Electric Cable Construction Parameter and Its Potential to Foresee the Cable Fire Properties

Abstract

:1. Introduction

2. Materials and Methods

3. Results of Empirical Tests and Discussion

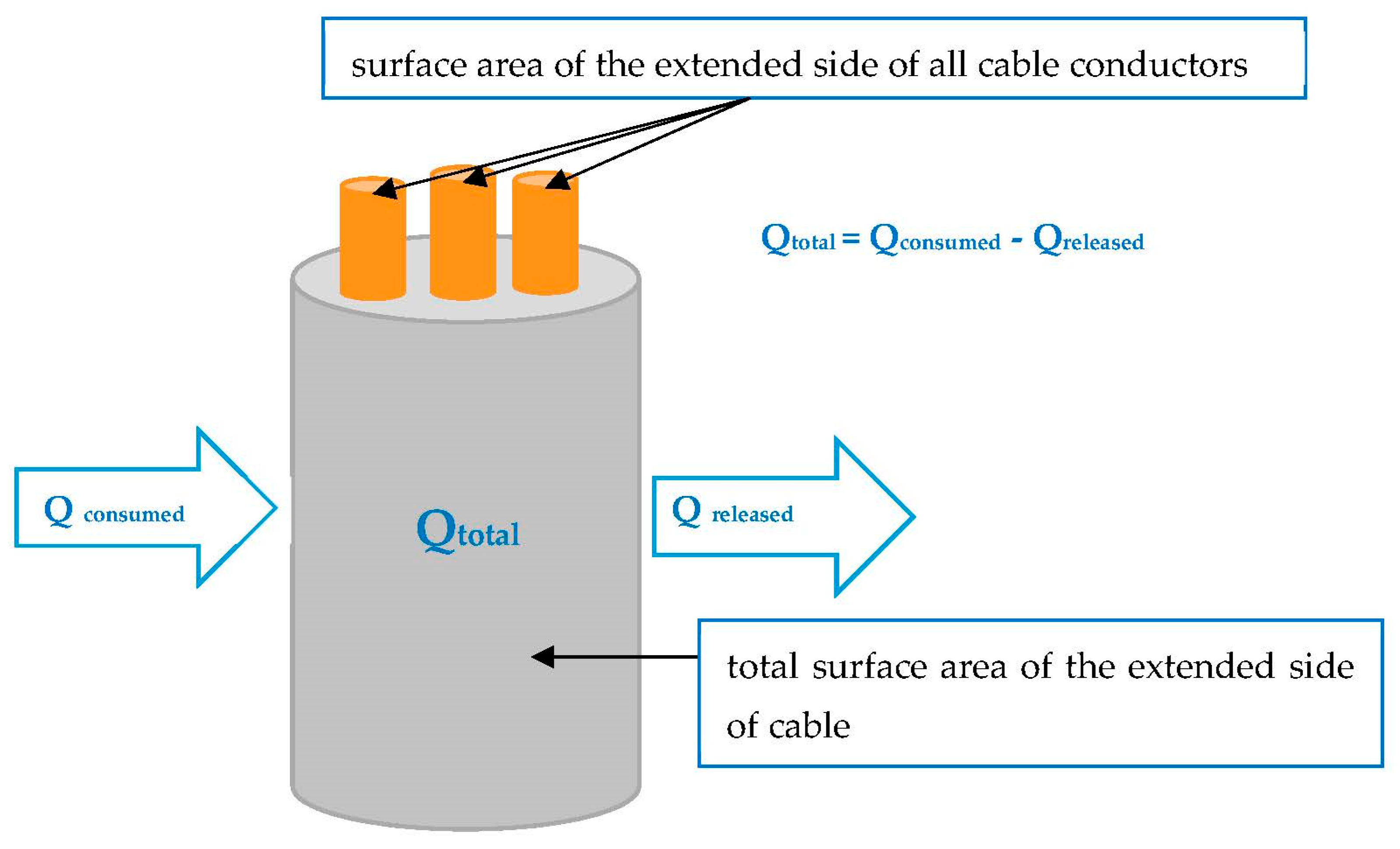

3.1. Cable Parameter Ω Proposal for Circular Cables

- Ω—volume of effective non-combustible content (cable parameter), [l/m of cable]

