Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin

Abstract

:1. Introduction

2. Materials and Methods

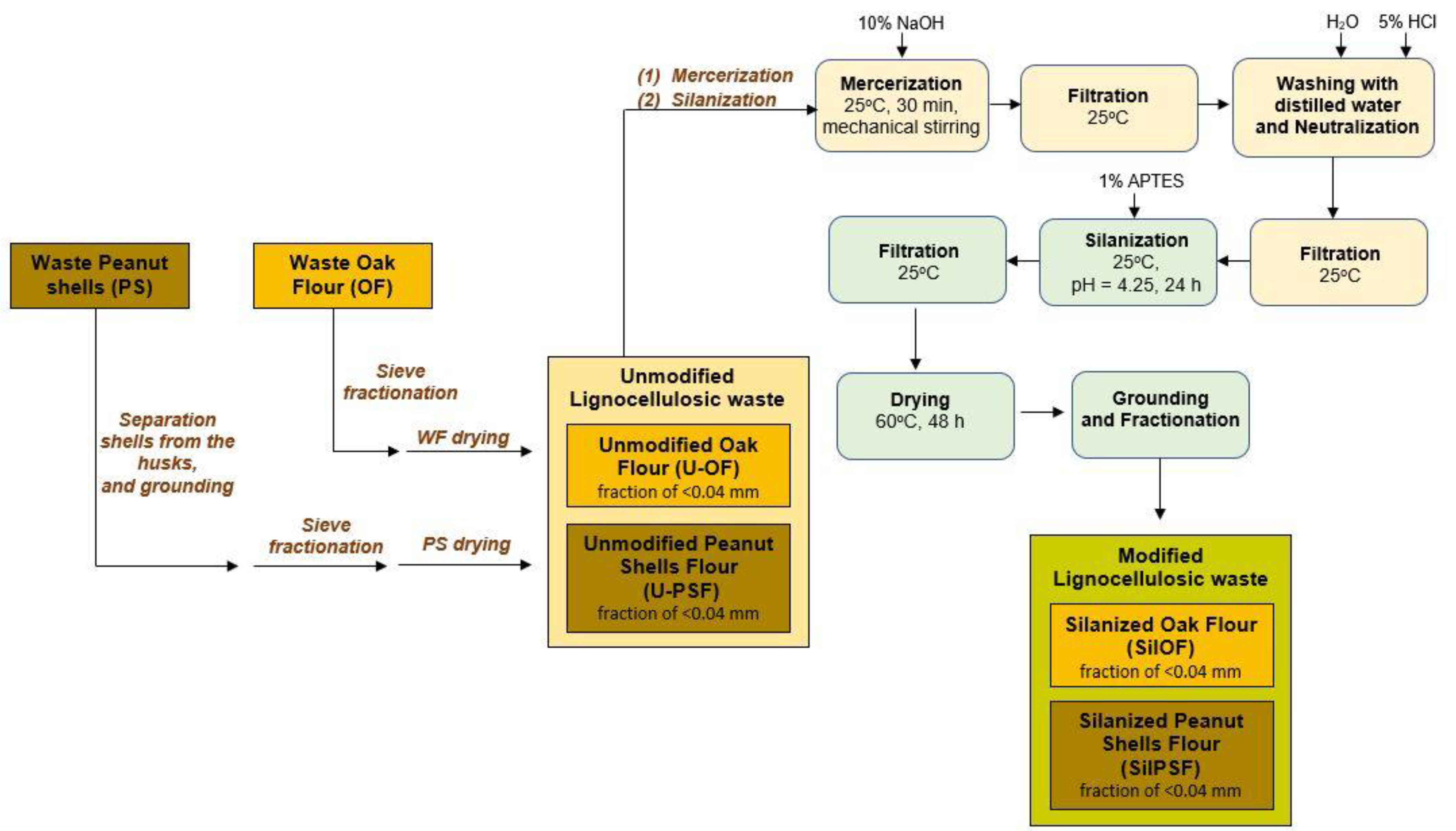

2.1. Natural Filler Preparation

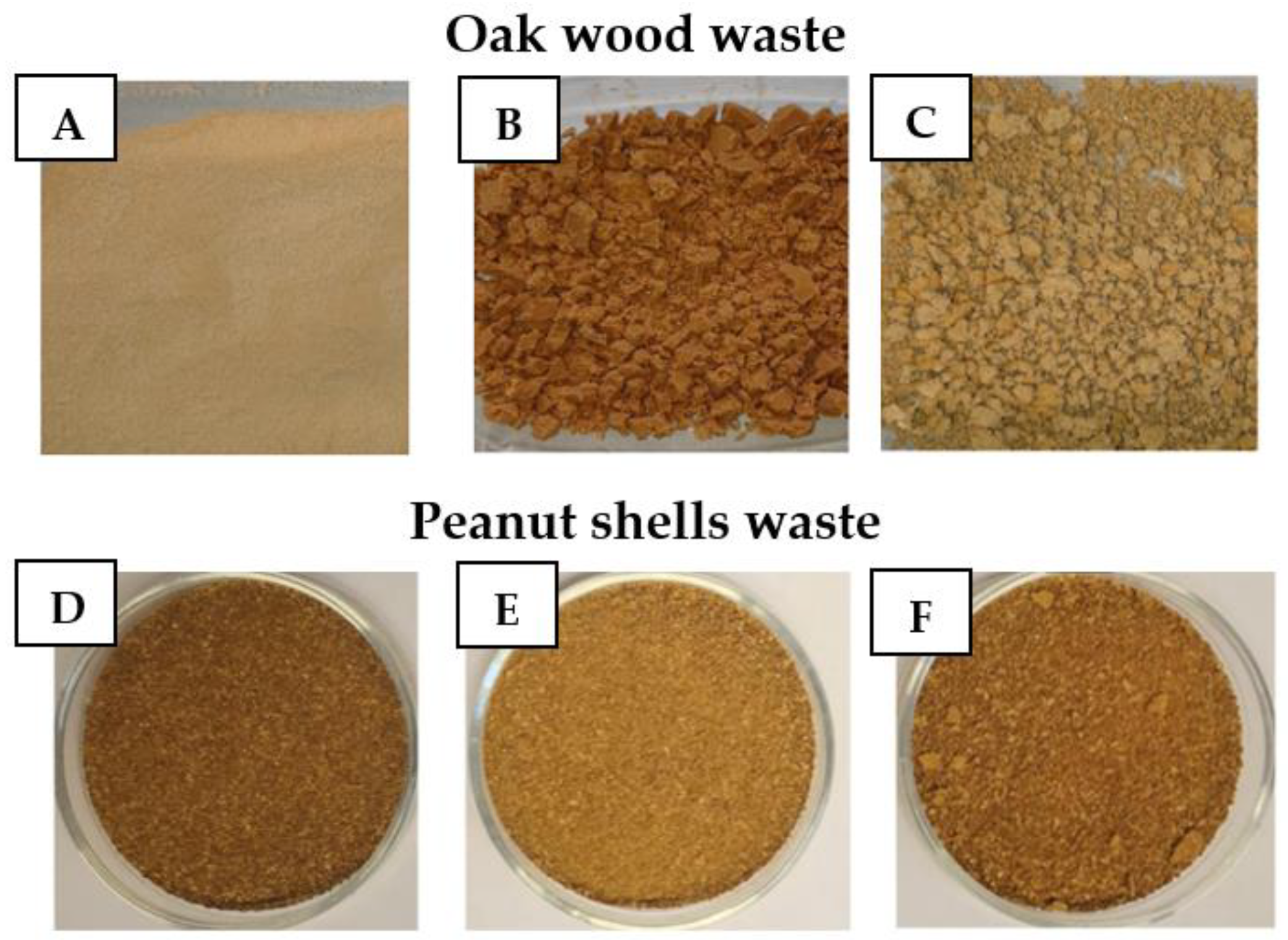

2.1.1. Initial Preparation

2.1.2. Chemical Modification of Waste Filler

2.2. Epoxy Composites with Modified Wood Waste

2.3. Spectroscopic Measurements

2.4. Morphological Analysis

2.5. The Mechanical Properties

3. Results and Discussion

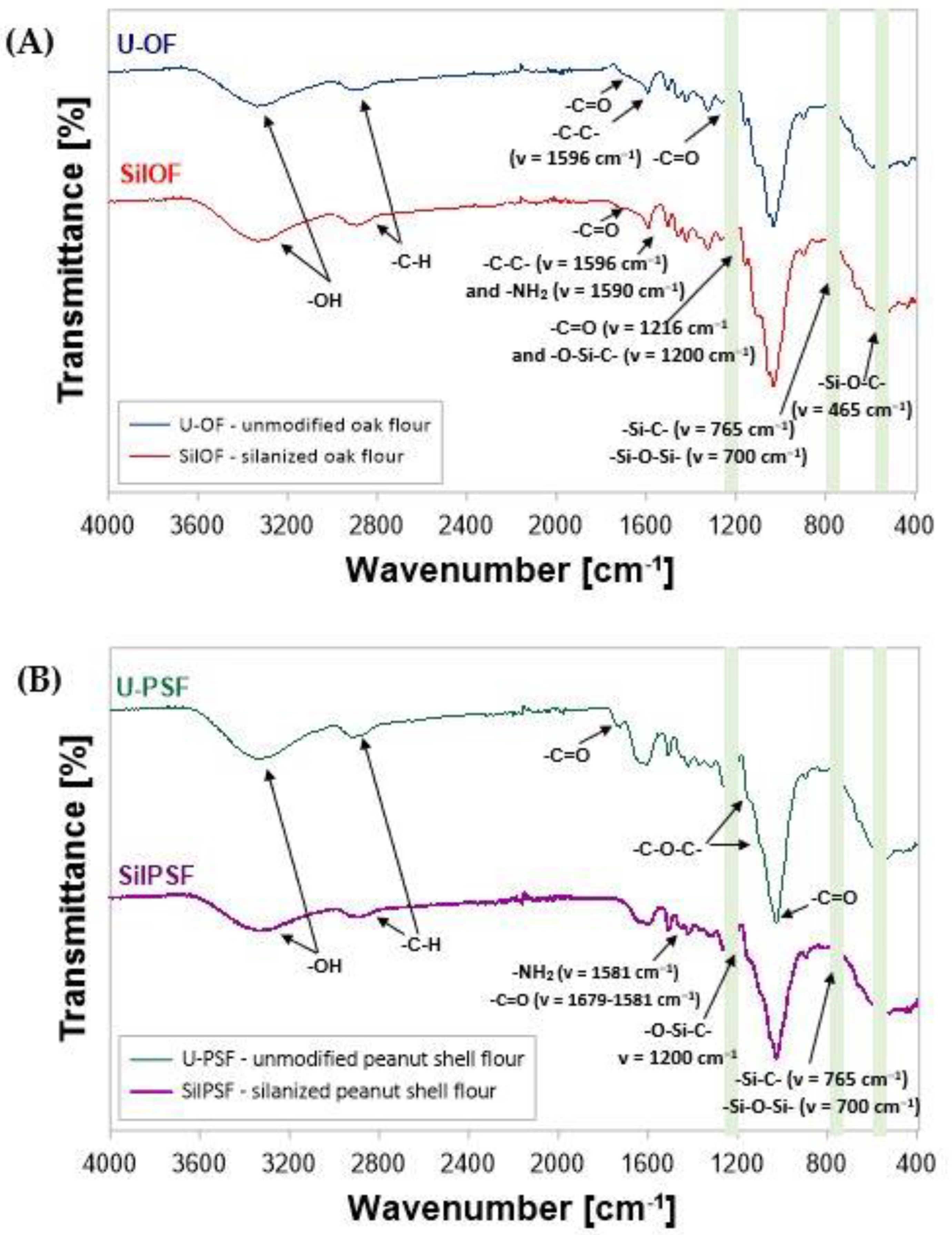

3.1. Chemical Modification of Waste Filler and the Analysis of Its Chemical Structure

- -

- The first step is hydrolysis, during which the silane molecules hydrolyze in the presence of water as a catalyst, releasing alcohol and silanol (Figure 3A).

- -

- Self-condensation of silanol molecules is also a possible reaction, however, during the silanization, the process of auto-condensation is considered a side process (Figure 3B).

- -

- Next, the adsorption of silanol molecules on the surface of the natural fiber occurs. It is important to mention here that during that time, not only silanol monomers but also silanol oligomers can undergo the adsorption reaction. In addition, silanol molecules adsorbed on the surface can react with subsequent silanol molecules to form polysiloxane structures (Figure 3C).

- -

- Finally, the last step of the process is the grafting of silanol molecules adsorbed on the surface of natural fibers. The grafting process occurs under the influence of the raised temperature, which causes dehydration of the structure.

