Experimental Investigation of Seismic Performance of Precast Concrete Wall–Beam–Slab Joints with Overlapping U-Bar Loop Connections

Abstract

:1. Introduction

1.1. Background and Previous Investigations

1.2. Motivation

2. Experimental Program

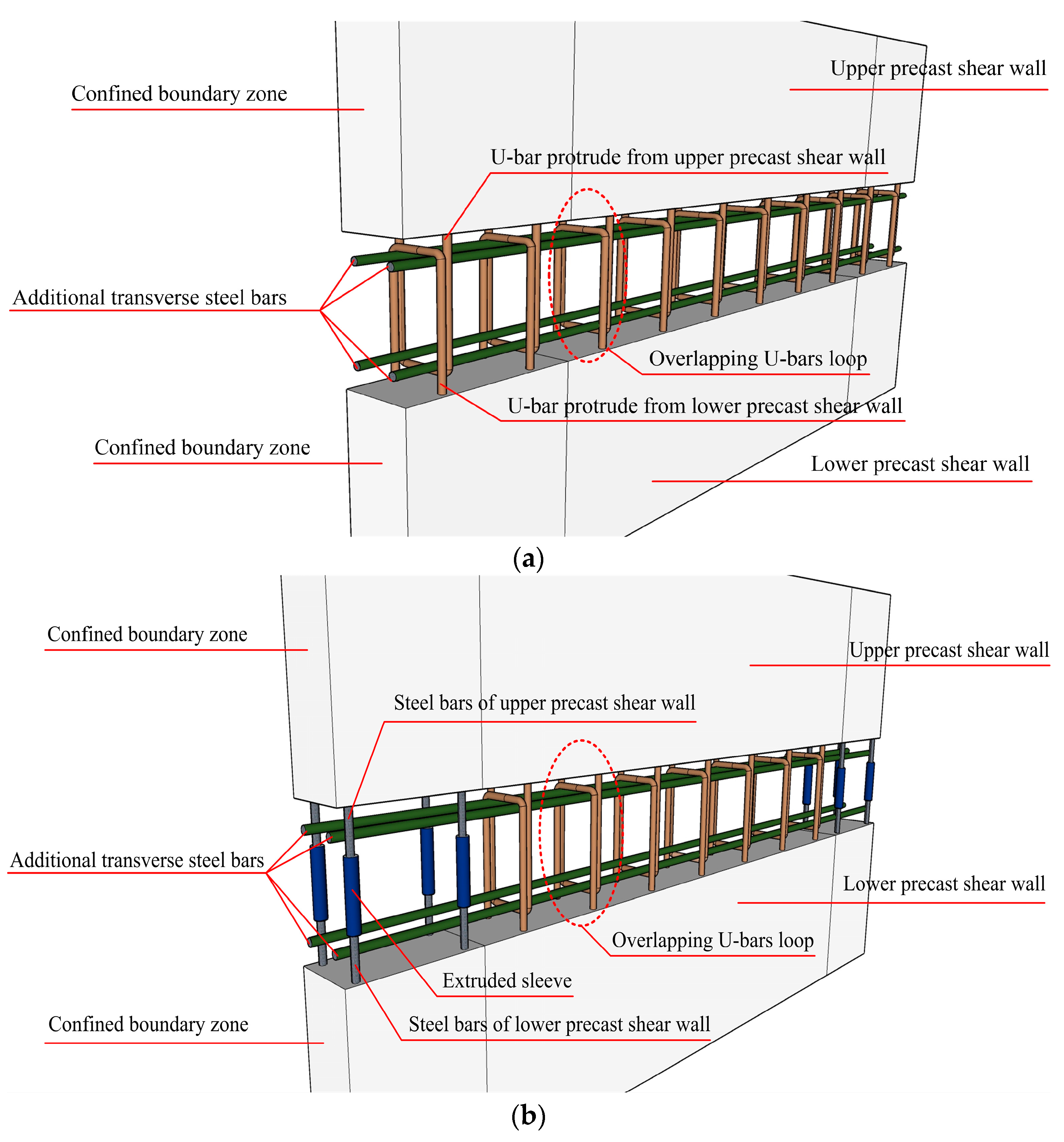

2.1. The Specimens

2.2. Material Properties

2.3. Test Setup and Loading Method

2.3.1. Test Setup

2.3.2. Loading Method

2.3.3. Measurement Items

3. Experiment Results and Discussion

3.1. Damage Process and Failure Mechanisms

3.1.1. Observations for the JD1 Specimen

3.1.2. Observations for the JD2 Specimen

3.1.3. Observations for the JD3 Specimen

3.2. Hysteretic Loops and Skeleton Curves

3.3. Load-Carrying Capacity, Displacement, and Ductility

3.4. Equivalent Stiffness

3.5. Energy Dissipation Performance

3.6. Strain of Longitudinal Steel Bars in Beam

4. Conclusions

- The overlapping U-bar loop connection adopted in assembling precast components is an effective and reasonable method. The stiffness of the PC joints was similar to that of the CIP joint; the load-carrying capacity, ductility, and energy dissipation of the PC joints were better than those of the CIP joint. Moreover, further experimental validations are still required to ensure that the mechanical properties of precast shear walls with this connection form can meet the seismic requirements.

- By comparing the relevant mechanical indicators of JD2 with pure overlapping U-bar loop connections with those of JD3 with a modified form-overlapping U-bar loop connection combined with an extruded sleeve connection, it can be found that JD3 shows slightly better mechanical properties in general.

- The failure mode of the PC joints was consistent with that of the CIP joint, which was marked by the buckling of the tensile steel bars, the crushing of concrete at the bottom of the beam, and a sharp decrease in load-carrying capacity. The generation, distribution, and development of cracks in the PC specimens were also similar to those in the CIP specimen. However, the precast-to-post-cast concrete interface between the web of the T-shaped shear wall and the beam cracked significantly during the loading process. Furthermore, there were fewer diagonal cracks distributed in the web of the T-shaped shear wall of the PC joints than that of the CIP joint.