- z—surface ratio, [-]

- Vcombust—non-metallic volume of combustible cable components, l/m bunched cable according to standard [17]

- ω—non-metallic, non-combustible component volume to non-metallic, combustible component volume ratio, [-]

- dmet—diameter of conductor, [m]

- n—number of conductors, [-]

- dcable—diameter of cable, [m]

- h—unit length of cable, [m]

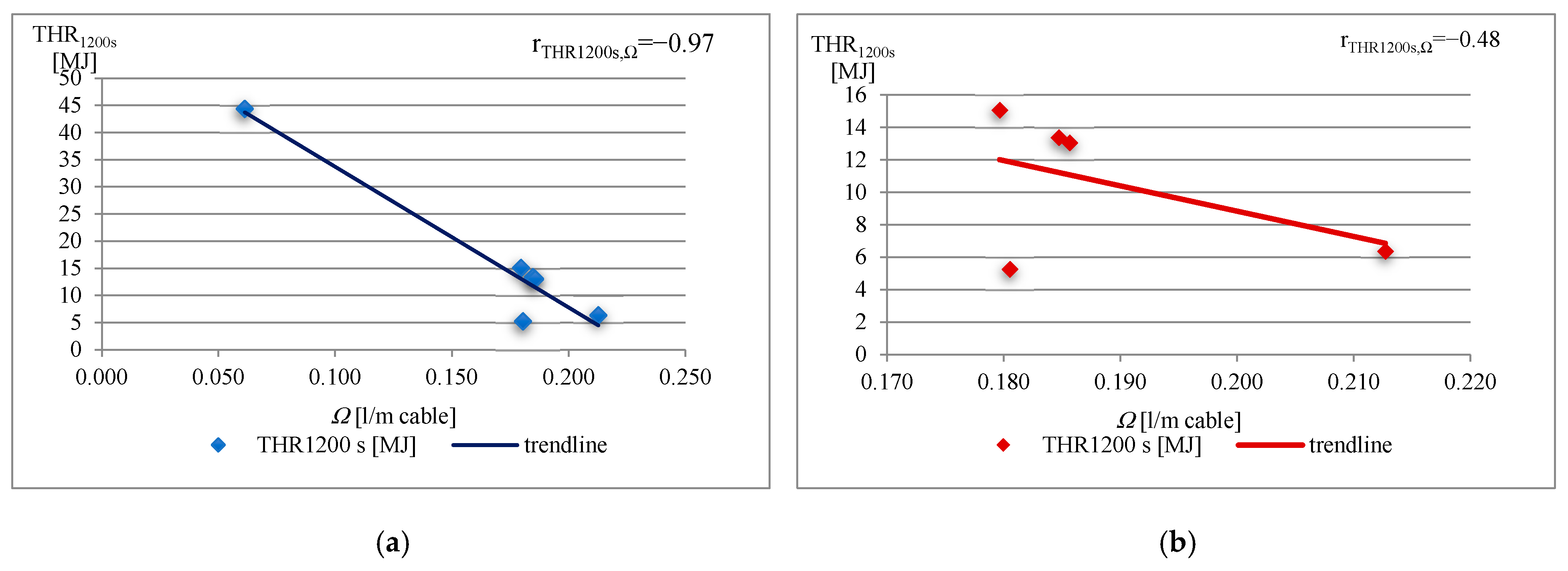

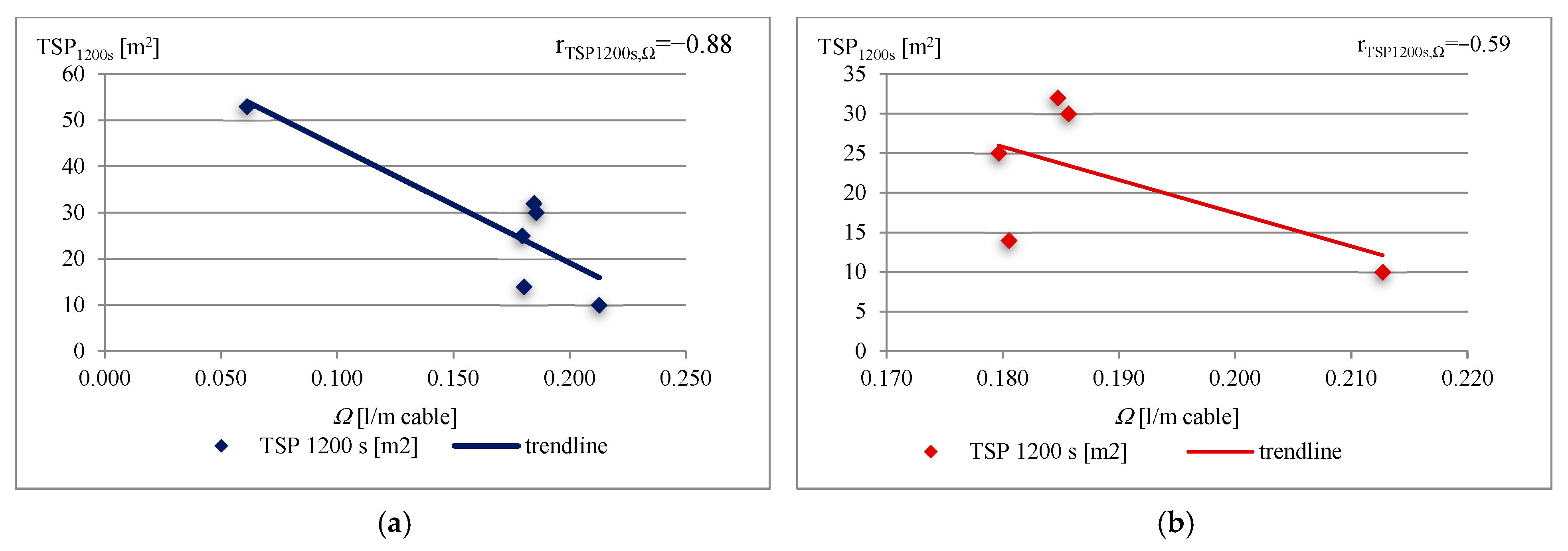

3.2. Experimental Verification of the Ω Cable Parameter

4. Cable Parameter Proposal for Non-Circular Cables and Cables with Sector-Shaped Conductors

- dmet—diameter of conductor, [m]

- n—number of conductors, [-]

- h—unit length of cable, [m]

- Scable—area of the side surface of cable, [m2]

- h—unit length of cable, [m]

- a—major axis, [m]

- b—minor axis, [m]

- (1)

- 3-conductor cable: internal angle in an isosceles triangle equal to 120°,

- (2)

- 4-conductor cable: internal angle in an isosceles triangle equal to 90°,

- (3)

- 5-conductor cable: internal angle in an isosceles triangle equal to 72°.

- n—number of conductors, [-]

- dcable—diameter of cable, [m]

- h—unit length of cable, [m]

- Pmet—area of the side of conductor, [m]

- h—unit length of cable, [m]

- a,b—sides of the triangles, [m]

5. Concluding Remarks

6. Directions for Further Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- An, W.; Li, S.; Yin, X.; Peng, L. Combustion and fire safety of energy conservation materials in building vertical channel: Effects of structure factor and coverage rate. Case Stud. Therm. Eng. 2021, 24, 100847. [Google Scholar] [CrossRef]

- Steen-Hansen, A.; Storesund, K.; Sesseng, C. Learning from fire investigations and research—A Norwegian perspective on moving from a reactive to a proactive fire safety management. Fire Saf. J. 2021, 120, 103047. [Google Scholar] [CrossRef]

- Kristensen, J.S.; Faudzi, F.B.M.; Jomaas, G. Experimental study of flame spread underneath photovoltaic (PV) modules. Fire Saf. J. 2021, 120, 103027. [Google Scholar] [CrossRef]

- Babrauskas, V. Research on electrical fires: The state of the art. Fire Saf. Sci. 2008, 9, 3–18. [Google Scholar] [CrossRef] [Green Version]

