Failure Analysis of Cracking of Cast Aluminum Alloy Manhole Cover

Abstract

:1. Introduction

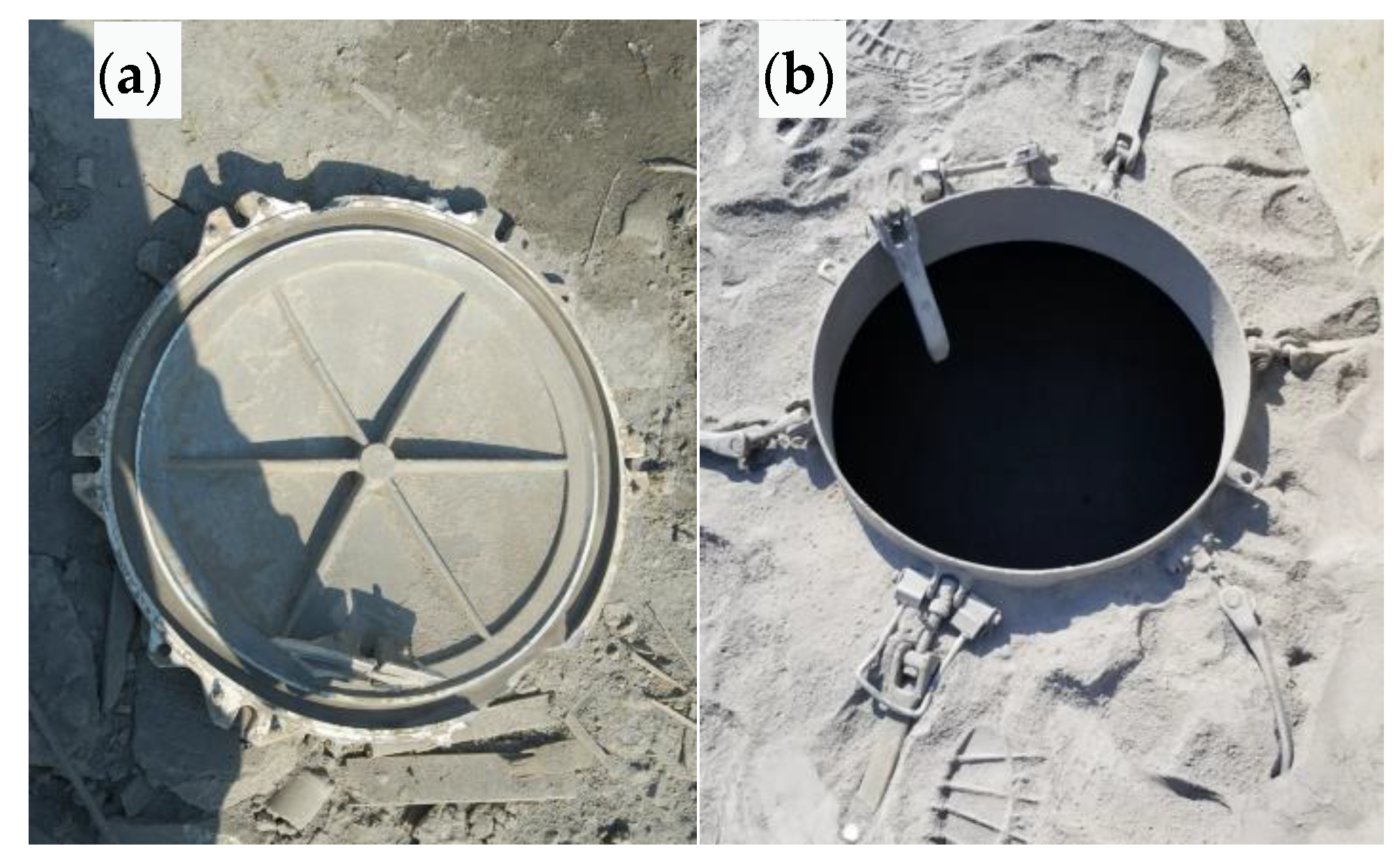

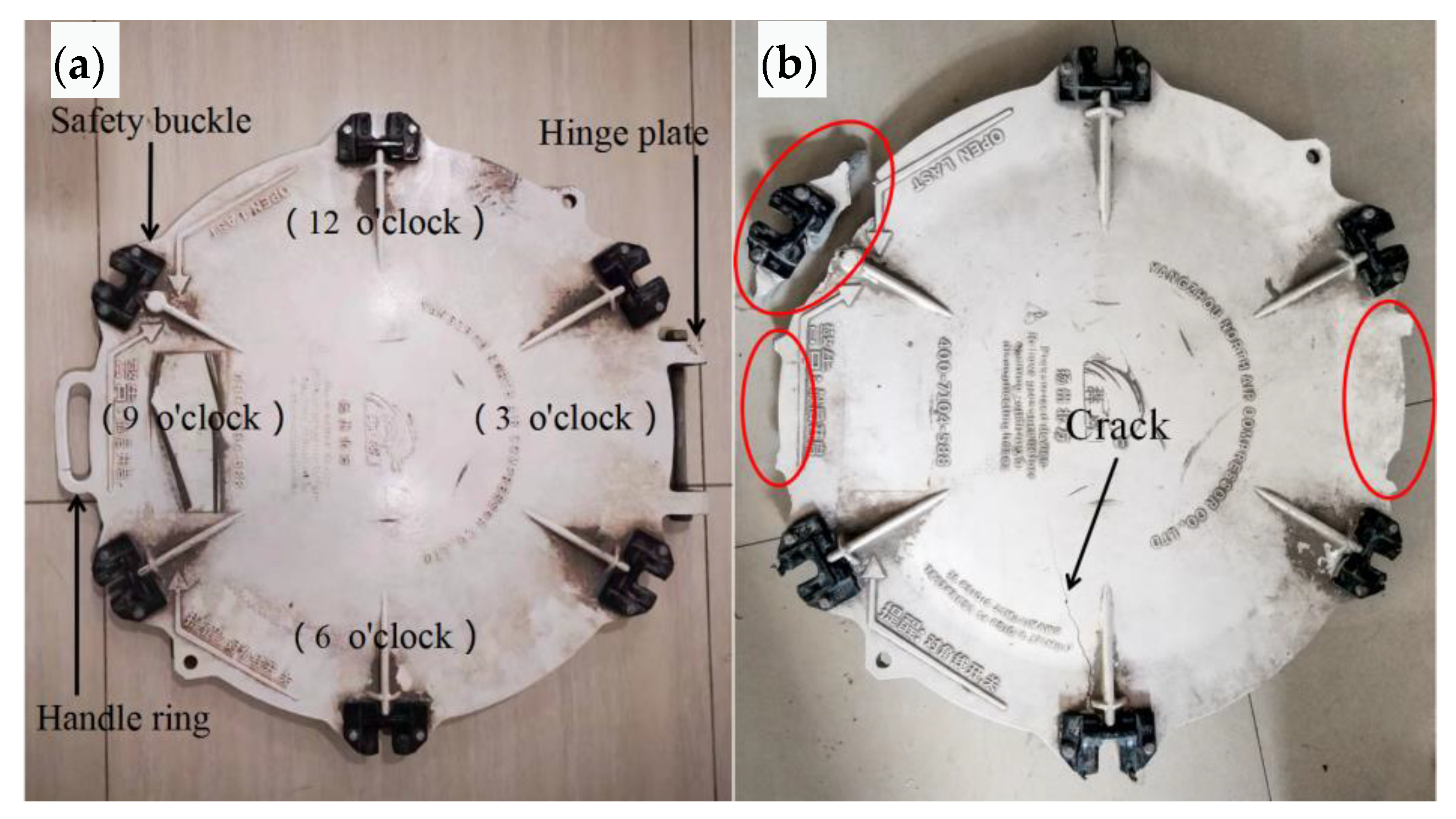

2. Description of Manhole Cover Fracture Failure

3. Materials and Experimental Methods

3.1. Materials

3.2. Safety Valve Effectiveness

3.3. Experimental Methods

4. Results and Discussion

4.1. Macro Morphology Analysis

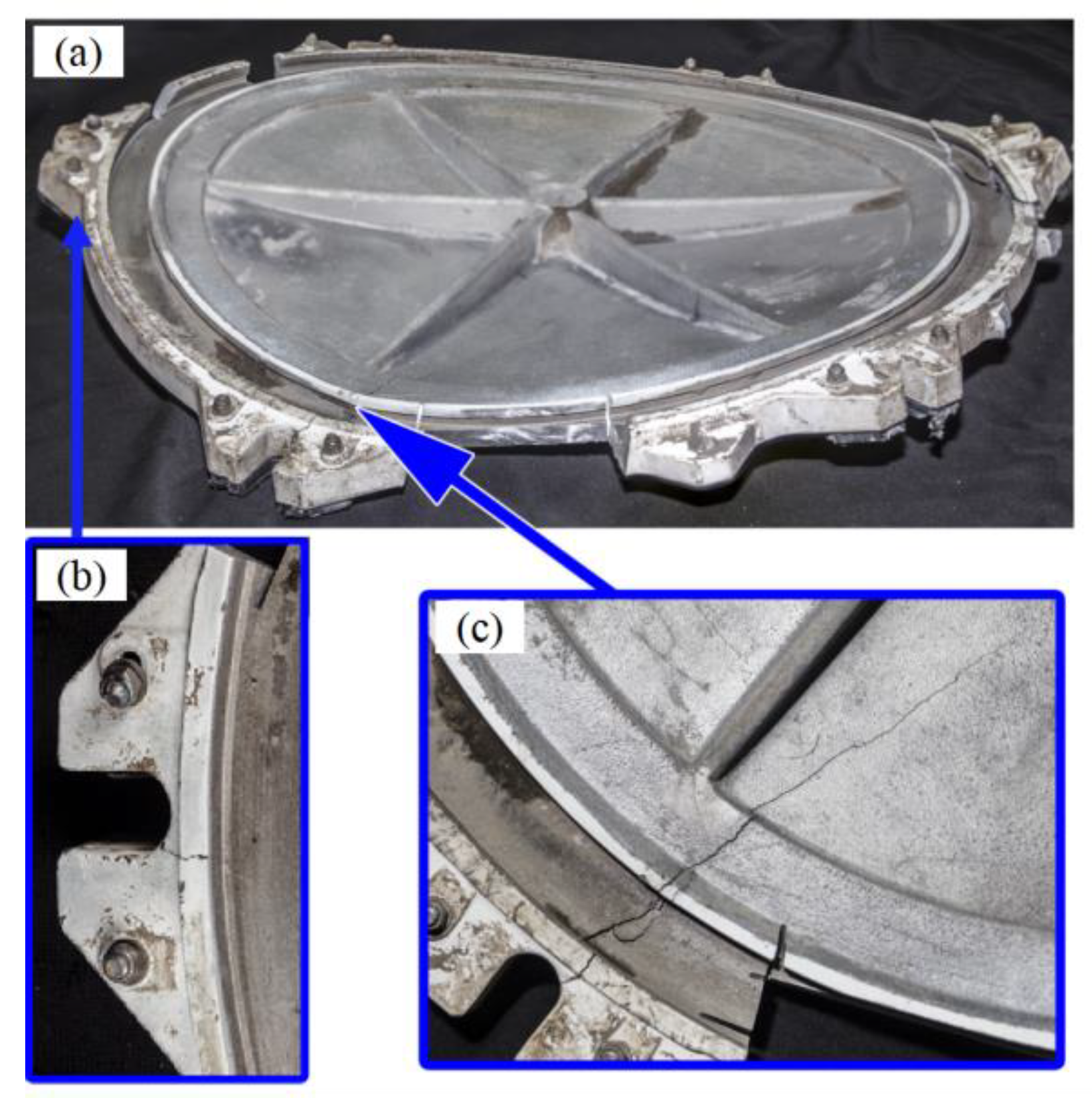

4.1.1. Overall Macro Morphology

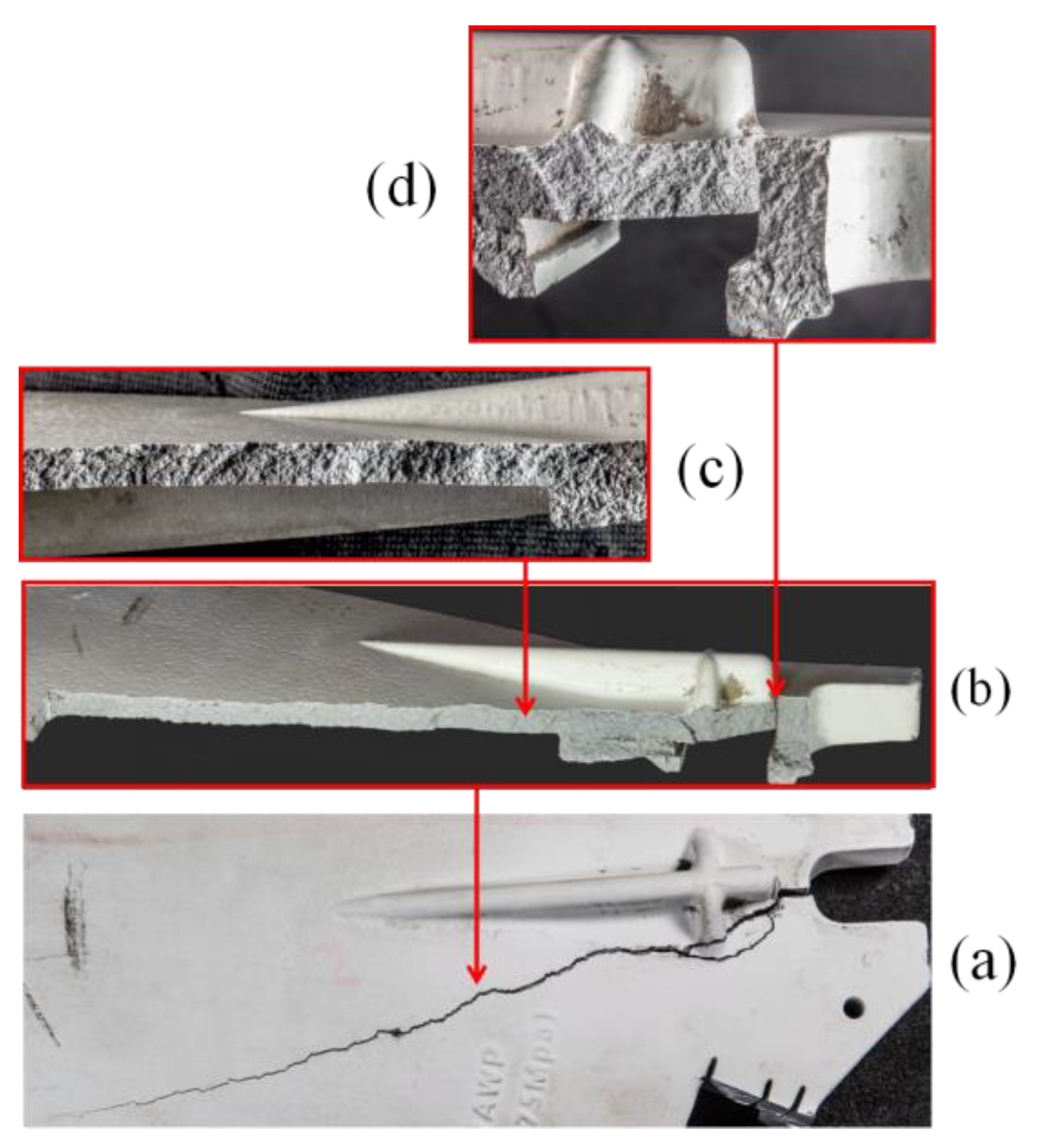

