Effects of Wall Thickness Variation on Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel with Lattice Auxetic Structures

Abstract

:1. Introduction

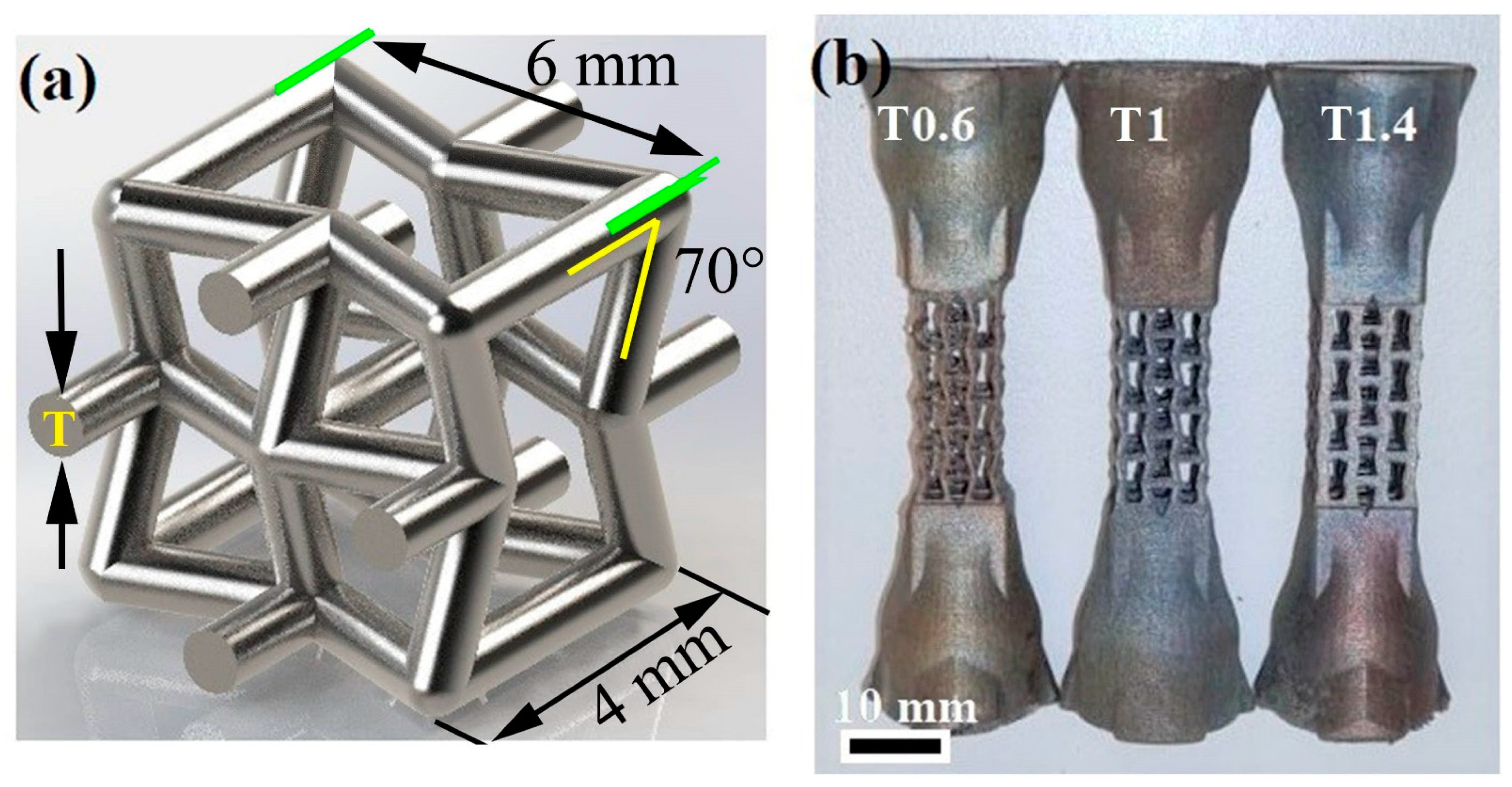

2. Experimental Procedures

2.1. Materials

2.2. H-Charging Setup

2.3. Microstructure Characterization

3. Results

3.1. Surface Morphology

3.2. Mechanical Tensile Properties: Effect of H-Charging

3.3. Fractography

4. Discussion

4.1. Effect of Thickness Change on HE Susceptibility

4.2. Microstructure Evolution in the H-Charged Specimens

5. Conclusions

- (1)

