Ultrafast Infrared Laser Crystallization of Amorphous Si/Ge Multilayer Structures

Abstract

:1. Introduction

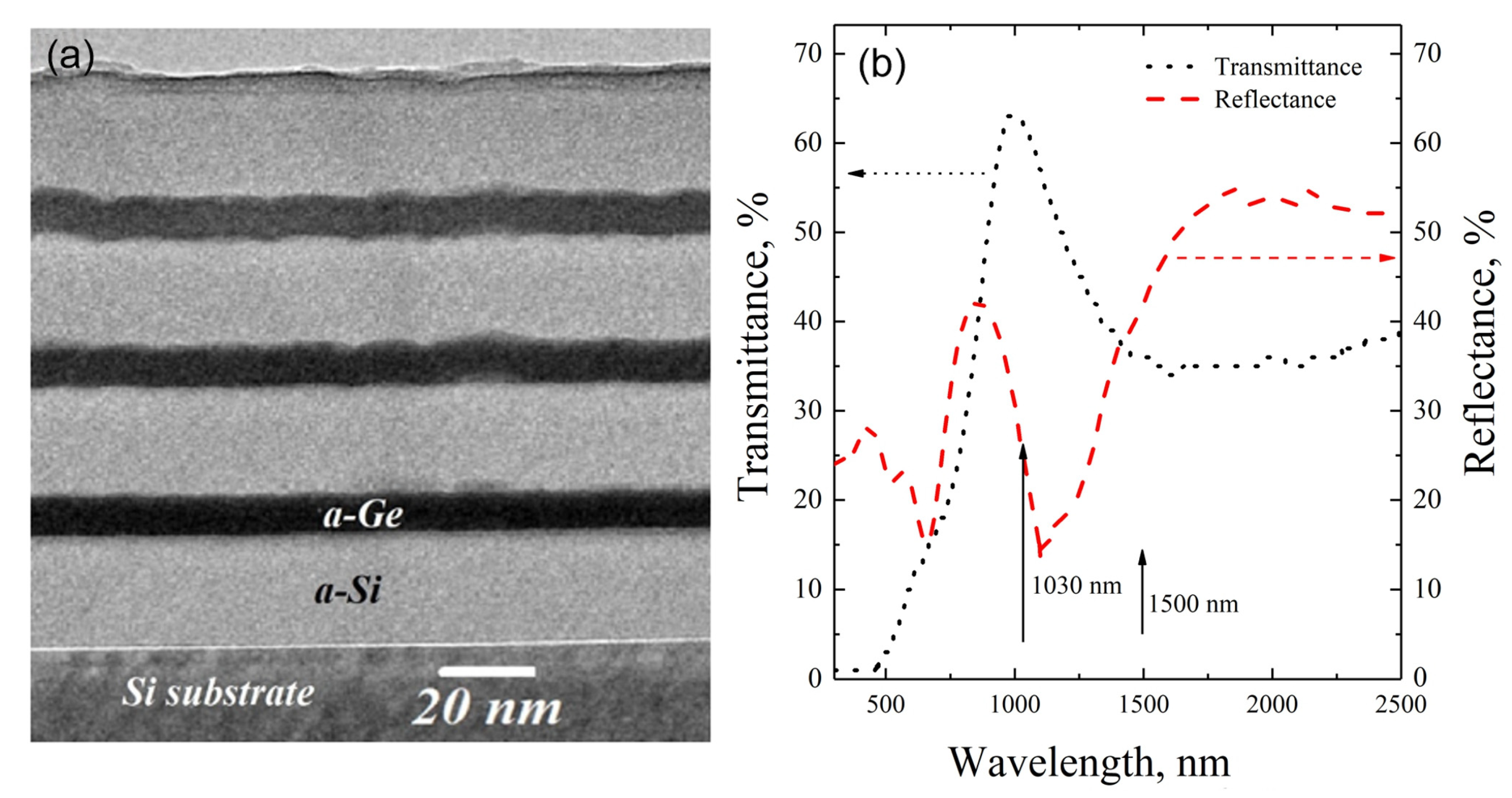

