Microstructure and Mechanical Properties of Solid-State Rotary Friction Welded Inconel 713C and 32CrMo4 Steel Joints Used in a Turbocharger Rotor

Abstract

:1. Introduction

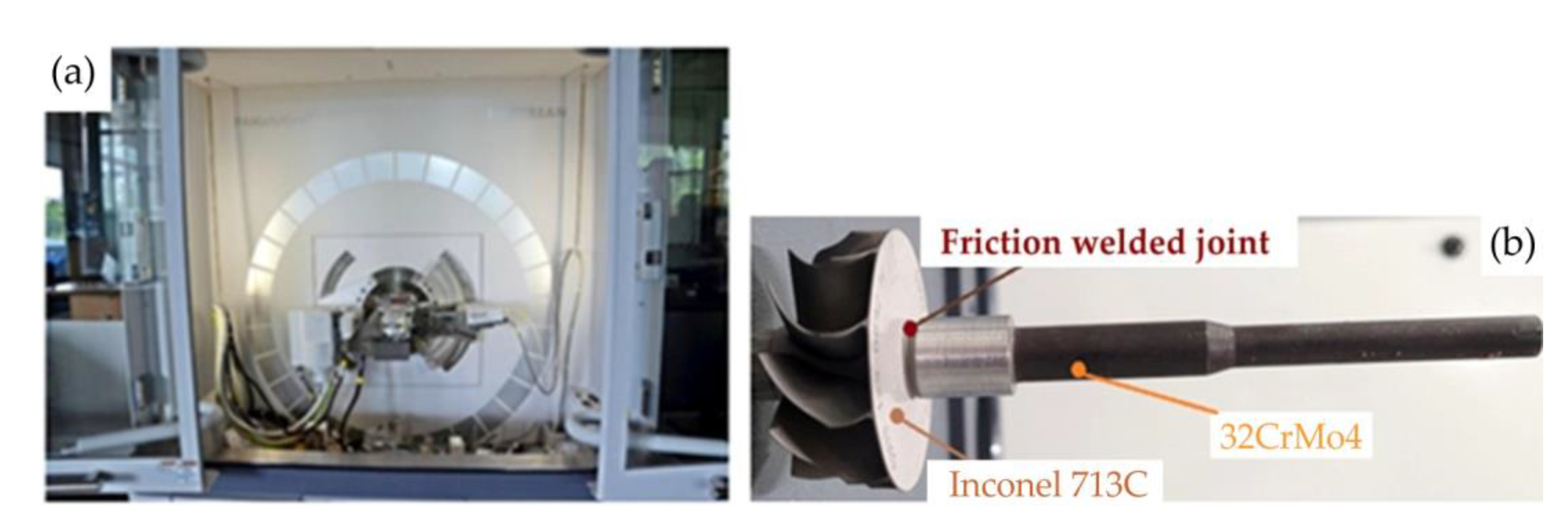

