The Effect of Cutting Fluid on Machined Surface Integrity of Ultra-High-Strength Steel 45CrNiMoVA

Abstract

:1. Introduction

2. Experimental Procedures

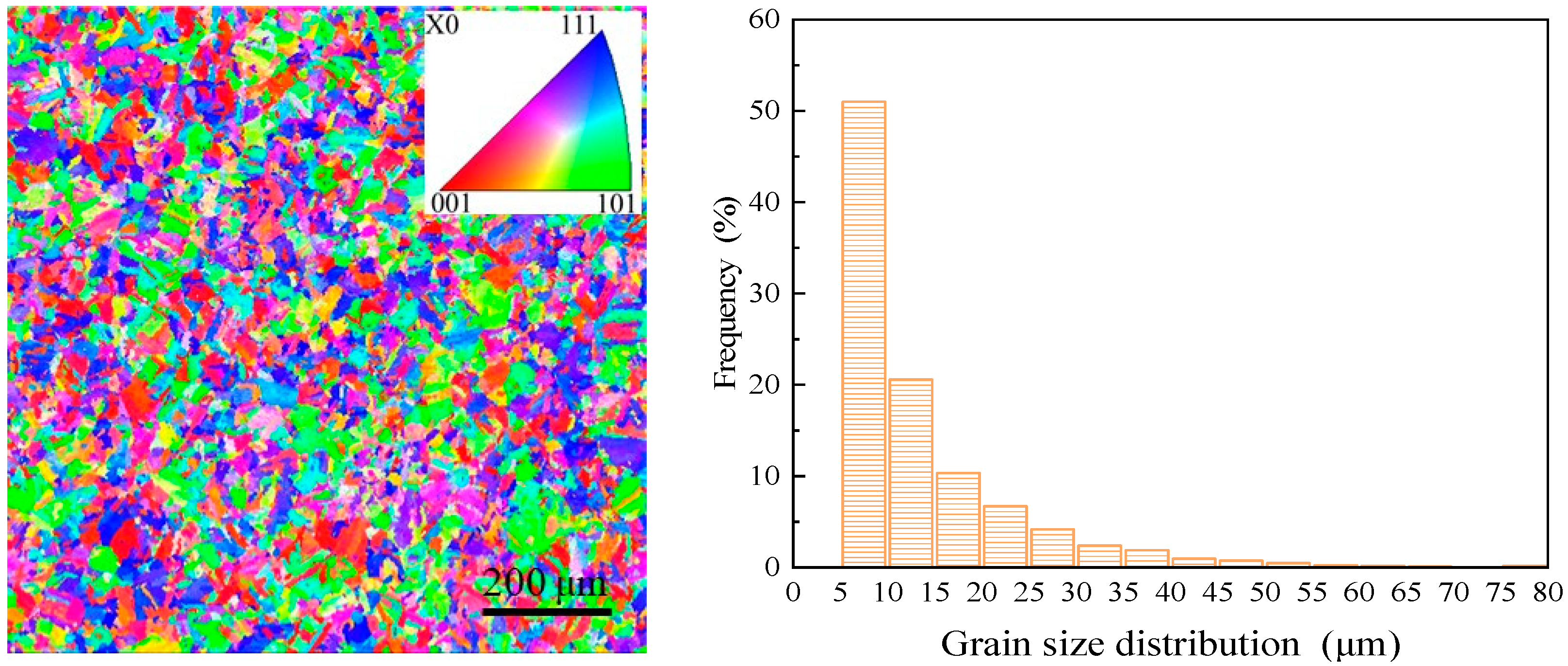

2.1. Material

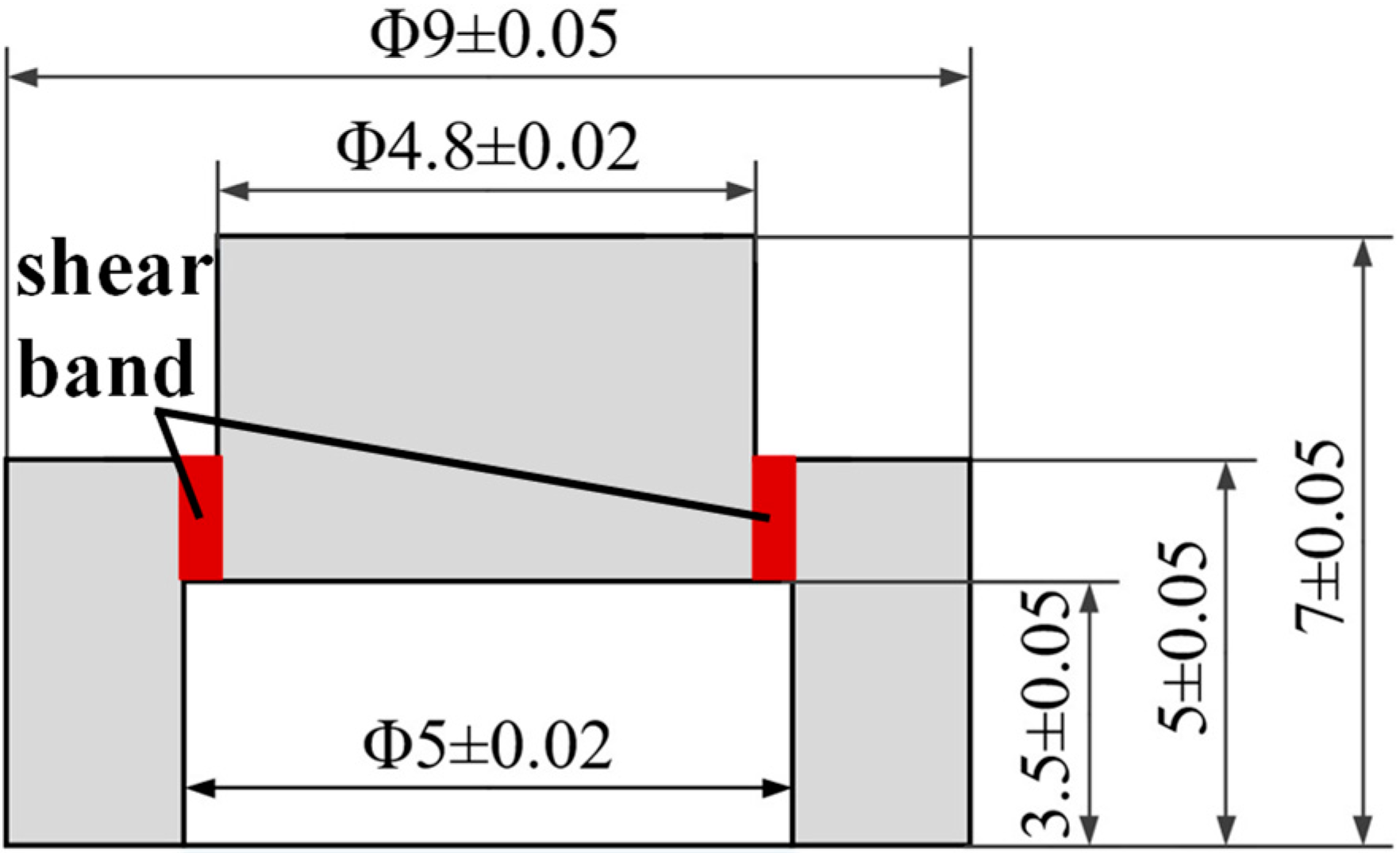

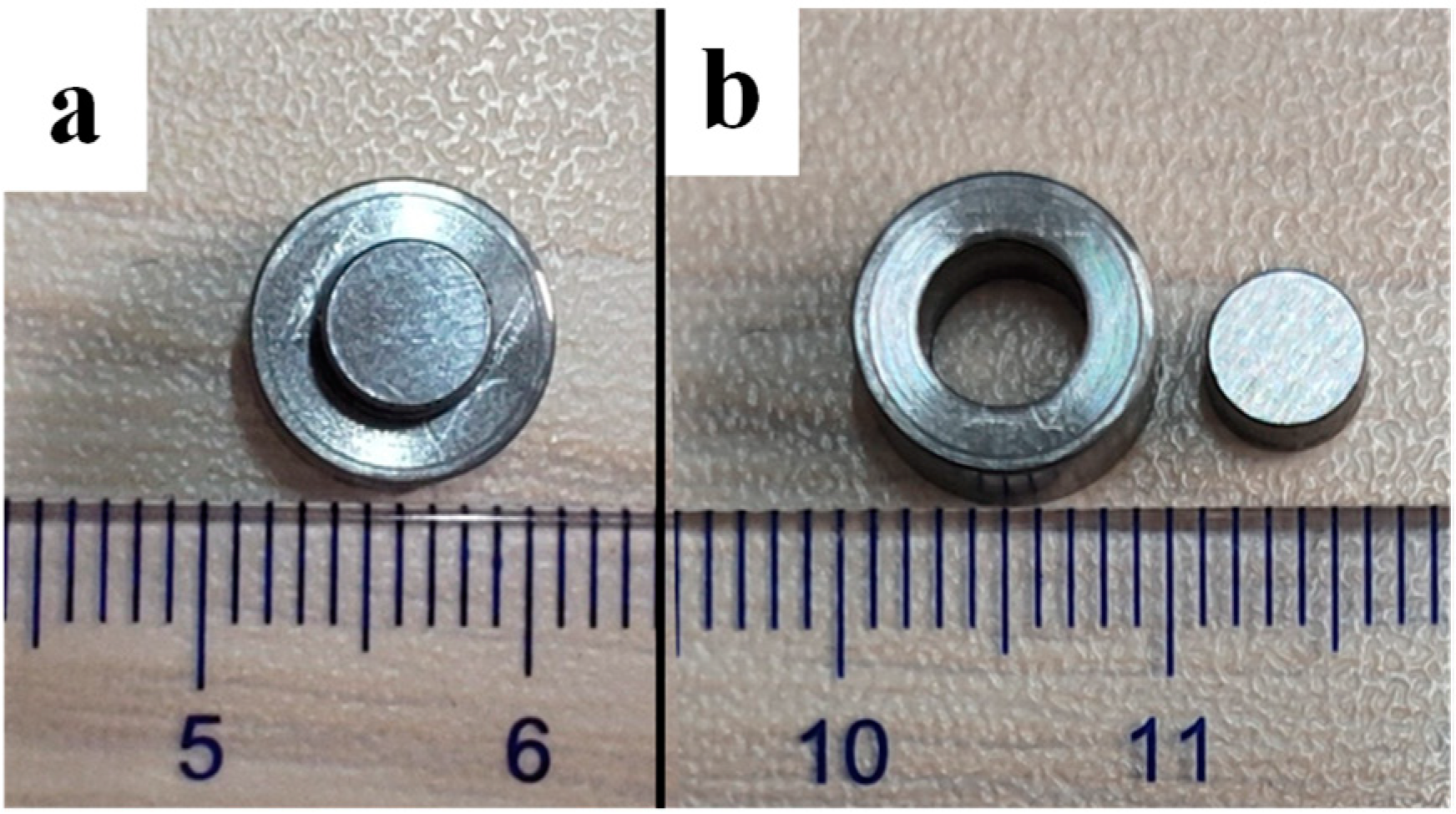

2.2. Split Hopkinson Pressure Bar Test

2.3. Turning Experiments

2.4. Integrity Indicator

3. Results

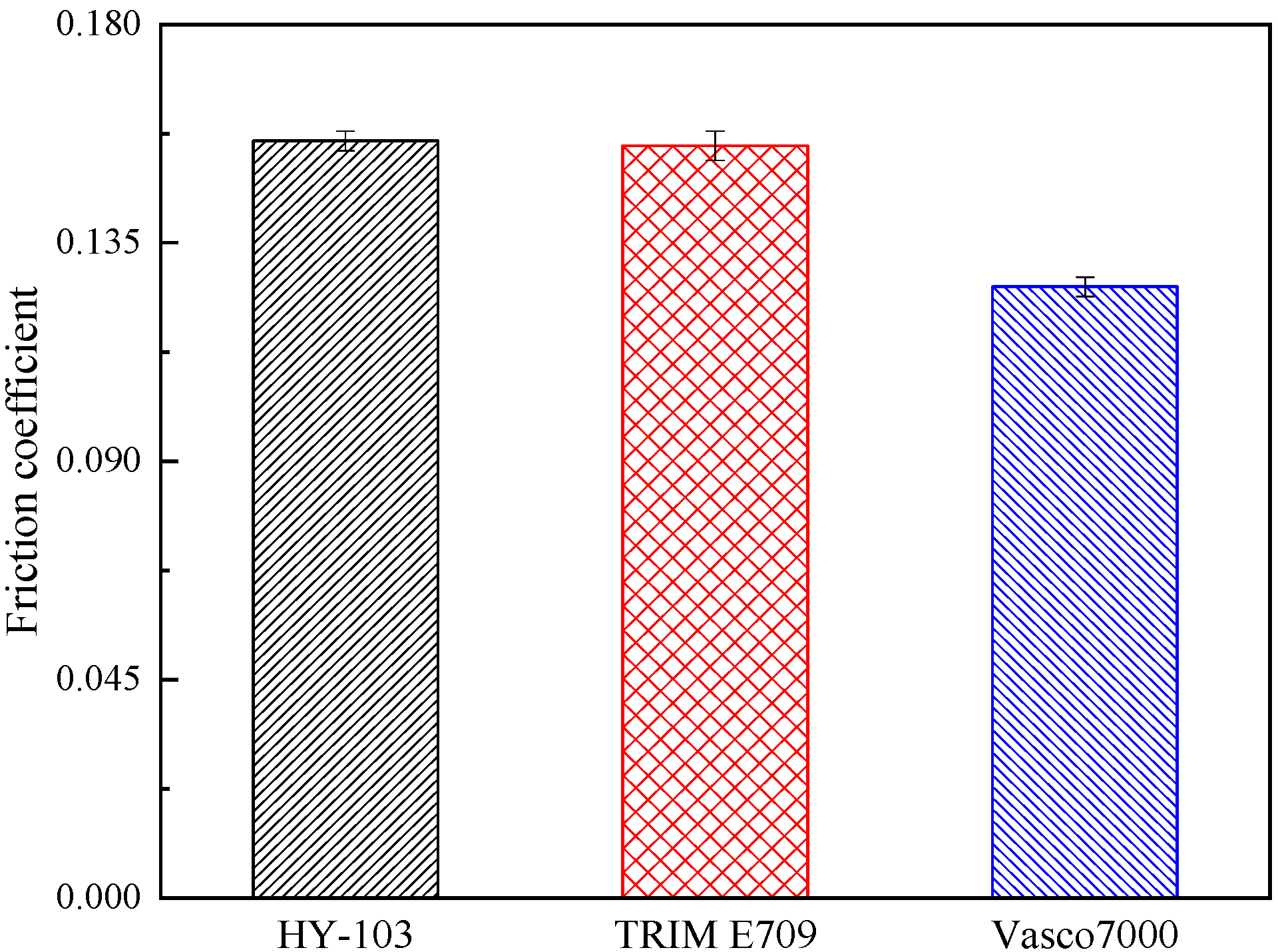

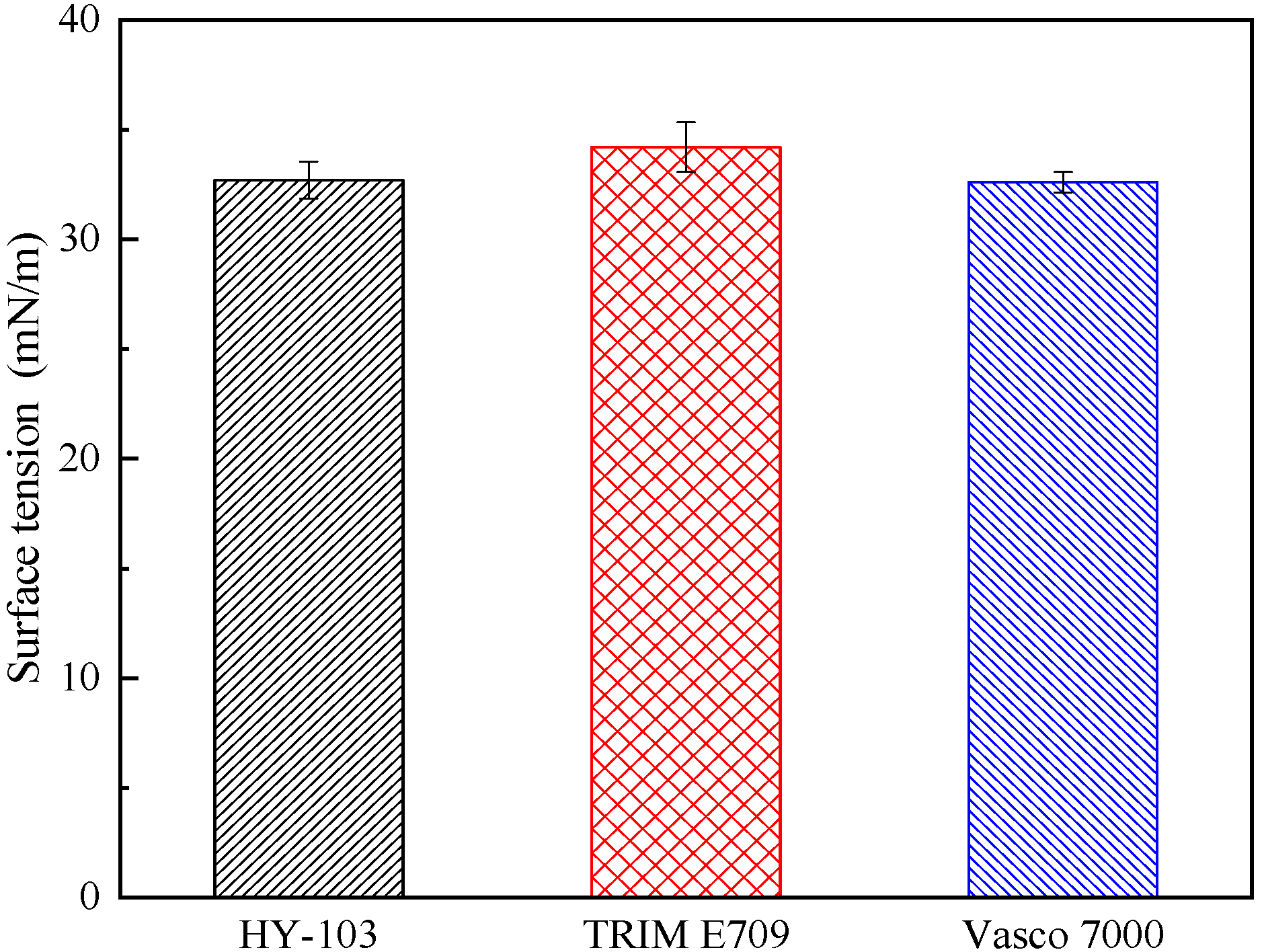

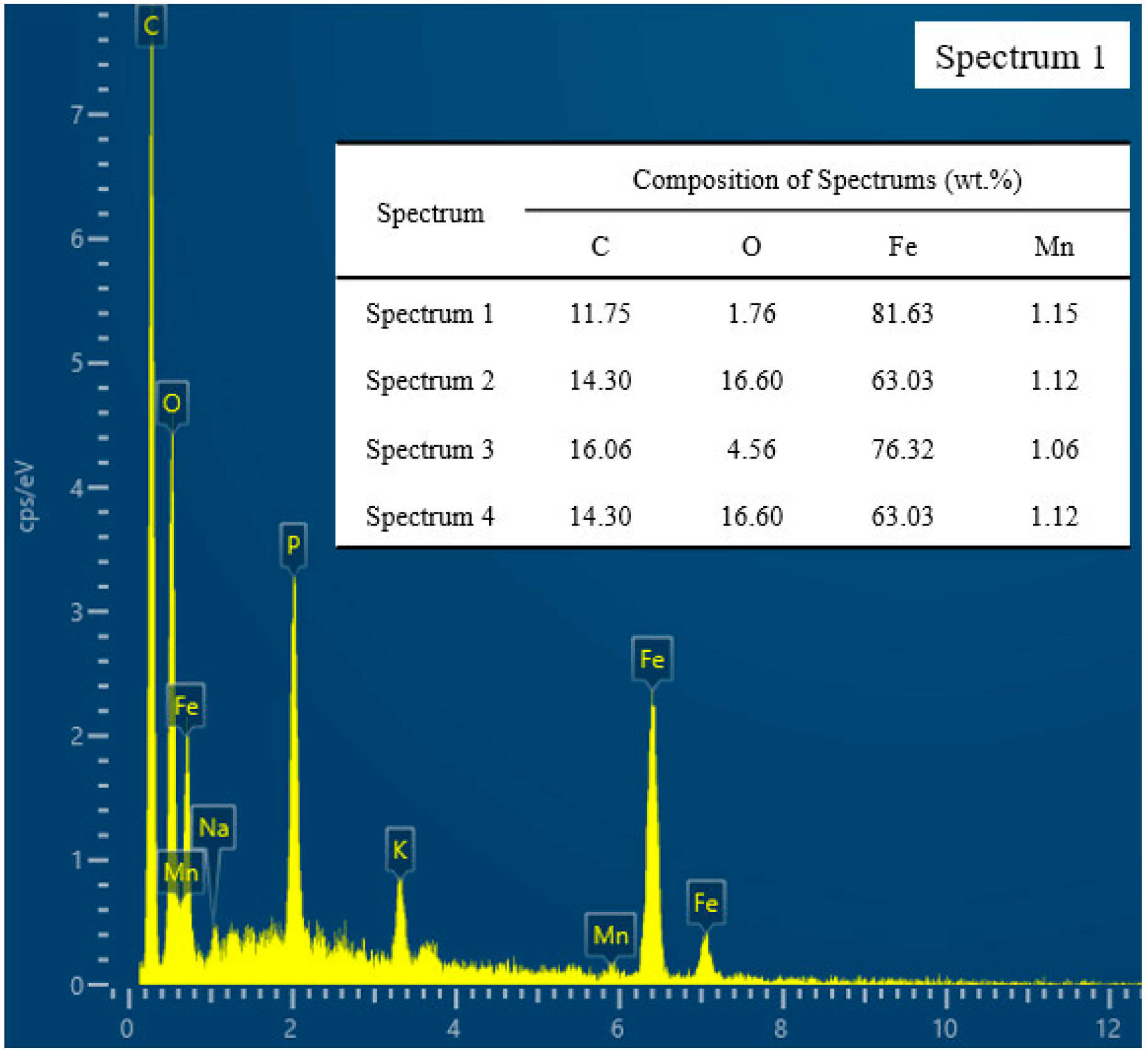

3.1. Physical and Chemical Properties

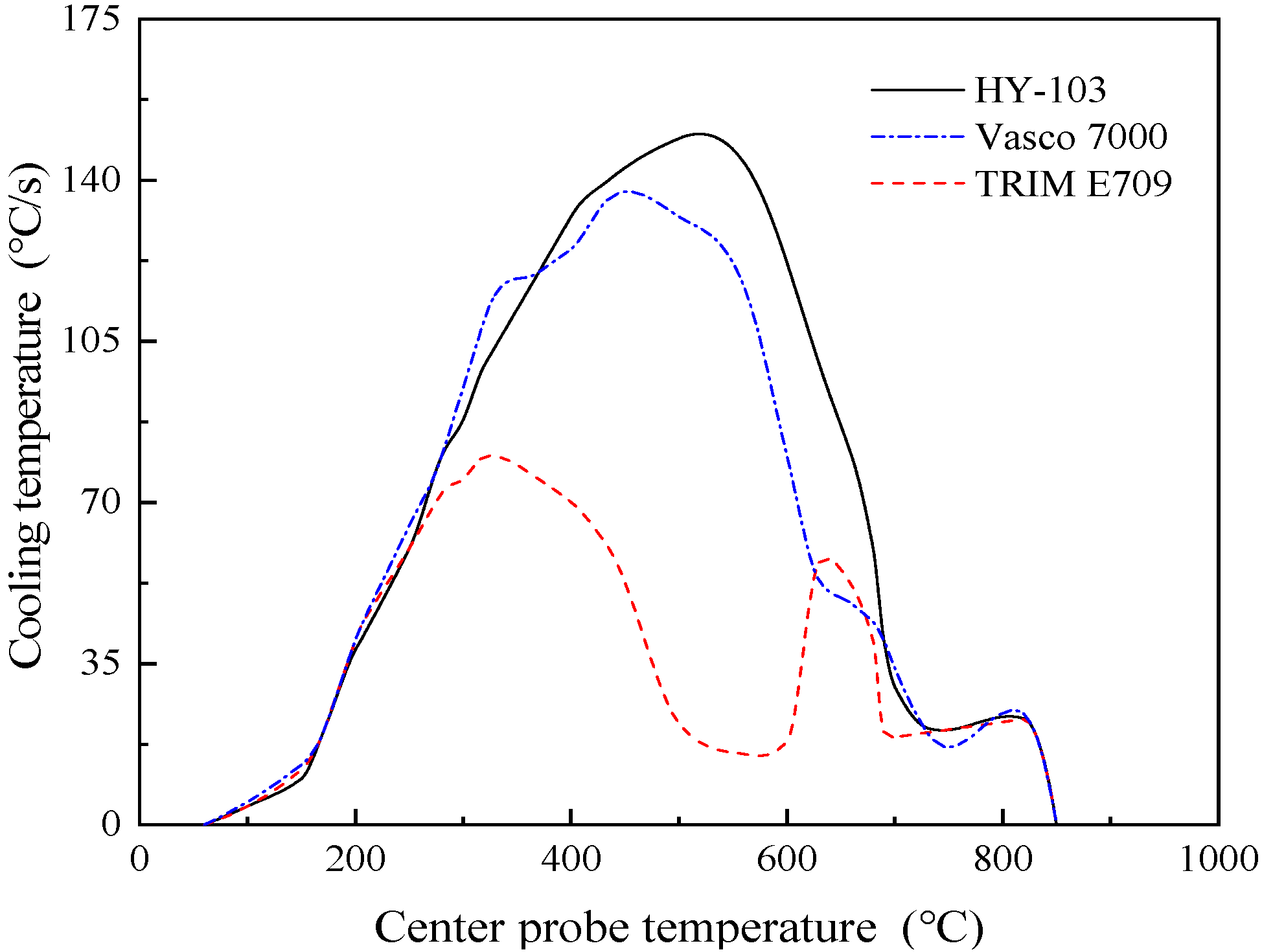

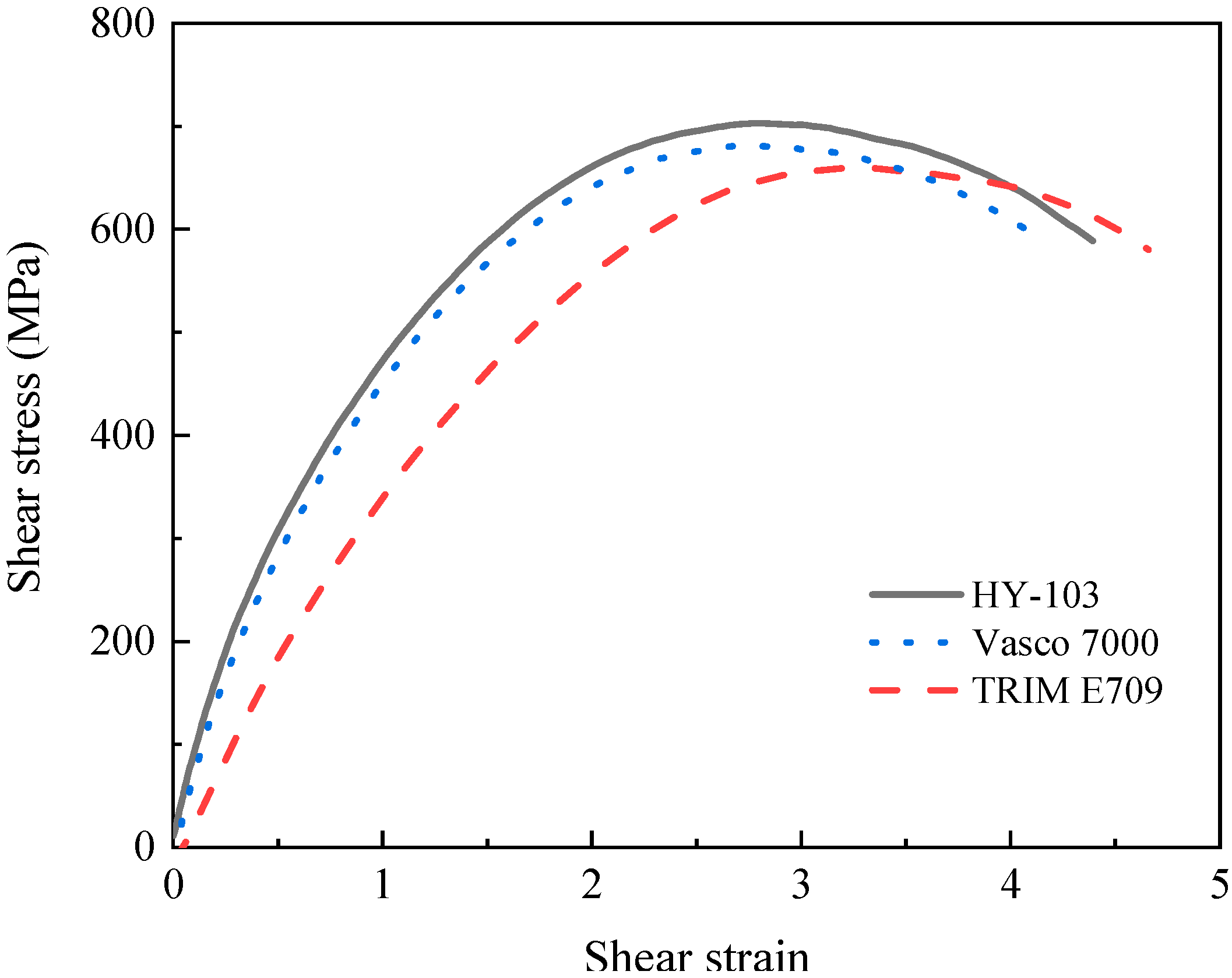

3.2. Dynamic Mechanical Property

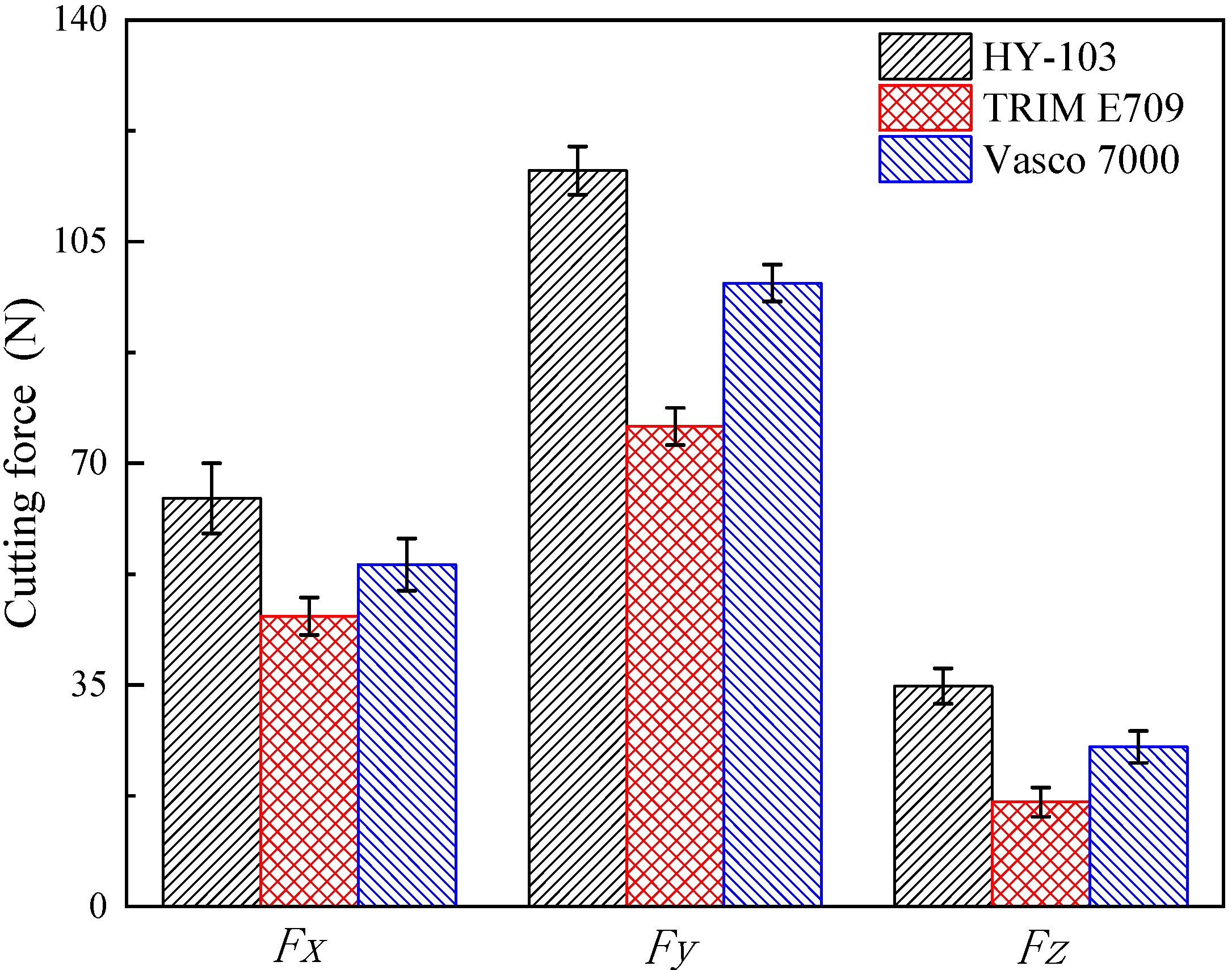

3.3. Cutting Force

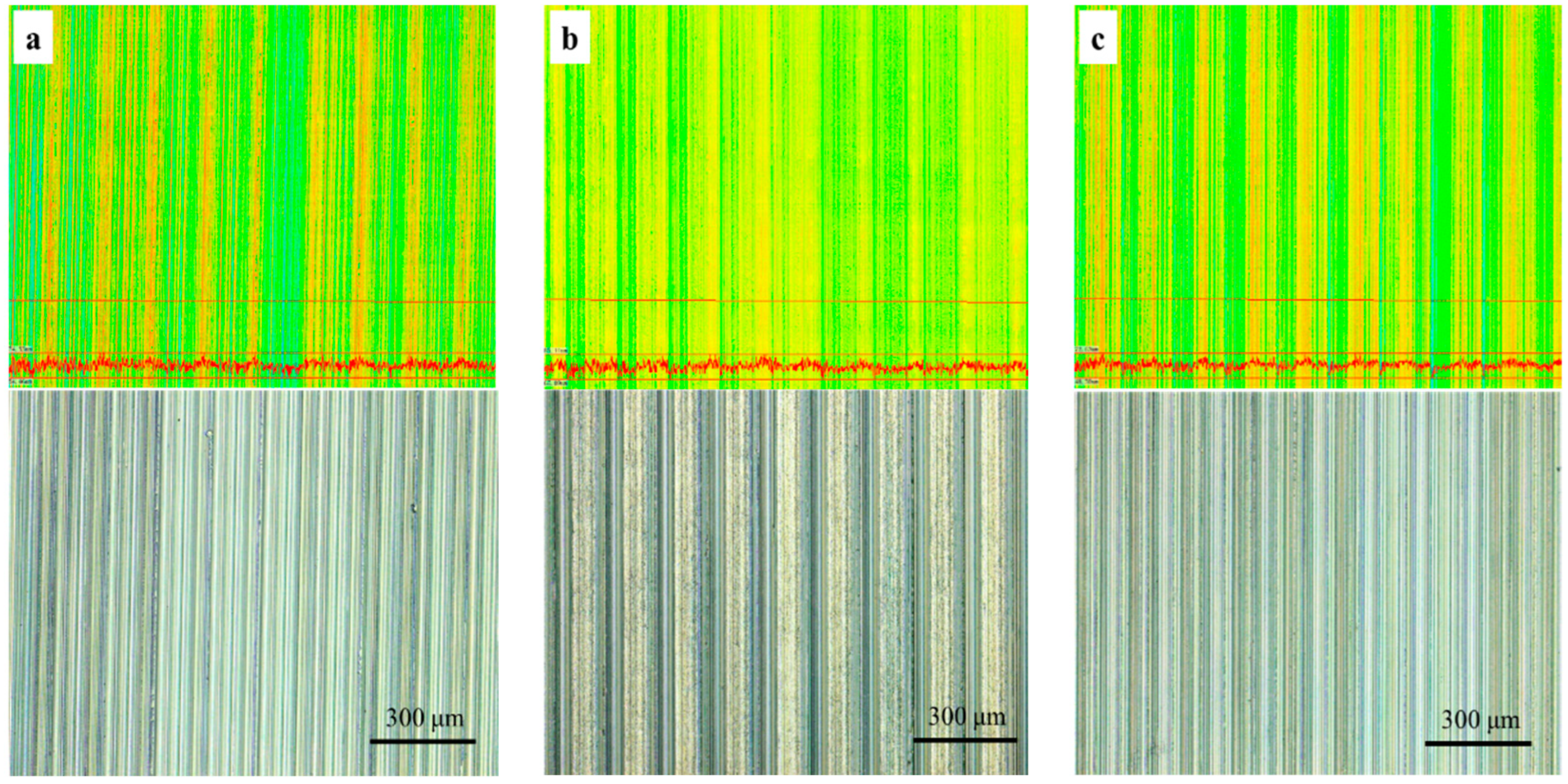

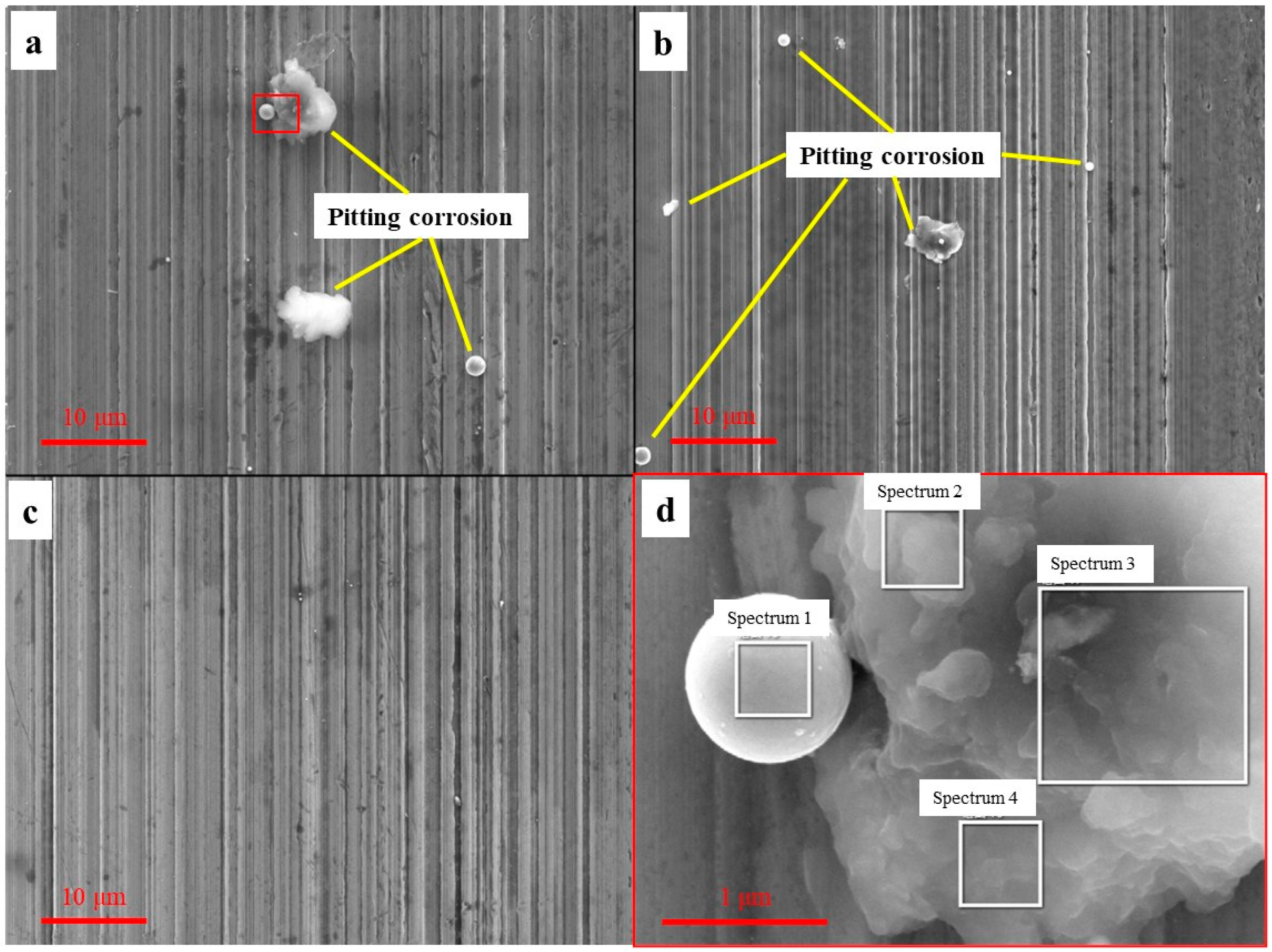

3.4. Surface Morphology

3.5. Residual Stress

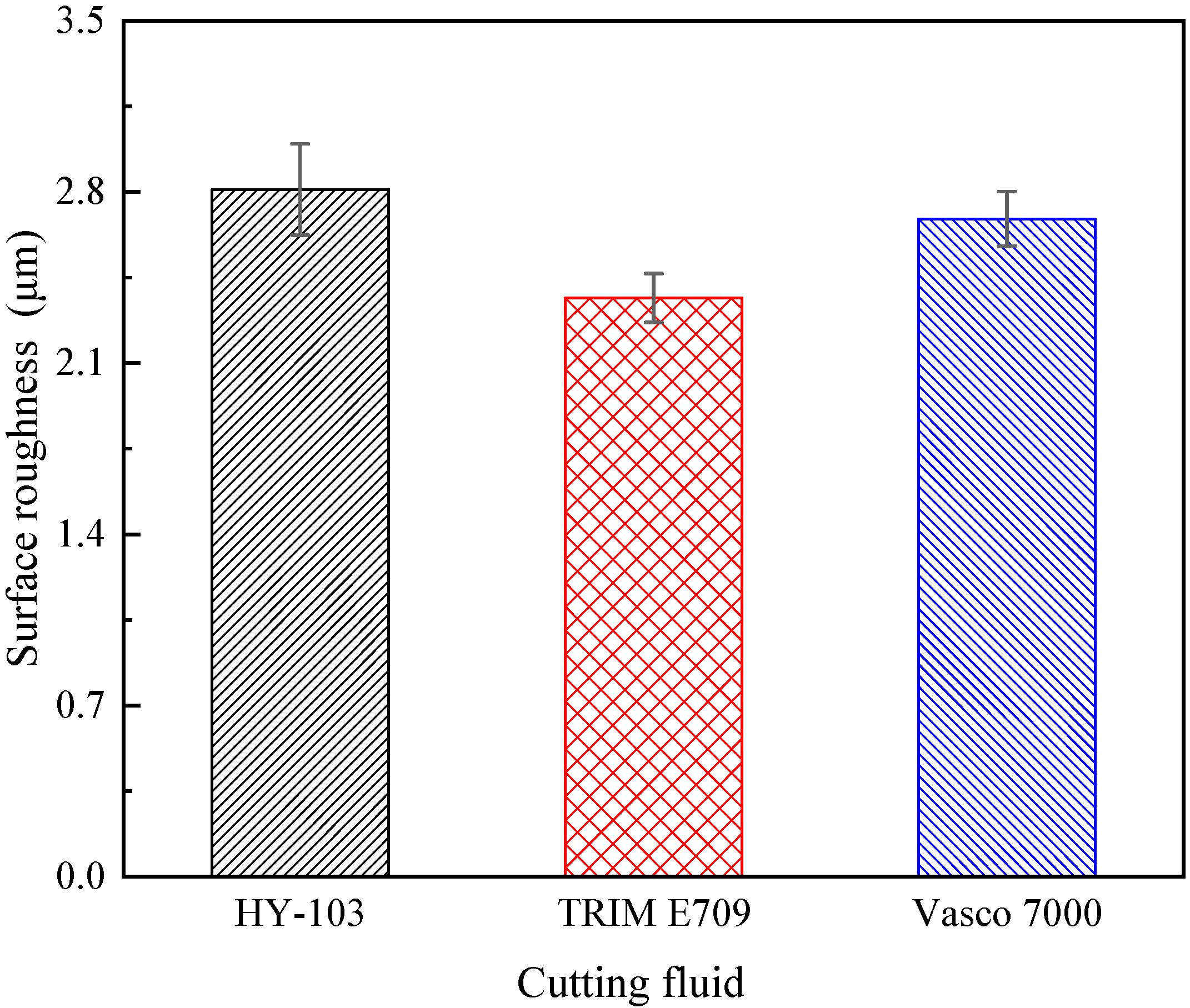

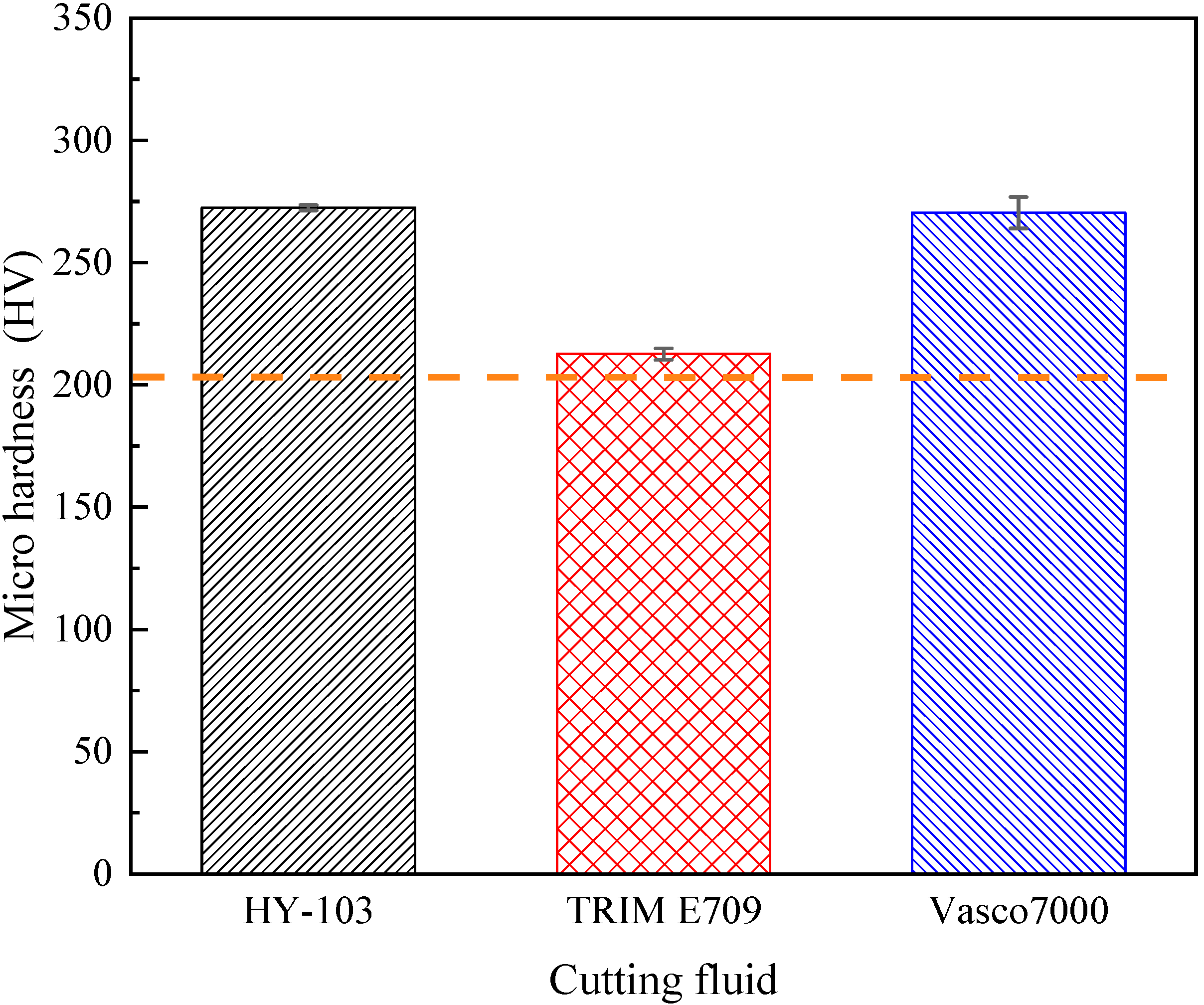

3.6. Microhardness

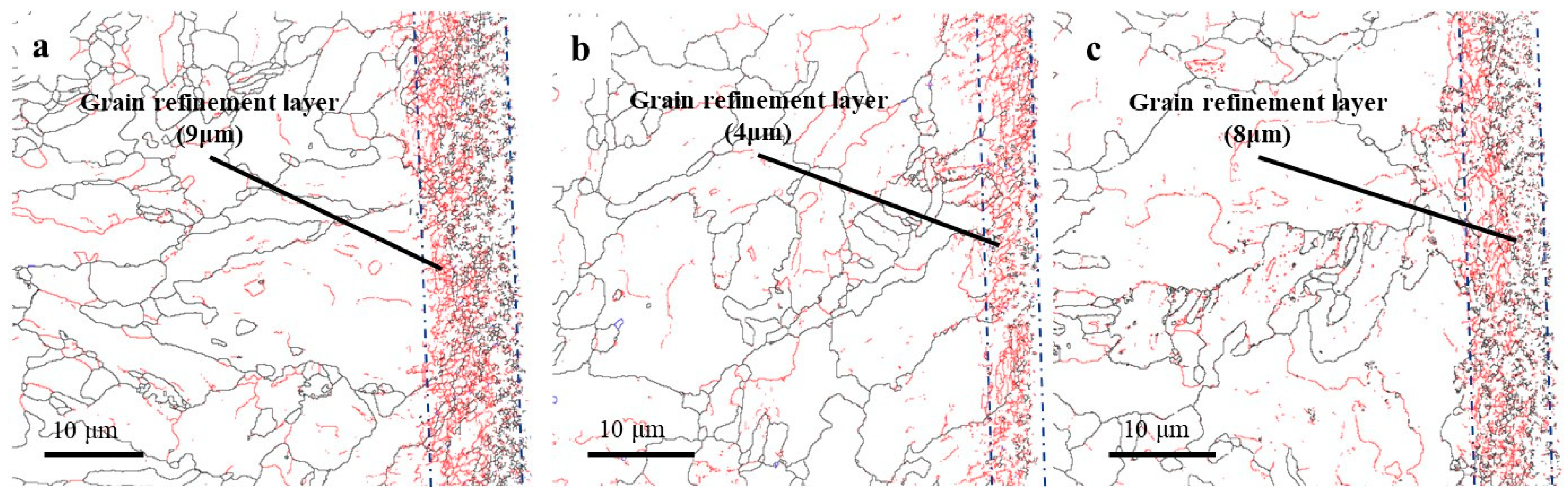

