Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding

Abstract

1. Introduction

2. Materials and Methods

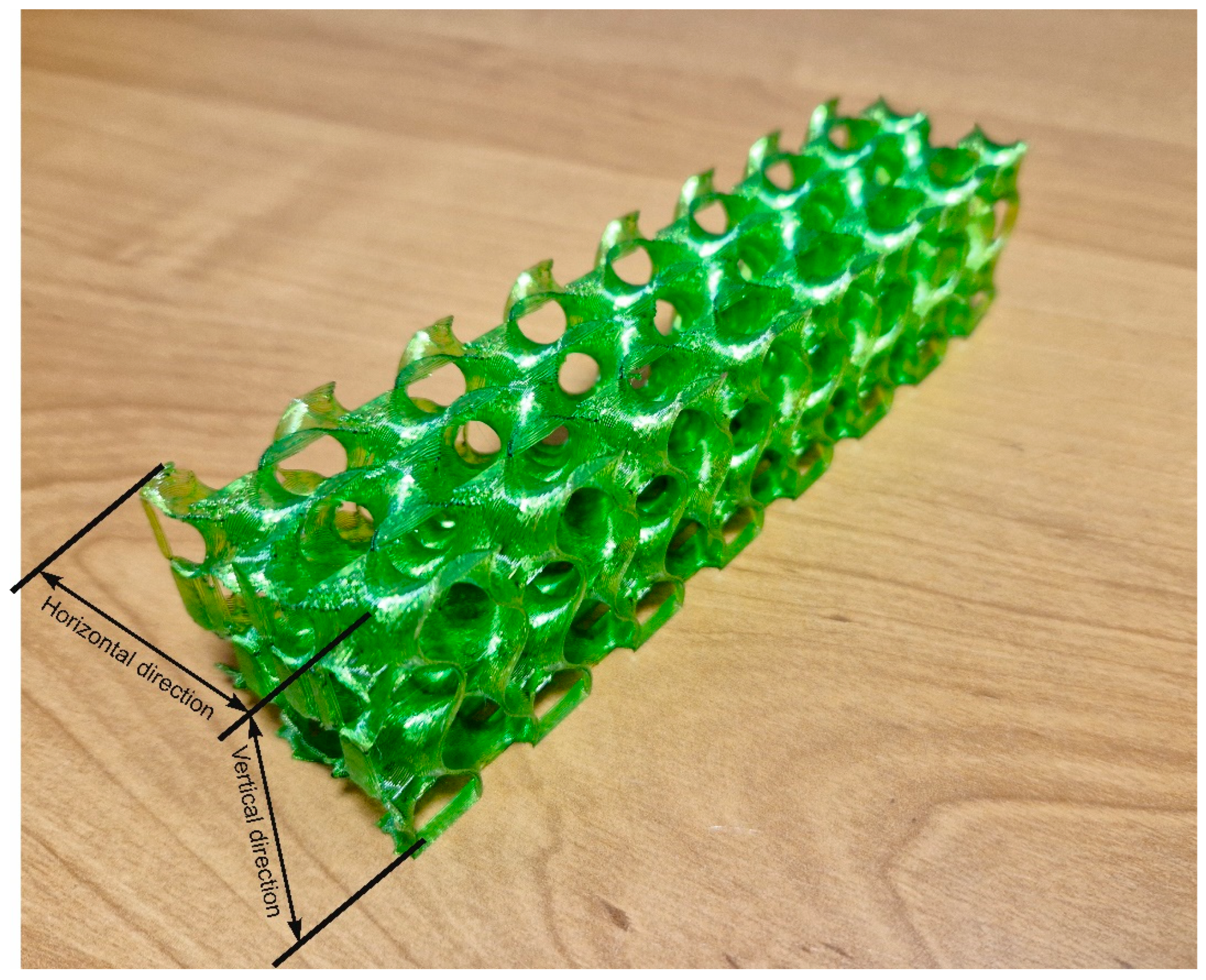

2.1. Characteristics of the AM Process and Polymeric Waste Material

- Hotend temperature: 240 °C;

- Substrate plate temperature: 85 °C;

- Layer thickness: 0.2 mm;

- Infill: 100%;

- Part cooling intensity: 40%;

- Printing speed: 50 mm/s;

- Nozzle diameter: 0.4 mm.

