Influence of Top Seal Damage on Contact Seal in Ram Blowout Preventer

Abstract

:1. Introduction

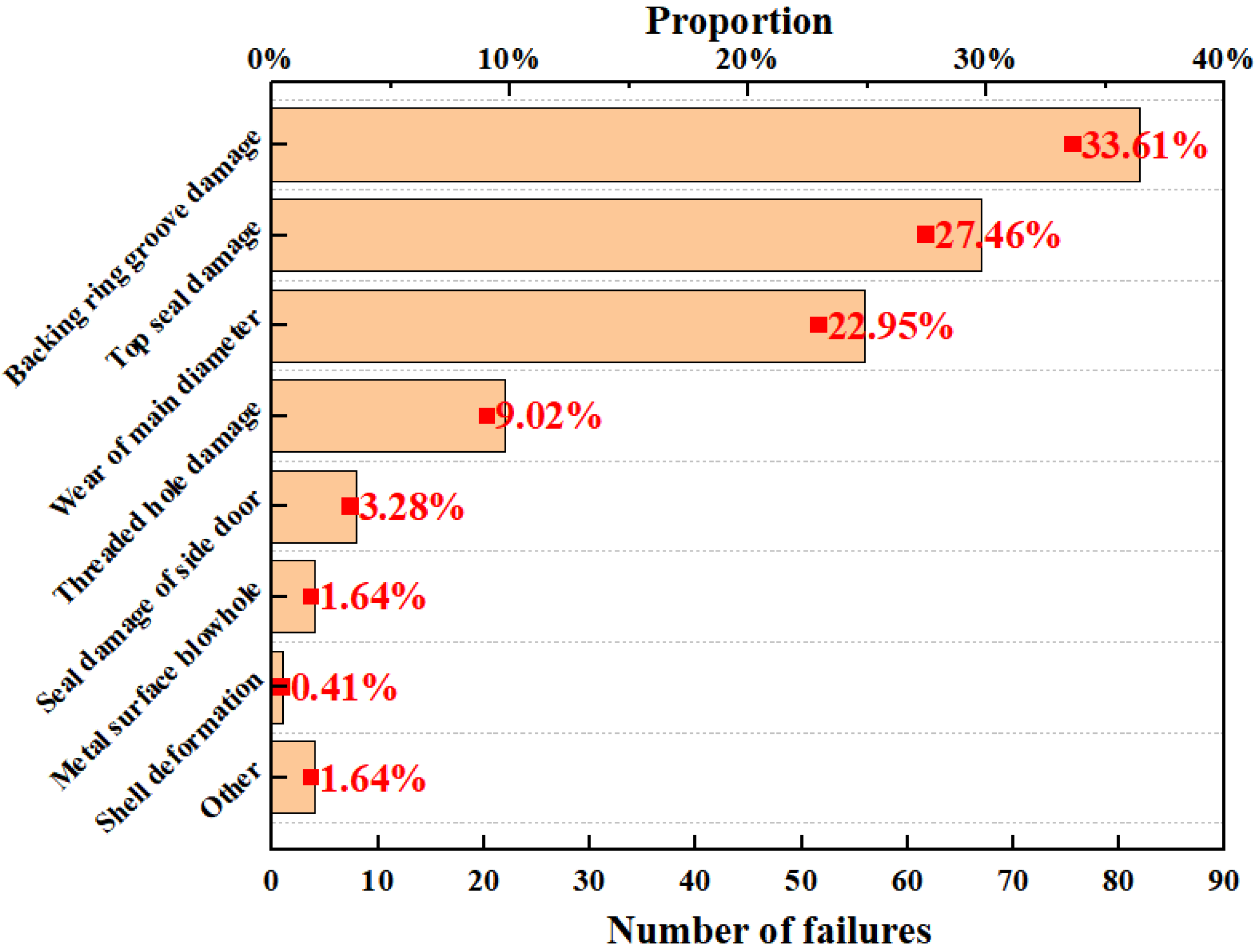

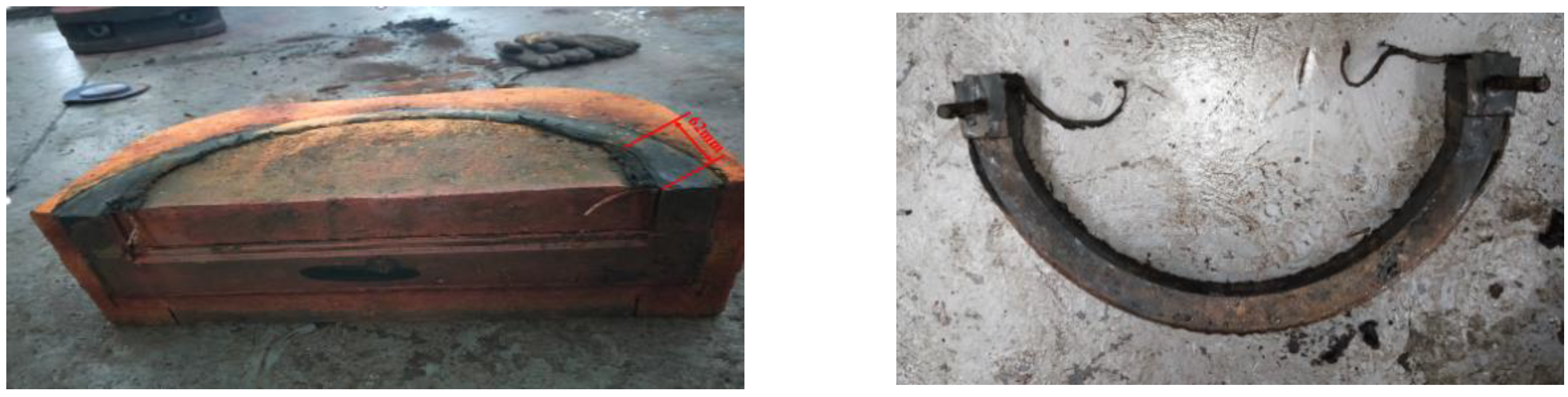

2. Statistical Analysis of BOP Failure Cases

3. Analysis of the Contact Seal Failure Evaluation Method for Ram BOP

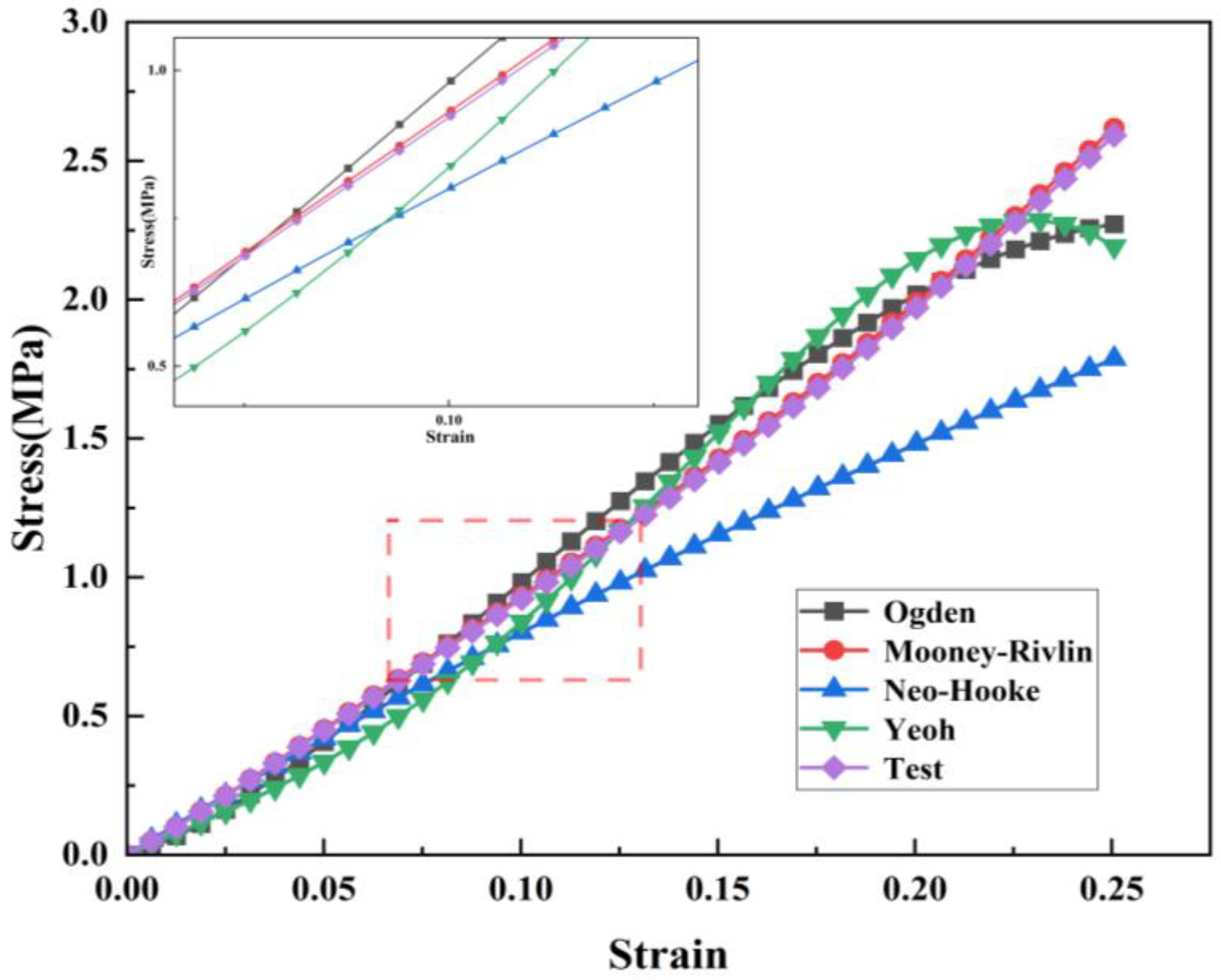