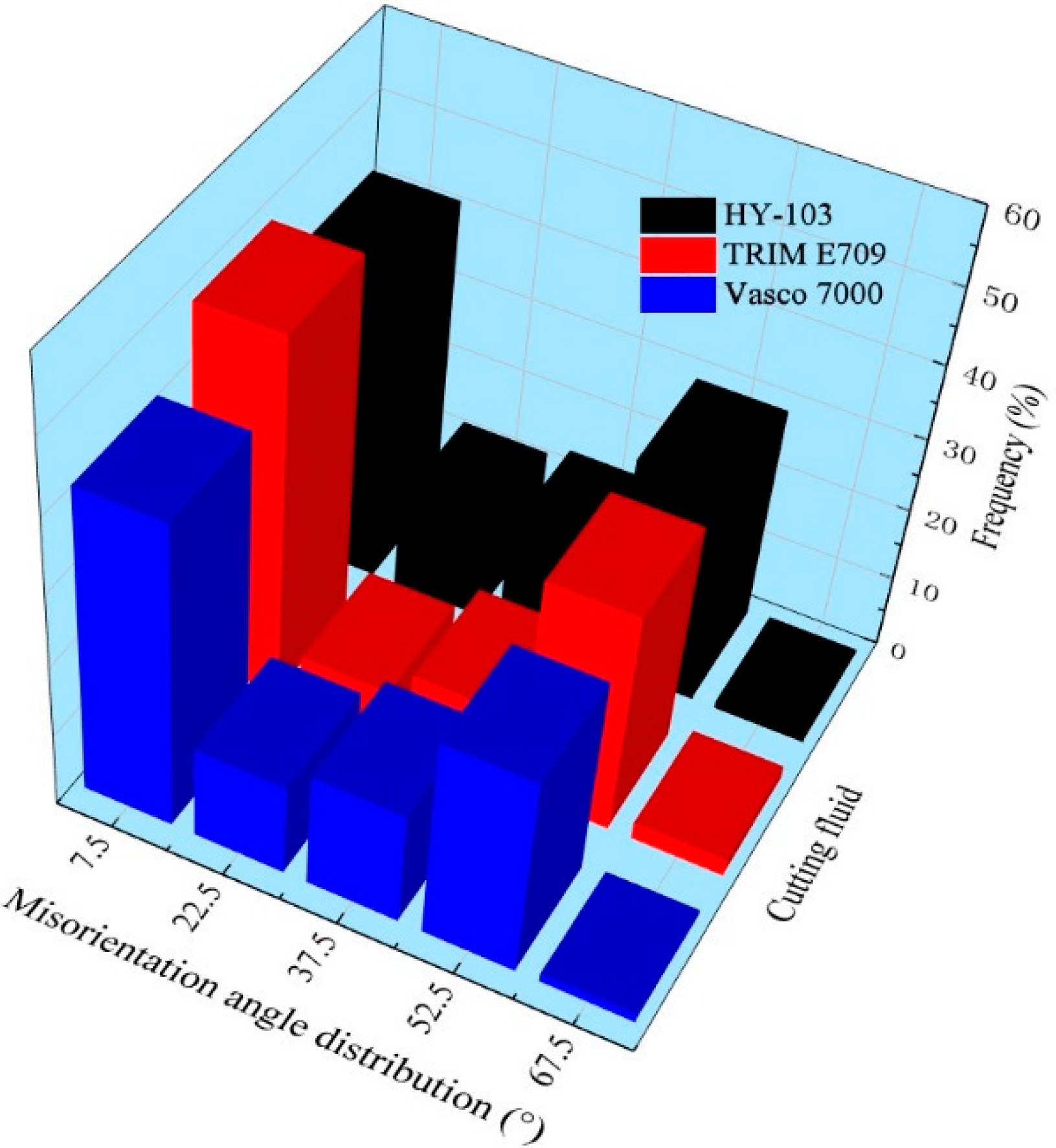

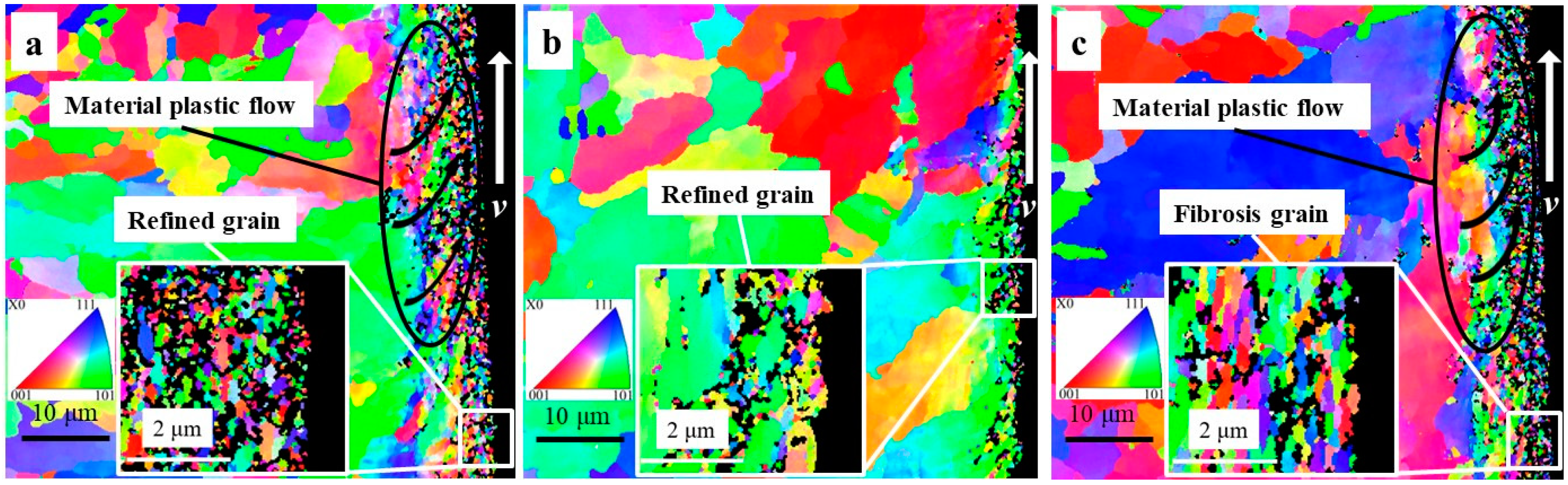

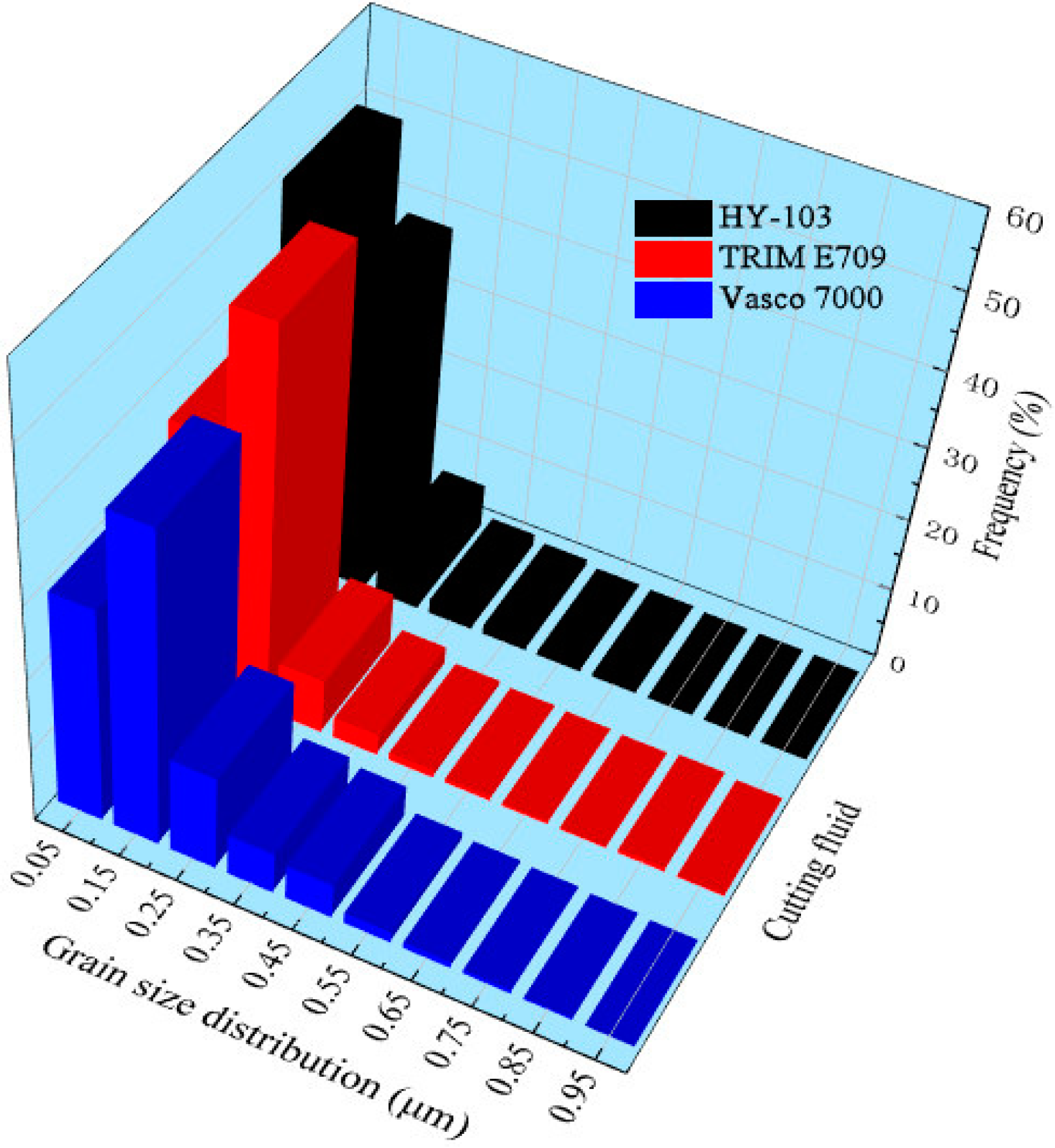

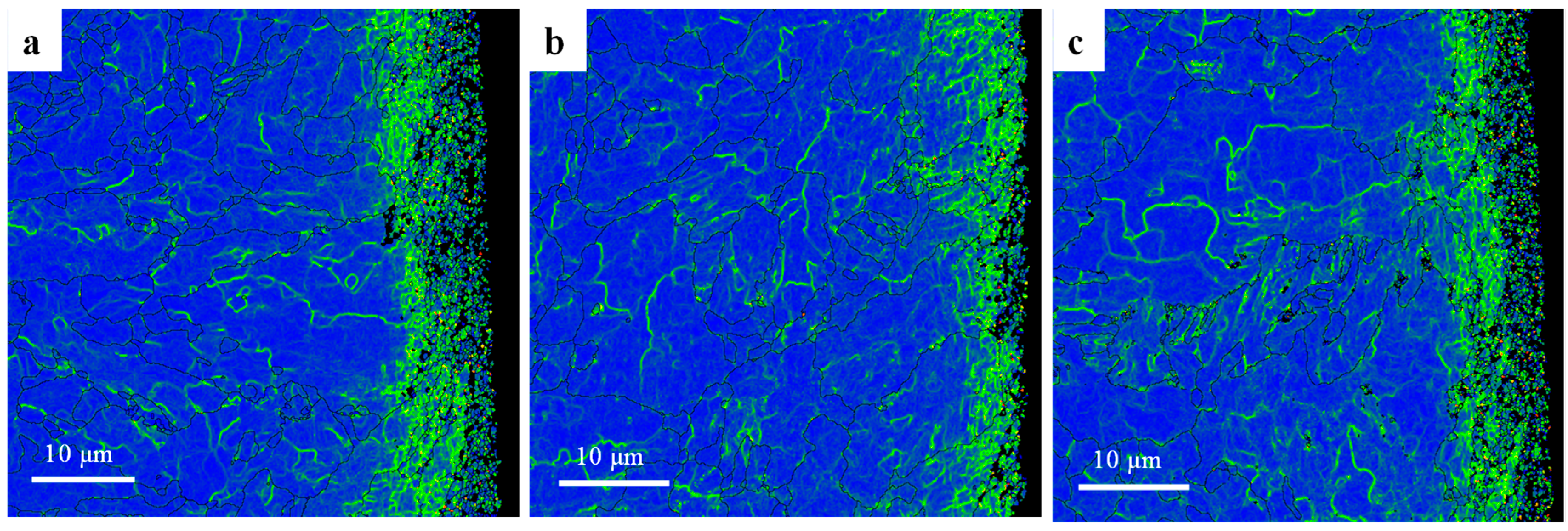

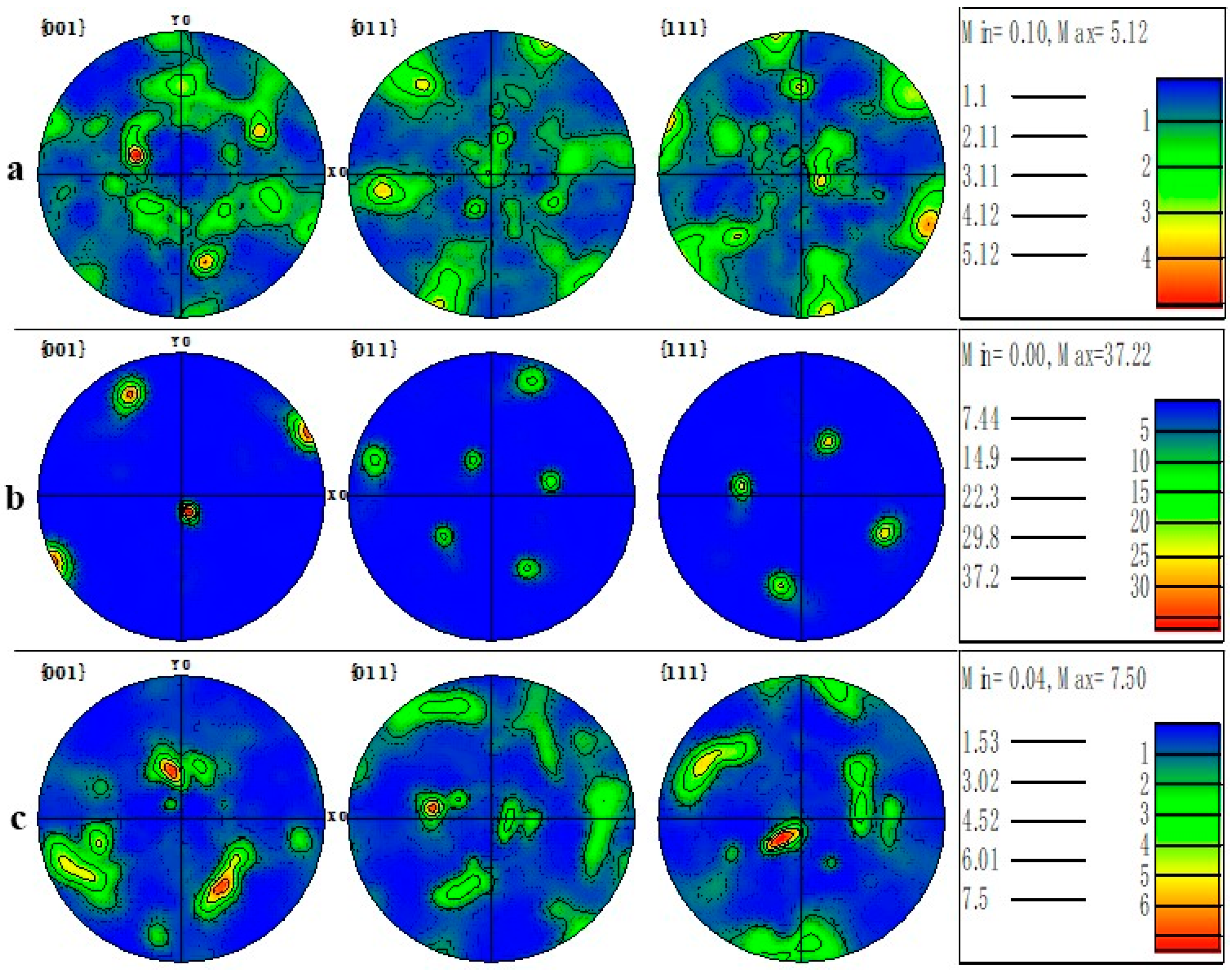

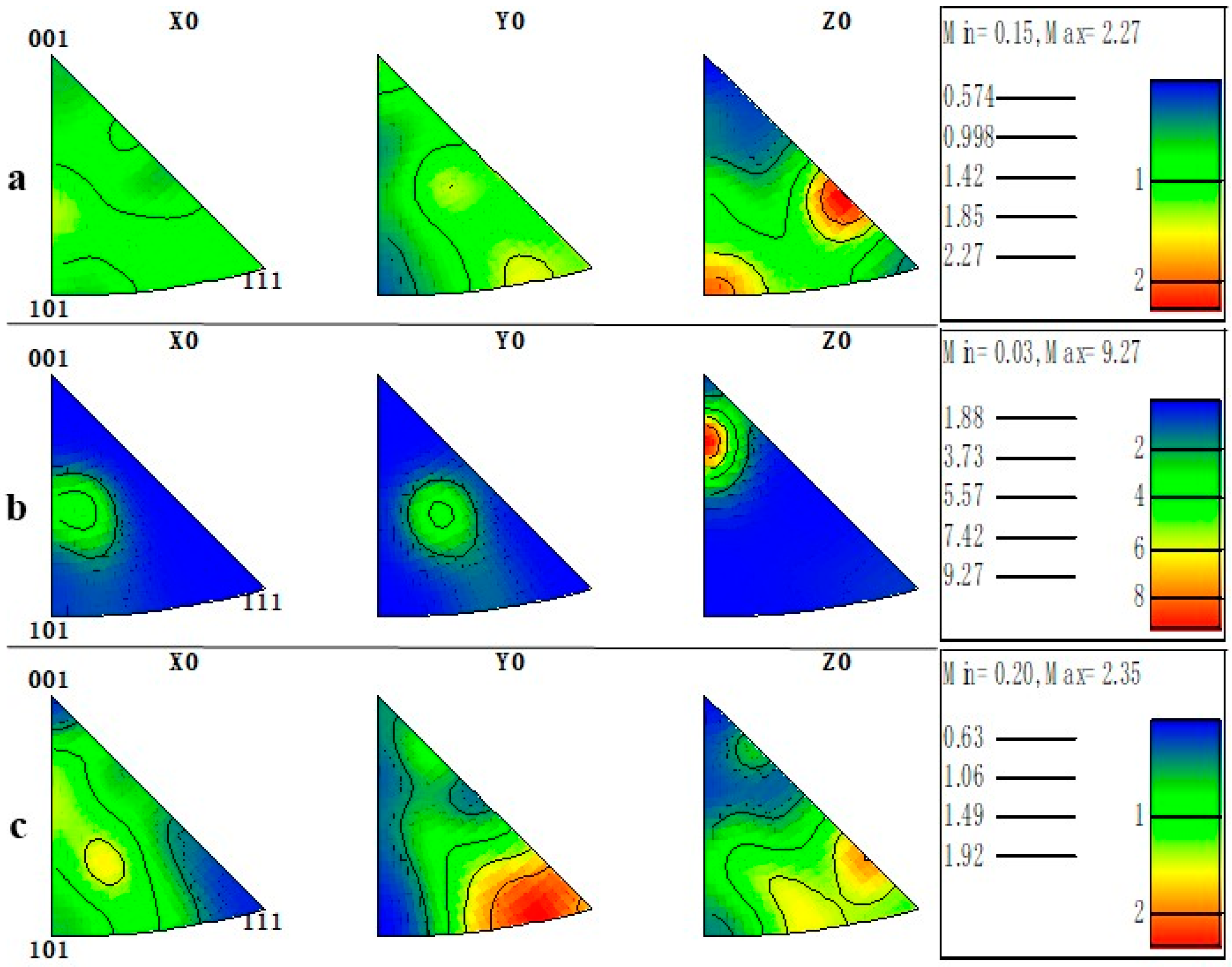

3.7. Microstructure Characterization

4. Discussion

4.1. Dynamic Mechanical Property

4.2. Cutting Force

4.3. Surface Morphology

4.4. Residual Stress

4.5. Microhardness

4.6. Microstructure Characterization

5. Conclusions

- Because of the different composition and properties of the three cutting fluids, the changing trend of the cutting forces in three directions is HY-103 > Vasco 7000 > TRIM E709;

- The TRIM E709 contains the maximum lubricants, which reduce cutting force and surface roughness (Sa), while the Vasco 7000 contains the minimum corrosive elements, which results in the least pitting;

- Both tangential and axial stresses under cutting fluid are tensile stresses. TRIM E709 and Vasco 7000 are reduced axially by 4.45% and 7.60% relative to HY-103, respectively;