2.2. Characterization of the Filler: Cement–Glass Mortar

2.3. The Manufacturing Process of Cement–Glass Composite Brick

2.4. Physical Properties Testing Methodology of Cement–Glass Composite Brick

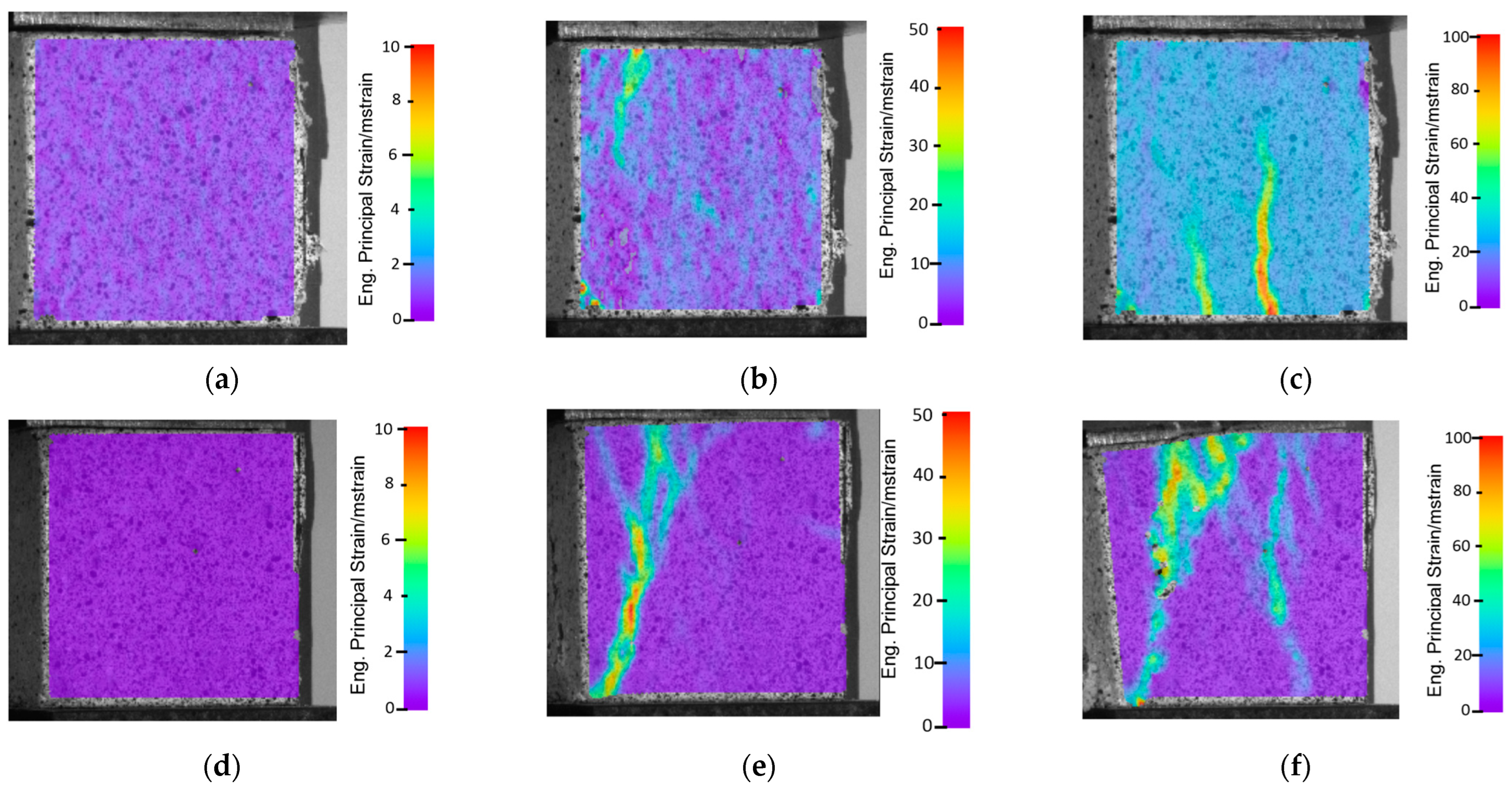

2.5. Mechanical Properties Testing Methodology with a Digital Image Correlation (DIC)

3. Results and Discussion

3.1. Physical Properties of Concrete–Glass Composite Brick

3.1.1. Density