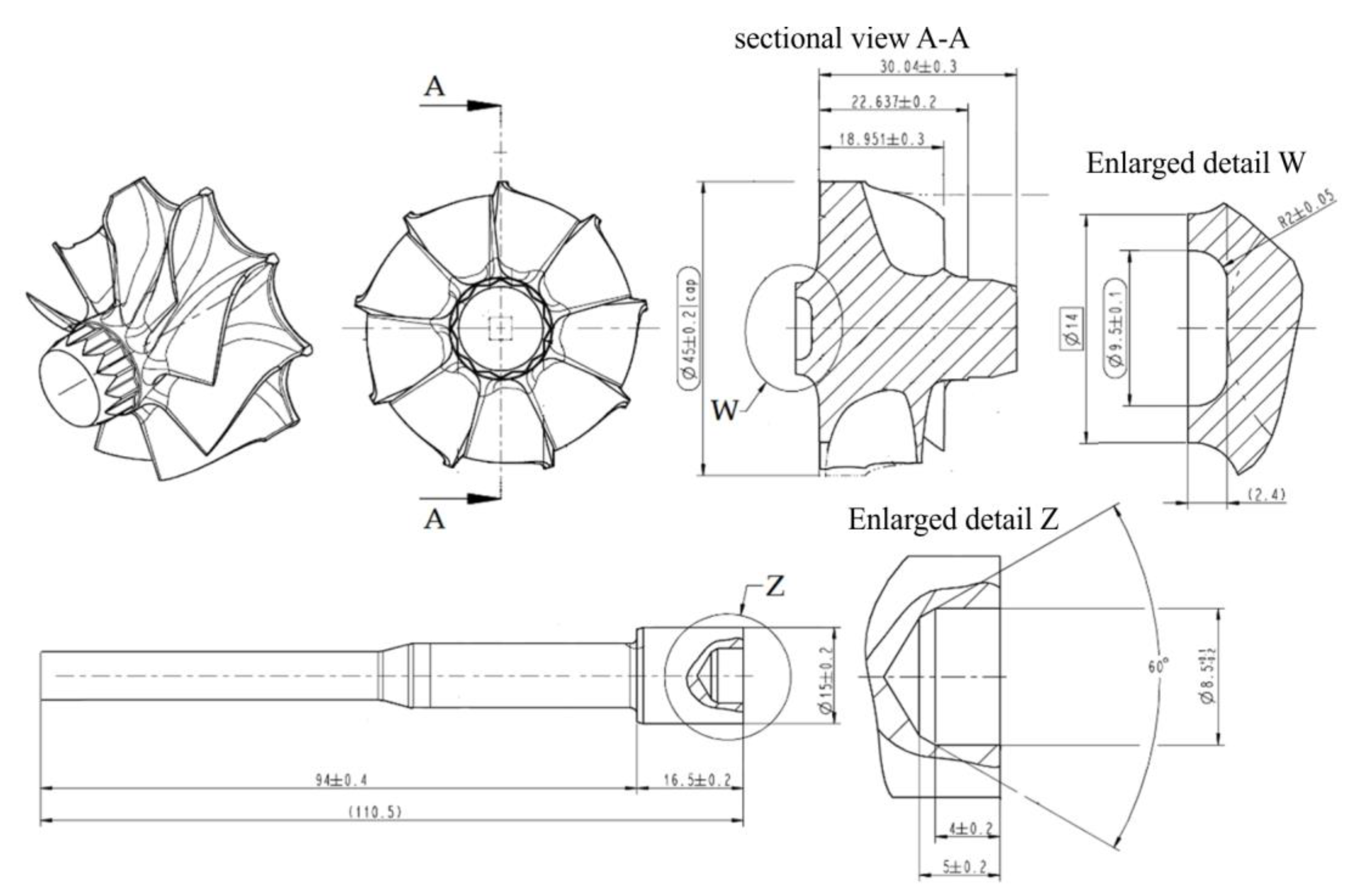

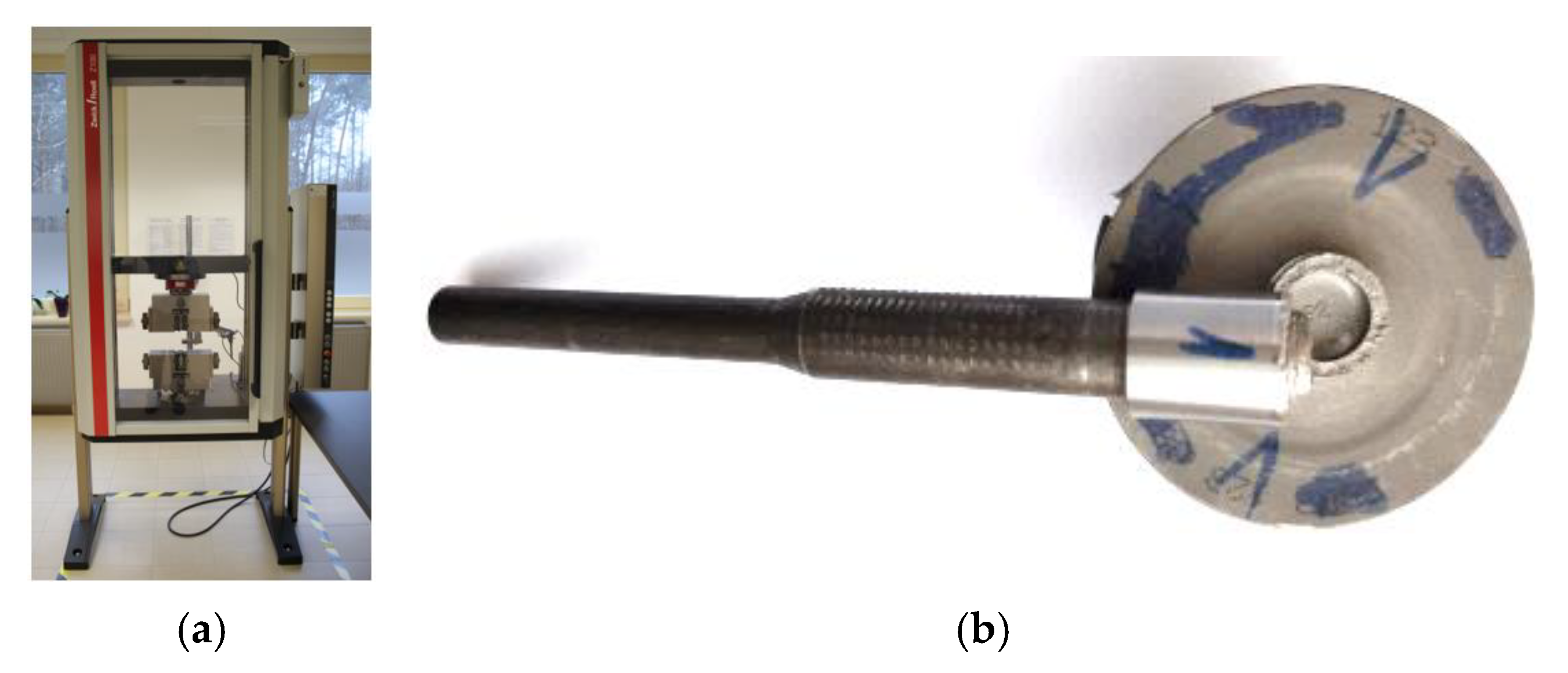

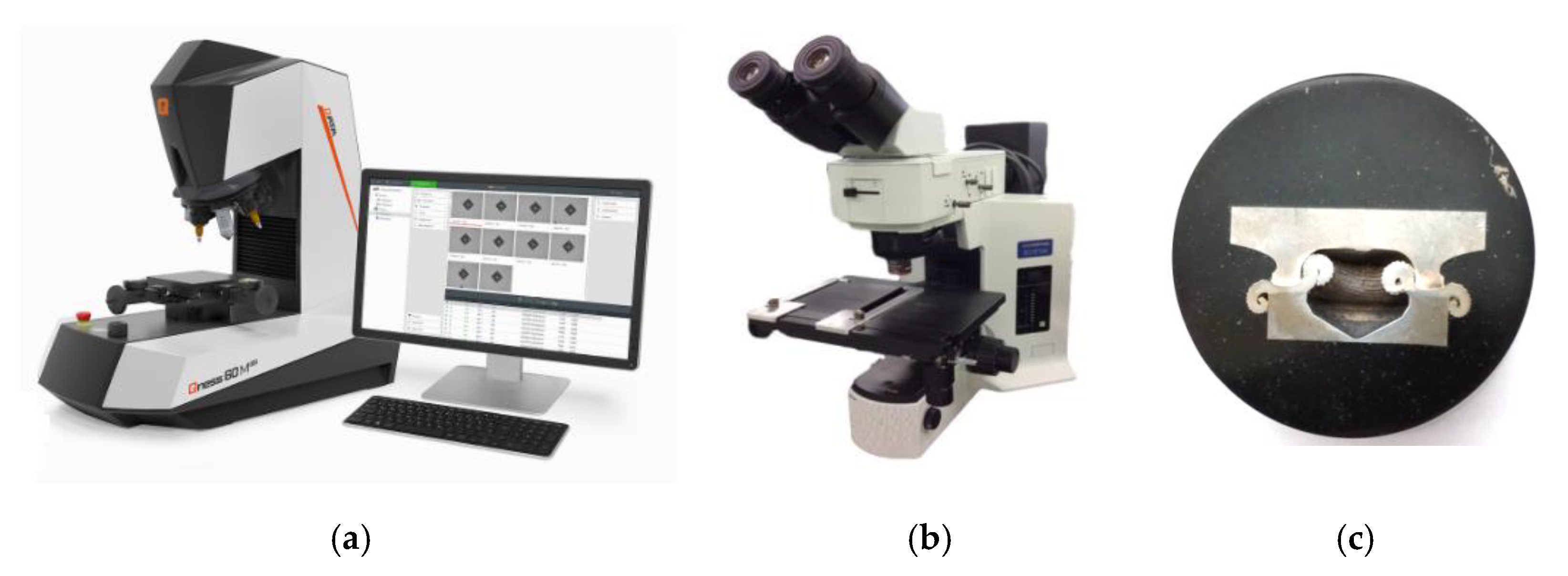

2. Materials and Methods

2.1. Materials

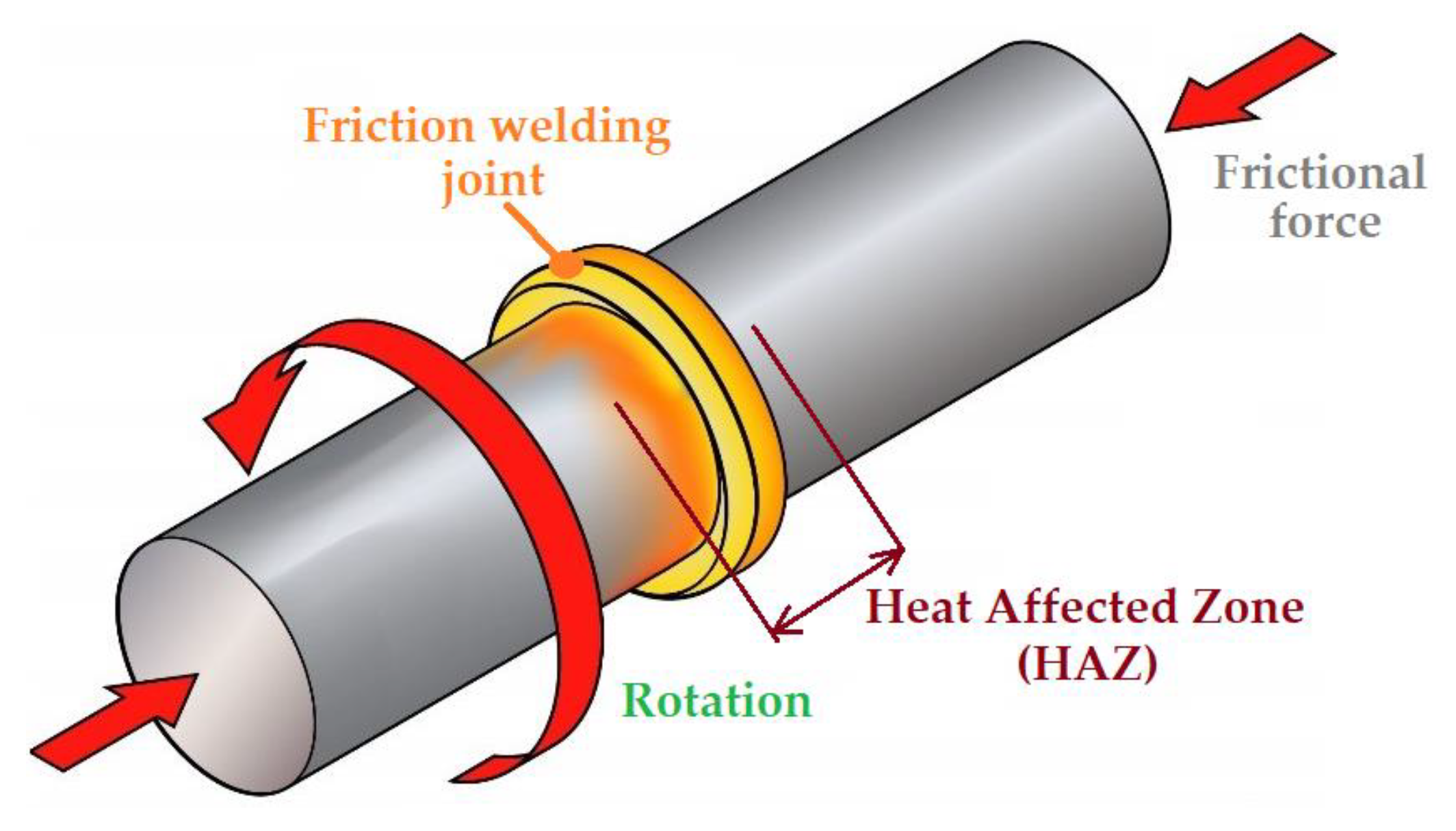

