Effect of the Second Phases on Composite Spinning-Extrusion Forming and Mechanical Properties of Al–Cu–Li Alloy

Abstract

1. Introduction

2. Materials and Experimental Design

3. Results

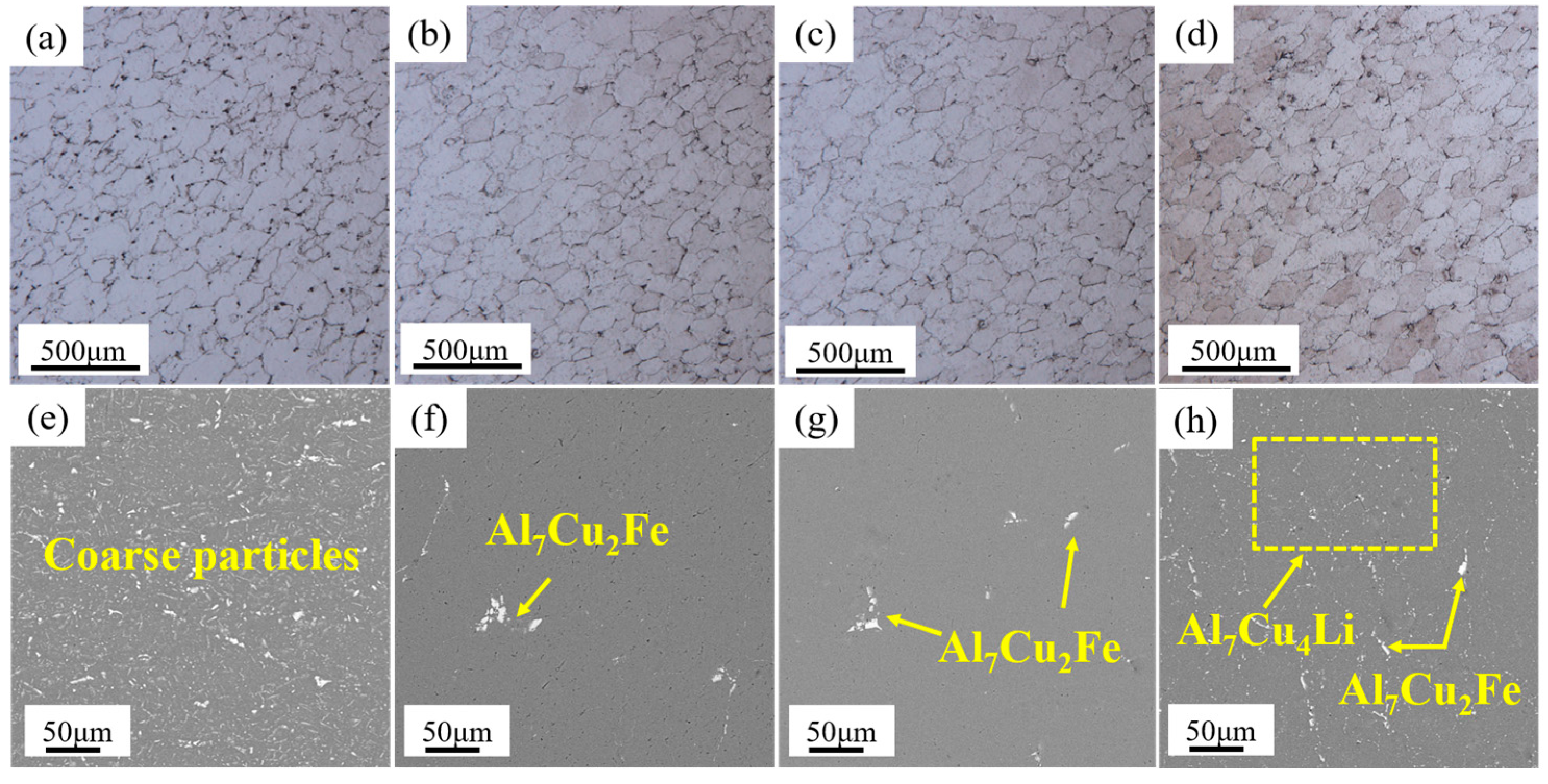

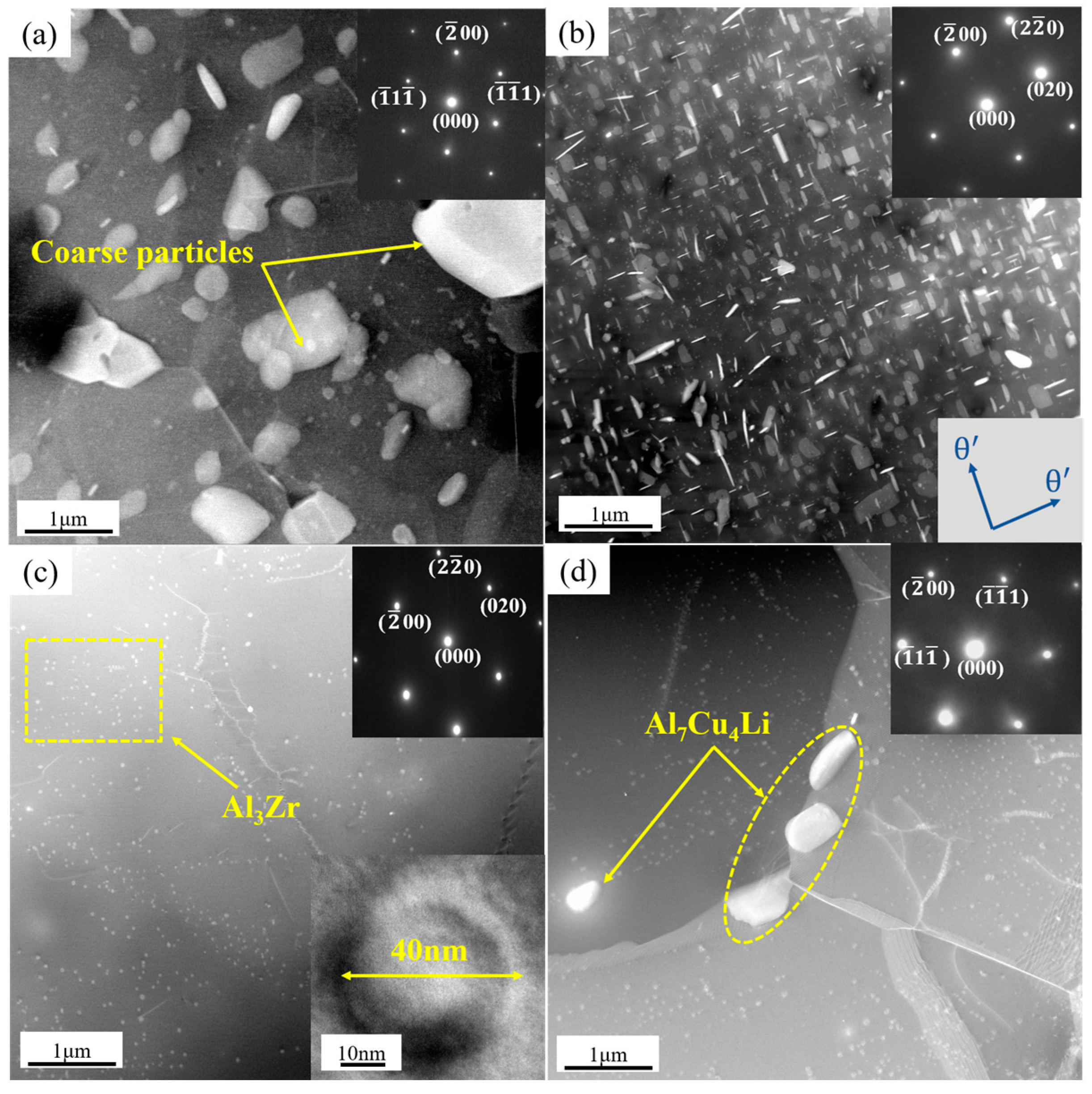