2. Materials and Methods

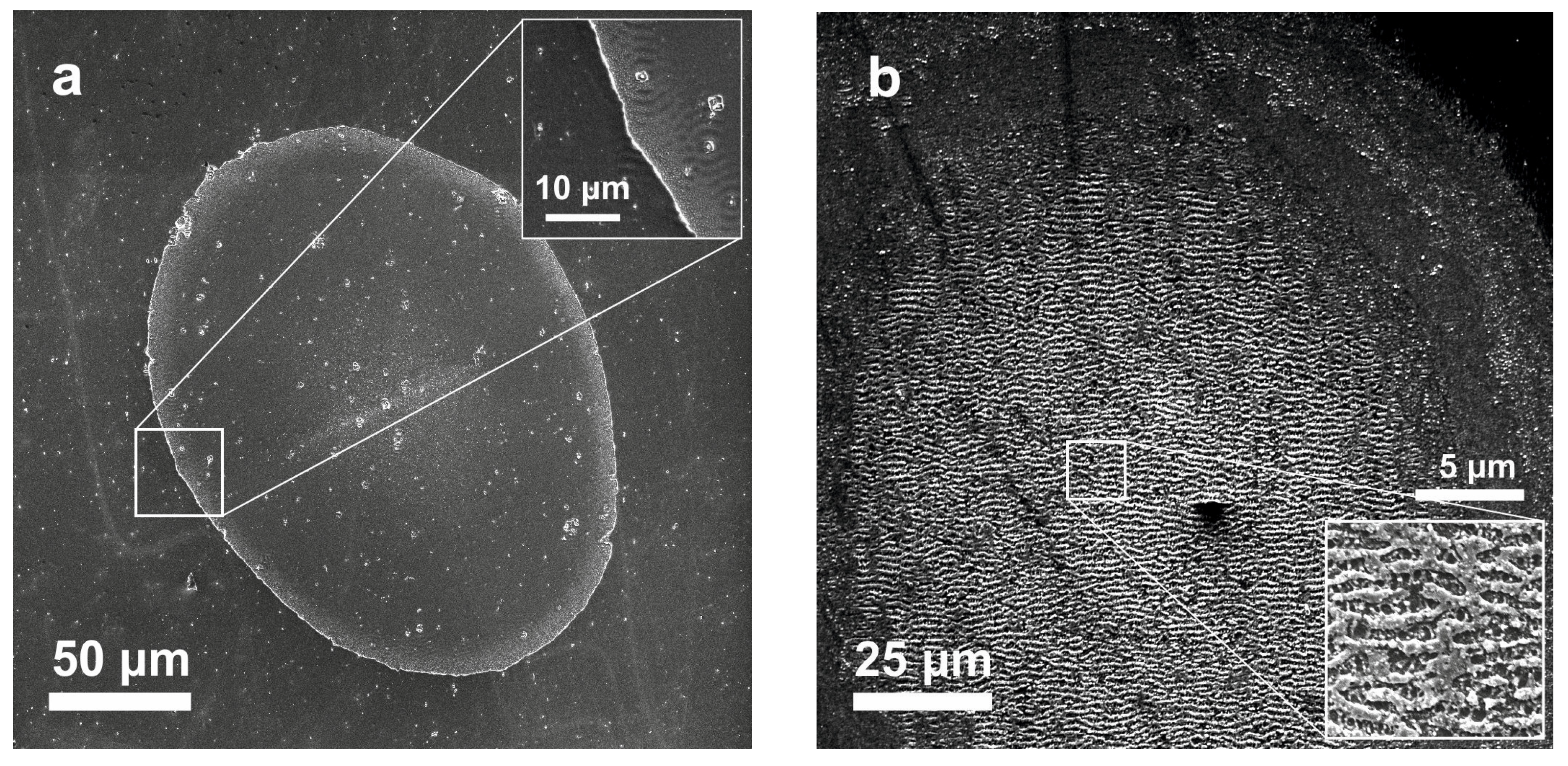

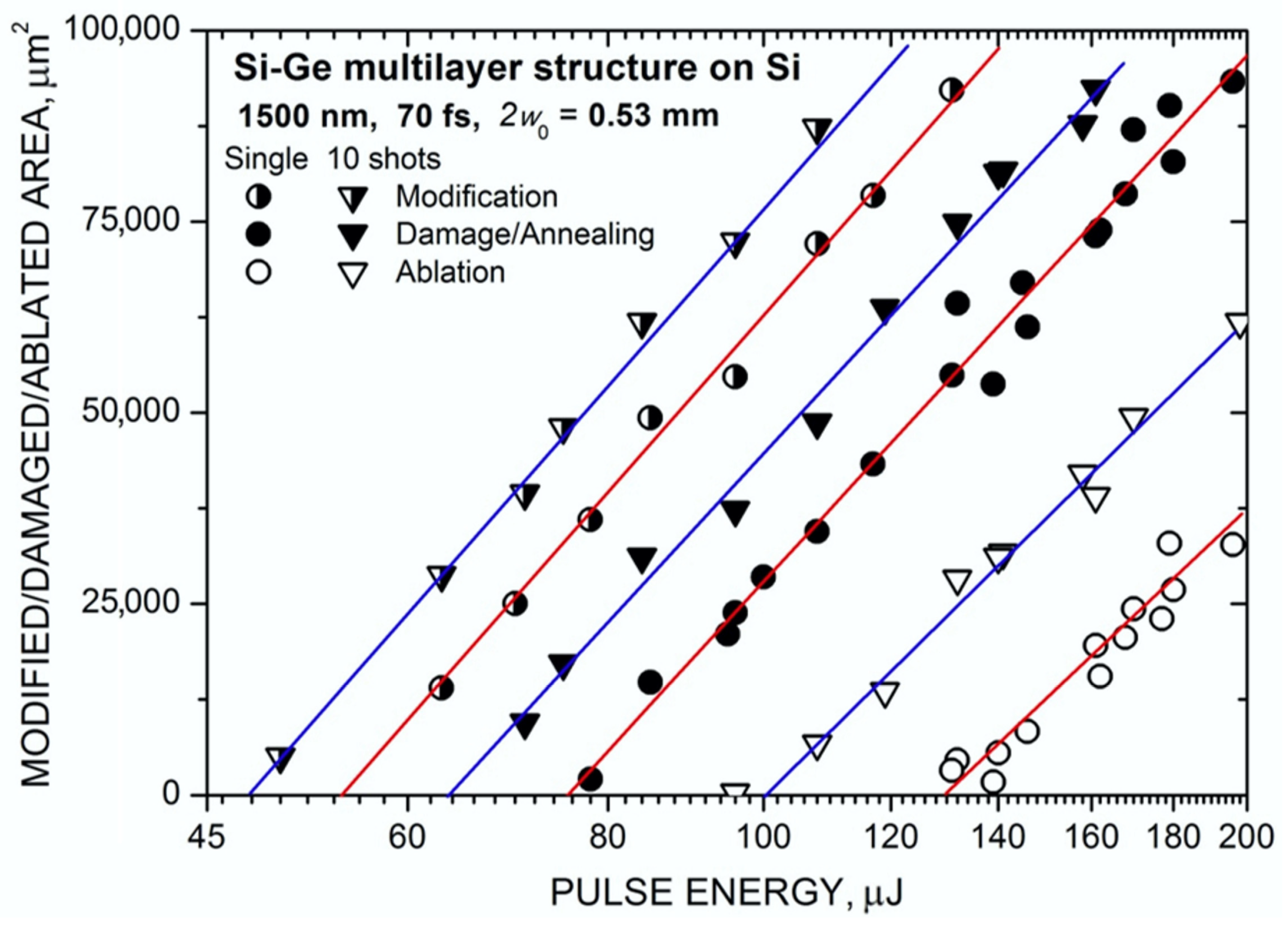

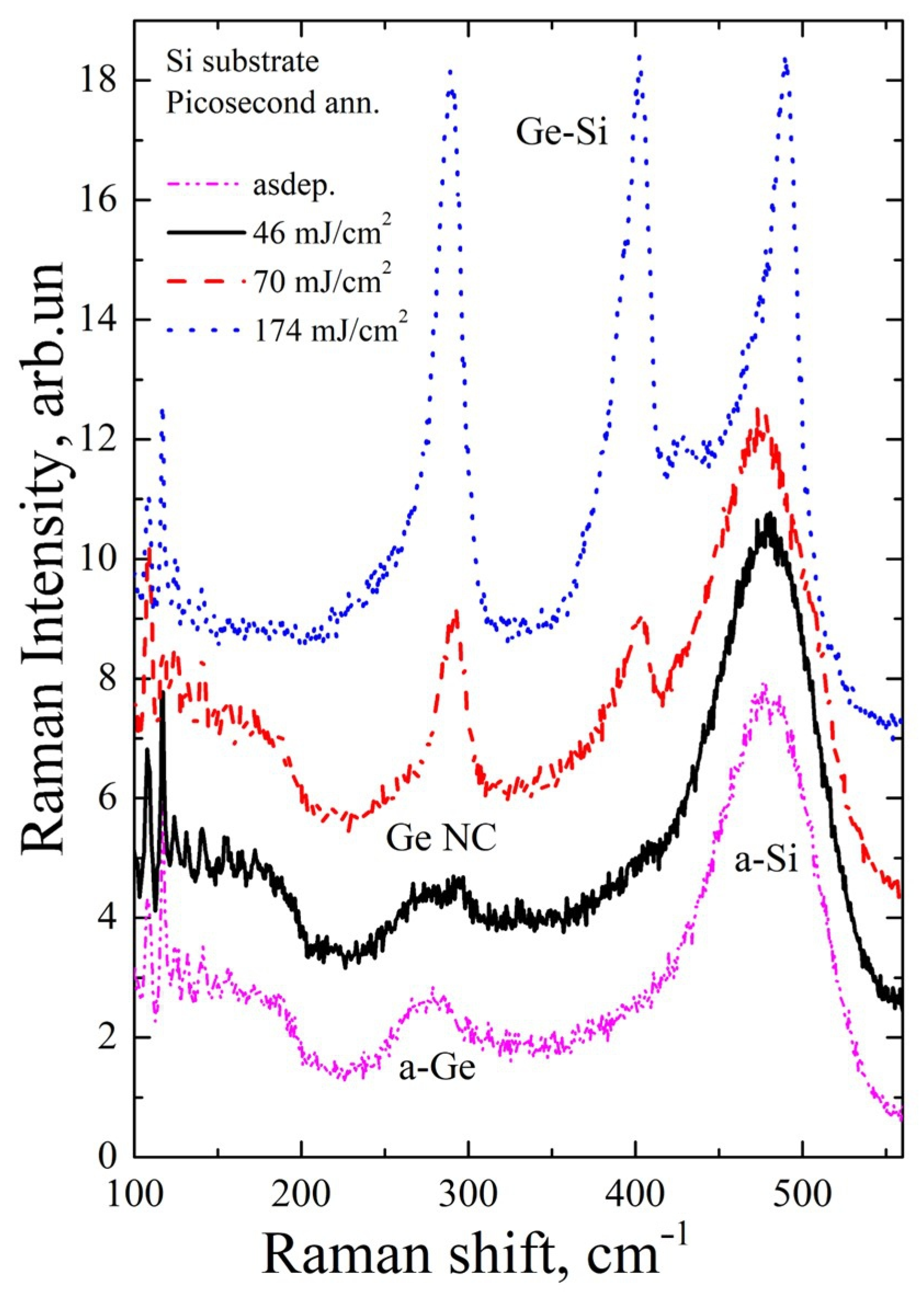

