154 | 51.5 ± 2.3 | 2.5 ± 0.9 | 15.8 ± 10.7 | 60.55 |

| PLA + 2% CNCd | 2852 ± 45 | 47.5 ± 2.0 | 2.3 ± 0.3 | 12.8 ± 3 | 59.54 |

| PCLdmf | 302 ± 23 | 27.0 ± 3.4 | 505 ± 50 | 48.8 ± 5.6 | −54.96 |

| PCL + 2%CNC | 358 ± 37 | 26 ± 1.3 | 135 ± 80 | 32.5 ± 1.9 | −54.7 |

| PCL + 2% CNCd | 365 ± 94 | 27 ± 2.5 | 248 ± 114 | 30.1 ± 9.3 | −54.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelnar, I.; Kaprálková, L.; Krejčíková, S.; Dybal, J.; Vyroubalová, M.; Abdel-Mohsen, A.M. Effect of Polydopamine Coating of Cellulose Nanocrystals on Performance of PCL/PLA Bio-Nanocomposites. Materials 2023, 16, 1087. https://doi.org/10.3390/ma16031087

Kelnar I, Kaprálková L, Krejčíková S, Dybal J, Vyroubalová M, Abdel-Mohsen AM. Effect of Polydopamine Coating of Cellulose Nanocrystals on Performance of PCL/PLA Bio-Nanocomposites. Materials. 2023; 16(3):1087. https://doi.org/10.3390/ma16031087

Chicago/Turabian StyleKelnar, Ivan, Ludmila Kaprálková, Sabina Krejčíková, Jiří Dybal, Michaela Vyroubalová, and A. M. Abdel-Mohsen. 2023. "Effect of Polydopamine Coating of Cellulose Nanocrystals on Performance of PCL/PLA Bio-Nanocomposites" Materials 16, no. 3: 1087. https://doi.org/10.3390/ma16031087

APA StyleKelnar, I., Kaprálková, L., Krejčíková, S., Dybal, J., Vyroubalová, M., & Abdel-Mohsen, A. M. (2023). Effect of Polydopamine Coating of Cellulose Nanocrystals on Performance of PCL/PLA Bio-Nanocomposites. Materials, 16(3), 1087. https://doi.org/10.3390/ma16031087