Influence of Waste Glass Particle Size on the Physico-Mechanical Properties and Porosity of Foamed Geopolymer Composites Based on Coal Fly Ash

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.3. Analytical Methods for Raw Materials and Geopolymers Characterization

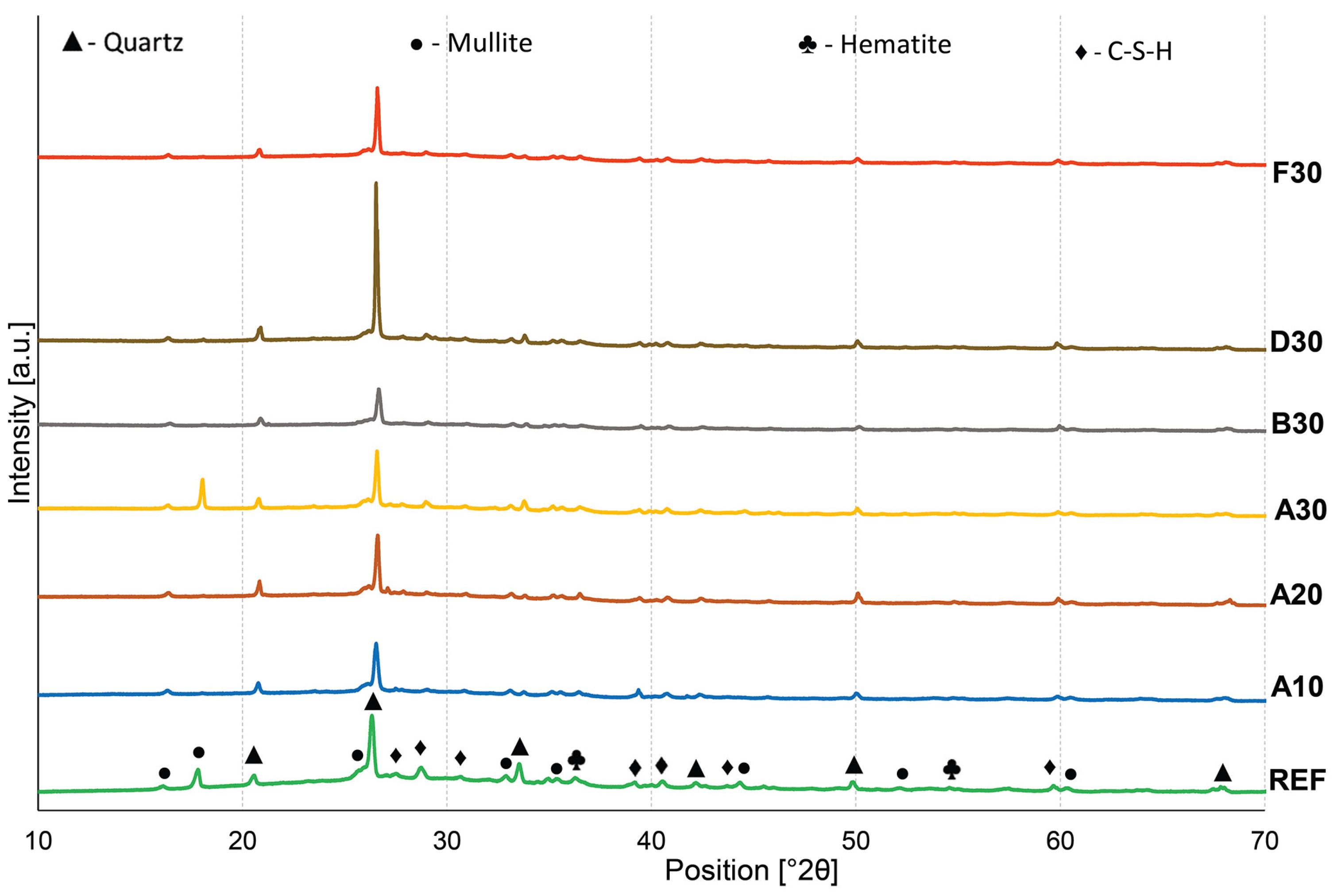

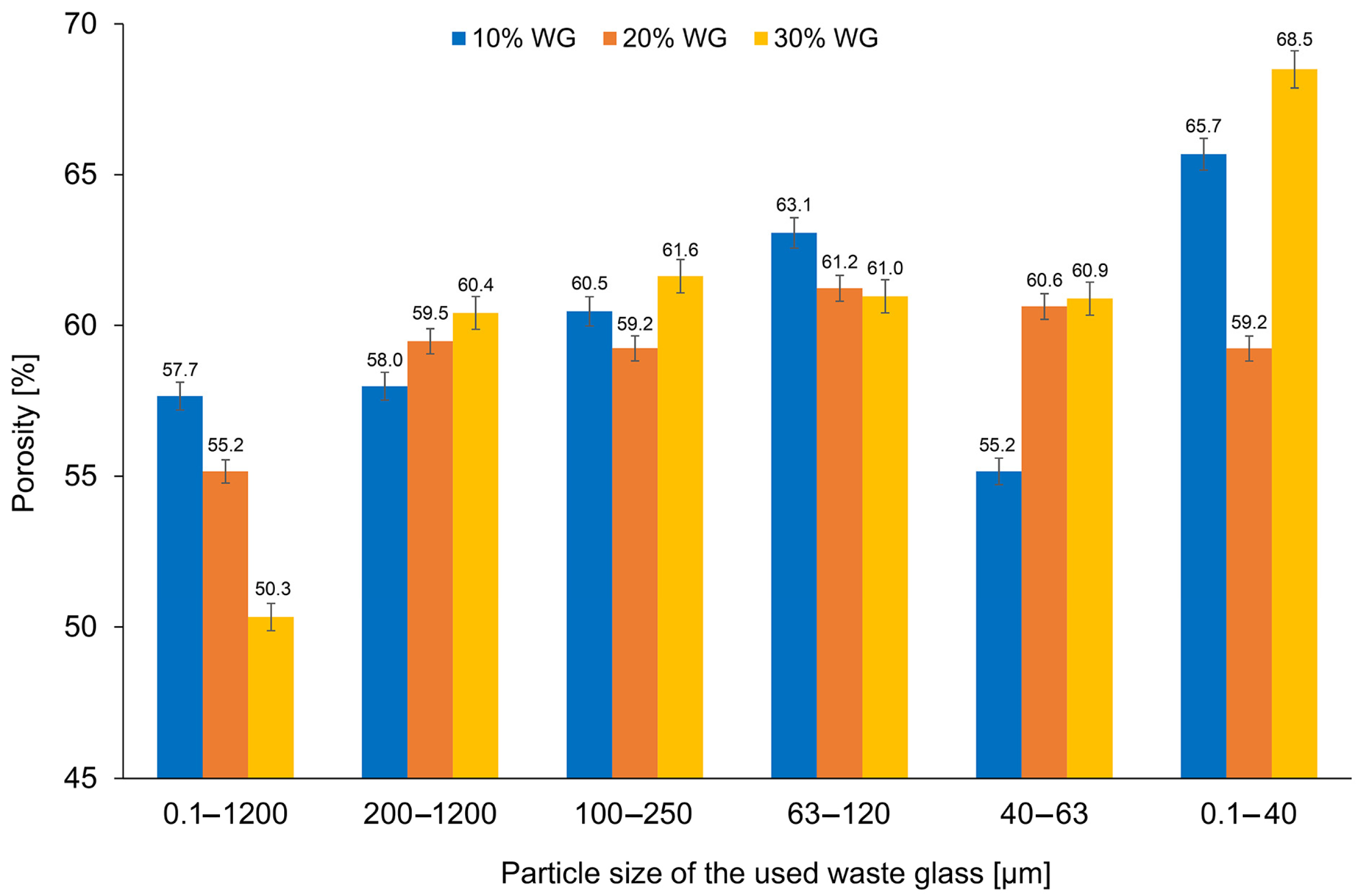

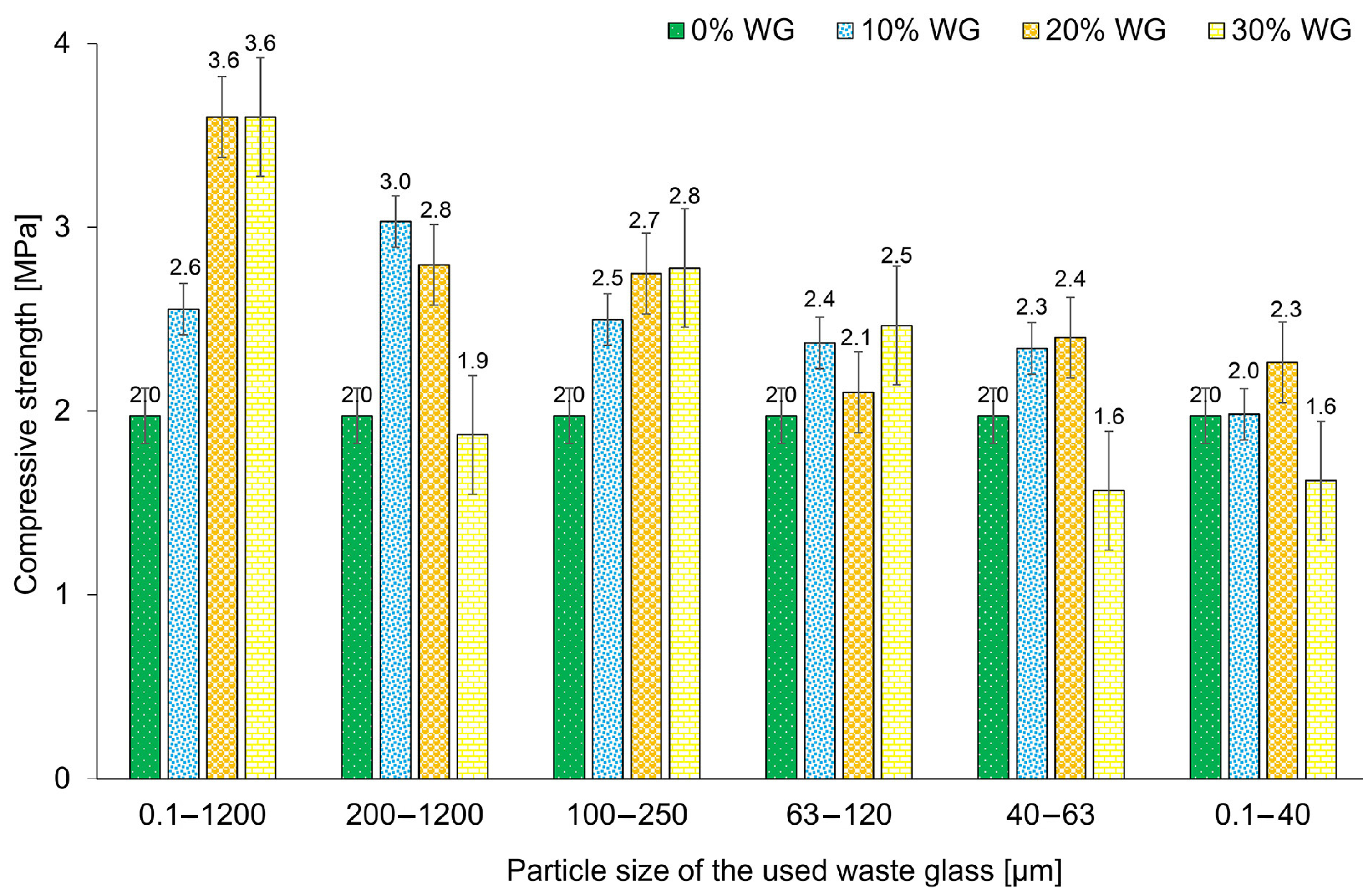

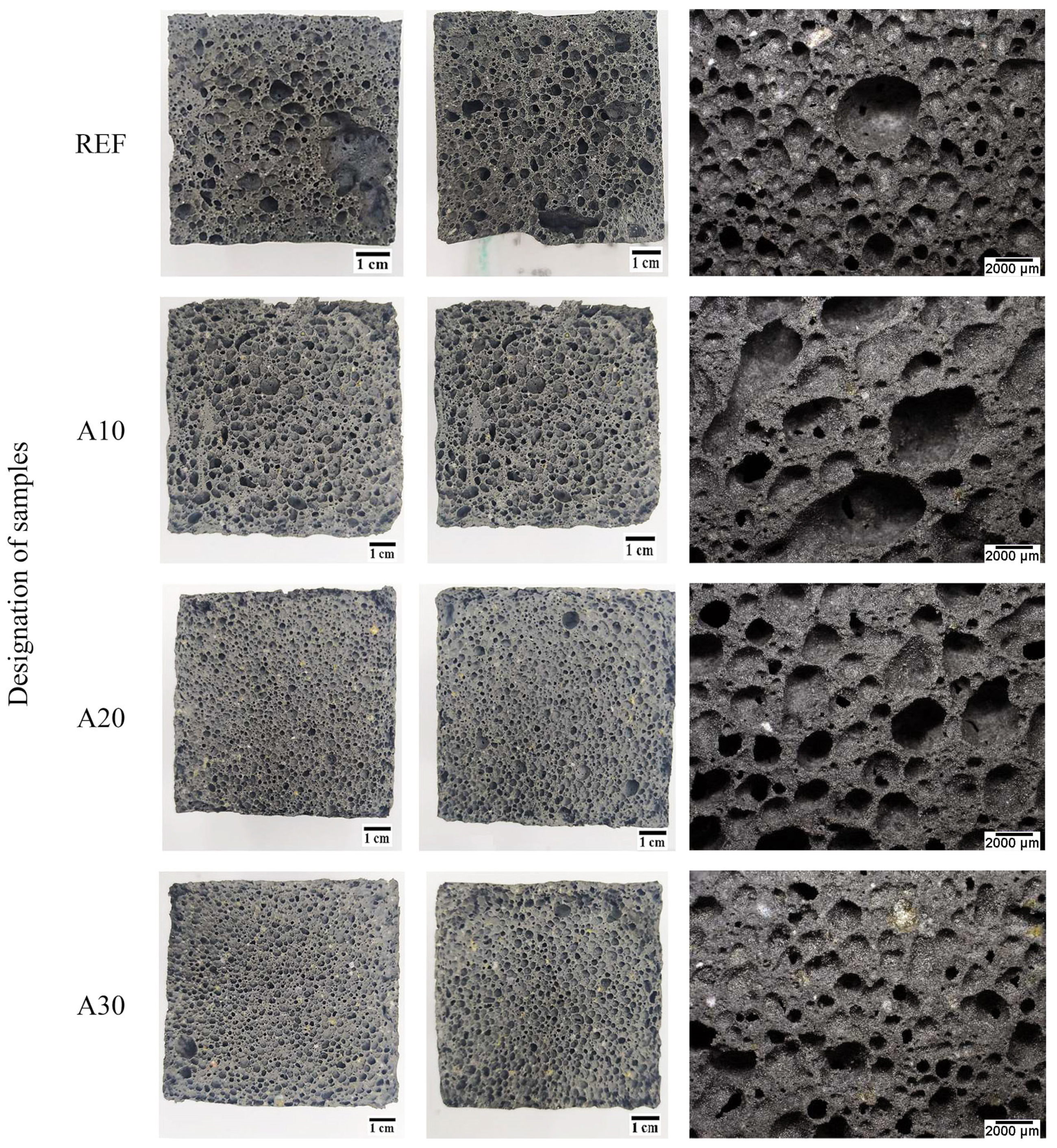