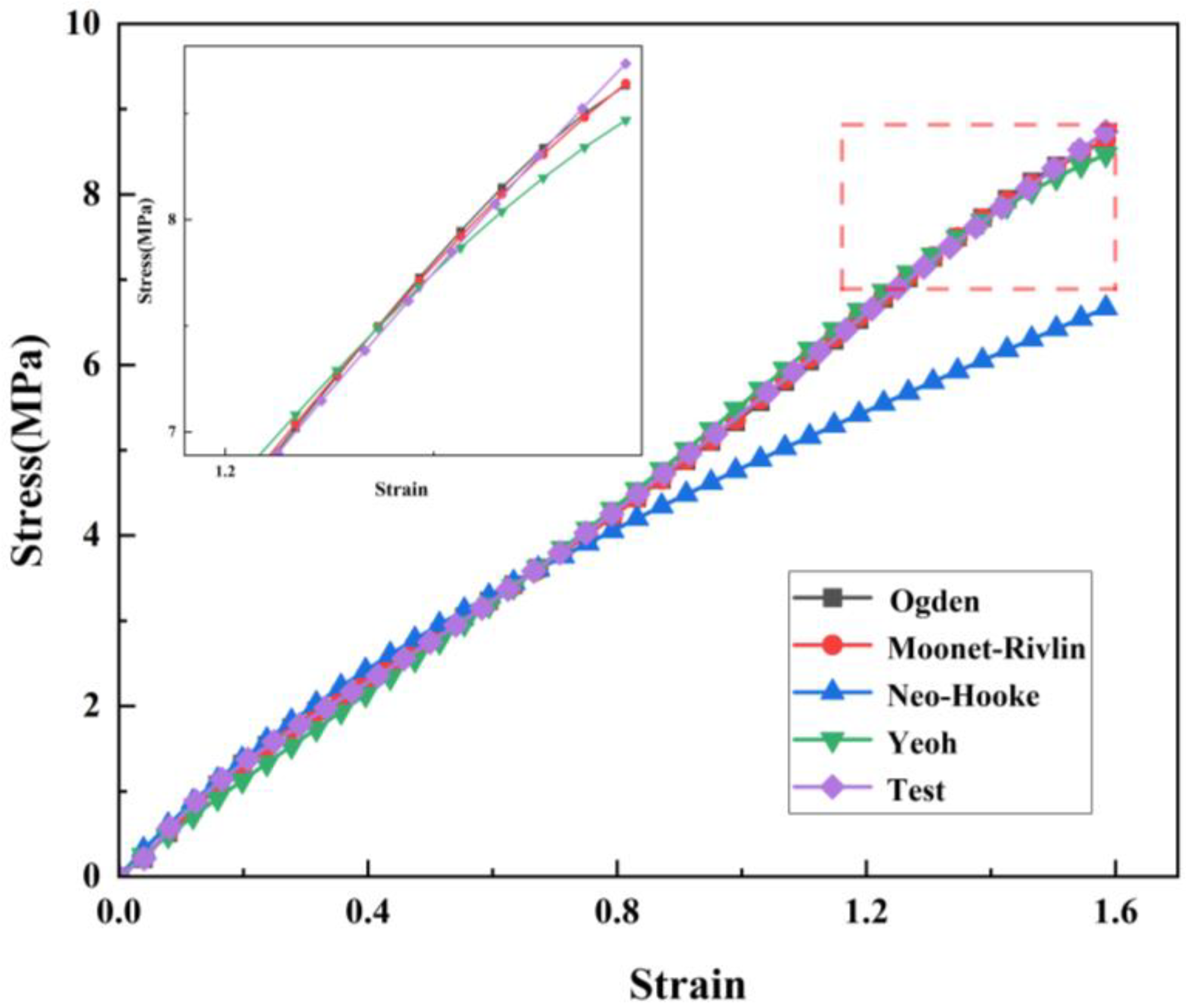

3.1. Constitutive Relation Analysis of Rubber

3.2. Uniaxial Compression and Tensile Testing of Nitrile Butadiene Rubber

3.3. Establishment of the BOP Model

3.4. Methods for Failure Analysis of Contact Seals

- If or , the ram BOP contact seal fails.

- If or , then the ram BOP contact seal is reliable and can be used continuously.