2.2. Welding Procedure

3. Results

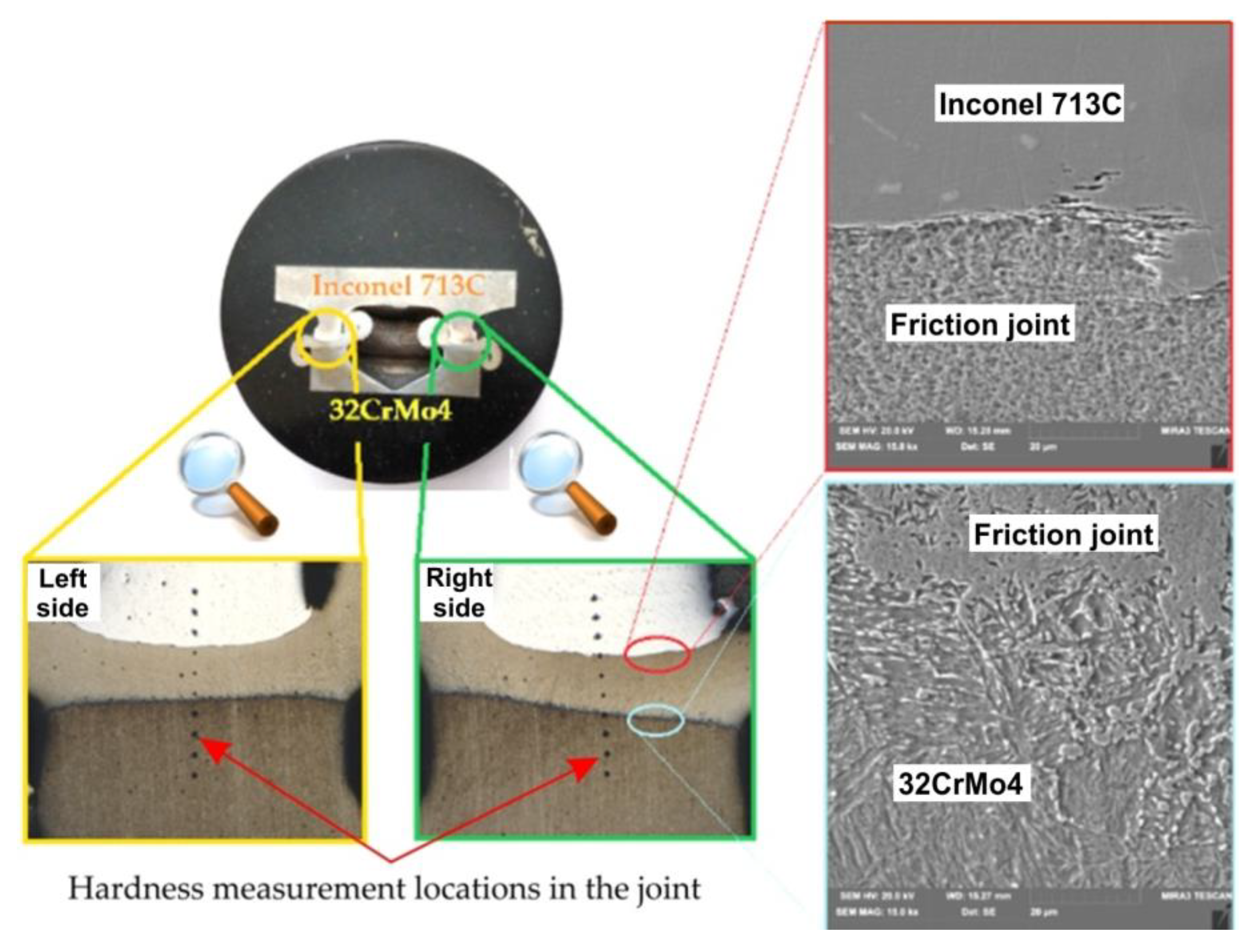

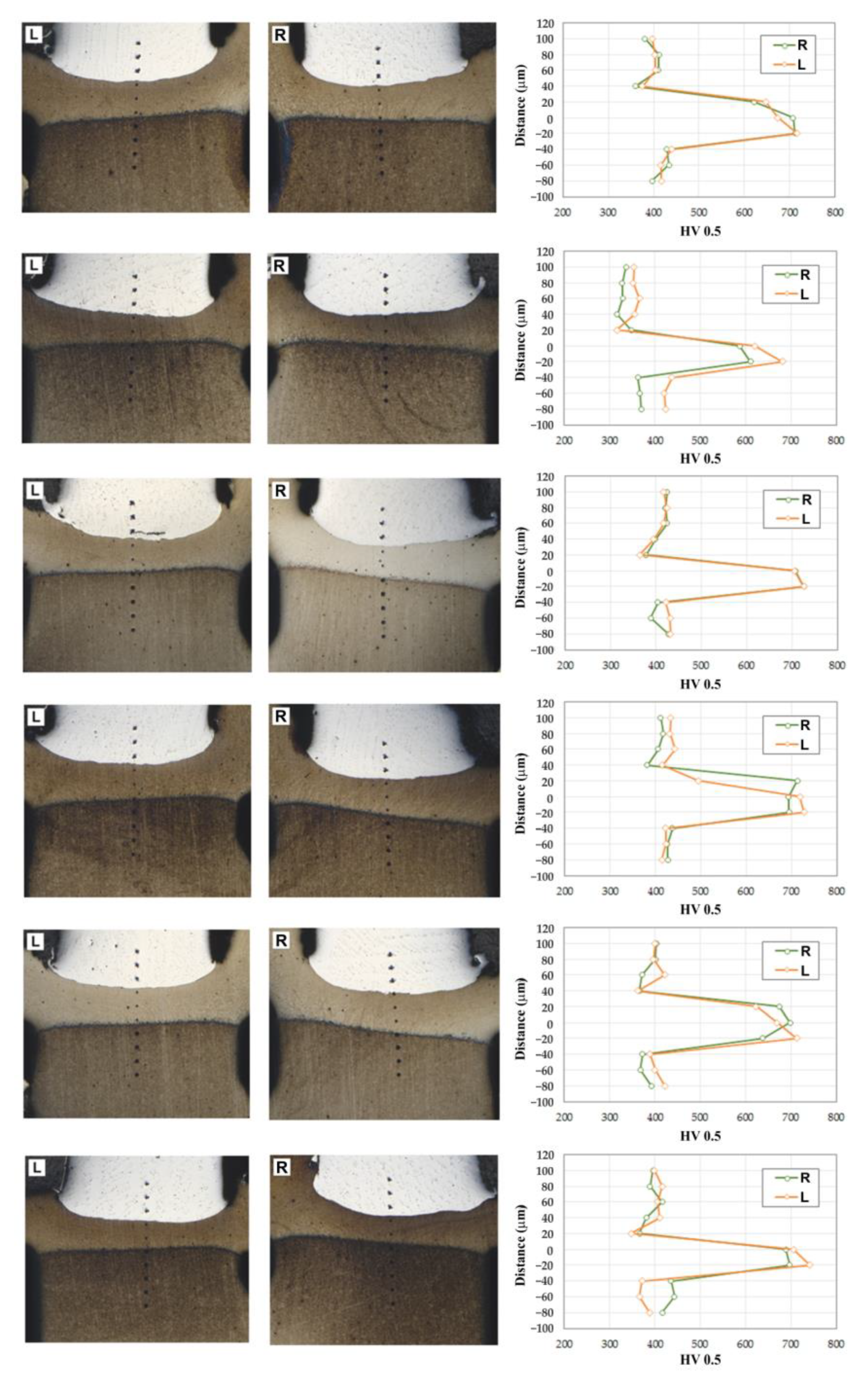

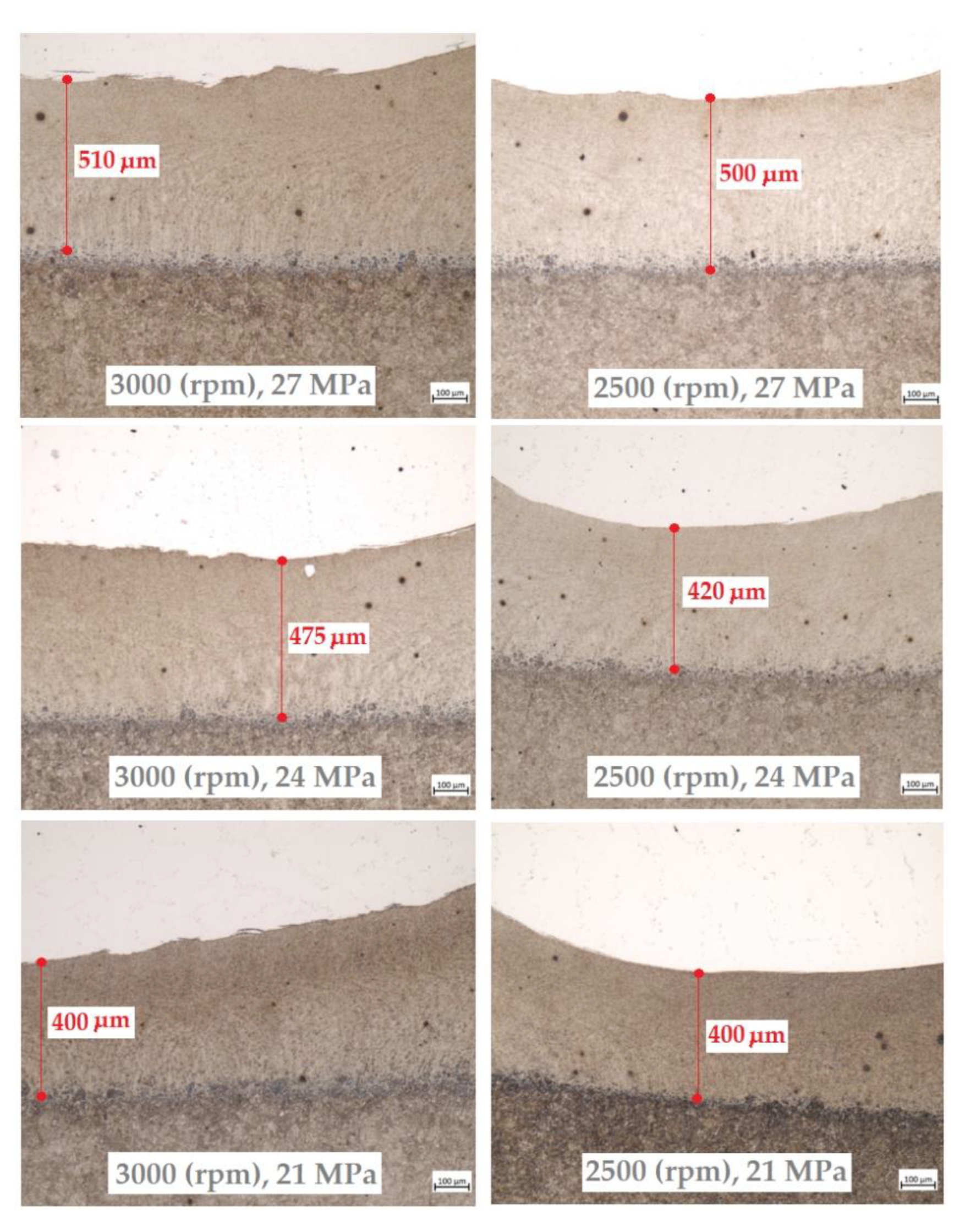

3.1. Hardness of the Joints

3.2. Tensile Strength