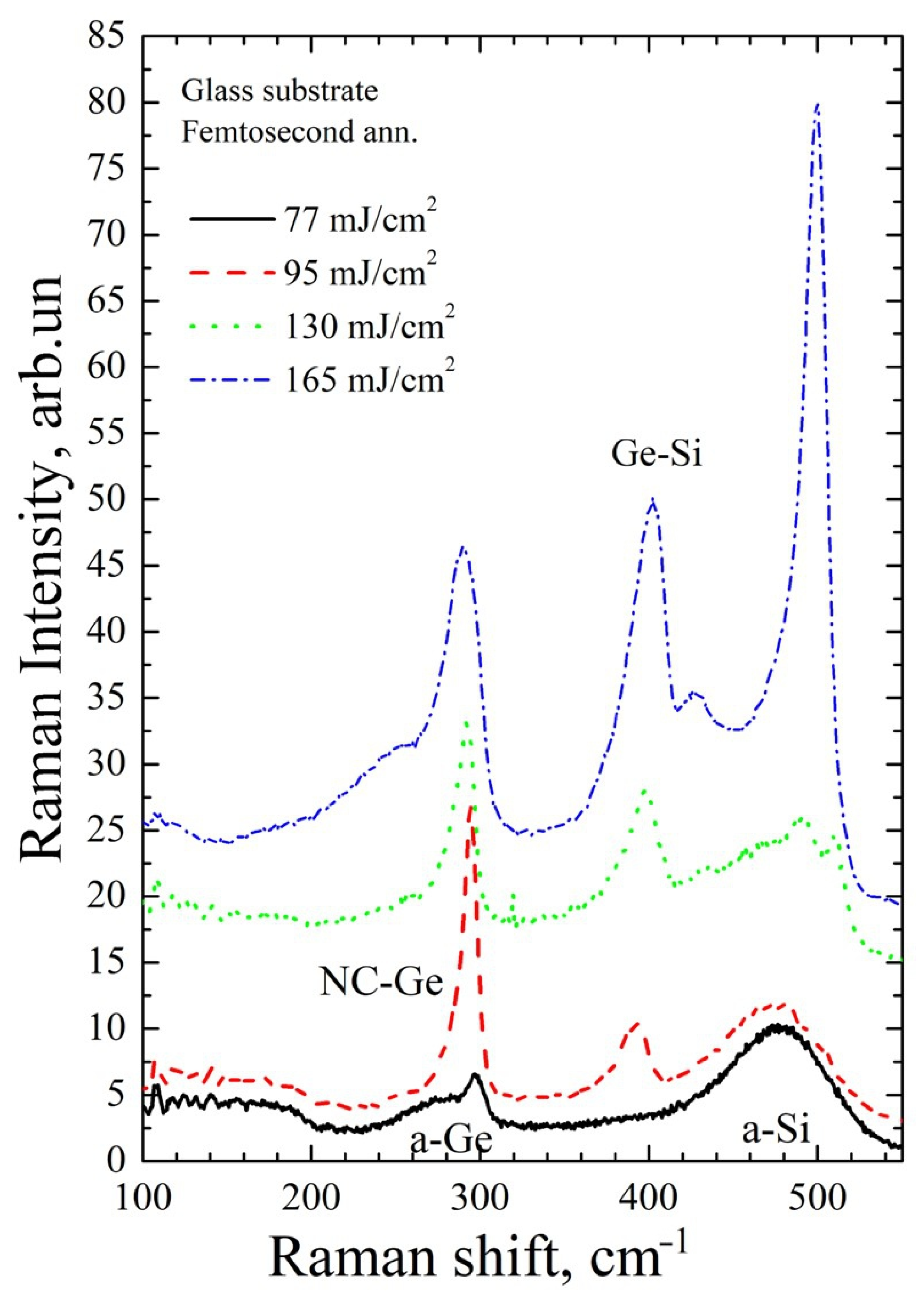

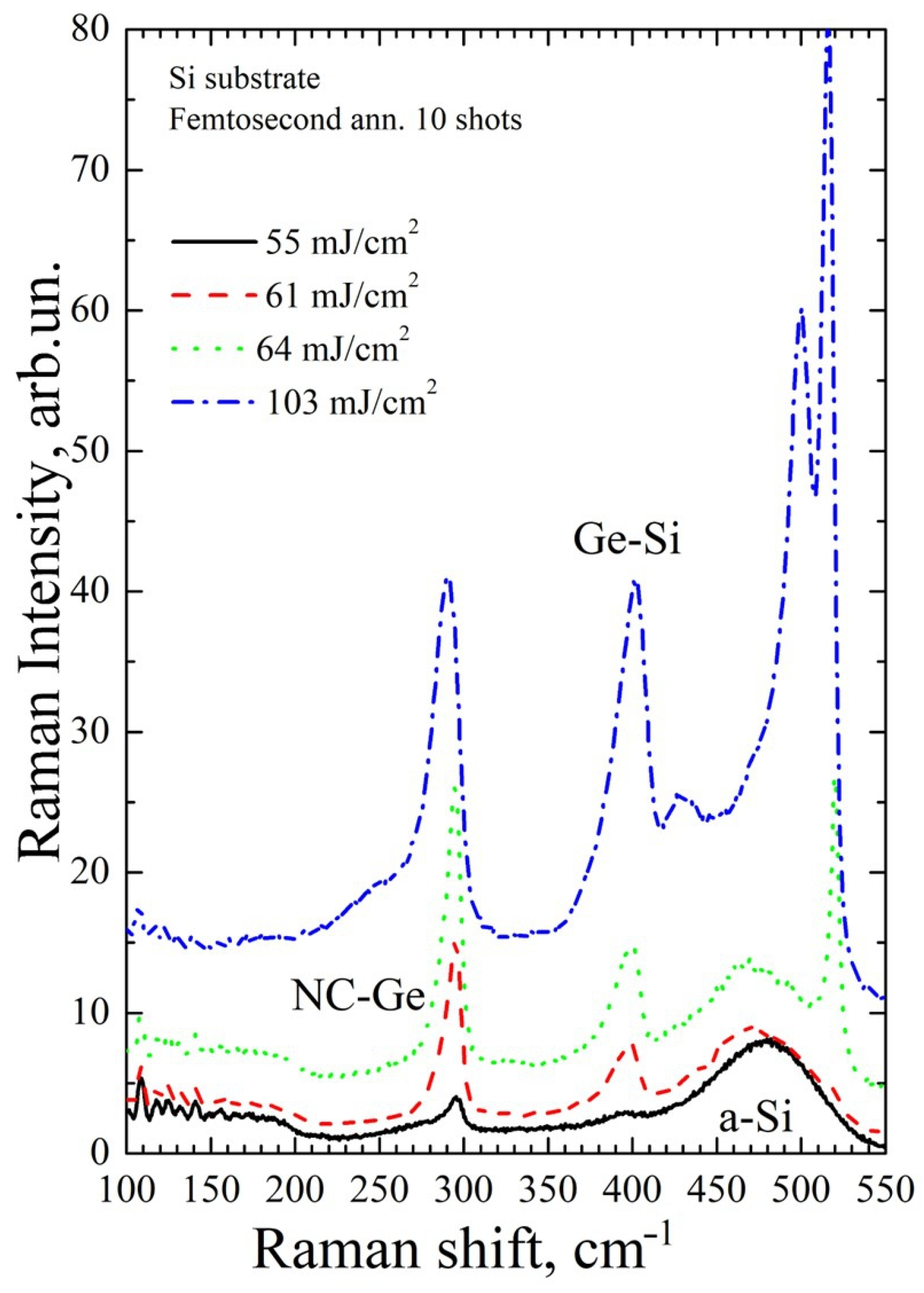

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akl, A.A.; Howari, H.J. Nanocrystalline Formation and Optical Properties of Germanium Thin Films Prepared by Physical Vapor Deposition. Phys. Chem. Solids 2009, 70, 1337–1343. [Google Scholar] [CrossRef]

- Socol, M.; Preda, N. Hybrid Nanocomposite Thin Films for Photovoltaic Applications: A Review. Nanomaterials 2021, 11, 1117. [Google Scholar] [CrossRef] [PubMed]