- The length of the longitudinal steel bars of the precast beam anchored into the web of the T-shaped shear wall was calculated in the same way as that of the CIP joint, so that it could meet the structural requirements of the PC joints. In the case where the requirements of anchor length were met, anchor damage did not occur.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kurama, Y.C.; Sritharan, S.; Fleischman, R.B.; Restrepo, J.I.; Henry, R.S.; Cleland, N.M.; Ghosh, S.K.; Bonelli, P. Seismic-Resistant Precast Concrete Structures: State of the Art. J. Struct. Eng. 2018, 144, 03118001.1–03118001.18. [Google Scholar] [CrossRef]

- Sha, M.; Liu, P.; Gao, J.; Ma, H. Research status and application of prefabricated concrete frame joints. E3S Web Conf. 2021, 260, 03025. [Google Scholar] [CrossRef]

- Priestley, M.J.N. Overview of PRESSS research program. PCI J. 1991, 36, 50–57. [Google Scholar] [CrossRef]

- Lachimpadi, S.K.; Pereira, J.J.; Taha, M.R.; Mokhtar, M. Construction waste minimisation comparing conventional and precast construction (Mixed System and IBS) methods in high-rise buildings: A Malaysia case study. Resour. Conserv. Recycl. 2012, 68, 96–103. [Google Scholar] [CrossRef]

- Ioani, A.M.; Tripa, E. Structural behavior of an innovative all–precast concrete dual system for residential buildings. PCI J. 2012, 57, 110–123. [Google Scholar] [CrossRef]

- Guan, D.; Jiang, C.; Guo, Z.; Ge, H. Development and seismic behavior of precast concrete beam-to-column connections. J. Earthq. Eng. 2018, 22, 234–256. [Google Scholar] [CrossRef]

- Brunesi, E.; Nascimbene, R. Experimental and numerical investigation of the seismic response of precast wall connections. Bull. Earthq. Eng. 2017, 15, 5511–5550. [Google Scholar] [CrossRef]

- Xu, G.; Wang, Z.; Wu, B.; Bursi, O.S.; Tan, X.; Yang, Q.; Wen, L. Seismic performance of precast shear wall with sleeves connection based on experimental and numerical studies. Eng. Struct. 2017, 150, 346–358. [Google Scholar] [CrossRef]

- Ameli, M.J.; Pantelides, C.P. Seismic analysis of precast concrete bridge columns connected with grouted splice sleeve connectors. J. Struct. Eng. 2017, 143, 04016176-1–04016176-13. [Google Scholar] [CrossRef]

