Microstructure Evolution and Mechanical Response of a Direct Quenched and Partitioned Steel at Different Finishing Rolling Temperatures

Abstract

1. Introduction

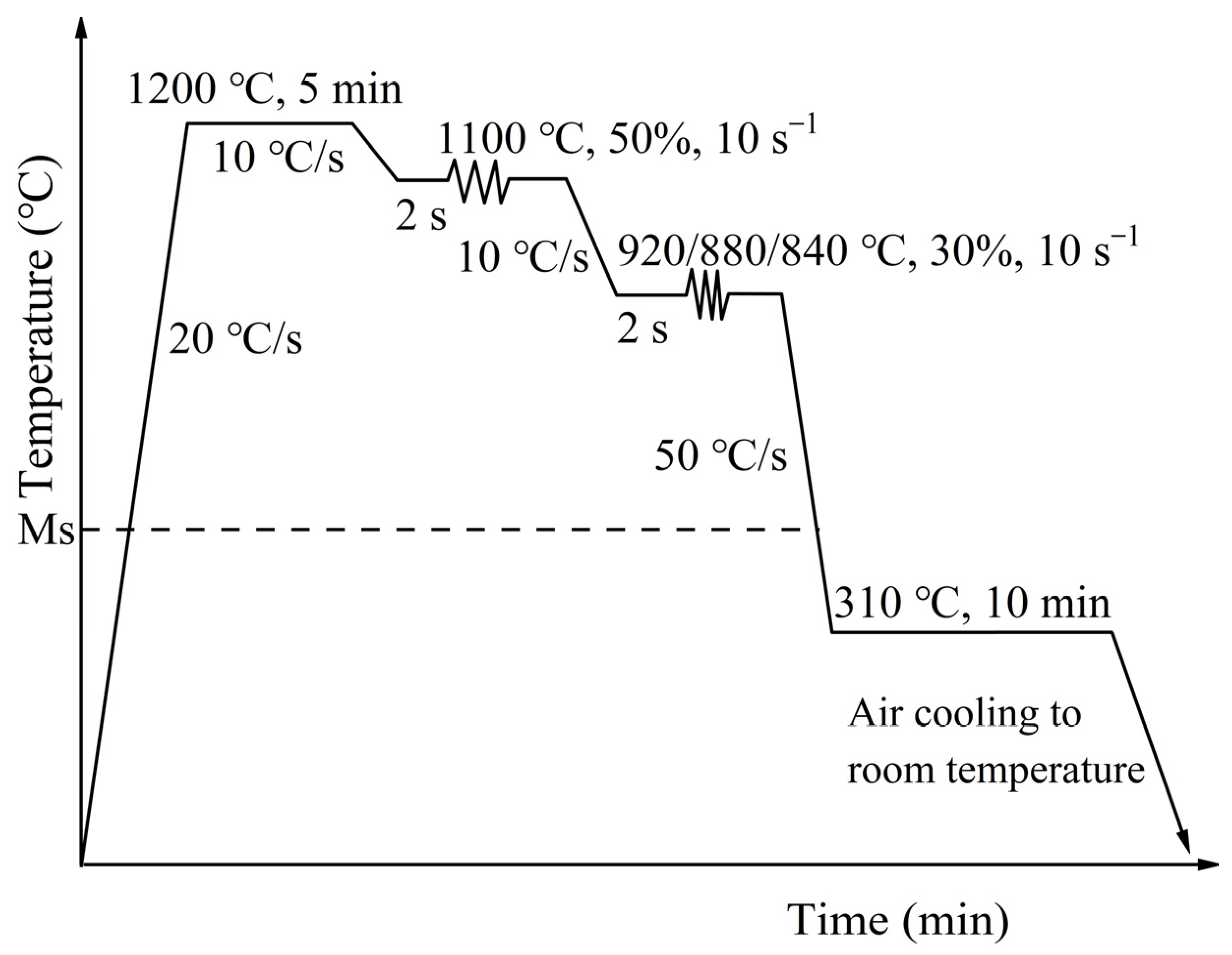

2. Experimental Material and Method