- Korkut, C.; Çınar, K.; Kabaçelik, İ.; Turan, R.; Kulakcı, M.; Bek, A. Laser Crystallization of Amorphous Ge Thin Films via a Nanosecond Pulsed Infrared Laser. Cryst. Growth Des. 2021, 21, 4632–4639. [Google Scholar] [CrossRef]

- Andrei, F.; Andrei, A.; Birjega, R.; Sirjita, E.N.; Radu, A.I.; Dinescu, M.; Ion, V.; Maraloiu, V.-A.; Teodorescu, V.Ş.; Scarisoreanu, N.D. The Influence of the Structural and Morphological Properties of WO3 Thin Films Obtained by PLD on the Photoelectrochemical Water-Splitting Reaction Efficiency. Nanomaterials 2021, 11, 110. [Google Scholar] [CrossRef] [PubMed]

- Rajan, S.T.; Subramanian, B.; Arockiarajan, A. A Comprehensive Review on Biocompatible Thin Films for Biomedical Application. Ceram. Int. 2022, 48, 4377–4400. [Google Scholar] [CrossRef]

- Lloyd, S.J.; Molina-Aldareguia, J.M. Multilayered materials: A palette for the materials artist. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2003, 361, 2931–2949. [Google Scholar] [CrossRef]

- Cancellieri, C.; Lorenzin, G.; Jeurgens, L.P.H. Microstructure-Property Control in Functional Materials by Multilayer Design. Chimia 2022, 76, 223–228. [Google Scholar] [CrossRef]

- Yang, L.; Watling, J.R.; Wilkins, R.C.W.; Borici, M.; Barker, J.R.; Asenov, A.; Roy, S. Si/SiGe Heterostructure Parameters for Device Simulations. Semicond. Sci. Technol. 2004, 19, 1174–1182. [Google Scholar] [CrossRef]

- Usami, N.; Amold, A.; Fujiwara, K.; Nakajima, K.; Yokoyama, T.; Shiraki, Y. New Solar Cells using Ge Dots Embedded in Si PIN Structures. In Proceedings of the 1st IEEE International Conference on Group IV Photonics, Hong Kong, China, 29 September–1 October 2004. [Google Scholar] [CrossRef]

- Li, C.; Ni, J.; Sun, X.; Wang, X.; Li, Z.; Cai, H.; Li, J.; Zhang, J. Nanocrystalline Germanium Nip Solar Cells with Spectral Sensitivities Extending into 1450 nm. J. Phys. D Appl. Phys. 2017, 50, 045108. [Google Scholar] [CrossRef]

- Krivyakin, G.K.; Volodin, V.A.; Kochubei, S.A.; Kamaev, G.N.; Purkrt, A.; Remeš, Z.; Fajgar, R.; Stuchlíková, T.H.; Stuchlík, J. Optical Properties of p–i–n Structures Based on Amorphous Hydrogenated Silicon with Silicon Nanocrystals Formed via Nanosecond Laser Annealing. Semiconductors 2016, 50, 935–940. [Google Scholar] [CrossRef]

- Volodin, V.A.; Krivyakin, G.K.; Shklyaev, A.A.; Kochubei, S.A.; Kamaev, G.N.; Dvurechendkii, A.V.; Purkrt, A.; Remeš, Z.; Fajgar, R.; Stuchlíková, T.H.; et al. Hydrogenated Amorphous Silicon Based p-i-n Structures with Si and Ge Nanocrystals in i-layers. Proc. SPIE 2016, 10224, 102240D. [Google Scholar] [CrossRef]

- Volodin, V.A.; Krivyakin, G.K.; Ivlev, G.D.; Prokopyev, S.L.; Gusakova, S.V.; Popov, A.A. Crystallization of Amorphous Germanium Films and Multilayer a-Ge/a-Si Structures upon Exposure to Nanosecond Laser Radiation. Semiconductors 2019, 53, 400–405. [Google Scholar] [CrossRef]

- Remeš, Z.; Stuchlík, J.; Stuchlíková, T.H.; Kupčík, J.; Mortet, V.; Taylor, A.; Ashcheulov, P.; Volodin, V.A. Electroluminescence of Thin Film p-i-n Diodes Based on a-SiC:H with Integrated Ge Nanoparticles. Eur. Phys. J. Appl. Phys. 2019, 88, 30302. [Google Scholar] [CrossRef]

- Sun, C.; Wade, M.T.; Lee, Y.; Orcutt, J.S.; Alloatti, L.; Georgas, M.S.; Waterman, A.S.; Shainline, J.M.; Avizienis, R.R.; Lin, S.; et al. Single-chip microprocessor that communicates directly using light. Nature 2015, 528, 534–538. [Google Scholar] [CrossRef]