3.1.2. Thermal Tests on CGM and CGCB

3.2. Compressive and Bending Tests with the Use of DIC

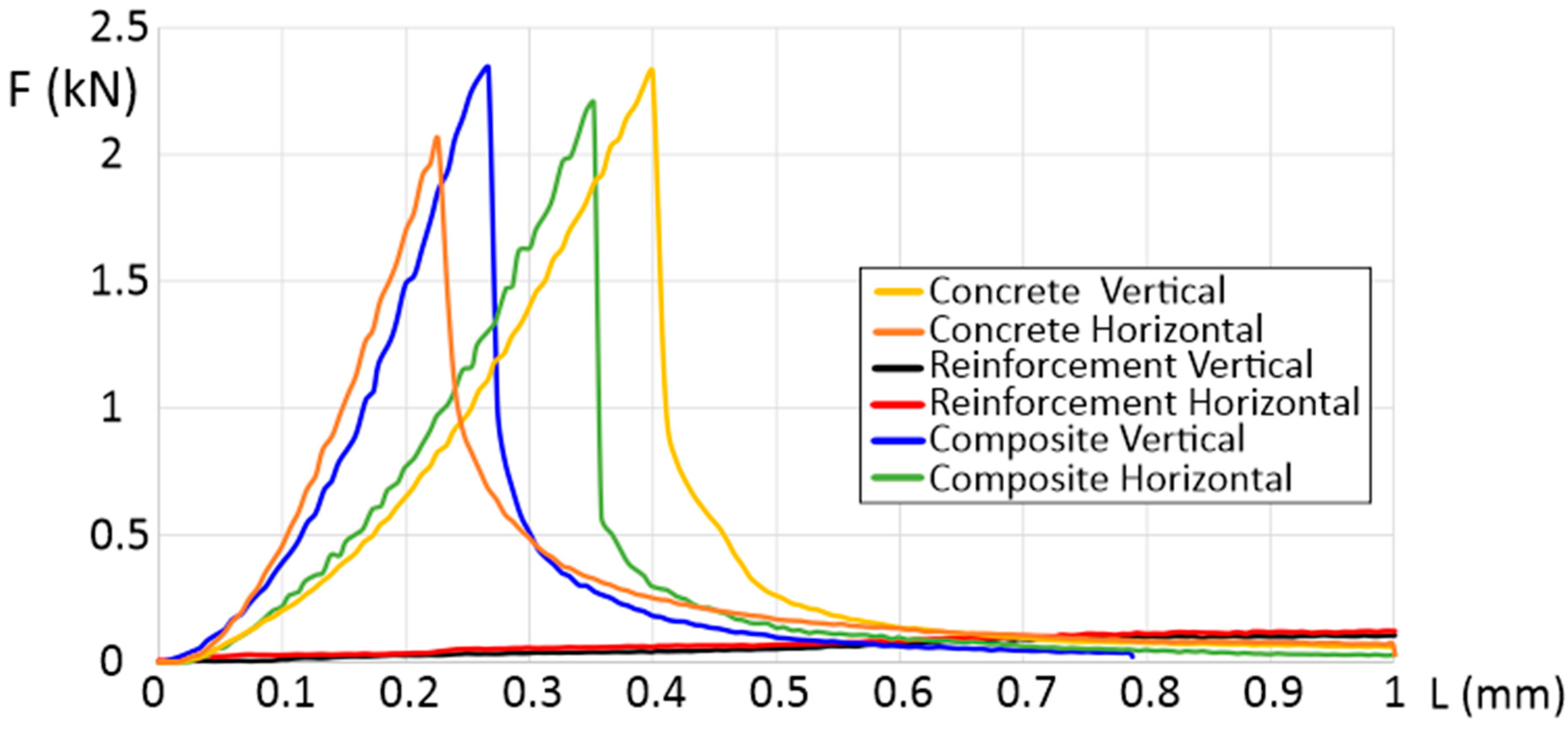

3.2.1. Three-Point Bending Tests

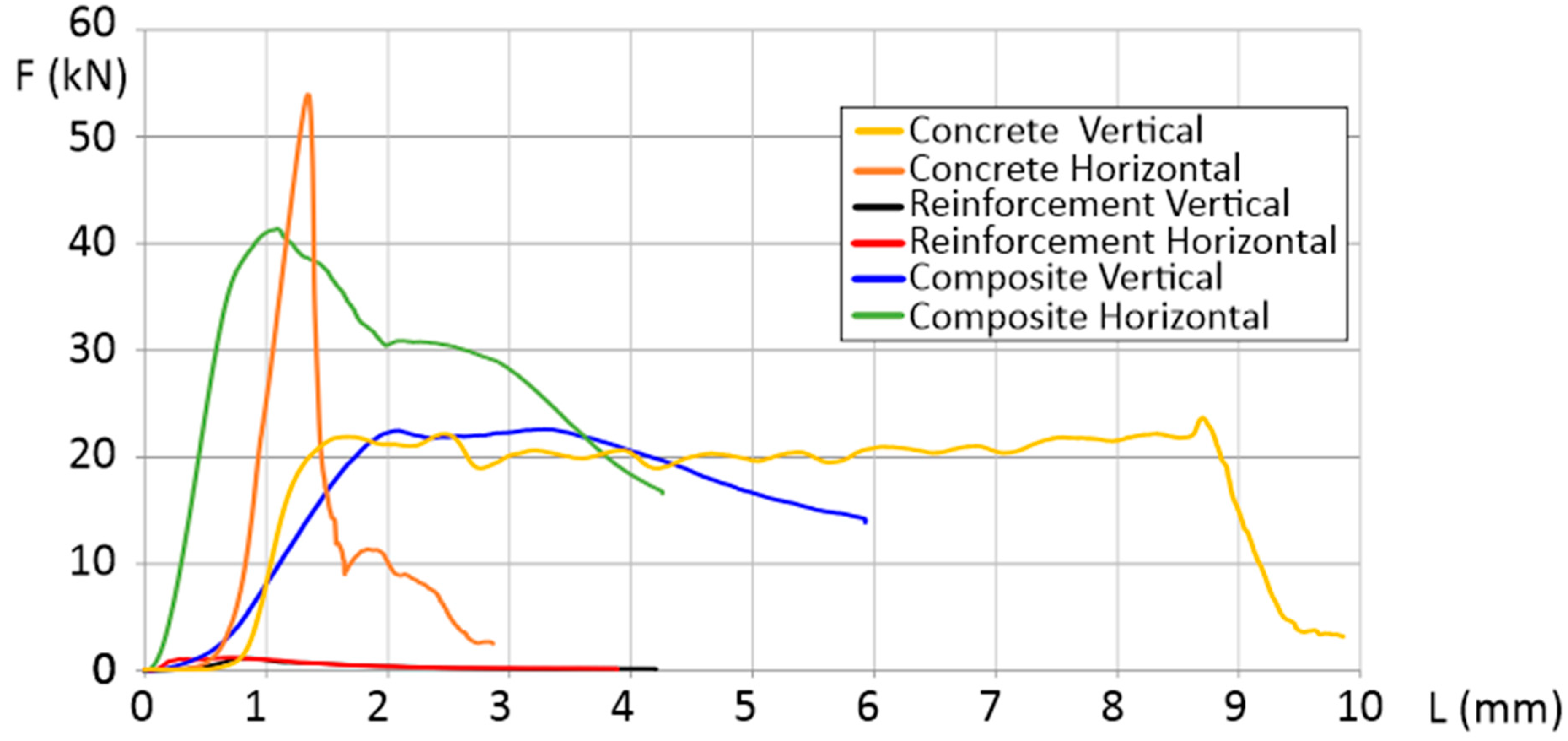

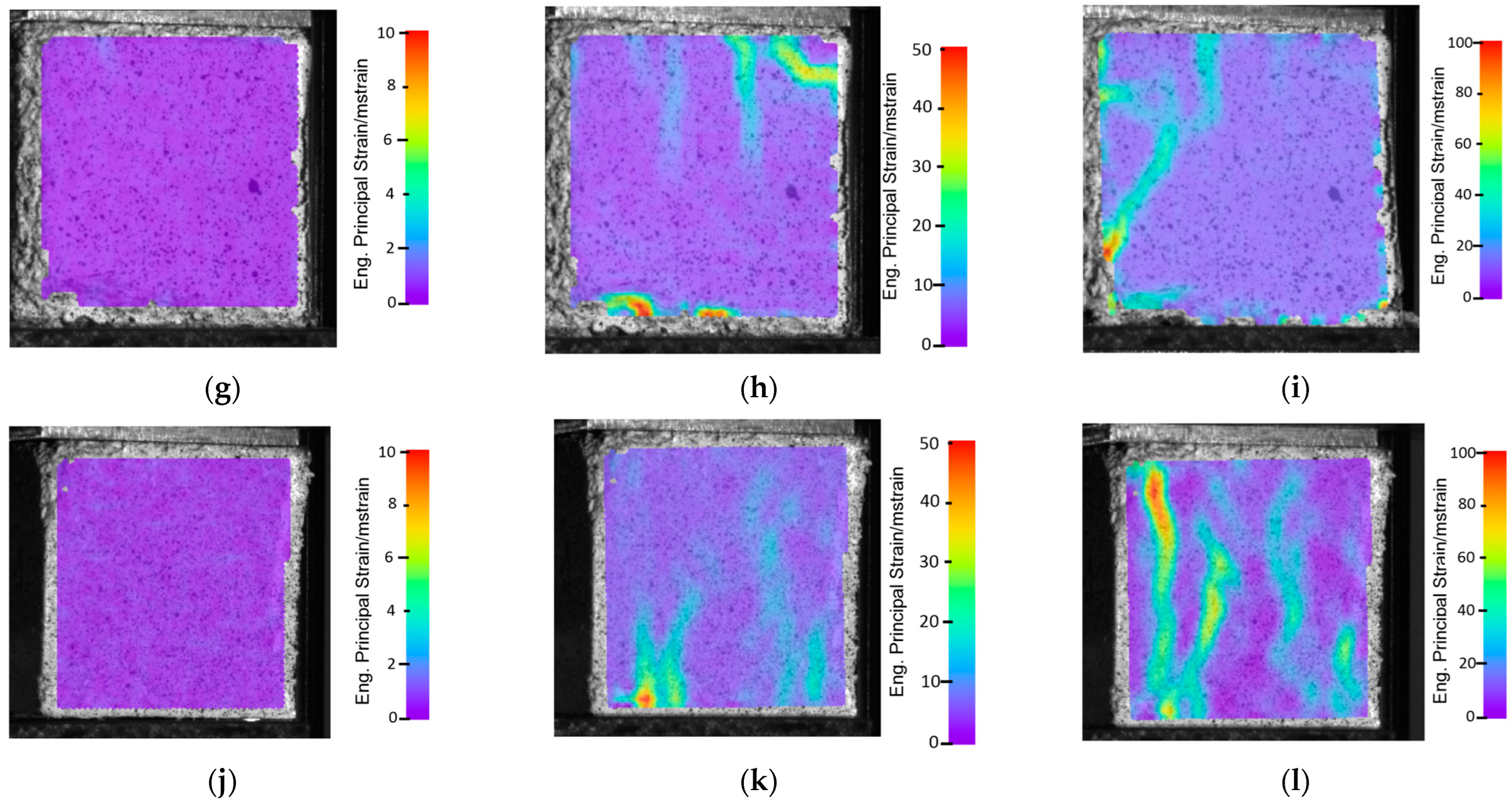

3.2.2. Compressive Tests Results and Discussion

- -

- the strain-softening stage;

- -

- the residual strength stage.

4. Conclusions

- The cement–glass composite brick, with a printed PET-G gyroidal structure, has better thermal properties than the cement–glass mortar itself, as thermal conductivity after the modification decreased by 12%, and specific heat was reduced by 20%. The thermal diffusivity, on the other hand, increased by 13%.

- After incorporating the gyroidal structure from PET-G into the cement–glass mortar matrix, the density changed from 2157 kg/m3 to 2051 kg/m3.

- The use of the AM gyroidal structure made the concrete brick’s mechanical properties more isotropic, with up to 50% lower beam deflection during the three-point bending test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kamiński, K.; Plis, A. Research on Compresive Strength and Strain of Expansive Concrete. Appl. Mech. Mater. 2015, 797, 79–87. [Google Scholar]

- Available online: https://tradingeconomics.com/commodity/steel (accessed on 20 February 2022).