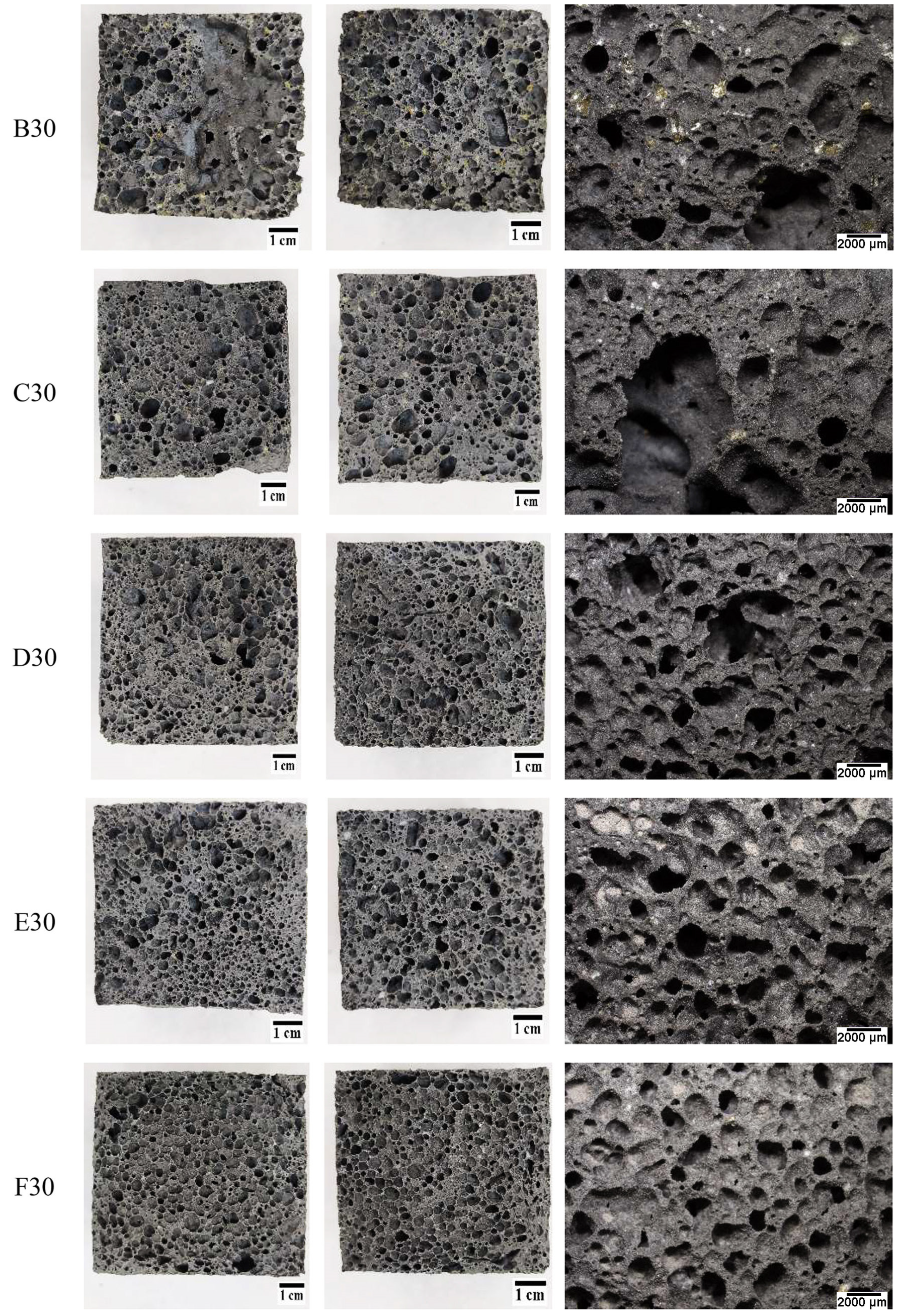

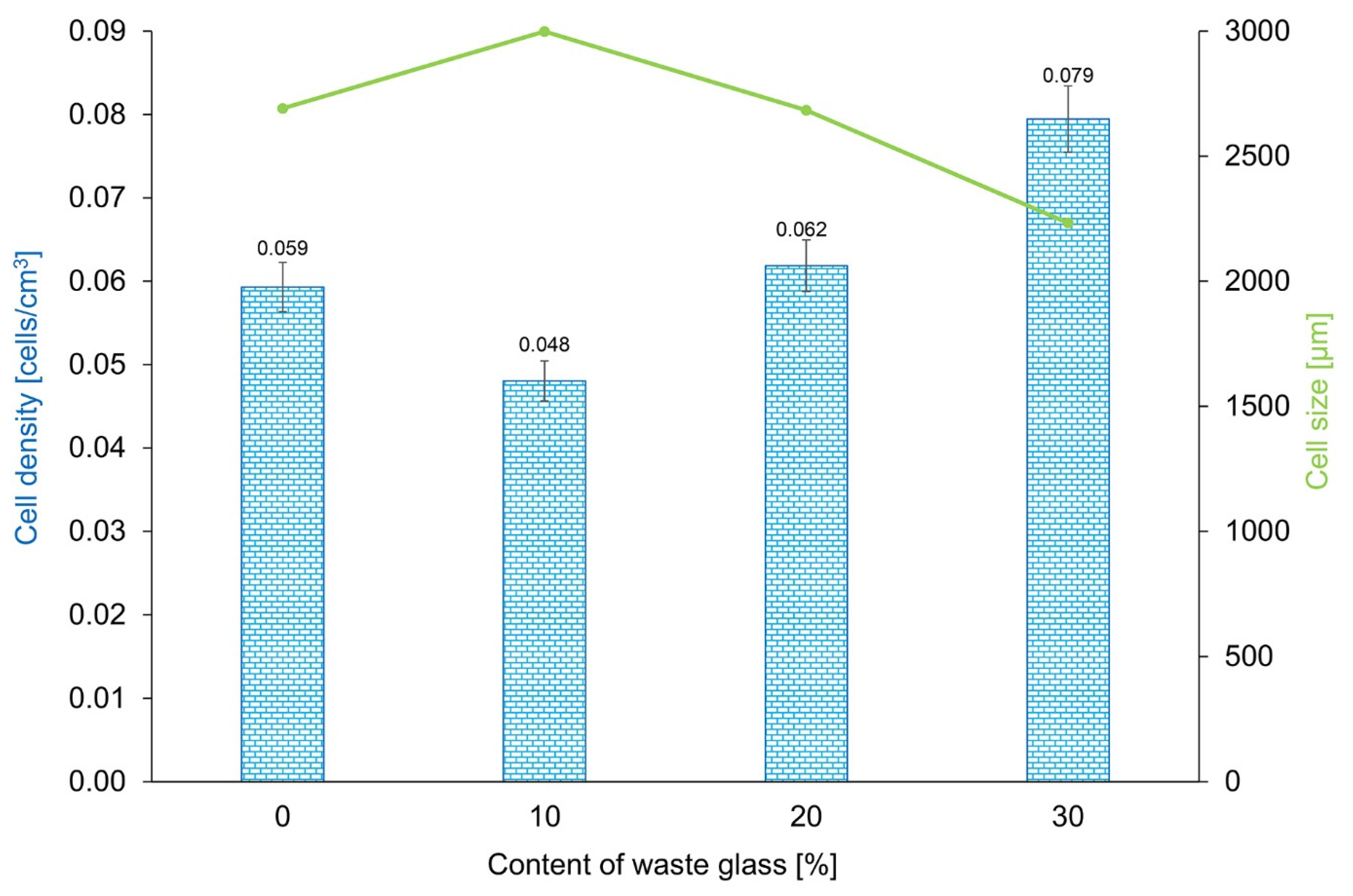

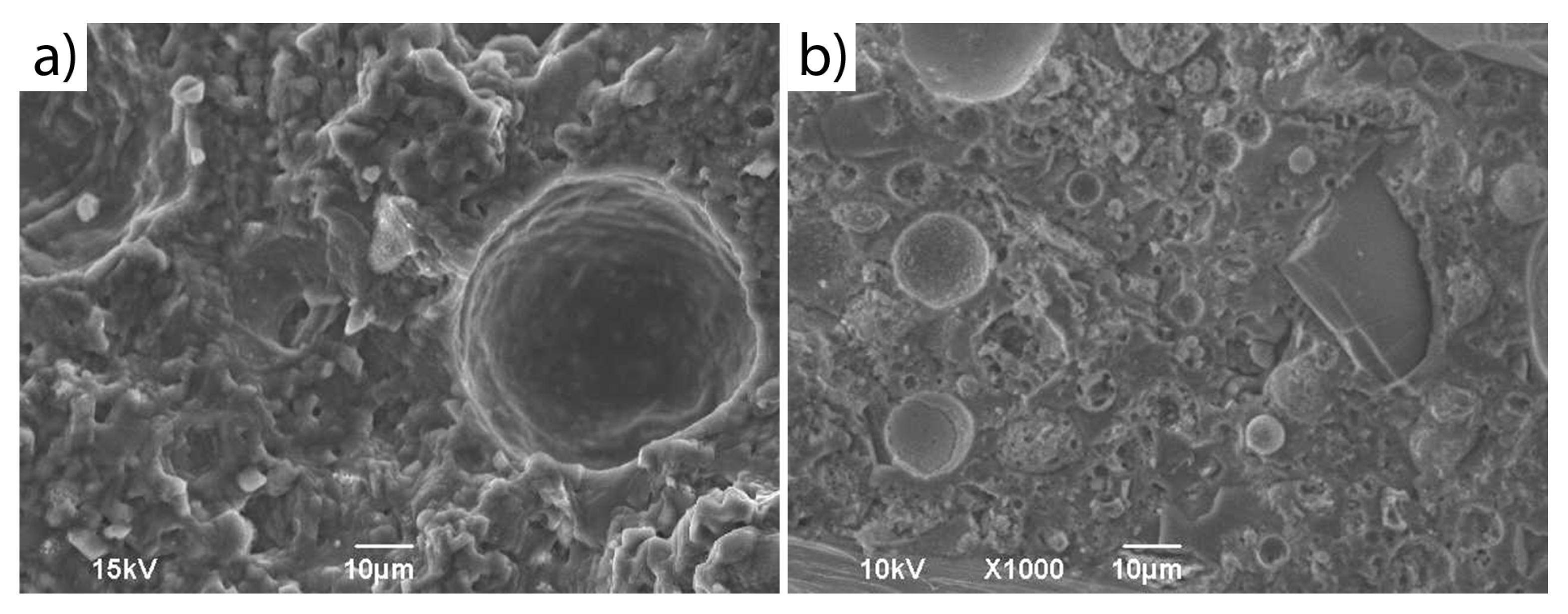

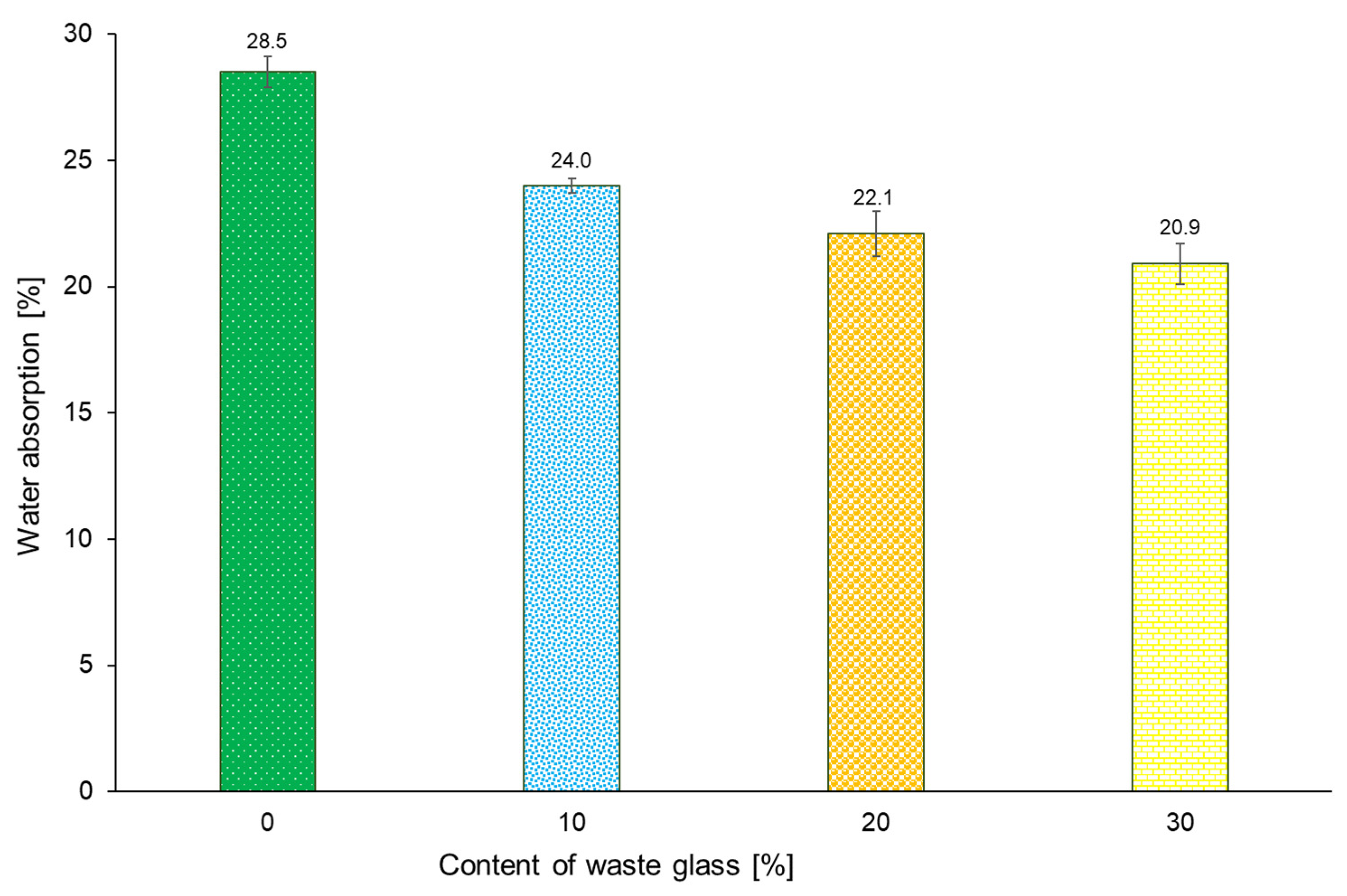

3. Results and Discussion

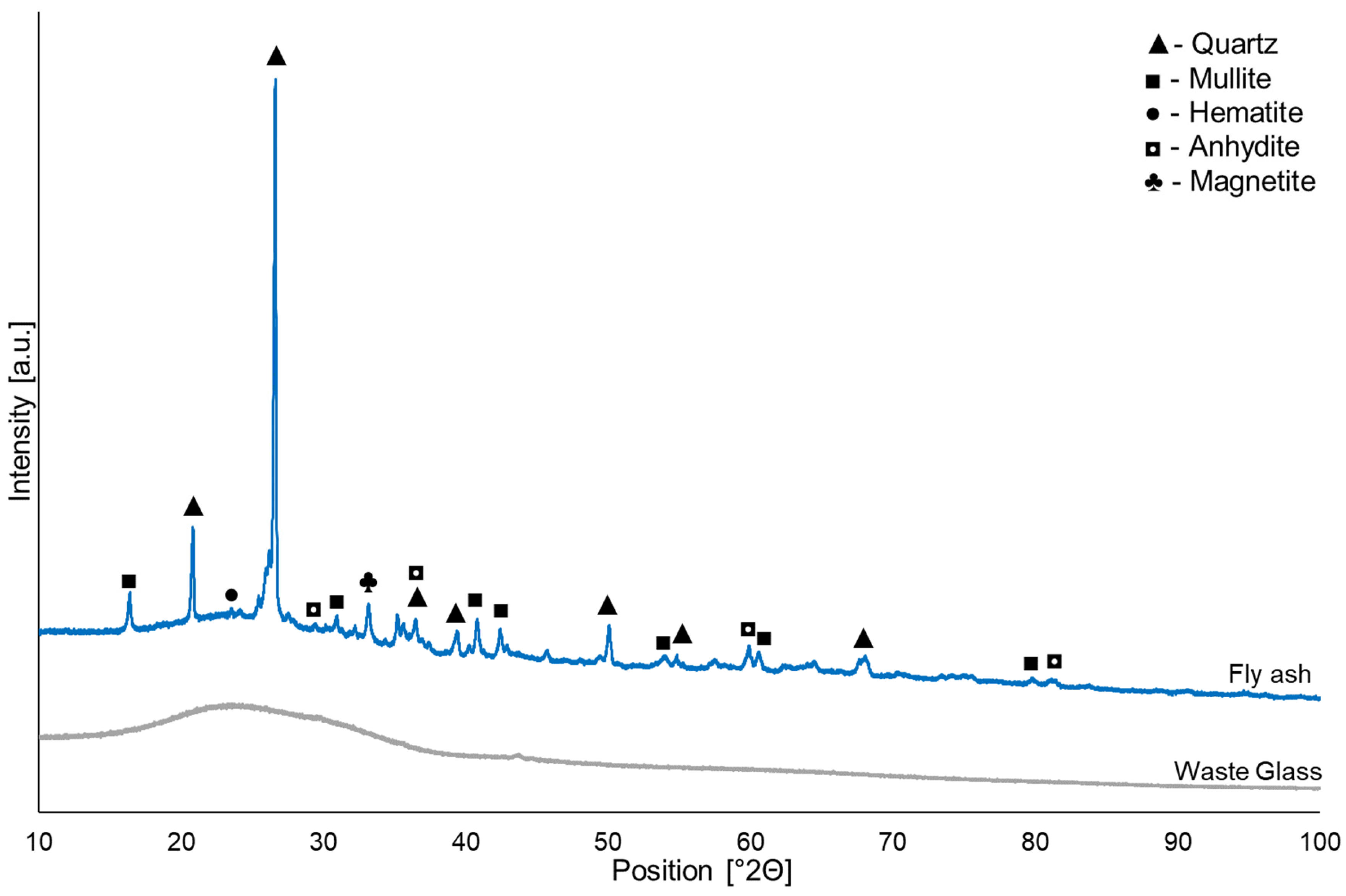

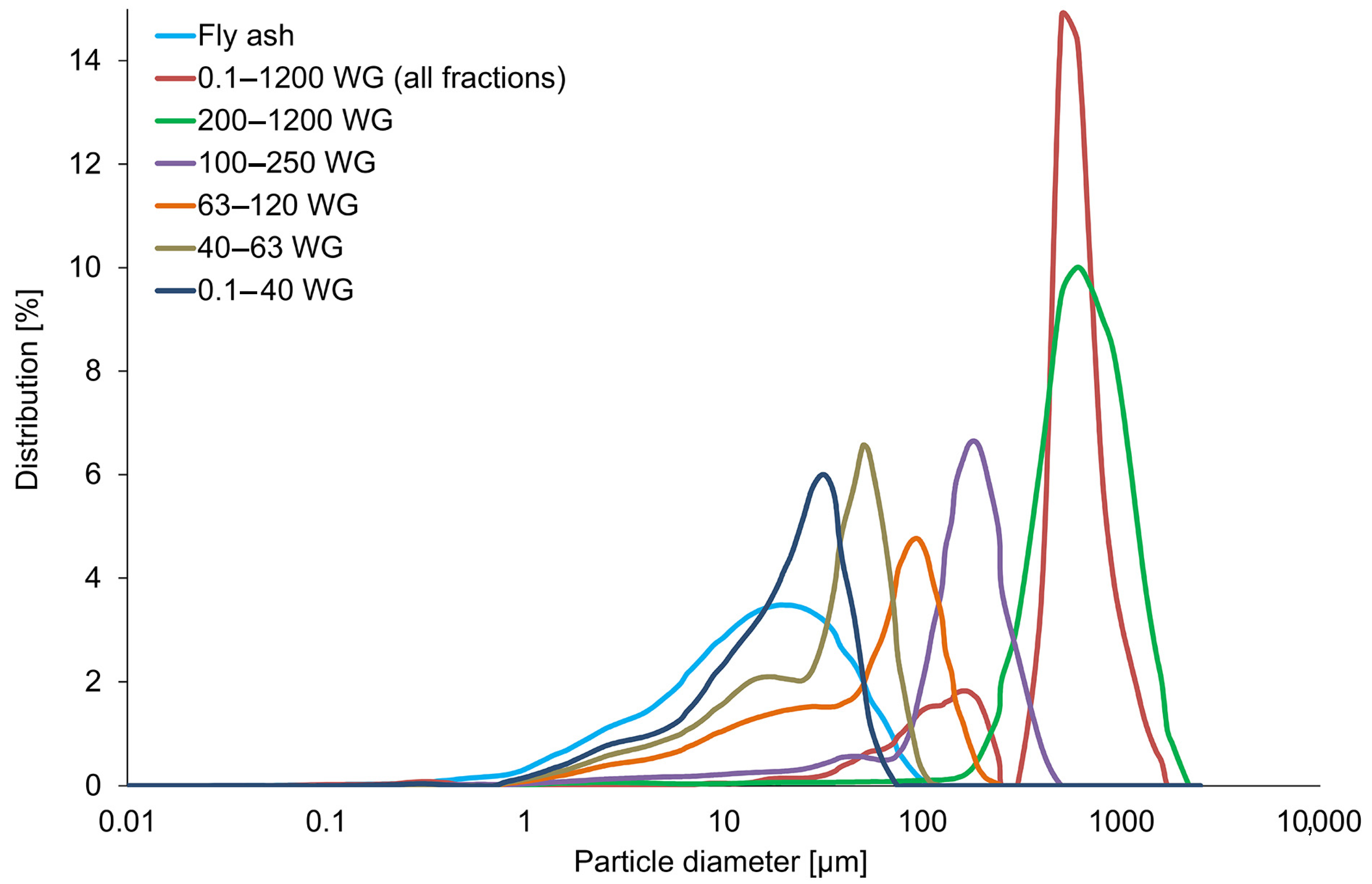

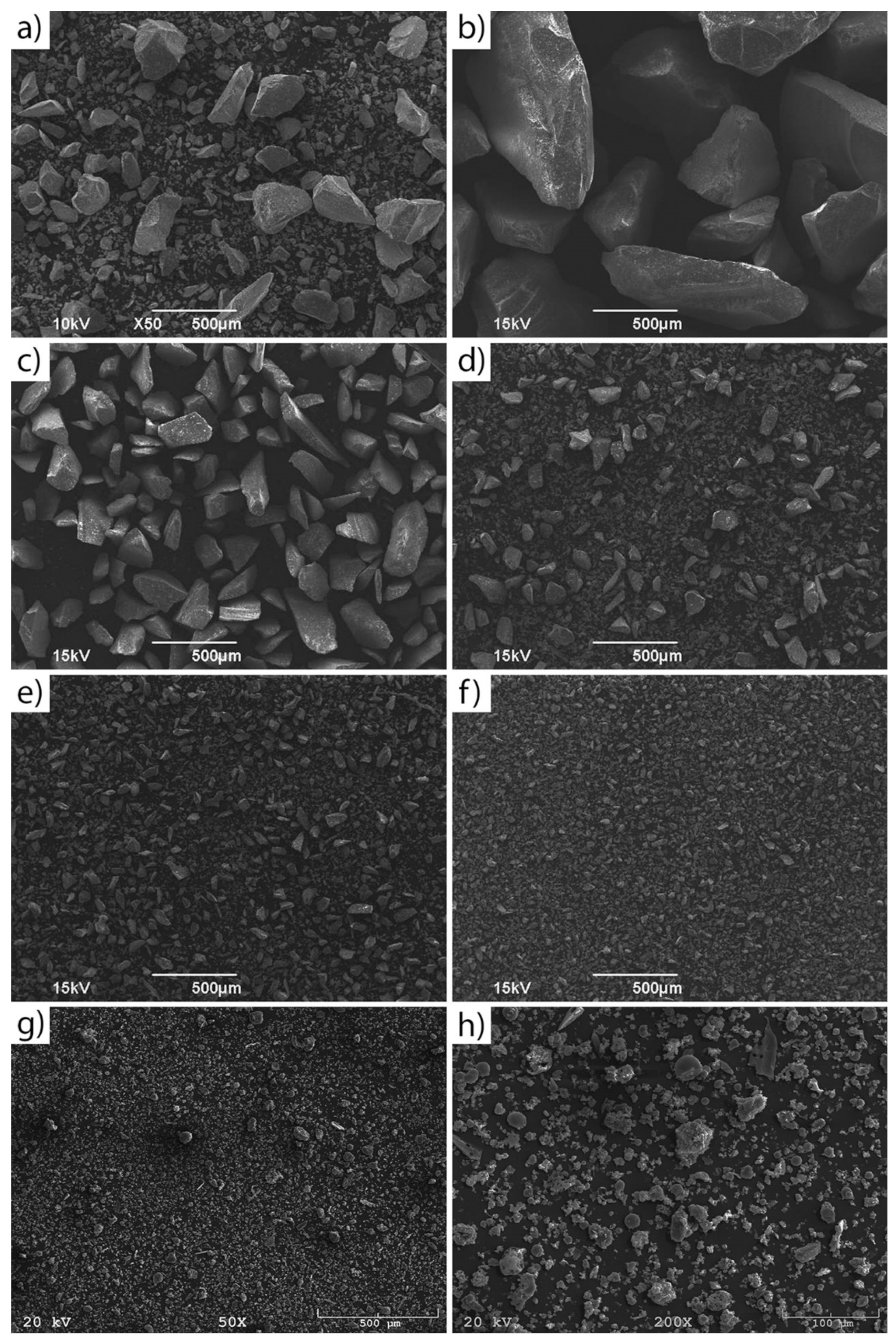

3.1. Properties of Raw Materials

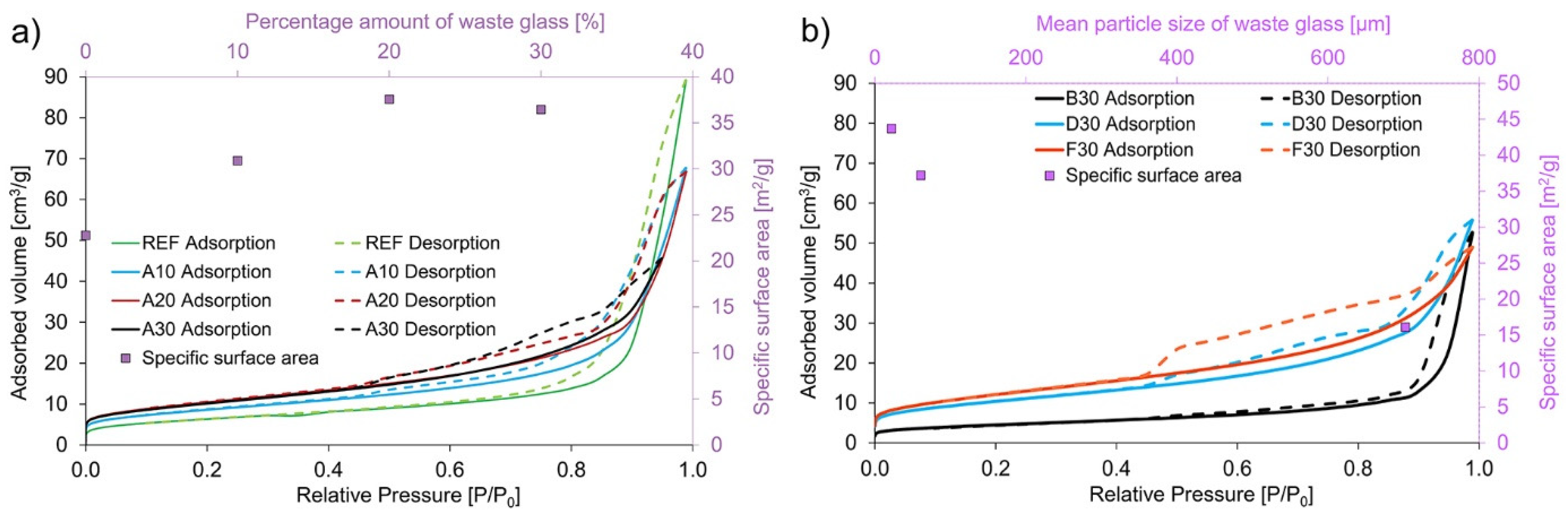

3.2. Properties of Produced Geopolymers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Belaïd, F. How Does Concrete and Cement Industry Transformation Contribute to Mitigating Climate Change Challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Marey, H.; Kozma, G.; Szabó, G. Effects of Using Green Concrete Materials on the CO2 Emissions of the Residential Building Sector in Egypt. Sustainability 2022, 14, 3592. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and Concrete as an Engineering Material: An Historic Appraisal and Case Study Analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Gibbs Michael, J.; Soyka, P.; Conneely, D. CO2 Emissions from Cement Production. In Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2000. [Google Scholar]

- Strunge, T.; Naims, H.; Ostovari, H.; Olfe-Kräutlein, B. Priorities for Supporting Emission Reduction Technologies in the Cement Sector–A Multi-Criteria Decision Analysis of CO2 Mineralisation. J. Clean. Prod. 2022, 340, 130712. [Google Scholar] [CrossRef]

- Fletcher, W.D.; Smith, C.B. Introduction. In Reaching Net Zero: What It Takes to Solve the Global Climate Crisis; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Ćirović, M.D. Risk Analysis of the European Union 2030 Greenhouse Gas Emission Target Compliance. Int. J. Glob. Warm. 2018, 16, 64. [Google Scholar] [CrossRef]

