Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities

Abstract

1. Introduction

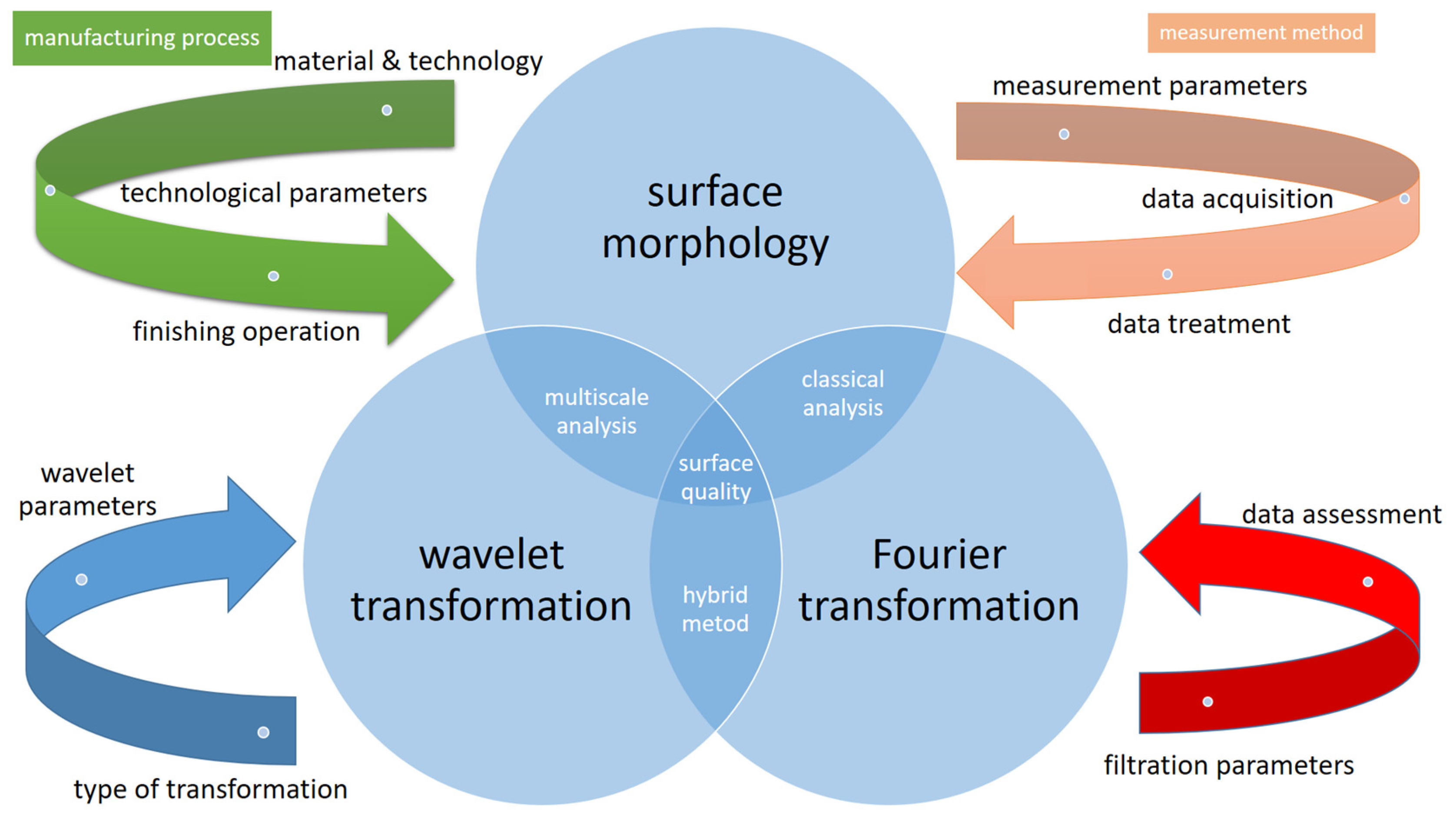

2. Metrological Approach

3. Results

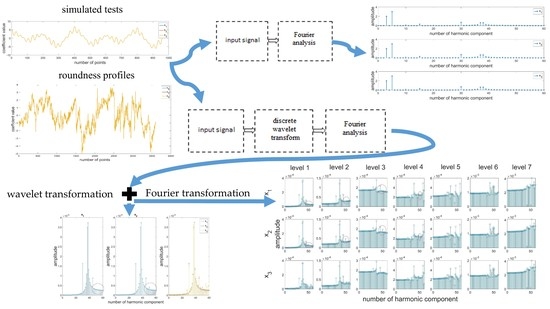

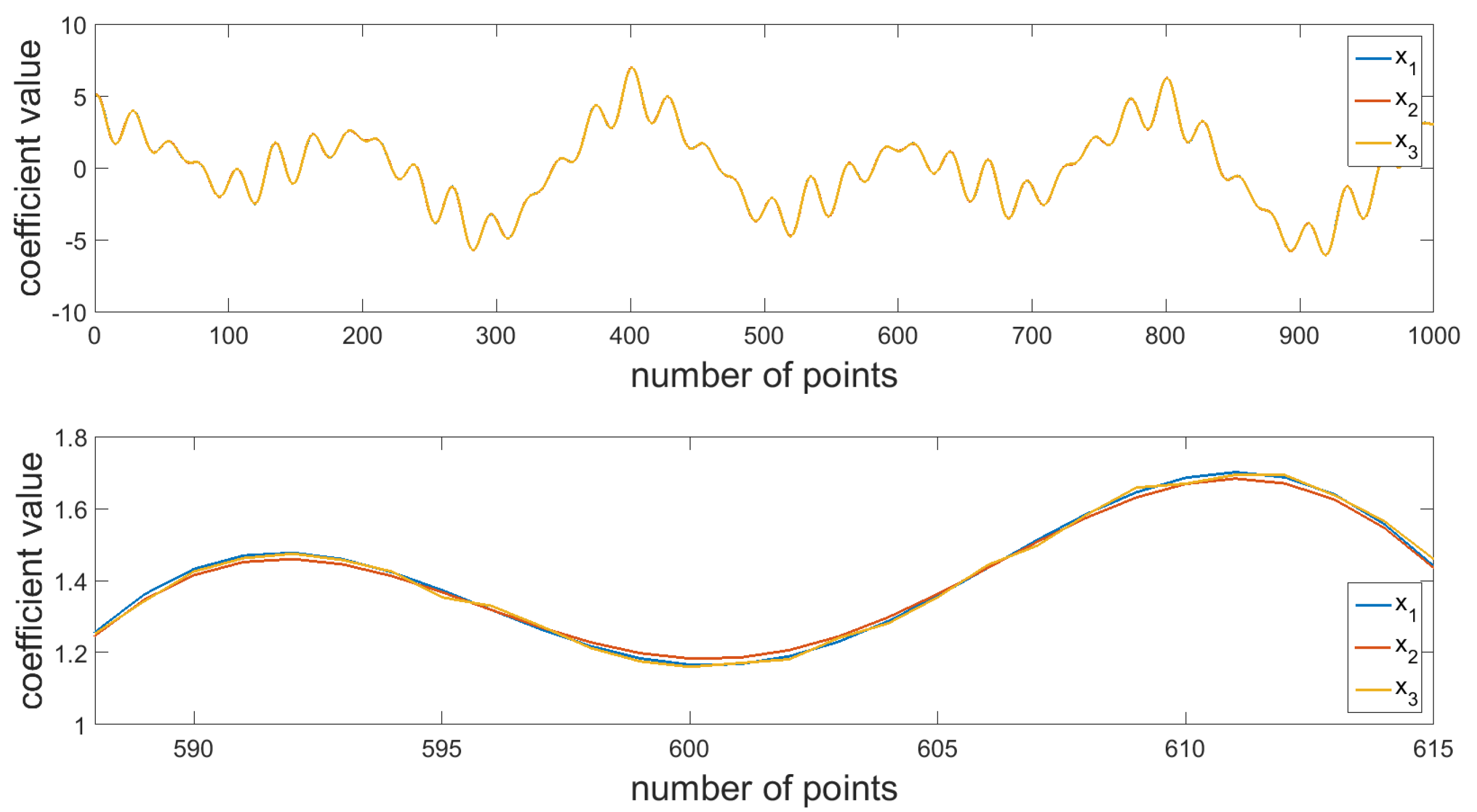

3.1. Simulated Tests

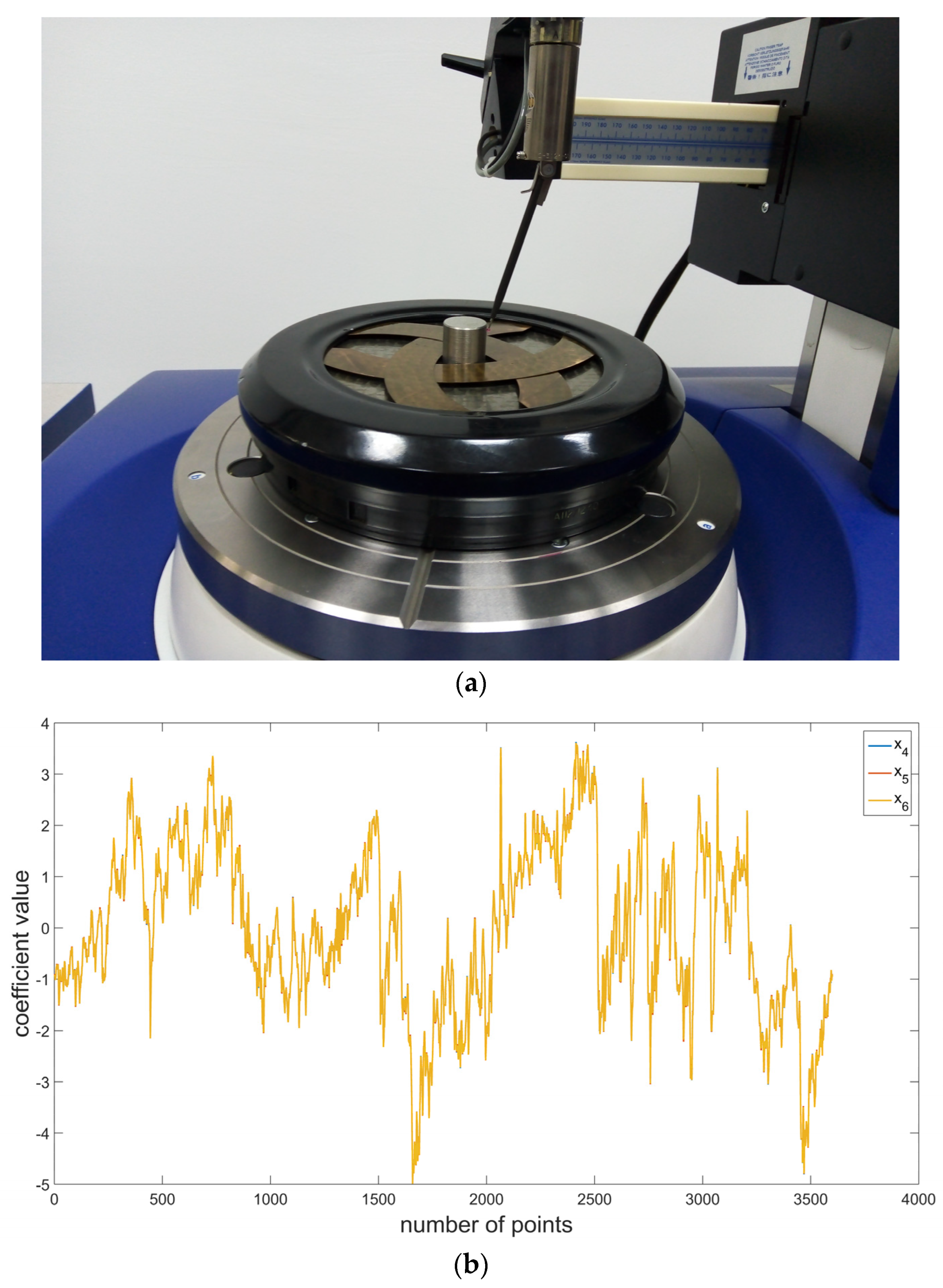

