Oil/Water Mixtures and Emulsions Separation Methods—An Overview

Abstract

:1. Introduction

1.1. From Biomass Fuels to a Fossil Fuel Economy

1.2. Oil Spills—An Overview

1.3. Oil/Water Conventional Separation Technologies

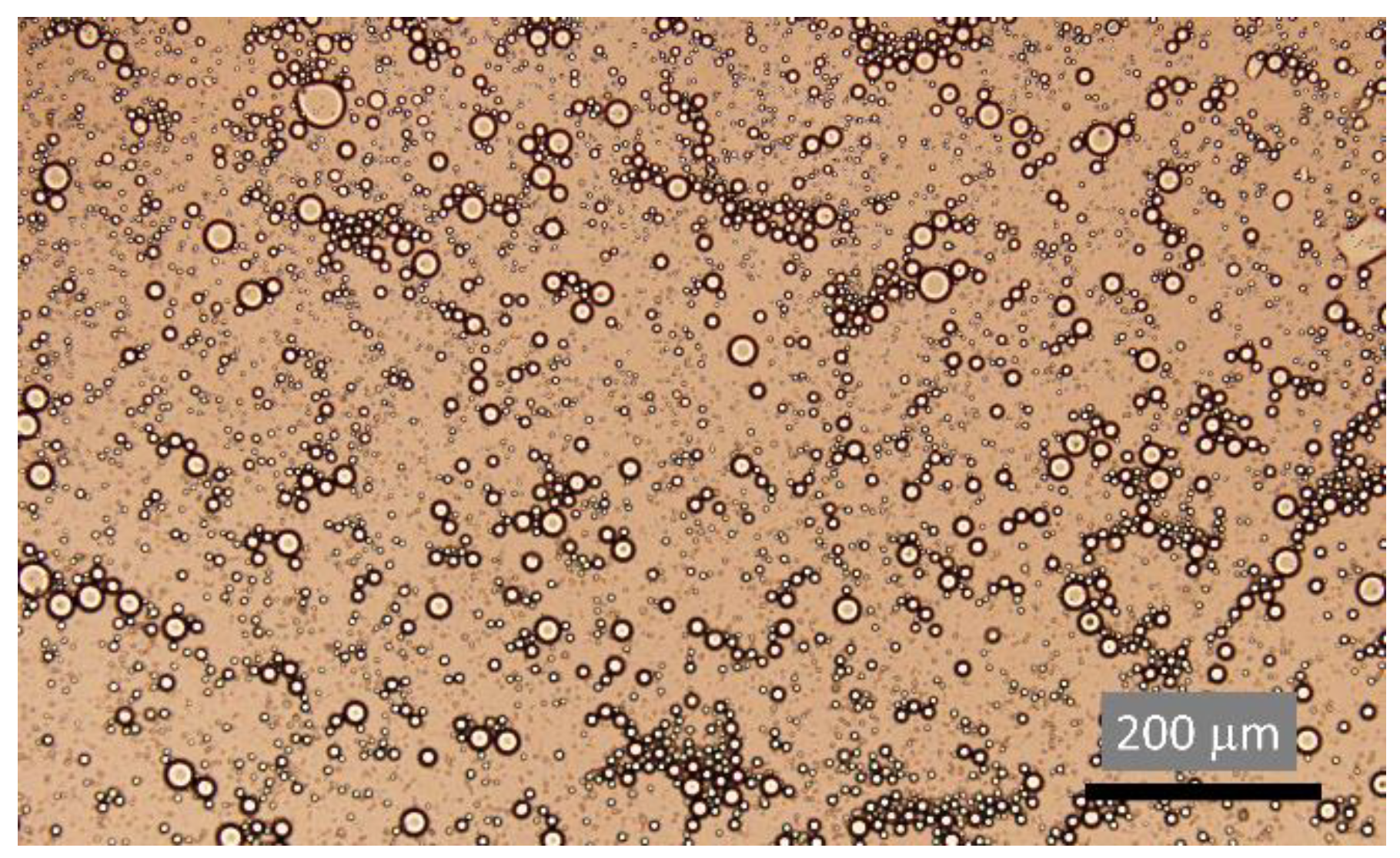

1.4. Microdroplets Removal Technologies

1.5. Nanotechnology

Nanoparticles

1.6. Oil/Water Separation Technologies

1.6.1. Existing Methods for Oil/Water Separation