- Kaczorek-Chrobak, K.; Fangrat, J. Influence of constructional-material parameters on the fire properties of electric cables. Energies 2019, 12, 4569. [Google Scholar] [CrossRef] [Green Version]

- Kaczorek-Chrobak, K.; Fangrat, J. Constructional-material parameters vs. fire properties of electric cables. In Proceedings of the 24th International Symposium on Combustion Processes, Wroclaw, Poland, 23–25 September 2019. [Google Scholar]

- Kaczorek-Chrobak, K.; Fangrat, J. PVC-based copper electric wires under various fire conditions: Toxicity of fire effluents. Materials 2020, 13, 1111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Courty, L.; Garo, J.P. External heating of electrical cables and auto-ignition investigation. J. Hazard. Mater. 2017, 321, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Lenartowicz, R. Bezpieczeństwo Użytkowania Instalacji Elektrycznych w Polsce (Safety in Using Electrical Installations in Poland); (In Polish). elektro.info nr 3/2014; Grupa MEDIUM Sp. zo.o. Sp.k.a.: Warszawa, Poland, 2014. [Google Scholar]

- Huang, X.; Nakamura, Y. A Review of Fundamental Combustion Phenomena in Wire Fires. Fire Technol. 2020, 56, 315–360. [Google Scholar] [CrossRef]

- Grayson, S.J.; Van Hees, P.; Green, A.M.; Breulet, H.; Vercellotti, U. Assessing the Fire Performance of Electric Cables (FIPEC). Fire Mater. 2001, 25, 49–60. [Google Scholar] [CrossRef]

- Kaczorek-Chrobak, K.; Fangrat, J.; Papis, B.K. Calorimetric Behavior of Electric Cables. Energies 2021, 14, 1007. [Google Scholar] [CrossRef]

- CEN. Fire Classification of Construction Products and Building Elements—Part 6: Classification Using Data from Reaction to Fire Tests on Power, Control and Communication Cables; EN 13501-6:2018; CEN: Brussels, Belgium, 2018. [Google Scholar]

- CLC. Electric Cables—Extended Application of Test Results for Reaction to Fire; CLC/TS 50576:2016; Slovenski inštitut za standardizacijo: Ljubljana, Slovenia, 2016. [Google Scholar]

- Kaczorek-Chrobak, K.; Fangrat, J. Combustible Material Content vs. Fire Properties of Electric Cables. Energies 2020, 13, 6172. [Google Scholar] [CrossRef]

- Atkins, P.W. Chemia Fizyczna. (Physical Chemistry); Wydawnictwo Naukowe PWN: Warszawa, Poland, 2001. (In Polish) [Google Scholar]

- Konecki, M. Wpływ Szybkości Wydzielania Ciepła i Emisji Dymu na Rozwój Pożaru w Układzie Pomieszczeń (Effect of Heat Release Rate and Smoke Emissions on Fire Development in Room Layout); Monografia Szkoły Głównej Służby Pożarniczej: Warszawa, Poland, 2007. (In Polish) [Google Scholar]

- Howell, B.A. Phenolic-based phosphorus flame retardants for polymeric materials. In Biobased Flame Retardant Technology for Polymeric Materials; Han, Y., Nabipour, H., Wang, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 9780323907729. [Google Scholar]

- Kaczorek-Chrobak, K. Electric Cables Used in Buildings—Dependency of Fire Properties on Constructional and Material Parameters. Ph.D. Thesis, Instytut Techniki Budowlanej, Warsaw, Poland, 2020. [Google Scholar]

- CEN. Common Test Methods for Cables under Fire Conditions—Heat Release and Smoke Production Measurement on Cables during Flame Spread Test—Test Apparatus, Procedures, Results; EN 50399:2011+A1:2016; Slovenski inštitut za standardizacijo: Ljubljana, Slovenia, 2016. [Google Scholar]

- Journeaux, T. European developments in the reaction to fire testing of cables. Wire J. Int. 2010, 43, 66–71. [Google Scholar]