3.2. Analysis of Roundness Profiles

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

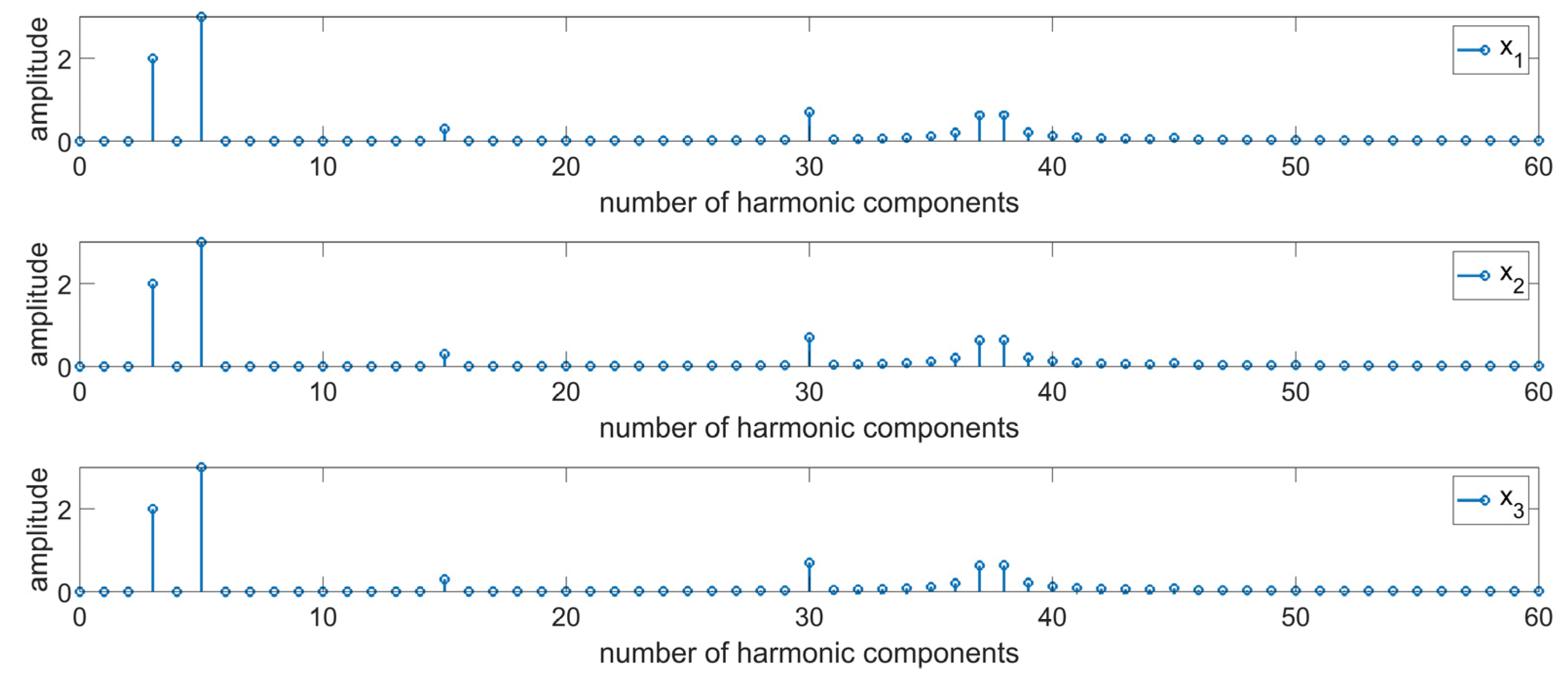

| x1 | A function that is a composition of periodic functions with various amplitude sizes and various periods. |

| x2 | A function that is a composition of periodic functions with various amplitude sizes and various periods, with additional noise from a periodic function with a relatively small amplitude and period. |

| x3 | A function that is a composition of periodic functions with various amplitude sizes and various periods, with additional noise from a series of coefficients with random values. |