1.6.2. Oil or Water Absorbent Materials

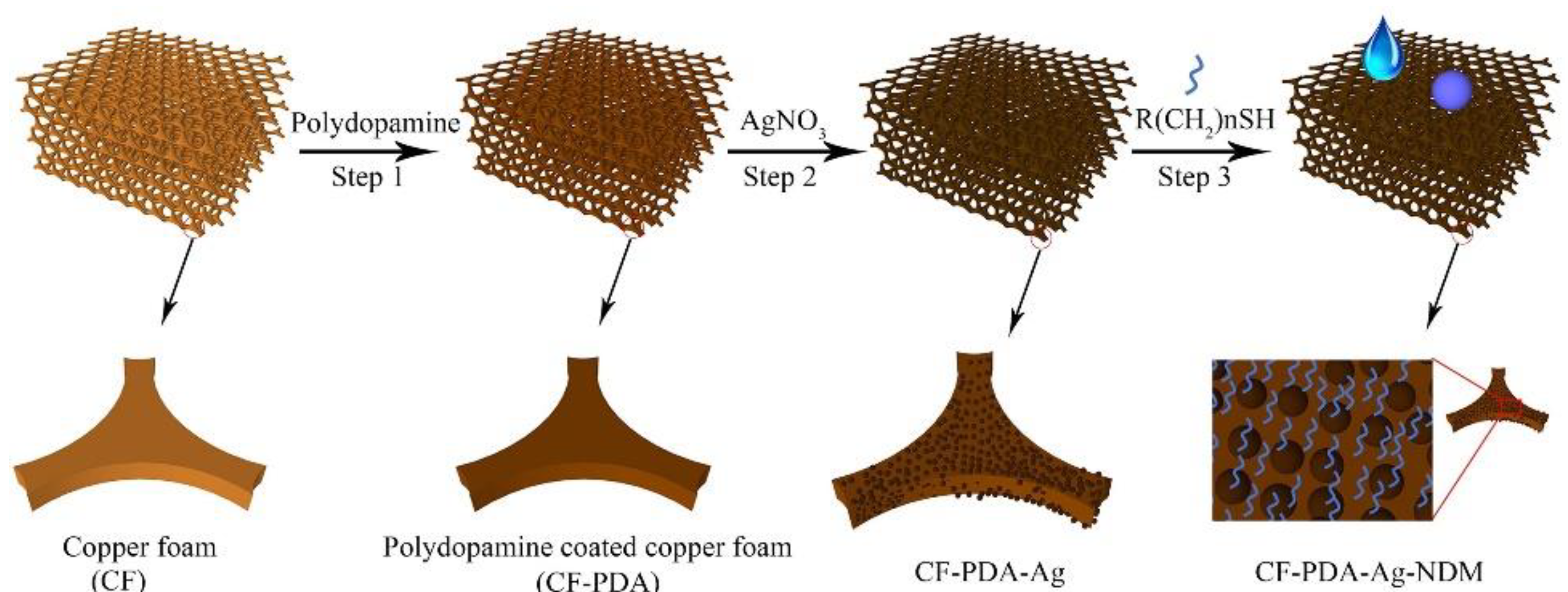

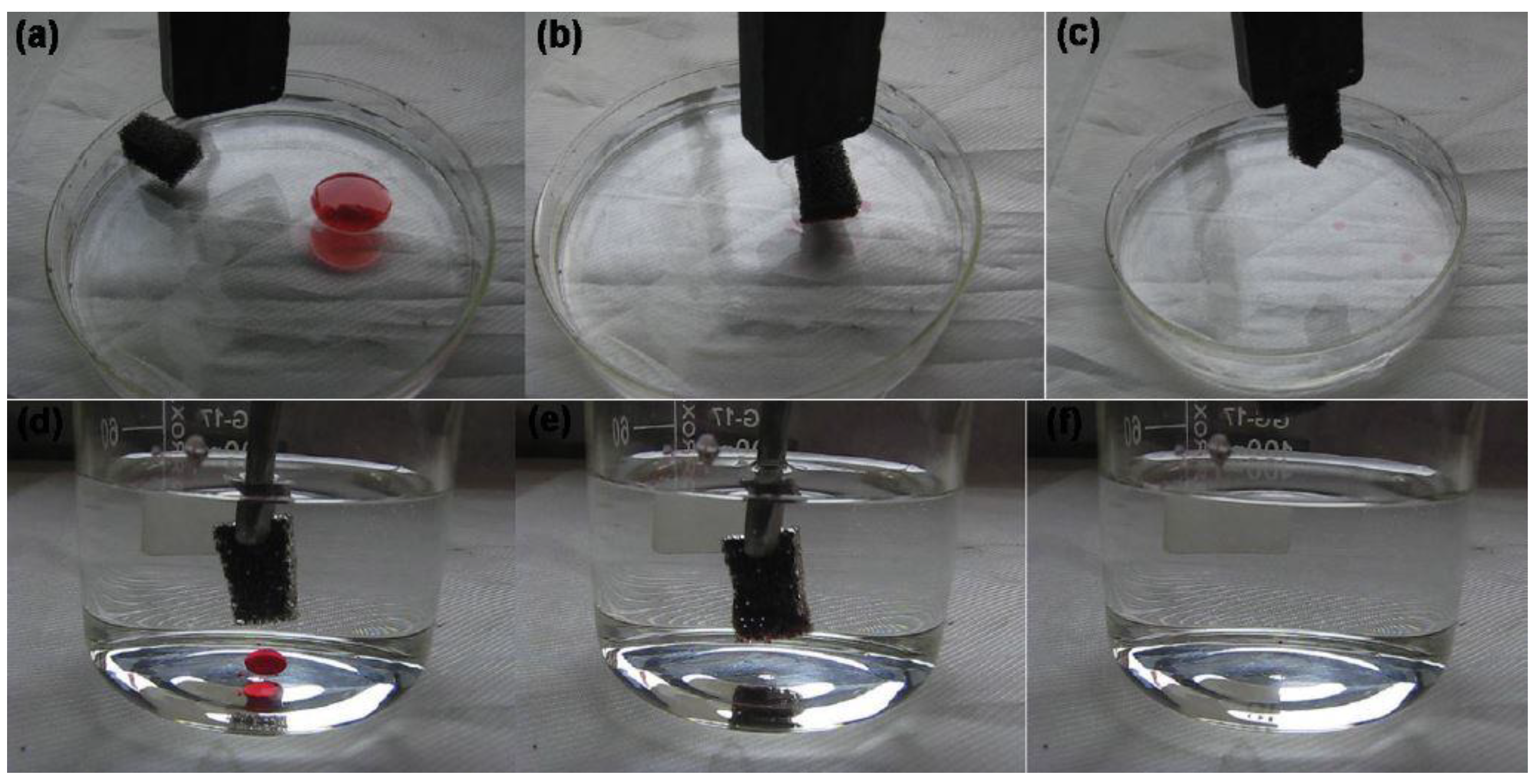

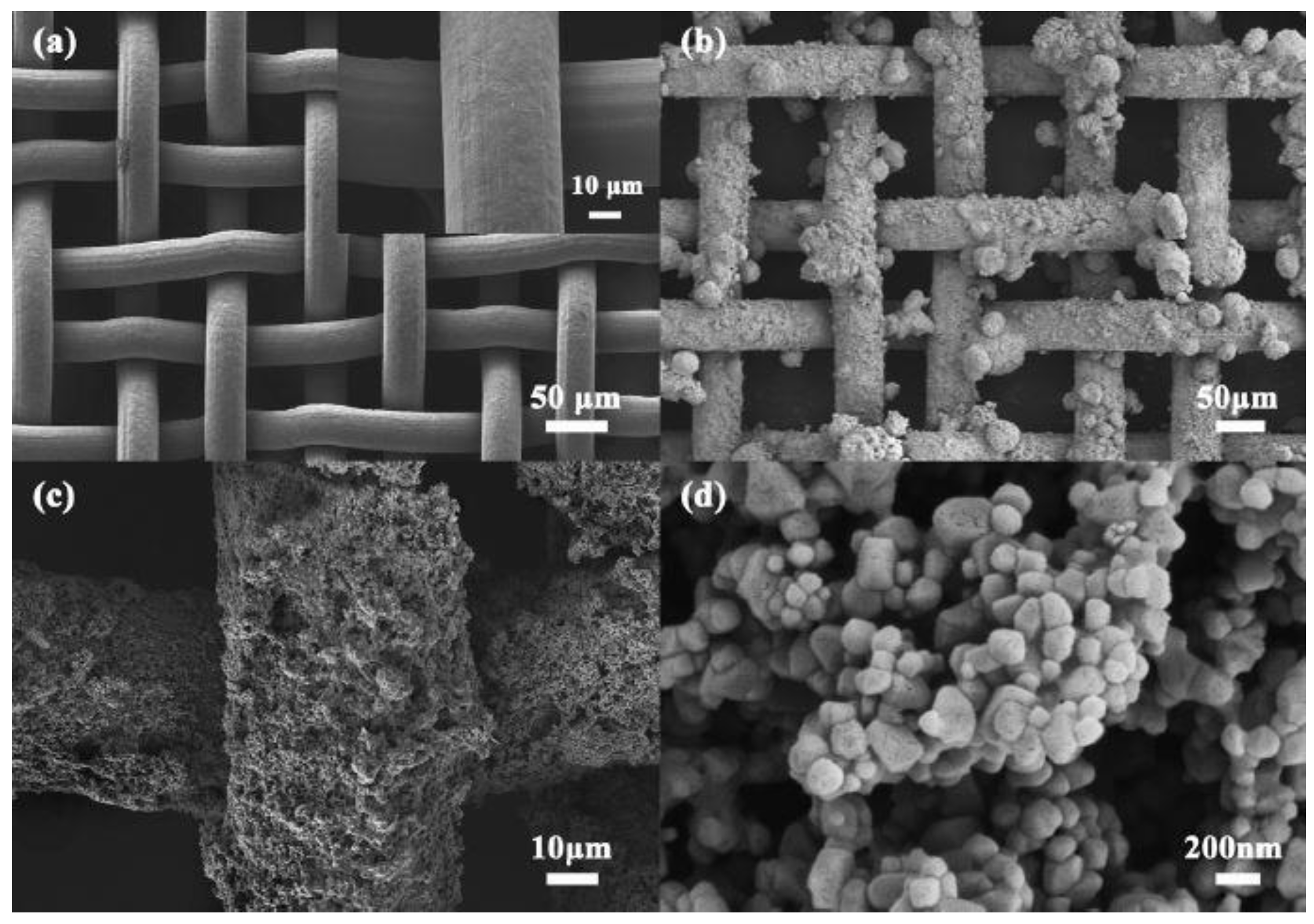

Foams and Sponges

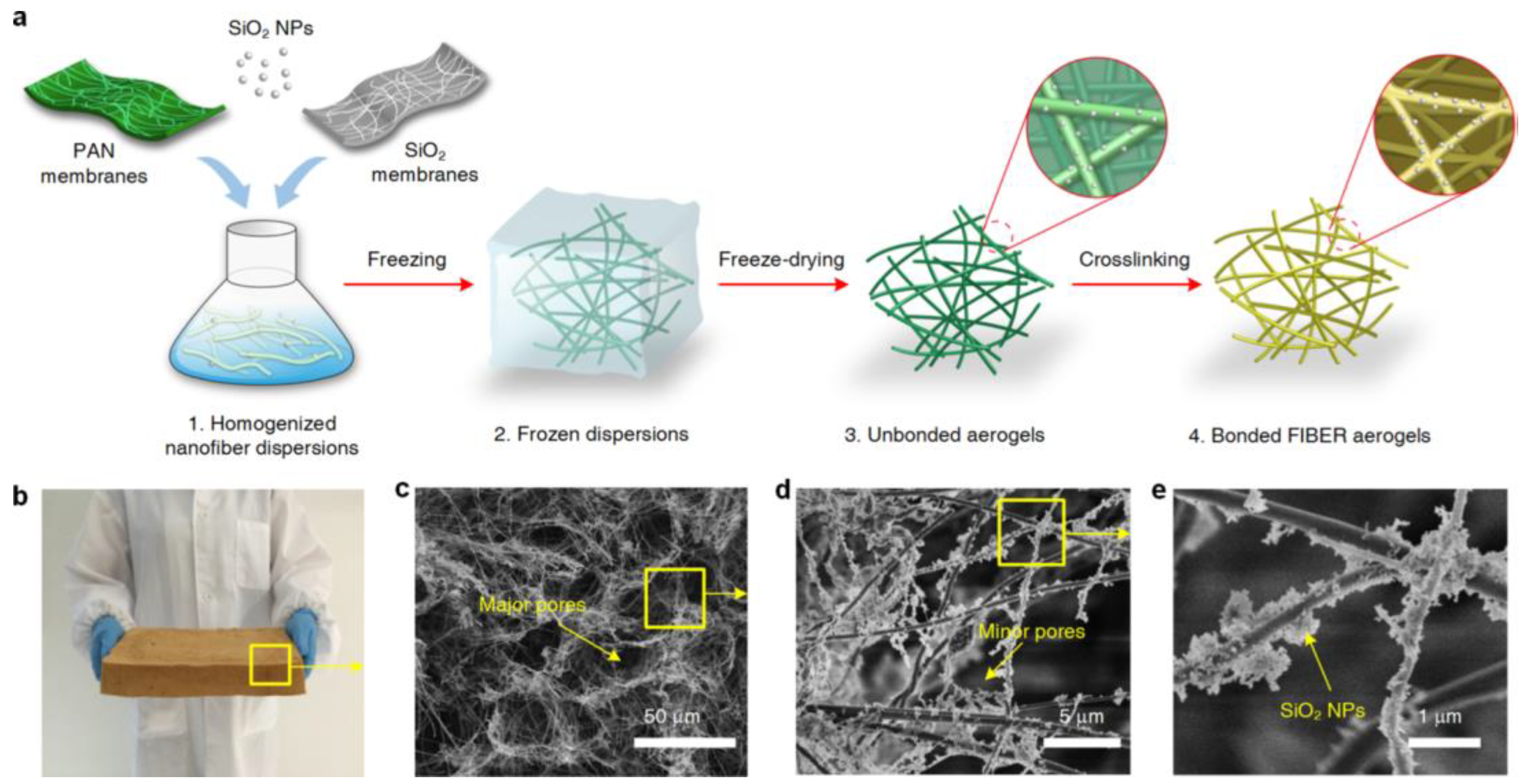

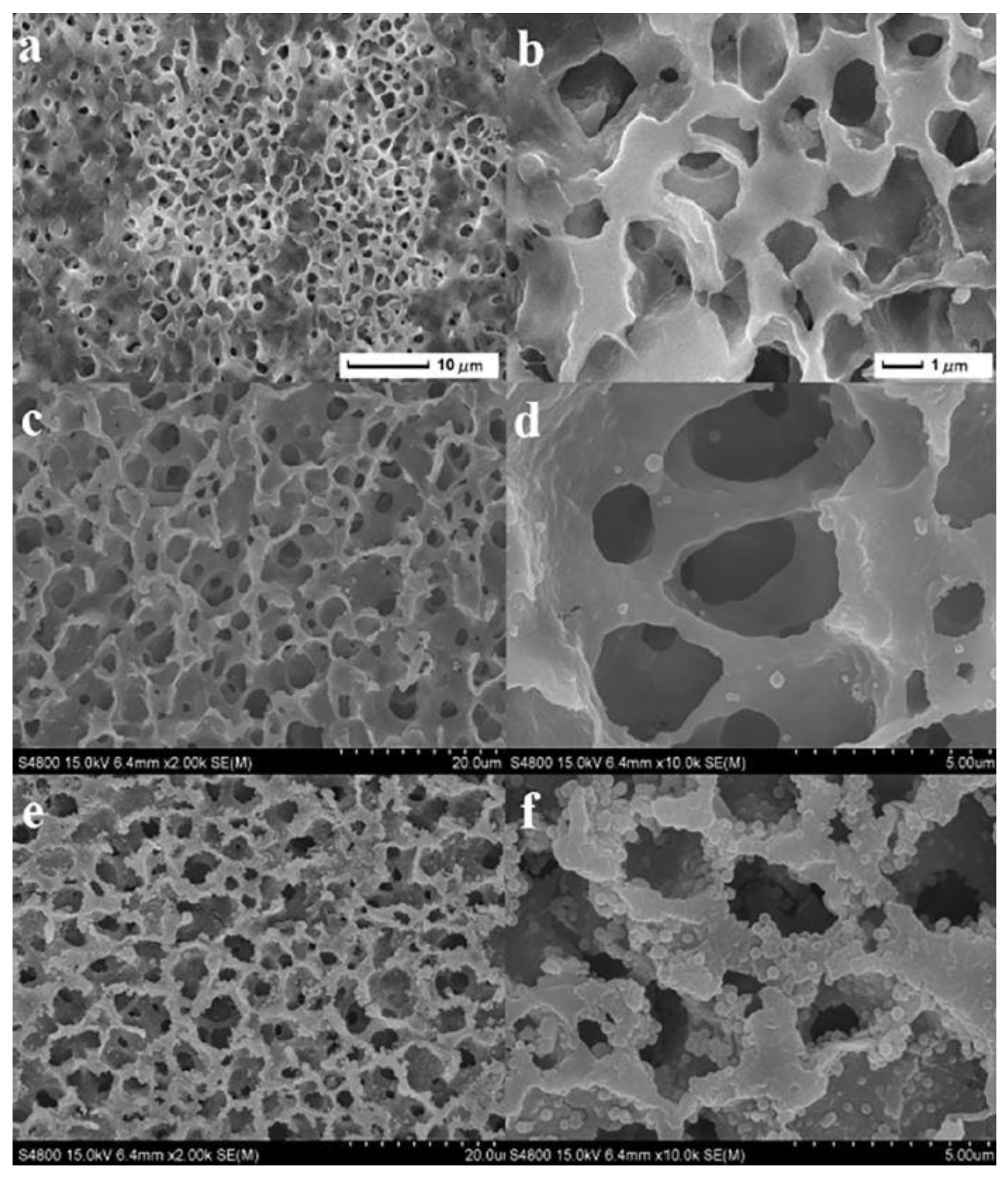

Aerogels

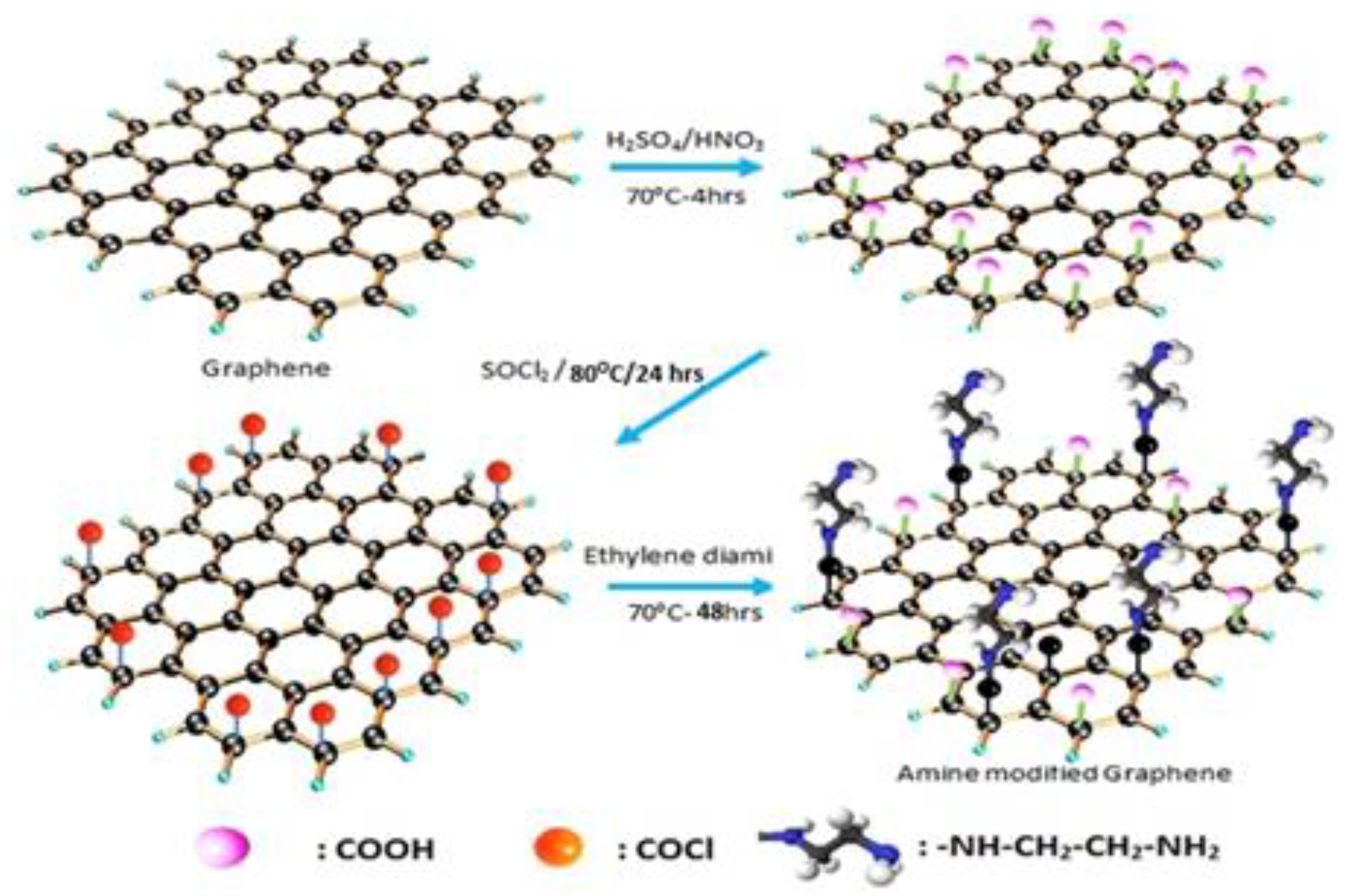

Nanoparticle Incorporation

1.6.3. Oil or Water Adsorbent Materials

Meshes

Clays

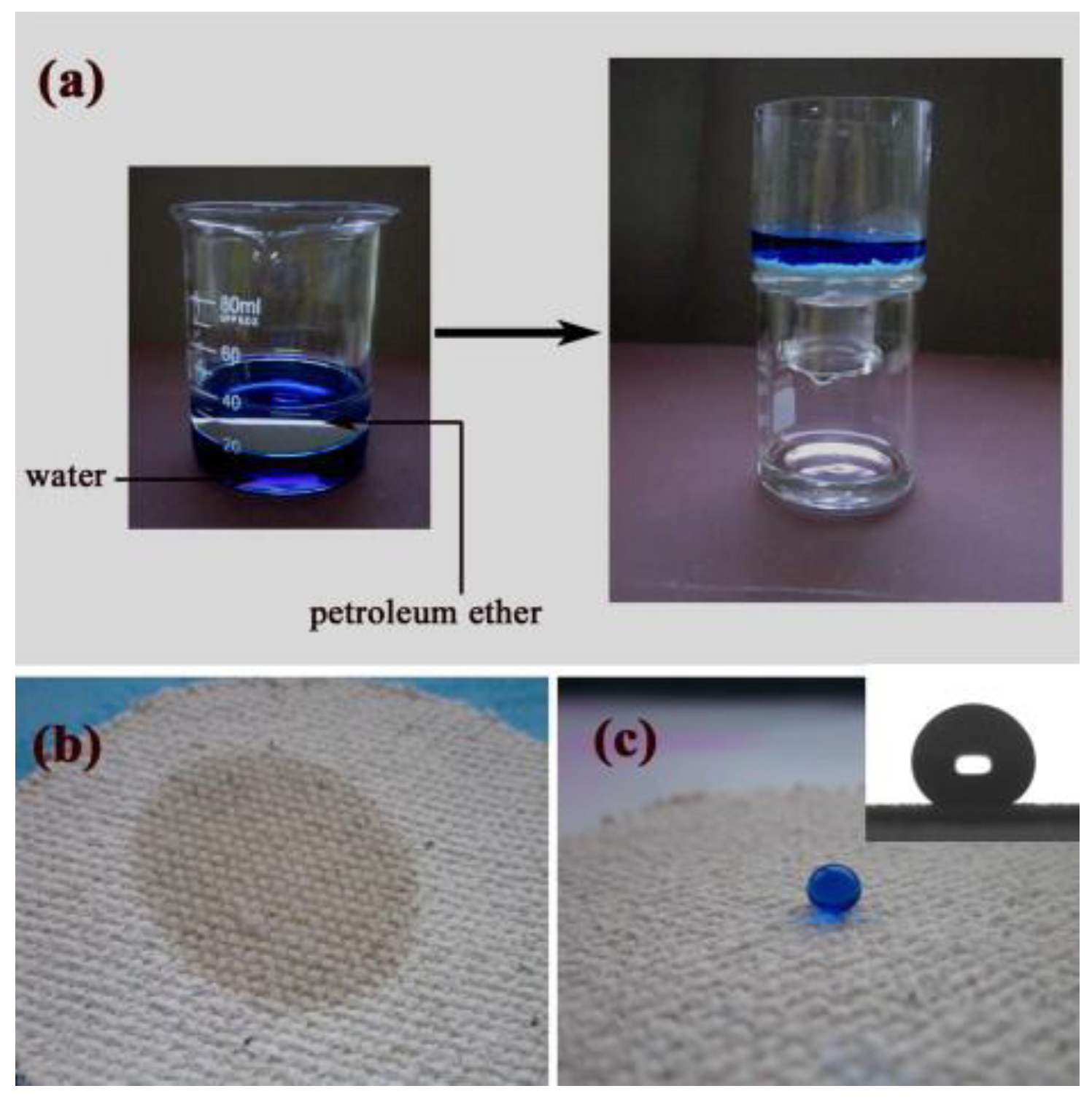

Textiles