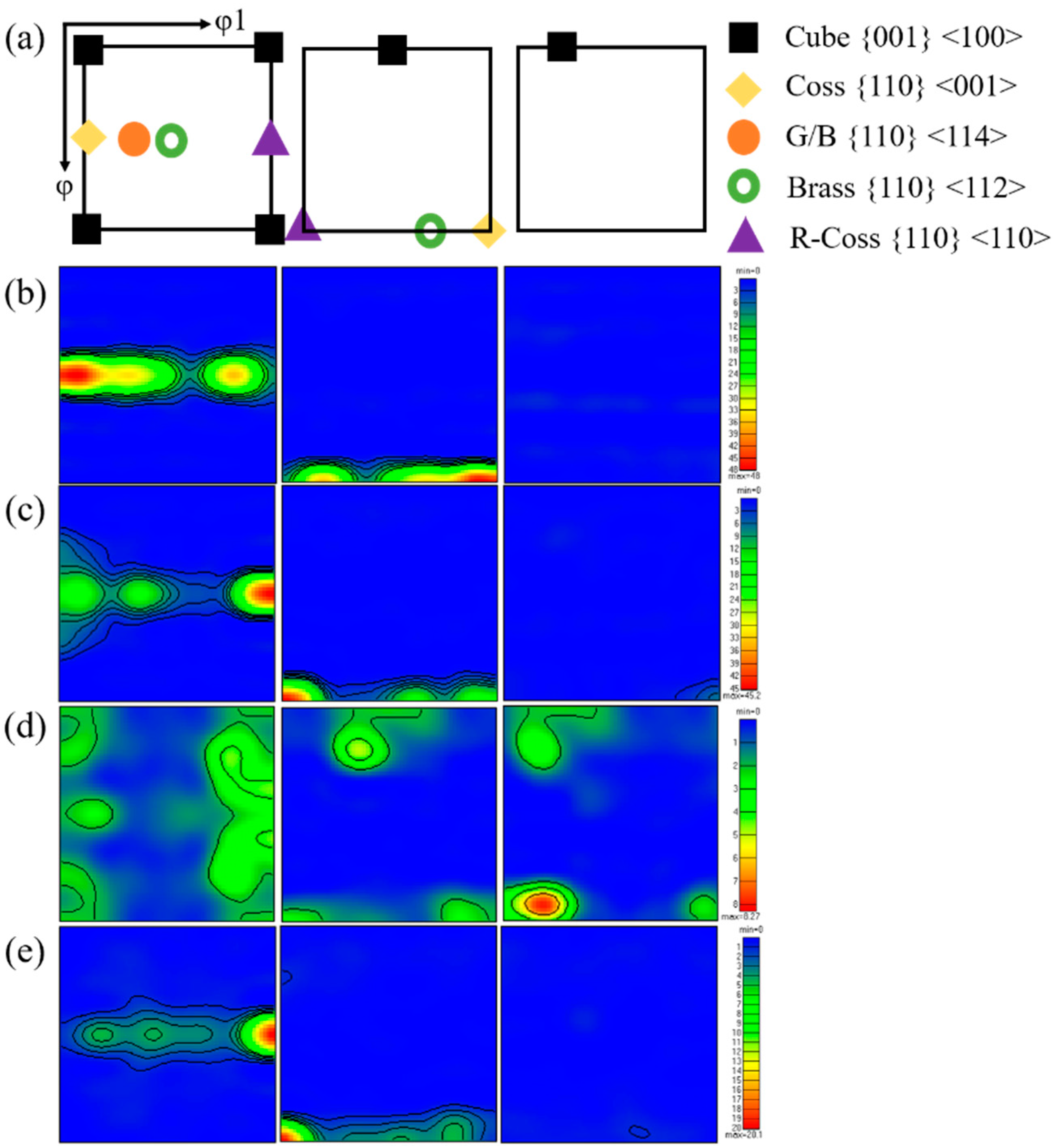

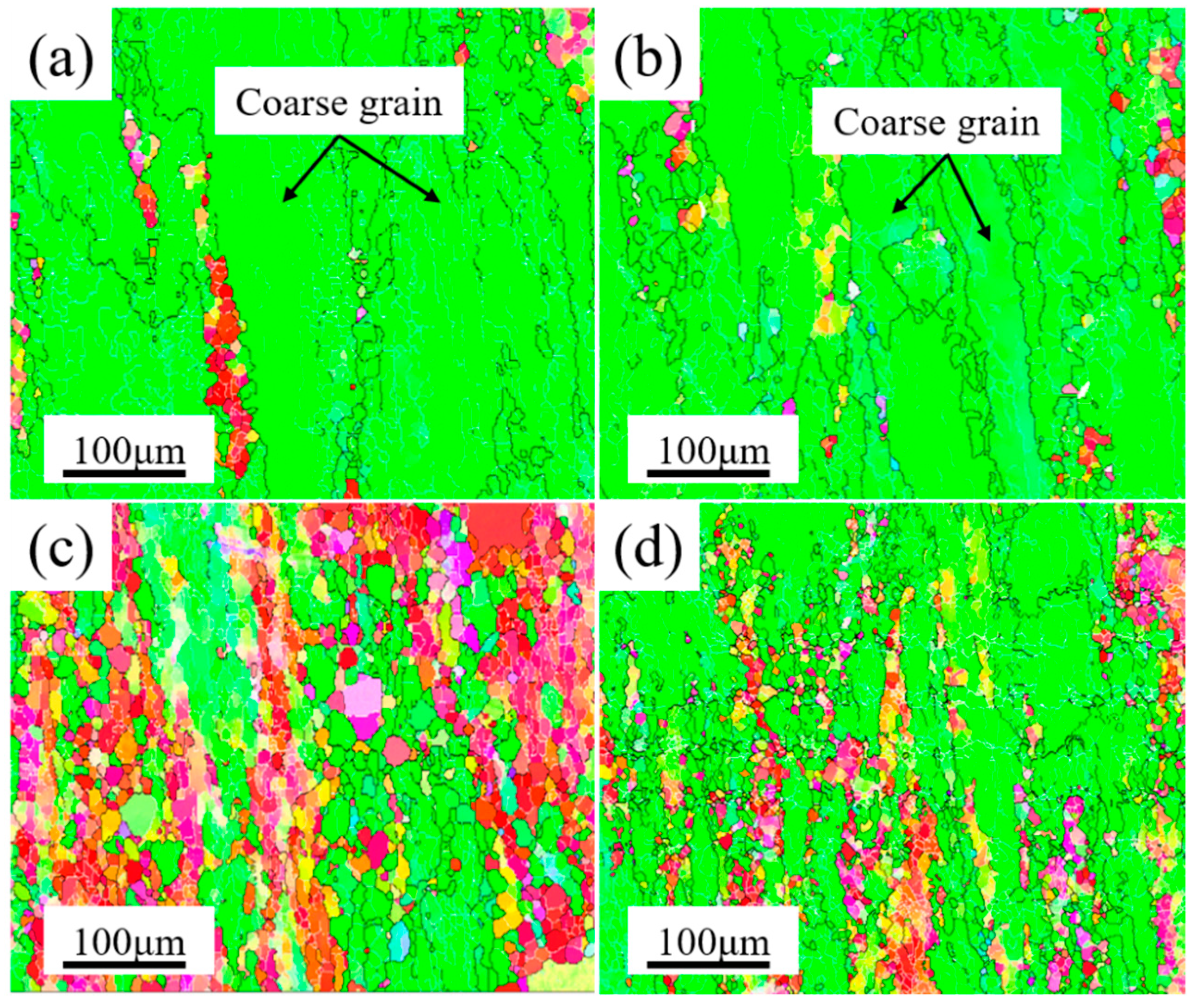

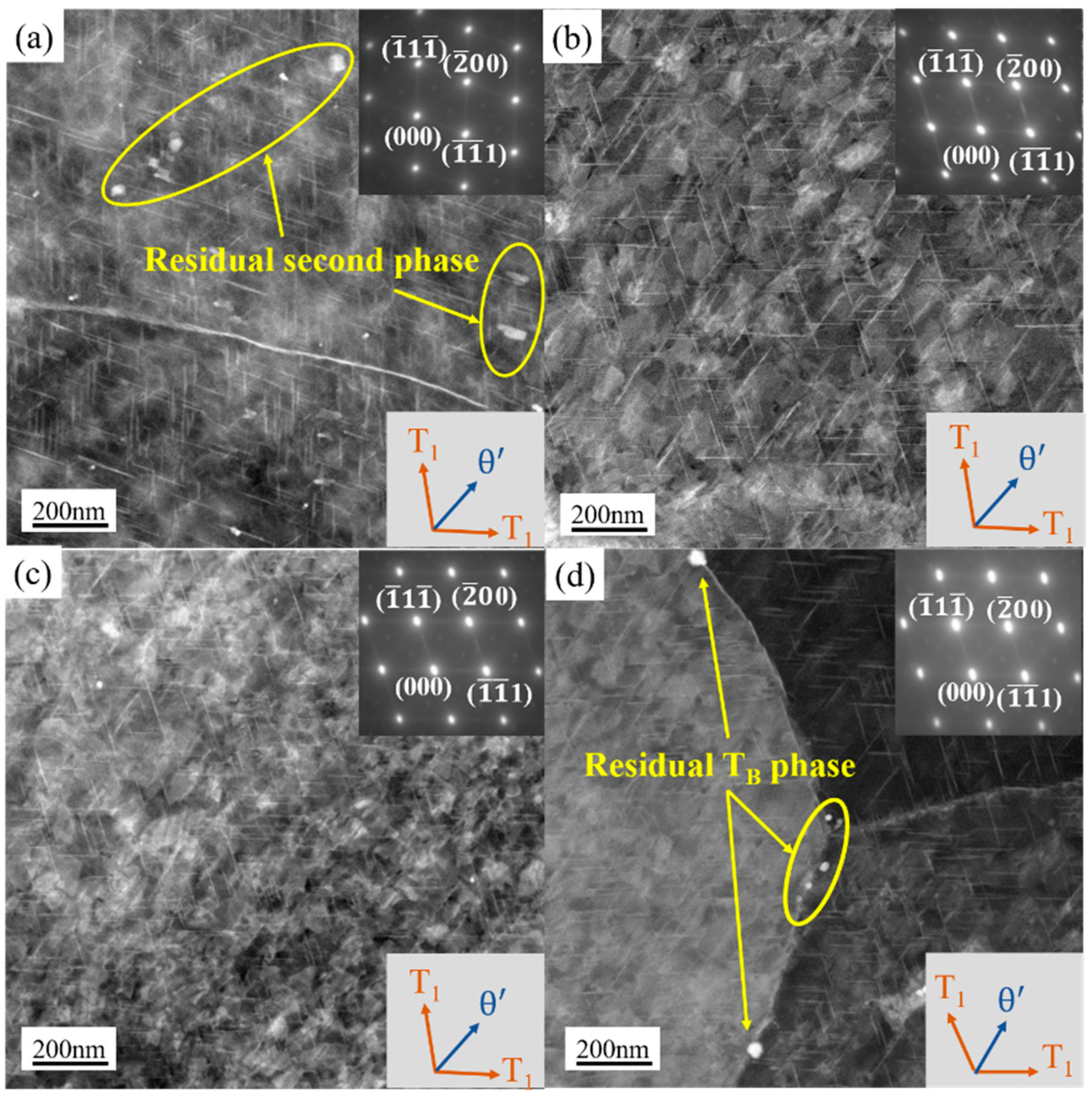

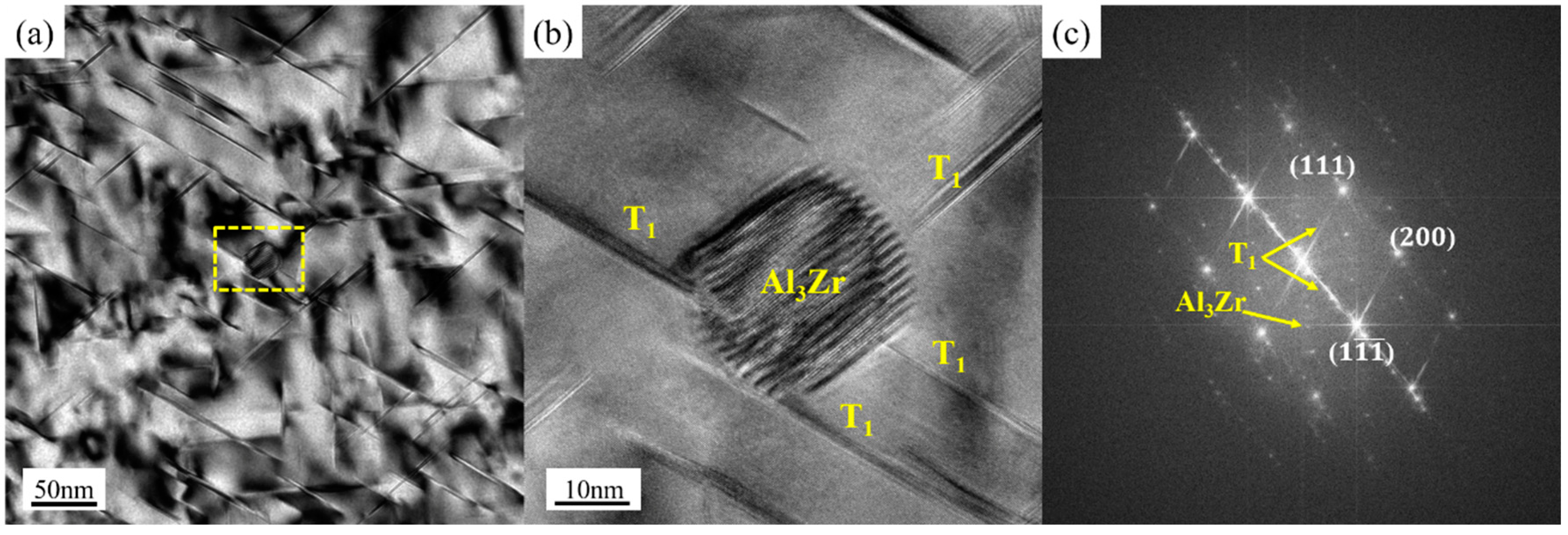

3.1. Microstructure of Samples under Different Heat Treatments

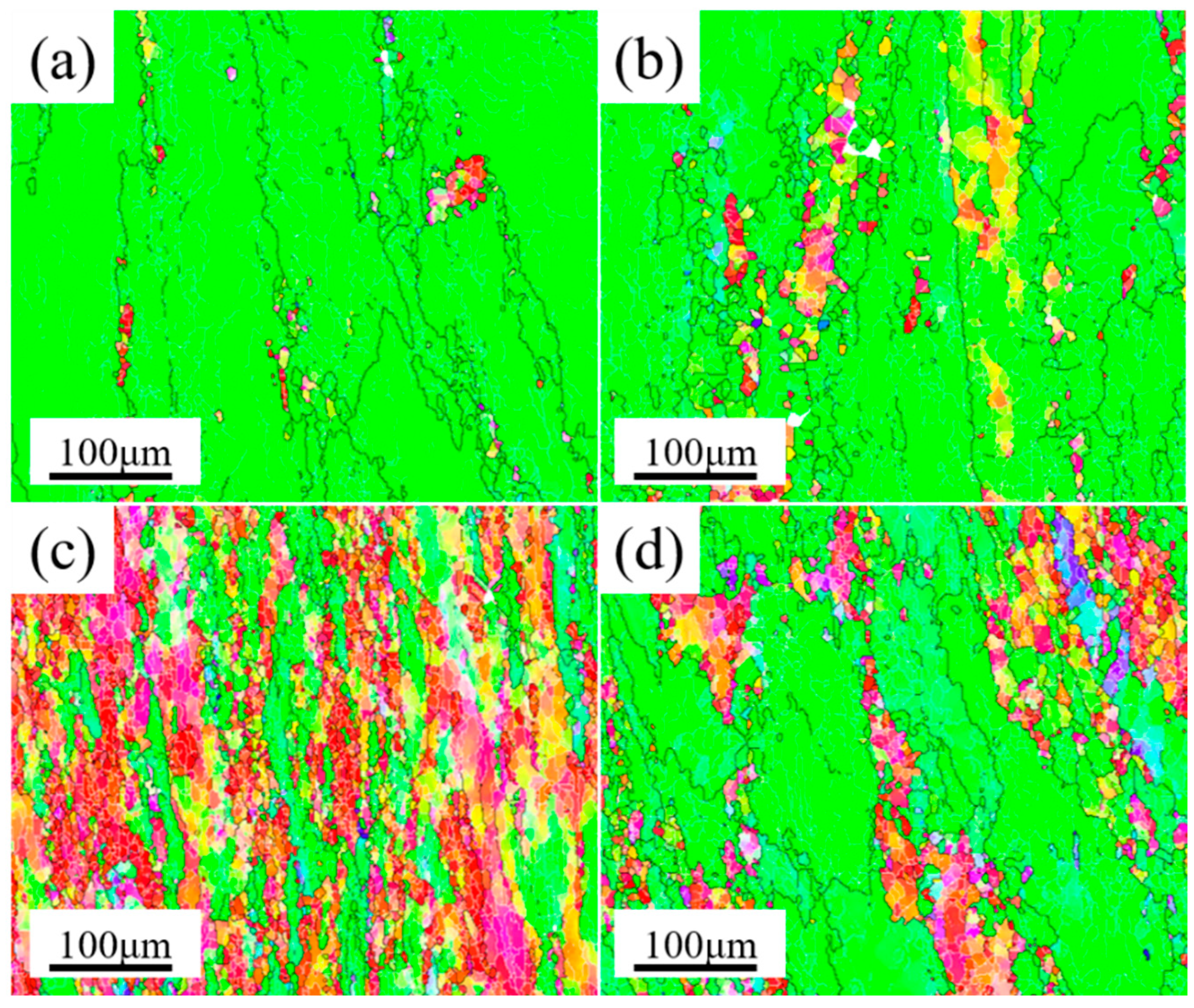