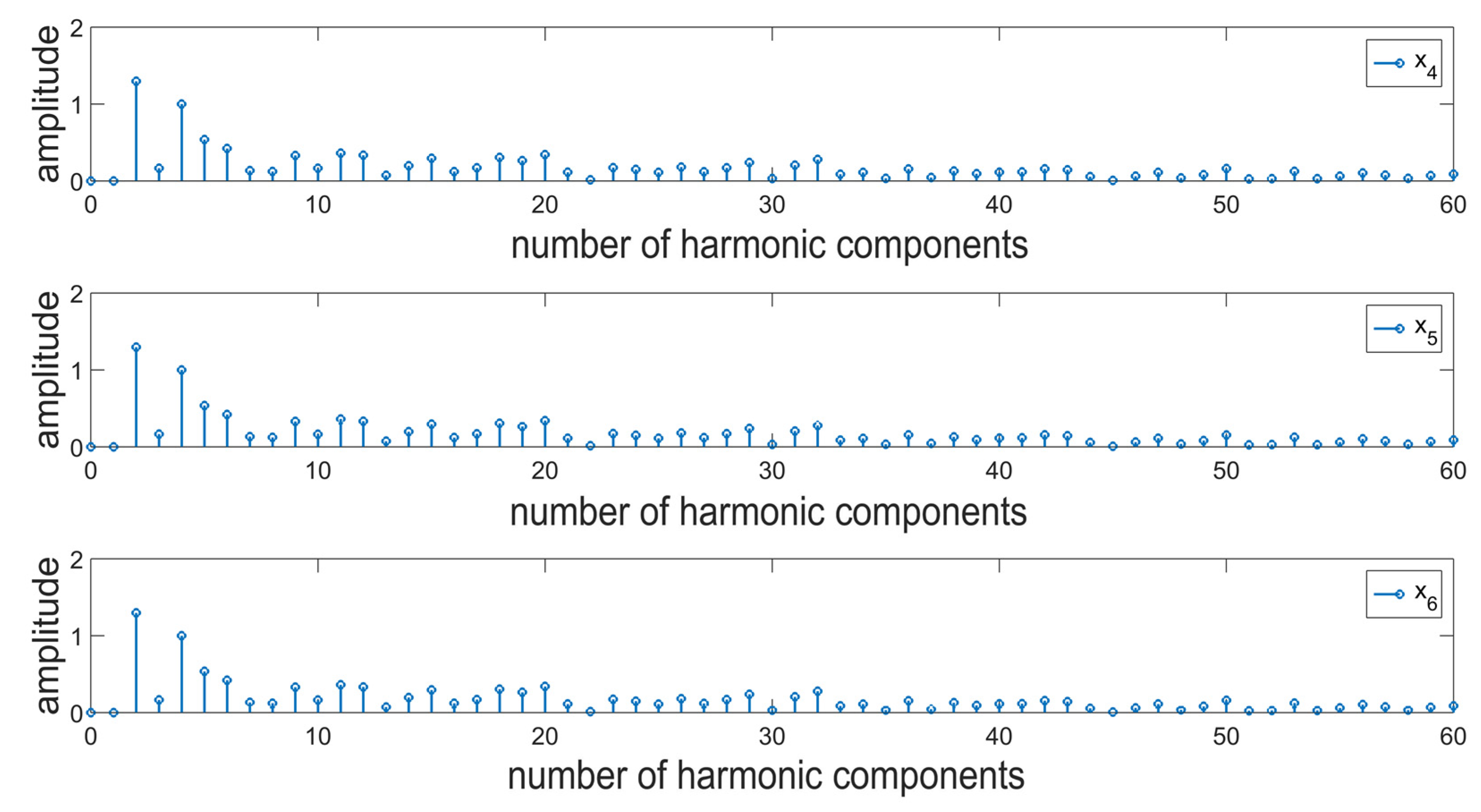

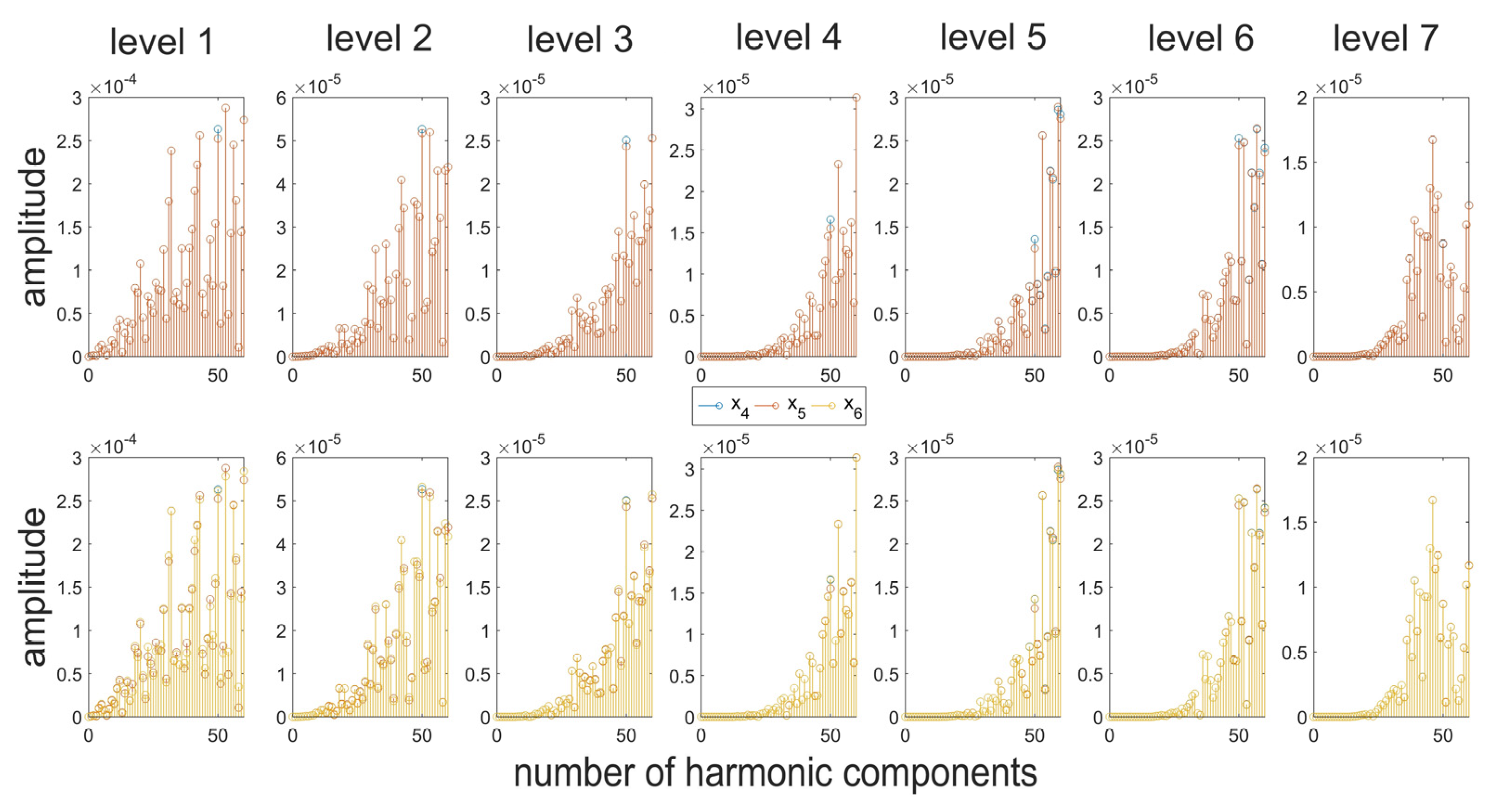

| x4 | The roundness profile of rollers in a rolling bearing. |

| x5 | The roundness profile of rollers in a rolling bearing, with additional noise from a periodic function with a relatively small amplitude and period. |

| x6 | The roundness profile of rollers in a rolling bearing, with additional noise from a series of coefficients with random values. |

| N | The number of vanishing moments. |

References

- Panda, A.; Sahoo, A.K.; Panigrahi, I.; Rout, A.K. Investigating Machinability in Hard Turning of AISI 52100 Bearing Steel through Performance Measurement: QR, ANN and GRA Study. Int. J. Automot. Mech. Eng. 2018, 15, 4935–4961. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.K.; Panigrahi, I.; Rout, A.K. Prediction models for on-line cutting tool and machined surface condition monitoring during hard turning considering vibration signal. Mech. Ind. 2020, 21, 520. [Google Scholar] [CrossRef]