- The grain refinement layer depths of HY-103, TRIM E709, and Vasco 7000 are 9 μm, 4 μm, and 8 μm, respectively, and TRIM E709 can induce recrystallized grains to grow along {001}.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Wang, X.; Liu, Z.; Liu, S.; Wang, S.; Chen, H.; Song, C.; Bai, Y.; Wang, P.; Liu, Y. A strain energy method exploration between machined surface integrity evolution and torsion fatigue behaviour of low-alloy medium-carbon steel. Chin. J. Aeronaut. 2021, 35, 412–429. [Google Scholar] [CrossRef]

- Hu, X.; Xie, L.; Gao, F.; Xiang, J. On the development of material constitutive model for 45crnimova ultra-high-strength steel. Metals 2019, 9, 374. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, X.; Zhu, J.; Jiao, L.; Liang, Z. Effect of cutting fluid on precision machined surface integrity of heat-resistant stainless steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1535–1548. [Google Scholar] [CrossRef]

- Wu, D.; Yao, C.; Zhang, D. Surface characterization and fatigue evaluation in gh4169 superalloy: Comparing results after finish turning. Int. J. Fatigue 2018, 113, 222–235. [Google Scholar] [CrossRef]

- Avila, R.F.; Abrao, A.M. The effect of cutting fuids on the machining of hardened aisi 4340 steel. J. Mater. Process. Technol. 2001, 119, 21–26. [Google Scholar] [CrossRef]

- Thepsonthi, T.; Hamdi, M.; Mitsui, K. Investigation into minimal-cutting-fluid application in high-speed milling of hardened steel using carbide mills. Int. J. Mach. Tools Manuf. 2009, 49, 156–162. [Google Scholar] [CrossRef]

- Shashidhara, Y.M.; Jayaram, S.R. Vegetable oils as a potential cutting fluid—An evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Baradie, M.E. Cutting fluids: Part II. Recycling and clean machining. J. Mater. Process. Technol. 1996, 56, 798–806. [Google Scholar] [CrossRef]

- Baradie, M.E. Cutting fluids: Part I. Characterisation. J. Mater. Process. Technol. 1996, 56, 786–797. [Google Scholar] [CrossRef]

