Numerical Simulation and Experimental Analysis on Seam Feature Size and Deformation for T-Joint Laser–GMAW Hybrid Welding

Abstract

:1. Introduction

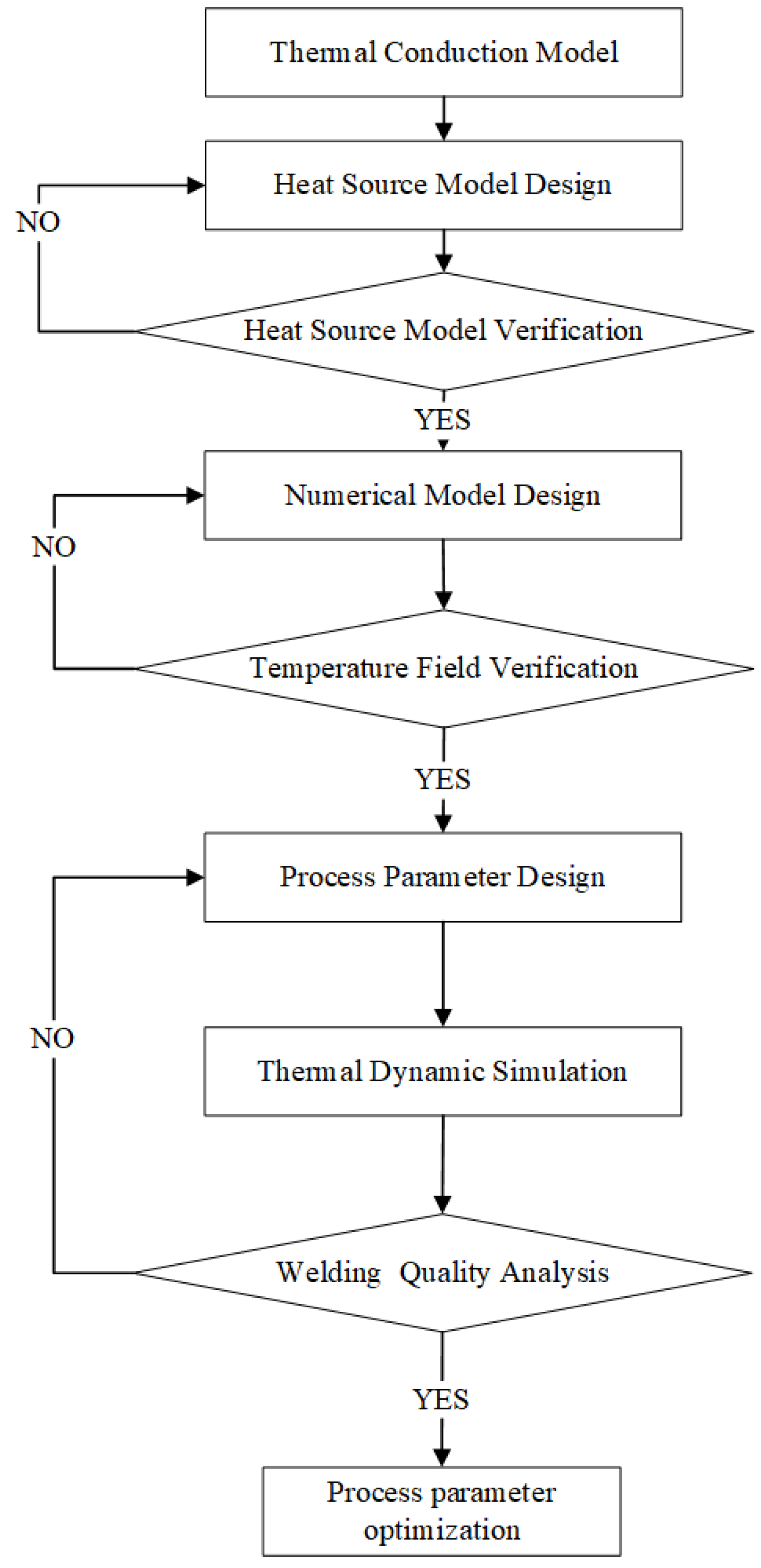

2. Methods of Simulation and Experiment

