Mechanical Behavior of a Medium-Entropy Fe65(CoNi)25Cr9.5C0.5 Alloy Produced by Selective Laser Melting

Abstract

:1. Introduction

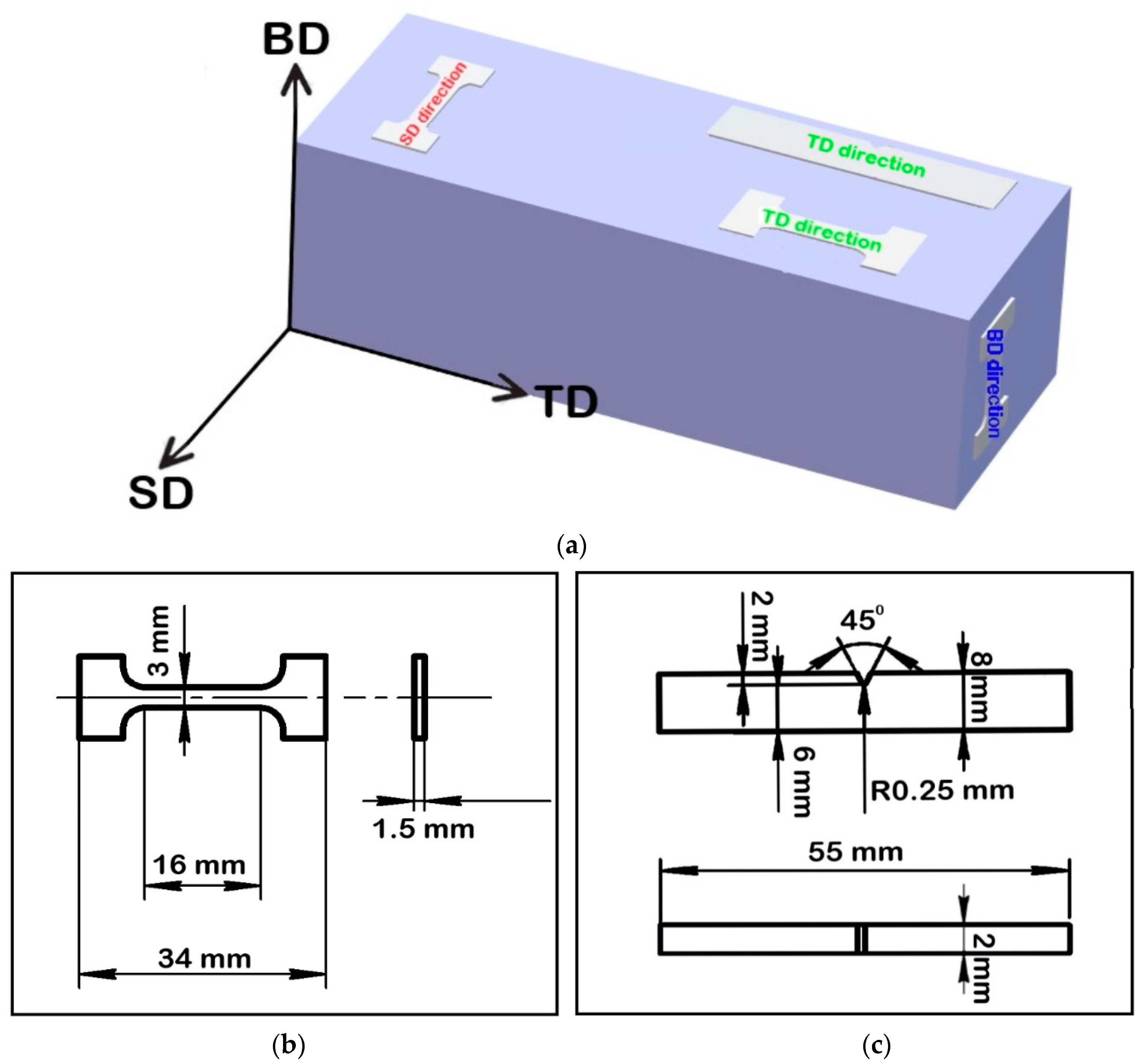

2. Experimental

3. Results

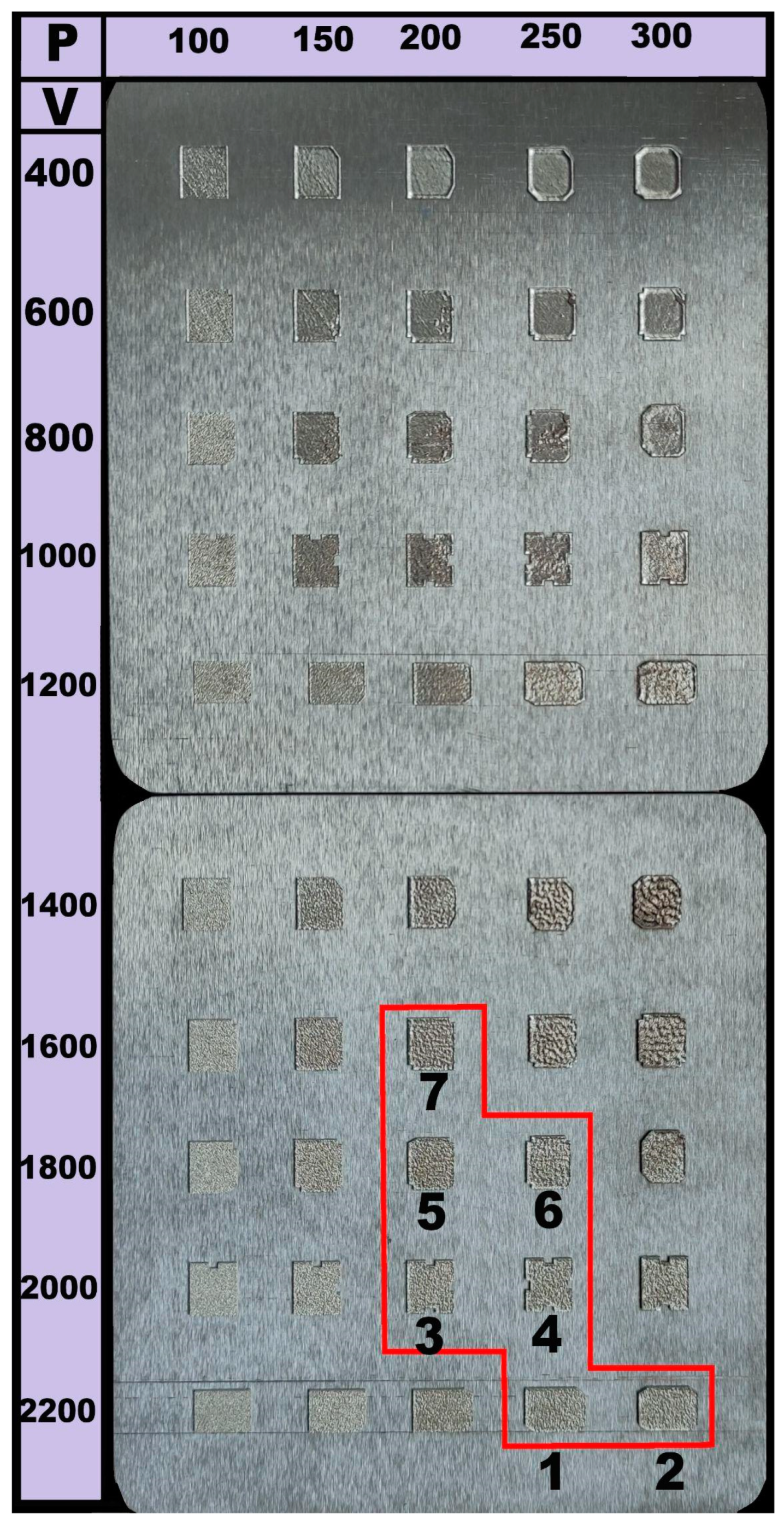

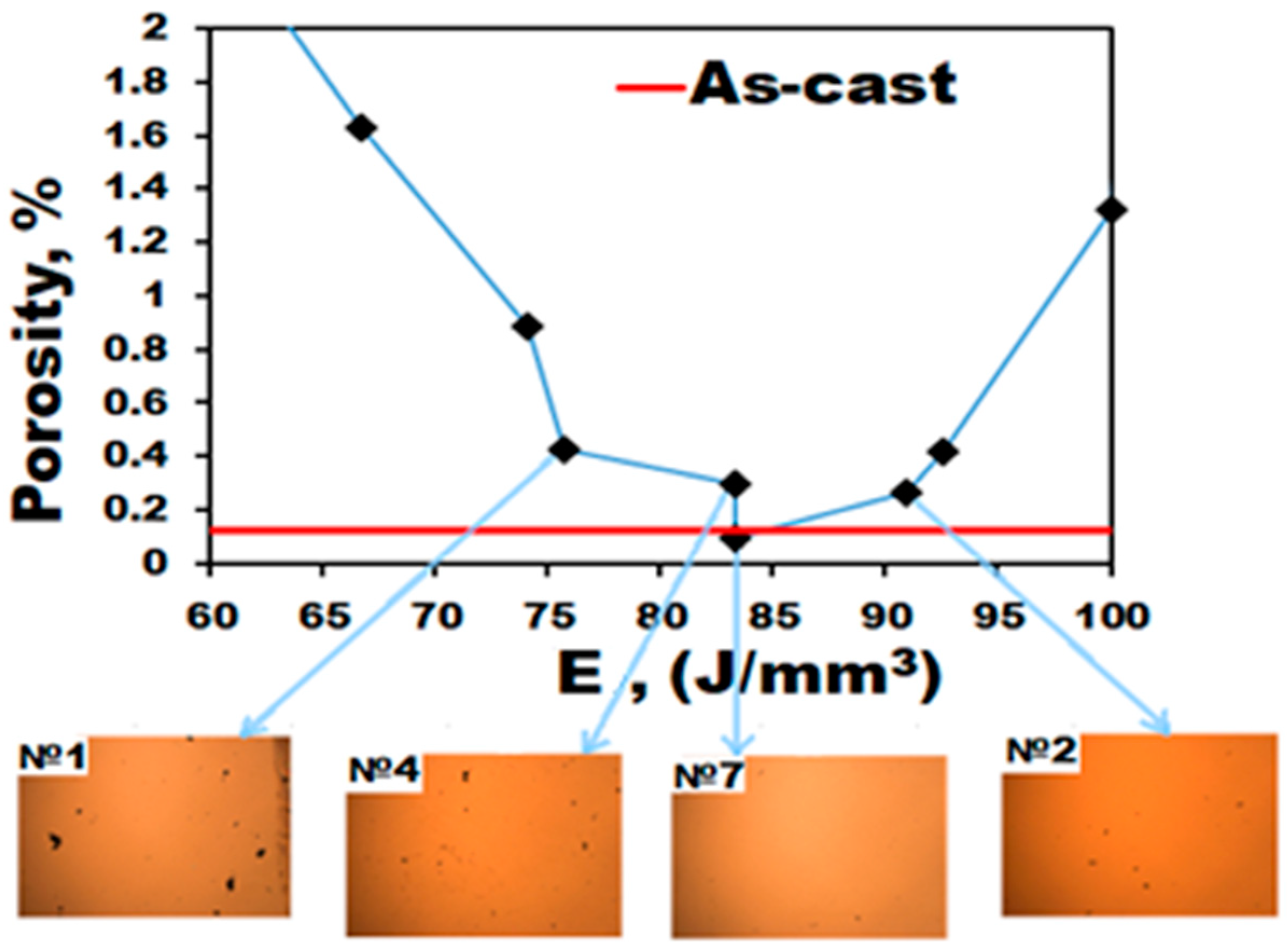

3.1. Selection of the SLM Parameters

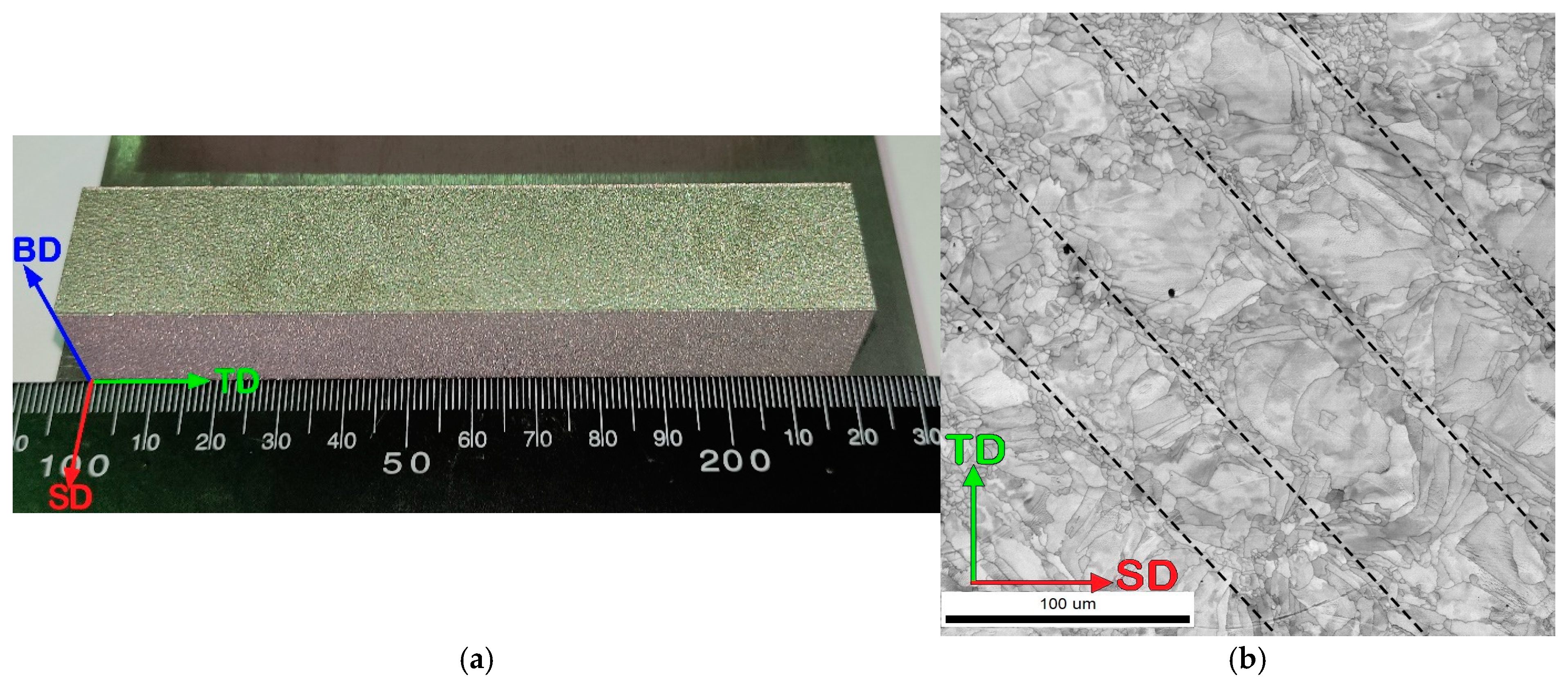

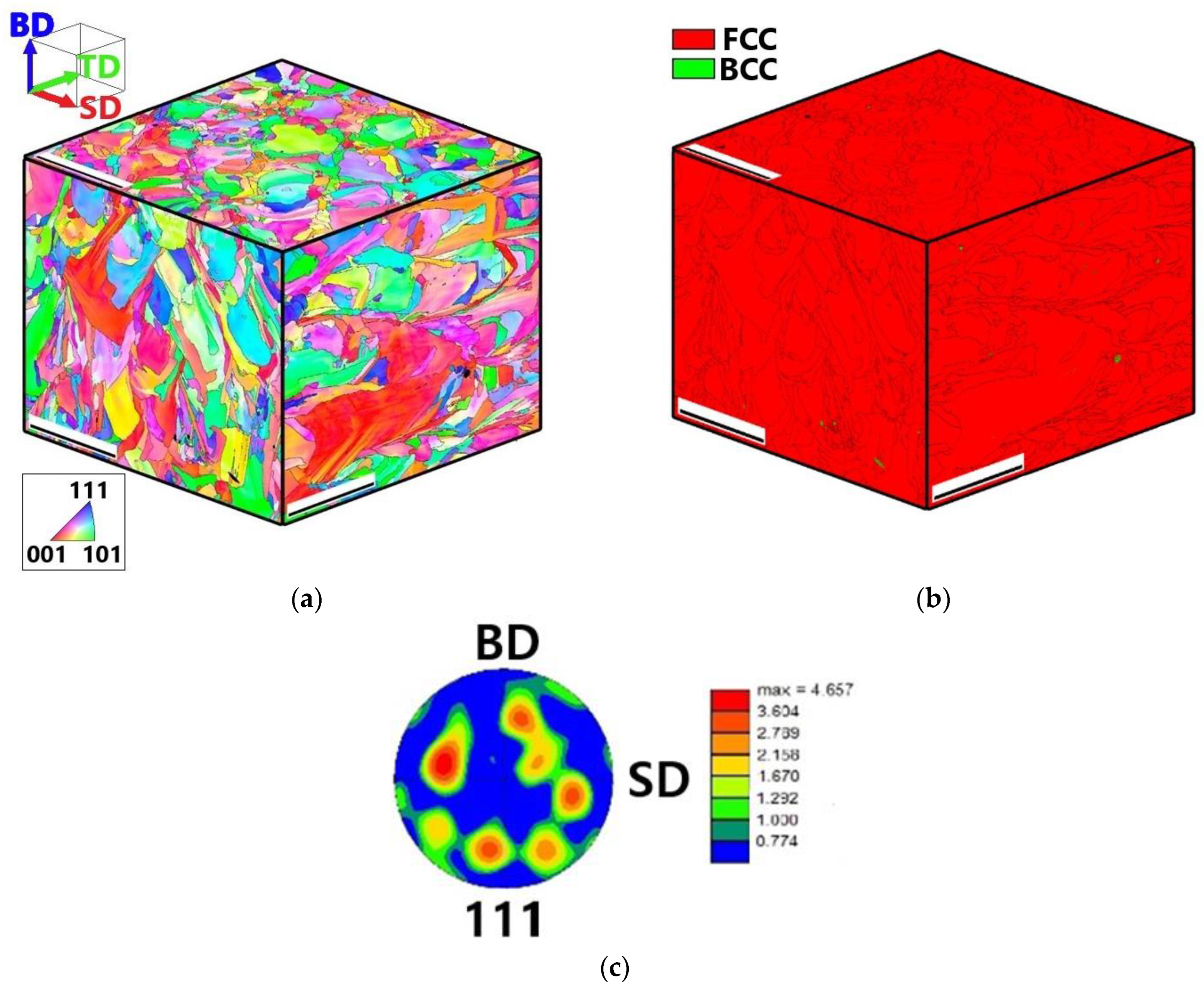

