Structure and Performance Optimization of Co Magnetic Thin Films Deposited by Vacuum Evaporation Coating

Abstract

:1. Introduction

2. Materials and Methods

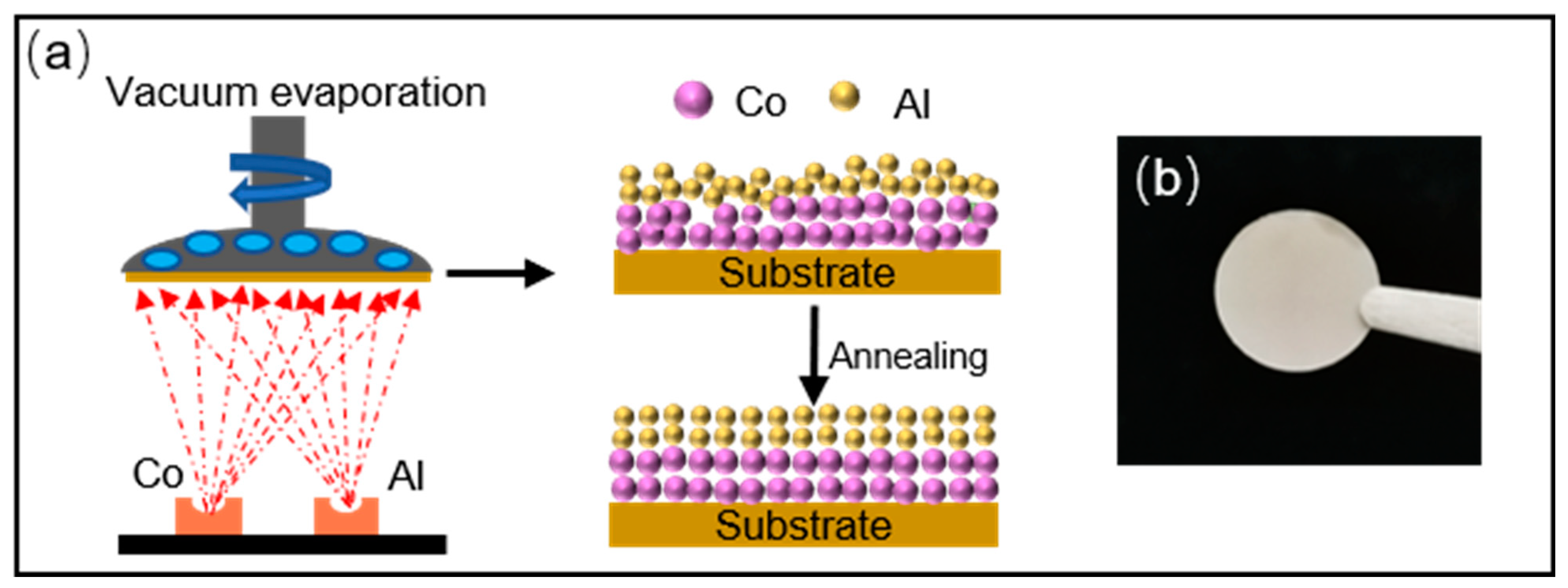

2.1. Film Preparation

2.2. Structural Characterization and Performance Testing

3. Results and Discussion

4. Conclusions

- (1)

