Study on the Evolution of Physical Parameters and Dynamic Compression Mechanical Properties of Granite after Different Heating and Cooling Cycles

Abstract

:1. Introduction

2. Specimen Preparation and Experimental Process

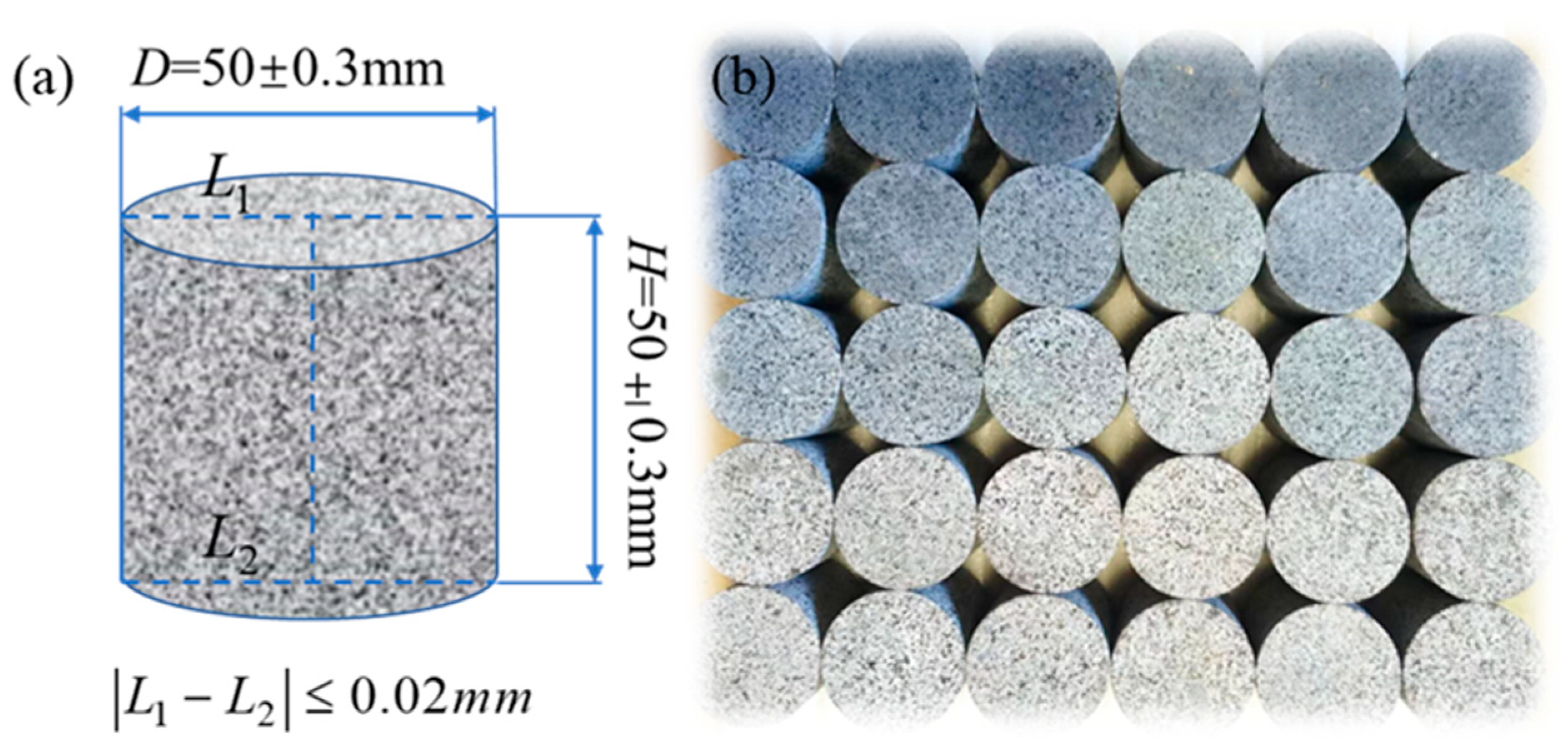

2.1. Preparation of Rock Specimens

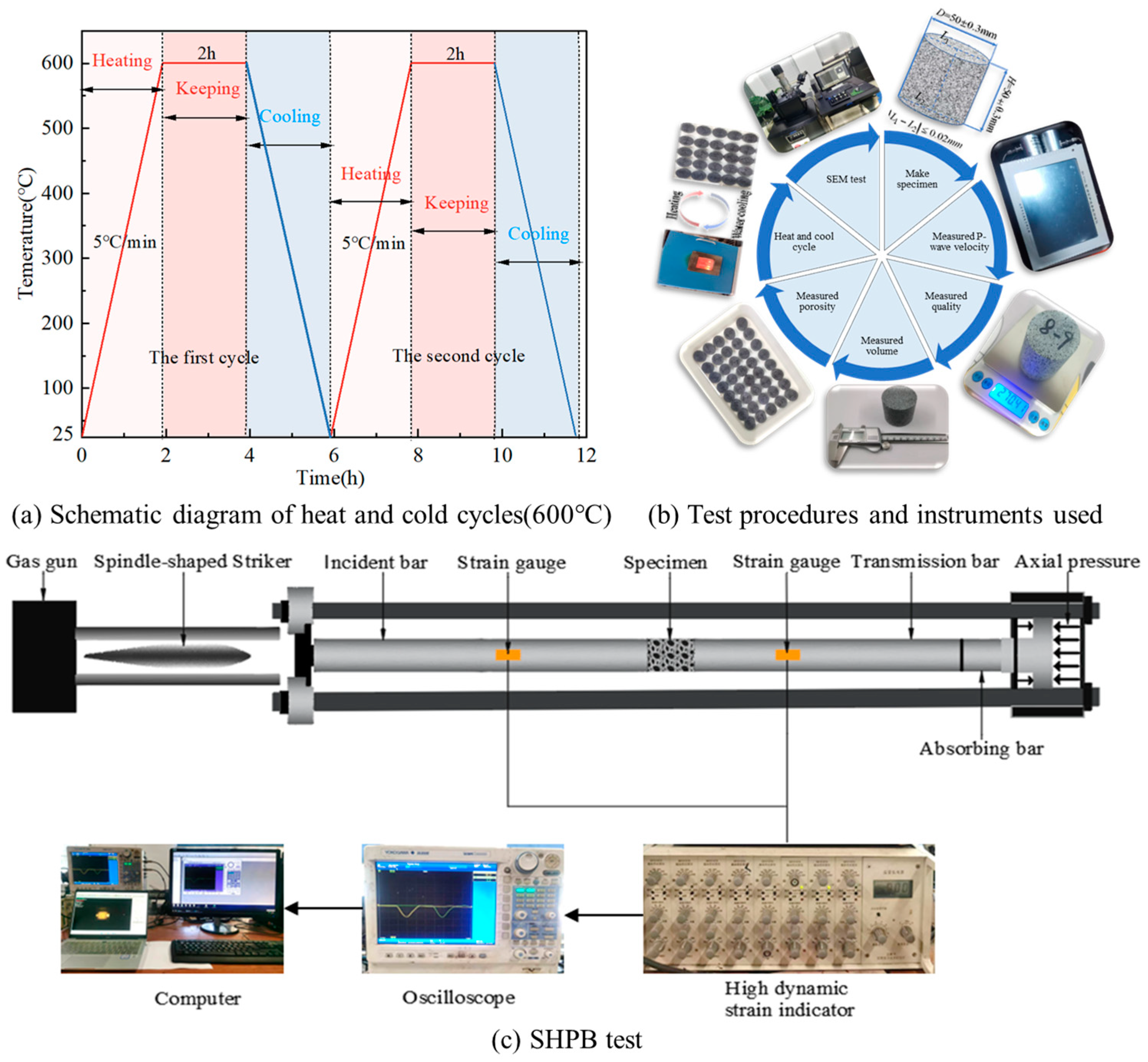

2.2. Experimental Process

2.3. Introduction of SHPB Test System

3. Evolutionary Patterns of Basic Physical Parameters of Granite

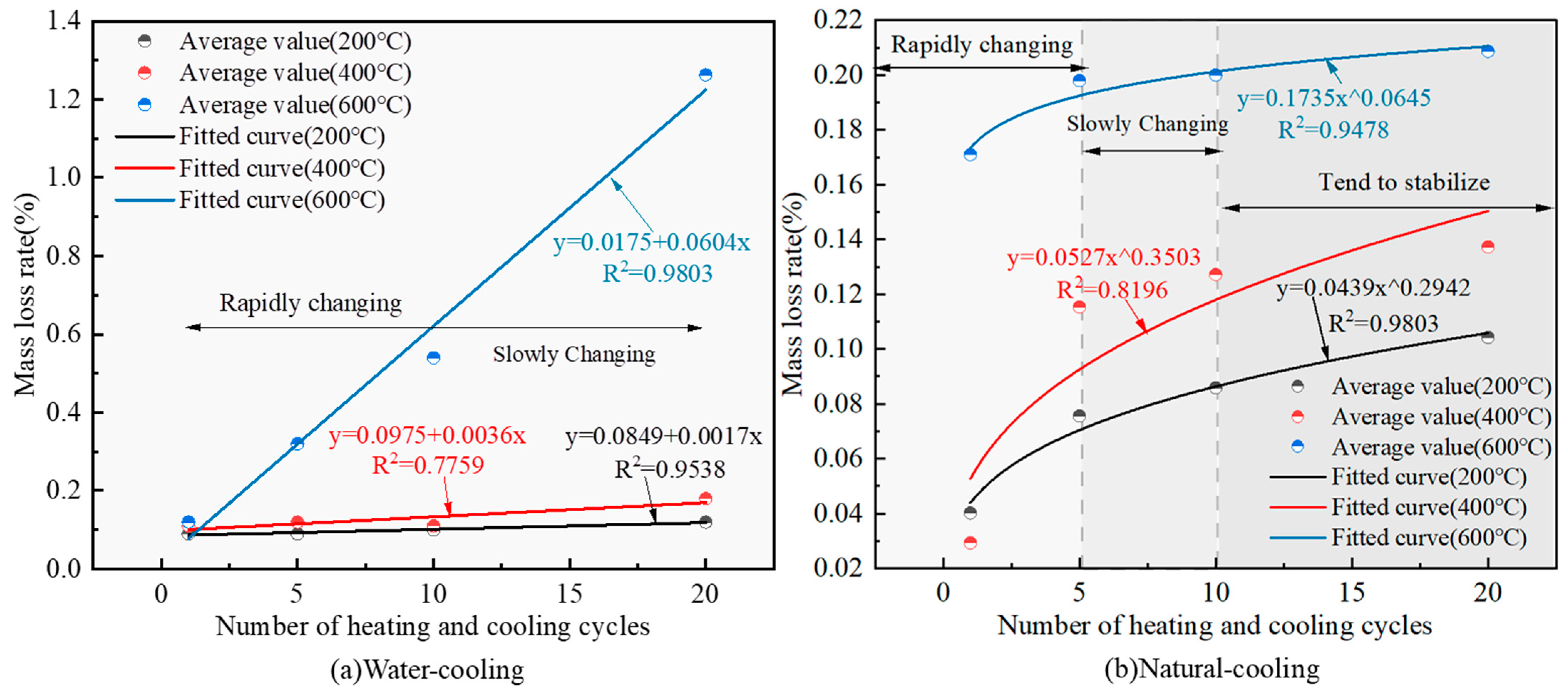

3.1. Mass Variation Pattern

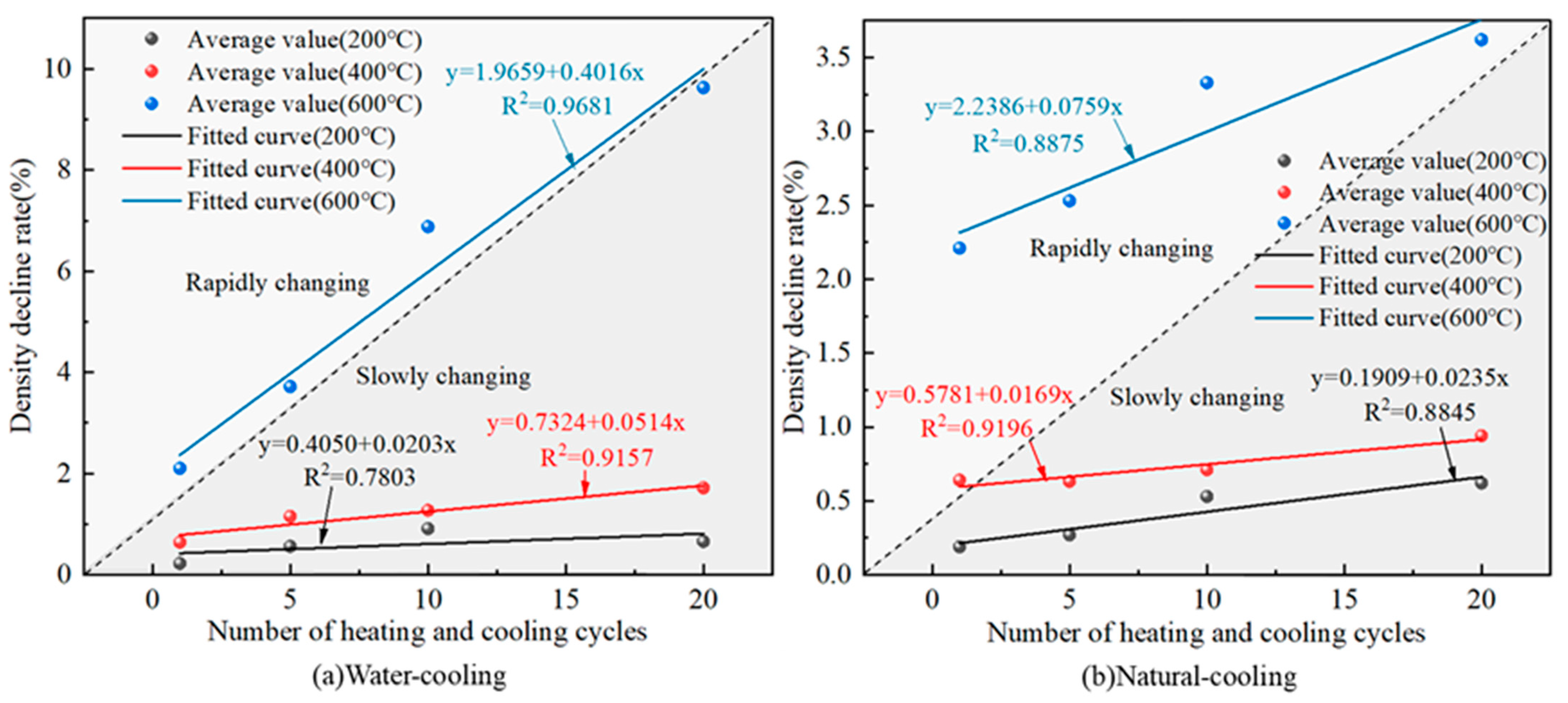

3.2. Density Variation Pattern

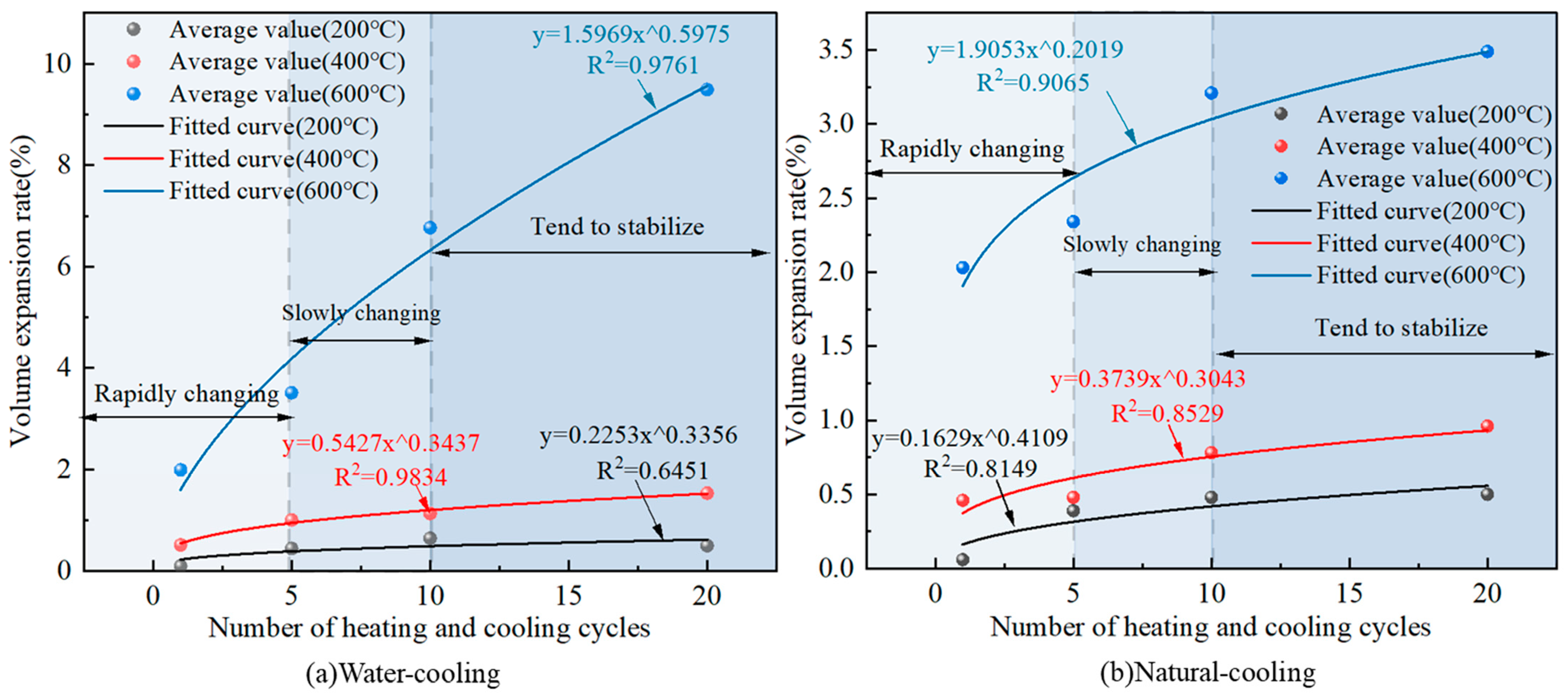

3.3. Volume Variation Pattern

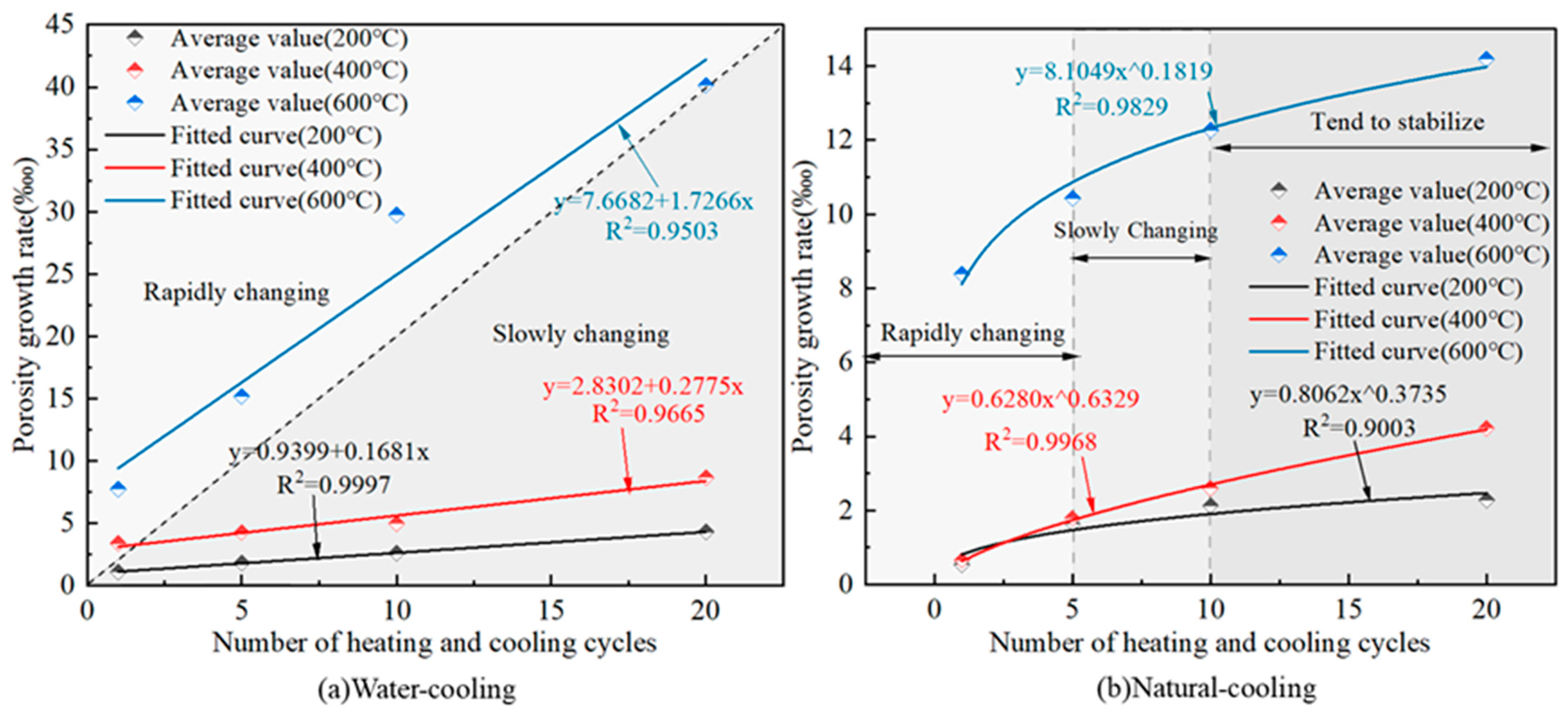

3.4. Porosity Variation Pattern

3.5. P-Wave Speed Variation Pattern

3.6. Granite Surface Color Variation Pattern