3.2. Forming Results of Samples under Different Second Phases

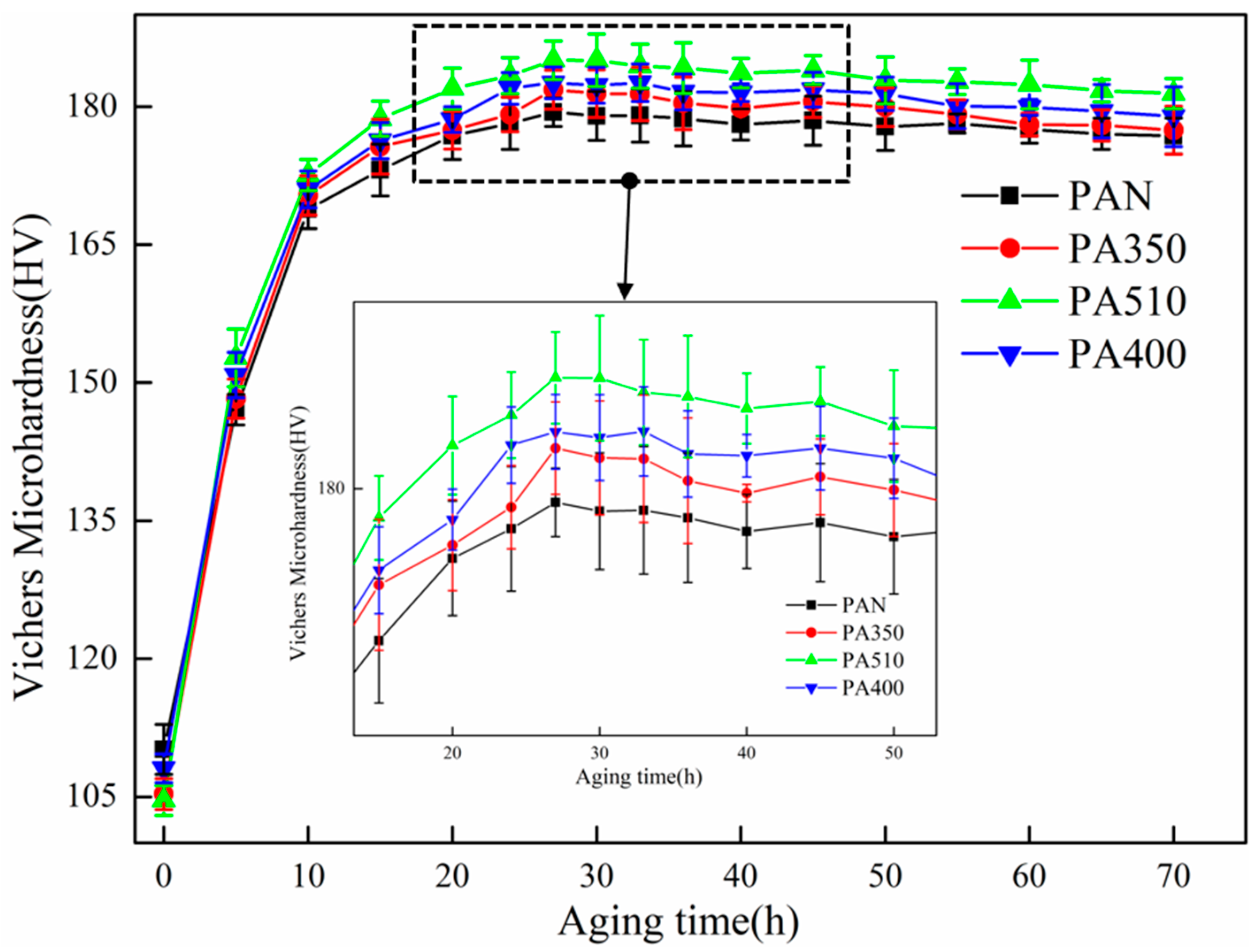

3.3. Mechanical Properties of Cylindrical Parts under Different Second Phases

4. Discussion

4.1. Effect of the Second Phases on the Composite Spinning-Extrusion of Al–Cu–Li Alloy