- Wu, D.; Liang, S.; Guo, Z.; Zhu, X.; Fu, Q. The development and experimental test of a new pore-forming grouted precast shear wall connector. KSCE J. Civ. Eng. 2016, 20, 1462–1472. [Google Scholar] [CrossRef]

- Zhi, Q.; Guo, Z.; Xiao, Q.; Yuan, F.; Song, J. Quasi-static test and strut-and-tie modeling of precast concrete shear walls with grouted lap-spliced connections. Constr. Build. Mater. 2017, 150, 190–203. [Google Scholar] [CrossRef]

- Ei-Sheikh, M.T.; Sause, R.; Pessiki, S.; Lu, L.-W. Seismic Behavior and Design of Unbonded Post-Tensioned Precast Concrete Frames. PCI J. 1999, 44, 54–71. [Google Scholar] [CrossRef]

- Nurjaman, H.; Faizal, L.; Sidjabat, H.; Hariandja, B.; Put, Y.; Rivky, R. Application of Precast System Buildings with Using Connection of Unbonded Post-tension and Local Dissipater Device. Procedia Eng. 2014, 95, 75–87. [Google Scholar] [CrossRef]

- Liu, D.; Hou, J. Comparative analysis of reinforcement connection method of precast members in residential industrialization. J. Jilin Jianzhu Univ. 2016, 33, 35–38. (In Chinese) [Google Scholar]

- Tang, H.; Xie, Y.; Zhao, T.; Xue, S. Identification of grout sleeve joint defect in prefabricated structures using deep learning. Front. Mater. 2020, 7, 298. [Google Scholar] [CrossRef]

- Pampanin, S.; Priestley, M.J.N.; Sritharan, S. Analytical modeling of the seismic behavior of precast concrete frame designed with ductile connections. J. Earthq. Eng. 2001, 5, 329–367. [Google Scholar] [CrossRef]

- Kurama, Y.C. Hybrid Post-Tensioned Precast Concrete Walls for Use in Seismic Regions. PCI J. 2002, 47, 36–59. [Google Scholar] [CrossRef]

- Aalami, B. Unbonded and Bonded Post-Tensioning Systems in Building Construction, A Design and Performance Review; Post-Tensioning Institute: Phoenix, AZ, USA, 1994; Technical Note, Issue 5. [Google Scholar]

- Yu, Z.; Peng, X.; Guo WPeng, M. New node connection mode and seismic performance of precast concrete shear wall structure. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.). 2015, 47, 160–164+191. (In Chinese) [Google Scholar]

- Yu, Z.; Peng, X.; Guo, W.; Peng, M. Research on anchorage performance of U-shaped ferrule reinforcement connections in precast shear wall. J. Railw. Sci. Eng. 2015, 12, 879–886. (In Chinese) [Google Scholar]

- Yu, Z.; Peng, X.; Guo, W.; Peng, M. Seismic Performance of Precast Shear Wall with U-type reinforcements ferrule connection. J. Zhejiang Univ. (Eng. Sci.) 2015, 49, 975–984. (In Chinese) [Google Scholar]

- Yu, Z.; Lv, X.; Yu, Y.; Ding, F.; Peng, X. Seismic Performance of Precast Concrete Columns with Improved U-type Reinforcement Ferrule Connections. Int. J. Concr. Struct. Mater. 2019, 13, 54. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, Z. Seismic performance research on wall-slab joints of new precast concrete shear walls tructure. J. Earthq. Eng. Eng. Vib. 2011, 31, 35–40. (In Chinese) [Google Scholar]

- Sun, W.; Meng, S. Lateral load behavior of unbonded post-tensioned coupled concrete wall subassemblages. J. Southeast Univ. (Nat. Sci. Ed.) 2007, 37, 190–194. (In Chinese) [Google Scholar]

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). GJ 3-2010; Technical Specification for Concrete Structures of Tall Building. China Architecture and Industry Press: Beijing, China, 2010. (In Chinese)

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Industry Press: Beijing, China, 2010. (In Chinese)

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). JB50009-2012; Load Code for the Design of Building Structures. China Architecture and Industry Press: Beijing, China, 2012. (In Chinese)

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). JGJ 101-2015; Specification for Seismic Test of Buildings. China Architecture and Industry Press: Beijing, China, 2015. (In Chinese)