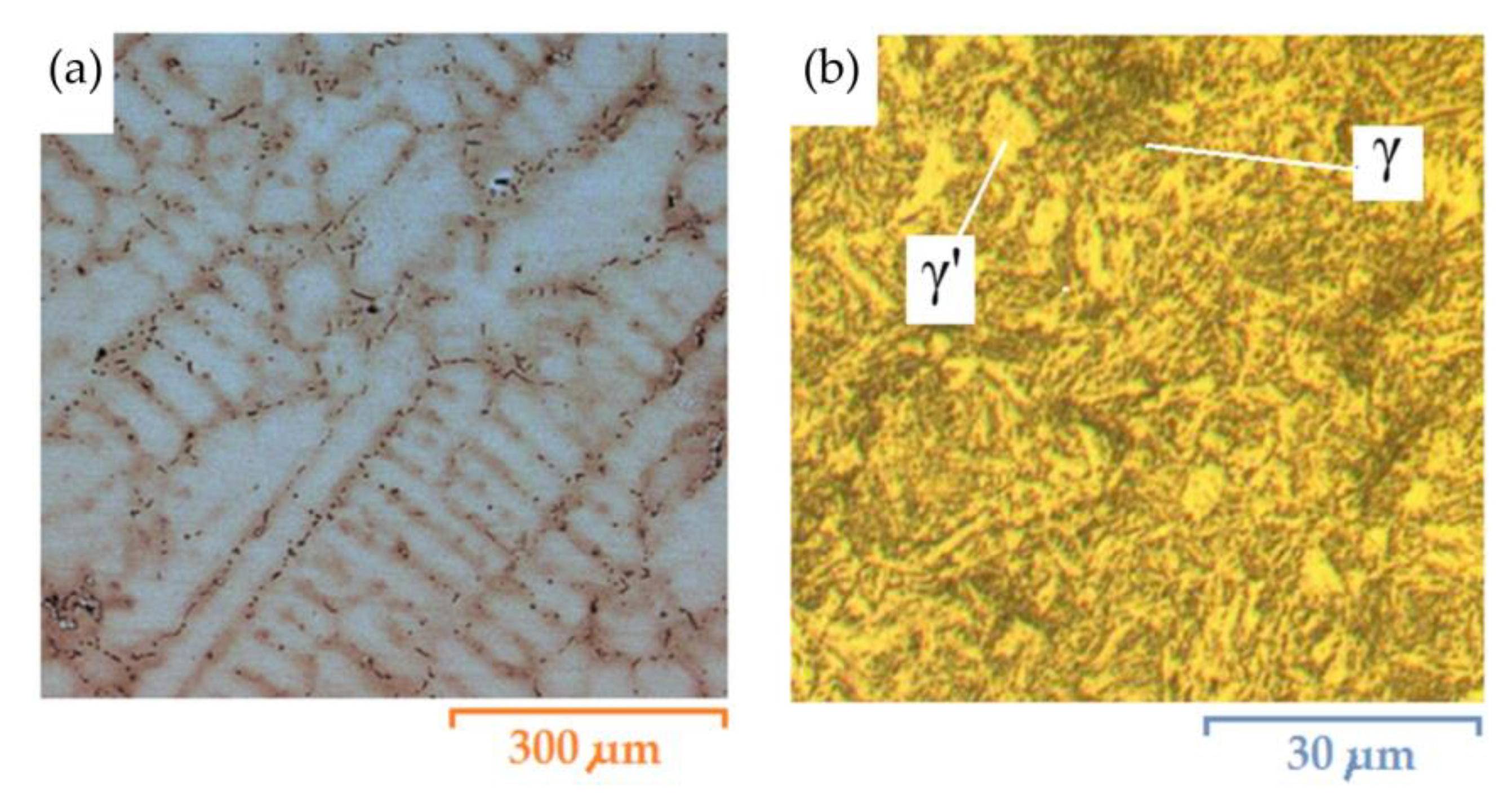

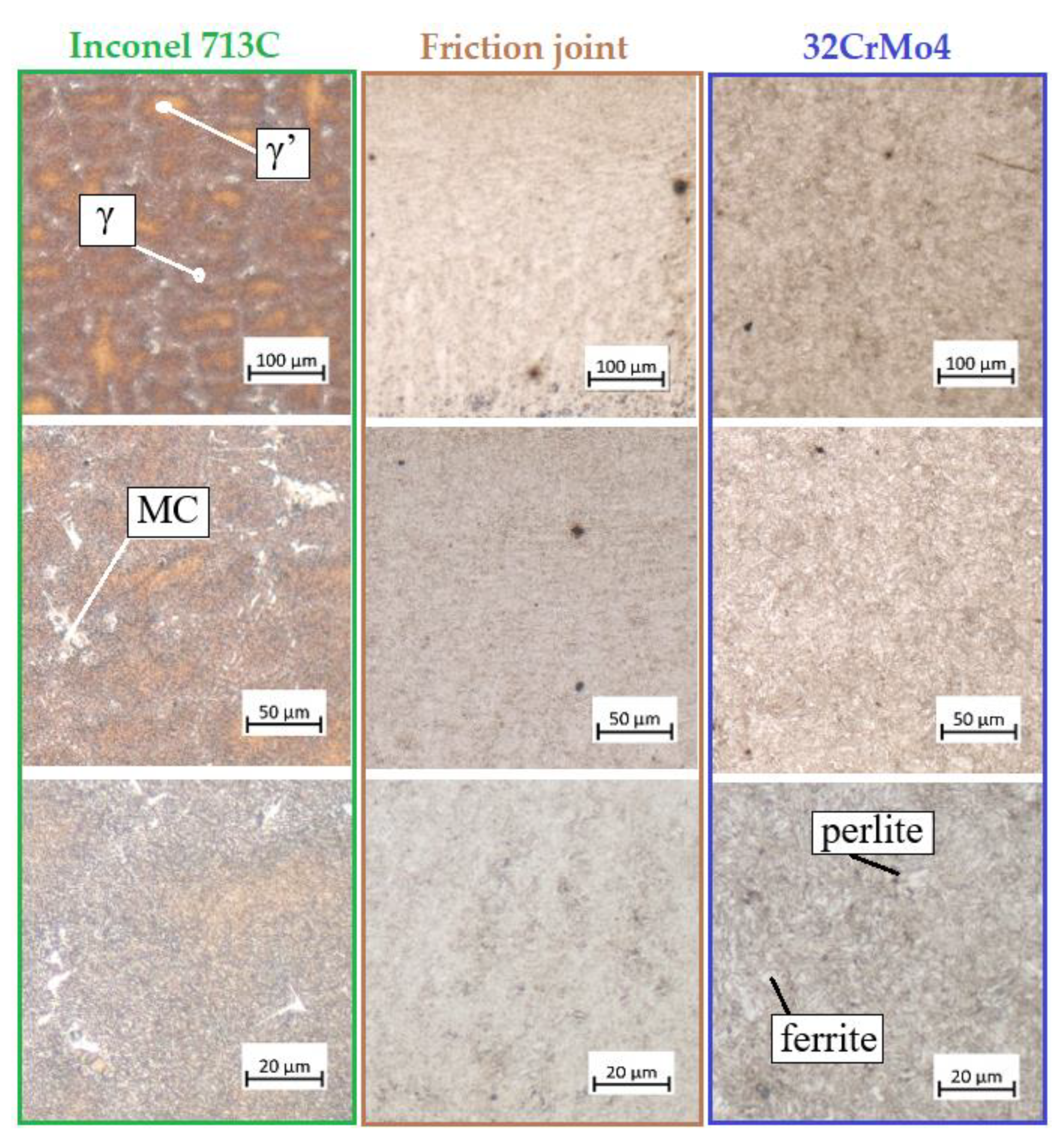

3.3. Optical Microscopy

- -

- austenitic disordered matrix γ,

- -

- ordered γ′ phase coherent with the matrix,

- -

- MC, M23C6 and M6C carbides.