3.2. Structure and Properties of Fe65(CoNi)25Cr9.5C0.5 Alloy Specimens Produced by SLM

4. Discussion

5. Conclusions

- The optimal parameters of SLM (P = 200 W, V = 1600 mm/s) of the Fe65(CoNi)25Cr9.5C0.5 medium-entropy alloy resulted in residual porosity of ~0.5%.

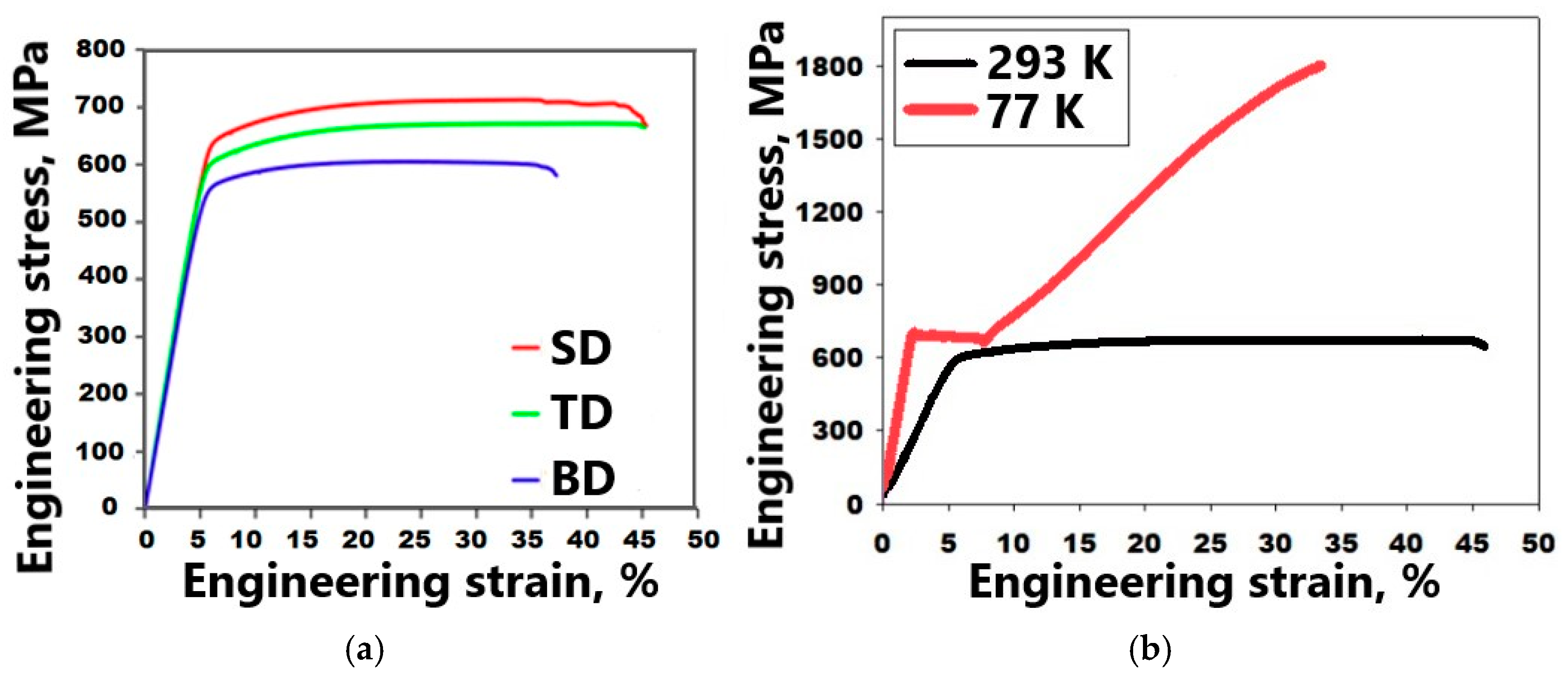

- Despite the similar microstructure of the alloy, mechanical properties of the scanning direction, transverse direction, and building direction (SD, TD, and BD, respectively) specimens showed some anisotropy in mechanical properties (strength varied ± 50 MPa). The tensile properties at room temperature for the TD direction were: YS = 560 MPa, UTS = 640 MPa, TE = 37% (yield strength, ultimate tensile strength, and tensile elongation, respectively).