- Gaurav, G.; Sharma, A.; Dangayach, G.S.; Meena, M. Assessment of jojoba as a pure and nano-fluid base oil in minimum quantity lubrication (mql) hard-turning of ti–6al–4v: A step towards sustainable machining. J. Clean Prod. 2020, 272, 122553. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, S.; Si, L.; Liu, T.; Dai, Y.; Yan, C.; Zhang, C. Investigation of a new water-based cutting fluid for machining of titanium alloys. J. Manuf. Process. 2021, 71, 398–406. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Lubricity and adsorption of castor oil sulfated sodium salt emulsion solution on titanium alloy. Tribol. Lett. 2019, 67, 61. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; de Lacalle, L.N.L.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining ti-6al-4v using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernandez-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of aisi 304. J. Clean. Prod. 2016, 139, 440e–449e. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; De Lacalle, L.L. Internal cryolubrication approach for inconel 718 milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- González, H.; Fernández-Lucio, P.; Pereira, O.; Calleja, A.; Fernández-Valdivielso, A.; de Lacalle, L.L. Abrasive tool behavior comparing lubri-cooling techniques for super abrasive machining full-slotting in inconel®718. Procedia Manuf. 2019, 41, 642–649. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid cryo-mql lubri-cooling strategy on the machining and tribological characteristics of inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K. Machinability of ti-6al-4v and nimonic-90 in ultrasonic-assisted turning under sustainable cutting fluid. Mater. Today Proc. 2022, 62, 7396–7400. [Google Scholar] [CrossRef]

- Rout, I.S.; Pandian, P.P.; Raj, A. Experimental study of response parameters during machining of inconel 718 with cryogenically treated ceramic round tool using cutting fluid. Mater. Today Proc. 2021, 47, 4281–4287. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, G. The effect of cutting fluids applied in metal cutting process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 19–37. [Google Scholar] [CrossRef]

- Saleem, M.Q.; Mehmood, A. Eco-friendly precision turning of superalloy inconel 718 using mql based vegetable oils: Tool wear and surface integrity evaluation. J. Manuf. Process. 2022, 73, 112–127. [Google Scholar] [CrossRef]

- Srikant, R.R.; Ramana, V.V. Studies on corrosion and quenching effects of cutting fluid with vegetable-based emulsifier on aisi 1040 steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 178–181. [Google Scholar] [CrossRef]

- Srikant, R.R.; Ramana, V. Performance evaluation of vegetable emulsifier based green cutting fluid in turning of american iron and steel institute (aisi) 1040 steel—An initiative towards sustainable manufacturing. J. Clean. Prod. 2015, 108, 104–109. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. Evaluation of vegetable and mineral oil-in-water emulsion cutting fluids in turning aisi 4340 steel with coated carbide tools. J. Clean. Prod 2014, 6, 610–618. [Google Scholar] [CrossRef]

- Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E. Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of aisi 304l by taguchi method. J. Clean. Prod. 2011, 19, 2049–2056. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja-Ochoa, A.; Fernández-Valdivielso, A.; Lopez de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Ruzzi, R.D.S.; de Paiva, R.L.; Gelamo, R.V.; Machado, A.R.; da Silva, R.B. Study on grinding of inconel 625 and 718 alloys with cutting fluid enriched with multilayer graphene platelets. Wear 2021, 476, 203697. [Google Scholar] [CrossRef]

- Vasu, V.; Kumar, K.M. Analysis of nanofluids as cutting fluid in grinding en-31 steel. Nanomicro Lett. 2011, 3, 209–214. [Google Scholar] [CrossRef]

- Yan, P.; Wang, Y.; Jin, X.; Zhu, J.; Jiao, L.; Qiu, T.; Wang, X. Effect of cutting fluid on high strain rate dynamic mechanical property and cutting performance of nickel based superalloy. J. Mater. Res. Technol. 2022, 17, 1146–1158. [Google Scholar] [CrossRef]

- Rebinder, P.A. Influence of changes in the surface energy on cleavage, hardness, and other properties of crystals. In Proceedings of the Sixth Conference of Russian Physicists, Compendium of Lectures, Moscow, Russia, 29 November–2 December 2022; Gosizdat: Moscow, Russia, 1928; Volume 29. (In Russian). [Google Scholar]

- Barlow, P.L. Rehbinder effect in lubricated metal cutting. Nature 1966, 211, 1076–1077. [Google Scholar] [CrossRef]

- Chaudhari, A.; Soh, Z.Y.; Wang, H.; Kumar, A.S. Rehbinder effect in ultraprecision machining of ductile materials. Int. J. Mach. Tools Manuf. 2018, 133, 47–60. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, S.; Yan, P.; Jiao, L.; Qiu, T.; Zhou, H.; Wang, X. Experimental research on cryogenic cutting performance of ni-based superalloy gh4169. Int. J. Adv. Manuf. Technol. 2022, 121, 379–392. [Google Scholar] [CrossRef]

- Luan, X.; Liang, X.; Zhao, W.; Shi, G.; Li, H.; Liu, X.; Zhu, G.; Wang, X. Strengthening mechanism of 45crnimova steel by pulse magnetic treatment. Acta Metall. Sin. 2021, 57, 1272–1280. [Google Scholar]

- ISO 9950:1995; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. International Organization for Standardization: Geneva, Switzerland, 1995.

- Hodgson, P.D.; Beladi, H.; Barnett, M.R. Grain refinement in steels through thermomechanical processing. Mater. Sci. Forum 2005, 500–501, 39–48. [Google Scholar] [CrossRef]

- Hao, L.; Jiang, Z.; Wei, D.; Zhao, Y.; Zhao, J.; Luo, M.; Ma, L.; Luo, S.; Jiang, L. Effect of extreme pressure agents on the anti-scratch behaviour of high-speed steel material. Tribol. Int. 2015, 81, 19–28. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; Nie, G.; Yang, Z.-Y.; Ding, H. Characterization of material strain and thermal softening effects in the cutting process. Int. J. Mach. Tools Manuf. 2021, 160, 103672. [Google Scholar] [CrossRef]

- Li, B.; Zhang, S.; Zhang, J. Plastic deformation and grain refinement in surface layer induced by thermo-mechanical loads for hard milling process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 233, 2033–2046. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, X.; Wang, Z.; Liu, Y.; You, T. Preparation of water-soluble nanographite and its application in water-based cutting fluid. Nanoscale Res. Lett. 2013, 8, 52. [Google Scholar] [CrossRef]

- Bzdek, B.R.; Reid, J.P.; Malila, J.; Prisle, N.L. The surface tension of surfactant-containing, finite volume droplets. Proc. Natl. Acad. Sci. USA 2020, 117, 8335–8343. [Google Scholar] [CrossRef]

- Guangjun, C.; Shuai, H.; Songxin, H. Research progress on effect of machined surface quality on corrosion resistance. Surf. Technol. 2019, 48, 25–33. [Google Scholar]

- Yan, X.; Gong, P.; Yang, C.; Zhang, G. Effect of temperature and dissolved oxygen on corrosion behavior of q235b steel in desulfurization solution. Met. Prot. 2020, 53, 20–25. [Google Scholar]

- Lu, Y.; Dong, J.; Ke, W. Effects of cl− ions on the corrosion behaviour of low alloy steel in deaerated bicarbonate solutions. J. Mater. Sci. Technol. 2016, 32, 341–348. [Google Scholar] [CrossRef]

- Wangyan, L.; Zhenyao, W.; Quancheng, Y.; Wei, S. Synergic effect of nahso3 and nacl on atmospheric corrosion of q235 steel. Corros. Sci. Prot. Technol. 2015, 27, 545–550. [Google Scholar]

- Liu, J.; Liu, Z.; Chen, S. Causes of corrosion and application of inhibitors in oil production. Corros. Prot. 2012, 33, 657–663. [Google Scholar]

- Zhenchao, Y.; Dinghua, Z.; Eng, Y.C.; Ren, J.; Tian, W. Influence mechanism of milling speed on tc4titanium alloy surface integrity in high-speed milling. J. Nanjing Univ. Aeronaut. Astronaut. 2009, 41, 644–648. [Google Scholar]

- Chen, C.; Lv, B.; Feng, X.; Zhang, F.; Beladi, H. Strain hardening and nanocrystallization behaviors in hadfield steel subjected to surface severe plastic deformation. Mater. Sci. Eng. A 2018, 729, 178–184. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Cui, F.K.; Xie, K.G.; Xie, Y.F.; Wang, X.Q.; Zhu, W.J.; Li, Y. Analysis of coupled thermal-mechanical mechanism based on work hardening phenomenon in high-speed cold roll-beating. Mater. Res. Innov. 2015, 19, 1212–1218. [Google Scholar] [CrossRef]

- Wang, S.Y.; Yang, W.J.; Ma, L.L. Advances in theoretical investigation of work hardening for metal cutting. Appl. Mech. Mater. 2012, 217–219, 2060–2064. [Google Scholar] [CrossRef]

- Zheng, Z.; Lee, Y.J.; Zhang, J.; Jin, X.; Wang, H. Ultra-precision micro-cutting of maraging steel 3j33c under the influence of a surface-active medium. J. Mater. Process. Technol. 2021, 292, 117054. [Google Scholar] [CrossRef]

- Raof, N.A.; Ghani, J.A.; Haron, C.H.C. Machining-induced grain refinement of aisi 4340 alloy steel under dry and cryogenic conditions. J. Mater. Res. Technol. 2019, 8, 4347–4353. [Google Scholar] [CrossRef]

| Element | Composition (wt.%) | Element | Composition (wt.%) |

|---|---|---|---|

| Ni | 1.30~1.80 | Si | 0.17~0.37 |

| Cr | 0.80~1.10 | Mn | 0.50~0.80 |

| V | 0.10~0.20 | C | 0.42~0.49 |

| Mo | 0.20~0.30 | Cu | ≤0.025 |

| S | ≤0.025 | P | ≤0.025 |

| Fe | Base |

| Young’s Modulus/GPa | Yield Stress/MPa | Tensile Strength/MPa | Elongation/% |

|---|---|---|---|

| 215 | 512 | 892 | 51 |

| Rake Angle (°) | Relief Angle (°) | Tool Cutting Edge Angle (°) | Tip Radius (mm) |

|---|---|---|---|

| 12.5 | 0 | 90 | 0.4 |

| Additive | Composition of Cutting Fluids (wt.%) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| pH regulator | 6.0~8.0 | 8.1~11.2 | 21.0~24.0 |

| Lubricant | 9.5~14 | 53.0~57.0 | 5.0~6.0 |

| Corrosion inhibitor | 3.3~4.5 | 8.1~11.1 | 11.4~14.6 |

| Emulsifier | 3.0~4.0 | 4.0~5.0 | 7.2~9.4 |

| Surfactant | 20.0~28.0 | 23.0~32.0 | 22.1~26.7 |

| Defoaming agent | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 |

| Extreme pressure agent | 0.0 | 0.3~0.5 | 12.0~14.0 |

| Other | Last | Last | Last |

| Element | Content of Cutting Fluids (mg/L) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| Cl | 921.19 | 1023.9 | 0 |

| S | 908.92 | 0 | 49.14 |

| Statistical Categories | Surface Roughness (μm) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| Average | 2.81 | 2.37 | 2.69 |

| Uncertainty (p = 0.95) | 0.46 | 0.25 | 0.27 |

| Standard deviation | 0.19 | 0.10 | 0.11 |

| Statistical Categories | Residual Stresses (MPa) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| Average | 506.10 | 536.97 | 365.27 |

| Uncertainty (p = 0.95) | 30.05 | 28.57 | 9.69 |

| Standard deviation | 12.10 | 11.50 | 3.90 |

| Statistical Categories | Residual Stresses (MPa) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| Average | 567.47 | 542.17 | 524.30 |

| Uncertainty (p = 0.95) | 30.50 | 18.01 | 13.99 |

| Standard deviation | 12.28 | 7.25 | 5.63 |

| Statistical Categories | Microhardness (HV) | ||

|---|---|---|---|

| HY-103 | TRIM E709 | Vasco 7000 | |

| Average | 272.42 | 212.57 | 270.43 |

| Uncertainty (p = 0.95) | 2.88 | 5.87 | 1.29 |

| Standard deviation | 1.15 | 2.36 | 6.47 |

| Extreme Pressure Agent | Extreme Pressure Film | Film-Forming Temperature/°C | Film-Melting Temperature/°C |

|---|---|---|---|

| Chlorine | Metal chloride | 180 | 670 |

| Phosphorus | Metal phosphide | 280 | 950 |

| Sulfur | Metal sulfide | 520 | 1100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Ren, Y.; Yan, P.; Li, S.; Dai, Z.; Jiao, L.; Zhao, B.; Pang, S.; Wang, X. The Effect of Cutting Fluid on Machined Surface Integrity of Ultra-High-Strength Steel 45CrNiMoVA. Materials 2023, 16, 3331. https://doi.org/10.3390/ma16093331

Wang Y, Ren Y, Yan P, Li S, Dai Z, Jiao L, Zhao B, Pang S, Wang X. The Effect of Cutting Fluid on Machined Surface Integrity of Ultra-High-Strength Steel 45CrNiMoVA. Materials. 2023; 16(9):3331. https://doi.org/10.3390/ma16093331

Chicago/Turabian StyleWang, Yubin, Yan Ren, Pei Yan, Siyu Li, Zhicheng Dai, Li Jiao, Bin Zhao, Siqin Pang, and Xibin Wang. 2023. "The Effect of Cutting Fluid on Machined Surface Integrity of Ultra-High-Strength Steel 45CrNiMoVA" Materials 16, no. 9: 3331. https://doi.org/10.3390/ma16093331

APA StyleWang, Y., Ren, Y., Yan, P., Li, S., Dai, Z., Jiao, L., Zhao, B., Pang, S., & Wang, X. (2023). The Effect of Cutting Fluid on Machined Surface Integrity of Ultra-High-Strength Steel 45CrNiMoVA. Materials, 16(9), 3331. https://doi.org/10.3390/ma16093331