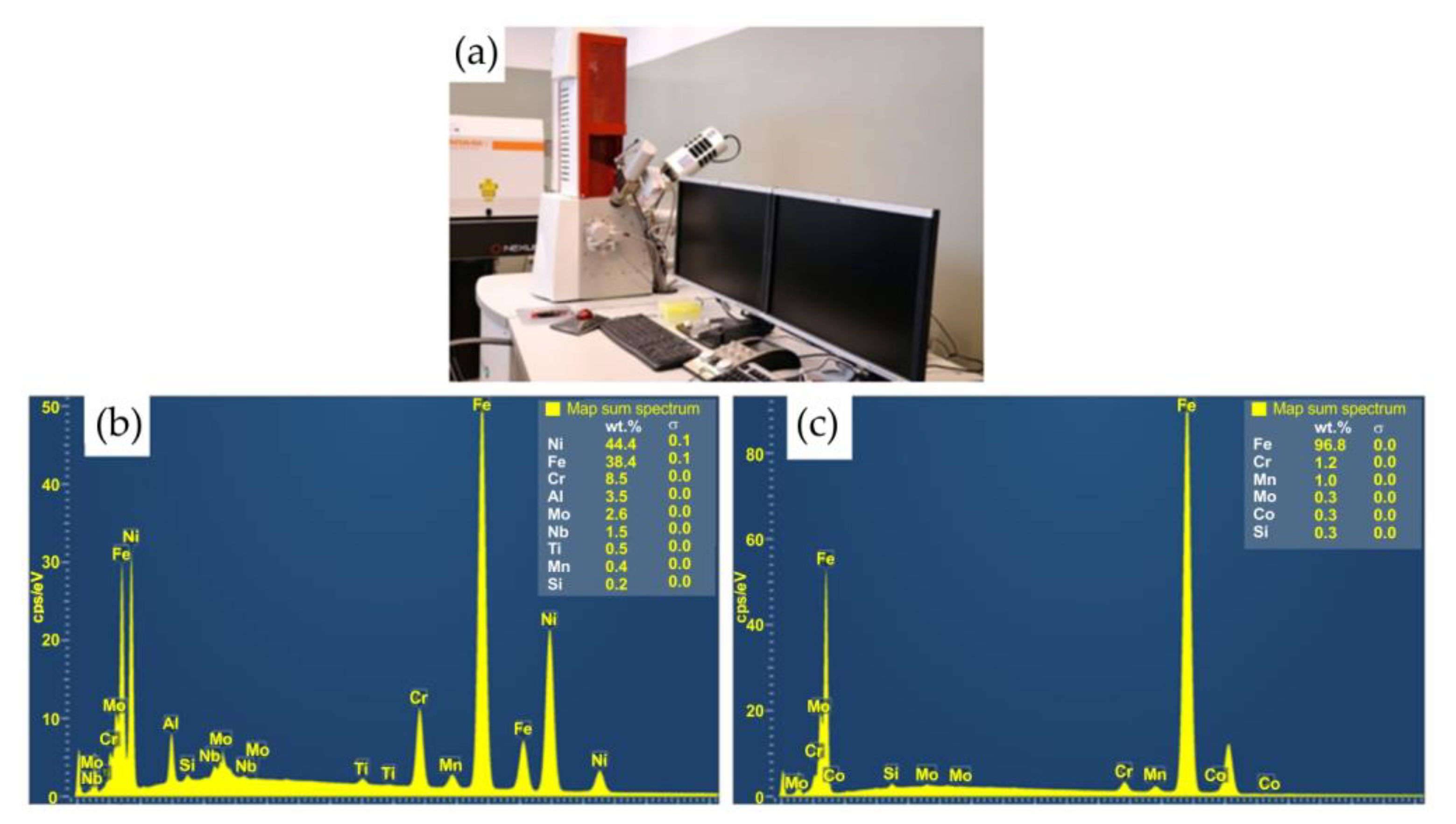

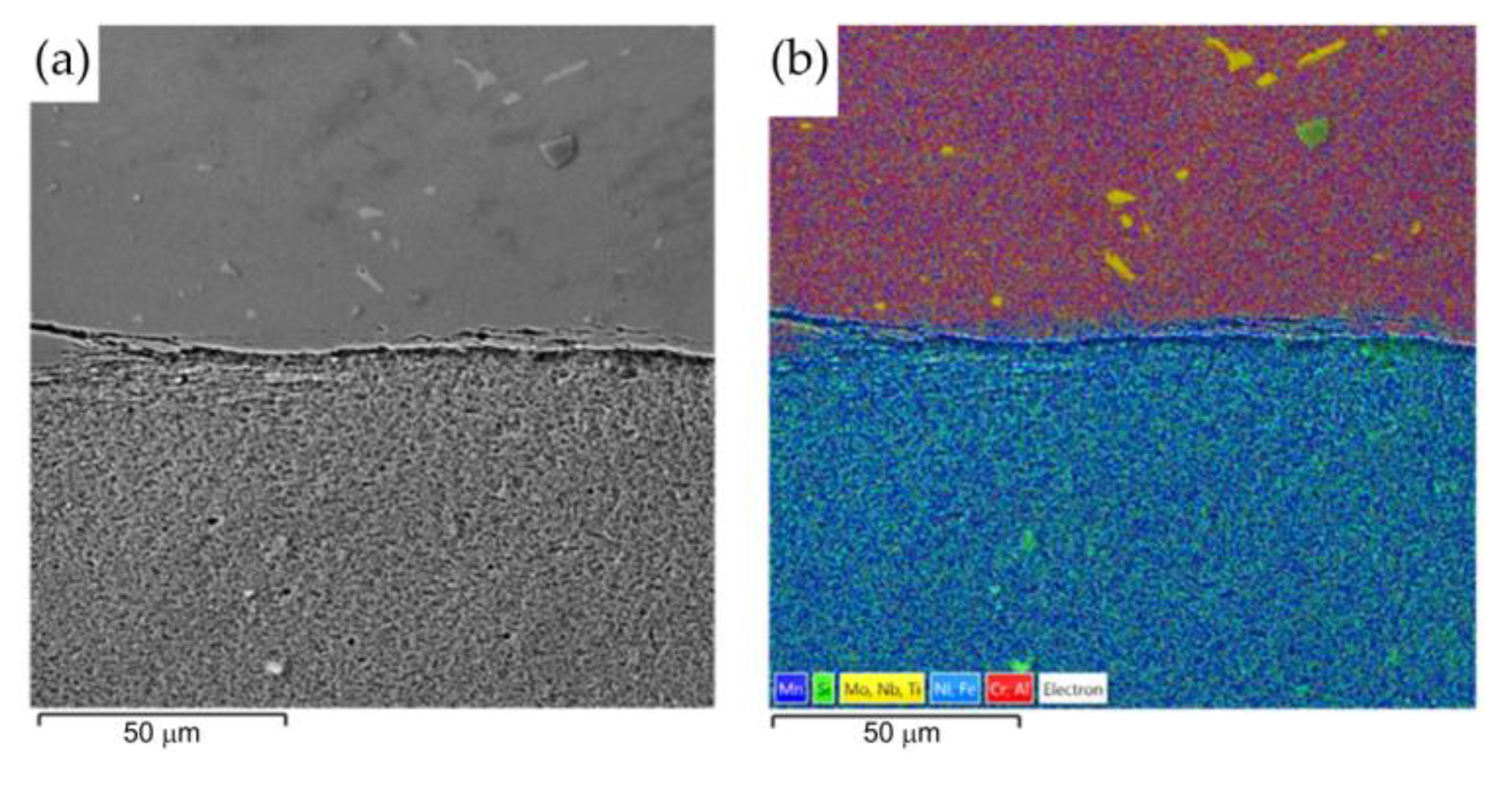

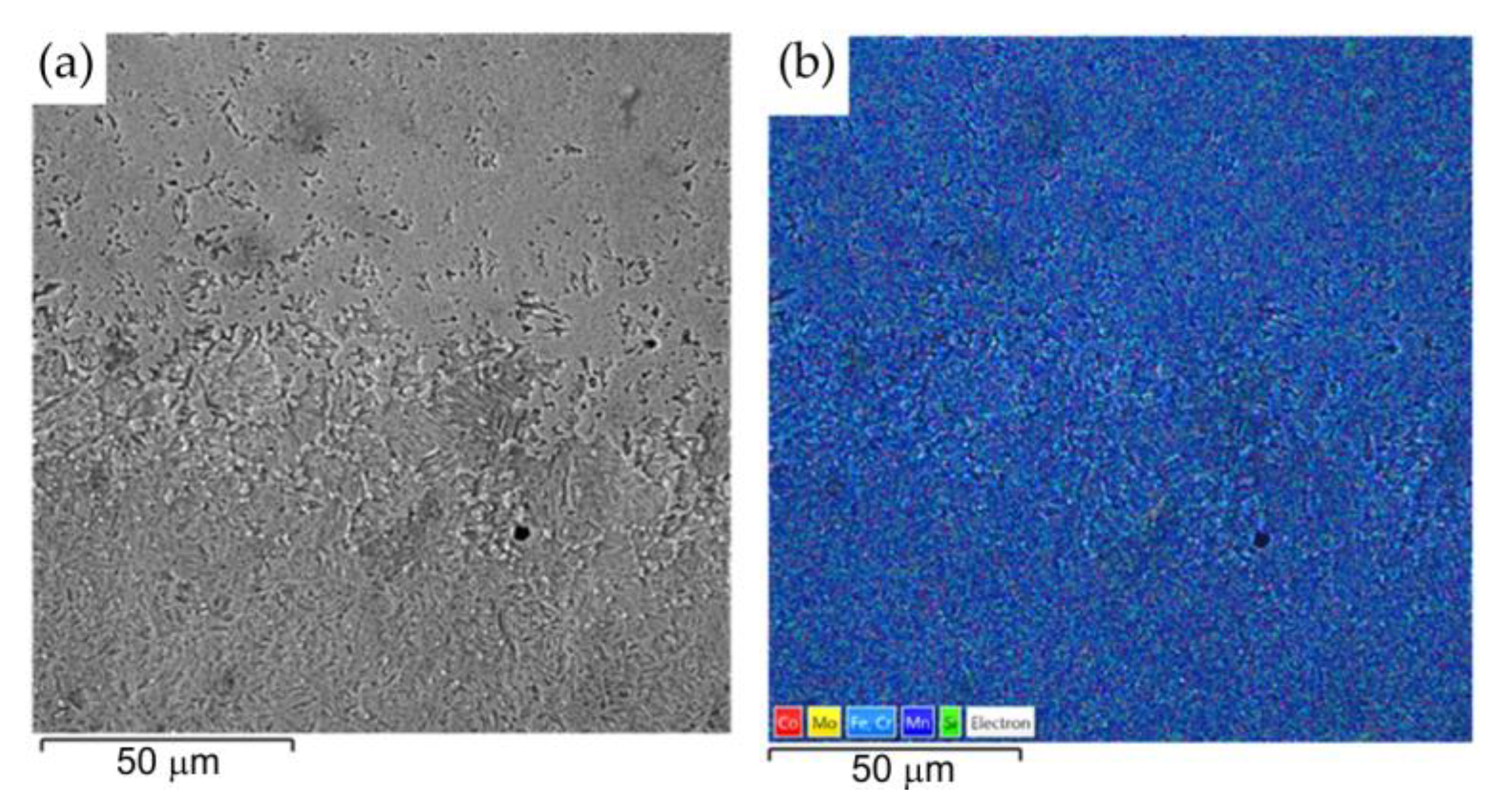

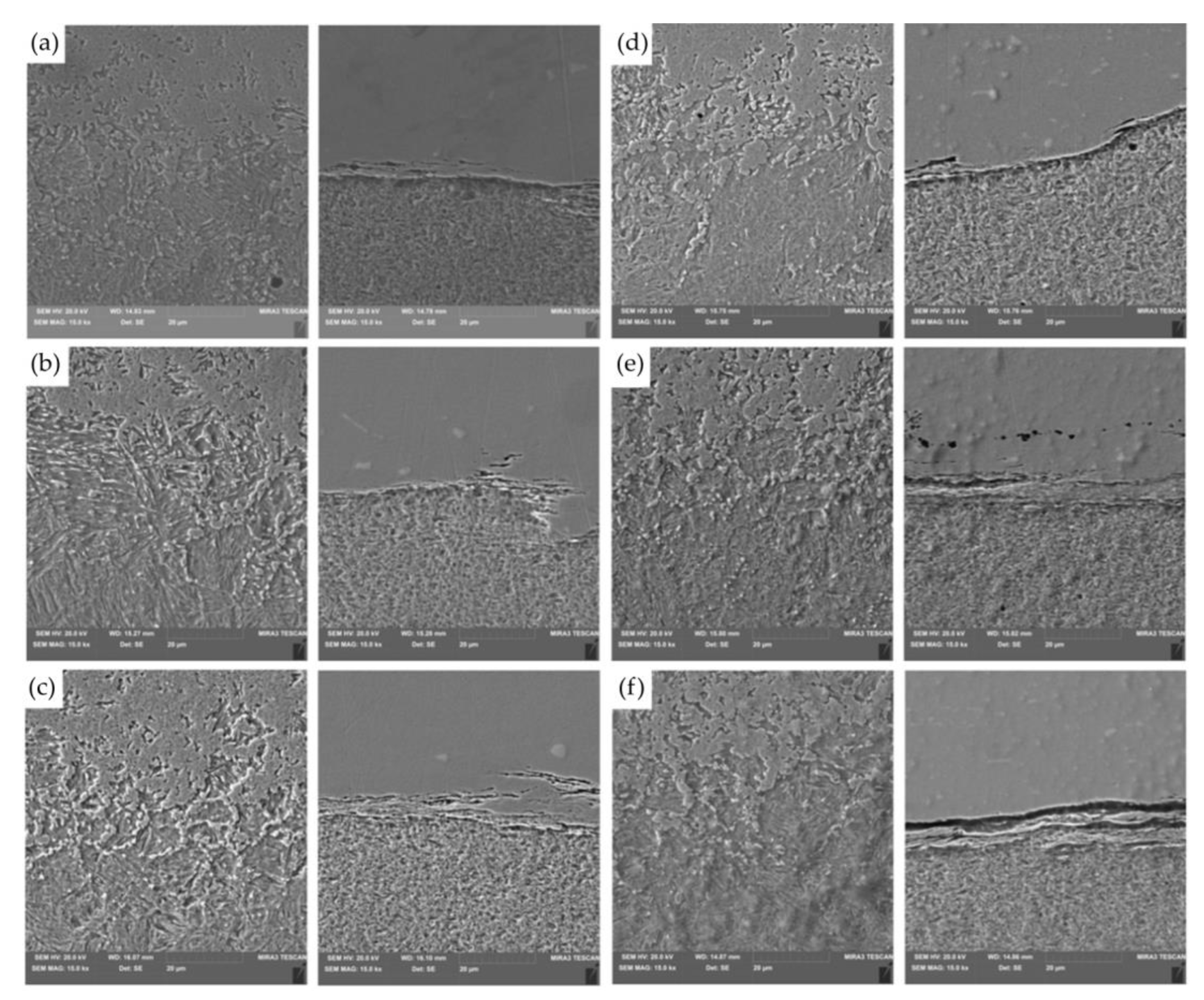

3.4. Scanning Electron Microscopy

4. Conclusions

- It is possible to conduct solid-state friction welding of an Inconel 713C and 32CrMo4 steel material pair.