3.7. Granite Microstructure Variation Pattern

4. Dynamic Compression Properties of Granite after Heating-Cooling Cycle

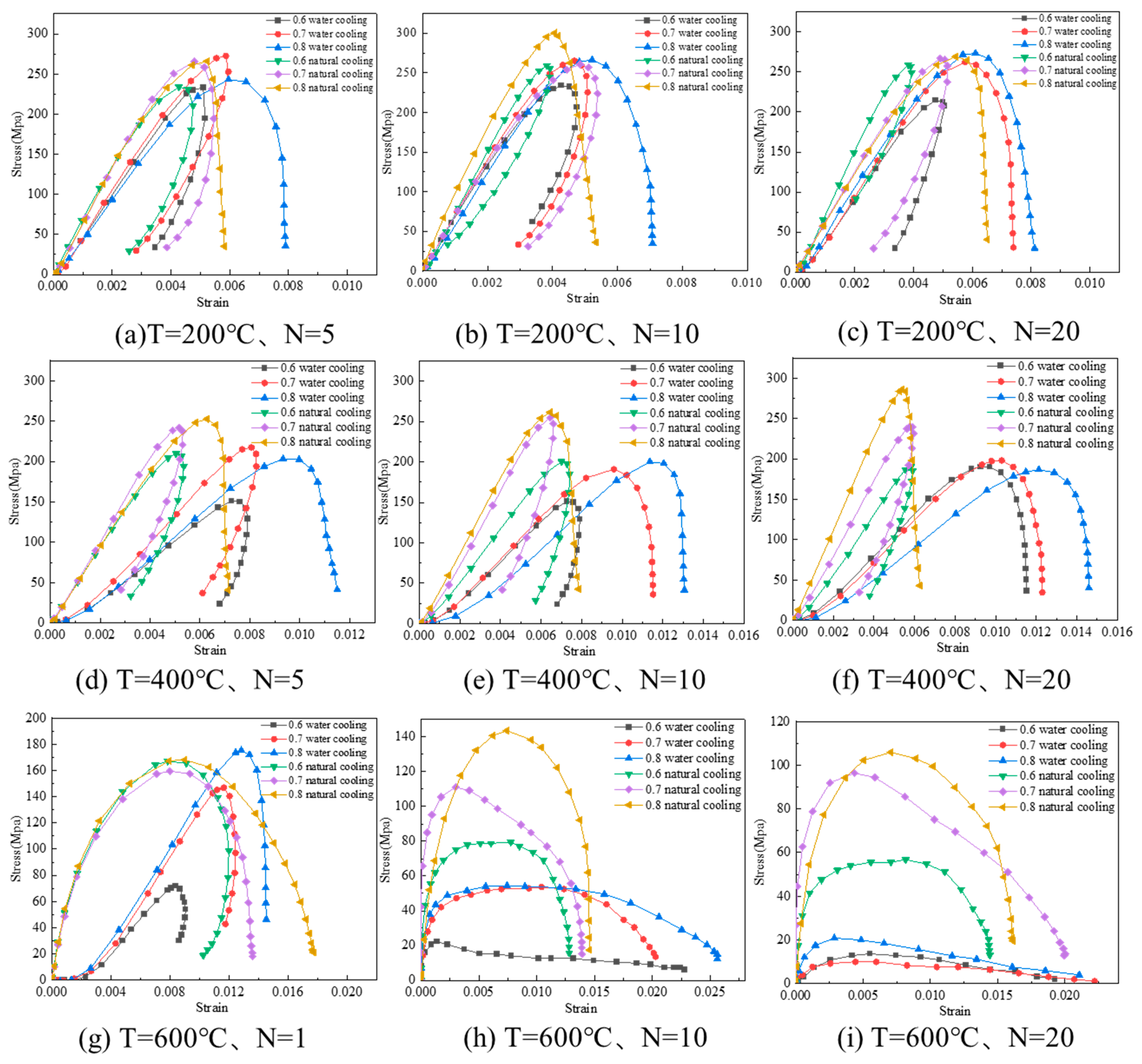

4.1. Dynamic Stress-Strain Curve of Granite

4.2. Dynamic Compression Strength Variation Law of Granite

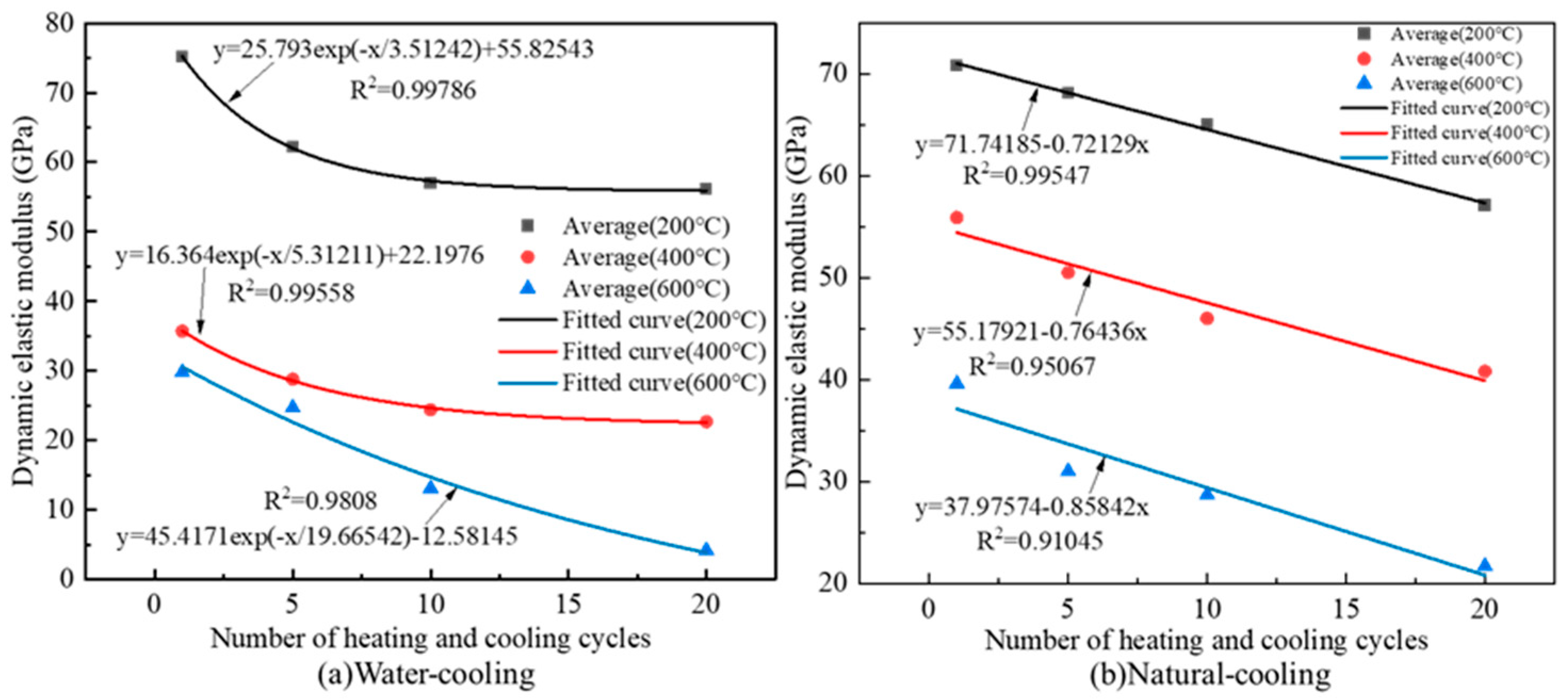

4.3. Dynamic Modulus of Elastic Change Law of Granite

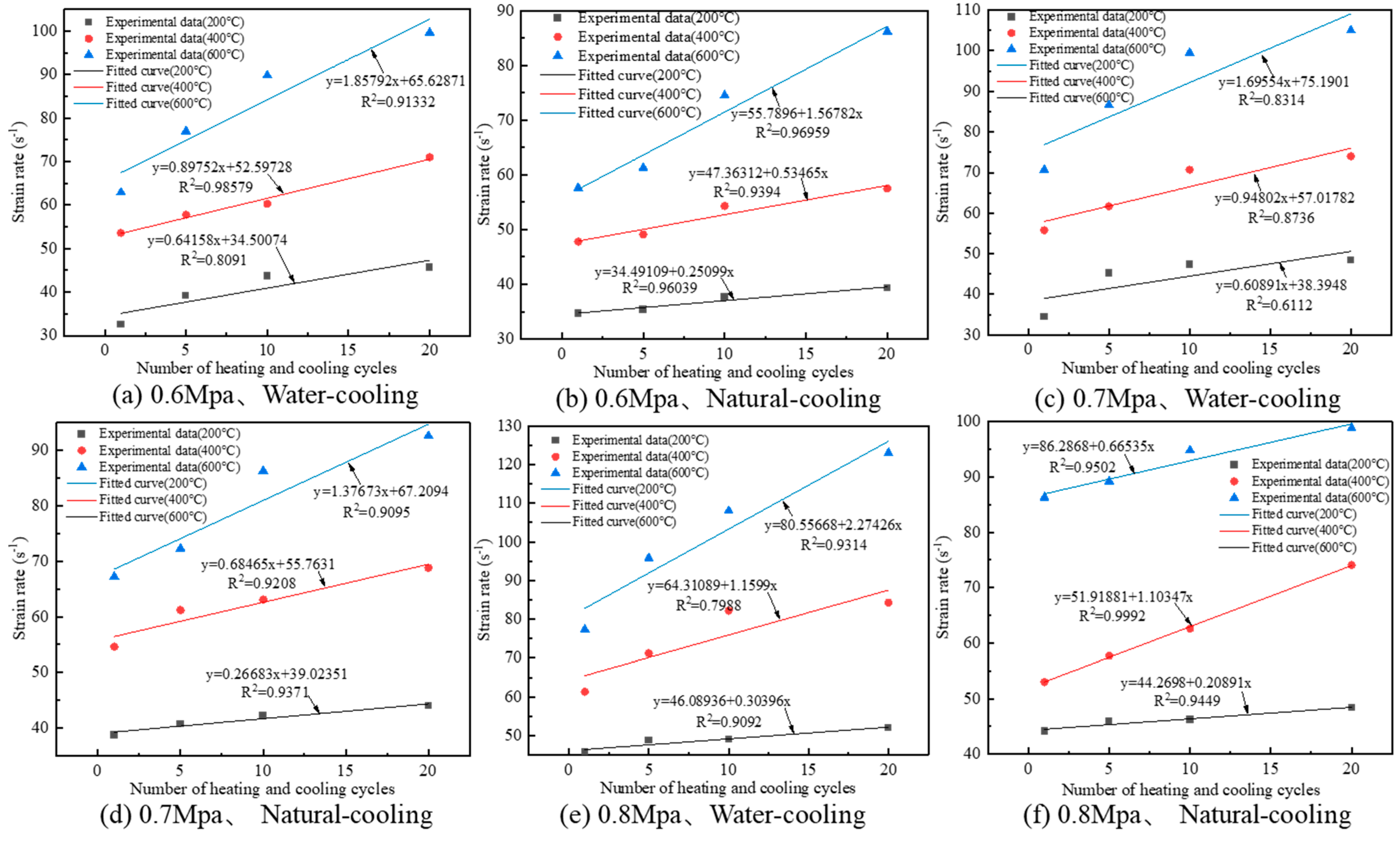

4.4. Granite Strain Rate Variation Pattern

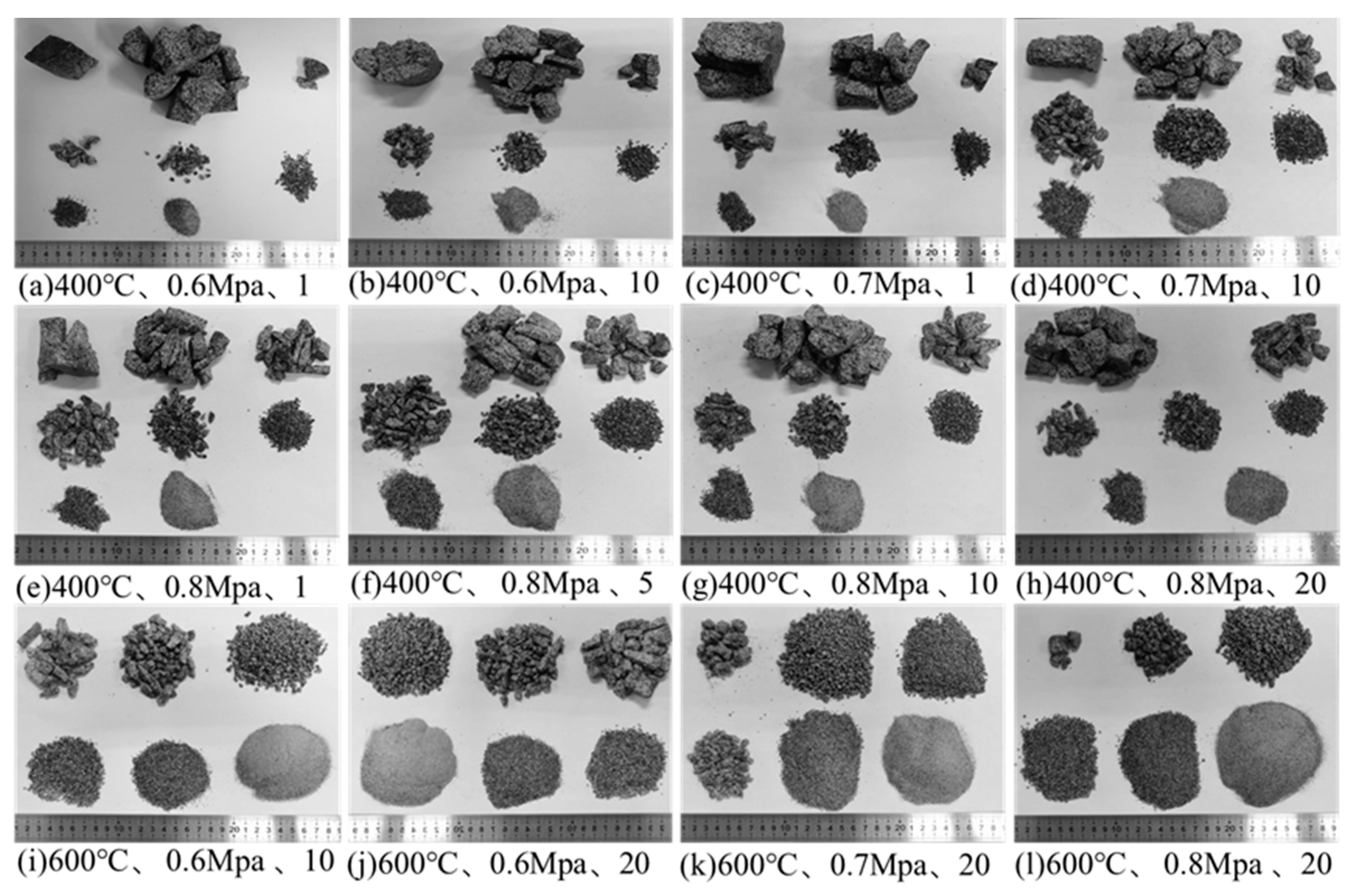

4.5. Granite Dynamic Crushing Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| SEM | Scanning electron microscope; |

| D | Diameter of granite specimen, mm; |

| SHPB | Split Hopkinson pressure bar; |

| L1, L2 | Horizontal distance from the upper and lower boundaries of the granite specimen to the central axis; |