3.2. Preparation of Epoxy Compounds Reinforced by the Addition of Oak or Peanut Shell Flour

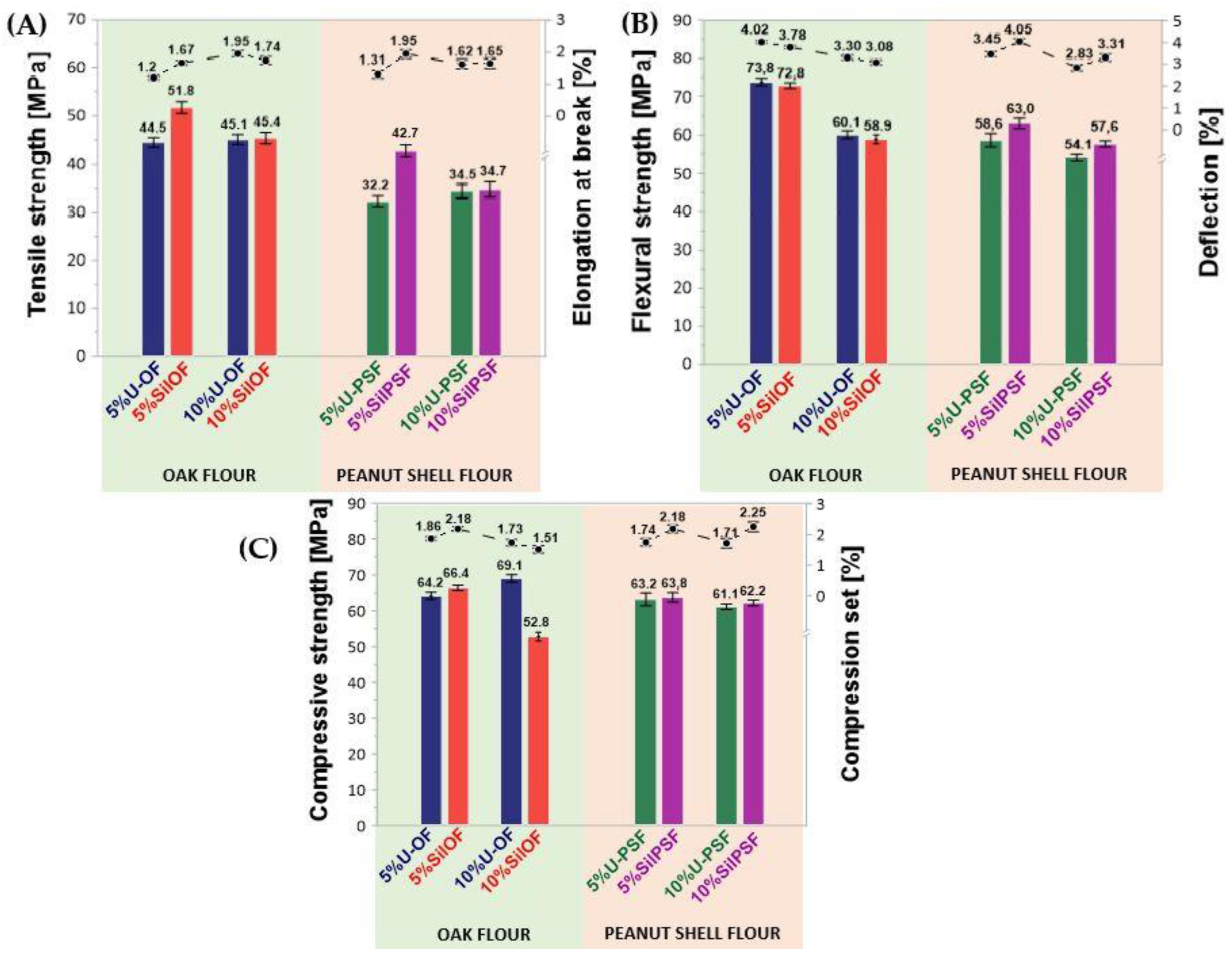

3.3. Results of Mechanical Tests of Epoxy/Oak (Peanut Shell) Flour Composites

3.4. Results of SEM Analysis of Epoxy/Wood (Peanut Shell) Flour Composite

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Corcione, C.E.; Ferrari, F.; Striani, R.; Visconti, P.; Greco, A. Recycling of organic fraction of municipal solid waste as an innovative precursor for the production of bio-based epoxy monomers. Waste Manag. 2020, 109, 212–221. [Google Scholar] [CrossRef] [PubMed]