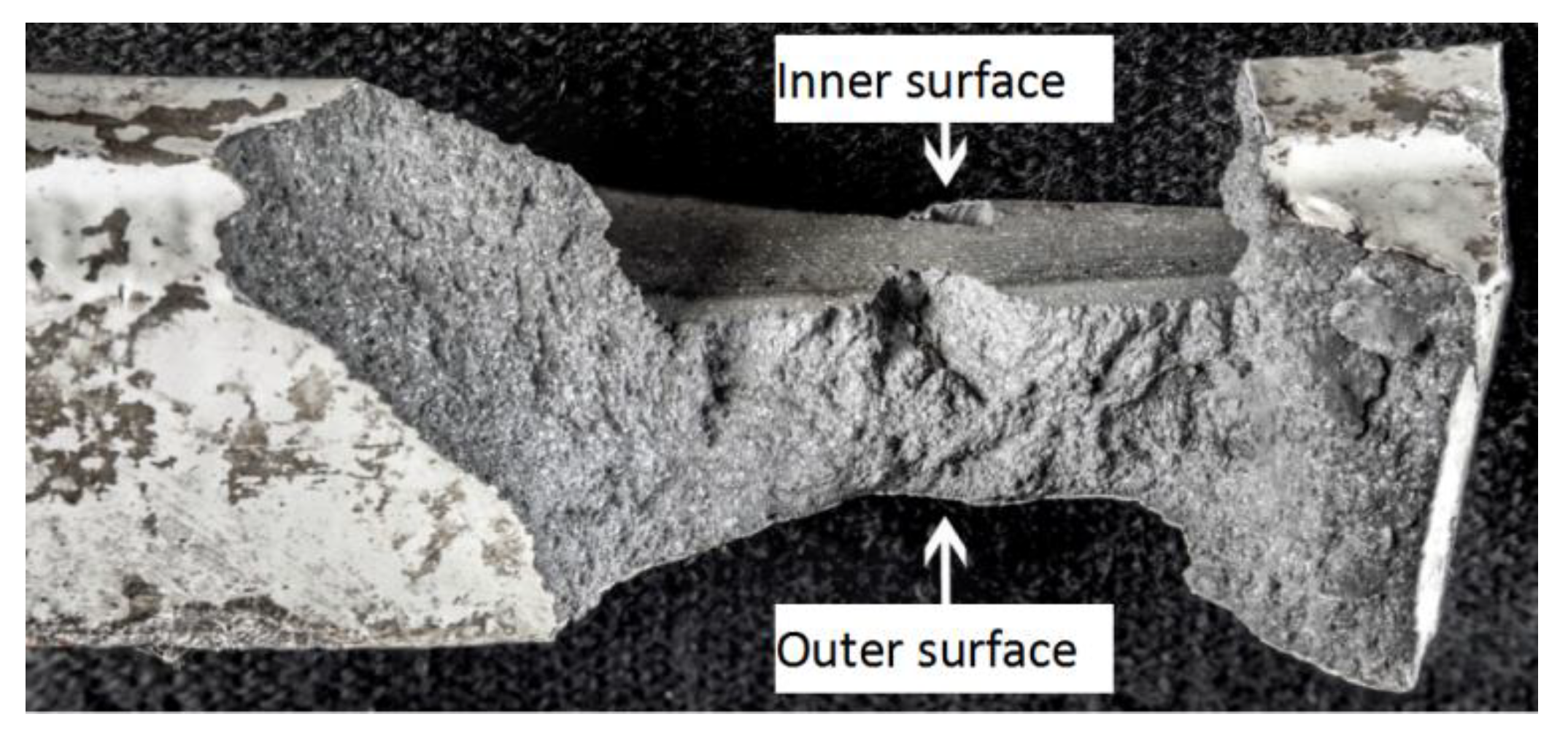

4.1.2. Cracked Surface at the Six O’Clock Position

4.1.3. Broken Area of Safety Buckle

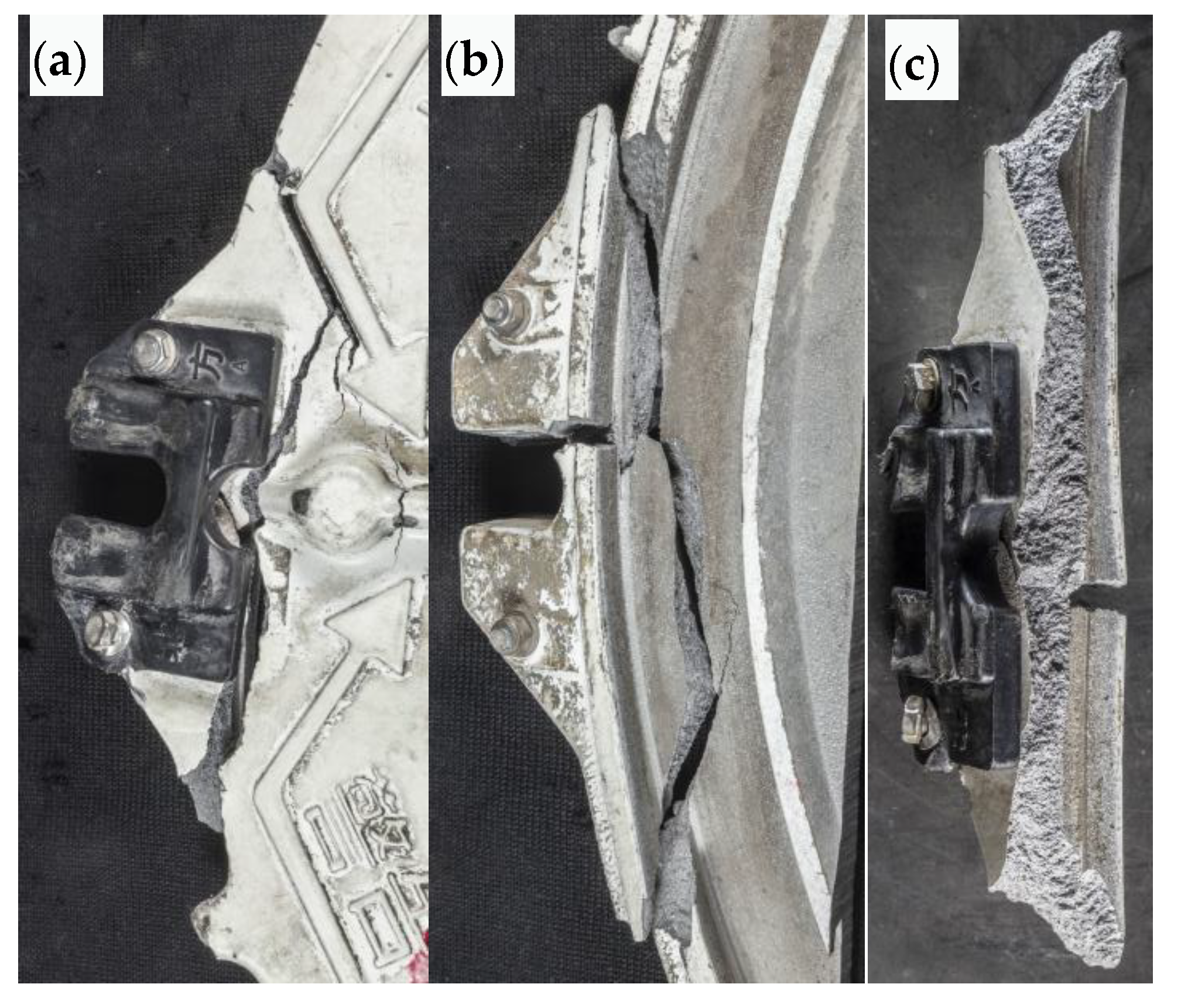

4.1.4. Fracture Surface of Hinged Plate

4.2. SEM Analysis of Fracture Surface

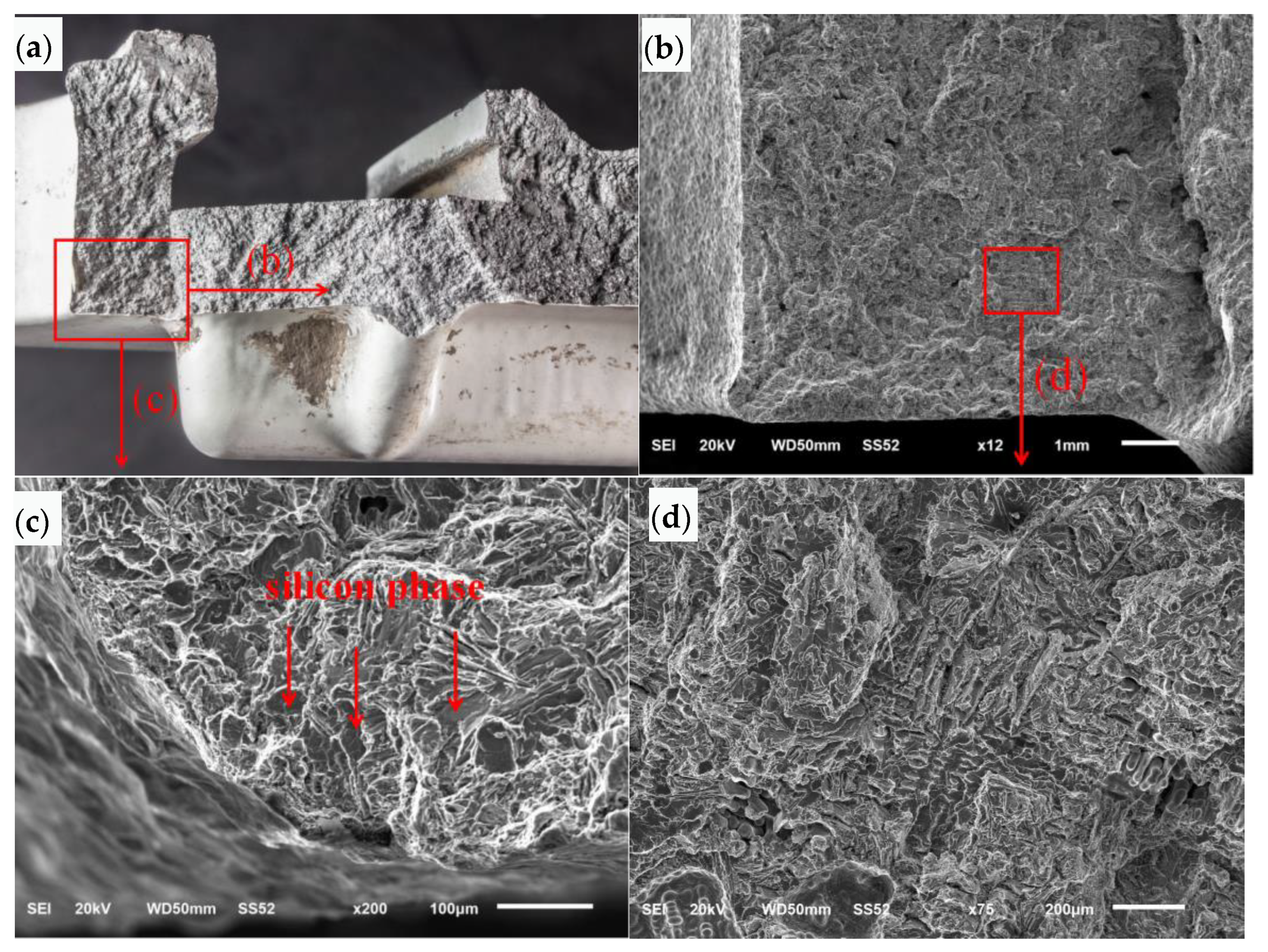

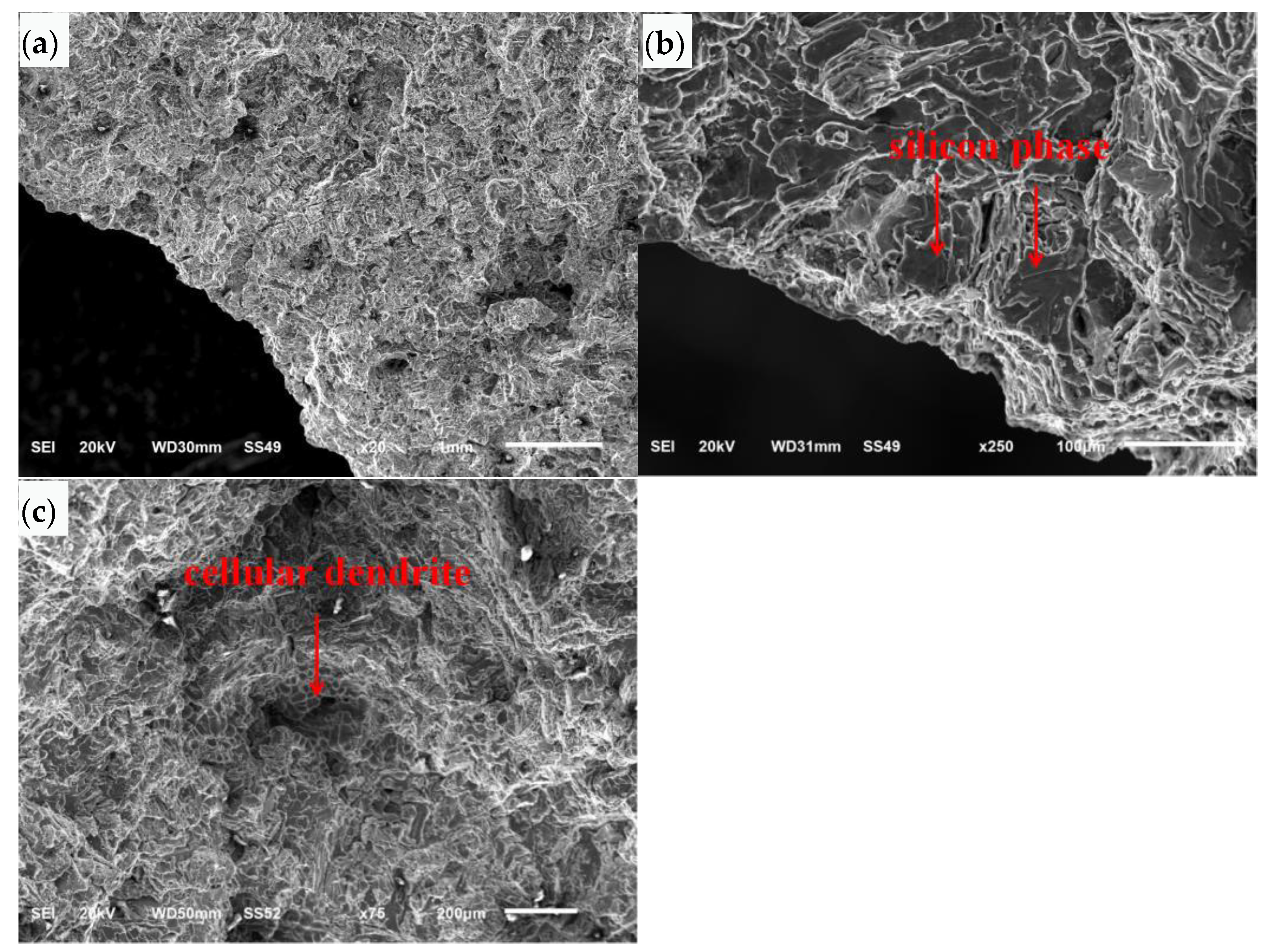

4.2.1. Cracked Surface at the Six O’Clock Position

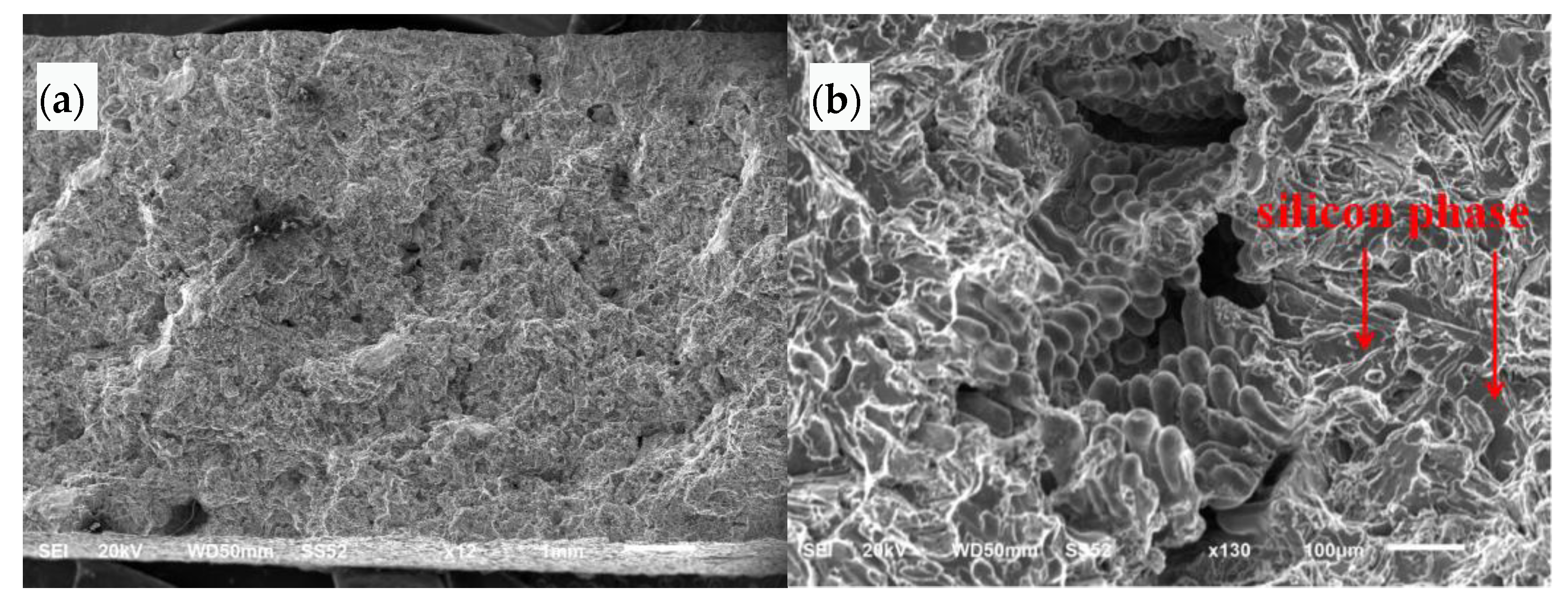

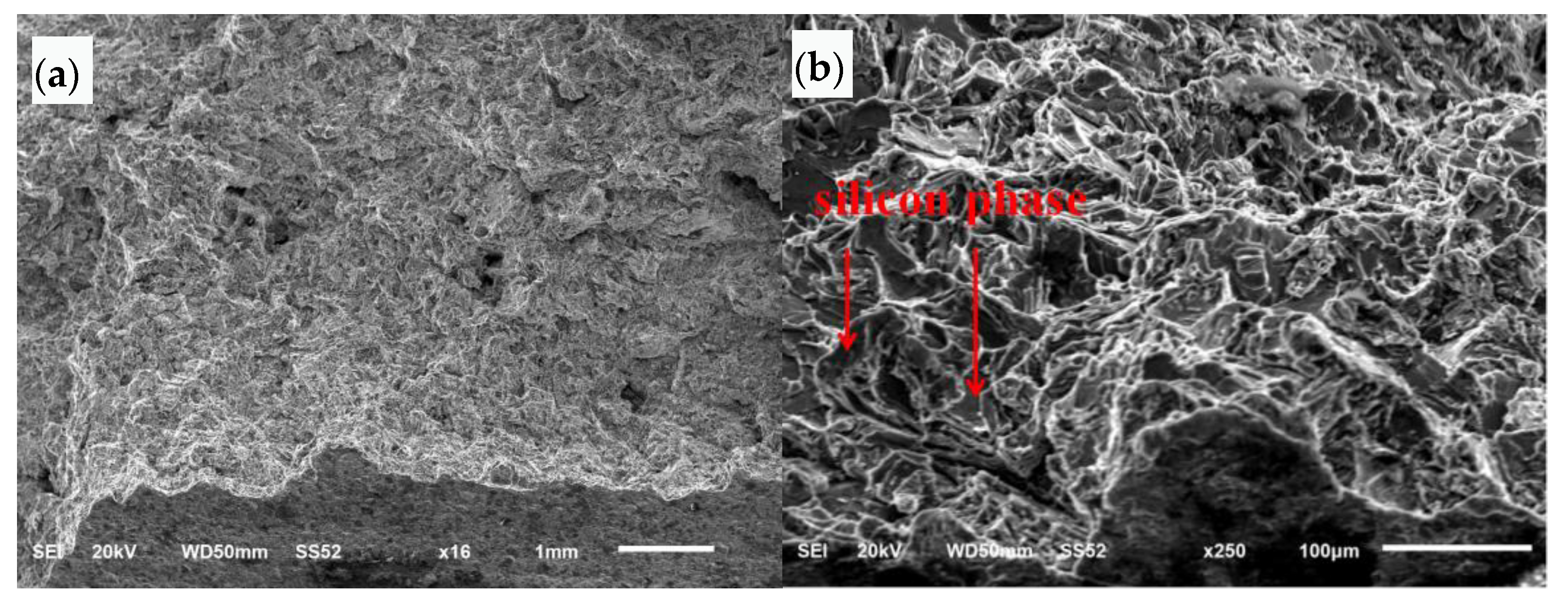

4.2.2. Fracture Area of Safety Buckle