| ,,,, | Granite mass, volume, density, porosity, p-wave velocity variation rate. |

| N | Number of heating and cooling cycles |

| ,, | Dynamic compression strength, dynamic elastic modulus, strain rate |

References

- Shao, S.; Wasantha, P.L.P.; Ranjith, P.G.; Chen, B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Chen, S.; Yang, C.; Wang, G. Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng. 2017, 110, 1533–1542. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yin, T. Effect of microwave heating on fracture behavior of granite: An experimental investigation. Eng. Fract. Mech. 2021, 250, 107758. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, L.; Chen, J.; Liu, Z.; Geng, Y. Dynamic mechanical behavior and macroscopic and microscopic characteristics of granites subject to heating treatment. Arab. J. Geosci. 2023, 16, 112. [Google Scholar] [CrossRef]

- Zhen, L.; Hong, W.; Jiang, Y.; Xin, S.; Yuan, G.; Qian, Y. Experimental investigation on damage characteristics and fracture behaviors of granite after high temperature exposure under different strain rates. Theor. Appl. Fract. Mech. 2020, 110, 102823. [Google Scholar]

- Yin, T.; Yang, Z.; Yin, J. Effect of open fire on dynamic compression mechanical behavior of granite under different strain rates. Arab. J. Geosci. 2021, 14, 2144. [Google Scholar] [CrossRef]

- Yin, T.; Chen, Y.; Li, X.; Li, Q. Effect of high temperature and strain rate on the elastic modulus of rocks: A review. Int. J. Earth Sci. 2021, 110, 2639–2660. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Wang, C.; Meng, F.; Lu, M. Mechanical properties of Beishan granite under complex dynamic loads after thermal treatment. Eng. Geol. 2020, 267, 105481. [Google Scholar] [CrossRef]