2.1. Simulation Model

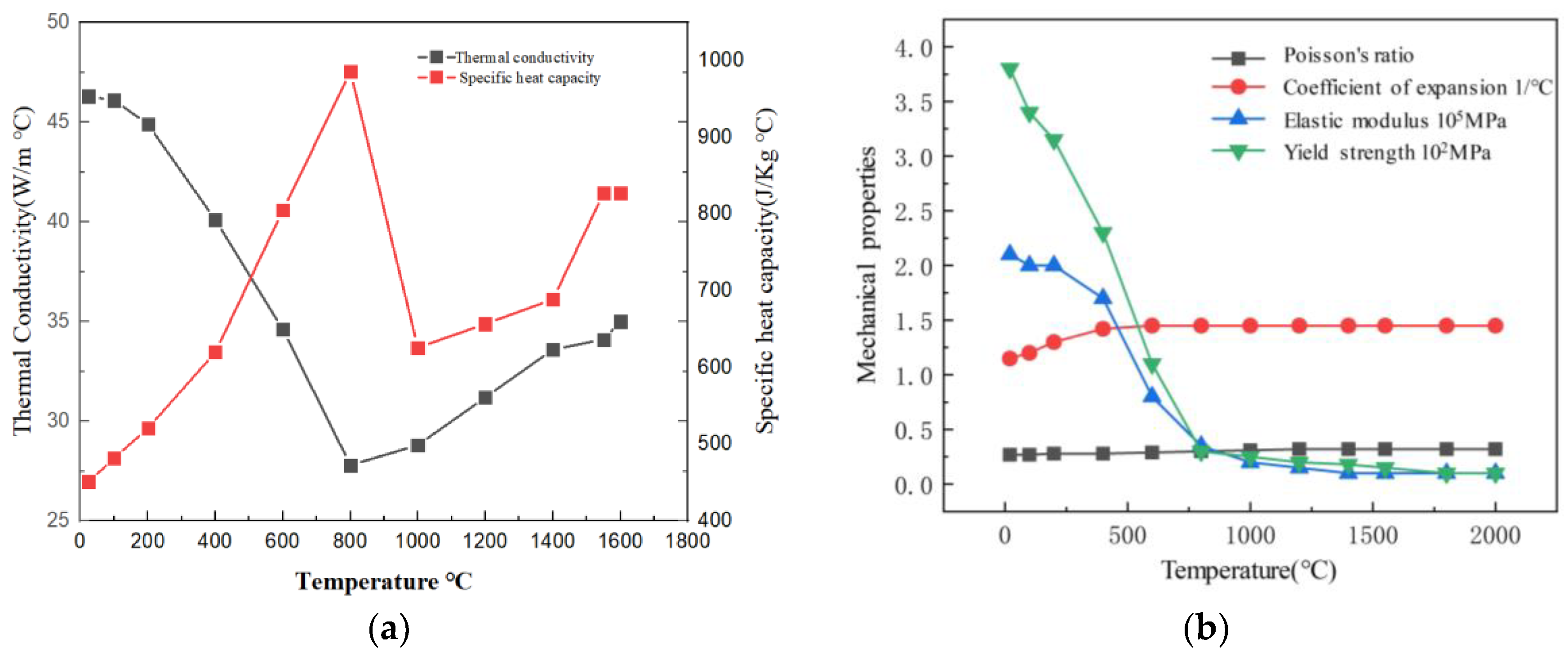

2.1.1. Thermal Conduction Model

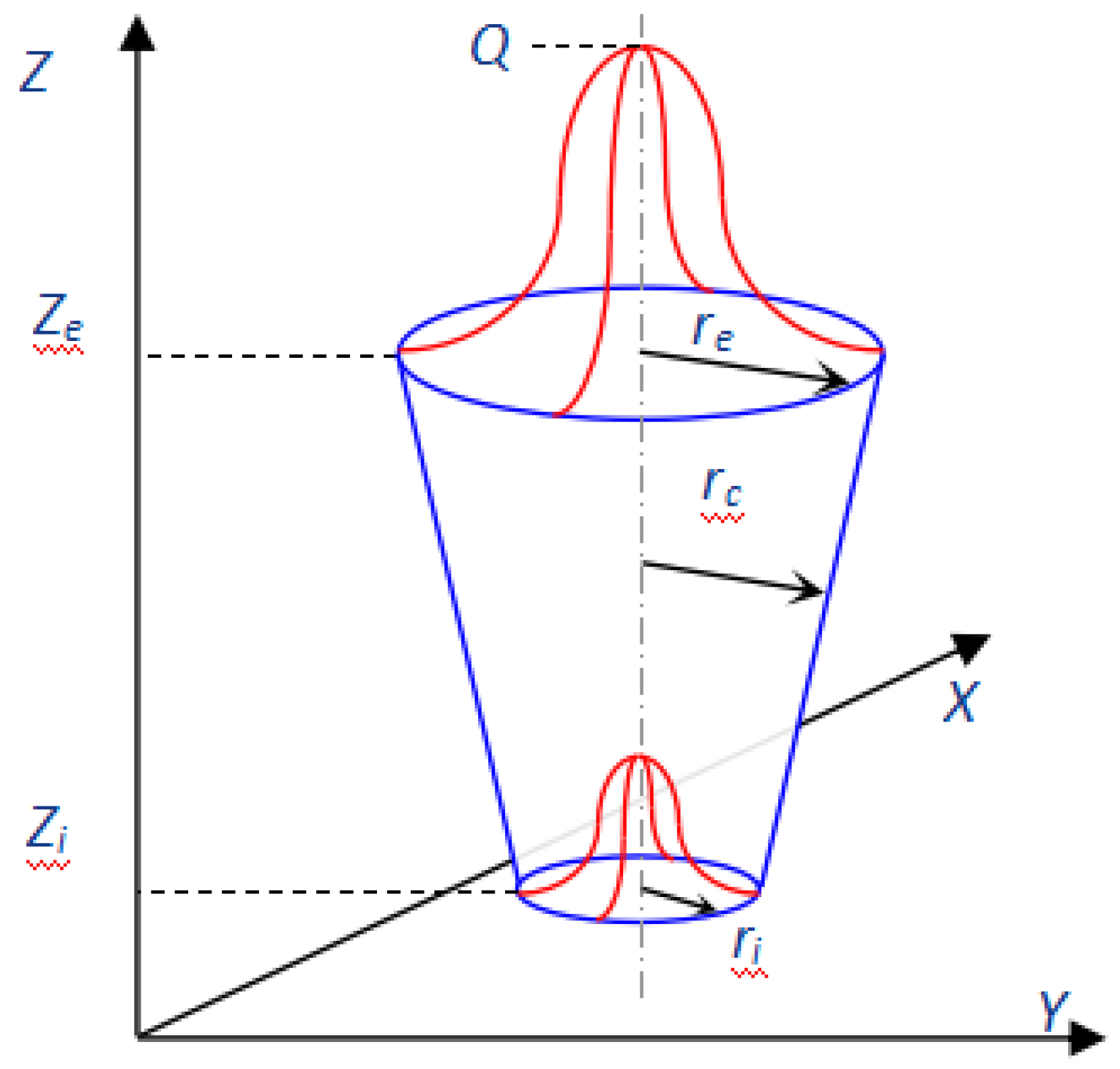