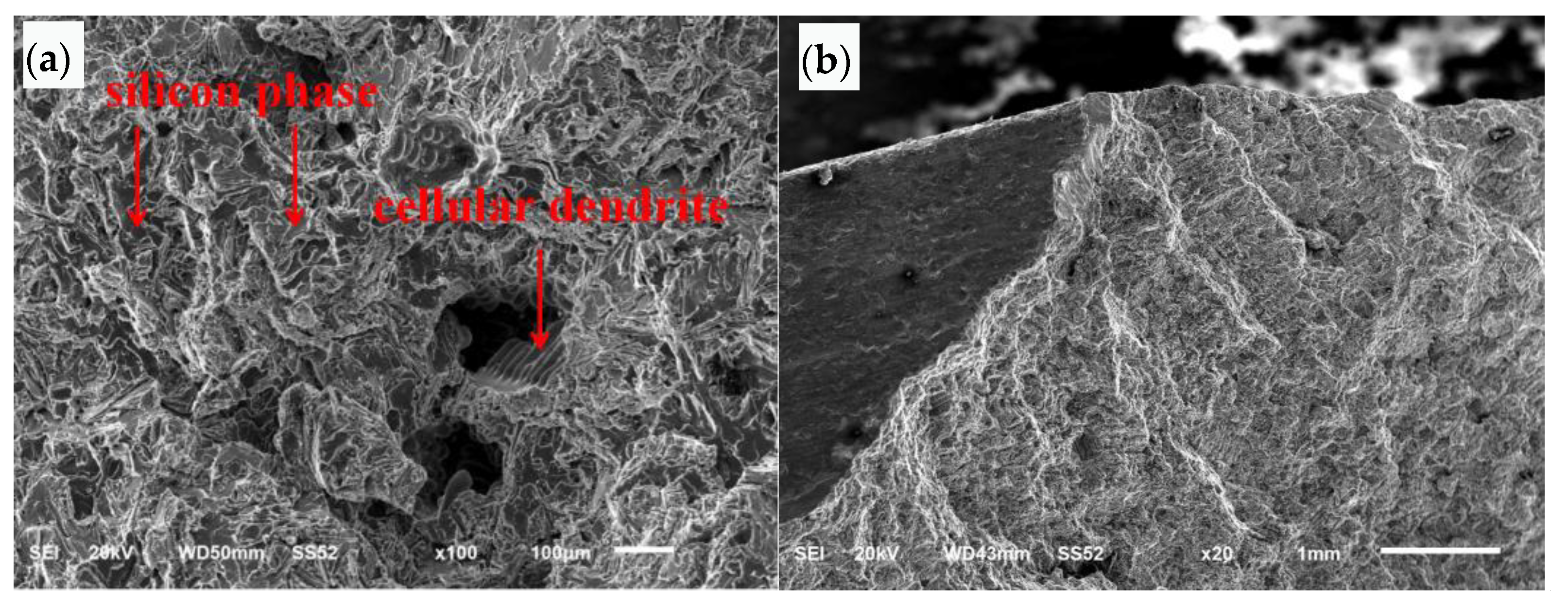

4.2.3. Fracture Area of Hinged Plate

4.3. Microstructure Analysis

4.3.1. Normal Section of Crack Surface at the Six O’Clock Position

4.3.2. Normal Section of Safety Buckle Fracture Section

4.3.3. Microstructure of Manhole Cover Matrix

4.3.4. Morphology of the Normal Section near the Outer Circle

4.4. Mechanical Property Analysis

4.5. Chemical Composition Analysis

5. Conclusions and Proposals