- Qiang, S.; Jh, D. Effects of heating on some physical properties of granite, Shandong, China. J. Appl. Geophys. 2021, 193, 104410. [Google Scholar]

- Xu, J.J.; Zhang, Y.H.; Rutqvist, J.; Hu, M.S.; Wang, Z.Z.; Tang, X.H. Thermally induced microcracks in granite and their effect on the macroscale mechanical behavior. J. Geophys. Res. Solid Earth 2023, 128, e2022JB024920. [Google Scholar] [CrossRef]

- Zhou, X.P.; Li, G.Q.; Ma, H.C. Real-time experiment investigations on the coupled thermomechanical and cracking behaviors in granite containing three pre-existing fissures. Eng. Fract. Mech. 2019, 224, 106797. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, M.; Lei, Z.; Chen, Y. A Multi-Scale Study on the Property Degradation of High-Temperature Treated Beishan Granite. Minerals 2022, 13, 27. [Google Scholar] [CrossRef]

- Hao, J.; Qiao, L.; Li, Q. Study on cross-scale pores fractal characteristics of granite after high temperature and rock failure precursor under uniaxial compression. Powder Technol. 2022, 401, 117330. [Google Scholar] [CrossRef]

- Ding, Q.-L.; Wang, P.; Cheng, Z. Influence of temperature and confining pressure on the mechanical properties of granite. Powder Technol. 2021, 394, 10–19. [Google Scholar] [CrossRef]

- Wang, F.; Konietzky, H. Thermal damage evolution of granite under slow and high-speed heating conditions. Comput. Geotech. 2020, 123, 103590. [Google Scholar] [CrossRef]

- Wang, F.; Frühwirt, T.; Konietzky, H.; Zhu, Q. Thermo-mechanical behaviour of granite during high-speed heating. Eng. Geol. 2019, 260, 105258. [Google Scholar] [CrossRef]