- Pavesi, L.; Negro, L.D.; Mazzoleni, C.; Franzò, G.; Priolo, F. Multicolor Light-Emitting Devices with Tb2O3 on Silicon. Nature 2000, 408, 440–444. [Google Scholar] [CrossRef] [PubMed]

- Stoffel, M.; Denker, U.; Schmidt, O.G. Electroluminescence of Self-Assembled Ge Hut Clusters. Appl. Phys. Lett. 2003, 82, 3236–3238. [Google Scholar] [CrossRef]

- Shklyaev, A.A.; Vdovin, V.I.; Volodin, V.A.; Gulyaev, D.V.; Kozhukhov, A.S.; Sakuraba, M.; Murota, J. Structure and Optical Properties of Si and SiGe Layers Grown on SiO2 by Chemical Vapor Deposition. Thin Solid Film. 2015, 579, 131–135. [Google Scholar] [CrossRef]

- Grevtsov, N.; Chubenko, E.; Bondarenko, V.; Gavrilin, I.; Dronov, A.; Gavrilov, S. Germanium Electrodeposition into Porous Silicon for Silicon-Germanium Alloying. Materialia 2022, 26, 101558. [Google Scholar] [CrossRef]

- Imajo, T.; Ishiyama, T.; Saitoh, N.; Yoshizawa, N.; Suemasu, T.; Toko, K. Record-High Hole Mobility Germanium on Flexible Plastic with Controlled Interfacial Reaction. ACS Appl. Electron. Mater. 2022, 4, 269–275. [Google Scholar] [CrossRef]

- Nozawa, K.; Nishida, T.; Ishiyama, T.; Suemasu, T.; Toko, K. n-Type Polycrystalline Germanium Layers Formed by Impurity-Doped Solid-Phase Growth. ACS Appl. Electron. Mater. 2023, 5, 1444–1450. [Google Scholar] [CrossRef]

- Volodin, V.A.; Cheng, Y.; Bulgakov, A.V.; Levy, Y.; Beránek, J.; Nagisetty, S.S.; Zukerstein, M.; Popov, A.A.; Bulgakova, N.M. Single-Shot Selective Femtosecond and Picosecond Infrared Laser Crystallization of an Amorphous Ge/Si Multilayer Stack. Opt. Laser Technol. 2023, 161, 109161. [Google Scholar] [CrossRef]

- Kolchin, A.V.; Shuleiko, D.V.; Pavlikov, A.V.; Zabotnov, S.V.; Golovan, L.A.; Presnov, D.E.; Volodin, V.A.; Krivyakin, G.K.; Popov, A.A.; Kashkarov, P.K. Femtosecond Laser Annealing of Multilayer Thin-Film Structures Based on Amorphous Germanium and Silicon. Tech. Phys. Lett. 2020, 46, 560–563. [Google Scholar] [CrossRef]

- Florian, C.; Fischer, D.; Freiberg, K.; Duwe, M.; Sahre, M.; Schneider, S.; Hertwig, A.; Krüger, J.; Rettenmayr, M.; Beck, U.; et al. Single Femtosecond Laser-Pulse-Induced Superficial Amorphization and Re-Crystallization of Silicon. Materials 2021, 14, 1651. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Baudach, S.; Krüger, J.; Kautek, W.; Lenzner, M. Femtosecond Laser Ablation of Silicon–Modification Thresholds and Morphology. Appl. Phys. A 2002, 74, 19–25. [Google Scholar] [CrossRef]

- Werner, K.; Gruzdev, V.; Talisa, N.; Kafka, K.; Austin, D.; Liebig, C.M.; Chowdhury, E. Single-Shot Multi-Stage Damage and Ablation of Silicon by Femtosecond Mid-infrared Laser Pulses. Sci. Rep. 2019, 9, 19993. [Google Scholar] [CrossRef]

- Armbruster, O.; Naghilou, A.; Kitzler, M.; Kautek, W. Spot Size and Pulse Number Dependence of Femtosecond Laser Ablation Thresholds of Silicon and Stainless Steel. Appl. Surf. Sci. 2017, 396, 1736–1740. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J. Pulse Number Dependence of Laser-Induced Periodic Surface Structures for Femtosecond Laser Irradiation of Silicon. J. Appl. Phys. 2010, 108, 034903. [Google Scholar] [CrossRef]

- Bonse, J.; Höhm, S.; Kirner, S.V.; Rosenfeld, A.; Krüger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Topics Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Liu, J.M. Simple Technique for Measurements of Pulsed Gaussian-Beam Spot Sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

- Starinskiy, S.V.; Shukhov, Y.G.; Bulgakov, A.V. Laser-Induced Damage Thresholds of Gold, Silver and Their Alloys in Air and Water. Appl. Surf. Sci. 2017, 396, 1765–1774. [Google Scholar] [CrossRef]