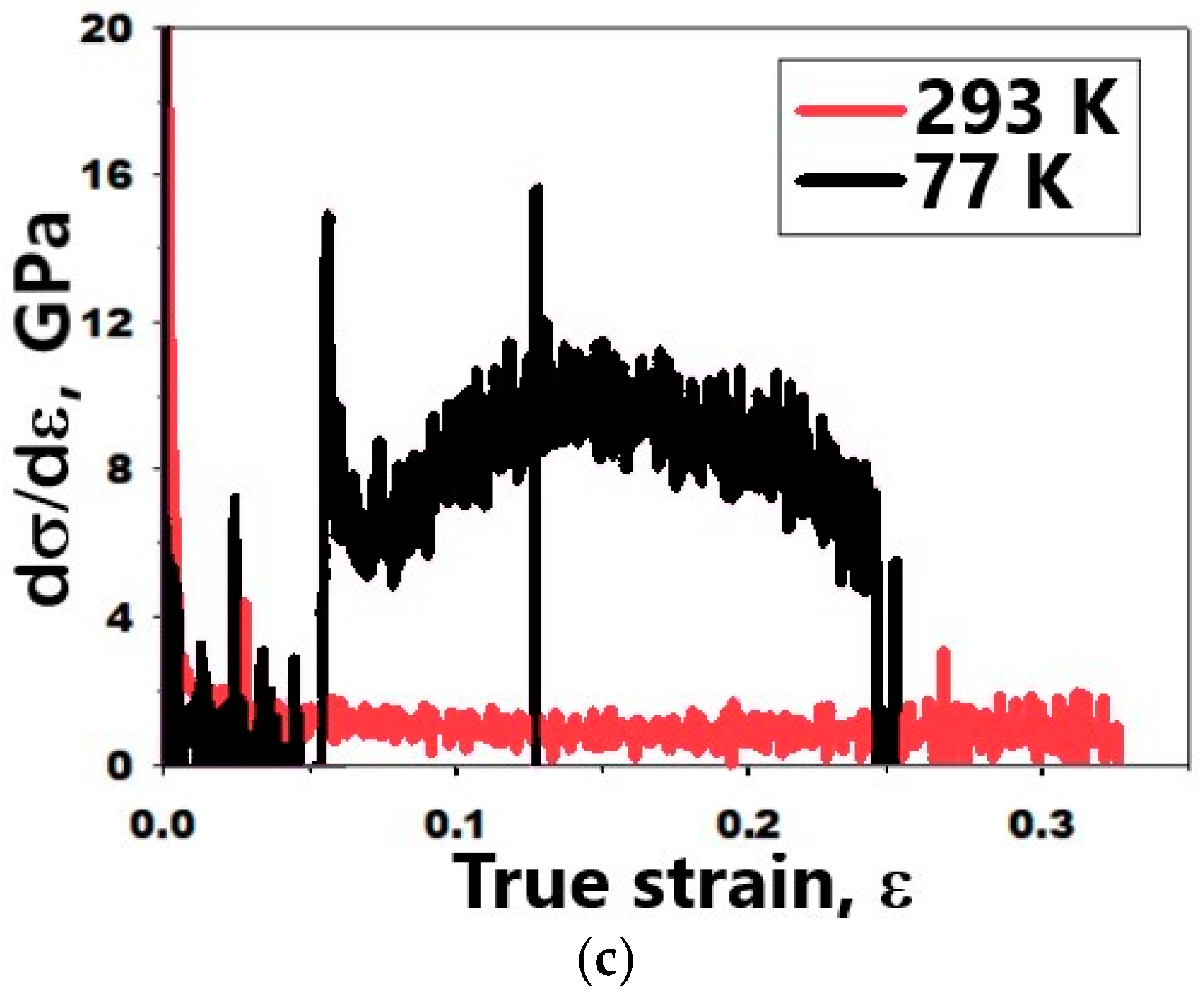

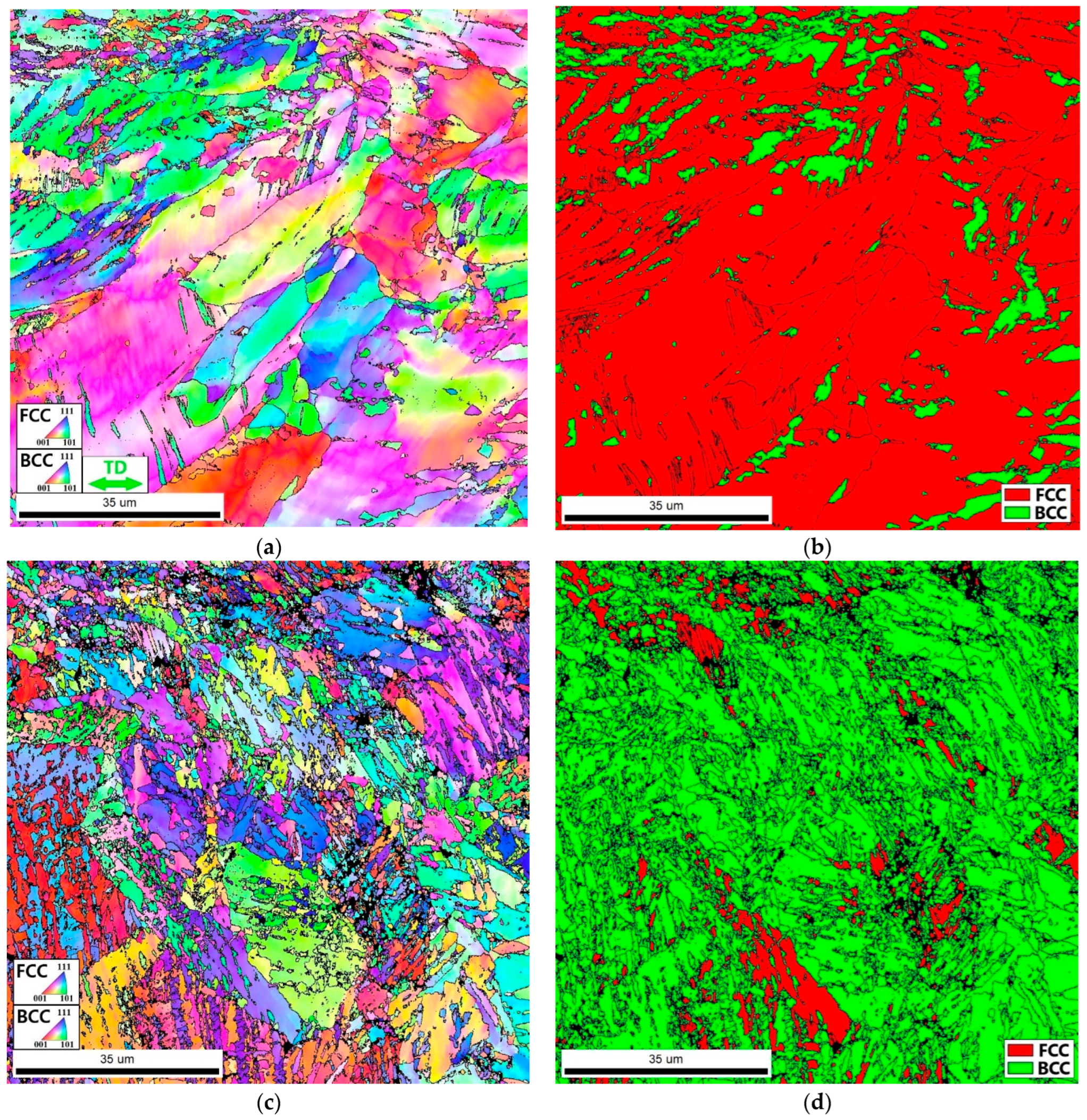

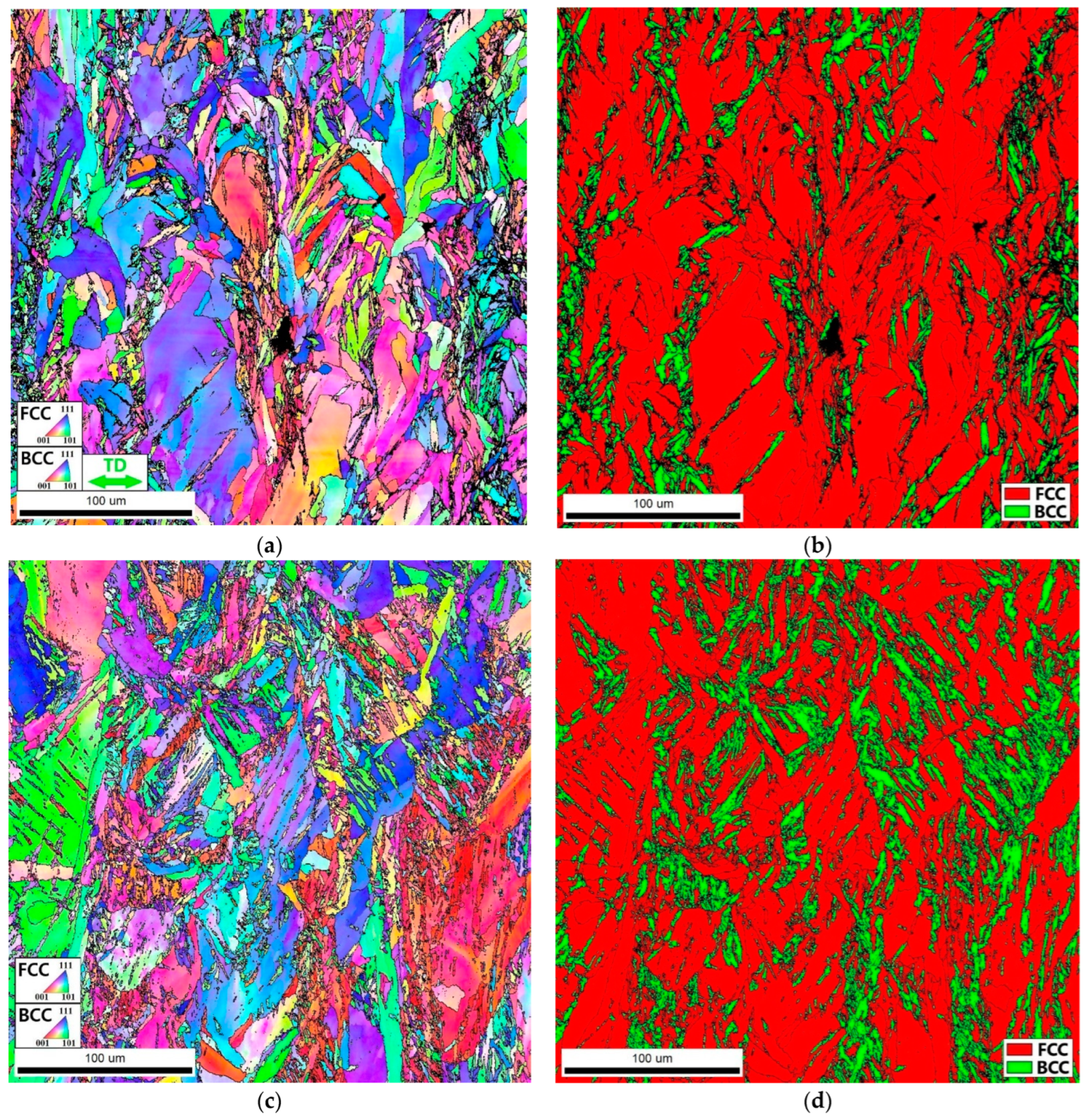

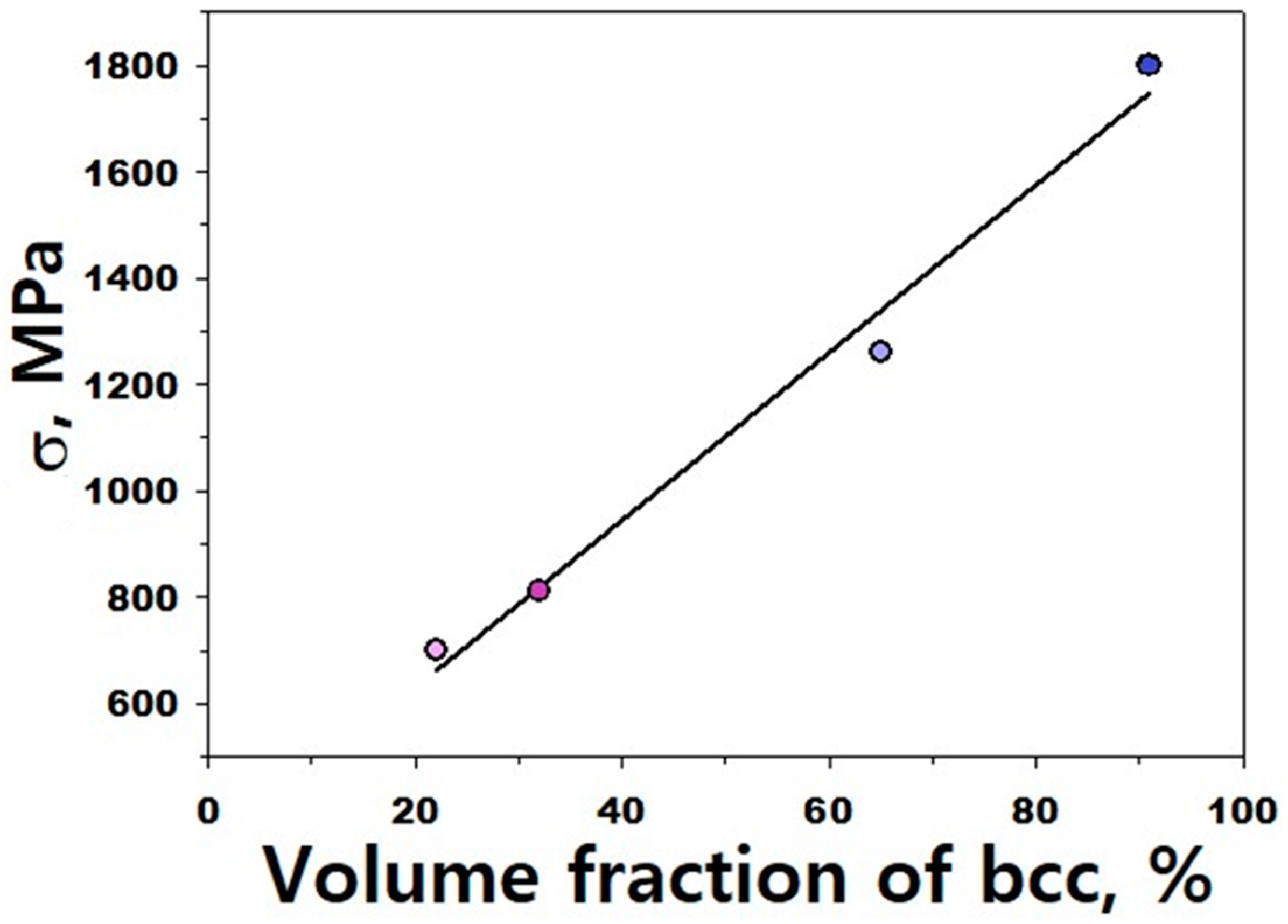

- A decrease in the temperature to 77 K resulted in a significant increase in both the yield strength and ultimate tensile strength to 680 MPa and 1800 MPa, respectively, and a subtle decrease in ductility (TE = 26%). The obtained high cryogenic properties are associated with the development of the transformation-induced plasticity (TRIP) effect due to the face-centered cubic to body-centered cubic (fcc-to-bcc). The microstructure of the alloy strained at 77 K became almost completely martensitic (the volume fraction of the martensitic phase reached 92%).