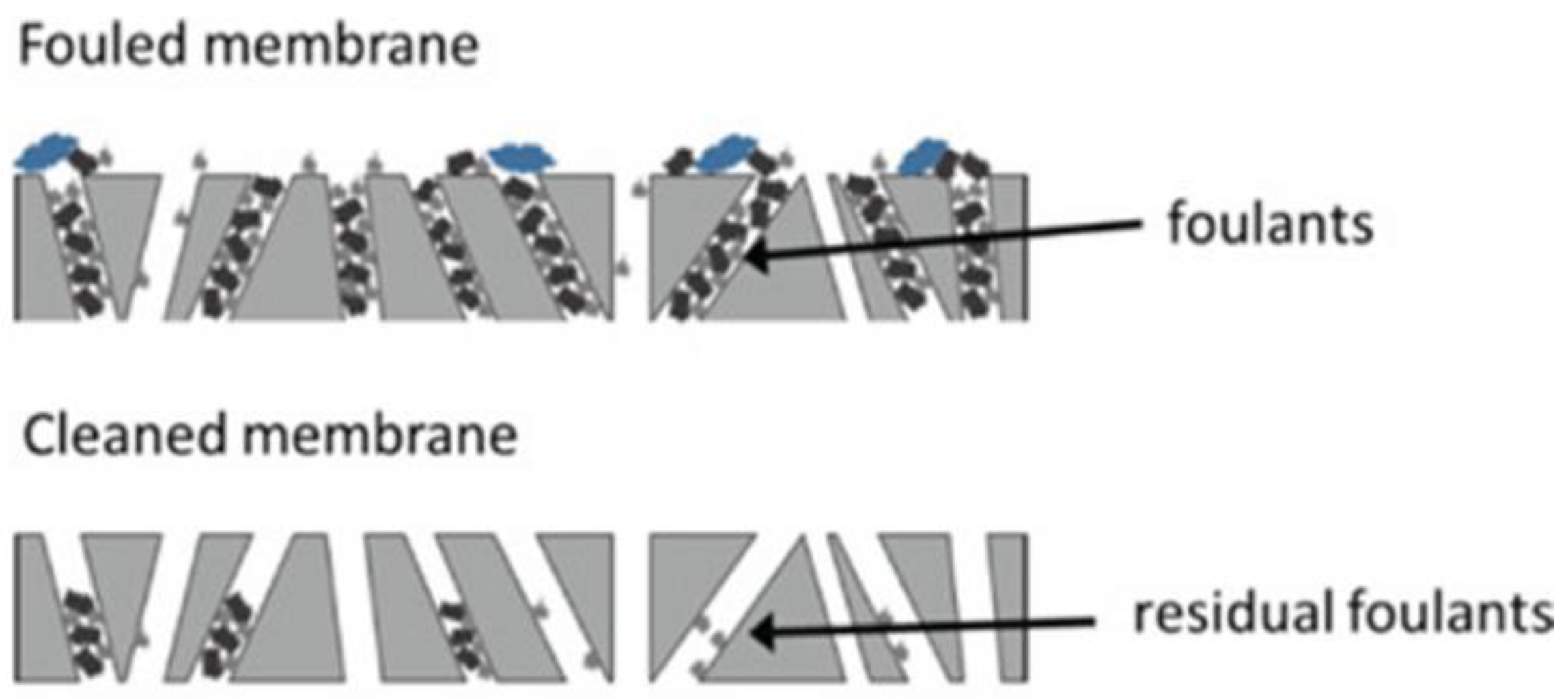

Membrane Technology for Oil and Oil Microdroplets Collection

1.7. Advantages in the Use of Nanofibers in Oil/Water Separation

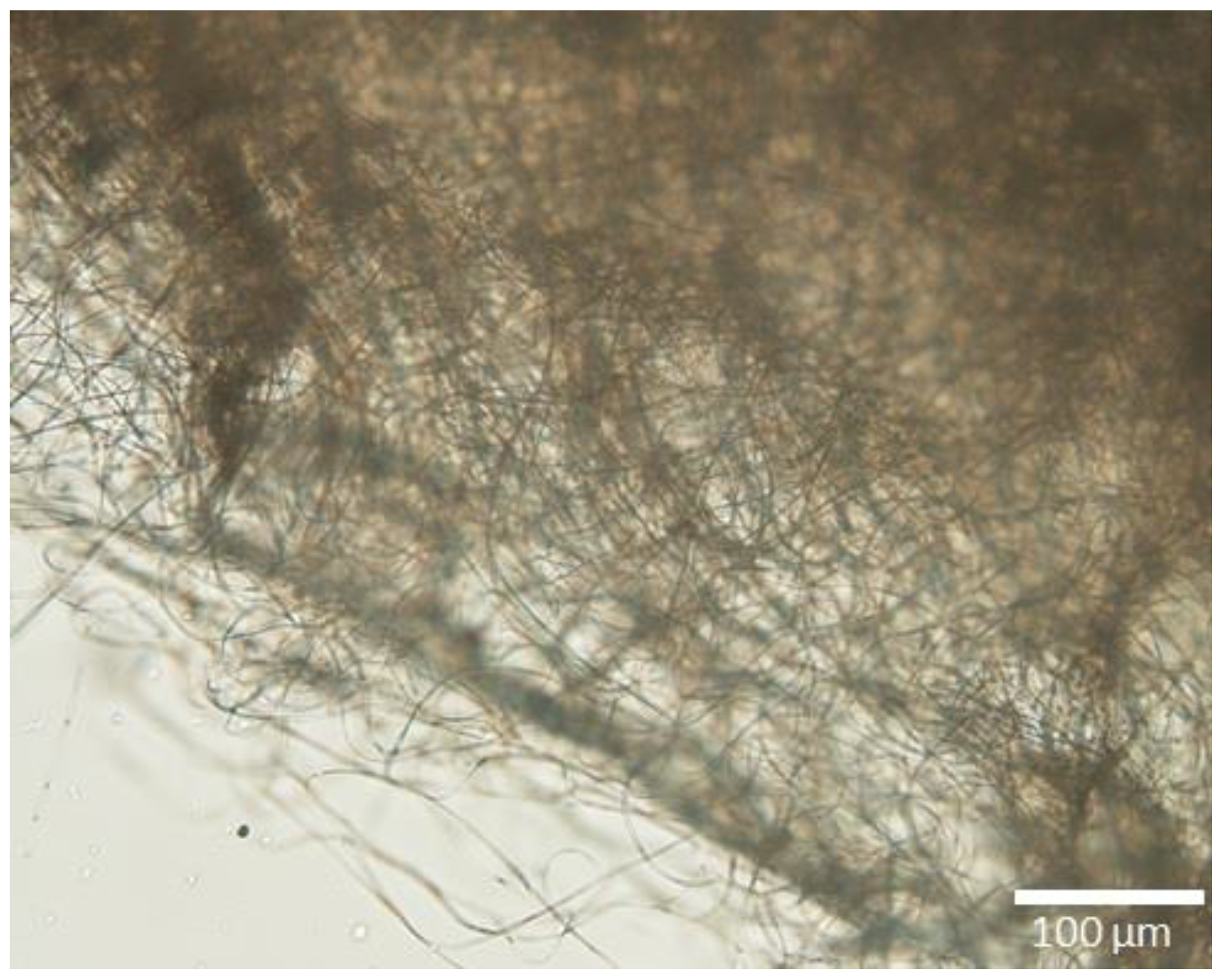

Nanofibers

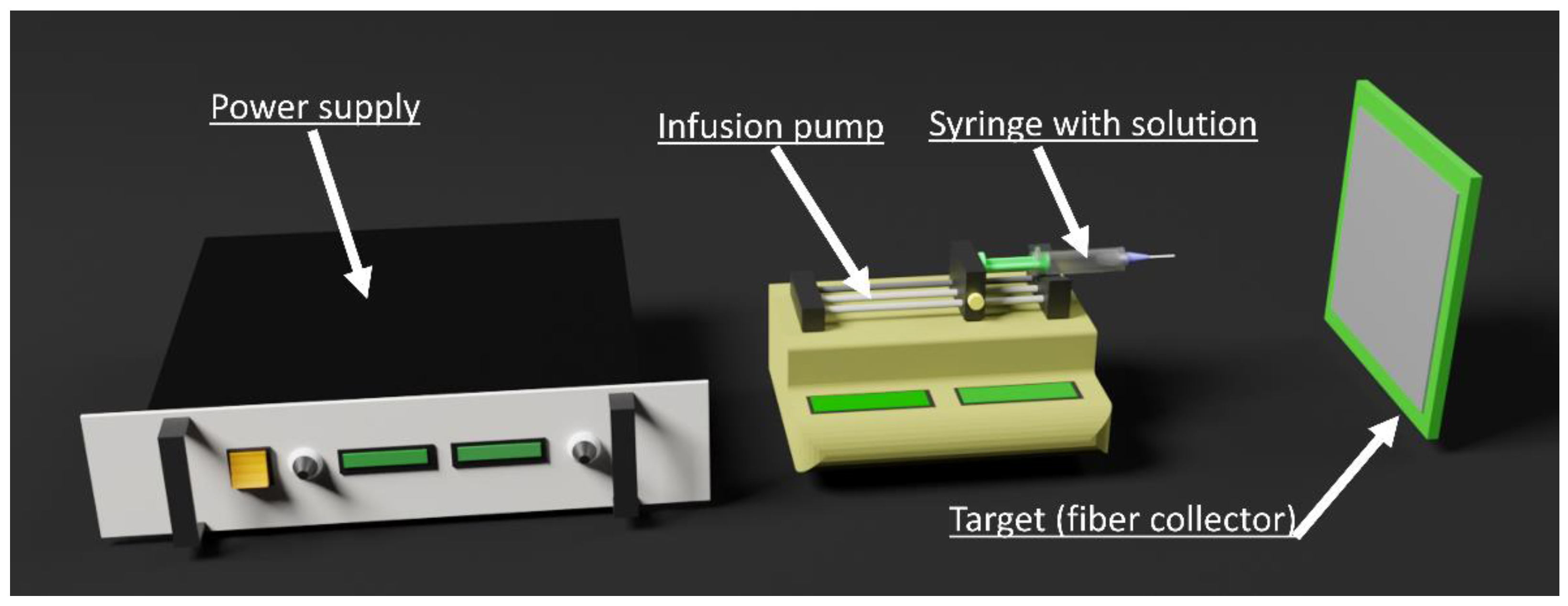

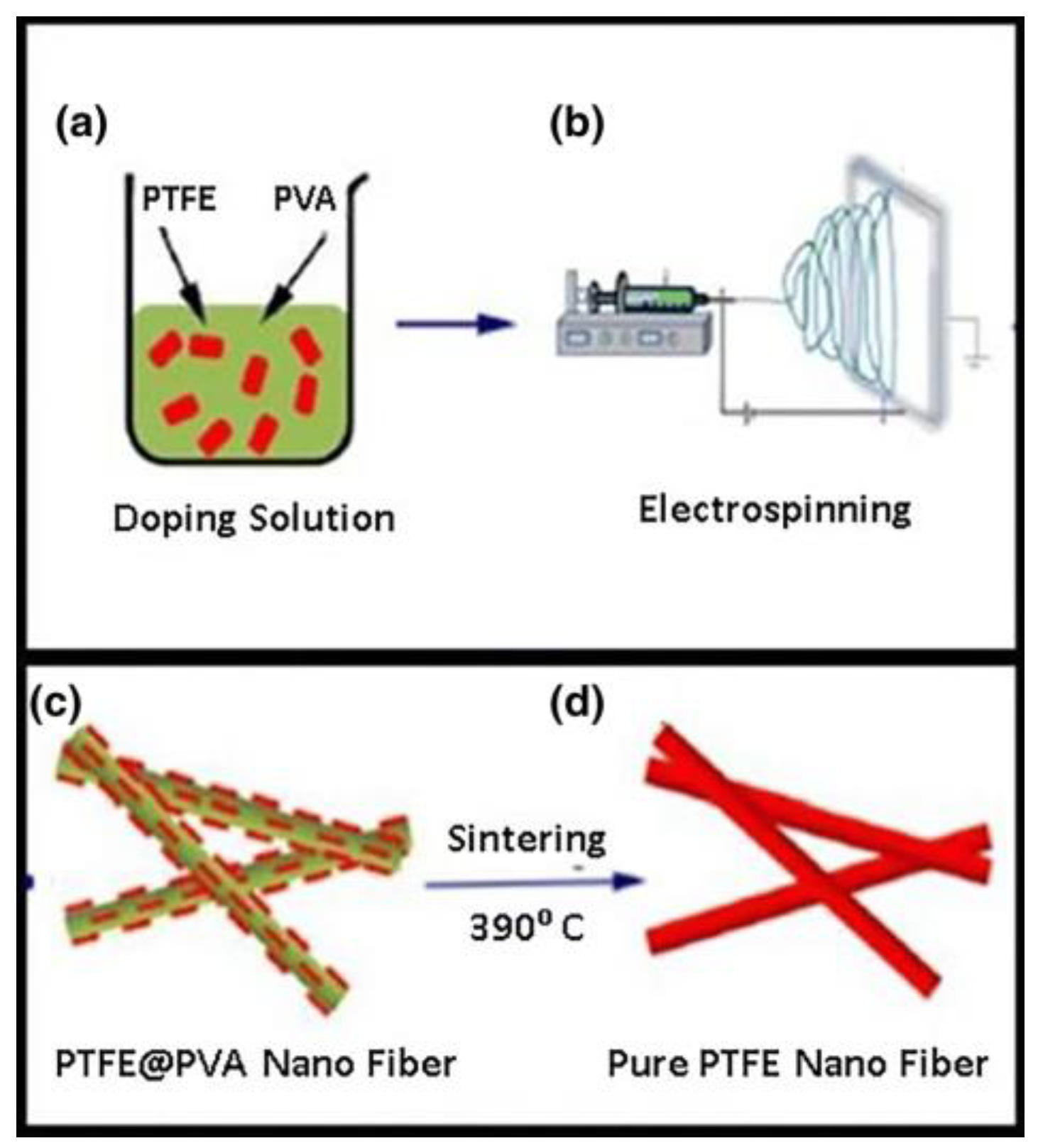

Nanofiber Fabrication Methods

Nanofiber Membranes for Oil/Water Separation

1.8. Oil/Water Emulsion Separation

1.8.1. Oil or Water Absorbent Materials

Foams

Aerogels

1.8.2. Oil or Water Adsorbent Materials

Membranes

Clays

2. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bithas, K.; Kalimeris, P. Revisiting the Energy-Development Link; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Lee, C.H.; Tiwari, B.; Zhang, D.; Yap, Y.K. Water purification: Oil–water separation by nanotechnology and environmental concerns. Environ. Sci. Nano 2017, 4, 514–525. [Google Scholar] [CrossRef]