- Wihl, W.; Cardona, M.; Tauc, J. Raman Scattering in Amorphous Ge and III–V Compounds. J. Non-Cryst. Solids 1972, 8–10, 172–178. [Google Scholar] [CrossRef]

- Iqbal, Z.; Veprek, S. Raman Scattering from Hydrogenated Microcrystalline and Amorphous Silicon. J. Phys. C Solid State Phys. 1982, 15, 377–392. [Google Scholar] [CrossRef]

- Volodin, V.A.; Efremov, M.D.; Deryabin, A.S.; Sokolov, L.V. Determination of the Composition and Stresses in GexSi(1−x) Heterostructures from Raman Spectroscopy Data: Refinement of Model Parameters. Semiconductors 2006, 40, 1314–1320. [Google Scholar] [CrossRef]

- Kolobov, A.V. Raman Scattering from Ge Nanostructures Grown on Si Substrates: Power and Limitations. J. Appl. Phys. 2000, 87, 2926–2930. [Google Scholar] [CrossRef]

- Volodin, V.A.; Efremov, M.D.; Yakimov, A.I.; Mikhalev, G.Y.; Nikiforov, A.I.; Dvurechenskii, A.V. Determination of the Composition and Strains in GexSi1−x -based Nanostructures from Raman Spectroscopy Data with Consideration of the Contribution of the Heterointerface. Semiconductors 2007, 41, 930–934. [Google Scholar] [CrossRef]

- Parker, J.H., Jr.; Feldman, D.W.; Ashkin, M. Raman Scattering by Silicon and Germanium. Phys. Rev. 1967, 155, 712–714. [Google Scholar] [CrossRef]

- Volodin, V.A.; Marin, D.V.; Sachkov, V.A.; Gorokhov, E.B.; Rinnert, H.; Vergnat, M. Applying an Improved Phonon Confinement Model to the Analysis of Raman Spectra of Germanium Nanocrystals. J. Exp. Theor. Phys. 2014, 118, 65–71. [Google Scholar] [CrossRef]

- Volodin, V.A.; Sachkov, V.A. Improved Model of Optical Phonon Confinement in Silicon Nanocrystals. J. Exp. Theor. Phys. 2013, 116, 87–94. [Google Scholar] [CrossRef]

- Reflectance Calculator. Available online: https://www.filmetrics.com/reflectance-calculator (accessed on 22 March 2023).

- Taylor, R.E. Thermal expansion of solids. In CINDAS Data Series on Material Properties; Ho, C.Y., Ed.; ASM International: Material Park, OH, USA, 1998; Volume 1–4. [Google Scholar]

- Gundrum, B.G.; Averback, R.S.; Cahill, D.G. Time Resolved Measurements of Melting and Solidification in Si Using Third Harmonic Generation of Light. Appl. Phys. Lett. 2007, 91, 011906. [Google Scholar] [CrossRef]

- Taylor, L.L.; Qiao, J.; Qiao, J. Optimization of Femtosecond Laser Processing of Silicon via Numerical Modeling. Opt. Mater. Express 2016, 6, 2745–2758. [Google Scholar] [CrossRef]

| Irradiation Conditions | Fth,m, mJ/cm2 | Fth,d, mJ/cm2 | Fth,a, mJ/cm2 | |||

|---|---|---|---|---|---|---|

| 1 Shot | 10 Shots | 1 Shot | 10 Shots | 1 Shot | 10 Shots | |

| 1500 nm, 70 fs | 50 | 45 | 70 | 60 | 115 | 90 |

| 1030 nm, 1.4 ps | 45 | 40 | 65 | 55 | 110 | 85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulgakov, A.V.; Beránek, J.; Volodin, V.A.; Cheng, Y.; Levy, Y.; Nagisetty, S.S.; Zukerstein, M.; Popov, A.A.; Bulgakova, N.M. Ultrafast Infrared Laser Crystallization of Amorphous Si/Ge Multilayer Structures. Materials 2023, 16, 3572. https://doi.org/10.3390/ma16093572

Bulgakov AV, Beránek J, Volodin VA, Cheng Y, Levy Y, Nagisetty SS, Zukerstein M, Popov AA, Bulgakova NM. Ultrafast Infrared Laser Crystallization of Amorphous Si/Ge Multilayer Structures. Materials. 2023; 16(9):3572. https://doi.org/10.3390/ma16093572

Chicago/Turabian StyleBulgakov, Alexander V., Jiří Beránek, Vladimir A. Volodin, Yuzhu Cheng, Yoann Levy, Siva S. Nagisetty, Martin Zukerstein, Alexander A. Popov, and Nadezhda M. Bulgakova. 2023. "Ultrafast Infrared Laser Crystallization of Amorphous Si/Ge Multilayer Structures" Materials 16, no. 9: 3572. https://doi.org/10.3390/ma16093572