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, M. Comparative study on corrosion resistance of Marine 5083 and 5059 aluminum alloy slabs. Ship Sci. Technol. 2021, 43, 1–4. [Google Scholar]

- Rambabu, P.P.N.K.V.; Eswara Prasad, N.; Kutumbarao, V.V.; Wanhill, R.J.H. Aluminium alloys for aerospace applications. Aerosp. Mater. Mater. Technol. 2017, 29–52. [Google Scholar] [CrossRef]

- Derry, C.; Robson, J. Characterisation and modelling of toughness in 6013-T6 aerospace aluminium alloy friction stir welds. Mater. Sci. Eng. A 2008, 490, 328–334. [Google Scholar] [CrossRef]

- Sunde, J.; Marioara, C.; Holmestad, R. The effect of low Cu additions on precipitate crystal structures in overaged Al-Mg-Si(-Cu) alloys. Mater. Charact. 2020, 160, 110087. [Google Scholar] [CrossRef]

- Mochugovskiy, A.; Kotov, A.; Ghayoumabadi, M.E.; Yakovtseva, O.; Mikhaylovskaya, A. A high-strain-rate superplasticity of the Al-Mg-Si-Zr-Sc alloy with Ni addition. Materials 2021, 14, 2028. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zhang, W.; Huang, S.; Yi, Y.; He, H. Effect of three-dimensional deformation at different temperatures on microstructure, strength, fracture toughness and corrosion resistance of 7A85 aluminum alloy. J. Alloy. Compd. 2022, 928, 167200. [Google Scholar] [CrossRef]

- Wang, D.; Yi, Y.; Li, C.; Huang, S.; He, H.; Zhang, J. Effects of different multidirectional forging processes on the microstructure and three-dimensional mechanical properties of ultra-high strength aluminum alloys. Mater. Sci. Eng. A 2021, 826, 141932. [Google Scholar] [CrossRef]

- Kim, Y.; Fujii, H.; Tsumura, T.; Komazaki, T.; Nakata, K. Effect of welding parameters on microstructure in the stir zone of FSW joints of aluminum die casting alloy. Mater. Lett. 2006, 60, 3830–3837. [Google Scholar] [CrossRef]

- Xu, T.; Zhu, Z.; Mi, G.; Wang, L.; Li, M.; Ma, X. Revealing the mechanism of laser welded aluminum alloy joints in-situ reinforced by carbon nanotubes based on microstructural evolution. Mater. Charact. 2022, 193, 112327. [Google Scholar] [CrossRef]