3. Results and Discussion

3.1. Mechanical Properties

3.2. Flow Behavior under Double-Passes Hot Deformation

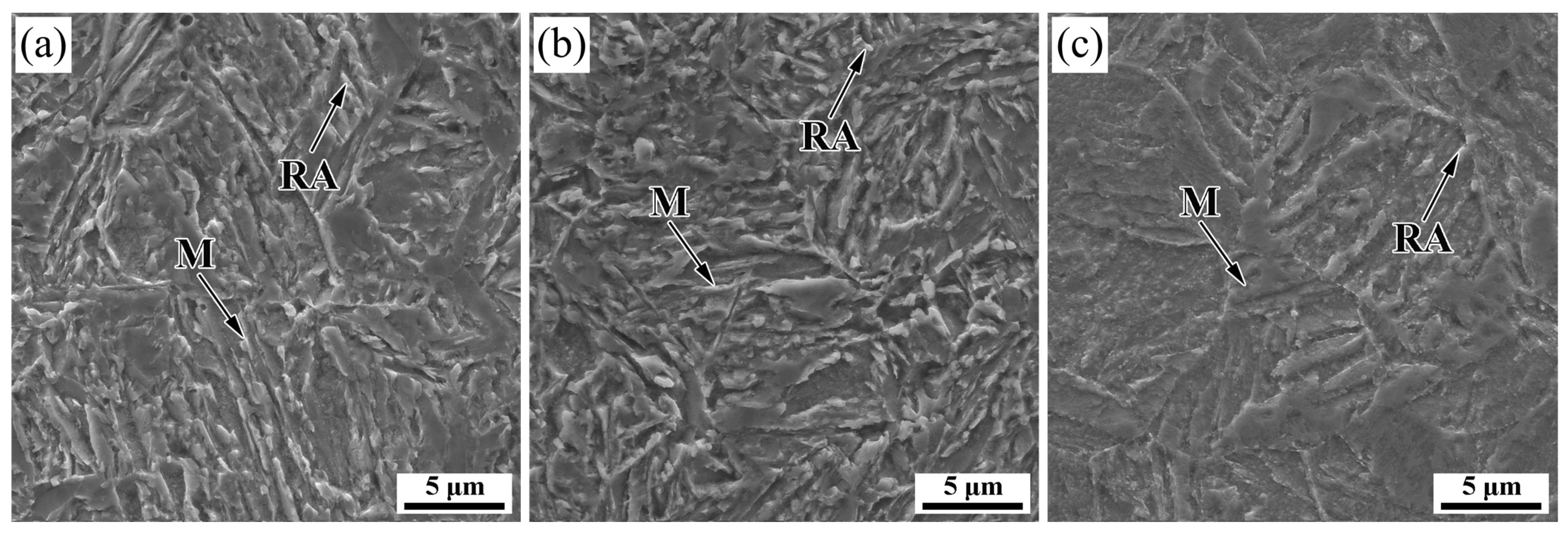

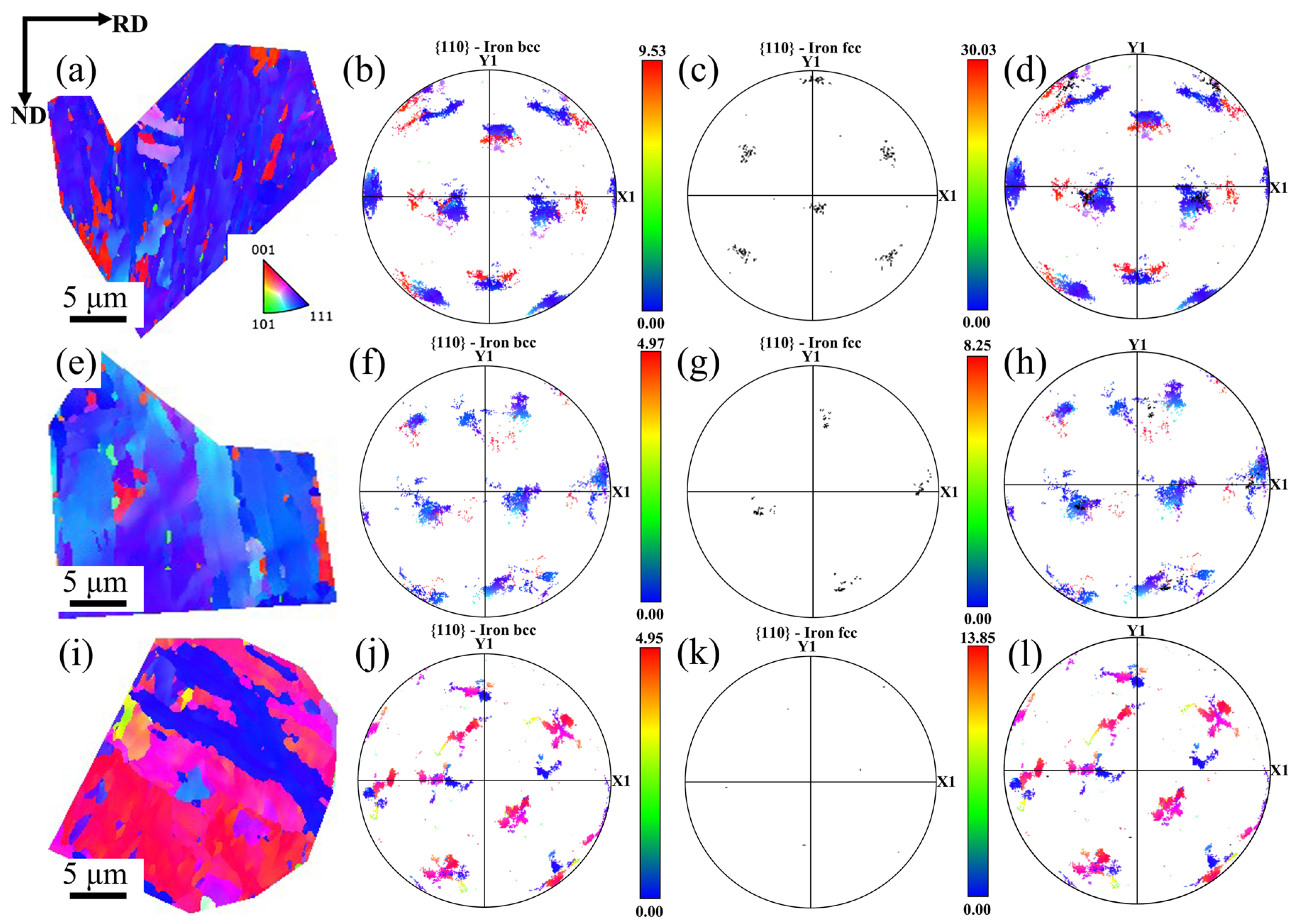

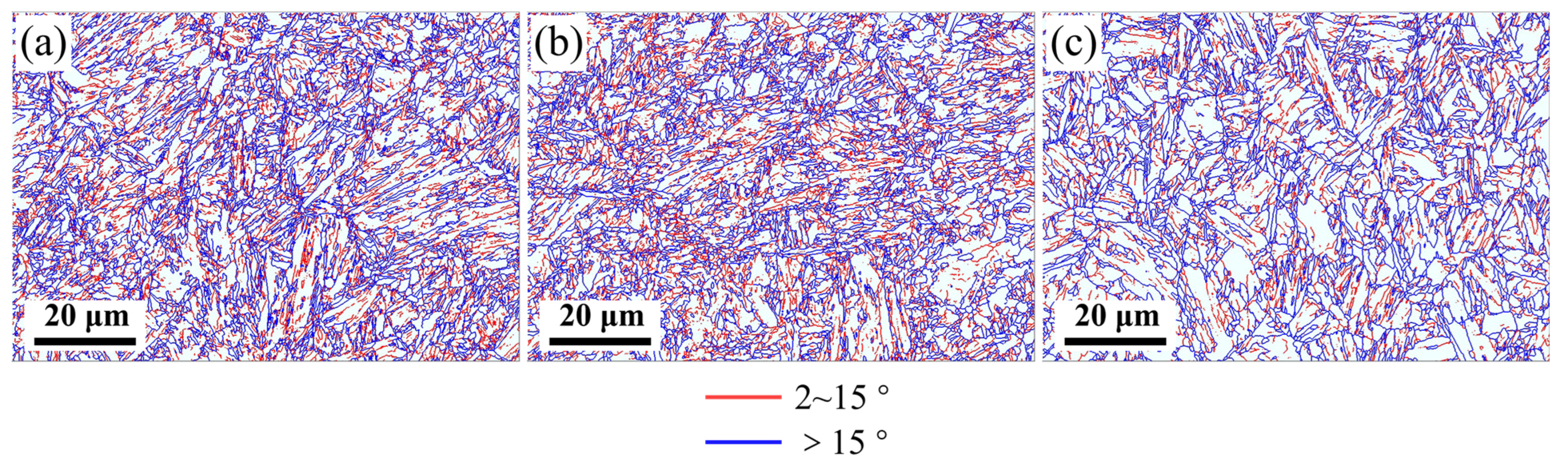