- La Rosa, A.D.; Blanco, I.; Banatao, D.R.; Pastine, S.J.; Björklund, A.; Cicala, G. Innovative chemical process for recycling thermosets cured with Recyclamines® by converting bio-epoxy composites in reusable thermoplastic—An LCA study. Materials 2018, 11, 353. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Hu, Y.; Tang, J.; Zhang, J.; Wang, C.; Shang, Q.; Feng, G.; Liu, C.; Zhou, Y.; Lei, W. High-performance soybean-oil-based epoxy acrylate resins:“Green” synthesis and application in UV-curable coatings. ACS Sustain. Chem. Eng. 2018, 6, 8340–8349. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, P.; Huang, K.; Zhang, J. Study of green epoxy resins derived from renewable cinnamic acid and dipentene: Synthesis, curing and properties. RSC Adv. 2014, 4, 8525–8532. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Zhang, L.; Yang, Y.; Wang, D.Y. Green synthesis of biomass phytic acid-functionalized UiO-66-NH2 hierarchical hybrids toward fire safety of epoxy resin. ACS Sustain. Chem. Eng. 2019, 8, 994–1003. [Google Scholar] [CrossRef]

- Sterligov, G.K.; Rzhevskiy, S.A.; Isaeva, D.K.; Belov, N.M.; Rasskazova, M.A.; Drokin, E.A.; Topchiy, M.A.; Minaeva, L.I.; Babkin, A.V.; Erdni-Goryaev, E.M.; et al. The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste. Polymers 2022, 14, 4456. [Google Scholar] [CrossRef]

- Pourchet, S.; Sonnier, R.; Ben-Abdelkader, M.; Gaillard, Y.; Ruiz, Q.; Placet, V.; Plasseraud, L.; Boni, G. New reactive isoeugenol based phosphate flame retardant: Toward green epoxy resins. ACS Sustain. Chem. Eng. 2019, 7, 14074–14088. [Google Scholar] [CrossRef]

- Wang, J.; Huo, S.; Wang, J.; Yang, S.; Chen, K.; Li, C.; Fang, D.; Fang, Z.; Song, P.; Wang, H. Green and facile synthesis of bio-based, flame-retardant, latent imidazole curing agent for single-component epoxy resin. ACS Appl. Polym. Mater. 2022, 4, 3564–3574. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Synthesis of high-molecular weight biobased epoxy resins: Determination of the course of the process by MALDI-TOF mass spectrometry. ACS Sustain. Chem. Eng. 2018, 6, 6084–6093. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Application of MALDI-TOF, 1H NMR and 13C NMR to follow the progress of the synthesis of high molecular weight epoxies from hydroxylated soybean oil and bisphenol A based epoxy resin. Polym. Test. 2019, 73, 200–207. [Google Scholar] [CrossRef]

- Ellis, B. Chemistry and Technology of Epoxy Resins; Blackie Academic & Professional: London, UK, 1993. [Google Scholar]

- Mohan, P. A critical review: The modification, properties, and applications of epoxy resins. Polym.-Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Fink, J.K. Epoxy Resins In: Reactive Polymers: Fundamentals and Applications: A Concise Guide to Industrial Polymers; William Andrew Publishing: Norwich, NY, USA, 2017. [Google Scholar]

- Subbiah, R.; Kaliappan, S.; Patil, P. Effect of nanosilica on mechanical, thermal, fatigue, and antimicrobial properties of cardanol oil/sisal fiber reinforced epoxy composite. Polym. Compos. 2022, 43, 7940–7951. [Google Scholar] [CrossRef]

- Kumaran, P.; Mohanamurugan, S.; Madhu, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjaj, M.R.; Siengchin, S. Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J. Ind. Text. 2020, 50, 427–459. [Google Scholar] [CrossRef]

- Kumaran, P.; Balaji, N.S.; Vijay, R.; Madhu, S.; Asokan, P.; Singaravelu, L.D. Utilization of waste black limestone filler in short jute fiber reinforced epoxy composites: Influence on the mechanical behaviour. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 09544089221078150. [Google Scholar] [CrossRef]

- Chowaniec, A. Using waste limestone powder as filler in a toxic epoxy resin coating and its influence on adhesive properties. Chem. Eng. Trans. 2021, 88, 1063–1068. [Google Scholar]

- Starokadomsky, D.L.; Ishenko, A.A. Epoxy Composites Filled with Gypsum (Alabaster G-5): Possible Ways for Strengthening, Stabilization, and Structuration. In Composite Materials for Industry, Electronics, and the Environment; Apple Academic Press: Waretown, NJ, USA, 2019; pp. 25–44. [Google Scholar]

- Banumathi, S.; Karthik, T.S.; Sasireka, M.; Ramaswamy, K.; Vishnu, J.; Yuvan, M.K.; Kavin, R.R.; Kumar, S. Investigation on Dielectric Properties of Press Board Coated with Epoxy Resin, Quartz, and Rice Husk Ash. Adv. Mater. Sci. Eng. 2021, 2021, 9839770. [Google Scholar]