4. Analysis of the Influence Law of the BOP Contact Seal

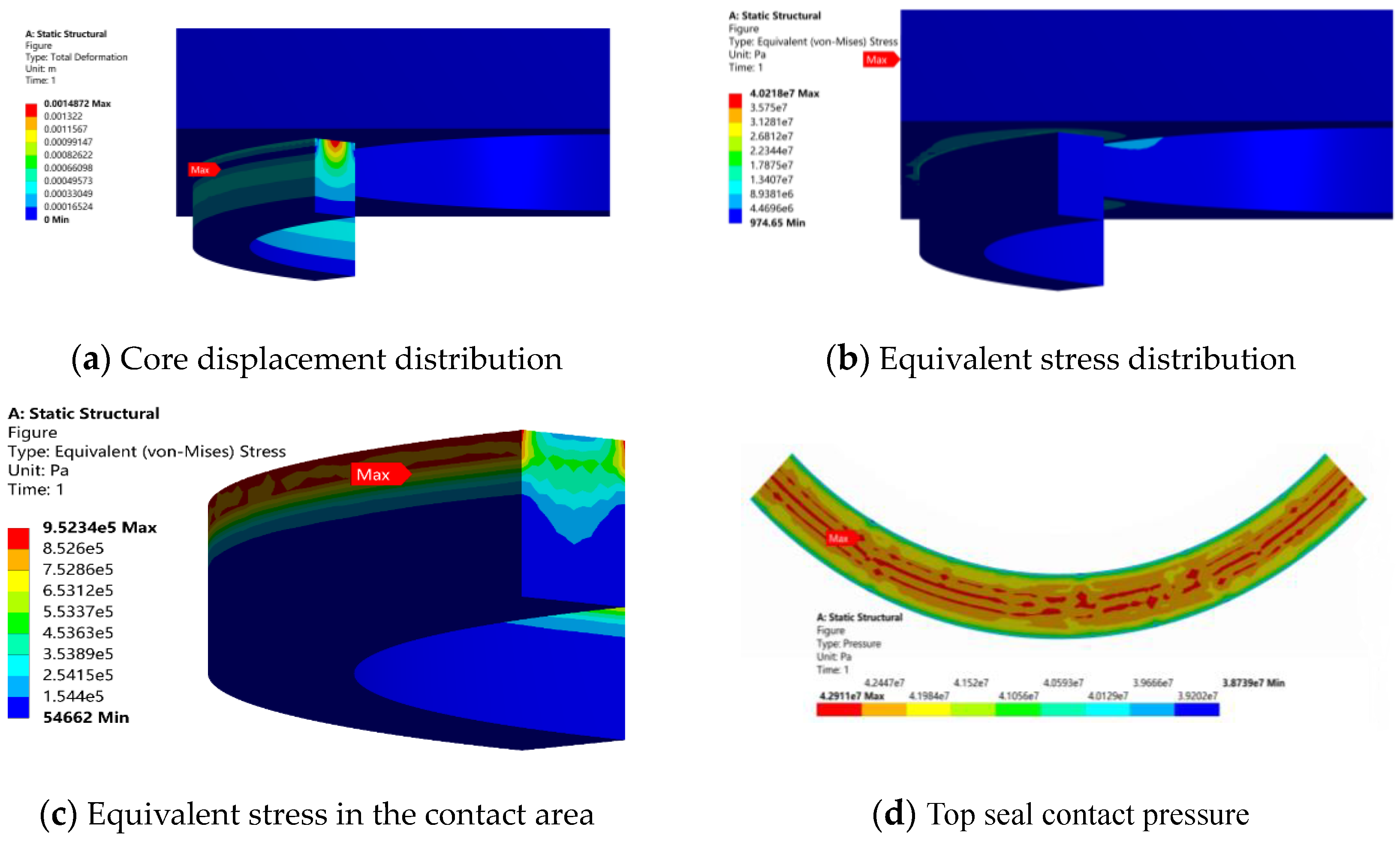

4.1. Sealing Performance Analysis of Defect-Free BOP Top Seal

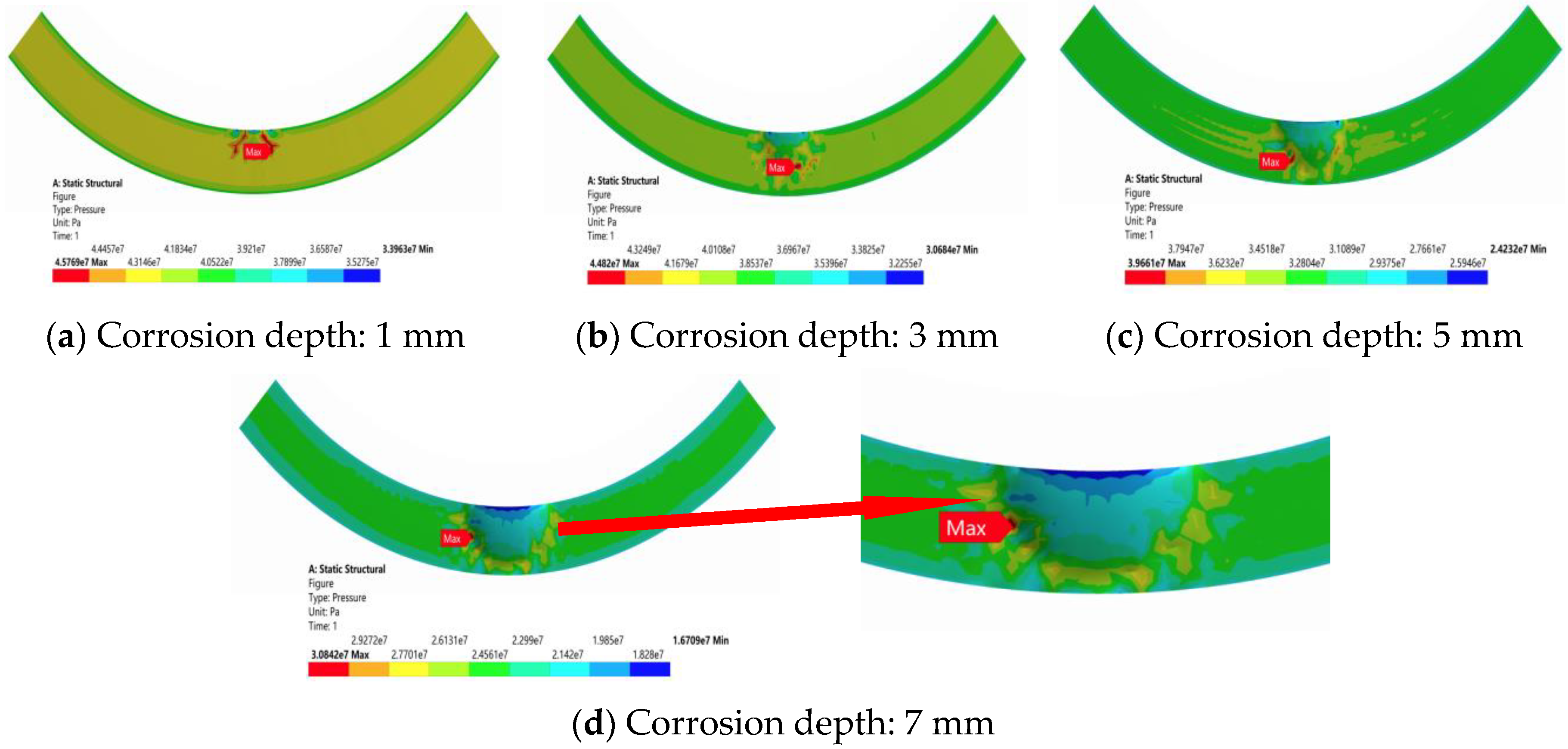

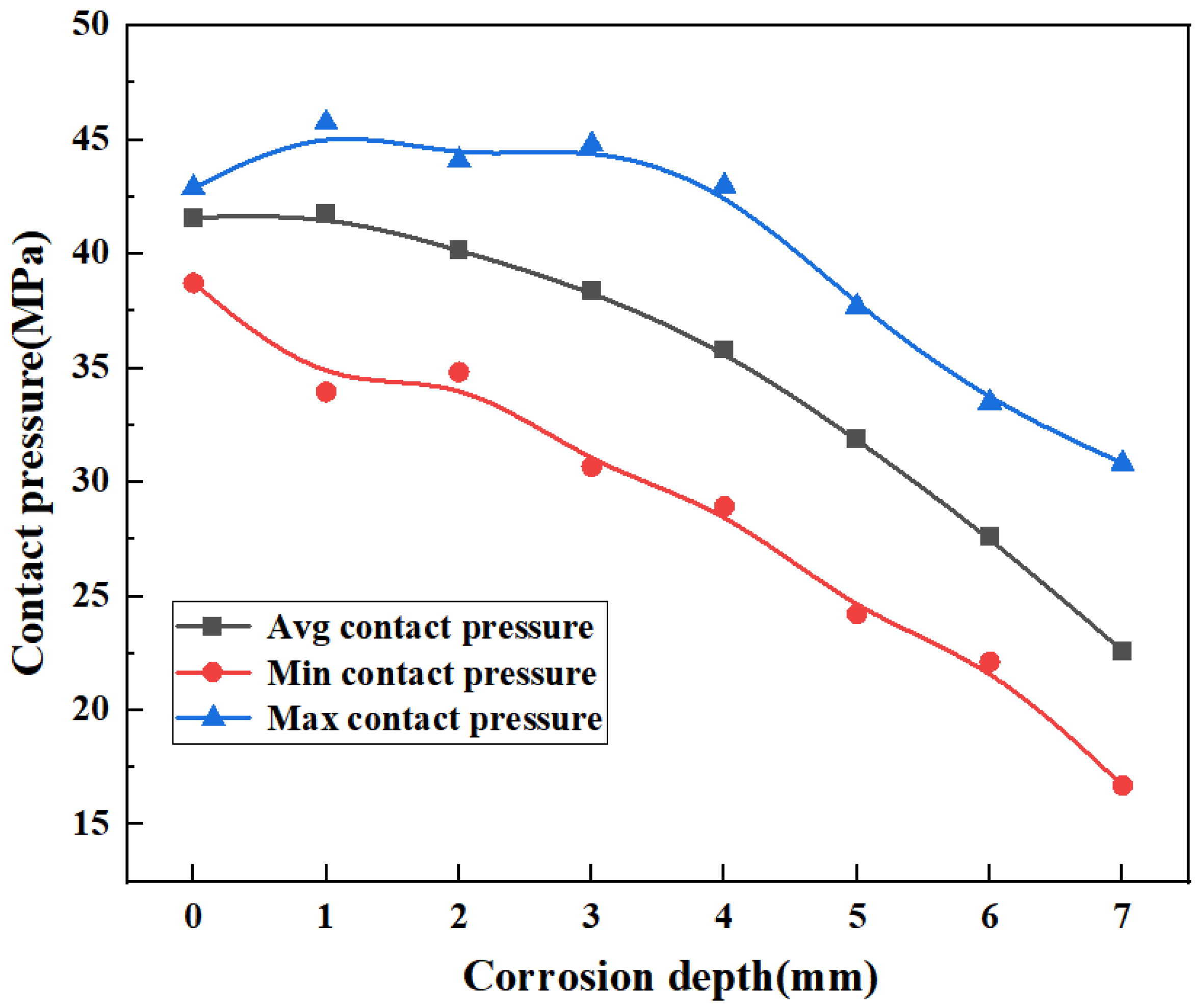

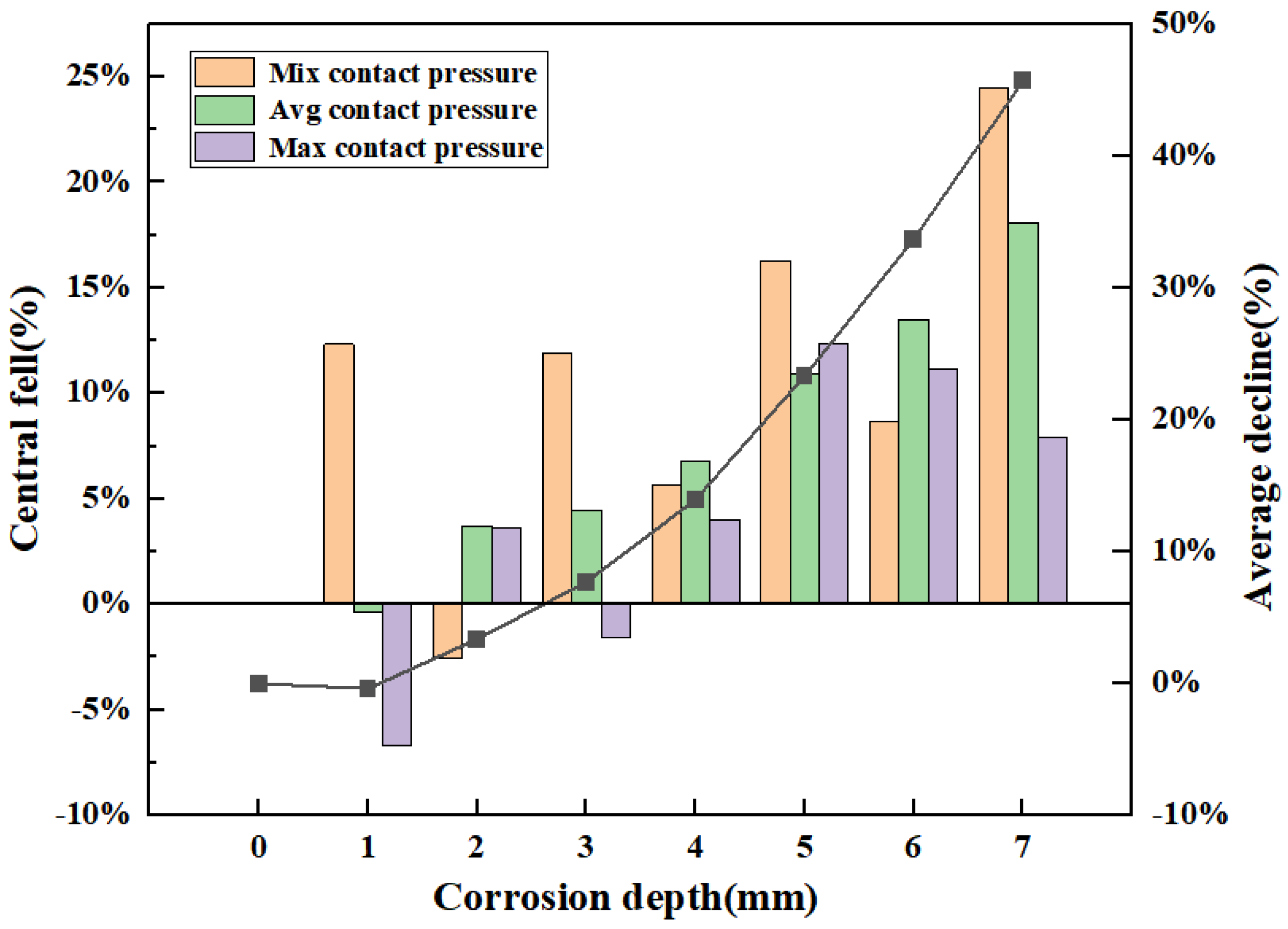

4.2. Sealing Performance Analysis of the BOP Top Seal with Corrosion Defects

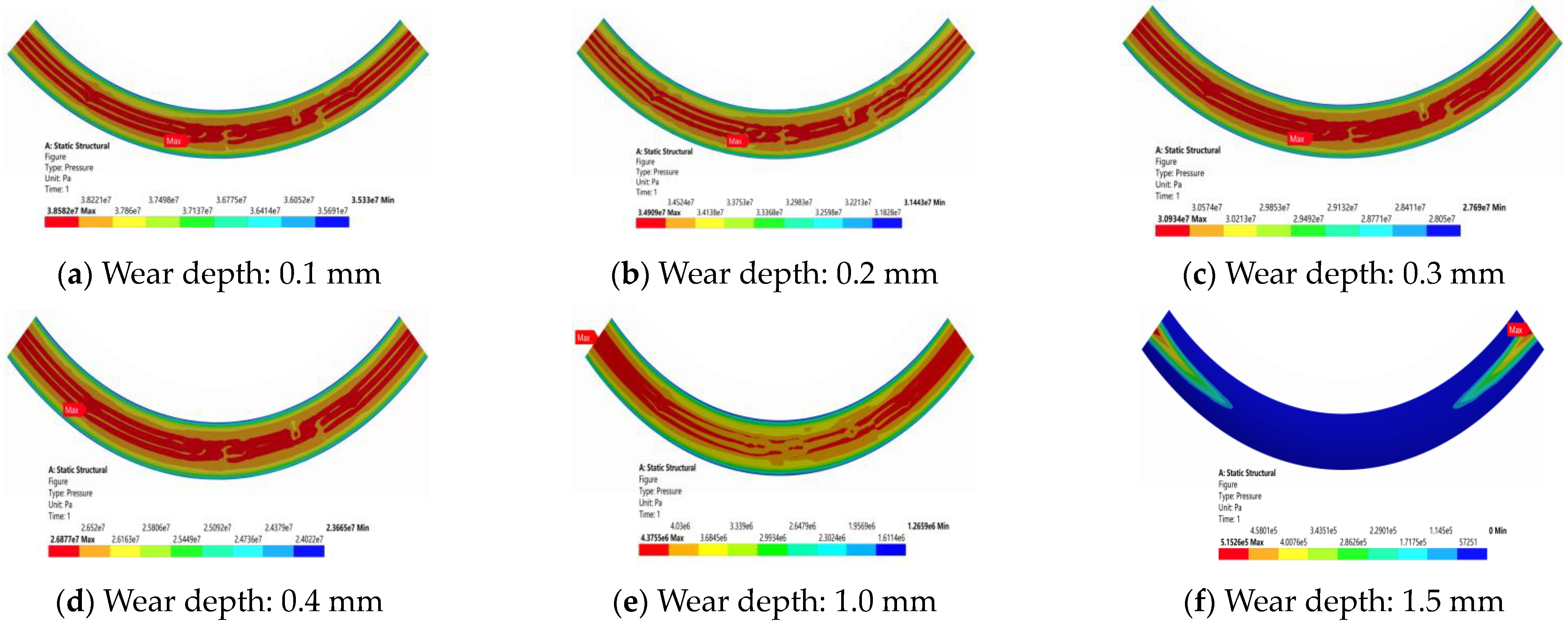

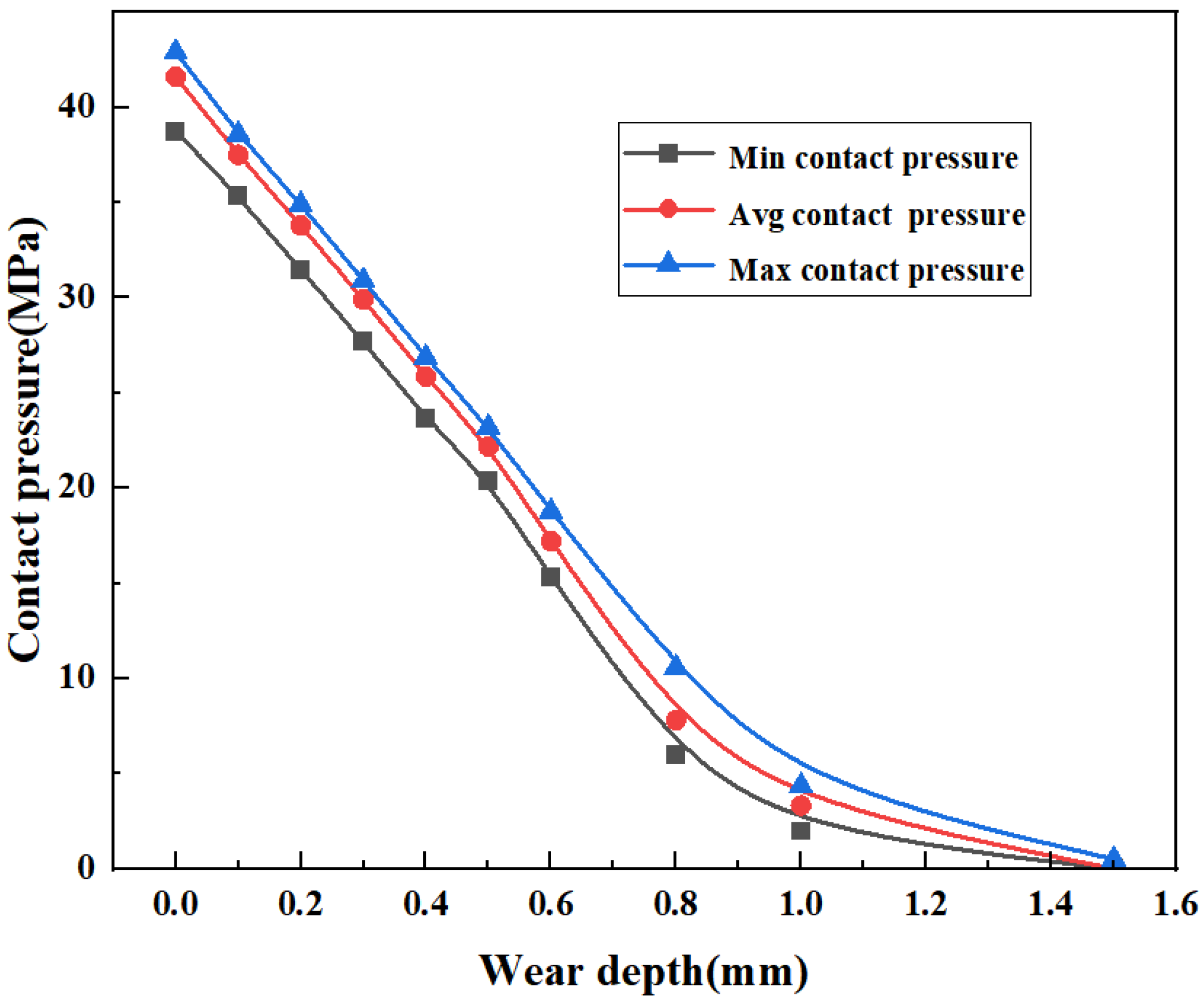

4.3. Sealing Performance Analysis of the BOP Top Seal with Wear Defects

5. Conclusions

- (1)

- The data were obtained by uniaxial tensile and compression tests of NBR. The stress and strain curves of the four constitutive models of hyperplastic materials were fitted using the test data. The Mooney–Rivilin constitutive model was selected, and the Rivilin coefficients were calculated as