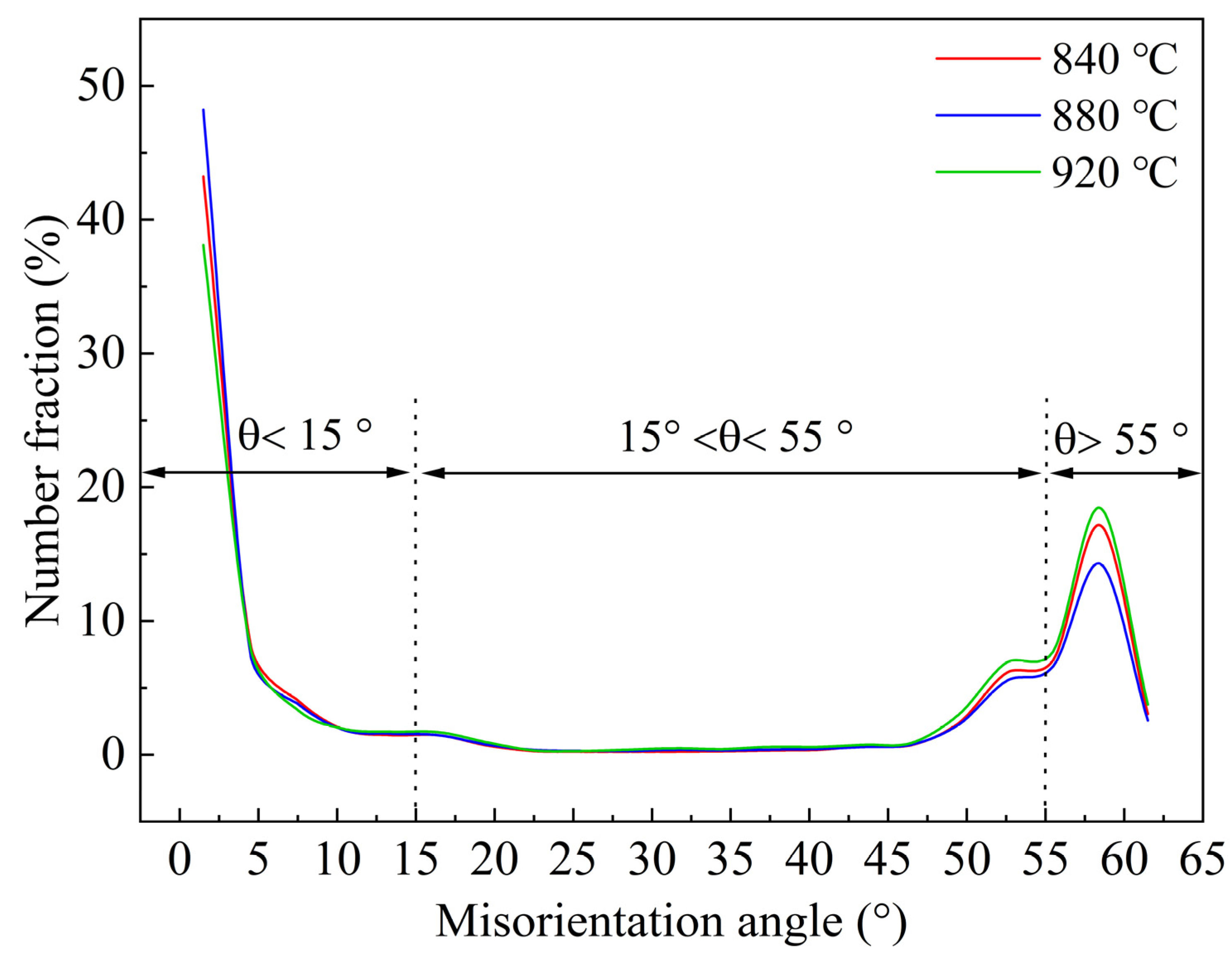

3.3. Microstructure Characteristics

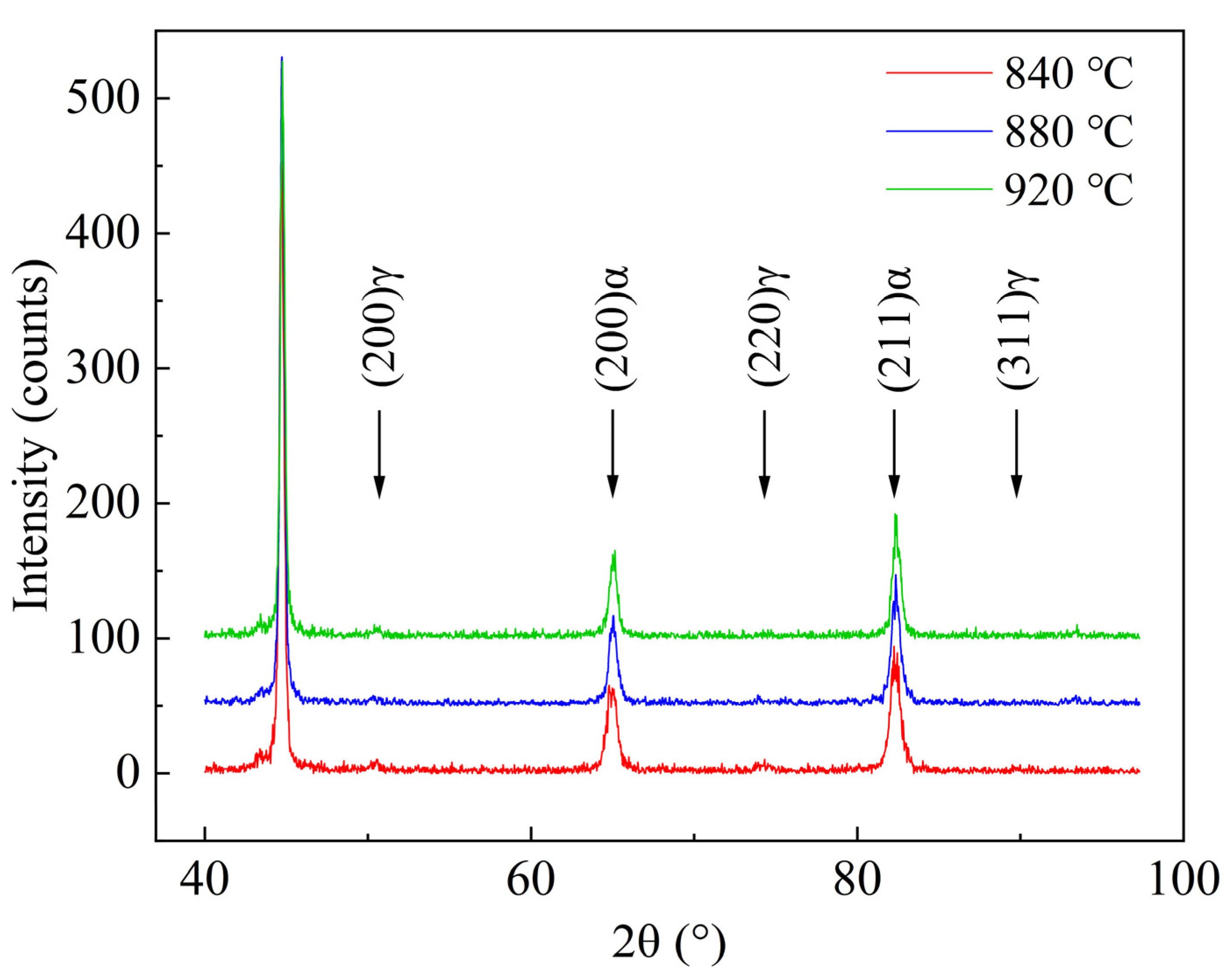

3.4. RA Analysis

4. Conclusions

- (1)

- Compared with Q&P steel with similar compositions, relatively excellent comprehensive mechanical properties can be obtained by DQ&P processes. The strength and total elongation of a low-carbon DQ&P steel were significantly improved after finishing rolling at 840 °C.

- (2)

- With the decrease of finishing rolling temperature from 920 °C to 840 °C, the strength and total elongation increased. High-yield strength of 1121 MPa, high tensile strength of 1134 MPa, and 11.7% total elongation at 840 °C were achieved.