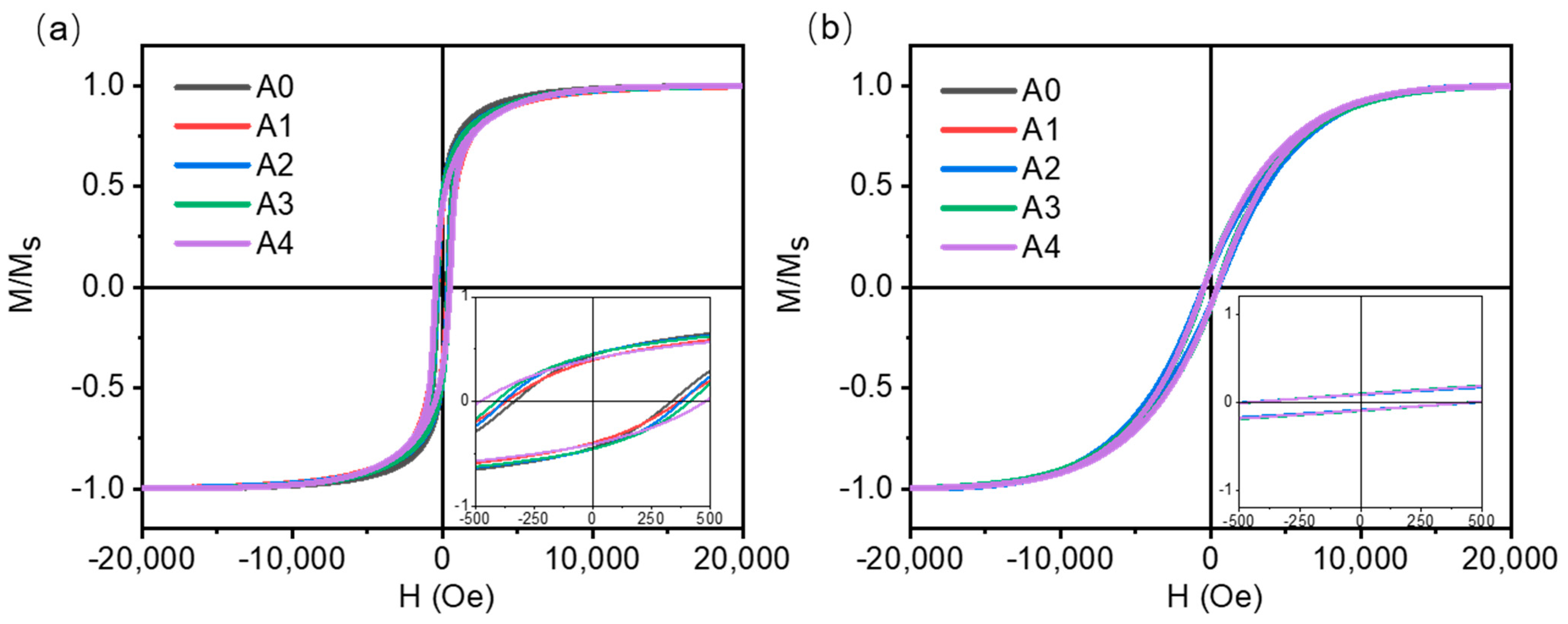

- When the film thickness was increased from 10 to 300 nm, the XRD results showed that the physical phase of the Co magnetic film did not change. The hysteresis line results showed that the magnetic properties of Co films changed significantly, the saturation magnetization strength and coercivity increased gradually, and the remanence of Co magnetic films at 10 nm was 0.82, which was much higher than that of films at 50 nm.

- (2)

- Co magnetic films and Cu/Co (without an Al protective layer) films were prepared by vacuum evaporation coating process, and then placed in a muffle furnace for annealing experiments (atmospheric environment). SEM images of the surface of the films before and after annealing showed that the outer Al layer in the Co magnetic films effectively protected the inner Co layer from oxidation.

- (3)