- Gas Sensing Solutions Ltd. Theory and Operation of NDIR Sensors; TN-169; Technical Note, RAE Systems: San Jose, CA, USA, 1995. [Google Scholar]

- Biteau, H.; Steinhaus, T.; Scheme, C.; Simeoni, A.; Marlair, G.; Bal, N.F.; Torero, J. Calculation Methods for the Heat Release Rate of Materials of Unknown Composition. Fire Saf. Sci. 2009, 9, 1165–1176. [Google Scholar] [CrossRef] [Green Version]

- Girardin, B.; Fontaine, G.; Duquesne, S.; Burbigot, S.; Delineau, L.; Försth, M.; Hewitt, F.; Witkowski, A.; Stec, A.A.; Hull, T.R. Small scale tests and numerical modelling of fire performance for electrical cable, Fire and Materials 2015. In Proceedings of the 14th International Conference and Exibition, San Francisco, CA, USA, 2–4 February 2015. [Google Scholar]

| Cable Sample No | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

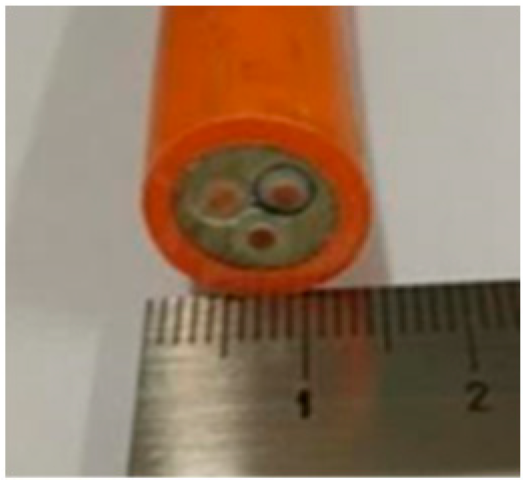

| Cross-section of cables |  |  |  |  |  |  |

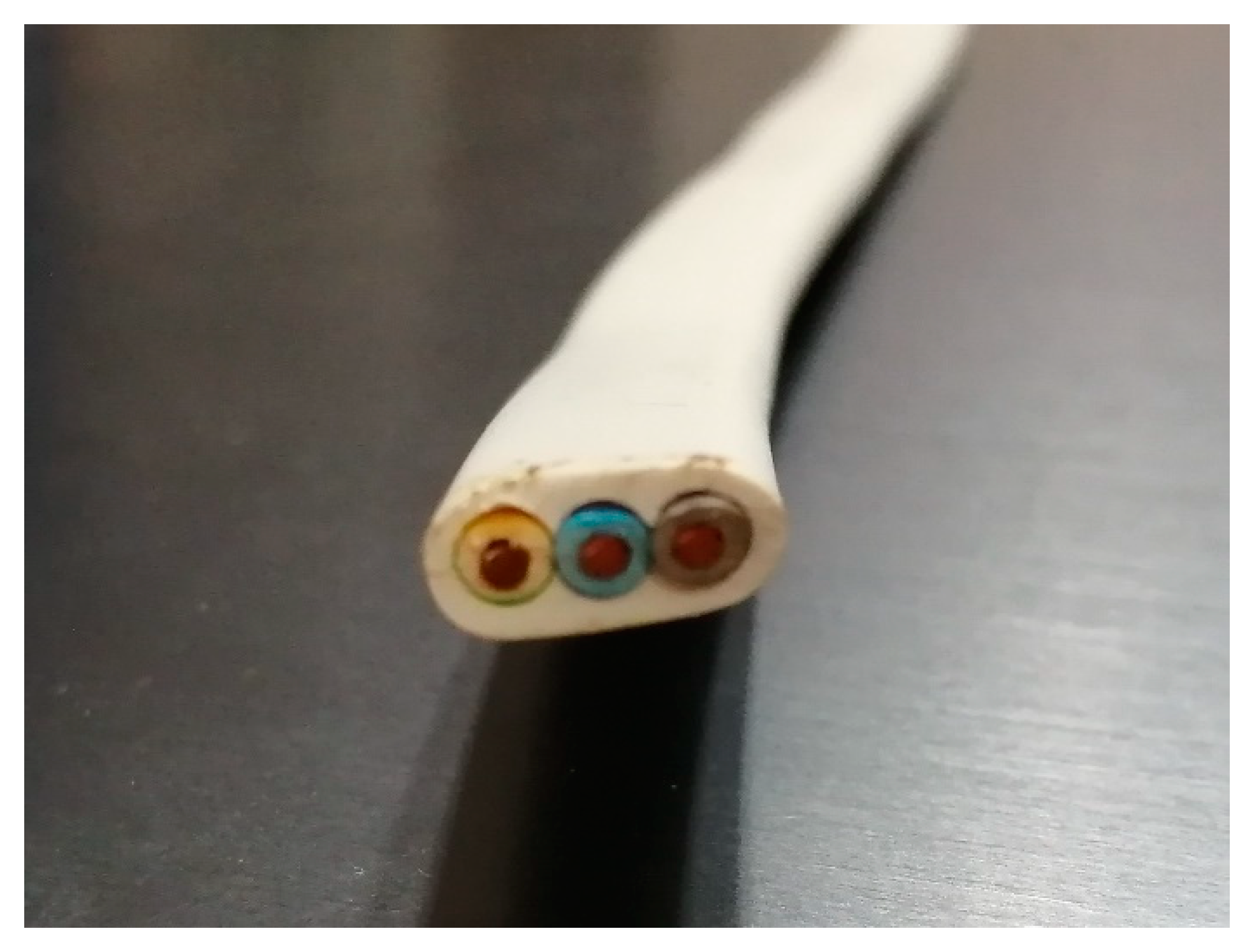

| Cable Size | 1 × 1.5 mm2 | 3 × 1.5 mm2 | 14 × 1.5 mm2 | 19 × 1.5 mm2 | 24 × 1.5 mm2 | 30 × 1.5 mm2 |

| dcable, mm | 6.7 | 13.6 | 22.4 | 24.7 | 27.0 | 30.5 |

| Conductors | Copper, circular | |||||

| Insulations | Silane cross-linked polyolefin (XLPO) and mica tape | |||||

| Bedding | none | Flame retardant cross-linked polyethylene (XLPE) | ||||