- (3)

- With the decrease of finishing temperature, the lath martensite became finer, and the RA fraction increased. Grain refinement and higher dislocation density contributed to carbon partitioning, leading to the higher stability of RA at a lower finishing temperature.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Speer, J.; Edmonds, D.; Rizzo, F.; Matlock, D. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid State Mater. Sci. 2004, 8, 219–237. [Google Scholar] [CrossRef]

- Speer, J.; De Moor, E.; Findley, K.; Matlock, D.; De Cooman, B.; Edmonds, D. Analysis of Microstructure Evolution in Quenching and Partitioning Automotive Sheet Steel. Metall. Mater. Trans. A 2011, 42, 3591–3601. [Google Scholar] [CrossRef]

- Liu, S.; Dong, S.; Yang, F.; Li, L.; Hu, B.; Xiao, F.; Chen, Q.; Liu, H. Application of quenching–partitioning–tempering process and modification to a newly designed ultrahigh carbon steel. Mater. Des. 2014, 56, 37–43. [Google Scholar] [CrossRef]

- Liu, M.; Wang, J.; Zhang, Q.; Hu, H.; Xu, G. Optimized Properties of a Quenching and Partitioning Steel by Quenching at Fine Martensite Start Temperature. Met. Mater. Int. 2021, 27, 2473–2480. [Google Scholar] [CrossRef]

- Guan, J.; Liu, M.; Tian, J.; Chen, Z.; Xu, G. Effects of Isothermal Transformation at the Quenching Temperature on the Microstructure and Mechanical Properties of a Medium-Carbon Steel. Trans. Indian Inst. Met. 2021, 74, 3265–3272. [Google Scholar] [CrossRef]

- Kantanen, P.; Somani, M.; Kaijalainen, A.; Haiko, O.; Porter, D.; Kömi, J. Microstructural Characterization and Mechanical Properties of Direct Quenched and Partitioned High-Aluminum and High-Silicon Steels. Metals 2019, 9, 2–17. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Wang, J.; Yang, Y.; Wang, H.; Lv, N.; Nan, J. Simultaneous increase of ultimate tensile strength and uniform elongation of 30Si2MnCrMoVE ultrahigh strength steel by hot deformation direct quenching and partitioning. J. Mater. Res. Technol. 2022, 19, 404–417. [Google Scholar] [CrossRef]

- Thomas, G.; Speer, J.; Matlock, D. Quenched and partitioned microstructures produced via Gleeble simulations of hot-strip mill cooling practices. Metall. Mater Trans A 2011, 42, 3652–3659. [Google Scholar] [CrossRef]

- Jirková, H.; Mašek, B.; Wagner, M.; Langmajerová, D.; Kučerová, L.; Treml, R.; Kiener, D. Influence of metastable retained austenite on macro and micromechanical properties of steel processed by the Q&P process. J. Alloys Compd. 2014, 615, S163–S168. [Google Scholar]

- Tan, X.; Xu, Y.; Ponge, D.; Yang, X.; Hu, Z.; Peng, F.; Ju, X.; Wu, D.; Raabe, D. Effect of intercritical deformation on microstructure and mechanical properties of a low-silicon aluminum-added hot-rolled directly quenched and partitioned steel. Mater. Sci. Eng. A 2016, 656, 200–215. [Google Scholar] [CrossRef]

- Tan, X.; Xu, Y.; Yang, X.; Hu, Z.; Peng, F.; Ju, X.; Wu, D. Austenite stabilization and high strength-elongation product of a low silicon aluminum-free hot-rolled directly quenched and dynamically partitioned steel. Mater. Charact. 2015, 104, 23–30. [Google Scholar] [CrossRef]

- Tan, X.; Xu, Y.; Yang, X.; Liu, Z.; Wu, D. Effect of partitioning procedure on microstructure and mechanical properties of a hot-rolled directly quenched and partitioned steel. Mater. Sci. Eng. A 2014, 594, 149–160. [Google Scholar] [CrossRef]

- Liu, H.; Lu, X.; Jin, X.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Scripta Mater. 2011, 64, 749–752. [Google Scholar] [CrossRef]

- Somani, M.; Pentti Karjalainen, L.; Porter, D.; Misra, D. Evaluation of the Behaviour and Properties of a High-Si Steel Processed Using Direct Quenching and Partitioning. Mater. Sci. Forum 2012, 706–709, 2824–2829. [Google Scholar] [CrossRef]

- Parthibana, R.; Chowdhury, S.; Harikumar, K.; Sankaran, S. Evolution of microstructure and its influence on tensile properties in thermo-mechanically controlled processed (TMCP) quench and partition (Q&P) steel. Mater. Sci. Eng. A 2017, 705, 376–384. [Google Scholar]

- Ostash, O.; Kulyk, V.; Poznyakov, D.; Gaivorons’kyi, O.; Vira, V. Influence of the modes of heat treatment on the strength and cyclic crack-growth resistance of 65G steel. Mater. Sci. 2019, 54, 776–782. [Google Scholar] [CrossRef]