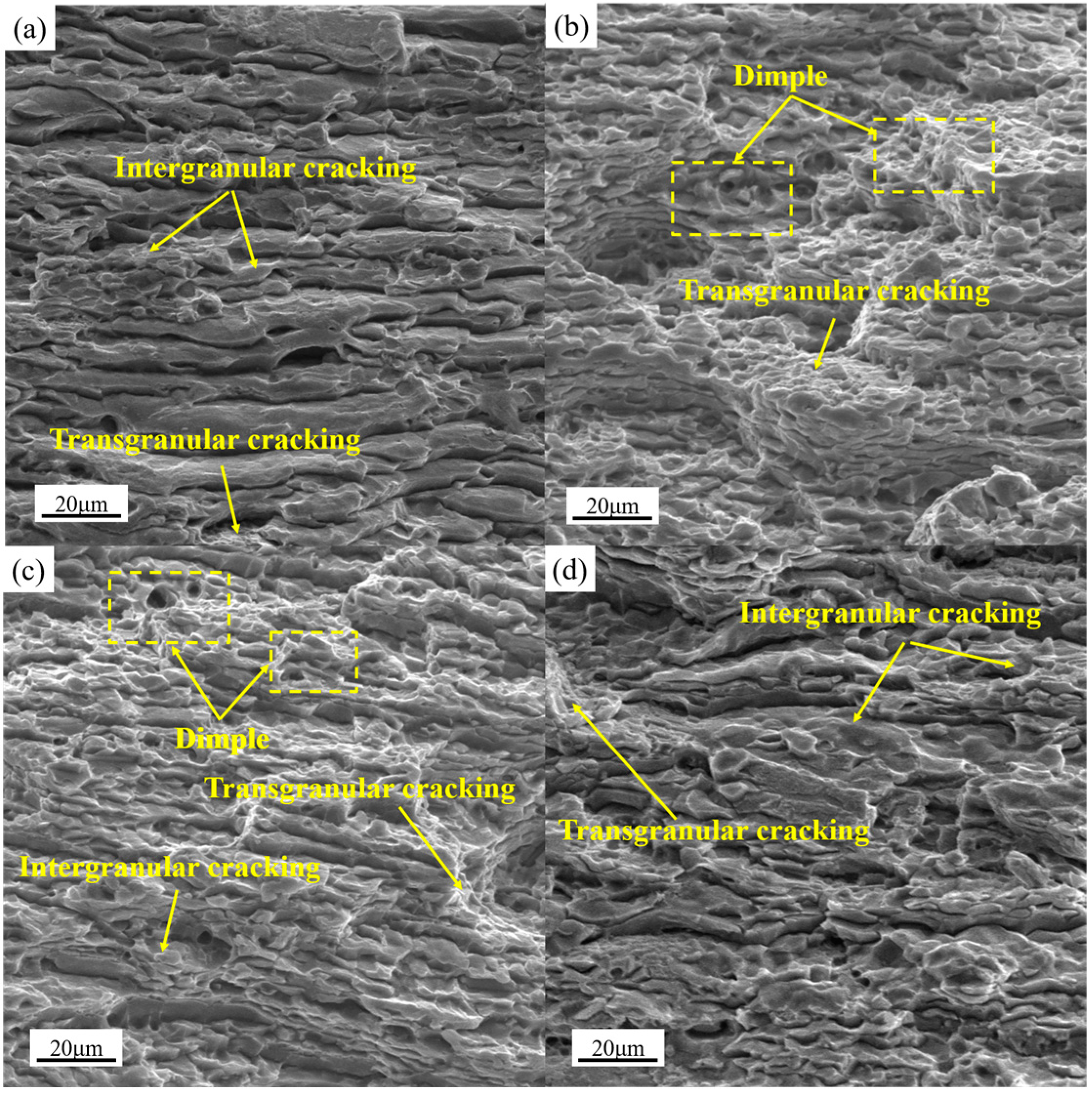

4.2. Effect of the Second Phases on the Mechanical Properties of Al–Cu–Li Alloy Cylindrical Parts

4.2.1. Strength

4.2.2. Elongation

5. Conclusions

- (1)

- The different second phases of Al–Cu–Li alloy can be adjusted via proper preheating treatment. The initial second phases of spray-formed Al–Cu–Li alloy is a mixture of coarse residual phases, such as Al2Cu, Al7Cu4Li and Al7Cu2Fe. Al2Cu and Al7Cu4Li can be dissolved during preheating at 510 °C/4 h. After quenching, the second phases mainly composed of θ’ phase and TB phase can be obtained by annealing at 350 °C/2 h and 400 °C/10 h, respectively. Al3Zr dispersoid can be precipitated in large quantities under the condition of slow slope heating (0.85 °C/min, 510 °C/12 h).