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.J.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 10143. [Google Scholar] [CrossRef] [PubMed]

- Klimova, M.V.; Semenyuk, A.O.; Shaysultanov, D.G.; Salishchev, G.A.; Zherebtsov, S.V.; Stepanov, N.D. Effect of carbon on cryogenic tensile behavior of CoCrFeMnNi-type high entropy alloys. J. Alloys Compd. 2019, 811, 152000. [Google Scholar] [CrossRef]

- Semenyuk, A.; Klimova, M.; Shaysultanov, D.; Chernichenko, R.; Zherebtsov, S.; Stepanov, N. Effect of carbon content on cryogenic mechanical properties of CoCrFeMnNi high entropy alloy. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012050. [Google Scholar] [CrossRef]

- Seol, J.B.; Bae, J.W.; Li, Z.; Chan Han, J.; Kim, J.G.; Raabe, D.; Kim, H.S. Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 2018, 151, 366–376. [Google Scholar] [CrossRef]

- Povolyaeva, E.; Mironov, S.; Shaysultanov, D.; Stepanov, N.; Zherebtsov, S. Outstanding cryogenic strength-ductility properties of a cold-rolled medium-entropy TRIP Fe65(CoNi)25Cr9·5C0.5 alloy. Mater. Sci. Eng. A 2022, 836, 142720. [Google Scholar] [CrossRef]

- Klimova, M.; Shaysultanov, D.; Semenyuk, A.; Zherebtsov, S.; Salishchev, G.; Stepanov, N. Effect of nitrogen on mechanical properties of CoCrFeMnNi high entropy alloy at room and cryogenic temperatures. J. Alloys Compd. 2020, 849, 156633. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Bae, J.W.; Seol, J.B.; Moon, J.; Sohn, S.S.; Jang, M.J.; Um, H.Y.; Lee, B.J.; Kim, H.S. Exceptional phase-transformation strengthening of ferrous medium-entropy alloys at cryogenic temperatures. Acta Mater. 2018, 161, 388–399. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-Transformation Ductilization of Brittle High-Entropy Alloys via Metastability Engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef]

- Wei, R.; Zhang, K.; Chen, L.; Han, Z.; Wang, T.; Chen, C.; Jiang, J.; Hu, T.; Li, F. Novel Co-free high performance TRIP and TWIP medium-entropy alloys at cryogenic temperatures. J. Mater. Sci. Technol. 2020, 57, 153–158. [Google Scholar] [CrossRef]

- He, Z.F.; Jia, N.; Ma, D.; Yan, H.L.; Li, Z.M.; Raabe, D. Joint contribution of transformation and twinning to the high strength-ductility combination of a FeMnCoCr high entropy alloy at cryogenic temperatures. Mater. Sci. Eng. A 2019, 759, 437–447. [Google Scholar] [CrossRef]

- Wei, D.; Li, X.; Schönecker, S.; Jiang, J.; Choi, W.M.; Lee, B.J.; Kim, H.S.; Chiba, A.; Kato, H. Development of strong and ductile metastable face-centered cubic single-phase high-entropy alloys. Acta Mater. 2019, 181, 318–330. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Li, X.; Jiang, J.; Heng, W.; Koizumi, Y.; Choi, W.M.; Lee, B.J.; Kim, H.S.; Kato, H.; Chiba, A. Novel Co-rich high performance twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) high-entropy alloys. Scr. Mater. 2019, 165, 39–43. [Google Scholar] [CrossRef]

- Shi, Y.; Li, S.; Lee, T.L.; Hui, X.; Zhang, Z.; Li, R.; Zhang, M.; Kabra, S.; Wang, Y.D. In situ neutron diffraction study of a new type of stress-induced confined martensitic transformation in Fe22Co20Ni19Cr20Mn12Al7 high-entropy alloy. Mater. Sci. Eng. A 2020, 771, 138555. [Google Scholar] [CrossRef]

- Chen, S.; Oh, H.S.; Gludovatz, B.; Kim, S.J.; Park, E.S.; Zhang, Z.; Ritchie, R.O.; Yu, Q. Real-time observations of TRIP-induced ultrahigh strain hardening in a dual-phase CrMnFeCoNi high-entropy alloy. Nat. Commun. 2020, 11, 826. [Google Scholar] [CrossRef]

- He, Z.; Jia, N.; Yan, H.; Shen, Y.; Zhu, M.; Guan, X.; Zhao, X.; Jin, S.; Sha, G.; Zhu, Y.; et al. Multi-heterostructure and mechanical properties of N-doped FeMnCoCr high entropy alloy. Int. J. Plast. 2021, 139, 102965. [Google Scholar] [CrossRef]

- Bae, J.W.; Kim, H.S. Towards ferrous medium-entropy alloys with low-cost and high-performance. Scr. Mater. 2020, 186, 169–173. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Farshidianfar, M.H.; Gerlich, A.P.; Nosko, M.; Trembošová, V.; Khajepour, A. Effects of laser additive manufacturing on microstructure and crystallographic texture of austenitic and martensitic stainless steels. Addit. Manuf. 2020, 31, 100915. [Google Scholar] [CrossRef]

- Zhou, K.; Wang, Z.; He, F.; Liu, S.; Li, J.; Kai, J.J.; Wang, J. A precipitation-strengthened high-entropy alloy for additive manufacturing. Addit. Manuf. 2020, 35, 101410. [Google Scholar] [CrossRef]

- Peng, H.; Xie, S.; Niu, P.; Zhang, Z.; Yuan, T.; Ren, Z.; Wang, X.; Zhao, Y.; Li, R. Additive manufacturing of Al0.3CoCrFeNi high-entropy alloy by powder feeding laser melting deposition. J. Alloys Compd. 2021, 862, 158286. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, S.; Xiong, Z.; Liang, Y.J.; Xue, Y.; Wang, L. Enabling stronger eutectic high-entropy alloys with larger ductility by 3D printed directional lamellae. Addit. Manuf. 2021, 39, 101901. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy. Addit. Manuf. 2018, 24, 386–390. [Google Scholar] [CrossRef]

- Bai, Y.; Jiang, H.; Yan, K.; Li, M.; Wei, Y.; Zhang, K.; Wei, B. Phase transition and heterogeneous strengthening mechanism in CoCrFeNiMn high-entropy alloy fabricated by laser-engineered net shaping via annealing at intermediate-temperature. J. Mater. Sci. Technol. 2021, 92, 129–137. [Google Scholar] [CrossRef]