- Gogolewski, D.; Bartkowiak, T.; Kozior, T.; Zmarzły, P. Multiscale Analysis of Surface Texture Quality of Models Manufactured by Laser Powder-Bed Fusion Technology and Machining from 316L Steel. Materials 2021, 14, 2794. [Google Scholar] [CrossRef]

- Gogolewski, D. Multiscale assessment of additively manufactured free-form surfaces. Metrol. Meas. Syst. 2023, 30. [Google Scholar]

- Fernandes, F.; van Spaendonck, R.; Burrus, C. A new framework for complex wavelet transforms. IEEE Trans. Signal Process. 2003, 51, 1825–1837. [Google Scholar] [CrossRef]

- Makieła, W.; Świderski, J.; Gogolewski, D.; Makieła, K. Compensation of temperature errors when measuring surface textures by applying a two-dimensional wavelet transform. Eng. Mech. 2018, 2018, 537–540. [Google Scholar]

- Bruzzone, A.; Montanaro, J.; Ferrando, A.; Lonardo, P. Wavelet Analysis for Surface Characterisation: An Experimental Assessment. CIRP Ann. 2004, 53, 479–482. [Google Scholar] [CrossRef]

- Edjeou, W.; Cerezo, V.; Zahouani, H.; Salvatore, F. Multiscale analyses of pavement texture during polishing. Surf. Topogr. Metrol. Prop. 2020, 8, 024008. [Google Scholar] [CrossRef]

- Méndez, A.; Reyes, Y.; Trejo, G.; StĘpień, K.; Ţălu, Ş. Micromorphological characterization of zinc/silver particle composite coatings. Microsc. Res. Tech. 2015, 78, 1082–1089. [Google Scholar] [CrossRef] [PubMed]

- Blateyron, F. Good practices for the use of areal filters. In Proceedings of the 3rd Seminar on Surface Metrology of the Americas (SSMA), Albuquerque, NM, USA, 12–13 May 2014. [Google Scholar]

- Lucas, K.; Sanz-Lobera, A.; Antón-Acedos, P.; Amatriain, A. A Survey of Bidimensional Wavelet Filtering in Surface Texture Characterization. Procedia Manuf. 2019, 41, 811–818. [Google Scholar] [CrossRef]

- Wang, X.; Shi, T.; Liao, G.; Zhang, Y.; Hong, Y.; Chen, K. Using Wavelet Packet Transform for Surface Roughness Evaluation and Texture Extraction. Sensors 2017, 17, 933. [Google Scholar] [CrossRef] [PubMed]

- Ali, J.M.; Jailani, H.S.; Murugan, M. Surface roughness evaluation of electrical discharge machined surfaces using wavelet transform of speckle line images. Measurement 2020, 149, 107029. [Google Scholar] [CrossRef]

- Adamczak, S.; Makieła, W.; Stepien, K. Investigating Advantages and Disadvantages of the Analysis of a Geometrical Surface Structure with the Use of Fourier and Wavelet Transform. Metrol. Meas. Syst. 2010, 17, 233–244. [Google Scholar] [CrossRef]

- Chowdhury, S.K.; Nimbarte, A.D. Comparison of Fourier and wavelet analysis for fatigue assessment during repetitive dynamic exertion. J. Electromyogr. Kinesiol. 2015, 25, 205–213. [Google Scholar] [CrossRef]

- Huang, L.; Kemao, Q.; Pan, B.; Asundi, A.K. Comparison of Fourier transform, windowed Fourier transform, and wavelet transform methods for phase extraction from a single fringe pattern in fringe projection profilometry. Opt. Lasers Eng. 2010, 48, 141–148. [Google Scholar] [CrossRef]

- Xu, B.; Shimizu, Y.; Takeishi, T.; Ito, S.; Gao, W. Surface Form Measurement and Analysis of a Cylindrical Workpiece with Microstructures. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 936–948. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- Gao, R.X.; Yan, R. Wavelets: Theory and Applications for Manufacturing; Springer: Boston, MA, USA, 2010; ISBN 978-1-4419-1545-0. [Google Scholar]

- Wang, C.; Gao, R.X.; Yan, R. Unified time–scale–frequency analysis for machine defect signature extraction: Theoretical framework. Mech. Syst. Signal Process. 2009, 23, 226–235. [Google Scholar] [CrossRef]