- Salazar, B.; Aghdasi, P.; Williams, I.D.; Ostertag, C.P.; Taylor, H.K. Polymer lattice-reinforcement for enhancing ductility of concrete. Mater. Des. 2020, 196, 109184. [Google Scholar] [CrossRef]

- Morretton, E.; Vignat, F.; Pourroy, F.; Marin, P. Impacts of the settings in a design for additive manufacturing process based on topological optimization. Int. J. Interact. Des. Manuf. 2019, 13, 295–308. [Google Scholar] [CrossRef]

- Doutre, P.-T.; Morretton, E.; Vo, T.H.; Marin, P.; Pourroy, F.; Prudhomme, G.; Vignat, F. Comparison of some approaches to define a CAD model from topological optimization in design for additive manufacturing. Lect. Notes Mech. Eng. 2017, 1, 233–240. [Google Scholar] [CrossRef]

- Gardan, N.; Schneider, A.; Gardan, J. Material and process characterization for coupling topological optimization to additive manufacturing. Comput. Aided. Des. Appl. 2015, 13, 39–49. [Google Scholar] [CrossRef]

- Xu, B.; Han, Y.; Zhao, L.; Xie, Y.M. Topological optimization of continuum structures for additive manufacturing considering thin feature and support structure constraints. Eng. Optim. 2020, 53, 2122–2143. [Google Scholar] [CrossRef]

- Shifeng, W.; Shuai, L.; Qingsong, W.; Yan, C.; Sheng, Z.; Yusheng, S. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Gan, Y.; Šavija, B. Cementitious composites reinforced with 3D printed functionally graded polymeric lattice structures: Experiments and modelling. Addit. Manuf. 2021, 39, 101887. [Google Scholar] [CrossRef]

- Qin, S.; Cao, S.; Yilmaz, E.; Li, J. Influence of types and shapes of 3D printed polymeric lattice on ductility performance of cementitious backfill composites. Constr. Build. Mater. 2021, 307, 124973. [Google Scholar] [CrossRef]

- Fadeel, A.; Mian, A.; Al Rifaie, M.; Srinivasan, R. Effect of Vertical Strut Arrangements on Compression Characteristics of 3D Printed Polymer Lattice Structures: Experimental and Computational Study. J. Mater. Eng. Perform. 2018, 28, 709–771. [Google Scholar] [CrossRef]

- Salazar, B.; Williams, I.; Aghdasi, P.; Ostertag, C.; Taylor, H. Bending and Crack Characteristics of Polymer Lattice-Reinforced Mortar. In Proceedings of the International Congress on Polymers in Concrete (ICPIC 2018), Washington, DC, USA, 29 April –1 May 2018; pp. 261–266. [Google Scholar] [CrossRef]

- Lin, A.; Tan, Y.K.; Wang, C.-H.; Kua, H.W.; Taylor, H. Utilization of waste materials in a novel mortar–polymer laminar composite to be applied in construction 3D-printing. Compos. Struct. 2020, 253, 112764. [Google Scholar] [CrossRef]

- Małek, M.; Grzelak, K.; Łasica, W.; Jackowski, M.; Kluczyński, J.; Szachogłuchowicz, I.; Torzewski, J.; Łuszczek, J. Cement-glass composite bricks (CGCB) with interior 3D printed PET-G scaffolding. J. Build. Eng. 2022, 52, 104429. [Google Scholar] [CrossRef]

- Grzelak, K.; Łaszcz, J.; Polkowski, J.; Mastalski, P.; Kluczyński, J.; Łuszczek, J.; Torzewski, J.; Szachogłuchowicz, I.; Szymaniuk, R. Additive Manufacturing of Plastics Used for Protection against COVID19—The Influence of Chemical Disinfection by Alcohol on the Properties of ABS and PETG Polymers. Materials 2021, 14, 4823. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; AlFayez, F.; Ahmed, T.; Bashir, Z. Poly(ethylene terephthalate) Powder—A Versatile Material for Additive Manufacturing. Polymers 2019, 11, 2041. [Google Scholar] [CrossRef]

- Dolzyk, G.; Jung, S. Tensile and Fatigue Analysis of 3D-Printed Polyethylene Terephthalate Glycol. J. Fail. Anal. Prev. 2019, 19, 511–518. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Dydek, K.; Boczkowska, A. Thermal, Rheological and Mechanical Properties of PETG/rPETG Blends. J. Polym. Environ. 2019, 27, 2600–2606. [Google Scholar] [CrossRef]

- EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 196-6:2019-01; Methods of Testing Cement—Part 6: Determination of Fineness. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 196-1:2016-07; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- Rudnicki, T. The method of aggregate skeleton in self compacting concrete designing with segment regression. CWB 2016, 1, 10–19. [Google Scholar] [CrossRef]

- EN 12620+A1:2010; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2010.