C10 = 5.002 MPa and C01 = −3.661 MPa. The model can accurately characterize the nominal stress–strain relationship in the working process of the top seal rubber core.

- (2)

- The damage to the ram BOP top seal can be effectively characterized by the contact seal method. With the increase in the top seal corrosion pit depth, the overall contact pressure distribution of the top seal connection structure is uniform, and the local contact pressure at the edge of the corrosion pit will increase, while the contact pressure at most other positions of the corrosion pit will gradually decrease. With increasing top seal wear depth, the overall contact pressure decreases linearly. The contact pressure at the maximum depth of the wear defect of the top seal is the smallest, and the contact pressure decreases gradually along the maximum depth of wear.

- (3)

- The failure analysis method of contact seals for ram BOP top seals is proposed and the reliability evaluation problem of quantitative seals for ram BOP top seals is solved. When the top seal corrosion pit depth reached 5.0 mm, the average contact pressure decreased by 23.3% compared with that without defects. When the top seal wear depth reached 0.3 mm, the average contact pressure decreased by 28.6% compared with the non-defect condition, and the ram BOP top seal was judged as sealing failure. These research results are aimed at ensuring the safe operation of a ram BOP. It is suggested that the acceptable depth of the seal corrosion pit at the top of the ram BOP is 4.0 mm, and the acceptable depth of the wear is 0.2 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Cao, J.; Liang, H.; Cheng, G. Research on