2.1.2. Heat Source Model

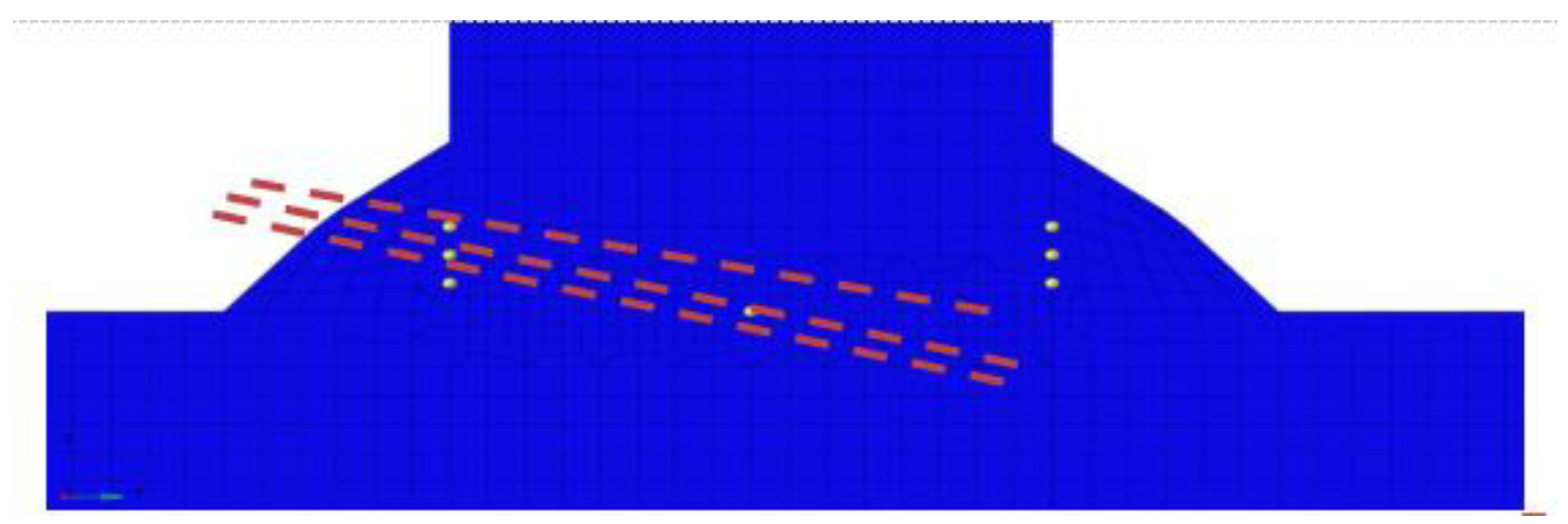

2.1.3. Numerical Model