- Górażdże Group: Cement, Concrete, Aggregate. Technical Data Sheet CEM I 42.5 R NA. Available online: http://www.gorazdze.pl (accessed on 15 June 2022).

- Rudnicki, T. Functional Method of Designing Self-Compacting Concrete. Materials 2021, 14, 267. [Google Scholar] [CrossRef] [PubMed]

- EN 12390-2:2019-07; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-7:2019-08; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. European Committee for Standardization: Brussels, Belgium, 2008.

- Bautista-Marín, J.; Esguerra-Arce, A. Use of an industrial solid waste as a pigment in clay bricks and its effects on the mechanical properties. Constr. Build. Mater. 2021, 306, 124848. [Google Scholar] [CrossRef]

- De Rosa, B.; Cultrone, G. Assessment of two clayey materials from northwest Sardinia (Alghero district, Italy) with a view to their extraction and use in traditional brick production. Appl. Clay Sci. 2014, 88–89, 100–110. [Google Scholar] [CrossRef]

- Shah, S.G.; Kishen, J.M.C. Fracture Properties of Concrete-Concrete Interfaces Using Digital Image Correlation. Exp. Mech. 2011, 51, 303–313. [Google Scholar] [CrossRef]

- Wu, Z.M.; Rong, H.; Zheng, J.J.; Xu, F.; Dong, W. An Experimental Investigation on the FPZ Properties in Concrete Using Digital Image Correlation Technique. Eng. Fract. Mech. 2011, 78, 2978–2990. [Google Scholar] [CrossRef]

- Zuo, H.; Wang, C.; Zhang, J.; Shao, J.; Zhao, Y.; Jiao, K. Comparison of oxidation behaviors of novel carbon composite brick with traditional carbon brick. Ceram. Int. 2015, 41, 7929–7936. [Google Scholar] [CrossRef]

- Zhou, X.P.; Wang, Y.T.; Zhang, J.Z.; Liu, F.N. Fracturing Behavior Study of Three-Flawed Specimens by Uniaxial Compression and 3D Digital Image Correlation: Sensitivity to Brittleness. Rock Mech. Rock Eng. 2019, 52, 691–718. [Google Scholar] [CrossRef]

| Compositions | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | TiO2 | Cl | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit (vol.%) | Cement | 19.5 | 4.9 | 2.9 | 63.3 | 1.3 | 2.8 | 0.1 | 0.9 | - | 0.05 |

| Glass | 70.0–74.0 | 0.5–2.0 | 0.0–0.1 | 7.0–11.0 | 3.0–5.0 | - | 6.0–8.0 | 7.0–9.0 | 0.0–0.1 | - | |

| Property | Specific Surface Area [m2/kg] | Specific Gravity [kg/m3] | Initial Setting Time [min] | Average Compressive Strength After 28 days [MPa] |

|---|---|---|---|---|

| Cement | 437 | 3090–3190 | 176 | 68.2 |

| Glass | 100 | 2450 | - | - |

| Mix symbol | Cement [kg] | Water [kg] | Chemical Admixture [kg] | Waste Glass Powder [kg] | Waste Glass Aggregate [kg] |

|---|---|---|---|---|---|

| CGM | 480 | 140 | 4.8 | 117.8 | 1782.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małek, M.; Kluczyński, J.; Łasica, W.; Jackowski, M.; Szachogłuchowicz, I.; Łuszczek, J.; Torzewski, J.; Grzelak, K. Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding. Materials 2023, 16, 1909. https://doi.org/10.3390/ma16051909

Małek M, Kluczyński J, Łasica W, Jackowski M, Szachogłuchowicz I, Łuszczek J, Torzewski J, Grzelak K. Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding. Materials. 2023; 16(5):1909. https://doi.org/10.3390/ma16051909

Chicago/Turabian StyleMałek, Marcin, Janusz Kluczyński, Waldemar Łasica, Mateusz Jackowski, Ireneusz Szachogłuchowicz, Jakub Łuszczek, Janusz Torzewski, and Krzysztof Grzelak. 2023. "Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding" Materials 16, no. 5: 1909. https://doi.org/10.3390/ma16051909

APA StyleMałek, M., Kluczyński, J., Łasica, W., Jackowski, M., Szachogłuchowicz, I., Łuszczek, J., Torzewski, J., & Grzelak, K. (2023). Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding. Materials, 16(5), 1909. https://doi.org/10.3390/ma16051909