- Peterson, C.H.; Anderson, S.S.; Cherr, G.N.; Ambrose, R.F.; Anghera, S.; Bay, S.; Blum, M.; Condon, R.; Dean, T.A.; Graham, M.; et al. A Tale of Two Spills: Novel Science and Policy Implications of an Emerging New Oil Spill Model. Bioscience 2012, 62, 461–469. [Google Scholar] [CrossRef] [Green Version]

- Căprărescu, S.; Modrogan, C.; Purcar, V.; Dăncilă, A.M.; Orbuleț, O.D. Study of Polyvinyl Alcohol-SiO2 Nanoparticles Polymeric Membrane in Wastewater Treatment Containing Zinc Ions. Polymers 2021, 13, 1875. [Google Scholar] [CrossRef] [PubMed]

- Zahid, M.; Rashid, A.; Akram, S.; Rehan, Z.A.; Razzaq, W. A Comprehensive Review on Polymeric Nano-Composite Membranes for Water Treatment. J. Membr. Sci. Technol. 2018, 8, 1000179. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Rosado, P. “Energy,” OurWorldInData.org. Available online: https://ourworldindata.org/energy (accessed on 1 February 2022).

- Huang, J.; Wang, S.; Lyu, S.; Fu, F. Preparation of a robust cellulose nanocrystal superhydrophobic coating for self-cleaning and oil-water separation only by spraying. Ind. Crops Prod. 2018, 122, 438–447. [Google Scholar] [CrossRef]

- Yu, L.; Han, M.; He, F. A review of treating oily wastewater. Arab. J. Chem. 2017, 10, S1913–S1922. [Google Scholar] [CrossRef] [Green Version]

- Almeida, A.P.C.; Oliveira, J.; Fernandes, S.N.; Godinho, M.H.; Canejo, J.P. All-cellulose composite membranes for oil microdroplet collection. Cellulose 2020, 27, 4665–4677. [Google Scholar] [CrossRef]

- Zhan, H.; Peng, N.; Lei, X.; Huang, Y.; Li, D.; Tao, R.; Chang, C. UV-induced self-cleanable TiO2/nanocellulose membrane for selective separation of oil/water emulsion. Carbohydr. Polym. 2018, 201, 464–470. [Google Scholar] [CrossRef]

- Xu, H.; Liu, J.; Wang, Y.; Cheng, G.; Deng, X.; Li, X. Oil removing efficiency in oil–water separation flotation column. Desalin. Water Treat. 2014, 53, 2456–2463. [Google Scholar] [CrossRef]

- Haddada, R.; Ferjani, E.; Roudesli, M.S.; Deratani, A. Properties of cellulose acetate nanofiltration membranes. Application to brackish water desalination. Desalination 2004, 167, 403–409. [Google Scholar] [CrossRef]

- Frising, T.; Noïk, C.; Dalmazzone, C. The Liquid/Liquid Sedimentation Process: From Droplet Coalescence to Technologically Enhanced Water/Oil Emulsion Gravity Separators: A Review. J. Dispers. Sci. Technol. 2006, 27, 1035–1057. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, Q.; Zhan, X.; Chen, F. A multifunctional gelatin-based aerogel with superior pollutants adsorption, oil/water separation and photocatalytic properties. Chem. Eng. J. 2019, 358, 1539–1551. [Google Scholar] [CrossRef]

- Cambiella, A.; Benito, J.M.; Pazos, C.; Coca, J. Centrifugal Separation Efficiency in the Treatment of Waste Emulsified Oils. Chem. Eng. Res. Des. 2006, 84, 69–76. [Google Scholar] [CrossRef]

- Chen, W.; Su, Y.; Zheng, L.; Wang, L.; Jiang, Z. The improved oil/water separation performance of cellulose acetate-graft-polyacrylonitrile membranes. J. Memb. Sci. 2009, 337, 98–105. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.A.; Madaeni, S.S.; Abidin, Z.Z. Review of technologies for oil and gas produced water treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef] [PubMed]

- Cheryan, M.; Rajagopalan, N. Membrane processing of oily streams. Wastewater treatment and waste reduction. J. Memb. Sci. 1998, 151, 13–28. [Google Scholar] [CrossRef]

- Song, J.; Lu, Y.; Luo, J.; Huang, S.; Wang, L.; Xu, W.; Parkin, I.P. Barrel-Shaped Oil Skimmer Designed for Collection of Oil from Spills. Adv. Mater. Interfaces 2015, 2, 1500350. [Google Scholar] [CrossRef]

- Mansour, L.B.; Chalbi, S. Removal of oil from oil/water emulsions using electroflotation process. J. Appl. Electrochem. 2006, 36, 577–581. [Google Scholar] [CrossRef]

- Changmai, M.; Pasawan, M.; Purkait, M.K. Treatment of oily wastewater from drilling site using electrocoagulation followed by microfiltration. Sep. Purif. Technol. 2019, 210, 463–472. [Google Scholar] [CrossRef]

- Butler, E.; Hung, Y.-T.; Yeh, R.Y.-L.; Suleiman Al Ahmad, M. Electrocoagulation in Wastewater Treatment. Water 2011, 3, 495–525. [Google Scholar] [CrossRef]

- Holt, P.; Barton, G.; Mitchell, C. Electrocoagulation as a wastewater treatment. Third Annu. Aust. Environ. Eng. Res. Event 1999, 1956. [Google Scholar]

- Guerra, F.; Attia, M.; Whitehead, D.; Alexis, F. Nanotechnology for Environmental Remediation: Materials and Applications. Molecules 2018, 23, 1760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thrall, J.H. Nanotechnology and Medicine. Radiology 2004, 230, 315–318. [Google Scholar] [CrossRef]

- Rae, A. Real life applications of nanotechnology in electronics. In IPC—Electronic Circuits World Convention, Printed Circuits Expo, Apex, and the Designers Summit 2005, ECWC 10: The Perfect Fit; SJR: Granada, Spain, 2005. [Google Scholar]

- Whitesides, G. Nanoscience, Nanotechnology, and Chemistry. Small 2005, 1, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.A. Nanotechnology Definitions, Research, Industry and Property Rights. In Nanoscience in Food and Agriculture; Springer: Berlin/Heidelberg, Germany, 2016; pp. 43–64. [Google Scholar]

- Drexler, K.E. Nanotechnology: From Feynman to Funding. Bull. Sci. Technol. Soc. 2004, 24, 21–27. [Google Scholar] [CrossRef] [Green Version]

- Subedi, S.K. An introduction to nanotechnology and its implications. Himal. Phys. 2015, 5, 78–81. [Google Scholar] [CrossRef] [Green Version]

- Kargozar, S.; Mozafari, M. Nanotechnology and Nanomedicine: Start small, think big. Mater. Today Proc. 2018, 5, 15492–15500. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Atta, A.; Al-Lohedan, H.; Al-Hussain, S. Functionalization of Magnetite Nanoparticles as Oil Spill Collector. Int. J. Mol. Sci. 2015, 16, 6911–6931. [Google Scholar] [CrossRef] [Green Version]

- João; Godinho, P.H.; Godinho, M.H. João Diogo Fidalgo Peça de Oliveira Membranas Celulósicas para Recolha de Microgotas de Óleo. 2019. Available online: http://hdl.handle.net/10362/77150 (accessed on 12 February 2023).

- Obaid, M.; Barakat, N.A.M.; Fadali, O.A.; Motlak, M.; Almajid, A.A.; Khalil, K.A. Effective and reusable oil/water separation membranes based on modified polysulfone electrospun nanofiber mats. Chem. Eng. J. 2015, 259, 449–456. [Google Scholar] [CrossRef]

- Obaid, M.; Yang, E.; Kang, D.-H.; Yoon, M.-H.; Kim, I.S. Underwater superoleophobic modified polysulfone electrospun membrane with efficient antifouling for ultrafast gravitational oil-water separation. Sep. Purif. Technol. 2018, 200, 284–293. [Google Scholar] [CrossRef]

- Ge, J.; Zhao, H.-Y.; Zhu, H.-W.; Huang, J.; Shi, L.-A.; Yu, S.-H. Advanced Sorbents for Oil-Spill Cleanup: Recent Advances and Future Perspectives. Adv. Mater. 2016, 28, 10459–10490. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.K.; Dunderdale, G.J.; England, M.W.; Hozumi, A. Oil/water separation techniques: A review of recent progresses and future directions. J. Mater. Chem. A 2017, 5, 16025–16058. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Liu, K.; Jiang, L. Bioinspired Multifunctional Foam with Self-Cleaning and Oil/Water Separation. Adv. Funct. Mater. 2013, 23, 2881–2886. [Google Scholar] [CrossRef]

- Jiang, S.; Agarwal, S.; Greiner, A. Low-Density Open Cellular Sponges as Functional Materials. Angew. Chemie Int. Ed. 2017, 56, 15520–15538. [Google Scholar] [CrossRef]

- Pinto, J.; Athanassiou, A.; Fragouli, D. Surface modification of polymeric foams for oil spills remediation. J. Environ. Manag. 2018, 206, 872–889. [Google Scholar] [CrossRef]

- Zhou, W.; Li, G.; Wang, L.; Chen, Z.; Lin, Y. A facile method for the fabrication of a superhydrophobic polydopamine-coated copper foam for oil/water separation. Appl. Surf. Sci. 2017, 413, 140–148. [Google Scholar] [CrossRef]

- Liu, S.; Xu, Q.; Latthe, S.S.; Gurav, A.B.; Xing, R. Superhydrophobic/superoleophilic magnetic polyurethane sponge for oil/water separation. RSC Adv. 2015, 5, 68293–68298. [Google Scholar] [CrossRef]

- Wu, C.; Huang, X.; Wu, X.; Qian, R.; Jiang, P. Mechanically Flexible and Multifunctional Polymer-Based Graphene Foams for Elastic Conductors and Oil-Water Separators. Adv. Mater. 2013, 25, 5658–5662. [Google Scholar] [CrossRef]

- He, Z.; Zhang, X.; Batchelor, W. Cellulose nanofibre aerogel filter with tuneable pore structure for oil/water separation and recovery. RSC Adv. 2016, 6, 21435–21438. [Google Scholar] [CrossRef]