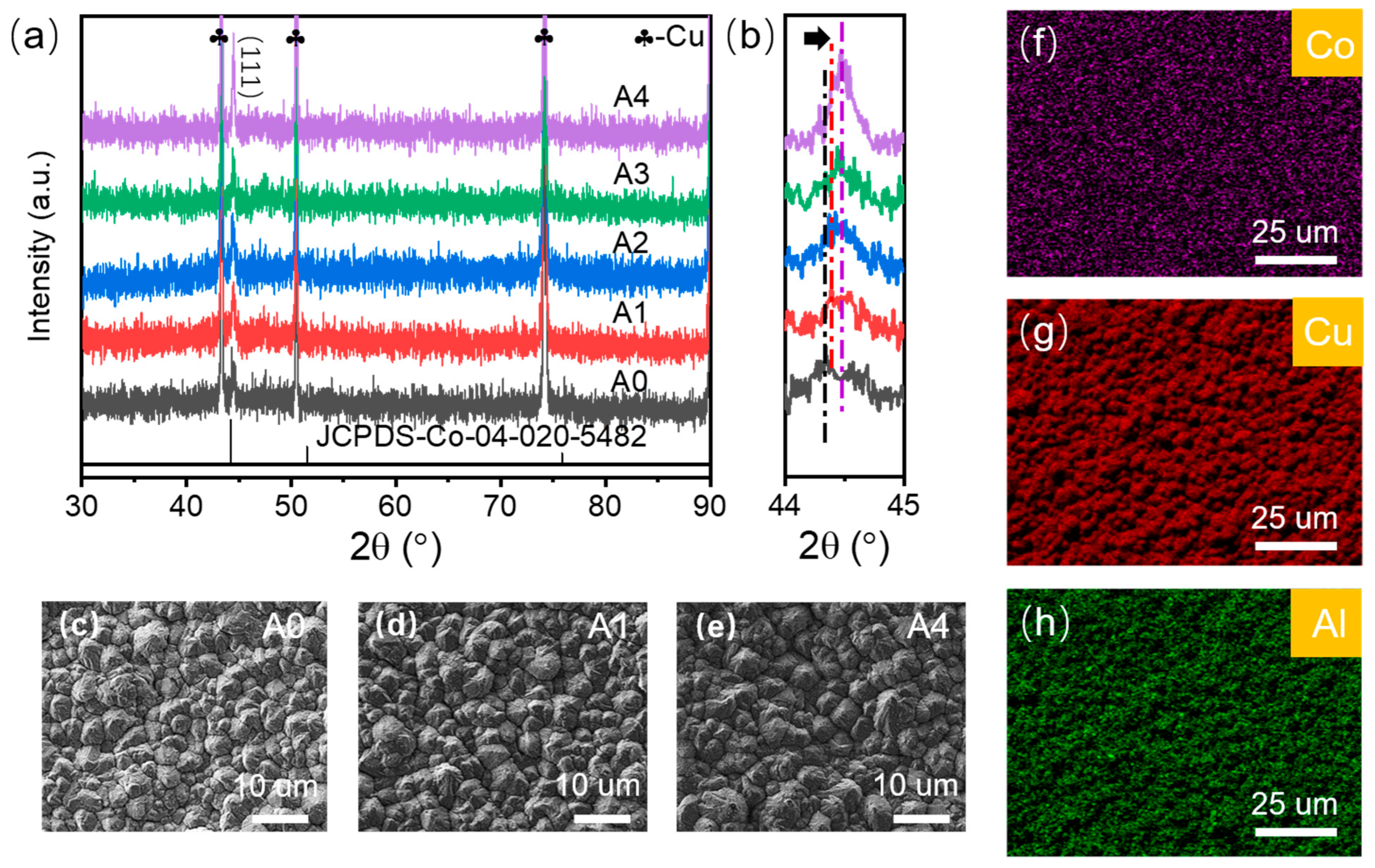

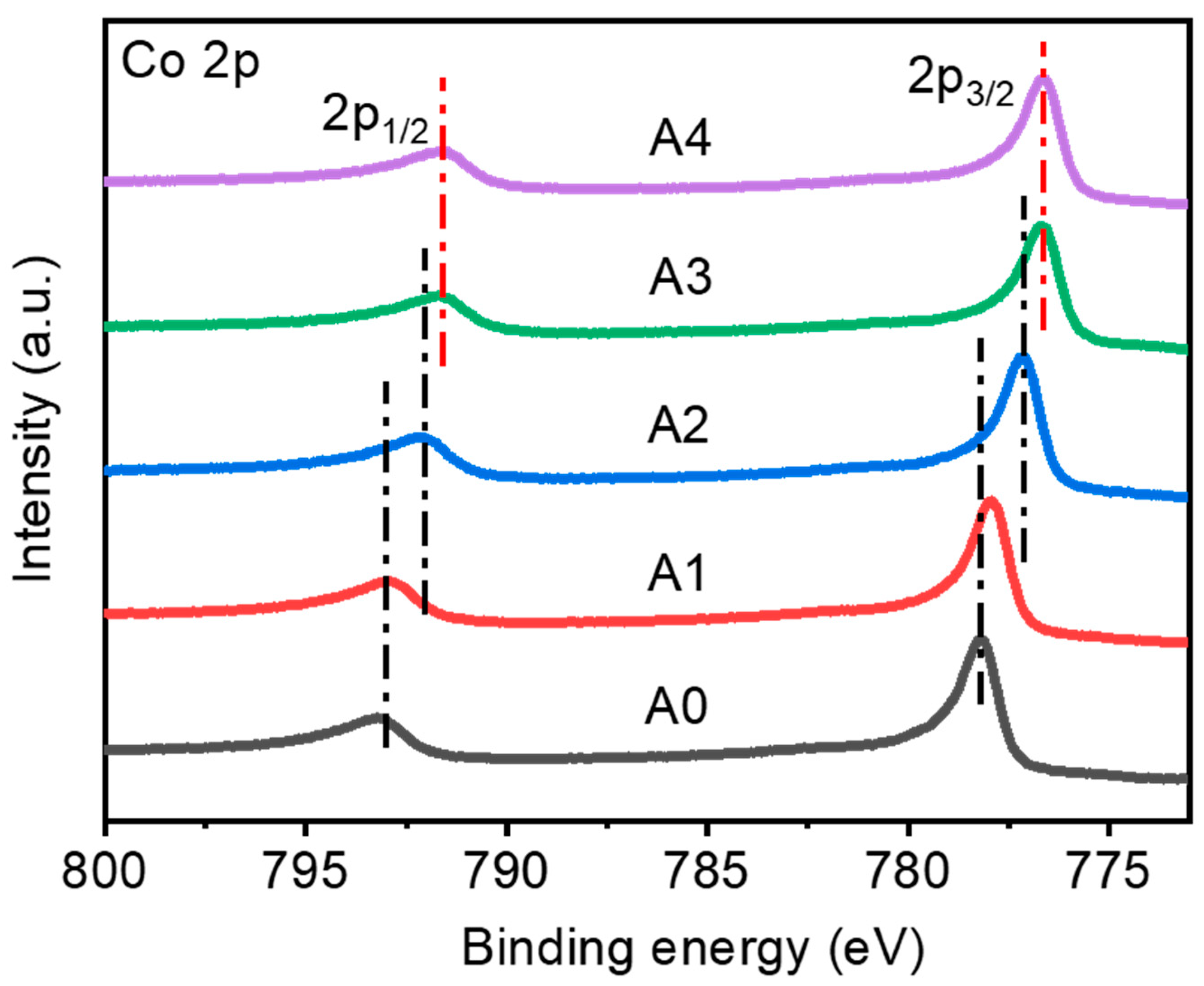

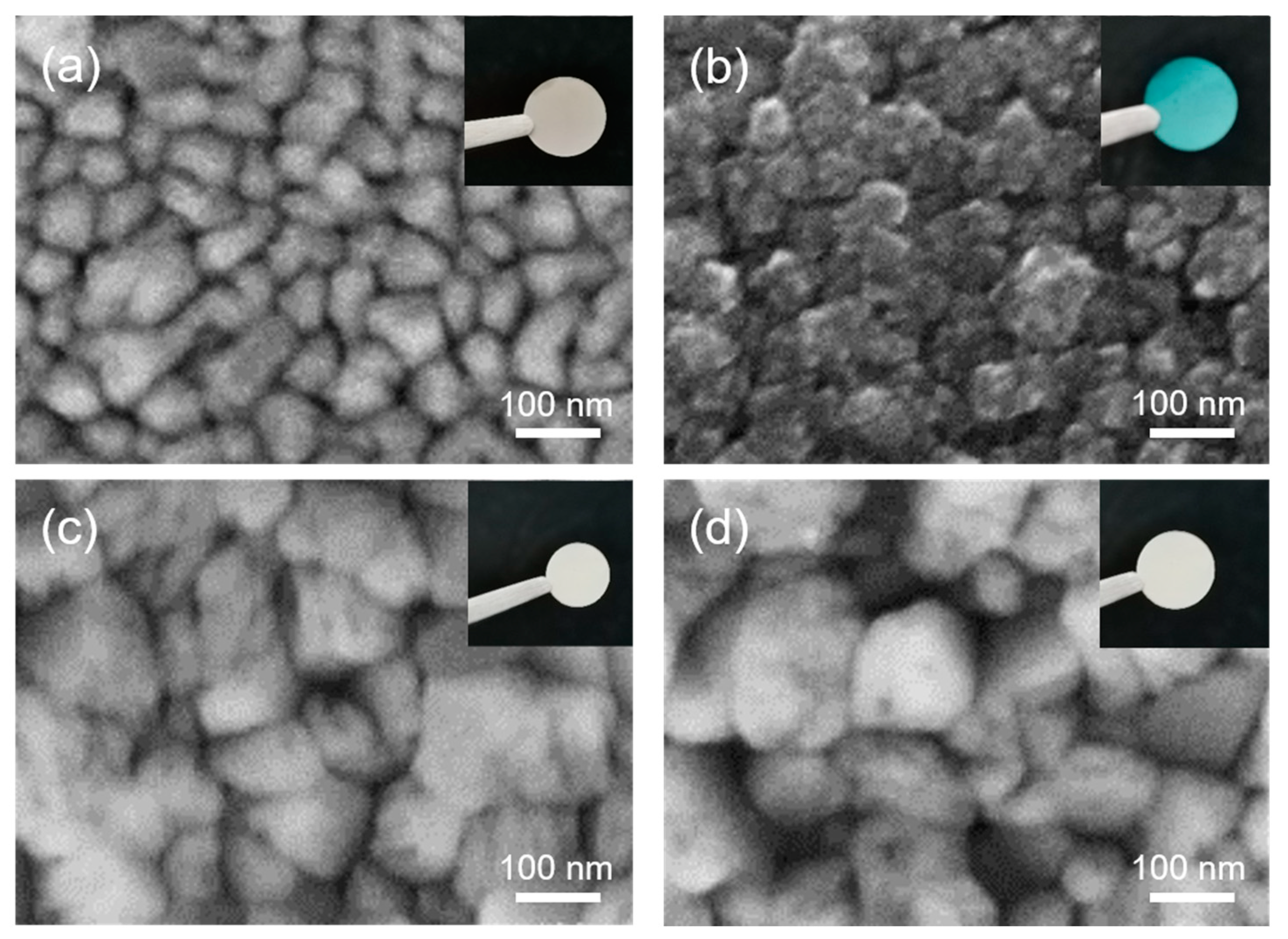

- To study the effect of heat treatment temperature on the Co magnetic films, we annealed the Co films with a thickness of 200 nm in a tube furnace at different temperatures for 2 h. The annealing temperatures were 100 °C, 200 °C, 300 °C, and 400 °C (H2 atmosphere), respectively. With the increase in annealing temperature, the XRD results showed that there was no significant change in the physical image of Co magnetic films, the half-peak width of Co characteristic diffraction peaks gradually decreased, and the grains gradually grew up; SEM morphology showed that the grains of Co magnetic films gradually grew up with the increase in annealing temperature, which was the same as the calculated results in XRD; the results of X-ray photoelectron spectroscopy showed that there was oxidation of Co in the inner layer of Co magnetic