- The surface morphology of the auxetic lattice structure was affected by the thickness variation. The minimum strut thickness (T0.6) displayed the highest surface roughness, Ra 21 μm, with significant surface flaws.

- (2)

- The mechanical strength of the auxetic structures slightly decreased, about 5–6%, for all strut thicknesses. However, the ductility (UE) of the highest strut thickness (T1.4) showed a considerable reduction, about 17.6%, with H charging.

- (3)

- The fracture surfaces of the noncharged 316L-SS are better than that of their counterparts in the H-charged sample. Whereas the fracture surfaces of the noncharged material mainly showed a dimple feature, the H-charged material exhibited a cleavage fracture region, which is due to the impact of HE susceptibility.

- (4)

- No phase transformation in the H-charged material occurred; however, the mechanical twinning deformation mechanism was enhanced in the high strut thickness materials. The fractions of Σ3 boundaries were 1.8% and 17.3% in T0.6 and T1.4, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ilbas, M.; Kumuk, O.; Karyeyen, S. Modelling of the gas-turbine colorless distributed combustion: An application to hydrogen enriched—Kerosene fuel. Int. J. Hydrogen Energy 2022, 47, 12354–12364. [Google Scholar] [CrossRef]

- Yusaf, T.; Fernandes, L.; Abu Talib, A.R.; Altarazi, Y.S.M.; Alrefae, W.; Kadirgama, K.; Ramasamy, D.; Jayasuriya, A.; Brown, G.; Mamat, R.; et al. Sustainable Aviation—Hydrogen Is the Future. Sustainability 2022, 14, 548. [Google Scholar] [CrossRef]

- Tarhan, C.; Çil, M.A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J. Energy Storage 2021, 40, 102676. [Google Scholar] [CrossRef]

- Wang, Y.; Vogel, A.; Sachs, M.; Sprick, R.S.; Wilbraham, L.; Moniz, S.J.; Godin, R.; Zwijnenburg, M.A.; Durrant, J.R.; Cooper, A.I.; et al. Current understanding and challenges of solar-driven hydrogen generation using polymeric photocatalysts. Nat. Energy 2019, 4, 746–760. [Google Scholar] [CrossRef]

- Khedr, M.; Li, W.; Zhu, X.; Zhou, P.; Gao, S.; Jin, X. Improving hydrogen embrittlement resistance of Hadfield steel by thermo-mechanical flash-treatment. Mater. Sci. Eng. A 2018, 712, 133–139. [Google Scholar] [CrossRef]

- Abraham, D.P.; Altstetter, C.J. Hydrogen-enhanced localization of plasticity in an austenitic stainless steel. Metall. Mater. Trans. A 1995, 26, 2859–2871. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. Hydrogen embrittlement of low carbon structural steel at macro-, micro- and nano-levels. Int. J. Hydrogen Energy 2020, 45, 2145–2156. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B.; Ngo, T.D. Influence of hydrogen-enhanced plasticity and decohesion mechanisms of hydrogen embrittlement on the fracture resistance of steel. Eng. Fail. Anal. 2021, 123, 105312. [Google Scholar] [CrossRef]