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Purcar, V.; Şomoghi, R.; Niţu, S.; Nicolae, C.-A.; Alexandrescu, E.; Gîfu, I.; Gabor, A.; Stroescu, H.; Ianchiş, R.; Căprărescu, S.; et al. The Effect of Different Coupling Agents on Nano-ZnO Materials Obtained via the Sol–Gel Process. Nanomaterials 2017, 7, 439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Y.; Wu, X.; Fang, J. Superhydrophobic and superoleophilic “sponge-like” aerogels for oil/water separation. J. Mater. Sci. 2015, 50, 5115–5124. [Google Scholar] [CrossRef]

- Ge, B.; Ren, G.; Yang, H.; Yang, J.; Pu, X.; Li, W.; Jin, C.; Zhang, Z. Fabrication of BiOBr-silicone aerogel photocatalyst in an aqueous system with degradation performance by sol-gel method. Sci. China Technol. Sci. 2020, 63, 859–865. [Google Scholar] [CrossRef]

- Ge, B.; Zhu, X.; Li, Y.; Men, X.; Li, P.; Zhang, Z. Versatile fabrication of magnetic superhydrophobic foams and application for oil–water separation. Colloids Surfaces A Physicochem. Eng. Asp. 2015, 482, 687–692. [Google Scholar] [CrossRef]

- Koh, J.J.; Lim, G.J.H.; Zhou, X.; Zhang, X.; Ding, J.; He, C. 3D-Printed Anti-Fouling Cellulose Mesh for Highly Efficient Oil/Water Separation Applications. ACS Appl. Mater. Interfaces 2019, 11, 13787–13795. [Google Scholar] [CrossRef]

- Li, J.; Yan, L.; Hu, W.; Li, D.; Zha, F.; Lei, Z. Facile fabrication of underwater superoleophobic TiO2 coated mesh for highly efficient oil/water separation. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 489, 441–446. [Google Scholar] [CrossRef]

- Milionis, A.; Bayer, I.S.; Loth, E. Recent advances in oil-repellent surfaces. Int. Mater. Rev. 2016, 61, 101–126. [Google Scholar] [CrossRef]

- Ou, R.; Wei, J.; Jiang, L.; Simon, G.P.; Wang, H. Robust Thermoresponsive Polymer Composite Membrane with Switchable Superhydrophilicity and Superhydrophobicity for Efficient Oil–Water Separation. Environ. Sci. Technol. 2016, 50, 906–914. [Google Scholar] [CrossRef]

- Wang, J.; Han, F.; Chen, Y.; Wang, H. A pair of MnO2 nanocrystal coatings with inverse wettability on metal meshes for efficient oil/water separation. Sep. Purif. Technol. 2019, 209, 119–127. [Google Scholar] [CrossRef]

- Fischer, S.; Thümmler, K.; Volkert, B.; Hettrich, K.; Schmidt, I.; Fischer, K. Properties and Applications of Cellulose Acetate. Macromol. Symp. 2008, 262, 89–96. [Google Scholar] [CrossRef]

- Kahraman, H.T.; Yar, A.; Avcı, A.; Pehlivan, E. Preparation of nanoclay incorporated PAN fibers by electrospinning technique and its application for oil and organic solvent absorption. Sep. Sci. Technol. 2018, 53, 303–311. [Google Scholar] [CrossRef]

- Kim, S.W.; Han, S.O.; Sim, I.N.; Cheon, J.Y.; Park, W.H. Fabrication and Characterization of Cellulose Acetate/Montmorillonite Composite Nanofibers by Electrospinning. J. Nanomater. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Ma, J.; Wang, Z.; Shi, F.; Liu, Q. Enhanced Separation Performance of PVDF/PVP-g-MMT Nanocomposite Ultrafiltration Membrane Based on the NVP-Grafted Polymerization Modification of Montmorillonite (MMT). Langmuir 2012, 28, 4776–4786. [Google Scholar] [CrossRef]

- Al-Samhan, M.; Samuel, J.; Al-Attar, F.; Abraham, G. Comparative Effects of MMT Clay Modified with Two Different Cationic Surfactants on the Thermal and Rheological Properties of Polypropylene Nanocomposites. Int. J. Polym. Sci. 2017, 2017, 5717968. [Google Scholar] [CrossRef] [Green Version]

- Darmanin, T.; Guittard, F. Recent advances in the potential applications of bioinspired superhydrophobic materials. J. Mater. Chem. A 2014, 2, 16319–16359. [Google Scholar] [CrossRef]

- Zhang, J.; Seeger, S. Polyester Materials with Superwetting Silicone Nanofilaments for Oil/Water Separation and Selective Oil Absorption. Adv. Funct. Mater. 2011, 21, 4699–4704. [Google Scholar] [CrossRef]

- Xue, C.-H.; Ji, P.-T.; Zhang, P.; Li, Y.-R.; Jia, S.-T. Fabrication of superhydrophobic and superoleophilic textiles for oil–water separation. Appl. Surf. Sci. 2013, 284, 464–471. [Google Scholar] [CrossRef]

- Zhang, X.; Geng, T.; Guo, Y.; Zhang, Z.; Zhang, P. Facile fabrication of stable superhydrophobic SiO2/polystyrene coating and separation of liquids with different surface tension. Chem. Eng. J. 2013, 231, 414–419. [Google Scholar] [CrossRef]

- Liang, B.; Zhang, G.; Zhong, Z.; Sato, T.; Hozumi, A.; Su, Z. Substrate-independent polyzwitterionic coating for oil/water separation membranes. Chem. Eng. J. 2019, 362, 126–135. [Google Scholar] [CrossRef]

- Shirazi, S.; Lin, C.-J.; Chen, D. Inorganic fouling of pressure-driven membrane processes—A critical review. Desalination 2010, 250, 236–248. [Google Scholar] [CrossRef]

- Chang, Q.; Zhou, J.; Wang, Y.; Liang, J.; Zhang, X.; Cerneaux, S.; Wang, X.; Zhu, Z.; Dong, Y. Application of ceramic microfiltration membrane modified by nano-TiO2 coating in separation of a stable oil-in-water emulsion. J. Memb. Sci. 2014, 456, 128–133. [Google Scholar] [CrossRef]

- Jin, F.; Lv, W.; Zhang, C.; Li, Z.; Su, R.; Qi, W.; Yang, Q.-H.; He, Z. High-performance ultrafiltration membranes based on polyethersulfone–graphene oxide composites. RSC Adv. 2013, 3, 21394. [Google Scholar] [CrossRef]

- Park, E.; Barnett, S.M. Oil/Water Separation Using Nanofiltration Membrane Technology. Sep. Sci. Technol. 2001, 36, 1527–1542. [Google Scholar] [CrossRef]

- Muppalla, R.; Jewrajka, S.K.; Reddy, A.V.R. Fouling resistant nanofiltration membranes for the separation of oil–water emulsion and micropollutants from water. Sep. Purif. Technol. 2015, 143, 125–134. [Google Scholar] [CrossRef]

- Hirose, M.; Ito, H.; Kamiyama, Y. Effect of skin layer surface structures on the flux behaviour of RO membranes. J. Memb. Sci. 1996, 121, 209–215. [Google Scholar] [CrossRef]

- Padaki, M.; Surya Murali, R.; Abdullah, M.S.; Misdan, N.; Moslehyani, A.; Kassim, M.A.; Hilal, N.; Ismail, A.F. Membrane technology enhancement in oil–water separation. A review. Desalination 2015, 357, 197–207. [Google Scholar] [CrossRef]

- Zhou, J.; Chang, Q.; Wang, Y.; Wang, J.; Meng, G. Separation of stable oil–water emulsion by the hydrophilic nano-sized ZrO2 modified Al2O3 microfiltration membrane. Sep. Purif. Technol. 2010, 75, 243–248. [Google Scholar] [CrossRef]

- Bruggen, B.V.D.; Vandecasteele, C.; Gestel, T.V.; Doyenb, W.; Leysenb, R. Review of Pressure-Driven Membrane Processes. Environ. Prog. 2003, 22, 46–56. [Google Scholar] [CrossRef]

- Almetwally, A.A.; El-Sakhawy, M.; Elshakankery, M.H.; Kasem, M.H. Technology of nano-fibers: Production techniques and properties—Critical review. J. Text. Assoc. 2017, 78, 5–14. [Google Scholar]

- Lam, Z.; Anlauf, H.; Nirschl, H. High-Pressure Jet Cleaning of Polymeric Microfiltration Membranes. Chem. Eng. Technol. 2020, 43, 457–464. [Google Scholar] [CrossRef]

- Jiang, Y.; Hou, J.; Xu, J.; Shan, B. Switchable oil/water separation with efficient and robust Janus nanofiber membranes. Carbon N. Y. 2017, 115, 477–485. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, W.; Wang, D.; Ni, X.; Han, G. Electrospun polyvinylidene fluoride-based fibrous nanocomposite membranes reinforced by cellulose nanocrystals for efficient separation of water-in-oil emulsions. J. Memb. Sci. 2019, 575, 71–79. [Google Scholar] [CrossRef]

- Alghoraibi, I.; Alomari, S. Different Methods for Nanofiber Design and Fabrication. In Handbook of Nanofibers; Barhoum, A., Bechelany, M., Makhlouf, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–46. [Google Scholar]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Arslan, O.; Aytac, Z.; Uyar, T. Superhydrophobic, Hybrid, Electrospun Cellulose Acetate Nanofibrous Mats for Oil/Water Separation by Tailored Surface Modification. ACS Appl. Mater. Interfaces 2016, 8, 19747–19754. [Google Scholar] [CrossRef]

- Hart, E. Theory of the tensile test. Acta Metall. 1967, 15, 351–355. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Sun, G.; Ding, B. Electrospun nanofibrous materials: A versatile medium for effective oil/water separation. Mater. Today 2016, 19, 403–414. [Google Scholar] [CrossRef]

- Chigome, S.; Darko, G.; Torto, N. Electrospun nanofibers as sorbent material for solid phase extraction. Analyst 2011, 136, 2879. [Google Scholar] [CrossRef] [Green Version]

- Persano, L.; Camposeo, A.; Pisignano, D. Active polymer nanofibers for photonics, electronics, energy generation and micromechanics. Prog. Polym. Sci. 2015, 43, 48–95. [Google Scholar] [CrossRef]

- Kenry; Lim, C.T. Nanofiber technology: Current status and emerging developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar] [CrossRef]

- Agarwal, S.; Greiner, A.; Wendorff, J.H. Functional materials by electrospinning of polymers. Prog. Polym. Sci. 2013, 38, 963–991. [Google Scholar] [CrossRef]

- He, S.; Zhan, Y.; Bai, Y.; Hu, J.; Li, Y.; Zhang, G.; Zhao, S. Gravity-driven and high flux super-hydrophobic/super-oleophilic poly(arylene ether nitrile) nanofibrous composite membranes for efficient water-in-oil emulsions separation in harsh environments. Compos. Part B Eng. 2019, 177, 107439. [Google Scholar] [CrossRef]