- (2)

- Dissolving the residual Al7Cu4Li and Al2Cu and precipitating Al3Zr dispersoid in the blank can effectively weaken the orientation consistency of the cylindrical parts and improve the quality of composite spinning-extrusion forming. After preheating treatment, the blank is well formed. At the same time, the grain distribution is more uniform and the average grain size is refined from about 80 μm to 40 μm.

- (3)

- Fine Al3Zr dispersoid can effectively improve the final mechanical properties of composite spinning-extrusion cylindrical parts. Meanwhile, fine Al3Zr dispersoid can inhibit the abnormal growth of recrystallized grains during heat treatment and promote the precipitation of fine and dense T1 phase during artificial aging. After regulation, the average grain size of the cylindrical parts is refined from about 90 μm to about 45 μm, and the average diameter of T1 phase is refined from 107 nm to 77 nm. In addition, the ultimate tensile strength, yield strength and elongation of cylindrical parts are increased from 555 MPa to 588 MPa, 530 MPa to 564 MPa, and 9.1% to 11%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, B.; Sujun, W. Aluminum Lithium Alloys (Al-Li-Cu-X)-New Generation Material for Aerospace Applications. Appl. Mech. Mater. 2014, 440, 104–111. [Google Scholar]

- Naihui, Y.; Jianzhong, S.; Yujun, C.; Dongxi, M.; Qiming, L. Comparative Analysis of Al-Li Alloy and Aluminum Honeycomb Panel for Aerospace Application by Structural Optimization. Math Probl. Eng. 2015, 12, 815257. [Google Scholar]

- El-Aty, A.A.; Yong, X.; Xunzhong, G.; Shihong, Z.; Yan, M.; Dayong, C. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al–Cu–Li alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- Gupta, R.K.; Nayan, N.; Nagasireesha, G.; Sharma, S.C. Development and characterization of Al–Li alloys. Mater. Sci. Eng. A 2006, 420, 228–234. [Google Scholar] [CrossRef]

- Rioja, R.J.; John, L. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Xu, F.; Huang, C. Regulating effect of pre-stretching degree on the creep aging process of Al-Cu-Li alloy. Mater. Sci. Eng. A 2019, 763, 138157. [Google Scholar] [CrossRef]

- Domack, M.S.; Wagner, J.A. Innovative Manufacturing of Cylinders with Integral Stiffeners; NASA: Washington, DC, USA, 2015.

- Vickers, J.; Fikes, J. Space Technology Mission Directorate Game Changing Development Program fy2015 Aunual Program Review; NASA: Washington, DC, USA, 2015.

- Wagner, J.; Domack, M.; Hoffman, E. Recent Advances in Near-Net-Shape Fabrication of Al-Li Alloy 2195 for Launch Vehicles. In Proceedings of the NSMMS, Indian Wells, CA, USA, 26–29 June 2017. [Google Scholar]

- Tayon, W.A.; Domack, M.S.; Wagner, J.A. Characterization of 10-ft. Diameter Aluminum Alloy 2219 Integrally Stiffened Cylinders; NASA: Washington, DC, USA, 2019.

- Wei, L.; Mei, Z.; Pengfei, G.; Fei, M.; Rui, L.; Hongrui, Z.; Yunda, D. Rib filling behavior in flow forming of thin-walled tube with helical grid-stiffened ribs. Int. J. Adv. Manuf. Technol. 2022, 119, 2877–2894. [Google Scholar]

- Hao, P.; Wang, Y.; Tang, H.; Feng, S.; Wang, B. A NURBS-based degenerated stiffener element for isogeometric static and buckling analysis. Comput. Method Appl. Mech. Eng. 2022, 398, 115245. [Google Scholar] [CrossRef]

- Lyu, W.; Zhan, M.; Gao, P.; Li, M.; Lei, Y.; Ma, F. Improvement of rib-grid structure of thin-walled tube with helical grid-stiffened ribs based on the multi-mode filling behaviors in flow forming. J. Mater. Process. Technol. 2021, 296, 115245. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, X.; Shan, D.; Li, J.; Deng, Q.; Cui, X.; Li, Z. Numerical simulation and experimental study on multi-pass stagger spinning of internally toothed gear using plate blank. J. Mater. Process. Technol. 2016, 229, 450–466. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, X.; Li, H.; Zhan, M.; Zhang, H.; Wu, K.; Ren, T.; Li, S. Die filling mechanism in flow forming of thin-walled tubular parts with cross inner ribs. J. Manuf. Process. 2020, 58, 832–844. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, X.; Li, H.; Zhan, M.; Li, S.; Wu, K.; Ren, T. Heterogeneous microstructure and mechanical property of thin-walled tubular part with cross inner ribs produced by flow forming. Mater. Sci. Eng. A 2020, 790, 139702. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.; Xi, H.; Zhao, G.; Wang, Y.; Xu, X. Effects of heat treatment on the microstructure and mechanical properties of extruded 2196 Al-Cu-Li alloy. Mater. Des. 2020, 192, 108746. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Robson, J.D. Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al–Cu–Li alloys. Acta Mater. 2015, 93, 73–86. [Google Scholar] [CrossRef]

- Dorin, T.; Geuser, D.F.; Lefebvre, W.; Sigli, C.; Deschamps, A. Strengthening mechanisms of T1 precipitates and their influence on the plasticity of an Al–Cu–Li alloy. Mater. Sci. Eng. A 2014, 605, 119–126. [Google Scholar] [CrossRef]

- Kim, J.H.; Jeun, J.H.; Chun, H.J.; Lee, Y.R.; Yoo, J.T.; Yoon, J.H.; Lee, H.S. Effect of precipitates on mechanical properties of AA2195. J. Alloys Compd. 2016, 669, 187–198. [Google Scholar]

- Chen, P.S.; Bhat, B.N. Time-Temperature-Precipitation Behavior in AI-Li Alloy 2195; NASA: Washington, DC, USA, 2002; p. 211548.