- Guan, S.; Solberg, K.; Wan, D.; Berto, F.; Welo, T.; Yue, T.M.; Chan, K.C. Formation of fully equiaxed grain microstructure in additively manufactured AlCoCrFeNiTi0.5 high entropy alloy. Mater. Des. 2019, 184, 108202. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Waseem, O.A.; Mantri, S.A.; Banerjee, R. Laser additive manufacturing of compositionally graded AlCrFeMoVx (x = 0 to 1) high-entropy alloy system. Opt. Laser Technol. 2019, 113, 330–337. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Li, X.; Jing, H.; Qin, G.; Pang, H.; Minami, F. A Si-containing FeCoCrNi high-entropy alloy with high strength and ductility synthesized in situ via selective laser melting. Addit. Manuf. 2020, 35, 101340. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, R.; Wei, B.; Ni, S.; Liu, Y.; Song, M. Nanosized precipitates and dislocation networks reinforced C-containing CoCrFeNi high-entropy alloy fabricated by selective laser melting. Mater. Charact. 2018, 144, 605–610. [Google Scholar] [CrossRef]

- Lin, D.; Xu, L.; Jing, H.; Han, Y.; Zhao, L.; Minami, F. Effects of annealing on the structure and mechanical properties of FeCoCrNi high-entropy alloy fabricated via selective laser melting. Addit. Manuf. 2020, 32, 101058. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, T.; He, D.; Li, Z.; Chen, L.; Su, H.; Fu, P.; Dai, P.; Huang, W. Sustaining strength-ductility synergy of SLM Fe50Mn30Co10Cr10 metastable high-entropy alloy by Si addition. Intermetallics 2022, 145, 107565. [Google Scholar] [CrossRef]

- Niu, P.; Li, R.; Fan, Z.; Yuan, T.; Zhang, Z. Additive manufacturing of TRIP-assisted dual-phases Fe50Mn30Co10Cr10 high-entropy alloy: Microstructure evolution, mechanical properties and deformation mechanisms. Mater. Sci. Eng. A 2021, 814, 141264. [Google Scholar] [CrossRef]

- Zhu, Z.G.; An, X.H.; Lu, W.J.; Li, Z.M.; Ng, F.L.; Liao, X.Z.; Ramamurty, U.; Nai, S.M.L.; Wei, J. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy. Mater. Res. Lett. 2019, 7, 453–459. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, J.; An, X.; Wang, H.; Zhang, Y.; Liao, X. Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy. Mater. Res. Lett. 2018, 6, 236–243. [Google Scholar] [CrossRef]

- Park, J.M.; Choe, J.; Park, H.K.; Son, S.; Jung, J.; Kim, T.S.; Yu, J.H.; Kim, J.G.; Kim, H.S. Synergetic strengthening of additively manufactured (CoCrFeMnNi)99C1 high-entropy alloy by heterogeneous anisotropic microstructure. Addit. Manuf. 2020, 35, 101333. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.Y.; Xie, Z.H.; Chen, H.; Li, W.; Liu, B.; Wang, B. Mechanical property and cellular structure of an additive manufactured FeCoNiCrMo0.2 high-entropy alloy at high-velocity deformation. J. Mater. Sci. Technol. 2023, 139, 156–166. [Google Scholar] [CrossRef]

- Thapliyal, S.; Agrawal, P.; Agrawal, P.; Nene, S.S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Segregation engineering of grain boundaries of a metastable Fe-Mn-Co-Cr-Si high entropy alloy with laser-powder bed fusion additive manufacturing. Acta Mater. 2021, 219, 117271. [Google Scholar] [CrossRef]

- Li, B.; Zhang, L.; Xu, Y.; Liu, Z.; Qian, B.; Xuan, F. Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: Process, particle behavior and effects. Powder Technol. 2020, 360, 509–521. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhang, L.C.; Fang, M.H.; Sercombe, T.B. The effect of atmosphere on the structure and properties of a selective laser melted Al–12Si alloy. Mater. Sci. Eng. A 2014, 597, 370–375. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Zhou, R.; Liu, Y.; Zhou, C.; Li, S.; Wu, W.; Song, M.; Liu, B.; Liang, X.; Liaw, P.K. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics 2018, 94, 165–171. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.K.; Grzesiak, D.; Lee, K.A. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Wei, R.; Feng, S.; Chen, C.; Han, Z.; Chen, L.; Wang, T.; Wu, S.; Li, F. Ultrahigh cryogenic strength and ductility in a duplex metastable ferrous medium-entropy alloy. Scr. Mater. 2023, 228, 115334. [Google Scholar] [CrossRef]

- Torganchuk, V.; Belyakov, A.; Kaibyshev, R. On the transformation-induced plasticity of a medium-manganese steel. Mater. Lett. 2021, 304, 130599. [Google Scholar] [CrossRef]

- Agrawal, P.; Thapliyal, S.; Nene, S.S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Excellent strength-ductility synergy in metastable high entropy alloy by laser powder bed additive manufacturing. Addit. Manuf. 2020, 32, 101098. [Google Scholar] [CrossRef]

- Khodashenas, H.; Mirzadeh, H. Post-processing of additively manufactured high-entropy alloys—A review. J. Mater. Res. Technol. 2022, 21, 3795–3814. [Google Scholar] [CrossRef]

- Liu, H.; Yang, D.; Jiang, Q.; Jiang, Y.; Yang, W.; Liu, L.; Zhang, L.-C. Additive manufacturing of metallic glasses and high-entropy alloys: Significance, unsettled issues, and future directions. J. Mater. Sci. Technol. 2023, 140, 79–120. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Shen, Q.; Kong, X.; Chen, X. Significant transitions of microstructure and mechanical properties in additively manufactured Al–Co–Cr–Fe–Ni high-entropy alloy under heat treatment. Mater. Sci. Eng. A 2021, 815, 141257. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, S.; Zhang, C.; Chen, J.; Zhang, J.; Liu, Y. Optimization of laser energy density and scanning strategy on the forming quality of 24CrNiMo low alloy steel manufactured by SLM. Mater. Charact. 2020, 170, 110718. [Google Scholar] [CrossRef]

- Zakrzewski, T.; Kozak, J.; Witt, M.; Dębowska-Wąsak, M. Dimensional Analysis of the Effect of SLM Parameters on Surface Roughness and Material Density. Procedia CIRP 2020, 95, 115–120. [Google Scholar] [CrossRef]

- Macoretta, G.; Monelli, B.D. SLM process parameters effects on the fatigue strength of AMed Inconel 718. Procedia Struct. Integr. 2022, 37, 632–643. [Google Scholar] [CrossRef]

- Hug, E.; Lelièvre, M.; Folton, C.; Ribet, A.; Martinez-Celis, M.; Keller, C. Additive manufacturing of a Ni-20 wt%Cr binary alloy by laser powder bed fusion: Impact of the microstructure on the mechanical properties. Mater. Sci. Eng. A 2022, 834, 142625. [Google Scholar] [CrossRef]

- Bertsch, K.M.; de Bellefon, G.M.; Kuehl, B.; Thoma, D.J. Origin of dislocation structures in an additively manufactured ausnitic stainless steel 316L. Acta Mater. 2020, 199, 19–33. [Google Scholar] [CrossRef]

- Lan, L.; Wang, W.; Cui, Z.; Hao, X.; Qiu, D. Anisotropy study of the microstructure and properties of AlCoCrFeNi2.1 eutectic high entropy alloy additively manufactured by selective laser melting. J. Mater. Sci. Technol. 2022, 129, 228–239. [Google Scholar] [CrossRef]

- Zhang, W.; Chabok, A.; Kooi, B.J.; Pei, Y. Additive manufactured high entropy alloys: A review of the microstructure and properties. Mater. Des. 2022, 220, 110875. [Google Scholar] [CrossRef]