- Grzesik, W.; Brol, S. Wavelet and fractal approach to surface roughness characterization after finish turning of different workpiece materials. J. Mater. Process. Technol. 2009, 209, 2522–2531. [Google Scholar] [CrossRef]

- Karolczak, P.; Kowalski, M.; Wiśniewska, M. Analysis of the Possibility of Using Wavelet Transform to Assess the Condition of the Surface Layer of Elements with Flat-Top Structures. Machines 2020, 8, 65. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, T.; Lim, E.; Lopez-Benitez, M.; Ma, F.; Yu, L. A Review of Wavelet Analysis and Its Applications: Challenges and Opportunities. IEEE Access 2022, 10, 58869–58903. [Google Scholar] [CrossRef]

- Trivizakis, E.; Ioannidis, G.S.; Souglakos, I.; Karantanas, A.H.; Tzardi, M.; Marias, K. A neural pathomics framework for classifying colorectal cancer histopathology images based on wavelet multi-scale texture analysis. Sci. Rep. 2021, 11, 15546. [Google Scholar] [CrossRef] [PubMed]

- Zmarzły, P. Multi-Dimensional Mathematical Wear Models of Vibration Generated by Rolling Ball Bearings Made of AISI 52100 Bearing Steel. Materials 2020, 13, 5440. [Google Scholar] [CrossRef] [PubMed]

- Gogolewski, D.; Kozior, T.; Zmarzły, P.; Mathia, T.G. Morphology of Models Manufactured by SLM Technology and the Ti6Al4V Titanium Alloy Designed for Medical Applications. Materials 2021, 14, 6249. [Google Scholar] [CrossRef]

- Skrzyniarz, M.; Nowakowski, L.; Blasiak, S. Geometry, Structure and Surface Quality of a Maraging Steel Milling Cutter Printed by Direct Metal Laser Melting. Materials 2022, 15, 773. [Google Scholar] [CrossRef]

- Zárybnická, L.; Petrů, J.; Krpec, P.; Pagáč, M. Effect of Additives and Print Orientation on the Properties of Laser Sintering-Printed Polyamide 12 Components. Polymers 2022, 14, 1172. [Google Scholar] [CrossRef] [PubMed]

- Mesicek, J.; Ma, Q.-P.; Hajnys, J.; Zelinka, J.; Pagac, M.; Petru, J.; Mizera, O. Abrasive Surface Finishing on SLM 316L Parts Fabricated with Recycled Powder. Appl. Sci. 2021, 11, 2869. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.K.; Rout, A.K. Investigations on surface quality characteristics with multi-response parametric optimization and correlations. Alex. Eng. J. 2016, 55, 1625–1633. [Google Scholar] [CrossRef]

- Sahoo, A.K. Application of Taguchi and regression analysis on surface roughness in machining hardened AISI D2 steel. Int. J. Ind. Eng. Comput. 2014, 5, 295–304. [Google Scholar] [CrossRef]

- Grochalski, K.; Wieczorowski, M.; Jakubek, B. Influence of thermal disturbances on profilometric measurements of surface asperities. Measurement 2022, 190, 110694. [Google Scholar] [CrossRef]

- Wieczorowski, M. Spiral sampling as a fast way of data acquisition in surface topography. Int. J. Mach. Tools Manuf. 2001, 41, 2017–2022. [Google Scholar] [CrossRef]

- Eifler, M.; Klauer, K.; Kirsch, B.; Aurich, J.C.; Seewig, J. Performance verification of areal surface texture measuring instruments with the Sk-parameters. Measurement 2021, 173, 8257–8283. [Google Scholar] [CrossRef]

- Zmarzły, P.; Kozior, T.; Gogolewski, D. The Effect of Non-Measured Points on the Accuracy of the Surface Topography Assessment of Elements 3D Printed Using Selected Additive Technologies. Materials 2023, 16, 460. [Google Scholar] [CrossRef] [PubMed]

- Adamczak, S.; Kundera, C.; Swiderski, J. Assessment of the state of the geometrical surface texture of seal rings by various measuring methods. IOP Conf. Series: Mater. Sci. Eng. 2017, 233, 012031. [Google Scholar] [CrossRef]

- Podulka, P. Thresholding Methods for Reduction in Data Processing Errors in the Laser-Textured Surface Topography Measurements. Materials 2022, 15, 5137. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Comparison of Results of Surface Texture Measurement Obtained with Stylus Methods and Optical Methods. Metrol. Meas. Syst. 2018, 25, 589–602. [Google Scholar]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Problem of Non-Measured Points in Surface Texture Measurements. Metrol. Meas. Syst. 2017, 24, 525–536. [Google Scholar] [CrossRef]

- Jiang, X.; Scott, P.; Whitehouse, D. Wavelets and their applications for surface metrology. CIRP Ann. 2008, 57, 555–558. [Google Scholar] [CrossRef]

- Li, G.; Zhang, K.; Gong, J.; Jin, X. Calculation method for fractal characteristics of machining topography surface based on wavelet transform. Procedia CIRP 2019, 79, 500–504. [Google Scholar] [CrossRef]