| Outer Sheath | ethylene/vinyl/acetate (EVA) copolymer filled with aluminium trihydrate (ATH) and zinc borate (ZnB) as a flame retardant | |||||

| Cable Sample No | n, [-] | dmet, [m·10−3] | dcable, [m·10−3] | Vcombust, [l/m Cable] | Δm *, [-] | ω, [-] | z, [-] | Ω, [l/m Cable] |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1.38 | 6.7 | 0.032 | 0.39 | 1.54 | 0.206 | 0.061 |

| 2 | 3 | 1.38 | 13.6 | 0.126 | 0.45 | 1.24 | 0.304 | 0.185 |

| 3 | 14 | 1.38 | 22.4 | 0.315 | 0.49 | 1.03 | 0.863 | 0.180 |

| 4 | 19 | 1.38 | 24.7 | 0.387 | 0.50 | 1.02 | 1.062 | 0.181 |

| 5 | 24 | 1.38 | 27 | 0.492 | 0.53 | 0.89 | 1.227 | 0.213 |

| 6 | 30 | 1.38 | 30.5 | 0.562 | 0.45 | 1.23 | 1.357 | 0.186 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczorek-Chrobak, K.; Fangrat, J. Electric Cable Construction Parameter and Its Potential to Foresee the Cable Fire Properties. Materials 2023, 16, 1689. https://doi.org/10.3390/ma16041689

Kaczorek-Chrobak K, Fangrat J. Electric Cable Construction Parameter and Its Potential to Foresee the Cable Fire Properties. Materials. 2023; 16(4):1689. https://doi.org/10.3390/ma16041689

Chicago/Turabian StyleKaczorek-Chrobak, Katarzyna, and Jadwiga Fangrat. 2023. "Electric Cable Construction Parameter and Its Potential to Foresee the Cable Fire Properties" Materials 16, no. 4: 1689. https://doi.org/10.3390/ma16041689