- Zhao, D.; Yang, Q.; Wang, D.; Yan, M.; Wang, P.; Jiang, M.; Liu, C.; Diao, D.; Lao, C.; Chen, Z.; et al. Ordered nitrogen complexes overcoming strength–ductility trade-off in an additively manufactured high-entropy alloy. Virtual Phys. Prototyp. 2020, 15, 532–542. [Google Scholar] [CrossRef]

- Chew, Y.; Zhu, Z.G.; Weng, F.; Gao, S.B.; Ng, F.L.; Lee, B.Y.; Bi, G.J. Microstructure and mechanical behavior of laser aided additive manufactured low carbon interstitial Fe49.5Mn30Co10Cr10C0.5 multicomponent alloy. J. Mater. Sci. Technol. 2021, 77, 38–46. [Google Scholar] [CrossRef]

- Tong, Z.; Ren, X.; Jiao, J.; Zhou, W.; Ren, Y.; Ye, Y.; Larson, E.A.; Gu, J. Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: Effect of heat treatment on microstructure, residual stress and mechanical property. J. Alloys Compd. 2019, 785, 1144–1159. [Google Scholar] [CrossRef]

- Chew, Y.; Bi, G.; Zhu, Z.; Ng, F.; Weng, F.; Liu, S.; Nai, S.; Lee, B. Microstructure and enhanced strength of laser aided additive manufactured CoCrFeNiMn high entropy alloy. Mater. Sci. Eng. A 2019, 744, 137–144. [Google Scholar] [CrossRef]

- Takaki, S.; Fukunaga, K.; Syarif, J.; Tsuchiyama, T. Effect of Grain Refinement on Thermal Stability of Metastable Austenitic Steel. Mater. Trans. 2004, 45, 2245–2251. [Google Scholar] [CrossRef]

- Effect of Grain Size on Thermal and Mechanical Stability of Austenite in Metastable Austenitic Stainless Steel. Available online: https://www.jstage.jst.go.jp/article/isijinternational/53/7/53_1224/_article (accessed on 3 March 2023).

- Yang, H.-S.; Bhadeshia, H.K.D.H. Austenite grain size and the martensite-start temperature. Scr. Mater. 2009, 60, 493–495. [Google Scholar] [CrossRef]

- García-Junceda, A.; Capdevila, C.; Caballero, F.G.; de Andrés, C.G. Dependence of martensite start temperature on fine austenite grain size. Scr. Mater. 2008, 58, 134–137. [Google Scholar] [CrossRef]

- Kim, D.G.; Jo, Y.H.; Yang, J.; Choi, W.M.; Kim, H.S.; Lee, B.J.; Sohn, S.S.; Lee, S. Ultrastrong duplex high-entropy alloy with 2 GPa cryogenic strength enabled by an accelerated martensitic transformation. Scr. Mater. 2019, 171, 67–72. [Google Scholar] [CrossRef]

- Park, J.M.; Asghari-Rad, P.; Zargaran, A.; Bae, J.W.; Moon, J.; Kwon, H.; Choe, J.; Yang, S.; Yu, J.-H.; Kim, H.S. Nano-scale heterogeneity-driven metastability engineering in ferrous medium-entropy alloy induced by additive manufacturing. Acta Mater. 2021, 221, 117426. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, X.; Zhang, E.; Wei, R.; Wang, L.; Chen, J.; Yuan, S.; Han, Z.; Chen, C.; Li, F. Strengthening of ferrous medium entropy alloys by promoting phase transformation. Intermetallics 2021, 136, 107265. [Google Scholar] [CrossRef]

- Quitzke, C.; Schröder, C.; Ullrich, C.; Mandel, M.; Krüger, L.; Volkova, O.; Wendler, M. Evaluation of strain-induced martensite formation and mechanical properties in N-alloyed austenitic stainless steels by in situ tensile tests. Mater. Sci. Eng. A 2021, 808, 140930. [Google Scholar] [CrossRef]

| Composition | Fe | Co | Ni | Cr | C | O | N |

|---|---|---|---|---|---|---|---|

| Nominal (at.%) | 65 | 12.5 | 12.5 | 9.5 | 0.5 | - | - |

| Actual (at.%) | 64.5 | 12.1 | 11.6 | 11.3 | 0.52 | 0.017 | 0.031 |

| Actual (wt.%) | 65.4 | 12.6 | 12.4 | 9.48 | 0.12 | 0.009 | 0.014 |

| #1 | #2 | #3 | #4 | #5 | #6 | #7 | |

|---|---|---|---|---|---|---|---|

| P, W | 250 | 300 | 200 | 250 | 200 | 250 | 200 |

| V, mm/s | 2200 | 2200 | 2000 | 2000 | 1800 | 1800 | 1600 |

| E, J/mm3 | 76 ± 1.5 | 90 ± 1.2 | 67 ± 0.6 | 83 ± 0.9 | 74 ± 1.1 | 93 ± 0.4 | 83 ± 0.5 |

| YS, MPa | UTS, MPa | TE, % | |

|---|---|---|---|

| Sample TD, 293 K | 560 ± 19 | 640 ± 11 | 37 ± 3 |

| Sample TD, 77 K | 680 ± 17 | 1800 ± 13 | 26 ± 1 |

| Sample SD, 293 K | 600 ± 13 | 710 ± 18 | 38 ± 2 |

| Sample BD, 293 K | 510 ± 16 | 600 ± 10 | 32 ± 2 |

| Testing Temperature, K | Fracture Toughness, kJ/m2 | Charpy V-Notch Impact Energy, J |

|---|---|---|

| 293 | 660 ± 16 | 10 ± 2 |

| 77 | 430 ± 12 | 7 ± 1 |

| Temperature, K | Condition | |||

|---|---|---|---|---|

| As-Produced | Strained to ε ≈ 5% | Strained to ε ≈ 10% | Strained to Fracture (ε ≈ 26%) | |

| 293 | 0.5% | - | - | 14% |

| 77 | 0% | 22% | 32% | 91% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Povolyaeva, E.; Shaysultanov, D.; Astakhov, I.; Evlashin, S.; Klimova, M.; Stepanov, N.; Zherebtsov, S. Mechanical Behavior of a Medium-Entropy Fe65(CoNi)25Cr9.5C0.5 Alloy Produced by Selective Laser Melting. Materials 2023, 16, 3193. https://doi.org/10.3390/ma16083193

Povolyaeva E, Shaysultanov D, Astakhov I, Evlashin S, Klimova M, Stepanov N, Zherebtsov S. Mechanical Behavior of a Medium-Entropy Fe65(CoNi)25Cr9.5C0.5 Alloy Produced by Selective Laser Melting. Materials. 2023; 16(8):3193. https://doi.org/10.3390/ma16083193

Chicago/Turabian StylePovolyaeva, Elizaveta, Dmitry Shaysultanov, Ilya Astakhov, Stanislav Evlashin, Margarita Klimova, Nikita Stepanov, and Sergey Zherebtsov. 2023. "Mechanical Behavior of a Medium-Entropy Fe65(CoNi)25Cr9.5C0.5 Alloy Produced by Selective Laser Melting" Materials 16, no. 8: 3193. https://doi.org/10.3390/ma16083193

APA StylePovolyaeva, E., Shaysultanov, D., Astakhov, I., Evlashin, S., Klimova, M., Stepanov, N., & Zherebtsov, S. (2023). Mechanical Behavior of a Medium-Entropy Fe65(CoNi)25Cr9.5C0.5 Alloy Produced by Selective Laser Melting. Materials, 16(8), 3193. https://doi.org/10.3390/ma16083193