- Jiang, T.; Carbone, E.J.; Lo, K.W.H.; Laurencin, C.T. Electrospinning of polymer nanofibers for tissue regeneration. Prog. Polym. Sci. 2015, 46, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Greiner, A.; Wendorff, J.H. Electrospinning: A fascinating method for the preparation of ultrathin fibers. Angew. Chemie—Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef]

- Costa, R.G.F.; Oliveira, J.E.; Paula, G.F.; Picciani, P.H.S.; Medeiros, E.S.; Ribeiro, C.; Mattoso, L.H.C. Eletrofiação de Polímeros em Solução: Parte I: Fundamentação TeÃ3rica. Polímeros 2012, 22, 170–177. [Google Scholar] [CrossRef]

- Patel, M.; Patel, J.; Pawar, Y.; Patel, N.; Shah, M. Membrane-based downhole oil–water separation (DOWS) technology: An alternative to hydrocyclone-based DOWS. J. Pet. Explor. Prod. Technol. 2020, 10, 2079–2088. [Google Scholar] [CrossRef] [Green Version]

- Si, Y.; Yan, C.; Hong, F.; Yu, J.; Ding, B. A general strategy for fabricating flexible magnetic silica nanofibrous membranes with multifunctionality. Chem. Commun. 2015, 51, 12521–12524. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, F.; Song, J.; Liu, L.; Si, Y.; Yu, J.; Ding, B. Electrospun flexible nanofibrous membranes for oil/water separation. J. Mater. Chem. A 2019, 7, 20075–20102. [Google Scholar] [CrossRef]

- Hong, S.K.; Bae, S.; Jeon, H.; Kim, M.; Cho, S.J.; Lim, G. An underwater superoleophobic nanofibrous cellulosic membrane for oil/water separation with high separation flux and high chemical stability. Nanoscale 2018, 10, 3037–3045. [Google Scholar] [CrossRef] [Green Version]

- Benito, J.M.; Conesa, A.; Rubio, F.; Rodríguez, M.A. Preparation and characterization of tubular ceramic membranes for treatment of oil emulsions. J. Eur. Ceram. Soc. 2005, 25, 1895–1903. [Google Scholar] [CrossRef]

- Soares, L.G.; Alves, A.K. Obtenção por Electrospinning e Caracterização de Fibras Nanoestruturadas de TiO2 e sua Aplicação Fotocatalítica. Digital Repository. 2013, p. 82. Available online: http://hdl.handle.net/10183/85045 (accessed on 12 February 2023).

- Zhang, R.; Wang, X.; Song, J.; Si, Y.; Zhuang, X.; Yu, J.; Ding, B. In situ synthesis of flexible hierarchical TiO 2 nanofibrous membranes with enhanced photocatalytic activity. J. Mater. Chem. A 2015, 3, 22136–22144. [Google Scholar] [CrossRef]

- Barbosa, A.S.; Barbosa, A.S.; Rodrigues, M.G.F. Synthesis of zeolite membrane (MCM-22/α-alumina) and its application in the process of oil-water separation. Desalin. Water Treat. 2015, 56, 3665–3672. [Google Scholar] [CrossRef]

- Al-anzi, B.S.; Siang, O.C. Recent developments of carbon based nanomaterials and membranes for oily wastewater treatment. RSC Adv. 2017, 7, 20981–20994. [Google Scholar] [CrossRef] [Green Version]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Prince, J.A.; Bhuvana, S.; Anbharasi, V.; Ayyanar, N.; Boodhoo, K.V.K.; Singh, G. Ultra-wetting graphene-based PES ultrafiltration membrane—A novel approach for successful oil-water separation. Water Res. 2016, 103, 311–318. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Bhushan, B.; Pan, Y.; Zhao, X. Bioinspired superoleophobic/superhydrophilic functionalized cotton for efficient separation of immiscible oil-water mixtures and oil-water emulsions. J. Colloid Interface Sci. 2019, 548, 123–130. [Google Scholar] [CrossRef]

- Meng, T.; Xie, R.; Ju, X.-J.; Cheng, C.-J.; Wang, S.; Li, P.-F.; Liang, B.; Chu, L.-Y. Nano-structure construction of porous membranes by depositing nanoparticles for enhanced surface wettability. J. Memb. Sci. 2013, 427, 63–72. [Google Scholar] [CrossRef]

- Chen, C.; Weng, D.; Mahmood, A.; Chen, S.; Wang, J. Separation Mechanism and Construction of Surfaces with Special Wettability for Oil/Water Separation. ACS Appl. Mater. Interfaces 2019, 11, 11006–11027. [Google Scholar] [CrossRef]

- Xue, Z.; Cao, Y.; Liu, N.; Feng, L.; Jiang, L. Special wettable materials for oil/water separation. J. Mater. Chem. A 2014, 2, 2445–2460. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Geng, G. Flame-retardant superhydrophobic coating derived from fly ash on polymeric foam for efficient oil/corrosive water and emulsion separation. J. Colloid Interface Sci. 2018, 525, 11–20. [Google Scholar] [CrossRef]

- Yang, S.; Yin, K.; Wu, J.; Wu, Z.; Chu, D.; He, J.; Duan, J.-A. Ultrafast nano-structuring of superwetting Ti foam with robust antifouling and stability towards efficient oil-in-water emulsion separation. Nanoscale 2019, 11, 17607–17614. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.-Y.; Lyu, S.-S.; Wang, Y.-Q.; Mo, D.-C. Fluorine-Induced Superhydrophilic Ti Foam with Surface Nanocavities for Effective Oil-in-Water Emulsion Separation. Ind. Eng. Chem. Res. 2017, 56, 699–707. [Google Scholar] [CrossRef]

- Yang, S.; Chen, L.; Liu, S.; Hou, W.; Zhu, J.; Zhang, Q.; Zhao, P. Robust Bifunctional Compressed Carbon Foam for Highly Effective Oil/Water Emulsion Separation. ACS Appl. Mater. Interfaces 2020, 12, 44952–44960. [Google Scholar] [CrossRef]

- Si, Y.; Fu, Q.; Wang, X.; Zhu, J.; Yu, J.; Sun, G.; Ding, B. Superelastic and Superhydrophobic Nanofiber-Assembled Cellular Aerogels for Effective Separation of Oil/Water Emulsions. ACS Nano 2015, 9, 3791–3799. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Zhang, T.; Yang, D.; Qiu, F.; Li, Z. Hybrid aerogels derived from banana peel and waste paper for efficient oil absorption and emulsion separation. J. Clean. Prod. 2018, 199, 411–419. [Google Scholar] [CrossRef]

- Chaudhary, J.P.; Vadodariya, N.; Nataraj, S.K.; Meena, R. Chitosan-Based Aerogel Membrane for Robust Oil-in-Water Emulsion Separation. ACS Appl. Mater. Interfaces 2015, 7, 24957–24962. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Zhang, Q.; Hua, D.; Xiong, R.; Zhao, J.; Rao, W.; Huang, S.; Zhan, X.; Chen, F.; Huang, C. Electrospun fibers for oil–water separation. RSC Adv. 2016, 6, 12868–12884. [Google Scholar] [CrossRef]

- Zarghami, S.; Mohammadi, T.; Sadrzadeh, M.; Van der Bruggen, B. Superhydrophilic and underwater superoleophobic membranes—A review of synthesis methods. Prog. Polym. Sci. 2019, 98, 101166. [Google Scholar] [CrossRef]

- Cui, J.; Zhou, Z.; Xie, A.; Meng, M.; Cui, Y.; Liu, S.; Lu, J.; Zhou, S.; Yan, Y.; Dong, H. Bio-inspired fabrication of superhydrophilic nanocomposite membrane based on surface modification of SiO2 anchored by polydopamine towards effective oil-water emulsions separation. Sep. Purif. Technol. 2019, 209, 434–442. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.; Cao, B. Fabrication of Superhydrophobic–Superoleophilic Fabrics by an Etching and Dip-Coating Two-Step Method for Oil–Water Separation. Ind. Eng. Chem. Res. 2016, 55, 5030–5035. [Google Scholar] [CrossRef]

- Obaid, M.; Mohamed, H.O.; Yasin, A.S.; Yassin, M.A.; Fadali, O.A.; Kim, H.; Barakat, N.A.M. Under-oil superhydrophilic wetted PVDF electrospun modified membrane for continuous gravitational oil/water separation with outstanding flux. Water Res. 2017, 123, 524–535. [Google Scholar] [CrossRef] [PubMed]

- Monticelli, O.; Bottino, A.; Scandale, I.; Capannelli, G.; Russo, S. Preparation and properties of polysulfone–clay composite membranes. J. Appl. Polym. Sci. 2007, 103, 3637–3644. [Google Scholar] [CrossRef]

- Mota, M.F.; Rodrigues, M.G.F.; Machado, F. Oil–water separation process with organoclays: A comparative analysis. Appl. Clay Sci. 2014, 99, 237–245. [Google Scholar] [CrossRef]

- Moazed, H.; Viraraghavan, T. Use of Organo-Clay/Anthracite Mixture in the Separation of Oil from Oily Waters. Energy Sources 2005, 27, 101–112. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, D. Novel clay-based nanofibrous membranes for effective oil/water emulsion separation. Ceram. Int. 2017, 43, 9465–9471. [Google Scholar] [CrossRef]

- Yu, T.; Swientoniewski, L.T.; Omarova, M.; Li, M.-C.; Negulescu, I.I.; Jiang, N.; Darvish, O.A.; Panchal, A.; Blake, D.A.; Wu, Q.; et al. Investigation of Amphiphilic Polypeptoid-Functionalized Halloysite Nanotubes as Emulsion Stabilizer for Oil Spill Remediation. ACS Appl. Mater. Interfaces 2019, 11, 27944–27953. [Google Scholar] [CrossRef]

- Wu, F.; Pickett, K.; Panchal, A.; Liu, M.; Lvov, Y. Superhydrophobic Polyurethane Foam Coated with Polysiloxane-Modified Clay Nanotubes for Efficient and Recyclable Oil Absorption. ACS Appl. Mater. Interfaces 2019, 11, 25445–25456. [Google Scholar] [CrossRef]

- Stehl, D.; Skale, T.; Hohl, L.; Lvov, Y.; Koetz, J.; Kraume, M.; Drews, A.; von Klitzing, R. Oilc-in-Water Pickering Emulsions Stabilized by Halloysite Clay Nanotubes Toward Efficient Filterability. ACS Appl. Nano Mater. 2020, 3, 11743–11751. [Google Scholar] [CrossRef]