- Shan, Z.; Yu, Z.; Chen, F.; Li, X.; Gao, J. Experimental Investigation of Mechanical Behaviors of Self-Compacting Concrete under Cyclic Direct Tension. Materials 2019, 12, 1047. [Google Scholar] [CrossRef] [PubMed]

| Specimens | Type | Connection Methods Applied to Different Precast Components | |||

|---|---|---|---|---|---|

| Wall–Wall | Wall–Slab | Wall–Beam | Beam–Slab | ||

| JD1 | CIP | integral | integral | integral | integral |

| JD2 | PC | overlapping U-bar loop connections | overlapping U-bar loop connections | directly anchored | overlapping U-bar loop connections |

| JD3 | PC | extruded sleeve connections (in confined boundary zone) overlapping U-bar loop connections (in intermediate region) | overlapping U-bar loop connections | directly anchored | overlapping U-bar loop connections |

| Type | Class | fcu/MPa |

|---|---|---|

| CIP specimen and precast components of PC specimens | C30 | 31.01 |

| post-pouring concrete of PC specimens | C40 | 35.11 |

| Type | Diameter Ds (mm) | Yield Strength fy (MPa) | Ultimate Strength fu (MPa) | Elastic Modulus Es (N/mm2) | Yield Strain εy (10−6) |

|---|---|---|---|---|---|

| HRB400 | 10 | 563 | 660 | 2.028×105 | 2776 |

| HRB400 | 14 | 442 | 656 | 1.884×105 | 2346 |

| Specimen | Cracking Cycle | Yield Cycle | Peak Cycle | Ultimate Cycle | Ductility | ||||

|---|---|---|---|---|---|---|---|---|---|

| Fcr (kN) | Δcr (mm) | Fy (kN) | Δy (mm) | Fp (kN) | Δp (mm) | Fu (kN) | Δu (mm) | ||

| JD1 | 39.505 | 2.45 | 79.468 | 9.34 | 111.786 | 29.8 | 93.567 | 30.68 | 3.285 |

| JD2 | 39.490 | 1.88 | 79.437 | 7.86 | 124.252 | 23.20 | 98.175 | 35.96 | 4.575 |

| JD3 | 39.612 | 1.26 | 79.346 | 7.04 | 121.023 | 35.14 | 106.522 | 40.10 | 5.696 |

| Specimen | Secant Stiffness | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 kN | 40 kN | 60 kN | 80 kN | 100 kN | 1Δa | 2Δa | 3Δa | 4Δa | 5Δa | 6Δa | |

| JD1 | 26.219 | 17.581 | 12.696 | 9.912 | - | 8.99 | 7.245 | 5.171 | 4.141 | 3.095 | - |

| JD2 | 24.602 | 19.196 | 13.311 | 10.812 | - | 11.997 | 7.382 | 5.424 | 4.275 | 3.289 | 2.495 |

| JD3 | 25.063 | 20.139 | 16.566 | 12.885 | 7.445 | 8.666 | 6.875 | 4.847 | 2.826 | 2.203 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Yu, Z.; Yu, Y.; Zhai, Z.; Liu, Q.; Li, X. Experimental Investigation of Seismic Performance of Precast Concrete Wall–Beam–Slab Joints with Overlapping U-Bar Loop Connections. Materials 2023, 16, 3318. https://doi.org/10.3390/ma16093318

Chen F, Yu Z, Yu Y, Zhai Z, Liu Q, Li X. Experimental Investigation of Seismic Performance of Precast Concrete Wall–Beam–Slab Joints with Overlapping U-Bar Loop Connections. Materials. 2023; 16(9):3318. https://doi.org/10.3390/ma16093318

Chicago/Turabian StyleChen, Feng, Zhiwu Yu, Yalin Yu, Zhipeng Zhai, Qun Liu, and Xiao Li. 2023. "Experimental Investigation of Seismic Performance of Precast Concrete Wall–Beam–Slab Joints with Overlapping U-Bar Loop Connections" Materials 16, no. 9: 3318. https://doi.org/10.3390/ma16093318

APA StyleChen, F., Yu, Z., Yu, Y., Zhai, Z., Liu, Q., & Li, X. (2023). Experimental Investigation of Seismic Performance of Precast Concrete Wall–Beam–Slab Joints with Overlapping U-Bar Loop Connections. Materials, 16(9), 3318. https://doi.org/10.3390/ma16093318