corrosion defect identification and risk assessment of well control equipment based on a machine learning algorithm. Petroleum 2022. [Google Scholar] [CrossRef]

- Bubbico, R.; Lee, S.; Moscati, D.; Paltrinieri, N. Dynamic assessment of safety barriers preventing escalation in offshore Oil&Gas. Saf. Sci. 2019, 121, 319–330. [Google Scholar]

- Necci, A.; Tarantola, S.; Vamanu, B.; Krausmann, E.; Ponte, L. Lessons learned from offshore oil and gas incidents in the Arctic and other ice-prone seas. Ocean. Eng. 2019, 185, 12–26. [Google Scholar] [CrossRef]

- Meng, X.; Chen, G.; Zhu, J.; Li, T. Application of integrated STAMP-BN in safety analysis of subsea blowout preventer. Ocean. Eng. 2022, 258, 111740. [Google Scholar] [CrossRef]

- Amin, M.T.; Khan, F.; Amyotte, P. A bibliometric review of process safety and risk analysis. Process Saf. Environ. Prot. 2019, 126, 366–381. [Google Scholar] [CrossRef]

- Chen, H.; Bo, T.; Wei, H. Analysis on Causes of Sealing Failure of Ram Bop and Corresponding Preventive Measures. Nat. Gas Ind. 2006, 26, 80. [Google Scholar]

- Di, C. Ram Blowout Preventer Rubber Effect and Measures to Prevent Sealing Failure. Value Eng. 2010, 29, 193. [Google Scholar] [CrossRef]

- Zou, L.; Yu, C.; Shao, J. Finite-element Analysis of Spherical BOP in Snubbing Service of Gas Well. In Proceedings of the 2016 2nd International Conference on Advances in Mechanical Engineering and Industrial Informatics (AMEII 2016), Hangzhou, China, 9–10 April 2016. [Google Scholar]

- Chen, Q.; Han, W.; Huang, S.; Li, T.; Sun, Q. Numerical Simulation and Experimental Study of Wellbore Kick-Control in the Snubbing Service; Springer: Singapore, 2019. [Google Scholar]