- Martin, M.L.; Dadfarnia, M.; Nagao, A.; Wang, S.; Sofronis, P. Enumeration of the hydrogen-enhanced localized plasticity mechanism for hydrogen embrittlement in structural materials. Acta Mater. 2019, 165, 734–750. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, H. A new perspective on hydrogen diffusion and hydrogen embrittlement in low-alloy high strength steel. Corros. Sci. 2020, 174, 108800. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, A.; Lv, J.; Peng, T.; Muzamil, M. A state-of-the-art review on energy consumption and quality characteristics in metal additive manufacturing processes. J Braz. Soc. Mech. Sci. Eng. 2020, 42, 249. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Abdel-Aziem, W.; Elkatatny, S.; Abd-Elaziem, A.E.; Khedr, M.; Abd El-baky, M.A.; Hassan, M.A.; Abu-Okail, M.; Mohammed, M.; Järvenpää, A.; Allam, T. On the current research progress of metallic materials fabricated by laser powder bed fusion process: A review. J. Mater. Res. Technol. 2022, 20, 681–707. [Google Scholar] [CrossRef]

- Baek, S.; Song, E.J.; Kim, J.H.; Jung, M.; Baek, U.B.; Nahm, S.H. Hydrogen embrittlement of 3-D printing manufactured austenitic stainless steel part for hydrogen service. Scr. Mater. 2017, 130, 87–90. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Zhu, Z.; Nai, S.M.L. Selective Laser Melting of 304L and 316L Stainless Steels: A Comparative Study of Microstructures and Mechanical Properties. Steel Res. Int. 2022, 93, 2100664. [Google Scholar] [CrossRef]

- Vukkum, V.; Gupta, R. Review on corrosion performance of laser powder-bed fusion printed 316L stainless steel: Effect of processing parameters, manufacturing defects, post-processing, feedstock, and microstructure. Mater. Des. 2022, 221, 110874. [Google Scholar] [CrossRef]

- Pham, M.; Dovgyy, B.; Hooper, P. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Hong, Y.; Zhou, C.; Wagner, S.; Schlabach, S.; Pundt, A.; Zhang, L.; Zheng, J. Strain-induced twins and martensite: Effects on hydrogen embrittlement of selective laser melted (SLM) 316 L stainless steel. Corros. Sci. 2022, 208, 110669. [Google Scholar] [CrossRef]

- Bertsch, K.; Nagao, A.; Rankouhi, B.; Kuehl, B.; Thoma, D. Hydrogen embrittlement of additively manufactured austenitic stainless steel 316 L. Corros. Sci. 2021, 192, 109790. [Google Scholar] [CrossRef]

- Metalnikov, P.; Ben-Hamu, G.; Eliezer, D. Hydrogen Trapping in Laser Powder Bed Fusion 316L Stainless Steel. Metals 2022, 12, 1748. [Google Scholar] [CrossRef]

- Maksimkin, I.P.; Yukhimchuk, A.A.; Malkov, I.L.; Boitsov, I.E.; Musyaev, R.K.; Buchirin, A.V.; Baluev, V.V.; Vertei, A.V.; Shevnin, E.V.; Shotin, S.V.; et al. Effect of Hydrogen on the Structure and Mechanical Properties of 316L Steel and Inconel 718 Alloy Processed by Selective Laser Melting. Materials 2022, 15, 4806. [Google Scholar] [CrossRef]

- Khaleghifar, F.; Razeghi, K.; Heidarzadeh, A.; Taherzadeh Mousavian, R. Effect of Hydrogen on the Tensile Behavior of Austenitic Stainless Steels 316L Produced by Laser-Powder Bed Fusion. Metals 2021, 11, 586. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Meng, L.; Liu, D.; Xu, T.; Xu, D.; Shao, X.; Shao, C.; Li, S.; Zhang, P.; et al. Significance of Melt Pool Structure on the Hydrogen Embrittlement Behavior of a Selective Laser-Melted 316L Austenitic Stainless Steel. Materials 2023, 16, 1741. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Zhang, K.; Hong, Y.; Zhu, H.; Zhang, W.; He, Y.; Zhou, C.; Zheng, J.; Zhang, L. The dependence of hydrogen embrittlement on hydrogen transport in selective laser melted 304L stainless steel. Int. J. Hydrogen Energy 2021, 46, 16153–16163. [Google Scholar] [CrossRef]