- Seo, E.; Cho, L.; De Cooman, B. Kinetics of the partitioning of carbon and substitutional alloying elements during quenching and partitioning (Q&P) processing of medium Mn steel. Acta Mater. 2016, 107, 354–365. [Google Scholar]

- Su, Y.; Chiu, L.; Chuang, T.; Chuang, T.; Huang, C.; Wu, C.; Liao, K. Retained austenite amount determination comparison in JIS SKD11 steel using quantitative metallography and X-ray diffraction methods. Adv. Mat. Res. 2012, 482, 1165–1168. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H. Microstructure development and mechanical properties of quenching and partitioning (Q&P) steel and an incorporation of hot-dipping galvanization during Q&P process. Mater. Sci. Eng. A 2013, 586, 100–107. [Google Scholar]

- Karam-Abian, M.; Zarei-Hanzaki, A.; Abedi, H.; Heshmati-Manesh, S. Micro and macro mechanical behavior of a transformation-induced plasticity steel developed by thermomechanical processing followed by quenching and partitioning. Mater. Sci. Eng. A 2016, 651, 233–240. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Mater. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Williamson, G.; Smallman, R., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. J. Theor. Appl. Phys. 1955, 13, 34–46. [Google Scholar] [CrossRef]

- Wolf, L.; Nürnberger, F.; Rodman, D.; Maier, H. 1-Step “Quenching and Partitioning” of the Press-Hardening Steel 22MnB5. Steel Res. Int. 2016, 87, 9999. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H. On factors affecting the phase transformation and mechanical properties of cold-rolled transformation-induced-plasticity-aided steel. Metall. Mater. Trans. 2008, 39, 2513–2527. [Google Scholar] [CrossRef]

- Kang, S.; Speer, J.; Krizan, D.; Matlock, D.; Moor, E. Prediction of tensile properties of intercritically annealed Al-containing 0.19C-4.5Mn (wt%) TRIP steels. Mater. Des. 2016, 97, 138–146. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, S. Microstructure-property relationship in the quenching and partitioning (Q&P) steel. Mater. Charact. 2023, 196, 112561. [Google Scholar]

- Nie, X.; Dong, S.; Wang, F.; Jin, L.; Dong, J. Effects of holding time and Zener-Hollomon parameters on deformation behavior of cast Mg-8Gd-3Y alloy during double-pass hot compression. J. Mater. Sci. Technol. 2018, 34, 2035–2041. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Miura, H.; Sakai, T. Effect of initial microstructures on grain refinement in a stainless steel by large strain deformation. Acta Mater. 2003, 51, 847–861. [Google Scholar] [CrossRef]

- Qin, F.; Qi, H.; Liu, C.; Qi, H.; Meng, Z. Constitutive Characteristics, Microstructure, and Texture Evolution of As-Cast 42CrMo Alloy in Nonisothermal Multipass Compression. Adv. Mater. Sci. Eng. 2021, 2021, 6638505. [Google Scholar] [CrossRef]

- Ryan, N.; Mcqueen, H. Bar mill torsional simulation of 304 stainless steel. Can. Metall. Q. 1991, 30, 113–124. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xiao, Y.; Jiang, Y.; Pang, G.; Li, H.; Zhang, X.; Zhou, K. Spheroidization and dynamic recrystallization mechanisms of Ti-55511 alloy with bimodal microstructures during hot compression in α + β region. Mater. Sci. Eng. A 2020, 782, 139282. [Google Scholar] [CrossRef]

- Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L. Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Jacques, P.; Delannay, F.; Ladrière, J. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A. 2001, 32, 2759–2768. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Liu, M.; Hu, H.; Kern, M.; Lederhaas, B.; Xu, G.; Bernhard, C. Effect of integrated austempering and Q&P treatment on the transformation kinetics, microstructure and mechanical properties of a medium-carbon steel. Mater. Sci. Eng. A 2023, 869, 144780. [Google Scholar]

- Sun, X.; Li, Z.; Yong, Q.; Yang, Z.; Dong, H.; Weng, Y. Third generation high strength low alloy steels with improved toughness. Sci. China Technol. Sci. 2012, 55, 1797–1805. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Xu, Y.; Tan, X.; Yang, X.; Hu, Z.; Peng, F.; Wu, D.; Wang, G. Microstructure evolution and mechanical properties of a hot-rolled directly quenched and partitioned steel containing proeutectoid ferrite. Mater. Sci. Eng. A 2014, 607, 460–475. [Google Scholar] [CrossRef]