- Tensile tests of the RFWed joints showed that the combination of 32CrMo4 alloy steel and Inconel 713C fully meets the minimum values assumed in the automotive industry (Rm > 760 MPa).

- The tensile strength of an RFWed joint decreases with increasing friction pressure. The fracture of the joint always occurs on the side of the 32CrMo4 material.

- An increase in the hardness value in the thermo-mechanically affected zone for the 32CrMo4 steel side was observed with increasing friction pressure.

- The highest tensile strength was obtained at a level of 1222 MPa in the friction welding experiments of sample no A (rotational speed of shaft 2500 rpm, friction pressure 21 MPa).

- SEM analysis showed carbide deposition at the grain boundaries in the thermo-mechanically affected zone on the Inconel 713C side.

- No influence of the rotational speed (in the tested range) in the friction process on the mechanical properties and microstructure of the joint was observed.

- The friction weld microstructure consisted of fine-grained, equiaxed grains formed as a result of dynamic recrystallisation. In addition, the flash was formed on the 32CrMo4 steel side.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heidarzadeh, A.; Mironov, S.; Kaibyshew, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A compre-hensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Eren, B.; Guvenc, M.A.; Mistikoglu, S. Artificial Intelligence Applications for Friction Stir Welding: A Review. Met. Mater. Int. 2021, 27, 193–219. [Google Scholar] [CrossRef]

- Mohan, D.G.; Wu, C.S. A Review on Friction Stir Welding of Steels. Chin. J. Mech. Eng. 2021, 34, 137. [Google Scholar] [CrossRef]

- Singh, R.P.; Dubey, S.; Singh, A.; Kumar, S. A review paper on friction stir welding process. Mater. Today Proc. 2021, 38, 6–11. [Google Scholar] [CrossRef]

- Vairis, A.; Papazaferiropoulos, G.; Tsainis, A.-M. A comparison between friction stir welding, linear friction welding and rotary friction welding. Adv. Manuf. 2016, 4, 296–304. [Google Scholar] [CrossRef]

- Kumar, S.; Wu, C.S. A novel technique to join Al and Mg alloys: Ultrasonic vibration assisted linear friction stir welding. Mater. Today Proc. 2018, 5, 17142–18151. [Google Scholar] [CrossRef]

- Lambiase, F.; Derazkola, H.A.; Simchi, A. Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials 2020, 13, 2291. [Google Scholar] [CrossRef] [PubMed]

- Gao, K.; Zhang, S.; Mondal, M.; Basak, S.; Hong, S.-T.; Shim, H. Friction Stir Spot Butt Welding of Dissimilar S45C Steel and 6061-T6 Aluminum Alloy. Metals 2021, 11, 1252. [Google Scholar] [CrossRef]

- Shah, L.H.; Walbridge, S.; Gerlich, A. Tool eccentricity in friction stir welding: A comprehensive review. Sci. Technol. Weld. Join. 2019, 24, 566–578. [Google Scholar] [CrossRef]

- Gebremlak, G.; Palani, S.; Sirhabizu, B.; Atnaw, S.M.; Gebremichael, E. Dissimilar friction stir welding process—A review. Ad-Vances Mater. Processing Technol. 2022, 8, 3900–3922. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, W.; Feng, J.; Lu, G.; Zhu, R.; Li, Y. A Review of the Friction Stir Welding of Dissimilar Materials between Alu-minum Alloys and Copper. Metals 2022, 12, 675. [Google Scholar] [CrossRef]

- Wang, P.Q.; Chen, D.L.; Ran, Y.; Yan, Y.Q.; She, X.W.; Peng, H.; Jiang, X.Q. Electromagnetic pulse welding of Al/Cu dissimilar materials: Microstructure and tensile properties. Mater. Sci. Eng. A 2020, 792, 139842. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.M.; Herbert, M.A.; Manjunath, P.G.C.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehen-sive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Saju, T.; Velu, M. Fracture toughness and fatigue crack growth rate studies on rotary friction weldments of nickel-based sup-eralloys. Mater. Lett. 2022, 327, 133027. [Google Scholar] [CrossRef]

- KUKA Brochure. Available online: https://www.kuka.com/-/media/kuka-downloads/imported/9cb8e311bfd744b4b0eab25ca-883f6d3/kuka_brochure_friction-welding.pdf (accessed on 8 May 2021).

- NMIS-AFRC with Rolls-Royce on the Rotary Friction Revolution. Available online: https://www.youtube.com/watch?v=v6-rBcg0sv4 (accessed on 25 August 2021).

- Cheepu, M.; Che, W.S. Effect of Burn-off Length on the Properties of Friction Welded Dissimilar Steel Bars. J. Weld. Join. 2019, 37, 40–45. [Google Scholar] [CrossRef]

- Sasmito, A.; Ilman, M.N.; Iswanto, P.T.; Muslih, R. Effect of Rotational Speed on Static and Fatigue Properties of Rotary Friction Welded Dissimilar AA7075/AA5083 Aluminium Alloy Joints. Metals 2022, 12, 99. [Google Scholar] [CrossRef]

- Cheepu, M.; Venukumar, S.; Phaninindra, K.H.; Likhith, N.; Sameer, M.; Johith, M.S.; Devuri, V.; Kantumunchu, C. Opti-mization of welding parameters for the joint interface of rotary friction welds. AIP Conf. Proc. 2022, 2648, 030035. [Google Scholar]

- Singh, C.J.; Singh, K.P.; Amit, H. Exploration of rotary friction welding technique. Stroj. Časopis-J. Mech. Eng. 2021, 71, 53–60. [Google Scholar] [CrossRef]

- Rotary Friction Welding. Available online: https://www.twi-global.com/technical-knowledge/job-knowledge/rotary-friction-welding-148 (accessed on 3 January 2023).

- Li, Z.; Zhao, S.; Li, Z.; Wang, M.; Wu, F.; Wang, H.; Zhou, J. Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy. Processes 2022, 10, 752. [Google Scholar] [CrossRef]

- Wang, K.; Wu, M.; Yan, Z.; Li, D.; Xin, R.; Liu, Q. Dynamic restoration and deformation heterogeneity during hot deformation of a duplex-structure TC21 titanium alloy. Mater. Sci. Eng. A 2018, 712, 440–452. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Peng, Y.; Ma, X. Microstructure and tensile strength of aluminum/stainless steel joint welded by inertia friction and continuous drive friction. Weld. World 2020, 64, 1799–1809. [Google Scholar] [CrossRef]

- Wen, H.Y.; You, G.Q.; Ding, Y.H.; Li, P.Q.; Tong, X.; Guo, W. Effect of Friction Pressure on Zk60/Ti Joints Formed by Inertia Friction Welding. J. Mater. Eng. Perform. 2019, 28, 7702–7709. [Google Scholar] [CrossRef]

- Nu, H.T.M.; Loc, N.H.; Minh, L.P. Influence of the rotary friction welding parameters on the microhardness and joint strength of Ti6Al4V alloys. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 795–805. [Google Scholar] [CrossRef]

- Janeczek, A.; Tomków, J.; Fydrych, D. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials 2021, 14, 3244. [Google Scholar] [CrossRef] [PubMed]

- El-Hladek, M.A. Sequential Transient Numerical Simulation of Inertia Friction Welding Process. Int. J. Comput. Methods Eng. Sci. Mech. 2009, 10, 224–230. [Google Scholar] [CrossRef]

- Skowrońska, B.; Bober, M.; Kołodziejczak, P.; Baranowski, M.; Kozłowski, M.; Chmielewski, T. Solid-State Rotary Friction-Welded Tungsten and Mild Steel Joints. Appl. Sci. 2022, 12, 9034. [Google Scholar] [CrossRef]

- Xie, M.; Shang, X.; Li, Y.; Zhang, Z.; Zhu, M.; Xiong, J. Rotary Friction Welding of Molybdenum without Upset Forging. Materials 2020, 13, 1957. [Google Scholar] [CrossRef]