- Lee, D.; Sun, B.; Lee, S.; Ponge, D.; Jägle, E.A.; Raabe, D. Comparative study of hydrogen embrittlement resistance between additively and conventionally manufactured 304L austenitic stainless steels. Mater. Sci. Eng. A 2021, 803, 140499. [Google Scholar] [CrossRef]

- Yamada, K.; Koyama, M.; Kaneko, T.; Tsuzaki, K. Positive and negative effects of hydrogen on tensile behavior in polycrystalline Fe–30Mn–(6 − x)Si–xAl austenitic alloys. Scr. Mater. 2015, 105, 54–57. [Google Scholar] [CrossRef] [Green Version]

- Robertson, I. The effect of hydrogen on dislocation dynamics. Eng. Fract. Mech. 2001, 65, 649–673. [Google Scholar] [CrossRef]

- Mustahsan, F.; Khan, S.Z.; Zaidi, A.A.; Alahmadi, Y.H.; Mahmoud, E.R.I.; Almohamadi, H. Re-Entrant Honeycomb Auxetic Structure with Enhanced Directional Properties. Materials 2022, 15, 8022. [Google Scholar] [CrossRef]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 23001. [Google Scholar] [CrossRef]

- Najafi, M.; Ahmadi, H.; Liaghat, G. Experimental investigation on energy absorption of auxetic structures. Mater Today Proc 2021, 34, 350–355. [Google Scholar] [CrossRef]

- Yang, H.; Wang, B.; Ma, L. Mechanical properties of 3D double-U auxetic structures. Int. J. Solids Struct. 2019, 180–181, 13–29. [Google Scholar] [CrossRef]

- Zhou, H.; He, N.; Zhang, D.Z.; Zhao, M.; Zhang, T.; Ma, X. Mechanical properties of functionally graded rotating lattice structures fabricated with SLM process. Mater. Today Commun. 2022, 33, 104740. [Google Scholar] [CrossRef]

- Maran, S.; Masters, I.G.; Gibbons, G.J. Additive Manufacture of 3D Auxetic Structures by Laser Powder Bed Fusion—Design Influence on Manufacturing Accuracy and Mechanical Properties. Appl. Sci. 2020, 10, 7738. [Google Scholar] [CrossRef]

- Delcuse, L.; Bahi, S.; Gunputh, U.; Rusinek, A.; Wood, P.; Miguelez, M. Effect of powder bed fusion laser melting process parameters, build orientation and strut thickness on porosity, accuracy and tensile properties of an auxetic structure in IN718 alloy. Addit. Manuf. 2020, 36, 101339. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Jiang, C.-P.; Wibisono, A.T.; Pasang, T. Selective Laser Melting of Stainless Steel 316L with Face-Centered-Cubic-Based Lattice Structures to Produce Rib Implants. Materials 2021, 14, 5962. [Google Scholar] [CrossRef]

- Rhode, M.; Richter, T.; Mente, T.; Mayr, P.; Nitsche, A. Thickness and microstructure effect on hydrogen diffusion in creep-resistant 9% Cr P92 steel and P91 weld metal. Weld World 2022, 66, 325–340. [Google Scholar] [CrossRef]

- Li, Y.; Gong, B.; Li, X.; Deng, C.; Wang, D. Specimen thickness effect on the property of hydrogen embrittlement in single edge notch tension testing of high strength pipeline steel. Int. J. Hydrogen Energy 2018, 43, 15575–15585. [Google Scholar] [CrossRef]

- Ahuja, B.; Schaub, A.; Karg, M.; Lechner, M.; Merklein, M.; Schmidt, M. Developing LBM Process Parameters for Ti-6Al-4V Thin Wall Structures and Determining the Corresponding Mechanical Characteristics. Phys. Procedia 2014, 56, 90–98. [Google Scholar] [CrossRef] [Green Version]