- Panchal, A.; Swientoniewski, L.T.; Omarova, M.; Yu, T.; Zhang, D.; Blake, D.A.; John, V.; Lvov, Y.M. Bacterial proliferation on clay nanotube Pickering emulsions for oil spill bioremediation. Colloids Surfaces B Biointerfaces 2018, 164, 27–33. [Google Scholar] [CrossRef]

| Efficiency for Oil/Water Mixture Separation | |

|---|---|

| Foams and sponges | |

| Commercial copper foam surface modified with polydopamine, AgNO3, n-dodecyl mercaptan | 95% for 30 cycles [42] |

| Commercial polyurethane (PU) sponge with magnetic properties due to a Fe3O4 nanoparticles coating | 35 times its weight [43] |

| Polymer-based graphene foam (PGB) by a low-cost self-assembly technique of graphene sheets on a PU skeleton | 90% for 300 cycles [44] |

| Aerogels | |

| A sponge-like aerogel produced by a sol-gel method using organoalkoxysilanes precursors | Absorption capacities up to 10 cycles [48] |

| Hydrophobic BiOBr-silicone aerogel, fabricated by a sol-gel method | Superhydrophobic aerogels with excellent mechanical properties, superhydrophobicity and degradation stability. |

| Nanoparticle incorporation | |

| Polyurethane sponge coated by dip-coating method with polyfluorowax and hydrophobic silica nanoparticles (HPS) | Absorption capacity up to 10 cycles [50] |

| Polyurethane foam functionalized with magnetic Fe3O4 superhydrophobic nanoparticles | 70 g/g up to 200 cycles, magnetic behavior [50] |

| Meshes | |

| Superoleophobic stainless steel mesh coated with TiO2 nanoparticles | 99% for 40 cycles [52] |

| Stainless steel mesh coated with the MnO2 nanocrystals by hydrothermal synthesis | 95.6% [55] |

| 3D printed cellulose acetate meshes | 95% [51] |

| Clays | |

| Hydrophobic and oleophilic electrospun polyacrylonitrile (PAN) membrane with Cloisite 30B incorporated onto the nanofibers | 180 g/g [57] |

| Textiles | |

| 70% cotton and 30% polyester immersed in a SiO2/PS suspension | 97% [64] |

| Membranes | |

| electrospun polytetrafluoroethylene (PTFE) | 99% [92] |

| poly(arylene ether nitrile) (PEN) nanofibrous membrane, produced by electrospinning and hot-pressing techniques | 99%, after 24 h [88] |

| electrospun polysulfone (PSf) membrane immersed in a NaOH solution | 99.99% [36] |

| electrospun cellulose acetate nanofibrous membrane | 99% for more than one cycle [95] |

| Efficiency for Oil/Water Emulsion Separation | |

|---|---|

| Foams and sponges | |

| Polyurethane (PU) foam coated in an alkaline medium containing dopamine, dodecanethiol, and fly ash | 93% for 15 cycles [107] |

| Commercial Ti foam treated with a one-step femtosecond laser | 99% [108] |

| Commercial titanium (Ti) foam anodized in non-toxic fluorine-containing electrolyte | 99% [109] |

| Compressed foam fabricated by carbonization of a 3D, commercially available melamine foam | Higher than 98% [110] |

| Aerogels | |

| SiO2 and polyacrylonitrile (PAN) with the incorporation of SiO2 nanoparticles | 99% [111] |

| Aerogel derived from wastepaper and banana peels | 99.6% [112] |

| Chitosan and agarose-based aerogel | 99% [113] |

| Membranes | |

| Al2O3 membrane modified with a ZrO2 coating, by hydrolysis of ZrCl4 | 97.8% [73] |

| SiO2 nanocomposite polyvinylidene fluoride membrane (PVDF) | 98% for10 cycles [116] |

| Polymer-based nanofiber membrane dip-coated in a solution containing a polymer of intrinsic microporosity (PIM-1) | 99.95% for 30 cycles [117] |

| Polymer-based nanofiber membrane dip-coated in a solution containing a polymer of intrinsic microporosity fluorinated al-kylsilane (PTES) | 99.97% for 30 cycles [117] |

| Electrospun composite membrane with cellulose nanocrystals (CNC) stamped by screen-printing | 83% |

| Electrospun Polyvinylidene fluoride (PVDF) nanofibrous membrane with Triethylamine | 99% [118] |

| Clays | |

| Brazilian clays (green calcium bentonite−aluminum clay minerals) modified with surfactants into their interlayer space | 96% [120] |

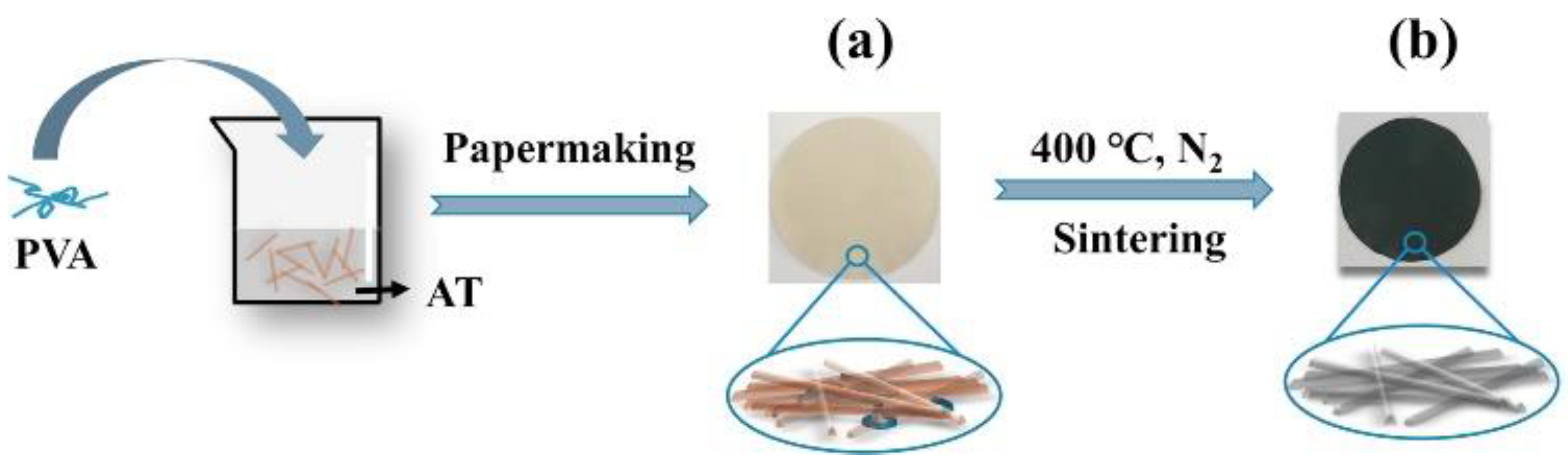

| Attapulgite and poly(vinyl alcohol) (PVA) nanofibrous membrane via papermaking and posterior sintering | 97% [122] |

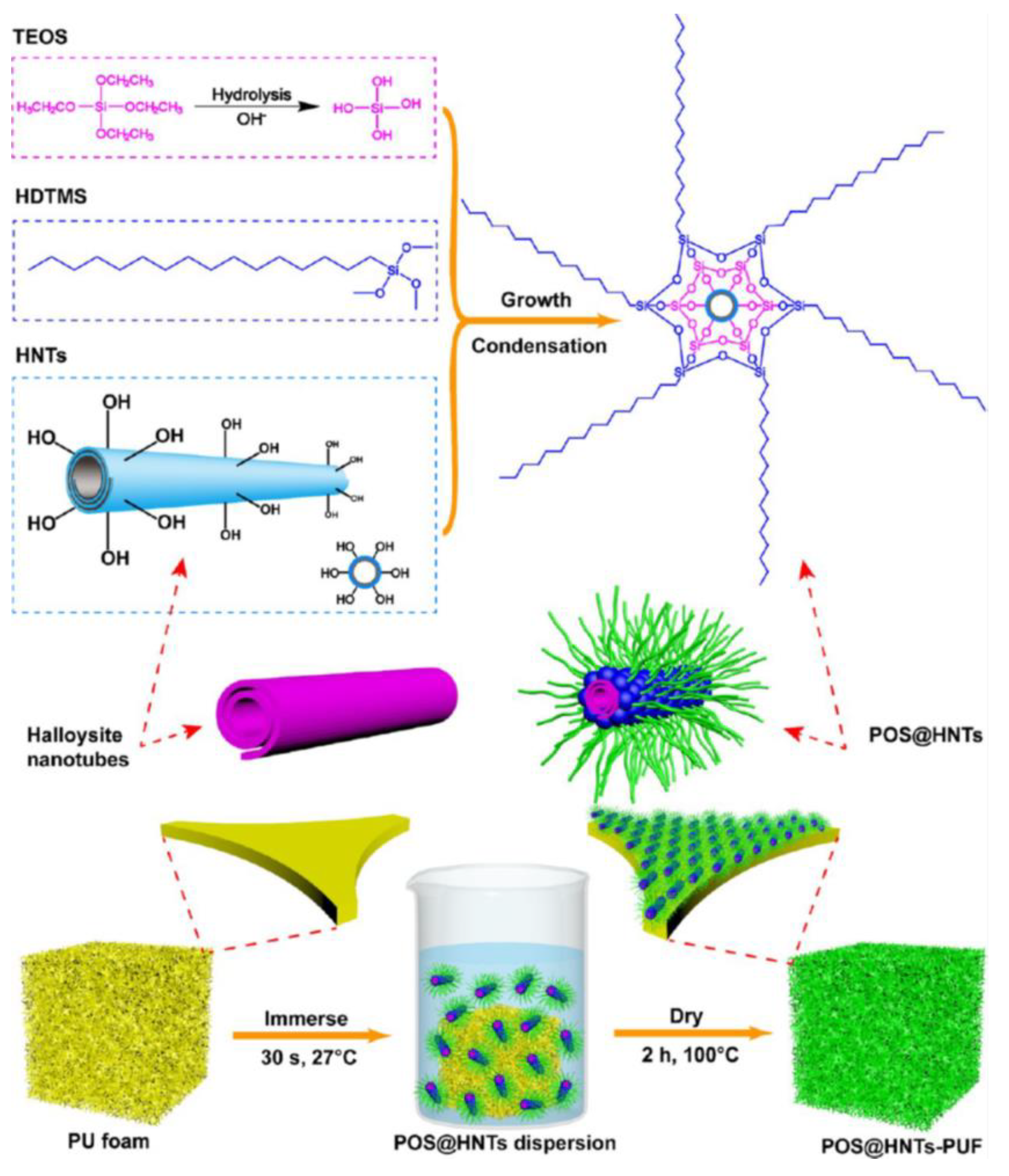

| Polymer foam prepared by dip coating in silanized clay nanotube dispersion | 105 times its weight in chloroform for 10 cycles [124] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

José, M.H.; Canejo, J.P.; Godinho, M.H. Oil/Water Mixtures and Emulsions Separation Methods—An Overview. Materials 2023, 16, 2503. https://doi.org/10.3390/ma16062503

José MH, Canejo JP, Godinho MH. Oil/Water Mixtures and Emulsions Separation Methods—An Overview. Materials. 2023; 16(6):2503. https://doi.org/10.3390/ma16062503

Chicago/Turabian StyleJosé, Maria Helena, João Paulo Canejo, and Maria Helena Godinho. 2023. "Oil/Water Mixtures and Emulsions Separation Methods—An Overview" Materials 16, no. 6: 2503. https://doi.org/10.3390/ma16062503

APA StyleJosé, M. H., Canejo, J. P., & Godinho, M. H. (2023). Oil/Water Mixtures and Emulsions Separation Methods—An Overview. Materials, 16(6), 2503. https://doi.org/10.3390/ma16062503