- Nguyen, D.M.; Vu, T.N.; Nguyen, T.M.L.; Nguyen, T.D.; Thuc, C.N.H.; Bui, Q.B.; Colin, J.; Perré, P. Synergistic influences of stearic acid coating and recycled PET microfibers on the enhanced properties of composite materials. Materials 2020, 13, 1461. [Google Scholar] [CrossRef]

- Yan, X.; Wu, L.; Jin, S.; Zhao, W.; Cao, H.; Ma, Y. Effect of curing conditions on the cutting resistance of fabrics coated with inorganic-powder-reinforced epoxy composite. RSC Adv. 2020, 10, 33576–33584. [Google Scholar] [CrossRef]

- Arun, K.K.; Bala Theja, M.; Girisha, L.; Arun Vignesh, N.; Sivakumar, N.S.; Subbiah, R.; Kaliappan, S. Time dependent behaviour of amino silane-treated aramid fibre and waste latex rubber powder toughened epoxy composite. Silicon 2021, 1–9. [Google Scholar] [CrossRef]

- Radouane, N.; Depriester, M.; Maaroufi, A.; Singh, D.P.; Ouaki, B.; Duponchel, B.; Elass, A.; Tidahy, L.; Hadj-Sahraoui, A. Synthesis, mechanical, thermal, and electrical characterization of graphite–epoxy composites. J. Chin. Chem. Soc. 2021, 68, 1456–1465. [Google Scholar] [CrossRef]

- Available online: https://www.textiletechnology.net/fibers/news/dnfi-stable-world-natural-fiber-production-in-2022-32691 (accessed on 25 January 2023).

- Available online: https://www.atlasbig.com/en-us/countries-peanut-production (accessed on 25 January 2023).

- Sorita, G.D.; Leimann, F.V.; Ferreira, S.R.S. Biorefinery approach: Is it an upgrade opportunity for peanut by-products? Trends Food Sci. Technol. 2020, 105, 56–69. [Google Scholar] [CrossRef]

- Zheng, W.; Phoungthong, K.; Lü, F.; Shao, L.M.; He, P.J. Evaluation of a classification method for biodegradable solid wastes using anaerobic degradation parameters. Waste Manag. 2013, 33, 2632–2640. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.; Dhungana, S.K.; Waqas Ali, M.; Adhikari, A.; Kim, I.-D.; Shin, D.-H. Antioxidant activities, polyphenol, flavonoid, and amino acid contents in peanut shell. J. Saudi Soc. Agric. Sci. 2019, 18, 437–442. [Google Scholar] [CrossRef]

- Ganguly, P.; Das, P. Integral approach for second-generation bio-ethanol production and wastewater treatment using peanut shell waste: Yield, removal, and ANN studies. Biomass Convers. Biorefinery 2022, 1–11. [Google Scholar] [CrossRef]

- Dalimunthe, Y.K.; Kasmungin, S.; Sugiarto, E.; Sugiarti, L.; Lagrama, A. Making briquettes from waste of coconut shell and peanut shell. Indones. J. Urban Environ. Technol. 2021, 4, 196–209. [Google Scholar] [CrossRef]

- Duc, P.A.; Dharanipriya, P.; Velmurugan, B.K.; Shanmugavadivu, M. Groundnut shell -a beneficial bio-waste. Biocatal. Agric. Biotechnol. 2019, 20, 101206. [Google Scholar] [CrossRef]

- Upendra, K.; Akshay, T.; Vedika, H.; Dhanashree, K.; Prathamesh, S.; Vivek, N. Production of paper from Groundnuts shell. Int. J. Adv. Res. Eng. Technol. Sci. 2018, 7, 288–293. [Google Scholar]

- Musekiwa, P.; Moyo, L.B.; Mamvura, T.A.; Danha, G.; Simate, G.S.; Hlabangana, N. Optimization of pulp production from groundnut shells using chemical pulping at low temperatures. Heliyon 2020, 6, e04184. [Google Scholar] [CrossRef]

- Shruthi, K.M.; Pavithra, M.P. A study on utilization of groundnut shell as biosorbent for heavy metals removal. Int. J. Eng. Technol. 2018, 4, 411–415. [Google Scholar]

- Chamarthy, S.; Seo, C.W.; Marshall, W.E. Adsorption of selected toxic metals by modified peanut shells. Journal of Chemical Technology & Biotechnology: International Research in Process. Environ. Clean Technol. 2001, 76, 593–597. [Google Scholar]