- Strzałkowska, E. Morphology, Chemical and Mineralogical Composition of Magnetic Fraction of Coal Fly Ash. Int. J. Coal. Geol. 2021, 240, 103746. [Google Scholar] [CrossRef]

- Cieślik, E.; Fabiańska, M.J. Preservation of Geochemical Markers during Co-Combustion of Hard Coal and Various Domestic Waste Materials. Sci. Total Environ. 2021, 768, 144638. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous Geopolymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Grela, A.; Łach, M.; Bajda, T.; Mikuła, J.; Hebda, M. Characterization of the products obtained from alkaline conversion of tuff and metakaolin. J. Therm. Anal Calorim. 2018, 133, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Kumar Yadav, V.; Hiraman Fulekar, M. Advances in Methods for Recovery of Ferrous, Alumina, and Silica Nanoparticles from Fly Ash Waste. Ceramics 2020, 3, 384–420. [Google Scholar] [CrossRef]

- Prabha, V.C.; Revathi, V. Geopolymer Mortar Incorporating High Calcium Fly Ash and Silica Fume. Arch. Civ. Eng. 2019, 65, 3–16. [Google Scholar] [CrossRef] [Green Version]

- Doğan-Sağlamtimur, N.; Bilgil, A.; Szechyńska-Hebda, M.; Parzych, S.; Hebda, M. Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse. Materials 2021, 14, 877. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, R.; Shrivastava, A.; Singh, M. Properties of Fly Ash Geopolymer Modified with Red Mud and Silica Fume: A Comparative Study. SN Appl. Sci. 2020, 2, 1846. [Google Scholar] [CrossRef]

- Łach, M.; Gado, R.A.; Marczyk, J.; Ziejewska, C.; Doğan-Sağlamtimur, N.; Mikuła, J.; Szechyńska-Hebda, M.; Hebda, M. Process Design for a Production of Sustainable Materials from Post-Production Clay. Materials 2021, 14, 953. [Google Scholar] [CrossRef] [PubMed]

- Feng, B.; Liu, J.; Chen, Y.; Tan, X.; Zhang, M.; Sun, Z. Properties and Microstructure of Self-Waterproof Metakaolin Geopolymer with Silane Coupling Agents. Constr. Build. Mater. 2022, 342, 128045. [Google Scholar] [CrossRef]

- Yong, H.C.; Ming, L.Y.; al Bakri Abdullah, M.M.; Hussin, K. Fire Resistant Properties of Geopolymers: A Review. Key Eng. Mater. 2015, 660, 39–43. [Google Scholar] [CrossRef]

- Lahoti, M.; Tan, K.H.; Yang, E.H. A Critical Review of Geopolymer Properties for Structural Fire-Resistance Applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, X.; Yu, Q. Effect of Curing Conditions on Freeze-Thaw Resistance of Geopolymer Mortars Containing Various Calcium Resources. Constr. Build. Mater. 2021, 313, 125507. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer Concrete: A Material for Sustainable Development in Indian Construction Industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of Geopolymer Materials to Acid Attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Neutral geopolymer foams reinforced with cellulose studied with the FT-Raman spectroscopy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 706, 012017. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Martínez-García, R. A Study on the Microstructure and Durability Performance of Rubberized Concrete with Waste Glass as Binding Material. J. Build. Eng. 2022, 49, 104054. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of Geopolymers Sourced from Construction and Demolition Waste: A Review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Guzmán-Carrillo, H.R.; Gasca-Tirado, J.R.; López-Romero, J.M.; Apátiga-Castro Luis, M.; Rivera-Muñoz Eric, M.; Pineda-Piñón, J.; Pérez-Bueno, J.J.; Feregrino-Montes, C.; López-Naranjo, E.J.; Manzano-Ramírez, A. Encapsulation of Toxic Heavy Metals from Waste CRT Using Calcined Kaolin Base-Geopolymer. Mater. Chem. Phys. 2021, 257, 123745. [Google Scholar] [CrossRef]

- Roopchund, R.; Andrew, J.; Sithole, B. Using Cellulose Nanocrystals to Improve the Mechanical Properties of Fly Ash-Based Geopolymer Construction Materials. Eng. Sci. Technol. Int. J. 2022, 25, 100989. [Google Scholar] [CrossRef]

- Refaie, F.A.Z.; Abbas, R.; Fouad, F.H. Sustainable Construction System with Egyptian Metakaolin Based Geopolymer Concrete Sandwich Panels. Case Stud. Constr. Mater. 2020, 13, e00436. [Google Scholar] [CrossRef]

- Kretzer, M.B.; Effting, C.; Schwaab, S.; Schackow, A. Hybrid Geopolymer-Cement Coating Mortar Optimized Based on Metakaolin, Fly Ash, and Granulated Blast Furnace Slag. Clean. Eng. Technol. 2021, 4, 100153. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B. Effect of Recycled Waste Glass on the Properties of High-Performance Concrete: A Critical Review. Case Stud. Constr. Mater. 2022, 17, e01149. [Google Scholar] [CrossRef]

- Li, S.; Zhang, J.; Du, G.; Mao, Z.; Ma, Q.; Luo, Z.; Miao, Y.; Duan, Y. Properties of Concrete with Waste Glass after Exposure to Elevated Temperatures. J. Build. Eng. 2022, 57, 104822. [Google Scholar] [CrossRef]

- Feng, J.; Wu, D.; Long, M.; Lei, K.; Sun, Y.; Zhao, X. Diopside Glass-Ceramics Were Fabricated by Sintering the Powder Mixtures of Waste Glass and Kaolin. Ceram. Int. 2022, 48, 27088–27096. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Ma, Y.; Zhang, M.; Bai, Y.; Huang, B. Influence of Waste Glass Powder on the Physico-Mechanical Properties and Microstructures of Fly Ash-Based Geopolymer Paste after Exposure to High Temperatures. Constr. Build. Mater. 2020, 262, 120579. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B.; Zhou, H.; Ma, Y.; Jiang, X. A State-of-the-Art Review of Crushed Urban Waste Glass Used in OPC and AAMs (Geopolymer): Progress and Challenges. Clean. Mater. 2022, 4, 100083. [Google Scholar] [CrossRef]

- Jochem, L.F.; Casagrande, C.A.; Onghero, L.; Venâncio, C.; Gleize, P.J.P. Effect of Partial Replacement of the Cement by Glass Waste on Cementitious Pastes. Constr. Build. Mater. 2021, 273, 121704. [Google Scholar] [CrossRef]

- Fu, C.; Liang, J.; Yang, G.; Dagestani, A.A.; Liu, W.; Luo, X.; Zeng, B.; Wu, H.; Huang, M.; Lin, L.; et al. Recycling of Waste Glass as Raw Materials for the Preparation of Self-Cleaning, Light-Weight and High-Strength Porous Ceramics. J. Clean. Prod. 2021, 317, 128395. [Google Scholar] [CrossRef]

- Maitlo, G.; Ali, I.; Maitlo, H.A.; Ali, S.; Unar, I.N.; Ahmad, M.B.; Bhutto, D.K.; Karmani, R.K.; Naich, S.U.R.; Sajjad, R.U.; et al. Plastic Waste Recycling, Applications, and Future Prospects for a Sustainable Environment. Sustainability 2022, 14, 11637. [Google Scholar] [CrossRef]

- Pickin, J.; Wardle, C.; O’farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C.; et al. National Waste Report 2022. Available online: https://www.dcceew.gov.au/environment/protection/waste/national-waste-reports/2022 (accessed on 26 February 2023).

- Novais, R.M.; Ascensão, G.; Seabra, M.P.; Labrincha, J.A. Waste Glass from End-of-Life Fluorescent Lamps as Raw Material in Geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical Property, Nanopore Structure and Drying Shrinkage of Metakaolin-Based Geopolymer with Waste Glass Powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Polat, D.; Güden, M. Processing and Characterization of Geopolymer and Sintered Geopolymer Foams of Waste Glass Powders. Constr. Build. Mater. 2021, 300, 124259. [Google Scholar] [CrossRef]

- Senff, L.; Novais, R.M.; Carvalheiras, J.; Labrincha, J.A. Eco-Friendly Approach to Enhance the Mechanical Performance of Geopolymer Foams: Using Glass Fibre Waste Coming from Wind Blade Production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, Microstructure, Efflorescence Behavior and Environmental Impacts of Waste Glass Geopolymers Cured at Ambient Temperature. J. Clean. Prod. 2020, 252, 119610. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Sustainable One-Part Geopolymer Foams with Glass Fines versus Sand as Aggregates. Constr. Build. Mater. 2018, 171, 223–231. [Google Scholar] [CrossRef]

- Du, Y.; Yang, W.; Ge, Y.; Wang, S.; Liu, P. Thermal Conductivity of Cement Paste Containing Waste Glass Powder, Metakaolin and Limestone Filler as Supplementary Cementitious Material. J. Clean. Prod. 2021, 287, 125018. [Google Scholar] [CrossRef]