2.2. Experimental Setup

2.2.1. Experimental Parameters

2.2.2. Experimental Design

3. Results and Discussions

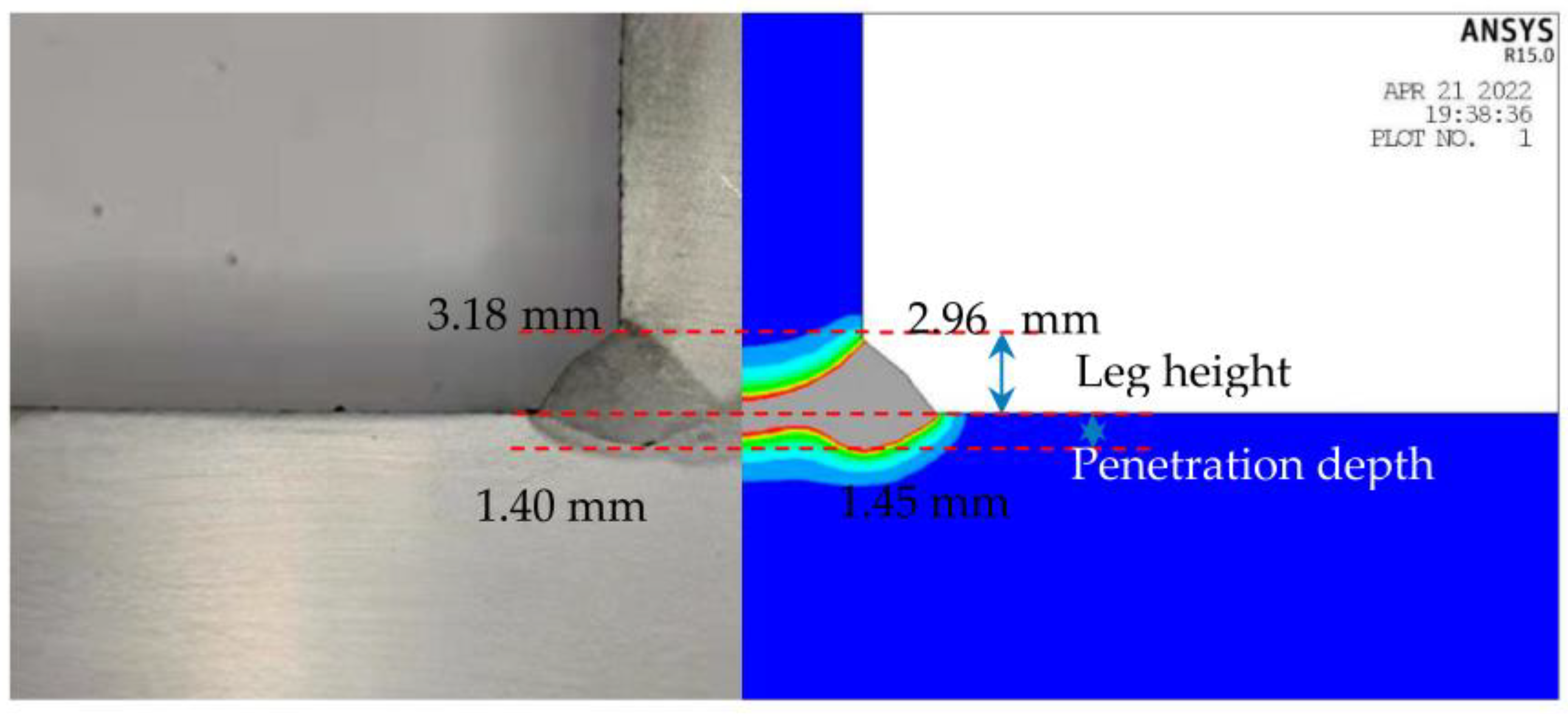

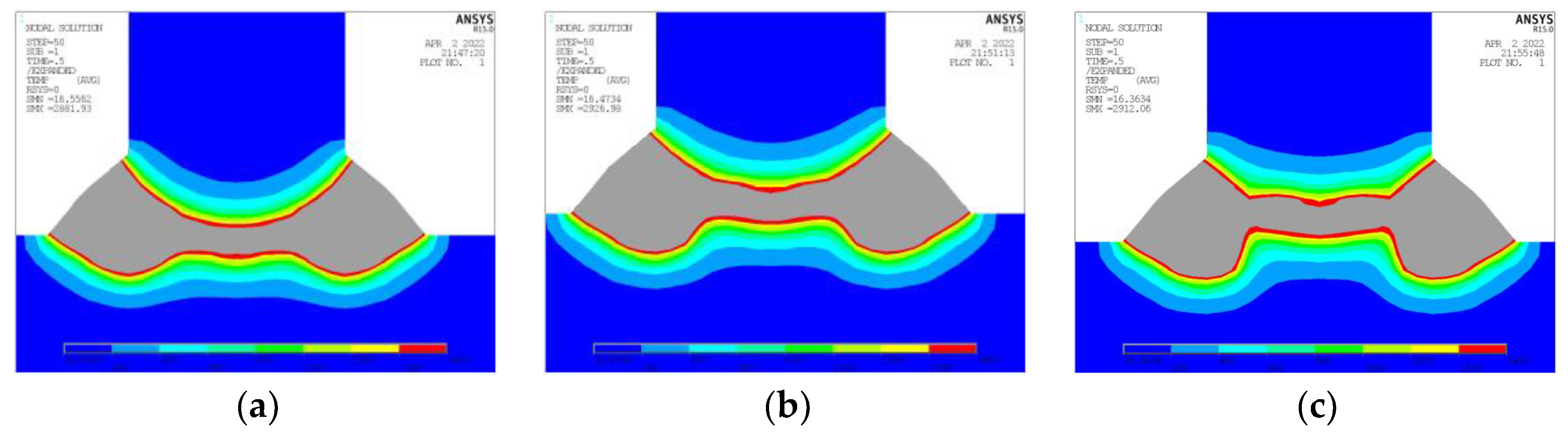

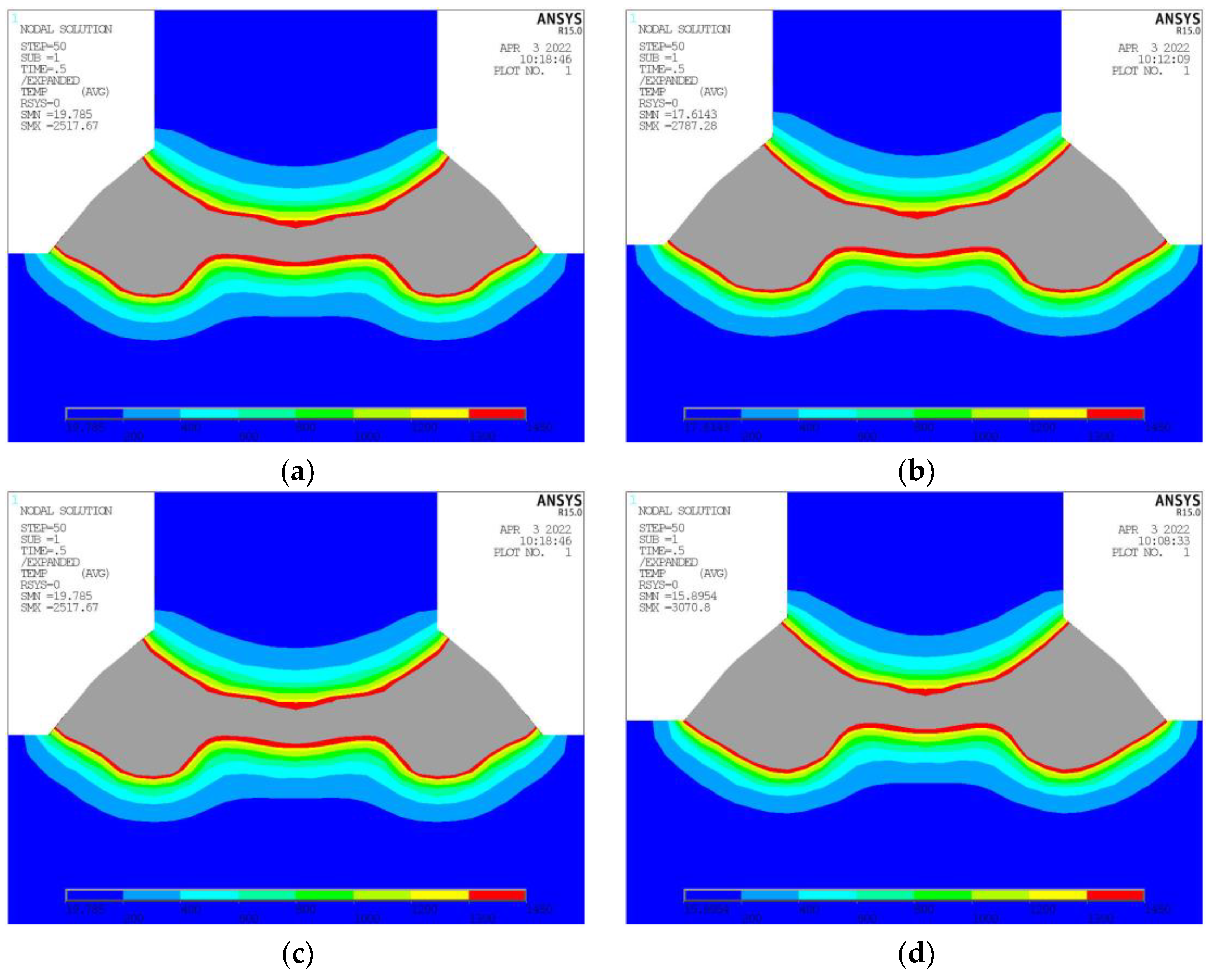