films, which was reduced after the annealing heat treatment. The hysteresis results show that the saturation magnetization intensity of Co magnetic films increases with the increase in annealing temperature, while the Co magnetic films have obvious magnetic anisotropy, with the magnetization axis biased toward the vertical plane of the films, and the annealing heat treatment does not induce the anisotropy change in the films.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lekas, M.; Davies, R.; Sturcken, N. Magnetic thin-film inductors with induced radial anisotropy for improved inductance density. IEEE Magn. Lett. 2019, 10, 1. [Google Scholar] [CrossRef]

- Dragan, D.; Mahmoud, S.; Martin, H. Microtransformer on silicon with CoFeB magnetic core for high-frequency signal applications. AIP Adv. 2020, 10, 015206. [Google Scholar] [CrossRef]

- Honig, H.L.; Hopfeld, M.; Schaaf, P. Preparation and Properties of Co/Fe Multilayers and Co-Fe Alloy Films for Application in Magnetic Field Sensors. Key Eng. Mater. 2020, 5941, 61. [Google Scholar] [CrossRef]

- Feng, H.M.; Zhu, Z.T.; Liu, W.S.; Li, X.L.; Wang, J.B. Investigation into the microstructure and soft magnetic property of co-sputtering FeNi–MgO nanogranular films. J. Mater. Sci. 2019, 54, 14189. [Google Scholar] [CrossRef]

- Greaves, S.J.; Kanai, Y. Effect of spin-torque oscillator tilt angle in microwave-assisted magnetic recording. IEEE Trans. Magn. 2019, 55, 1. [Google Scholar] [CrossRef]

- Sayama, J.; Shimatsua, T.; Nemoto, H.; Okamoto, S.; Kitakami, O.; Aoi, H. Temperature dependence of the magnetic properties of L11-type Co-Ni-Pt ordered alloy films for thermally assisted recording media. J. Appl. Phys. 2011, 110, 013918. [Google Scholar] [CrossRef]

- Arregi, J.A.; Gonzalez-Diaz, J.B.; Idigoras, O.; Berger, A. Strain-induced magneto-optical anisotropy in epitaxial hcp Co films. Phys. Rev. B. 2015, 92, 184405. [Google Scholar] [CrossRef]