- Ulugöl, H.; Kul, A.; Yıldırım, G.; Şahmaran, M.; Aldemir, A.; Figueira, D.; Ashour, A. Mechanical and Microstructural Characterization of Geopolymers from Assorted Construction and Demolition Waste-Based Masonry and Glass. J. Clean. Prod. 2021, 280, 124358. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Ferdous, W.; Sahajwalla, V.; Blanco, I.; Catauro, M. Roles of Waste Glass and the Effect of Process Parameters on the Properties of Sustainable Cement and Geopolymer Concrete-A State-of-the-Art Review. Polymers 2021, 13, 3935. [Google Scholar] [CrossRef]

- Kiliçoglu, C.; Çoruh, S. Recycling of Waste Glass in Concrete Plant as Aggregate and Pozzolan Replacement. Int. J. Glob. Warm. 2017, 11, 250–262. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and Pozzolanic Reactivity of Glass Powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Badanoiu, A.I.; al Saadi, T.H.A.; Stoleriu, S.; Voicu, G. Preparation and Characterization of Foamed Geopolymers from Waste Glass and Red Mud. Constr. Build. Mater. 2015, 84, 284–293. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Onghero, L.; Batista Passos, A.; Simão, L.; Honorato Piva, R.; Longuini Repette, W.; Novaes de Oliveira, A.P. Sustainable Glass Foams Produced with Stone Waste as a Pore-Forming Agent: Assessing the Role of Heating Rate in Foamability and Glass Foams Recyclability. J. Clean. Prod. 2022, 338, 130596. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Sahajwalla, V. Recycling of Automotive Vehicle’s Waste Glass to Develop Sustainable Glass Foam Using a Curing-Sintering Process. In Proceedings of the Concrete Institute of Australia’s Biennial National Conference (Concrete 2021), Perth, Australia, 8 September 2021. [Google Scholar]

- Zhang, Y.; Xiao, R.; Jiang, X.; Li, W.; Zhu, X.; Huang, B. Effect of Particle Size and Curing Temperature on Mechanical and Microstructural Properties of Waste Glass-Slag-Based and Waste Glass-Fly Ash-Based Geopolymers. J. Clean. Prod. 2020, 273, 122970. [Google Scholar] [CrossRef]

- Ruan, S.; Kastiukas, G.; Liang, S.; Zhou, X. Waste Glass Reuse in Foamed Alkali-Activated Binders Production: Technical and Environmental Assessment. Front. Mater. 2020, 7, 581358. [Google Scholar] [CrossRef]

- Catauro, M.; Dal Poggetto, G.; Sgarlata, C.; Vecchio Ciprioti, S.; Pacifico, S.; Leonelli, C. Thermal and Microbiological Performance of Metakaolin-Based Geopolymers Cement with Waste Glass. Appl. Clay. Sci. 2020, 197, 105763. [Google Scholar] [CrossRef]

- Mahesh, Y.; Lalitha, G. Durablilty Propeties of Geopolymer Concrete Partial Replacement of Fine Aggaregate with Waste Crushed Glass. Mater. Today Proc. 2022, 51, 2466–2470. [Google Scholar] [CrossRef]

- Marczyk, J.; Ziejewska, C.; Gadek, S.; Korniejenko, K.; Łach, M.; Góra, M.; Kurek, I.; Dogan-Saglamtimur, N.; Hebda, M.; Szechynska-Hebda, M. Hybrid Materials Based on Fly Ash, Metakaolin, and Cement for 3D Printing. Materials 2021, 14, 6874. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.J.; Shih, N.H.; Wu, C.H.; Lin, S.K. Effects of the Loss on Ignition of Fly Ash on the Properties of High-Volume Fly Ash Concrete. Sustainability 2019, 11, 2704. [Google Scholar] [CrossRef] [Green Version]

- Vafaei, M.; Allahverdi, A. High Strength Geopolymer Binder Based on Waste-Glass Powder. Adv. Powder Technol. 2017, 28, 215–222. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Elrahman, M.A. Properties of Ultra-High Performance Geopolymer Concrete Incorporating Recycled Waste Glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Azdast, T.; Hasanzadeh, R. Increasing Cell Density/Decreasing Cell Size to Produce Microcellular and Nanocellular Thermoplastic Foams: A Review. J. Cell. Plast. 2020, 57, 769–797. [Google Scholar] [CrossRef]

- Mucsi, G. Mechanical Activation of Power Station Fly Ash by Grinding—A Review. Epa.-J. Silic. Based Compos. Mater. 2016, 68, 56–61. [Google Scholar] [CrossRef]

- Shee-Ween, O.; Cheng-Yong, H.; Yun-Ming, L.; Abdullah, M.M.A.B.; Li Ngee, H.; Chan, L.W.L.; Wan-En, O.; Jaya, N.A.; Yong-Sing, N. Cold-Pressed Fly Ash Geopolymers: Effect of Formulation on Mechanical and Morphological Characteristics. J. Mater. Res. Technol. 2021, 15, 3028–3046. [Google Scholar] [CrossRef]

- Ankrah, A.F.; Tokay, B.; Snape, C.E. Heavy Metal Removal from Aqueous Solutions Using Fly-Ash Derived Zeolite NaP1. Int. J. Environ. Res. 2022, 16, 17. [Google Scholar] [CrossRef]

- Segneanu, A.E.; Marin, C.N.; Vlase, G.; Cepan, C.; Mihailescu, M.; Muntean, C.; Grozescu, I. Highly Efficient Engineered Waste Eggshell-Fly Ash for Cadmium Removal from Aqueous Solution. Sci. Rep. 2022, 12, 9676. [Google Scholar] [CrossRef] [PubMed]

- Janowska-Renkas, E.; Kaliciak, A. Properties of Geopolymers from Conventional Fly Ash Activated at Increased Temperature with Sodium Hydroxide Containing Glass Powder Obtained from the Recycling of Waste Glass. MATEC Web Conf. 2020, 322, 01018. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Characteristics of Concrete with Waste Glass as Fine Aggregate Replacement. Int. J. Eng. Technol. 2014, 2, 11–17. [Google Scholar]

- Barkauskas, K.; Nagrockienė, D.; Girnienė, I. The Effect of Glass Powder on Physical and Mechanical Properties of Hardened Cement Paste. In Proceedings of the 13th International Conference Modern Building Materials, Structures and Techniques, Vilnius, Lithuania, 16–17 May 2019. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Carvalho, J.M.F.; Ribeiro, J.C.L.; Albuini-Oliveira, N.M.; Andrade, I.K.R. Evaluation of Eco-Efficient Geopolymer Using Chamotte and Waste Glass-Based Alkaline Solutions. Case Stud. Constr. Mater. 2022, 16, e00847. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; de-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef]

- Rahman, M.M.; Muttakin, M.; Pal, A.; Shafiullah, A.Z.; Saha, B.B. A Statistical Approach to Determine Optimal Models for IUPAC-Classified Adsorption Isotherms. Energies 2019, 12, 4565. [Google Scholar] [CrossRef] [Green Version]

- Henderson, J. The Analysis of Ancient Glasses Part I: Materials, Properties, and Early European Glass. JOM 1995, 47, 62–64. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Springer Science & Business Media: Berlin, Germany, 2004; Volume 16. [Google Scholar] [CrossRef]

- Yurdakal, S.; Garlisi, C.; Özcan, L.; Bellardita, M.; Palmisano, G. (Photo)Catalyst Characterization Techniques: Adsorption Isotherms and BET, SEM, FTIR, UV–Vis, Photoluminescence, and Electrochemical Characterizations. In Heterogeneous Photocatalysis: Relationships with Heterogeneous Catalysis and Perspectives; Elsevier: Amsterdam, The Netherlands, 2019; pp. 87–152. [Google Scholar] [CrossRef]

- Arokiasamy, P.; al Bakri Abdullah, M.M.; Rahim, S.Z.A.; Arif Zainol, M.R.R.M.; Salleh, M.A.A.M.; Kheimi, M.; Chaiprapa, J.; Sandu, A.V.; Vizureanu, P.; Razak, R.A.; et al. Metakaolin/Sludge Based Geopolymer Adsorbent on High Removal Efficiency of Cu2+. Case Stud. Constr. Mater. 2022, 17, e01428. [Google Scholar] [CrossRef]

- Qiu, J.; Zhao, Y.; Xing, J.; Sun, X. Fly Ash/Blast Furnace Slag-Based Geopolymer as a Potential Binder for Mine Backfilling: Effect of Binder Type and Activator Concentration. Adv. Mater. Sci. Eng. 2019, 2019, 2028109. [Google Scholar] [CrossRef] [Green Version]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and Strength of Lignite Bottom Ash Geopolymer Mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef]

- Toniolo, N.; Rincón, A.; Roether, J.A.; Ercole, P.; Bernardo, E.; Boccaccini, A.R. Extensive Reuse of Soda-Lime Waste Glass in Fly Ash-Based Geopolymers. Constr. Build. Mater. 2018, 188, 1077–1084. [Google Scholar] [CrossRef]