- Witek-Krowiak, A.; Szafran, R.G.; Modelski, S. Biosorption of heavy metals from aqueous solutions onto peanut shell as a low-cost biosorbent. Desalination 2011, 265, 126–134. [Google Scholar] [CrossRef]

- Adeosun, S.; Tajwan, O.; Akpan, E.; Gbenebor, O.; Gbagba, S.; Olaleye, S. Mechanical characteristics of groundnut shell particle reinforced polylactide nano fibre. Rev. Mater. 2016, 21, 482–491. [Google Scholar] [CrossRef]

- Obasi, H.C. Peanut Husk Filled Polyethylene Composites: Effects of Filler Content and Compatibilizer on Properties. J. Polym. 2015, 2015, 189289. [Google Scholar] [CrossRef]

- Zong, G.; Hao, X.; Hao, J.; Tang, W.; Fang, Y.; Ou, R.; Wang, Q. High-strength, lightweight, co-extruded wood flour-polyvinyl chloride/lumber composites: Effects of wood content in shell layer on mechanical properties, creep resistance, and dimensional stability. J. Clean. Prod. 2020, 244, 118860. [Google Scholar] [CrossRef]

- Jain, N.K.; Gupta, M.K. Dynamic Mechanical Properties of Hybrid Teak/Shorea Robusta Wood Reinforced Epoxy Composite. Mater. Today Proc. 2018, 5, 19893–19898. [Google Scholar] [CrossRef]

- Yang, Y.; Haurie, L.; Wen, J.; Zhang, S.; Ollivier, A.; Wang, D.Y. Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites. Ind. Crops Prod. 2019, 130, 301–309. [Google Scholar] [CrossRef]

- Galeev, R.R.; Nizamov, R.K.; Abdrakhmanova, L.A. Filling of epoxy polymers with chemically precipitated chalk from chemical water treatment sludge. In Proceedings of the International Conference Industrial and Civil Construction, International Conference Industrial and Civil Construction, Belgorod, Russia, 18–19 January 2021; pp. 93–97. [Google Scholar]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Wróbel-Kwiatkowska, M.; Szopa, J.; Dymińska, L.; Maczka, M.; Hanuza, J. Spectroscopic characterization of genetically modified flax fibres enhanced with poly-3-hydroxybutyric acid. J. Mol. Struct. 2009, 920, 214–219. [Google Scholar] [CrossRef]

- Paiva, M.C.; Ammar, I.; Campos, A.R.; Cheikh, R.B.; Cunha, A.M. Alfa fibres: Mechanical, morphological and interfacial characterization. Compos. Sci. Technol. 2007, 67, 1132–1138. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Adapa, P.K.; Tabil, L.G.; Schoenau, G.J.; Canam, T.; Dumonceaux, T. Quantitative Analysis of Lignocellulosic Components of Non-Treated and Steam Exploded Barley, Canola, Oat and Wheat Straw Using Fourier Transform Infrared Spectroscopy. J. Agric. Sci. Technol. B 2011, 1, 177–188. [Google Scholar]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.; Smith, A.; Guinebretiere, R.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Isora fibre: Morphology, chemical composition, surface modification, physical, mechanical and thermal properties–A potential natural reinforcement. J. Nat. Fibers 2007, 3, 13–27. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Gwon, J.G.; Lee, S.Y.; Doh, G.H.; Kim, J.H. Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. J. Appl. Polym. Sci. 2010, 116, 3212–3219. [Google Scholar] [CrossRef]

- García, E.; Louvier-Hernández, J.F.; Cervantes-Vallejo, F.J.; Flores-Martínez, M.; Hernández, R.; Alcaraz-Caracheo, L.A. Mechanical, dynamic and tribological characterization of HDPE/peanut shell composites. Polym. Test. 2021, 98, 107075. [Google Scholar] [CrossRef]

- Raju, G.U.; Kumarappa, S. Experimental Study on Mechanical and Thermal Properties of Epoxy Composites Filled with Agricultura Residue. Polym. Renew. Resour. 2012, 3, 117–138. [Google Scholar]

- Sienkiewicz, A.; Czub, P. A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil. Materials 2022, 15, 7737. [Google Scholar] [CrossRef]