- Lei, G.; Wang, B.; Lu, J.; Wang, C.; Li, Y.; Luo, F. Microstructure, mechanical properties, and corrosion resistance of continuous heating aging 6013 aluminum alloy. J. Mater. Res. Technol. 2022, 18, 370–383. [Google Scholar] [CrossRef]

- Kairy, S.; Rometsch, P.; Davies, C.; Birbilis, N. On the intergranular corrosion and hardness evolution of 6xxx series Al alloys as a function of Si: Mg ratio, Cu content, and aging condition. Corrosion 2017, 73, 1280–1295. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qin, W.; Yu, S.; La, J.; Fu, Y.; Li, J.; Yang, W.; Zhan, Y. Effect of aging treatment on the corrosion resistance properties of 7N01 extrusion aluminum alloy. Materials 2021, 14, 3615. [Google Scholar] [CrossRef] [PubMed]

- Zhan, X.; Tang, J.; Li, H.; Liang, X.; Lu, Y.; Che, Y.; Tu, W.; Zhang, Y. Effects of non-isothermal aging on mechanical properties, corrosion behavior and microstructures of Al-Cu-Mg-Si alloy. J. Alloy. Compd. 2020, 819, 152960. [Google Scholar] [CrossRef]

- Luiz, L.; Gobi, C.; Andrade, J.; Peres, E.; Paro, O. Failure analysis of corroded 500 kV connectors made of silver plated ASTM 356 aluminum alloy. Eng. Fail. Anal. 2022, 136, 106229. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. Casting defects induced fatigue damage in aircraft frames of ZL205A aluminum alloy—A failure analysis. Mater. Des. 2011, 32, 2570–2582. [Google Scholar] [CrossRef]

- Liu, W.; Li, J.; Zhong, Y.; Shi, T.; Zhang, J.; Li, S. Failure analysis on aluminum alloy drill pipe with pits and parallel transverse cracks. Eng. Fail. Anal. 2022, 131, 105809. [Google Scholar] [CrossRef]

- Reinke, G.; Badibanga, R.; Pestana, M.; Ferreira, J.; Araujo, J.; Silva, C. Failure analysis of aluminum wires in all aluminum alloy conductors -AAAC. Eng. Fail. Anal. 2020, 107, 104197. [Google Scholar] [CrossRef]

- Carboni, M. Failure analysis of two aluminium alloy sonotrodes for ultrasonic plastic welding. Int. J. Fatigue 2014, 60, 110–120. [Google Scholar] [CrossRef]

- JY/T 010; General Rules for Analytical Scanning Electron Microscopy. Ministry of Education of the People’s Republic of China: Beijing, China, 1996.

- GB/T 7999; Optical Emission Spectrometric Analysis Method of Aluminum and Aluminum Alloys. Ministry of Education of the People’s Republic of China: Beijing, China, 2015.

- GB/T 13298; Inspection Methods of Microstructure for Metals. Ministry of Education of the People’s Republic of China: Beijing, China, 2015.

- JB/T 7946.1; Metallograph of Cast Aluminium Alloys Cast Aluminium-Silicon Alloys-Modification. Ministry of Education of the People’s Republic of China: Beijing, China, 1999.

- GB/T 231.1; Metallic Materials-Brinell Hardness Test-Part 1, Test Method. Ministry of Education of the People’s Republic of China: Beijing, China, 2009.

- Cao, F.; Li, Z.; Zhang, N.; Ding, H.; Yu, F.; Zuo, L. Superplasticity, flow and fracture mechanism in an Al-12.7Si-0.7Mg alloy. Mater. Sci. Eng. A 2013, 571, 167–183. [Google Scholar] [CrossRef]

- Yıldırım, M.; Özyürek, D. The effects of Mg amount on the microstructure and mechanical properties of Al-Si-Mg alloys. Mater. Des. 2013, 51, 767–774. [Google Scholar] [CrossRef]

| Specimen | Tensile Strength (N/mm2) | Elongation (%) | |

|---|---|---|---|

| No. 1 | 155 | 2.42 | |

| No. 2 | 162 | 4.15 | |

| No. 3 | 154 | 3.00 | |

| Average | 157 | 3.19 | |

| ZL104 (GB/T 1173-2013) | F | ≥150 × 75% = 112.5 | ≥2 × 50% = 1 |

| J, T1 | ≥200 × 75% = 150 | ≥1.5 × 50% = 0.75 | |

| J, T6 | ≥240 × 75% = 180 | ≥2 × 50% = 1 | |

| Specimen | Brinell Hardness (HBW) | ||

|---|---|---|---|

| Manhole cover | 64.0 | 63.0 | 64.0 |

| ZL104 (GB/T 1173-2013) | ≥50 | ||

| Element | Si | Mg | Mn | Fe | Zn | Ti | Sn | Cu | Pb | Ti + Zr |

|---|---|---|---|---|---|---|---|---|---|---|

| Manhole cover | 8.81 | 0.45 | 0.24 | 0.22 | 0.005 | 0.032 | 0.009 | 0.030 | 0.007 | 0.032 |

| ZL104 (GB/T1173-2013) | 8.0~10.5 | 0.17~0.35 | 0.2~0.5 | ≤0.9 | ≤0.25 | ≤0.2 | ≤0.05 | ≤0.1 | ≤0.05 | ≤0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, F.; Li, H. Failure Analysis of Cracking of Cast Aluminum Alloy Manhole Cover. Materials 2023, 16, 1561. https://doi.org/10.3390/ma16041561

Ren F, Li H. Failure Analysis of Cracking of Cast Aluminum Alloy Manhole Cover. Materials. 2023; 16(4):1561. https://doi.org/10.3390/ma16041561

Chicago/Turabian StyleRen, Facai, and Hezong Li. 2023. "Failure Analysis of Cracking of Cast Aluminum Alloy Manhole Cover" Materials 16, no. 4: 1561. https://doi.org/10.3390/ma16041561

APA StyleRen, F., & Li, H. (2023). Failure Analysis of Cracking of Cast Aluminum Alloy Manhole Cover. Materials, 16(4), 1561. https://doi.org/10.3390/ma16041561