- Wang, S.; Yu, L.; Xu, L.; Wu, K.; Yang, Z. The Failure Mechanisms of Precast Geopolymer after Water Immersion. Materials 2021, 14, 5299. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, A.; Moukannaa, S. A New Approach to the Reuse of Waste Glass in the Production of Alkali-Activated Materials. Clean. Eng. Technol. 2021, 4, 100212. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Gailitis, R.; Korniejenko, K.; Mierzwiński, D. Foamed Geopolymer Composites with the Addition of Glass Wool Waste. Materials 2021, 14, 4978. [Google Scholar] [CrossRef]

- Łach, M.; Pławecka, K.; Bąk, A.; Lichocka, K.; Korniejenko, K.; Cheng, A.; Lin, W.T. Determination of the Influence of Hydraulic Additives on the Foaming Process and Stability of the Produced Geopolymer Foams. Materials 2021, 14, 5090. [Google Scholar] [CrossRef]

- Al-Bakri Abdullah, M.M.; Jamaludin, L.; Hussin, K.; Bnhussain, M.; Ghazali, C.M.R.; Ahmad, M.I. Fly Ash Porous Material Using Geopolymerization Process for High Temperature Exposure. Int. J. Mol. Sci. 2012, 13, 4388. [Google Scholar] [CrossRef] [Green Version]

- Luna-Galiano, Y.; Fernández-Pereira, C.; Izquierdo, M. Contributions to the Study of Porosity in Fly Ash-Based Geopolymers. Relationship between Degree of Reaction, Porosity and Compressive Strength. Mater. De Construcción 2016, 66, e098. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Optimal Design of PH-Neutral Geopolymer Foams for Their Use in Ecological Plant Cultivation Systems. Materials 2019, 12, 2999. [Google Scholar] [CrossRef] [Green Version]

- Deng, Q.; Lai, Z.; Xiao, R.; Wu, J.; Liu, M.; Lu, Z.; Lv, S. Effect of Waste Glass on the Properties and Microstructure of Magnesium Potassium Phosphate Cement. Materials 2021, 14, 2073. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled Glass as a Partial Replacement for Fine Aggregate in Self Compacting Concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Toniolo, N.; Taveri, G.; Hurle, K.; Roether, J.A.; Ercole, P.; Dlouhý, I.; Boccaccini, A.R. Fly-Ash-Based Geopolymers: How the Addition of Recycled Glass or Red Mud Waste Influences the Structural and Mechanical Properties. J. Ceram. Sci. Technol. 2017, 8, 411–419. [Google Scholar] [CrossRef]

- Dadsetan, S.; Siad, H.; Lachemi, M.; Sahmaran, M. Extensive Evaluation on the Effect of Glass Powder on the Rheology, Strength, and Microstructure of Metakaolin-Based Geopolymer Binders. Constr. Build. Mater. 2021, 268, 121168. [Google Scholar] [CrossRef]

- Korniejenko, K.; Figiela, B.; Miernik, K.; Ziejewska, C.; Marczyk, J.; Hebda, M.; Cheng, A.; Lin, W.-T. Mechanical and Fracture Properties of Long Fiber Reinforced Geopolymer Composites. Materials 2021, 14, 5183. [Google Scholar] [CrossRef]

- Wielgus, N.; Kubica, J.; Górski, M. Influence of the Composition and Curing Time on Mechanical Properties of Fluidized Bed Combustion Fly Ash-Based Geopolymer. Polymers 2021, 13, 2527. [Google Scholar] [CrossRef]

- Taher, S.M.S.; Saadullah, S.T.; Haido, J.H.; Tayeh, B.A. Behavior of Geopolymer Concrete Deep Beams Containing Waste Aggregate of Glass and Limestone as a Partial Replacement of Natural Sand. Case Stud. Constr. Mater. 2021, 15, e00744. [Google Scholar] [CrossRef]

- Ercoli, R.; Laskowska, D.; Nguyen, V.V.; Le, V.S.; Louda, P.; Łoś, P.; Ciemnicka, J.; Prałat, K.; Renzulli, A.; Paris, E.; et al. Mechanical and Thermal Properties of Geopolymer Foams (GFs) Doped with By-Products of the Secondary Aluminum Industry. Polymers 2022, 14, 703. [Google Scholar] [CrossRef] [PubMed]

- van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Lorenzen, L. Factors Affecting the Immobilization of Metals in Geopolymerized Flyash. Met. Mater. Trans. B 1998, 29, 283–291. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, Y.; Sun, Q.; Ta, X. Eluviation and Leaching of Elements from Broken Fly-Ash-Based Porous Geopolymer. Materials 2021, 14, 6884. [Google Scholar] [CrossRef] [PubMed]

- Bobirică, C.; Shim, J.H.; Park, J.Y. Leaching Behavior of Fly Ash-Waste Glass and Fly Ash-Slag-Waste Glass-Based Geopolymers. Ceram. Int. 2018, 44, 5886–5893. [Google Scholar] [CrossRef]

- Council of the European Union. Council Decision Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, 11, 27–49. [Google Scholar]

- Luhar, S.; Cheng, T.W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of Glass Wastes for the Development of Geopolymer Composites–Durability, Thermal and Microstructural Properties: A Review. Constr. Build. Mater. 2019, 222, 673–687. [Google Scholar] [CrossRef]

- Fei, Y.; Chen, F.; Fang, W.; Xu, L.; Ruan, S.; Liu, X.; Zhong, M.; Kuang, T. High-Strength, Flexible and Cycling-Stable Piezo-Resistive Polymeric Foams Derived from Thermoplastic Polyurethane and Multi-Wall Carbon Nanotubes. Compos. B Eng. 2020, 199, 108279. [Google Scholar] [CrossRef]

- Jindal, B.B.; Jangra, P.; Garg, A. Effects of Ultra Fine Slag as Mineral Admixture on the Compressive Strength, Water Absorption and Permeability of Rice Husk Ash Based Geopolymer Concrete. Mater. Today Proc. 2020, 32, 871–877. [Google Scholar] [CrossRef]

- Boum, R.B.E.; Kaze, C.R.; Nemaleu, J.G.D.; Djaoyang, V.B.; Rachel, N.Y.; Ninla, P.L.; Owono, F.M.; Kamseu, E. Thermal Behaviour of Metakaolin-Bauxite Blends Geopolymer: Microstructure and Mechanical Properties. SN Appl. Sci. 2020, 2, 1358. [Google Scholar] [CrossRef]

| Compound (%) | Material | |

|---|---|---|

| Coal Fly Ash | Waste Glass | |

| SiO2 | 48.22 | 73.40 |

| Al2O3 | 26.13 | 1.43 |

| Fe2O3 | 7.01 | - |

| FeO | - | 0.45 |

| CaO | 5.12 | 11.30 |

| K2O | 3.48 | 0.20 |

| Na2O | 1.62 | 11.96 |

| MgO | 1.72 | 1.25 |

| SO3 | 1.11 | - |

| TiO2 | 1.11 | - |

| P2O5 | 0.70 | - |

| MnO | 0.090 | - |

| Cl | 0.09 | - |

| Designation of Samples | Composition | |||

|---|---|---|---|---|

| Waste Glass Quantities (%) | Waste Glass Particle Size (µm) | Coal Fly Ash (%) | Sand (%) | |

| REF | - | - | 90 | 10 |

| A10 | 10 | 0.1–1200 | 80 | 10 |

| B10 | 10 | 200–1200 | 80 | 10 |

| C10 | 10 | 100–250 | 80 | 10 |

| D10 | 10 | 63–120 | 80 | 10 |

| E10 | 10 | 40–63 | 80 | 10 |

| F10 | 10 | 0.1–40 | 80 | 10 |

| A20 | 20 | 0.1–1200 | 70 | 10 |

| B20 | 20 | 200–1200 | 70 | 10 |

| C20 | 20 | 100–250 | 70 | 10 |

| D20 | 20 | 63–120 | 70 | 10 |

| E20 | 20 | 40–63 | 70 | 10 |

| F20 | 20 | 0.1–40 | 70 | 10 |

| A30 | 30 | 0.1–1200 | 60 | 10 |

| B30 | 30 | 200–1200 | 60 | 10 |

| C30 | 30 | 100–250 | 60 | 10 |

| D30 | 30 | 63–120 | 60 | 10 |

| E30 | 30 | 40–63 | 60 | 10 |

| F30 | 30 | 0.1–40 | 60 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziejewska, C.; Grela, A.; Hebda, M. Influence of Waste Glass Particle Size on the Physico-Mechanical Properties and Porosity of Foamed Geopolymer Composites Based on Coal Fly Ash. Materials 2023, 16, 2044. https://doi.org/10.3390/ma16052044

Ziejewska C, Grela A, Hebda M. Influence of Waste Glass Particle Size on the Physico-Mechanical Properties and Porosity of Foamed Geopolymer Composites Based on Coal Fly Ash. Materials. 2023; 16(5):2044. https://doi.org/10.3390/ma16052044

Chicago/Turabian StyleZiejewska, Celina, Agnieszka Grela, and Marek Hebda. 2023. "Influence of Waste Glass Particle Size on the Physico-Mechanical Properties and Porosity of Foamed Geopolymer Composites Based on Coal Fly Ash" Materials 16, no. 5: 2044. https://doi.org/10.3390/ma16052044