- Tu, X.; Shi, X.; Yan, W.; Changsheng, L.; Shi, Q.; Shan, Y.; Yang, K. Tensile deformation behavior of ferrite-bainite dual-phase pipeline steel. Mater. Sci. Eng. A 2022, 831, 142230. [Google Scholar] [CrossRef]

- Tian, J.; Xu, G.; Zhou, M.; Hu, H.; Xue, Z. Effects of Al addition on bainite transformation and properties of high-strength carbide-free bainitic steels. J. Iron Steel Res. Int. 2019, 26, 846–855. [Google Scholar] [CrossRef]

- Larzabal, G.; Isasti, N.; Rodriguez-Ibabe, J.; Uranga, P. Precipitation strengthening by induction treatment in high strength low carbon microalloyed hot-rolled plates. Metall. Mater. Trans. A. 2018, 49, 946–961. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Amano, Y.; Uranaka, S.; Masumura, T. Effect of Initial Austenite Grain Size on Microstructure Development and Mechanical Properties in a Medium-carbon Steel Treated with One-step Quenching and Partitioning. ISIJ Int. 2021, 61, 537–545. [Google Scholar] [CrossRef]

- Santofimia, M.; Nguyen-Minh, T.; Zhao, L.; Petrov, R.; Sabirov, I.; Sietsma, J. New low carbon Q&P steels containing film-like intercritical ferrite. Mater. Sci. Eng. A 2010, 527, 6429–6439. [Google Scholar]

- Zinsaz-Borujerdi, A.; Zarei-Hanzaki, A.; Abedi, H.; Karam-Abiana, M.; Ding, H.; Han, D.; Kheradmand, N. Room temperature mechanical properties and microstructure of a low alloyed TRIP-assisted steel subjected to one-step and two-step quenching and partitioning process. Mater. Sci. Eng. A 2018, 725, 341–349. [Google Scholar] [CrossRef]

- Seo, E.; Cho, L.; Estrin, Y.; De Cooman, B. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Li, Y.; Liu, D.; Chen, D.; Kang, J.; Wang, X.; Yuan, G.; Misra, R.; Wang, G. Response of retained austenite to quenching temperature in a novel low density Fe-Mn-Al-C steel processed by hot rolling-air cooling followed by non-isothermal partitioning. Mater. Sci. Eng. A 2019, 753, 197–207. [Google Scholar] [CrossRef]

- Liu, H.; Jin, X.; Dong, H.; Shi, J. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process. Mater. Charact. 2011, 62, 223–227. [Google Scholar] [CrossRef]

| C | Si | Mn | Ti | N | Al | S | P |

|---|---|---|---|---|---|---|---|

| 0.21 | 1.8 | 2.03 | 0.017 | 0.004 | 0.04 | 0.002 | 0.015 |

| Temperature (°C) | 840 | 880 | 920 |

|---|---|---|---|

| Volume fraction of retained austenite (%) | 5.90 | 4.30 | 3.01 |

| Carbon content (%) | 1.51 | 1.48 | 1.41 |

| Dislocation density (m−2) | 2.06 × 1016 | 1.41 × 1016 | 1.23 × 1016 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Gan, X.; Liang, W.; Xu, G.; Qi, J.; Liu, M. Microstructure Evolution and Mechanical Response of a Direct Quenched and Partitioned Steel at Different Finishing Rolling Temperatures. Materials 2023, 16, 3575. https://doi.org/10.3390/ma16093575

Liu Y, Gan X, Liang W, Xu G, Qi J, Liu M. Microstructure Evolution and Mechanical Response of a Direct Quenched and Partitioned Steel at Different Finishing Rolling Temperatures. Materials. 2023; 16(9):3575. https://doi.org/10.3390/ma16093575

Chicago/Turabian StyleLiu, Yajun, Xiaolong Gan, Wen Liang, Guang Xu, Jianghua Qi, and Man Liu. 2023. "Microstructure Evolution and Mechanical Response of a Direct Quenched and Partitioned Steel at Different Finishing Rolling Temperatures" Materials 16, no. 9: 3575. https://doi.org/10.3390/ma16093575

APA StyleLiu, Y., Gan, X., Liang, W., Xu, G., Qi, J., & Liu, M. (2023). Microstructure Evolution and Mechanical Response of a Direct Quenched and Partitioned Steel at Different Finishing Rolling Temperatures. Materials, 16(9), 3575. https://doi.org/10.3390/ma16093575