- Sun, J.; Song, Z.; He, G.; Sang, Y. An improved signal determination method on machined surface topography. Precis. Eng. 2018, 51, 338–347. [Google Scholar] [CrossRef]

- Abdul-Rahman, H.; Jiang, X.; Scott, P. Freeform surface filtering using the lifting wavelet transform. Precis. Eng. 2013, 37, 187–202. [Google Scholar] [CrossRef]

- Lucido, M. Helmholtz–Galerkin Regularizing Technique for the Analysis of the THz-Range Surface-Plasmon-Mode Resonances of a Graphene Microdisk Stack. Micro 2022, 2, 295–312. [Google Scholar] [CrossRef]

- Hirschberg, V.; Wilhelm, M.; Rodrigue, D. Combining mechanical and thermal surface fourier transform analysis to follow the dynamic fatigue behavior of polymers. Polym. Test. 2021, 96, 107070. [Google Scholar] [CrossRef]

- Markovska, I.; Pavlov, S.; Yovkova, F.; Michalev, T.; Yaneva, S. Estimation of ceramics surface roughness by fourier analysis. J. Chem. Technol. Metall. 2018, 53, 1139–1143. [Google Scholar]

- Liu, M.; Dong, L.; Zhang, Z.; Li, L.; Wang, L.; Song, Z.; Weng, Z.; Han, X.; Zhou, L.; Wang, Z. Fast Fourier transport analysis of surface structures fabricated by laser interference lithography. Appl. Phys. Express 2014, 12, 096503. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Lee, C.-H. Deep Learning Approach for Vibration Signals Applications. Sensors 2021, 21, 3929. [Google Scholar] [CrossRef]

- Singru, P.; Krishnakumar, V.; Natarajan, D.; Raizada, A. Bearing failure prediction using Wigner-Ville distribution, modified Poincare mapping and fast Fourier transform. J. Vibroeng. 2018, 20, 127–137. [Google Scholar] [CrossRef]

- Holub, M.; Jankovych, R.; Vetiska, J.; Sramek, J.; Blecha, P.; Smolik, J.; Heinrich, P. Experimental Study of the Volumetric Error Effect on the Resulting Working Accuracy—Roundness. Appl. Sci. 2020, 10, 6233. [Google Scholar] [CrossRef]

- Adamczak, S.; Zmarzły, P.; Janecki, D. Theoretical And Practical Investigations Of V-Block Waviness Measurement Of Cylindrical Parts. Metrol. Meas. Syst. 2015, 22, 181–192. [Google Scholar] [CrossRef]

- Liu, J.; Shao, Y. Vibration modelling of nonuniform surface waviness in a lubricated roller bearing. J. Vib. Control. 2015, 23, 1115–1132. [Google Scholar] [CrossRef]

- Wrzochal, M.; Adamczak, S. The problems of mathematical modelling of rolling bearing vibrations. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 1363–1372. [Google Scholar]

- Misiti, M.; Misiti, Y.; Oppenheim, G.; Poggi, J.-M. MathWorks Wavelet Toolbox User’s Guide; MathWorks Inc.: Natick, MA, USA, 2015. [Google Scholar]

- Kumar, R.N.; Jagadale, B.N.; Bhat, J.S. A lossless image compression algorithm using wavelets and fractional Fourier transform. SN Appl. Sci. 2019, 1, 266. [Google Scholar] [CrossRef]

- Gogolewski, D. Influence of the edge effect on the wavelet analysis process. Measurement 2020, 152, 107314. [Google Scholar] [CrossRef]

- Gogolewski, D. Fractional spline wavelets within the surface texture analysis. Measurement 2021, 179, 109435. [Google Scholar] [CrossRef]

- Herrmann, F.J. A Scaling Medium Representation a Discussion on Well-Logs, Fractals and Waves. Ph.D Thesis, Beeld en Gra sch Centrum, Technische Universiteit Delft, Delft, The Netherlands, 1997. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gogolewski, D.; Zmarzły, P.; Kozior, T.; Mathia, T.G. Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities. Materials 2023, 16, 1228. https://doi.org/10.3390/ma16031228

Gogolewski D, Zmarzły P, Kozior T, Mathia TG. Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities. Materials. 2023; 16(3):1228. https://doi.org/10.3390/ma16031228

Chicago/Turabian StyleGogolewski, Damian, Paweł Zmarzły, Tomasz Kozior, and Thomas G. Mathia. 2023. "Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities" Materials 16, no. 3: 1228. https://doi.org/10.3390/ma16031228

APA StyleGogolewski, D., Zmarzły, P., Kozior, T., & Mathia, T. G. (2023). Possibilities of a Hybrid Method for a Time-Scale-Frequency Analysis in the Aspect of Identifying Surface Topography Irregularities. Materials, 16(3), 1228. https://doi.org/10.3390/ma16031228