- Jata, K.V.; Panchanadeeswaran, S.; Vasudevan, A.K. Evolution of texture, micro structure and mechanical property anisotropy in an Al-Li-Cu alloy. Mater. Sci. Eng. A 1998, 257, 37–46. [Google Scholar]

- Duan, S.; Guo, F.; Zhang, Y.; Chong, K.; Lee, S.; Matsuda, K.; Zou, Y. Effects of texture and precipitates characteristics on anisotropic hardness evolution during artificial aging for an Al-Cu-Li alloy. Mater. Des. 2021, 212, 110216. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of deformation temperature on second-phase particles and mechanical properties of 2219 Al-Cu alloy. Mater. Sci. Eng. A 2018, 712, 414–423. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of cold predeformation on dissolution of second-phase Al2Cu particles during solution treatment of 2219 Al-Cu alloy forgings. Mater. Charact. 2018, 135, 18–24. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Guo, W.; Zhang, Y. Effects of thermomechanical treatment on grain refinement, second-phase particle dissolution, and mechanical properties of 2219 Al alloy. J. Mater. Process. Technol. 2020, 278, 116506. [Google Scholar] [CrossRef]

- Dorin, T.; Vahid, A.; Lamb, J. Aluminium Lithium Alloys. In Fundamentals of Aluminium Metallurgy; Woodhead Publishing: Duxford, UK, 2018; pp. 387–438. [Google Scholar]

- Zhang, C.; Liu, M.; Meng, Z.; Zhang, Q.; Zhao, G.; Chen, L.; Zhang, H.; Wang, J. Microstructure evolution and precipitation characteristics of spray-formed and subsequently extruded 2195 Al-Li alloy plate during solution and aging process. J. Mater. Process. Technol. 2020, 283, 116718. [Google Scholar] [CrossRef]

- Mishra, S.; Suresh, M.; More, A.M.; Bisht, A.; Nayan, N.; Suwas, S. Texture control to reduce yield strength anisotropy in the third generation aluminum-copper-lithium alloy: Experiments and modeling. Mater. Sci. Eng. A 2021, 799, 140047. [Google Scholar] [CrossRef]

- Cheng, W.; Jin, Z.; Youping, Y.; Chunnan, Z. Effect of Pretreatment and Cryogenic Temperatures on Mechanical Properties and Microstructure of Al-Cu-Li Alloy. Materials 2021, 14, 4873. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.; Zhan, L.; Liu, C.; Wang, Q.; Li, H.; Liu, D.; Hu, Z. Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy. J. Alloys Compd. 2019, 790, 8–19. [Google Scholar] [CrossRef]

- Wang, X.-M.; Shao, W.-Z.; Jiang, J.-T.; Li, G.-A.; Wang, X.-Y.; Zhen, L. Quantitative analysis of the influences of pre-treatments on the microstructure evolution and mechanical properties during artificial ageing of an Al-Cu-Li-Mg-Ag alloy. Mater. Sci. Eng. A 2020, 782, 139253. [Google Scholar] [CrossRef]

- Araullo-Peters, V.; Gault, B.; Geuser, F.D.; Deschamps, A.; Cairney, J.M. Microstructural evolution during ageing of Al-Cu-Li-x alloys. Acta Mater. 2014, 66, 199–208. [Google Scholar] [CrossRef]

| Cu | Li | Mg | Ag | Zr | Fe | Si | Zn | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 3.77 | 1.16 | 0.46 | 0.31 | 0.13 | 0.08 | 0.06 | 0.008 | 0.001 | 0.001 | Bal |

| Blank Dimensions (mm) | Forming Temperature T (°C) | Mandrel Speed n (r/min) | Feed Rate f (mm/r) | Reduction Rate ψ (%) |

|---|---|---|---|---|

| φ200 × 20 | 300 | 140 | 1.07 | 82.5 |

| Samples | Difference of the Second Phases |

|---|---|

| AN | The mixture of Al2Cu and Al7Cu4Li phases |

| A350 | Mainly based on θ’ phase |

| A510 | Uniform distribution of Al3Zr dispersoid |

| A400 | The mixture of Al3Zr and Al7Cu4Li phases |

| Parts | UTS/MPa | YS/MPa | EI/% |

|---|---|---|---|

| PAN | 555 ± 3 | 528 ± 4 | 9.1 ± 0.3 |

| PA350 | 560 ± 5 | 530 ± 12 | 11.0 ± 0.4 |

| PA510 | 588 ± 7 | 564 ± 8 | 11.3 ± 0.5 |

| PA400 | 568 ± 4 | 543 ± 11 | 9.3 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, H.; Shi, D.; Zheng, Y.; Zhang, J. Effect of the Second Phases on Composite Spinning-Extrusion Forming and Mechanical Properties of Al–Cu–Li Alloy. Materials 2023, 16, 3573. https://doi.org/10.3390/ma16093573

Zeng H, Shi D, Zheng Y, Zhang J. Effect of the Second Phases on Composite Spinning-Extrusion Forming and Mechanical Properties of Al–Cu–Li Alloy. Materials. 2023; 16(9):3573. https://doi.org/10.3390/ma16093573

Chicago/Turabian StyleZeng, Huaqiang, Dongfeng Shi, Ying Zheng, and Jin Zhang. 2023. "Effect of the Second Phases on Composite Spinning-Extrusion Forming and Mechanical Properties of Al–Cu–Li Alloy" Materials 16, no. 9: 3573. https://doi.org/10.3390/ma16093573

APA StyleZeng, H., Shi, D., Zheng, Y., & Zhang, J. (2023). Effect of the Second Phases on Composite Spinning-Extrusion Forming and Mechanical Properties of Al–Cu–Li Alloy. Materials, 16(9), 3573. https://doi.org/10.3390/ma16093573