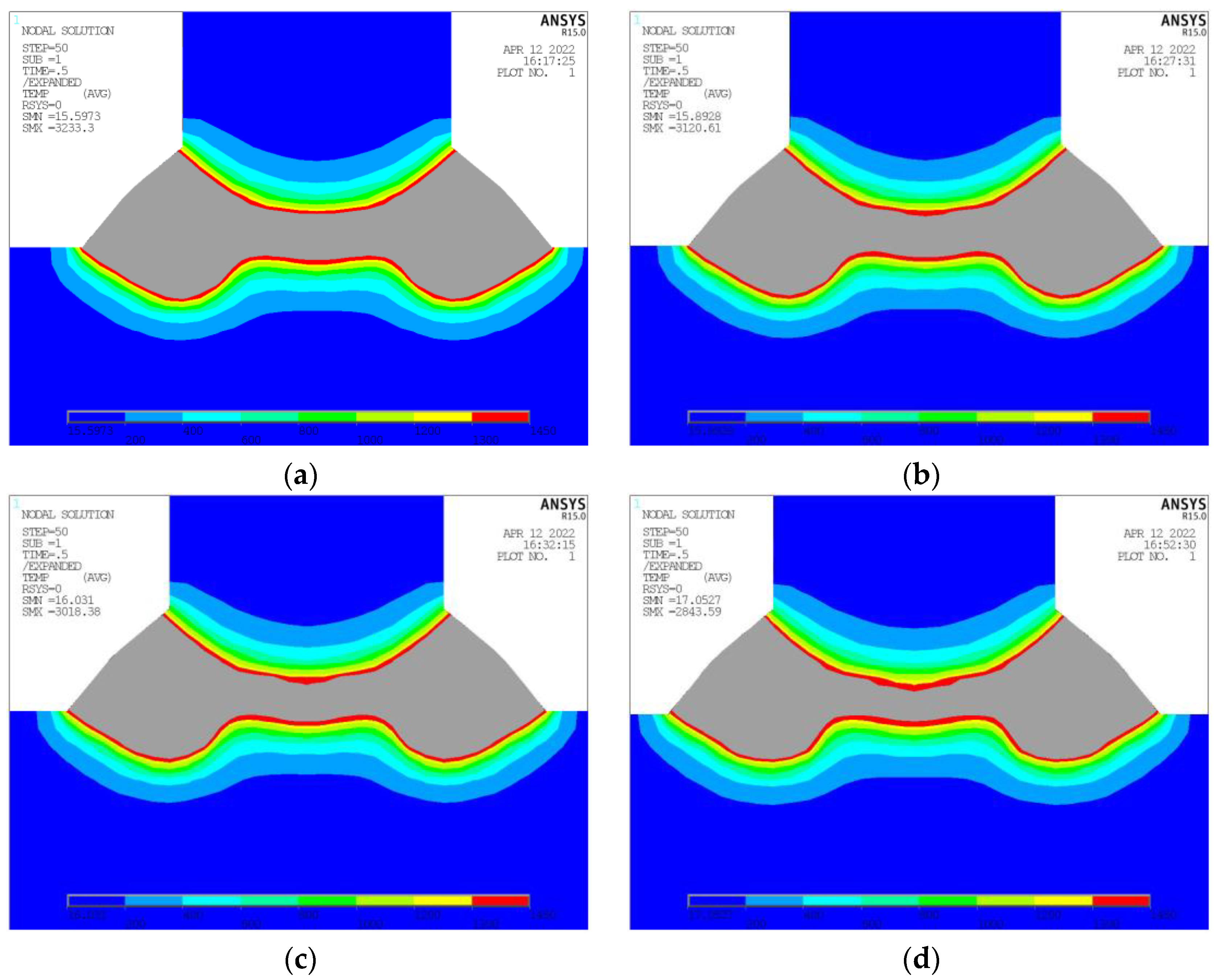

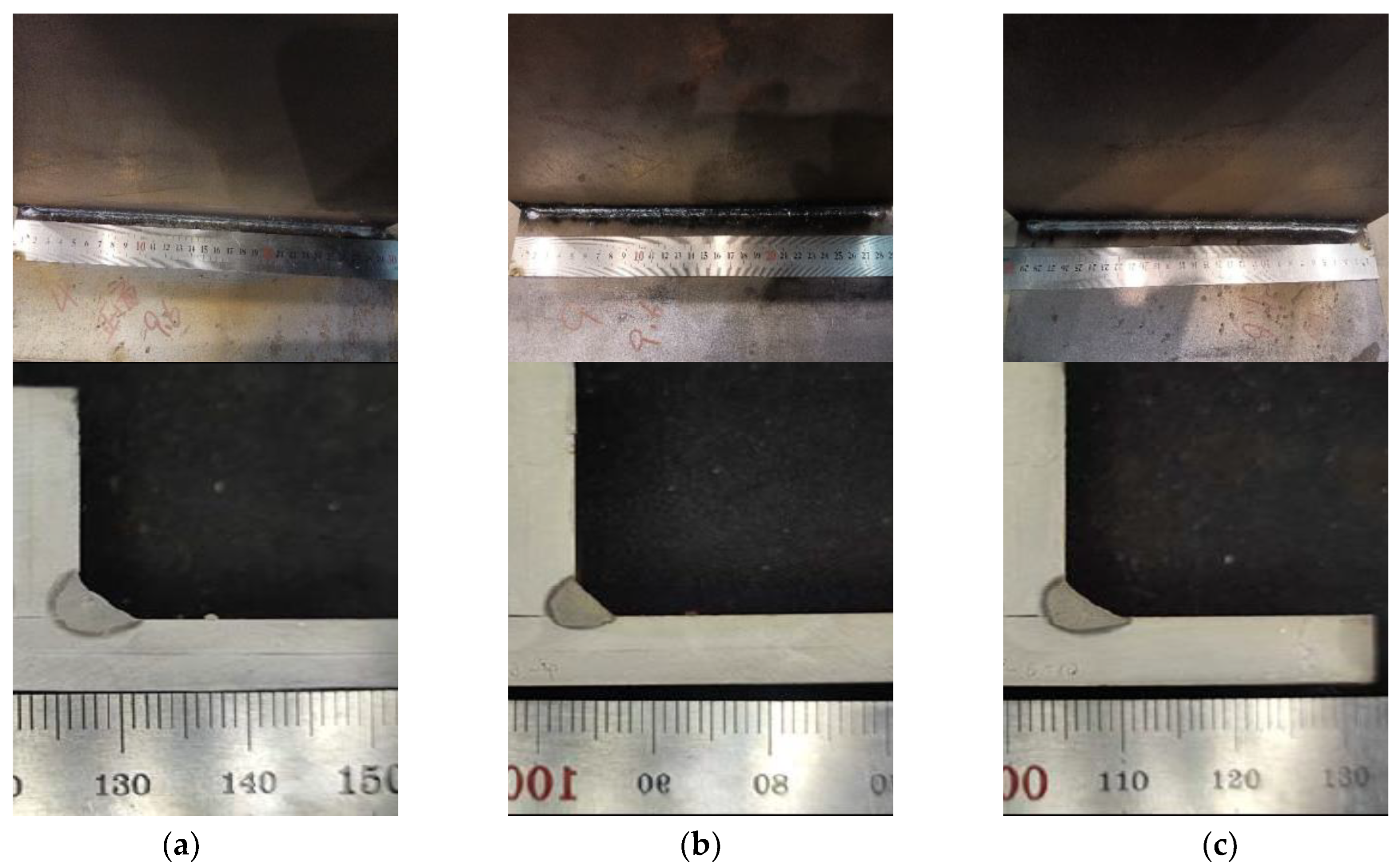

3.1. Verification of Heat Source Model