- Xi, Y.; Wang, H.; Li, J.; Dong, W.; Li, H.; Guo, B. Experimental comparison of mechanical properties and fractal characteristics of geothermal reservoir rocks after different cooling treatments. Energy Rep. 2022, 8, 5158–5176. [Google Scholar] [CrossRef]

- Zhao, F.; Sun, Q.; Ge, Z.; Dang, C. Laboratory investigation on engineering mechanics properties of granite after various heating/cooling treatments. Environ. Sci. Pollut. Res. 2022, 30, 12532–12544. [Google Scholar] [CrossRef]

- Tang, Z.C.; Peng, M.H.; Xiao, S. Basic friction angle of granite fracture after heating and rapid cooling treatments. Eng. Geol. 2022, 302, 106626. [Google Scholar] [CrossRef]

- Shao, Z.; Wang, Y.; Tang, X. The influences of heating and uniaxial loading on granite subjected to liquid nitrogen cooling. Eng. Geol. 2020, 271, 105614. [Google Scholar] [CrossRef]

- Chen, Z.; Sha, S.; Xu, L.; Quan, J.; Rong, G.; Jiang, M. Damage Evaluation and Statistic Constitutive Model of High-Temperature Granites Subjected to Liquid Nitrogen Cold Shock. Rock Mech. Rock Eng. 2022, 55, 2299–2321. [Google Scholar] [CrossRef]

- Rong, G.; Sha, S.; Li, B.; Chen, Z.; Zhang, Z. Experimental Investigation on Physical and Mechanical Properties of Granite Subjected to Cyclic Heating and Liquid Nitrogen Cooling. Rock Mech. Rock Eng. 2021, 54, 2383–2403. [Google Scholar] [CrossRef]

- Yin, T.; Li, Q.; Li, X. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Eng. Fract. Mech. 2019, 222, 106740. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yin, T. Factors affecting pore structure of granite under cyclic heating and cooling: A nuclear magnetic resonance investigation. Geothermics 2021, 96, 102198. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, S.; Shen, B.; Li, Y.; Wang, C. Mechanical properties and failure characteristics of granite treated with a combined water–air cooling cycle. Case Stud. Therm. Eng. 2022, 34, 101964. [Google Scholar] [CrossRef]

- Zhu, Z.; Ranjith, P.G.; Tian, H.; Jiang, G.; Dou, B.; Mei, G. Relationships between P-wave velocity and mechanical properties of granite after exposure to different cyclic heating and water cooling treatments. Renew. Energy 2021, 168, 375–392. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Z.; Cheng, Z.; Zhang, S.; Song, H.; Zhao, X. Effects of cyclic heating and LN2-cooling on the physical and mechanical properties of granite. Appl. Therm. Eng. 2019, 156, 99–110. [Google Scholar] [CrossRef]

- Wang, F.; Frühwirt, T.; Konietzky, H. Influence of repeated heating on physical-mechanical properties and damage evolution of granite. Int. J. Rock Mech. Min. Sci. 2020, 136, 104514. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, J.; Zhu, C.; Wang, Q.; Zhang, Q.; Jing, H.; Xie, J. The role of multiple heating and water cooling cycles on physical and mechanical responses of granite rocks. Géoméch. Geophys. Geo-Energy Geo-Resour. 2021, 7, 69. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, G.-F. A multiphysics method for long-term deformation analysis of reservoir rock considering thermal damage in deep geothermal engineering. Renew. Energy 2023, 204, 432–448. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, S.; Ranjith, P.G.; Tian, W.; Tian, H.; Zheng, J.; Jiang, G.; Dou, B. A comprehensive review on mechanical responses of granite in enhanced geothermal systems (EGSs). J. Clean. Prod. 2022, 383, 135378. [Google Scholar] [CrossRef]

- Sun, Q.; Hu, J. The effect of rapid cooling on the thermal diffusivity of granite. J. Appl. Geophys. 2019, 168, 71–78. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, Q. Acoustic emission (AE) characteristics of granite after heating and cooling cycles. Eng. Fract. Mech. 2018, 200, 418–429. [Google Scholar] [CrossRef]

- Jiang, Z.; Yin, Q.; Wu, J.; Zhu, Q.; Li, M.; Su, H.; Jing, H. The effect of cyclic heating and cooling on mechanical and deformation responses of granites under preset angle shearing. Environ. Earth Sci. 2023, 82, 29. [Google Scholar] [CrossRef]

- Li, X.; Li, B.; Li, X.; Yin, T.; Wang, Y.; Dang, W. Thermal shock effects on the mechanical behavior of granite exposed to dynamic loading. Arch. Civ. Mech. Eng. 2020, 20, 66. [Google Scholar] [CrossRef]

- T/CSRME 001-2019; Chinese Society of Rock Mechanics and Engineering. Test Procedure for Dynamic Properties of Rocks. China Standards Press: Beijing, China, 2019.

- Yin, T.; Ma, J.; Wu, Y.; Zhuang, D.; Yang, Z. Effect of high temperature on the brittleness index of granite: An experimental investigation. Bull. Eng. Geol. Environ. 2022, 81, 476. [Google Scholar] [CrossRef]

- Xie, H. Introduction for Fractals-Rock Mechanics; Science Press: Beijing, China, 1996. (In Chinese) [Google Scholar]

- Wu, Y.; Huang, L.; Li, X.; Guo, Y.; Liu, H.; Wang, J. Effects of Strain Rate and Temperature on Physical Mechanical Properties and Energy Dissipation Features of Granite. Mathematics 2022, 10, 1521. [Google Scholar] [CrossRef]

- Tarasov, B.G.; Stacey, T.R. Features of the energy balance and fragmentation mechanisms at spontaneous failure of class I and class II rocks. Rock Mech. Rock Eng. 2017, 50, 2563–2584. [Google Scholar] [CrossRef]