- Brown, B.; Everhart, W.; Dinardo, J. Characterization of bulk to thin wall mechanical response transition in powder bed AM. Rapid Prototyp. J. 2016, 22, 801–809. [Google Scholar] [CrossRef]

- Zhong, T.; He, K.; Li, H.; Yang, L. Mechanical properties of lightweight 316L stainless steel lattice structures fabricated by selective laser melting. Mater. Des. 2019, 181, 108076. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Queiroga, L.R.; Marcolino, G.F.; Santos, M.; Rodrigues, G.; Eduardo dos Santos, C.; Brito, P. Influence of machining parameters on surface roughness and susceptibility to hydrogen embrittlement of austenitic stainless steels. Int. J. Hydrogen Energy 2019, 44, 29027–29033. [Google Scholar] [CrossRef]

- Kim, K. Mechanical performance of additively manufactured austenitic 316L stainless steel. Nucl. Eng. Technol. 2022, 54, 244–254. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Tor, S.B.; Chua, C.K. Improvement of densification and microstructure of ASTM A131 EH36 steel samples additively manufactured via selective laser melting with varying laser scanning speed and hatch spacing. Mater. Sci. Eng. A 2019, 746, 300–313. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, surface quality, microhardness and microstructure of selective laser melted 316L stainless steel resulting from finish machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- Todaro, C.; Easton, M.; Qiu, D.; Brandt, M.; StJohn, D.; Qian, M. Grain refinement of stainless steel in ultrasound-assisted additive manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Wang, C.; Loh, Y.M.; Cheung, C.F.; Liang, X.; Zhang, Z.; Ho, L.T. Post processing of additively manufactured 316L stainless steel by multi-jet polishing method. J. Mater. Res. Technol. 2023, 23, 530–550. [Google Scholar] [CrossRef]

- Khedr, M.; Li, W.; Min, N.; Liu, W.; Jin, X. Effects of increasing the strain rate on mechanical twinning and dynamic strain aging in Fe-12.5Mn-1.1C and Fe–24Mn-0.45C–2Al austenitic steels. Mater. Sci. Eng. A 2022, 842, 143024. [Google Scholar] [CrossRef]

- Wang, S.; Hashimoto, N.; Ohnuki, S. Effects of hydrogen on activation volume and density of mobile dislocations in iron-based alloy. Mater. Sci. Eng. A 2013, 562, 101–108. [Google Scholar] [CrossRef]

- Navi, N.U.; Tenenbaum, J.; Sabatani, E.; Kimmel, G.; Ben David, R.; Rosen, B.A.; Barkay, Z.; Ezersky, V.; Tiferet, E.; Ganor, Y.I.; et al. Hydrogen effects on electrochemically charged additive manufactured by electron beam melting (EBM) and wrought Ti–6Al–4V alloys. Int. J. Hydrogen Energy 2020, 45, 25523–25540. [Google Scholar] [CrossRef]

- Jaskari, M.; Ghosh, S.; Miettunen, I.; Karjalainen, P.; Järvenpää, A. Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities. Materials 2021, 14, 5809. [Google Scholar] [CrossRef] [PubMed]

- Bozzolo, N.; Bernacki, M. Viewpoint on the Formation and Evolution of Annealing Twins During Thermomechanical Processing of FCC Metals and Alloys. Metall. Mater. Trans. A 2020, 51, 2665–2684. [Google Scholar] [CrossRef]

- Monier, L.; Buttard, M.; Veron, M.; Blandin, J.; Martin, G.; Villaret, F.; Shen, Y.; Yrieix, B.; Ernould, C.; Guyon, J.; et al. On the origin of grain refinement and twin boundaries in as-fabricated austenitic stainless steels produced by laser powder bed fusion. Addit. Manuf. 2023, 61, 103351. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D. Dislocation Arrays and Crystal Boundaries. Introduction to Dislocations, 5th ed.; Science Direct: Amsterdam, The Netherlands; pp. 171–204. [CrossRef]