- Li, T.; Pickel, A.D.; Yao, Y.; Chen, Y.; Zeng, Y.; Lacey, S.D.; Li, Y.; Wang, Y.; Dai, J.; Wang, Y.; et al. Thermoelectric properties and performance of flexible reduced graphene oxide films up to 3,000 K. Nat. Energy 2018, 3, 148–156. [Google Scholar] [CrossRef]

- Hoop, M.; Ribeiro, A.S.; Rösch, D.; Weinand, P.; Mendes, N.; Mushtaq, F.; Chen, X.Z.; Shen, Y.; Pujante, C.F.; Puigmartí-Luis, J.; et al. Mobile Magnetic Nanocatalysts for Bioorthogonal Targeted Cancer Therapy. Adv. Funct. Mater. 2018, 28, 1705920. [Google Scholar] [CrossRef]

- Saccone, M.; Scholl, A.; Velten, S.; Dhuey, S.; Hofhuis, K.; Wuth, C.; Huang, Y.-L.; Chen, Z.; Chopdekar, R.V.; Farhan, A. Towards artificial Ising spin glasses: Thermal ordering in randomized arrays of Ising-type nanomagnets. Phys. Rev. B 2020, 99, 224403. [Google Scholar] [CrossRef]

- Skjærvø, S.H.; Marrows, C.H.; Stamps, R.L.; Heyderman, L.J. Advances in artificial spin ice. Nat. Rev. Phys. 2019, 2, 13–28. [Google Scholar] [CrossRef]

- Lehmann, J.; Donnelly, C.; Derlet, P.M.; Heyderman, L.J.; Fiebig, M. Poling of an artificial magneto-toroidal crystal. Nat. Nanotechnol. 2018, 14, 141–144. [Google Scholar] [CrossRef]

- Ruiz-Clavijo, A.; Caballero-Calero, O.; Martín-González, M.S. Revisiting anodic alumina templates: From fabrication to applications. Nanoscale 2021, 13, 2227–2265. [Google Scholar] [CrossRef]

- Rhen, F.; Roy, S. Electrodeposited CoNiFeP soft-magnetic films for high-frequency applications. IEEE Trans. Magn. 2008, 44, 3917. [Google Scholar] [CrossRef]

- Moschel, A.; Usadel, K.D. Influence of the film thickness on the direction of the magnetization in thin ferromagnetic films. J. Magn. Magn. Mater. 1995, 140, 649. [Google Scholar] [CrossRef]

- Neilinger, P.; Ščepka, T.; Mruczkiewicz, M.; Dérer, J.; Manca, D.; Dobročka, E.; Samardak, A.S.; Grajcar, M.; Cambel, V. Ferromagnetic resonance study of sputtered Pt/Co/Pt multilayers. Appl. Surf. Sci. 2018, 461, 202. [Google Scholar] [CrossRef]

- Nozaki, T.; Konoto, M.; Nozaki, T.; Kubota, H.; Fukushima, A.; Yuasa, S. Voltage-induced coercivity change in Co film grown on Cr2O3 barrier. Jpn. J. Appl. Phys. 1995, 58, 100911. [Google Scholar] [CrossRef]

- Indrajit, S.; Ken, K.; Hiroaki, N.; Shinji, K. Impact of growth conditions on the structural and magnetic properties of (Zn,Fe)Te thin films grown by molecular beam epitaxy (MBE). J. Cryst. Growth 2022, 580, 126492. [Google Scholar] [CrossRef]

- Wang, J.W.; Wei, Y.Y.; He, Y.F.; Dong, C.Z.; Lin, X.Q.; Chen, H.H.; Liang, X.F.; Yu, C.J.; Zhu, M.M.; Zhang, Y.; et al. Thermal annealing on the soft magnetism, microwave properties, and magnetostriction in Co-Fe-C alloy films. J. Alloys Compd. 2021, 874, 159783. [Google Scholar] [CrossRef]

- Zhang, Q.P.; Fang, Q.Q.; Wang, W.N.; Lv, Q.R.; Liu, Y.M. Buffer layer effects on the structure and morphology of SmCo/Cu thin films. Adv. Mater. Res. 2012, 476, 2415. [Google Scholar] [CrossRef]

- Vopsaroiu, M.; Georgieva, M.; Grundy, P.J. Preparation of high moment CoFe films with controlled grain size and coercivity. J. Appl. Phys. 2005, 97, 10N303. [Google Scholar] [CrossRef]