| T (°C) | Type of Cooling | N | Rate of Change of Physical Parameter | ||||

|---|---|---|---|---|---|---|---|

| /% | /% | /% | /% | /% | |||

| 200 | Water | 1 | 0.09 | 0.13 | 0.22 | 108.9 | 17.0 |

| 5 | 0.09 | 0.45 | 0.56 | 180.7 | 21.5 | ||

| 10 | 0.10 | 0.80 | 0.91 | 260.9 | 22.2 | ||

| 20 | 0.12 | 0.50 | 0.66 | 430.3 | 28.0 | ||

| Natural | 1 | 0.04 | 0.06 | 0.19 | 54.2 | 12.2 | |

| 5 | 0.08 | 0.39 | 0.27 | 164.6 | 13.6 | ||

| 10 | 0.10 | 0.48 | 0.53 | 213.5 | 15.5 | ||

| 20 | 0.10 | 0.50 | 0.62 | 228.7 | 23.1 | ||

| 400 | Water | 1 | 0.11 | 0.52 | 0.64 | 338.5 | 41.9 |

| 5 | 0.12 | 1.01 | 1.15 | 427.2 | 59.9 | ||

| 10 | 0.11 | 1.14 | 1.27 | 499.4 | 64.8 | ||

| 20 | 0.18 | 1.53 | 1.71 | 693.7 | 67.7 | ||

| Natural | 1 | 0.03 | 0.46 | 0.64 | 66.5 | 32.1 | |

| 5 | 0.12 | 0.48 | 0.63 | 179.1 | 39.1 | ||

| 10 | 0.13 | 0.78 | 0.71 | 260.4 | 44.6 | ||

| 20 | 0.14 | 0.96 | 0.94 | 422.5 | 46.3 | ||

| 600 | Water | 1 | 0.12 | 1.99 | 2.10 | 773.9 | 78.1 |

| 5 | 0.31 | 3.51 | 3.72 | 1518.4 | 86.9 | ||

| 10 | 0.54 | 6.77 | 6.88 | 2976.4 | - | ||

| 20 | 1.01 | 9.49 | 9.63 | 4014.5 | - | ||

| Natural | 1 | 0.17 | 2.03 | 2.21 | 838.5 | 74.9 | |

| 5 | 0.20 | 2.34 | 2.53 | 1042.5 | 81.2 | ||

| 10 | 0.20 | 3.21 | 3.33 | 1226.6 | 82.9 | ||

| 20 | 0.21 | 3.49 | 3.62 | 1419.4 | 86.2 | ||

| 800 | Water | 1 | 0.23 | 2.51 | 2.61 | 1476.2 | 78.6 |

| Natural | 1 | 0.21 | 2.48 | 2.66 | 1454.4 | 75.7 | |

| Furnace | 1 | 0.20 | 2.02 | 2.21 | 1277.7 | 74.9 | |

| T (°C) | Type of Cooling | N | Pressure of Impact (Mpa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.6 | 0.7 | 0.8 | |||||||||

| 25 | 1 | 283 | 66.5 | 41.6 | 288 | 61.4 | 42.0 | 295 | 64.8 | 43.8 | |

| 200 | Water | 1 | 255 | 73.0 | 32.5 | 277 | 77.7 | 34.5 | 289 | 74.9 | 45.6 |

| 5 | 232 | 61.2 | 39.2 | 272 | 60.1 | 45.2 | 277 | 65.4 | 48.7 | ||

| 10 | 231 | 54.1 | 43.7 | 265 | 58.5 | 47.4 | 268 | 58.3 | 49.0 | ||

| 20 | 215 | 53.9 | 45.7 | 257 | 54.5 | 48.4 | 262 | 60.0 | 52.0 | ||

| Natural | 1 | 260 | 71.8 | 34.7 | 267 | 68.3 | 38.7 | 301 | 72.4 | 44.1 | |

| 5 | 234 | 65.5 | 35.4 | 266 | 69.0 | 40.7 | 299 | 69.8 | 45.9 | ||

| 10 | 259 | 63.4 | 37.6 | 261 | 66.0 | 42.3 | 289 | 65.5 | 46.2 | ||

| 20 | 220 | 54.1 | 39.3 | 260 | 59.2 | 44.0 | 269 | 58.1 | 48.4 | ||

| 400 | Water | 1 | 178 | 35.5 | 53.6 | 221 | 38.5 | 55.8 | 206 | 33.0 | 61.3 |

| 5 | 152 | 25.9 | 57.8 | 219 | 31.9 | 61.7 | 206 | 28.7 | 71.2 | ||

| 10 | 151 | 24.3 | 60.3 | 191 | 25.1 | 70.7 | 201 | 23.7 | 82.2 | ||

| 20 | 191 | 22.1 | 71.0 | 190 | 24.7 | 74.0 | 197 | 21.4 | 84.3 | ||

| Natural | 1 | 174 | 54.1 | 47.8 | 244 | 58.1 | 54.6 | 265 | 55.4 | 53.0 | |

| 5 | 210 | 47.5 | 49.1 | 242 | 54.9 | 61.2 | 253 | 49.2 | 57.7 | ||

| 10 | 200 | 43.4 | 54.3 | 255 | 47.1 | 63.1 | 261 | 47.4 | 62.6 | ||

| 20 | 192 | 39.5 | 57.5 | 240 | 42.5 | 68.8 | 286 | 40.5 | 74.1 | ||

| 600 | Water | 1 | 71 | 32.1 | 62.9 | 147 | 27.8 | 70.7 | 175 | 29.4 | 77.3 |

| 5 | 86 | 22.8 | 77.0 | 107 | 26.6 | 86.6 | 115 | 24.8 | 95.8 | ||

| 10 | 22 | 14.8 | 89.8 | 54 | 14.0 | 99.5 | 56 | 10.5 | 108 | ||

| 20 | 14 | 3.4 | 99.7 | 16 | 4.9 | 105 | 21 | 4.2 | 123 | ||

| Natural | 1 | 167 | 39.1 | 57.6 | 159 | 39.6 | 67.2 | 168 | 40 | 86.3 | |

| 5 | 114 | 33.3 | 61.3 | 154 | 28.7 | 72.3 | 93 | 30.9 | 89.2 | ||

| 10 | 80 | 28.7 | 74.5 | 111 | 28.4 | 86.3 | 144 | 29.1 | 94.8 | ||

| 20 | 57 | 20.9 | 86.2 | 97 | 21.9 | 92.6 | 106 | 22.2 | 98.8 | ||

| 800 | Water | 1 | 90 | 20.7 | 73.3 | 147 | 21.5 | 85.1 | 140 | 22.7 | 96.6 |

| Natural | 1 | 123 | 26.8 | 71.8 | 154 | 24.1 | 81.9 | 168 | 29.3 | 88.4 | |

| Furnace | 1 | 141 | 21.8 | 72.5 | 187 | 36.1 | 77.0 | 188 | 33.9 | 86.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Huang, L.; Li, X.; Hu, X.; Wu, Y. Study on the Evolution of Physical Parameters and Dynamic Compression Mechanical Properties of Granite after Different Heating and Cooling Cycles. Materials 2023, 16, 2300. https://doi.org/10.3390/ma16062300

Zhang H, Huang L, Li X, Hu X, Wu Y. Study on the Evolution of Physical Parameters and Dynamic Compression Mechanical Properties of Granite after Different Heating and Cooling Cycles. Materials. 2023; 16(6):2300. https://doi.org/10.3390/ma16062300

Chicago/Turabian StyleZhang, Hongzhong, Linqi Huang, Xibing Li, Xingmiao Hu, and Yangchun Wu. 2023. "Study on the Evolution of Physical Parameters and Dynamic Compression Mechanical Properties of Granite after Different Heating and Cooling Cycles" Materials 16, no. 6: 2300. https://doi.org/10.3390/ma16062300

APA StyleZhang, H., Huang, L., Li, X., Hu, X., & Wu, Y. (2023). Study on the Evolution of Physical Parameters and Dynamic Compression Mechanical Properties of Granite after Different Heating and Cooling Cycles. Materials, 16(6), 2300. https://doi.org/10.3390/ma16062300