- Gao, S.; Hu, Z.; Duchamp, M.; Krishnan, P.S.R.; Tekumalla, S.; Song, X.; Seita, M. Recrystallization-based grain boundary engineering of 316L stainless steel produced via selective laser melting. Acta Mater. 2020, 200, 366–377. [Google Scholar] [CrossRef]

- Koyama, M.; Akiyama, E.; Lee, Y.; Raabe, D.; Tsuzaki, K. Overview of hydrogen embrittlement in high-Mn steels. Int. J. Hydrogen Energy 2017, 42, 12706–12723. [Google Scholar] [CrossRef]

- Khedr, M.; Wei, L.; Na, M.; Yu, L.; Xuejun, J. Evolution of Fracture Mode in Nano-twinned Fe-1.1C-12.5Mn Steel. JOM 2019, 71, 1338–1348. [Google Scholar] [CrossRef]

- Laadel, N.; El Mansori, M.; Kang, N.; Marlin, S.; Boussant-Roux, Y. Permeation barriers for hydrogen embrittlement prevention in metals—A review on mechanisms, materials suitability and efficiency. Int. J. Hydrogen Energy 2022, 47, 32707–32731. [Google Scholar] [CrossRef]

| Element | C | Cr | Ni | Mn | Mo | Si | Ti | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.02 | 17.7 | 12.9 | 0.6 | 2.5 | 0.7 | 0.01 | 0.02 | Bal. |

| Specimen | Without H | With H | UTS Reduction, % | UE Reduction, % | ||||

|---|---|---|---|---|---|---|---|---|

| YS, MPa | UTS, MPa | UE, % | YS, MPa | UTS, MPa | UE, % | |||

| T0.6 | 132 ± 3 | 340 ± 6 | 17.4 ± 0.1 | 125± 4 | 320 ± 7 | 16.7 ± 0.1 | 6 | 4 |

| T1 | 257 ± 6 | 486 ± 10 | 19.1 ± 0.4 | 245 ± 5 | 462 ± 10 | 16.4 ± 0.5 | 5 | 14 |

| T1.4 | 299 ± 7 | 550 ± 10 | 29 ± 0.3 | 284 ± 5 | 523 ± 10 | 23.9 ± 0.3 | 5 | 17.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khedr, M.; Hamada, A.; Abd-Elaziem, W.; Jaskari, M.; Elsamanty, M.; Kömi, J.; Järvenpää, A. Effects of Wall Thickness Variation on Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel with Lattice Auxetic Structures. Materials 2023, 16, 2523. https://doi.org/10.3390/ma16062523

Khedr M, Hamada A, Abd-Elaziem W, Jaskari M, Elsamanty M, Kömi J, Järvenpää A. Effects of Wall Thickness Variation on Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel with Lattice Auxetic Structures. Materials. 2023; 16(6):2523. https://doi.org/10.3390/ma16062523

Chicago/Turabian StyleKhedr, Mahmoud, Atef Hamada, Walaa Abd-Elaziem, Matias Jaskari, Mahmoud Elsamanty, Jukka Kömi, and Antti Järvenpää. 2023. "Effects of Wall Thickness Variation on Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel with Lattice Auxetic Structures" Materials 16, no. 6: 2523. https://doi.org/10.3390/ma16062523

APA StyleKhedr, M., Hamada, A., Abd-Elaziem, W., Jaskari, M., Elsamanty, M., Kömi, J., & Järvenpää, A. (2023). Effects of Wall Thickness Variation on Hydrogen Embrittlement Susceptibility of Additively Manufactured 316L Stainless Steel with Lattice Auxetic Structures. Materials, 16(6), 2523. https://doi.org/10.3390/ma16062523