- Ueda, Y.; Adachi, H.; Takakura, W.; Rizal, C.L.S.; Chikazawa, S. Magnetoresistance effect and magnetoanisotropy of Co/Cu multilayered films prepared by electron beam evaporation. Phys. Status Solidi (C) 2004, 1, 1752. [Google Scholar] [CrossRef]

- Sharma, A.; Tripathi, S.; Shripathi, T. X-ray photoelectron study of annealed Co thin film on Si surface. Appl. Surf. Sci. 2009, 256, 530. [Google Scholar] [CrossRef]

- Warot-Fonrose, B.; Traverse, A.; Calmels, L.; Serin, V.; Snoeck, E. Structural and magnetic studies of Co thin films. Micron 2005, 37, 478–485. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Mazur, M.; Pokora, P.; Wrona, A.; Bilewska, K.; Kijaszek, W.; Kotwica, T.; Posadowski, W.; Domaradzki, J. Properties of Metallic and Oxide Thin Films Based on Ti and Co Prepared by Magnetron Sputtering from Sintered Targets with Different Co-Content. Materials 2021, 14, 3797. [Google Scholar] [CrossRef]

- Vovk, A.; Bunyaev, S.A.; Štrichovanec, P.; Vovk, N.R.; Postolnyi, B.; Apolinario, A.; Pardo, J.Á.; Algarabel, P.A.; Kakazei, G.N.; Araujo, J.P. Control of Structural and Magnetic Properties of Polycrystalline Co2FeGe Films via Deposition and Annealing Temperatures. Nanomaterials 2021, 11, 1229. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Nafady, A.; Abu-Dief, A.M.; Díaz Crespo, R.; Fernández-García, M.P.; Andrés, J.P.; López Antón, R.; Blanco, J.A.; Álvarez-Alonso, P. Enhancement of Exchange Bias and Perpendicular Magnetic Anisotropy in CoO/Co Multilayer Thin Films by Tuning the Alumina Template Nanohole Size. Nanomaterials 2022, 12, 2544. [Google Scholar] [CrossRef]

- Cao, D.; Wang, Z.; Feng, E.; Wei, J.; Wang, J.; Liu, Q. Magnetic properties and microstructure investigation of electrodeposited FeNi/ITO films with different thickness. J. Alloy Compd. 2013, 581, 66. [Google Scholar] [CrossRef]

- Li, J.C.; Zhan, Q.F.; Pan, M.J.; Liu, L.P.; Yang, H.L.; Xie, Y.L.; Xie, S.H.; Li, R.W. Preparation and magnetic anisotropy of NiFe film with stripe domains. Acta Phys. Sinica. 2016, 65, 217501. [Google Scholar] [CrossRef]

- Liu, W.S.; Gao, R.L.; Feng, H.M.; Liu, Y.Y.; Huang, Y.; Wang, J.B.; Liu, Q.F. Influence of magentic annealing temperature on microstructure and magnetic properties of NiCu alloy film. Acta Phys. Sinica. 2020, 69, 097401. [Google Scholar] [CrossRef]

- Patterson, A.L. The scherrer formula for X-Ray particle size determination. Phys. Rev. 1939, 56, 978. [Google Scholar] [CrossRef]

| Thickness (nm) | 10 | 20 | 100 | 200 | 300 |

|---|---|---|---|---|---|

| D1 (nm) | 8 ± 2 | 12 ± 2 | 23 ± 3 | 31 ± 3 | 39 ± 3 |

| Temperature (°C) | 0 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| D2 (nm) | 31 ± 3 | 41 ± 3 | 65 ± 3 | 97 ± 3 | 137 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, M.; Ke, S.; Tang, D.; Sang, X.; He, D. Structure and Performance Optimization of Co Magnetic Thin Films Deposited by Vacuum Evaporation Coating. Materials 2023, 16, 3395. https://doi.org/10.3390/ma16093395

Mao M, Ke S, Tang D, Sang X, He D. Structure and Performance Optimization of Co Magnetic Thin Films Deposited by Vacuum Evaporation Coating. Materials. 2023; 16(9):3395. https://doi.org/10.3390/ma16093395

Chicago/Turabian StyleMao, Mingheng, Shaoqiu Ke, Dingguo Tang, Xiahan Sang, and Danqi He. 2023. "Structure and Performance Optimization of Co Magnetic Thin Films Deposited by Vacuum Evaporation Coating" Materials 16, no. 9: 3395. https://doi.org/10.3390/ma16093395