- Yang, H.; Dong, L.; Xiangjun, Y.U.; Tang, Y.; Tan, A.J. Study on sensitivity of annular BOP parameters to sealing performance in gas well snubbing service. Mech. Eng. J. 2021, 8, 20-00533. [Google Scholar] [CrossRef]

- Dong, L.; Tang, Y.; Tang, G.; Li, H.; Wu, K.; Luo, W. Sealing performance analysis of rubber core of annular BOP: FEM simulation and optimization to prevent the SBZ. Petroleum 2021. [Google Scholar] [CrossRef]

- Hu, G.; Wang, M.; Wang, G.; Zhu, T.; Wei, L. Sealing performance and failure mechanism analysis of packing unit used in rotary blowout preventer for under-balanced drilling. Eng. Fail. Anal. 2021, 129, 105654. [Google Scholar] [CrossRef]

- Wu, J.; He, Y.; Wu, K.; Dai, M.; Xia, C. The performance optimization of the stripper rubber for the rotating blowout preventer based on experiments and simulation. J. Pet. Sci. Eng. 2021, 204, 108623. [Google Scholar] [CrossRef]

- Li, B.; Zhang, S.M. Contact Pressure Research of Drill Pipe and Packer of Rotating Blowout Preventer. Appl. Mech. Mater. 2011, 121–126, 3200–3204. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J. Investigation of Static and Dynamic Seal Performances of a Rubber O-Ring. J. Tribol. 2018, 140, 042202. [Google Scholar] [CrossRef]

- Ma, W.; Qu, B.; Guan, F. Effect of the friction coefficient for contact pressure of packer rubber. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 2881–2887. [Google Scholar] [CrossRef]

- Polonsky, V.L.; Tyurin, A.P. Design of Packers for Sealing of the Inter-Tube Space in Equipment used for Recovery of Oil and Gas. Chem. Pet. Eng. 2015, 51, 37–40. [Google Scholar] [CrossRef]

- Treloar, L.R. The Physics of Rubber Elasticity, 3rd ed.; Clarendon Press: Oxford, UK, 1975. [Google Scholar]

- Beda, T. Modeling hyperelastic behavior of rubber: A novel invariant-based and a review of constitutive models. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 1713–1732. [Google Scholar] [CrossRef]

- Guo, L.; Zeng, Y.; Huang, J.; Wang, Z.; Li, J.; Han, X.; Xia, C.; Qian, L. Fatigue optimization of rotary control head rubber core based on steady sealing. Eng. Fail. Anal. 2022, 132, 105935. [Google Scholar] [CrossRef]

- Gajewski, M.; Szczerba, R.; Jemio, O.S. Modelling of Elastomeric Bearings with Application of Yeoh Hyperelastic Material Model. Procedia Eng. 2015, 111, 220–227. [Google Scholar] [CrossRef]

- Renaud, C.; Cros, J.M.; Feng, Z.Q.; Yang, B. The Yeoh model applied to the modeling of large deformation contact/impact problems. Int. J. Impact Eng. 2009, 36, 659–666. [Google Scholar] [CrossRef]

- Yeoh, O.H. Some Forms of the Strain Energy Function for Rubber. Rubber Chem. Technol. 2012, 66, 754–771. [Google Scholar] [CrossRef]

- Meck, K.D.; Zhu, G. Improving mechanical seal reliability with advanced computational engineering tools, part 2, CFD and application examples. Seal. Technol. 2008, 2008, 7–10. [Google Scholar] [CrossRef]

- Angerhausen, J.; Woyciniuk, M.; Murrenhoff, H.; Schmitz, K. Simulation and experimental validation of translational hydraulic seal wear. Tribol. Int. 2019, 134, 296–307. [Google Scholar] [CrossRef]

- Zheng, C.; Zheng, X.; Qin, J.; Liu, P.; Aibaibu, A.; Liu, Y. Nonlinear finite element analysis on the sealing performance of rubber packer for hydraulic fracturing. J. Nat. Gas Sci. Eng. 2021, 85, 103711. [Google Scholar] [CrossRef]

- Zhang, F.; Shui, H.; Yang, J.M. Sealing performance and fatigue life of the fracturing packer rubber of various materials. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 095440621985991. [Google Scholar] [CrossRef]

| Statistical Year | BOP Fault Model/Ratio | Underwater BOP Fault Model/Ratio | ||||

|---|---|---|---|---|---|---|

| Failure Type | Wear and Tear | Maintenance Error | Design Issue | Wear and Tear | Maintenance Error | Design Issue |

| 2017 | 53.6% | 12.5% | 7% | 57.7% | 13.5% | 8.3% |

| 2018 | 56.5% | 7.2% | 7.2% | 52.4% | 9.5% | 14.3% |

| 2019 | 46.5% | 27.9% | 7% | 46.9% | 20% | 11.1% |

| Part | Material | Tensile Strength (MPa) | Yield Strength (MPa) | Modulus of Elasticity (GPa) | Poisson’s Ratio | Shrinkage (%) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| Ram | 40CrNiMo | 1050 | 960 | 210 | 0.295 | 53 | 13 |

| Shell | 25CrNiMo | 724 | 438 | 214 | 0.28 | 54 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhang, L.; Yu, J.; Fan, J. Influence of Top Seal Damage on Contact Seal in Ram Blowout Preventer. Materials 2023, 16, 3413. https://doi.org/10.3390/ma16093413

Wang S, Zhang L, Yu J, Fan J. Influence of Top Seal Damage on Contact Seal in Ram Blowout Preventer. Materials. 2023; 16(9):3413. https://doi.org/10.3390/ma16093413

Chicago/Turabian StyleWang, Shiqiang, Laibin Zhang, Jiamin Yu, and Jianchun Fan. 2023. "Influence of Top Seal Damage on Contact Seal in Ram Blowout Preventer" Materials 16, no. 9: 3413. https://doi.org/10.3390/ma16093413