- Ikladious, N.E.; Shukry, N.; El-Kalyoubi, S.F.; Asaad, J.N.; Mansour, S.H.; Tawfik, S.Y.; Abou-Zeid, R.E. Eco-friendly composites based on peanut shell powder/unsaturated polyester resin. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 955–964. [Google Scholar] [CrossRef]

| Frequency [cm−1] | Associated Band | ||||||

|---|---|---|---|---|---|---|---|

| Waste Oak Flour | Peanut Shell Flour | ||||||

| U-OF | MOF | SilOF | U-PSF | MPSF | SilPSF | ||

| 3570–3100 | 3600–3035 | 3550–3060 | 3685–2993 | 3600–3018 | 3649–3007 | -OH | v valencene |

| 1724 | - | - | 1710–1528 | 1714–1532 | 1679–1581 | -C-O | v valencene |

| - | - | 1590 | - | - | 1581 | -NH2 | δ scissor |

| 1596 | 1590 | 1501 | 1500 | 1498 | -C-C- | v valencene | |

| - | - | 1230 | - | - | 1254 | -C-N- | v valencene |

| 1178–860 | 1172–930 | - | 1216 | - | - | -C-O | v valencene |

| - | - | 1030 | - | - | 1033 | -Si-O | δ deformation |

| 1170 | 1172 | 1028 | 1021 | 1019 | 1018 | -C-O-C- | v valencene |

| Epoxy Composition | Epoxy Resin | Hardener | Deaerator | Filler | |

|---|---|---|---|---|---|

| Oak Flour | Peanut Shell Flour | ||||

| REF | Epidian 6 | Isophorone-diamine | BYK A530 | – | – |

| 5%U-OF | 5 wt.% of unmodified oak flour | – | |||

| 10%U-OF | 10 wt.% of unmodified oak flour | – | |||

| 5%SilOF | 5 wt.% of unmodified oak flour | – | |||

| 10%SilOF | 10 wt.% of unmodified oak flour | – | |||

| 5%U-PSF | – | 5 wt.% of unmodified peanut shells flour | |||

| 10%U-PSF | – | 10 wt.% of peanut shells flour | |||

| 5%SilPSF | – | 5 wt.% of silanized peanut shells flour | |||

| 10%SilPSF | – | 10 wt.% of silanized peanut shells flour | |||

| Mechanical Properties | Tested Epoxy Compositions Based on Epidian 6 Filled with Wood or Peanut Shell Flour | |||||||

|---|---|---|---|---|---|---|---|---|

| Unmodified Oak Flour [wt.%] | Silanized Oak Flour [wt.%] | Unmodified Peanut Shell Flour [wt.%] | Silanized Peanut Shell Flour [wt.%] | |||||

| 5%U-OF | 10%U-OF | 5%SilOF | 10%SilOF | 5%U-PSF | 10%U-PSF | 5%SilPSF | 10%SilPSF | |

| Modulus of elasticity [MPa] | 599.1 ± 8.4 | 1020.0 ± 436.4 | 671.2 ± 120.9 | 583.0 ± 167.4 | 1467.4 ± 825.8 | 977.4 ± 310.3 | 1618.2 ± 886.7 | 569.1 ± 240.1 |

| Elasticity flexural modulus [MPa] | 1795.7 ± 35.0 | 1736.8 ± 82.8 | 1832.5 ± 62.9 | 1552.3 ± 19.3 | 1446.0 ± 193.0 | 1572.3 ± 112.1 | 1352.3 ± 49.4 | 1159.0 ± 30.7 |

| Rockwell Hardness [MPa] | 77.2 ± 10.3 | 92.9 ± 1.2 | 74.1 ± 10.0 | 76.0 ± 2.0 | 68.1 ± 10.4 | 72.0 ± 12.7 | 86.6 ± 9.5 | 88.6 ± 14.3 |

| Impact toughness [kJ/m2] | 15.82 ± 1.79 | 7.09 ± 0.74 | 15.43 ± 2.70 | 8.36 ± 0.45 | 8.42 ± 0.72 | 8.00 ± 1.33 | 8.19 ± 0.76 | 9.81 ± 1.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sienkiewicz, A.; Czub, P. Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin. Materials 2023, 16, 3149. https://doi.org/10.3390/ma16083149

Sienkiewicz A, Czub P. Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin. Materials. 2023; 16(8):3149. https://doi.org/10.3390/ma16083149

Chicago/Turabian StyleSienkiewicz, Anna, and Piotr Czub. 2023. "Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin" Materials 16, no. 8: 3149. https://doi.org/10.3390/ma16083149

APA StyleSienkiewicz, A., & Czub, P. (2023). Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin. Materials, 16(8), 3149. https://doi.org/10.3390/ma16083149