- Kwiatkowski, M.; Zaba, K.; Nowosielski, M.; Pociecha, D.; Tokarski, T.; Kita, P. Temperature Measurement in the Rotary Forming Process of a Nickel Superalloys (INCONEL) Sheet during Induction Heating. Key Eng. Mater. 2014, 622–623, 823–830. [Google Scholar] [CrossRef]

- Żaba, K.; Puchlerska, S.; Kwiatkowski, M.; Nowosielski, M.; Głodzik, M.; Tokarski, T.; Seibt, P. Comparative analysis of properties and microstructure of the plastically deformed alloy Inconel®718, manufactured by plastic working and Direct Metal Laser Sintering. Arch. Metall. Mater. 2016, 61, 143–148. [Google Scholar] [CrossRef]

- Sirohi, S.; Pandey, S.M.; Świerczyńska, A.; Rogalski, G.; Kumar, N.; Landowski, M.; Fydrych, D.; Pandey, C. Microstructure and Mechanical Properties of Combined GTAW and SMAW Dissimilar Welded Joints between Inconel 718 and 304L Austenitic Stainless Steel. Metals 2023, 13, 14. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kishore Babu, N.; Talari, M.K.; Anwar, S.; Usmani, Y.; Al-Samhan, A.M. Dissimilar Rotary Friction Welding of Inconel 718 to F22 Using Inconel 625 Interlayer. Appl. Sci. 2021, 11, 10684. [Google Scholar] [CrossRef]

- Firmanto, H.; Candra, S.; Hadiyat, M.A.; Triastomo, Y.P.; Wirawan, I. Tensile Strength and Microstructure of Rotary-Friction-Welded Carbon-Steel and Stainless-Steel Joints. J. Manuf. Mater. Process. 2023, 7, 7. [Google Scholar] [CrossRef]

- Rehman, A.U.; Usmani, Y.; Al-Samhan, A.M.; Anwar, S. Rotary Friction Welding of Inconel 718 to Inconel 600. Metals 2021, 11, 244. [Google Scholar] [CrossRef]

- Damodaram, R.; Raman, S.G.S.; Rao, K.P. Microstructure and mechanical properties of friction welded alloy 718. Mater. Sci. Eng. A 2013, 560, 781–786. [Google Scholar] [CrossRef]

- Kong, Y.S.; Cheepu, M.; Kim, D.G. Microstructure and Mechanical Properties of Friction-Welded and Post-Heat-Treated In-conel 718. Trans. Indian Inst. Met. 2020, 73, 1449–1453. [Google Scholar] [CrossRef]

- Gaikwad, V.T.; Mishra, M.K.; Hiwarkar, V.D.; Singh, R.K.P. Microstructure and mechanical properties of friction welded carbon steel (EN24) and nickel-based superalloy (IN718). Int. J. Miner. Met. Mater. 2021, 28, 111–119. [Google Scholar] [CrossRef]

- Demouche, M.; Ouakdi, E.H.; Louahdi, R. Effect of Welding Parameters on the Microstructure and Mechanical Properties of Friction-Welded Joints of 100Cr6 Steel. J. Inf. 2019, 16, 24–31. [Google Scholar] [CrossRef]

- Madhusudhan, R.G.; Venkata, R.P. Role of nickel as an interlayer in dissimilar metal friction welding of maraging steel to low alloy steel. J. Mat. Proc. Tech. 2012, 212, 66–77. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Xiong, J.; Zhou, W.; Zhang, F. Study on microstructure evolution of AISI 304 stainless steel joined by rotary friction welding. Weld. World 2018, 62, 1187–1193. [Google Scholar] [CrossRef]

- Taysom, B.S.; Sorensen, C.D.; Nelson, T.W. Strength in Rotary Friction Welding of Five Dissimilar Nickel-Based Superalloys. Weld. J. 2021, 100, 300–308. [Google Scholar] [CrossRef]

- Cheepu, M.; Cheepu, H.; Karpagaraj, A.; Che, W.S. Influence of joint interface on mechanical properties in dissimilar friction welds. Adv. Mater. Process. Technol. 2022, 8, 732–744. [Google Scholar] [CrossRef]

- Cheepu, M.; Ashfaq, M.; Muthupandi, V. A New Approach for Using Interlayer and Analysis of the Friction Welding of Titanium to Stainless Steel. Trans. Indian Inst. Met. 2017, 70, 2591–2600. [Google Scholar] [CrossRef]

- Cheepu, M.; Susila, P. Growth rate of intermetallics in aluminium to copper dissimilar welding. Trans. Indian Inst. Met. 2020, 73, 1509–1514. [Google Scholar] [CrossRef]

- Cheepu, M.; Che, W.S. Influence of Friction Pressure on Microstructure and Joining Phenomena of Dissimilar Joints. Trans. Indian Inst. Met. 2020, 73, 1455–1460. [Google Scholar] [CrossRef]

- Cheepu, M.; Susila, P. Interface microstructure characteristics of friction welded joint of titanium to stainless steel with inter-layer. Trans. Indian Inst. Met. 2020, 73, 1497–1501. [Google Scholar] [CrossRef]

- Abhijith, B.; Reddy, A.C. Effect of Inter Layer on Penetration, Sliding and Sticking Characteristics in Rotary Friction Welding of Inconel 600 and SS 304 Dissimilar Materials. Int. J. Eng. Invent. 2017, 6, 32–39. [Google Scholar]

- Kong, Y.S.; Cheepu, M.; Lee, J.-K. Evaluation of the mechanical properties of Inconel 718 to SCM 440 dissimilar friction welding through real-time monitoring of the acoustic emission system. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1181–1190. [Google Scholar] [CrossRef]

- Cheepu, M.; Muthupandi, V.; Che, W.S. Interface Microstructural Characterization of Titanium to Stainless Steel Dissimilar Friction Welds. In Proceedings of the TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings, San Antonio, TX, USA, 10–14 March 2019; Springer: Cham, Swizterland, 2019; pp. 259–268. [Google Scholar]

- Kong, Y.-S.; Park, Y.W. Optimization of PWHT on Dissimilar Friction Welding for Piping Material of A105 to A312. J. Weld. Join. 2019, 37, 60–65. [Google Scholar] [CrossRef] [Green Version]

| C | Si | Mn | P | S | Cr | Mo | Cu |

|---|---|---|---|---|---|---|---|

| 0.41 | 0.35 | 0.85 | 0.015 | 0.025 | 1.15 | 0.25 | 0.15 |

| Ni | Cr | Al | Mo | Nb | Zr | W | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| 70.30 | 13.20 | 5.8 | 4.4 | 2.1 | 0.04 | 0.30 | 0.47 | 0.15 |

| Sample | Rotational Speed of Shaft (rpm) | Friction Pressure (MPa) | Friction Time (s) |

|---|---|---|---|

| A | 2500 | 21 | 4 |

| B | 3000 | 21 | 4 |

| C | 2500 | 24 | 4 |

| D | 3000 | 24 | 4 |

| E | 2500 | 27 | 4 |

| F | 3000 | 27 | 4 |

| Rotational Speed of Shaft (rpm) | Friction Pressure (MPa) | Tensile Strength Rm (MPa) |

|---|---|---|

| 2500 | 21 | 1222 |

| 3000 | 21 | 1207 |

| 2500 | 24 | 1106 |

| 3000 | 24 | 1095 |

| 2500 | 27 | 1057 |

| 3000 | 27 | 1028 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwajka, K.; Zielińska-Szwajka, J.; Trzepieciński, T. Microstructure and Mechanical Properties of Solid-State Rotary Friction Welded Inconel 713C and 32CrMo4 Steel Joints Used in a Turbocharger Rotor. Materials 2023, 16, 2273. https://doi.org/10.3390/ma16062273

Szwajka K, Zielińska-Szwajka J, Trzepieciński T. Microstructure and Mechanical Properties of Solid-State Rotary Friction Welded Inconel 713C and 32CrMo4 Steel Joints Used in a Turbocharger Rotor. Materials. 2023; 16(6):2273. https://doi.org/10.3390/ma16062273

Chicago/Turabian StyleSzwajka, Krzysztof, Joanna Zielińska-Szwajka, and Tomasz Trzepieciński. 2023. "Microstructure and Mechanical Properties of Solid-State Rotary Friction Welded Inconel 713C and 32CrMo4 Steel Joints Used in a Turbocharger Rotor" Materials 16, no. 6: 2273. https://doi.org/10.3390/ma16062273

APA StyleSzwajka, K., Zielińska-Szwajka, J., & Trzepieciński, T. (2023). Microstructure and Mechanical Properties of Solid-State Rotary Friction Welded Inconel 713C and 32CrMo4 Steel Joints Used in a Turbocharger Rotor. Materials, 16(6), 2273. https://doi.org/10.3390/ma16062273