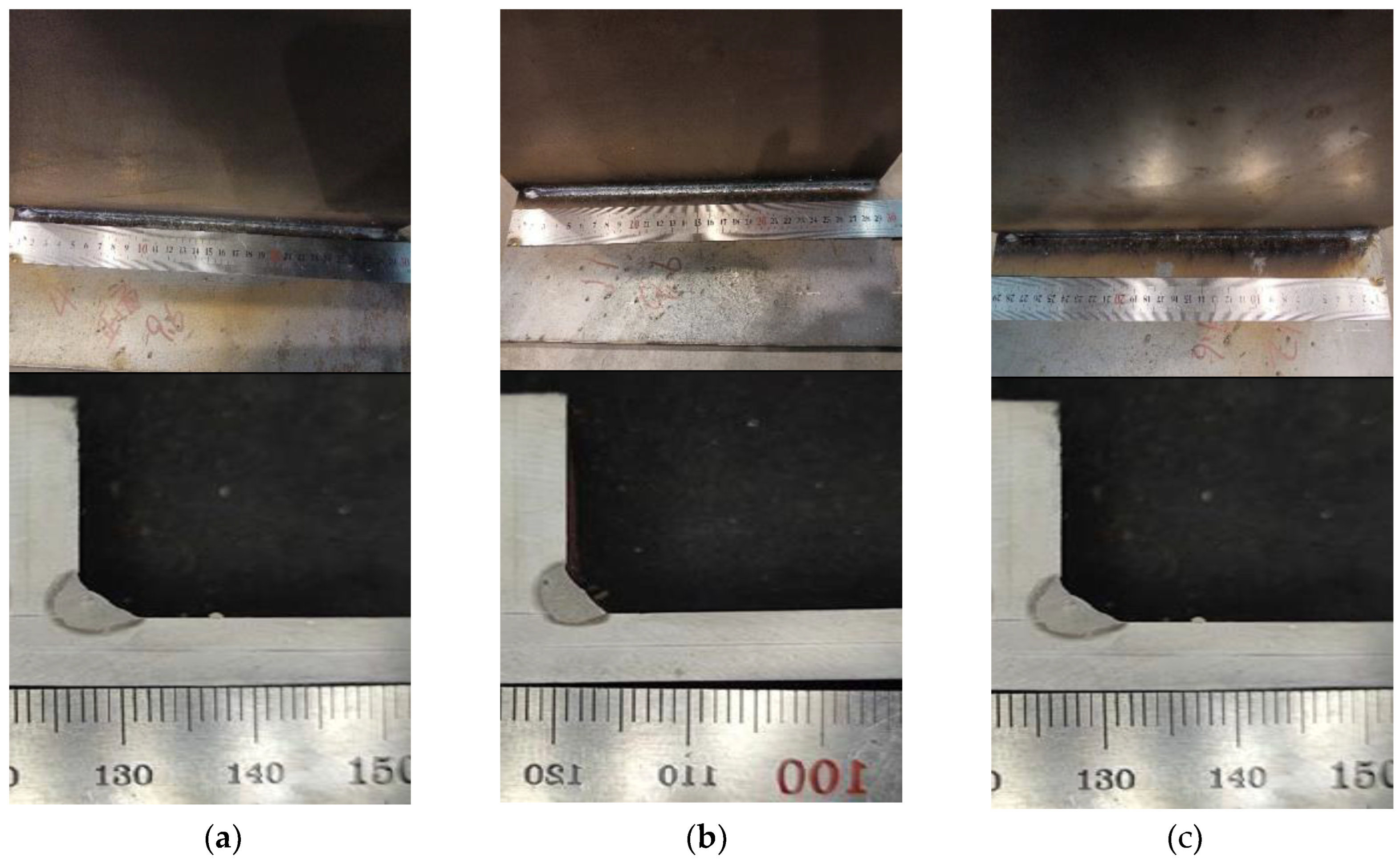

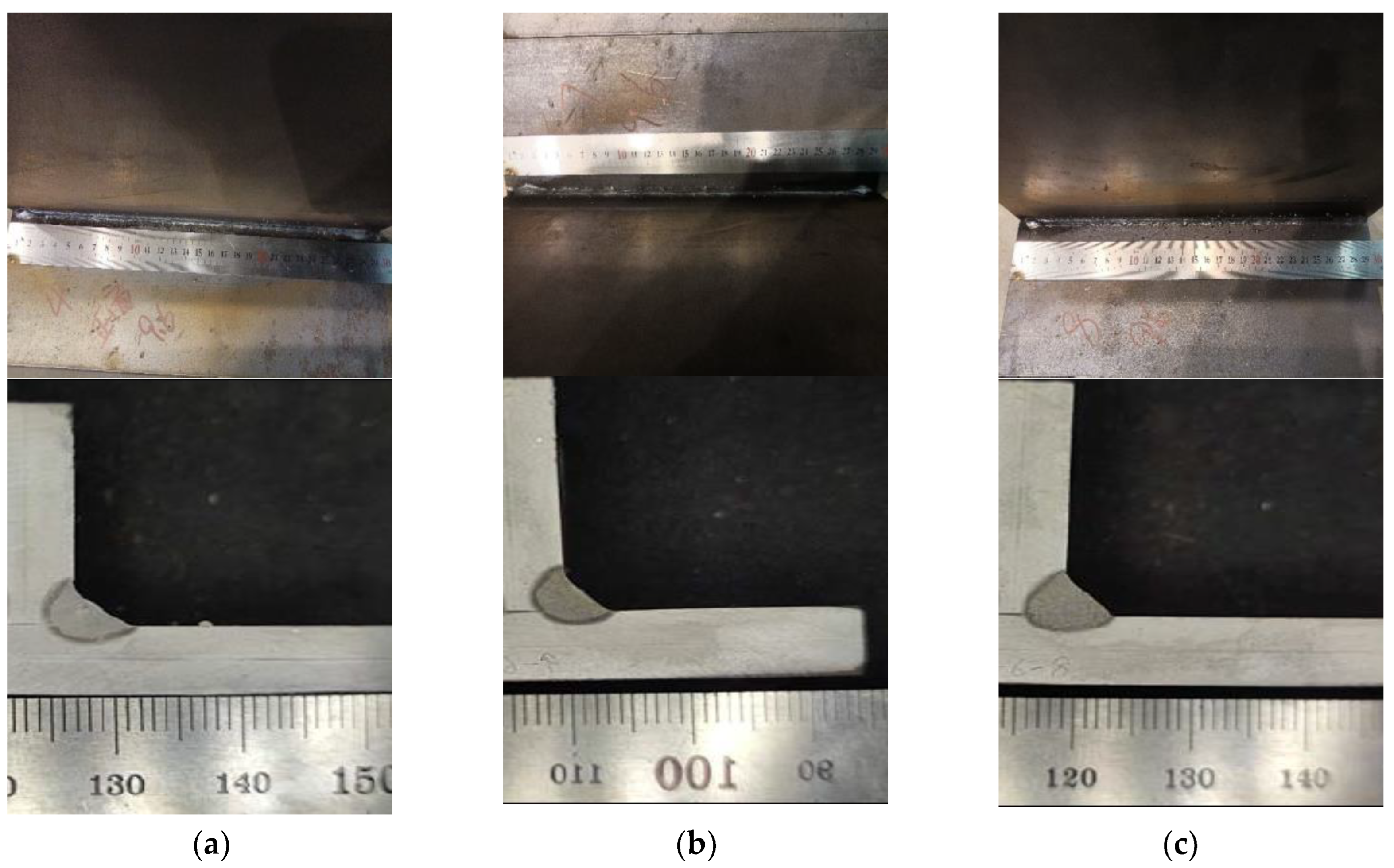

3.2. Effects of Incident Position

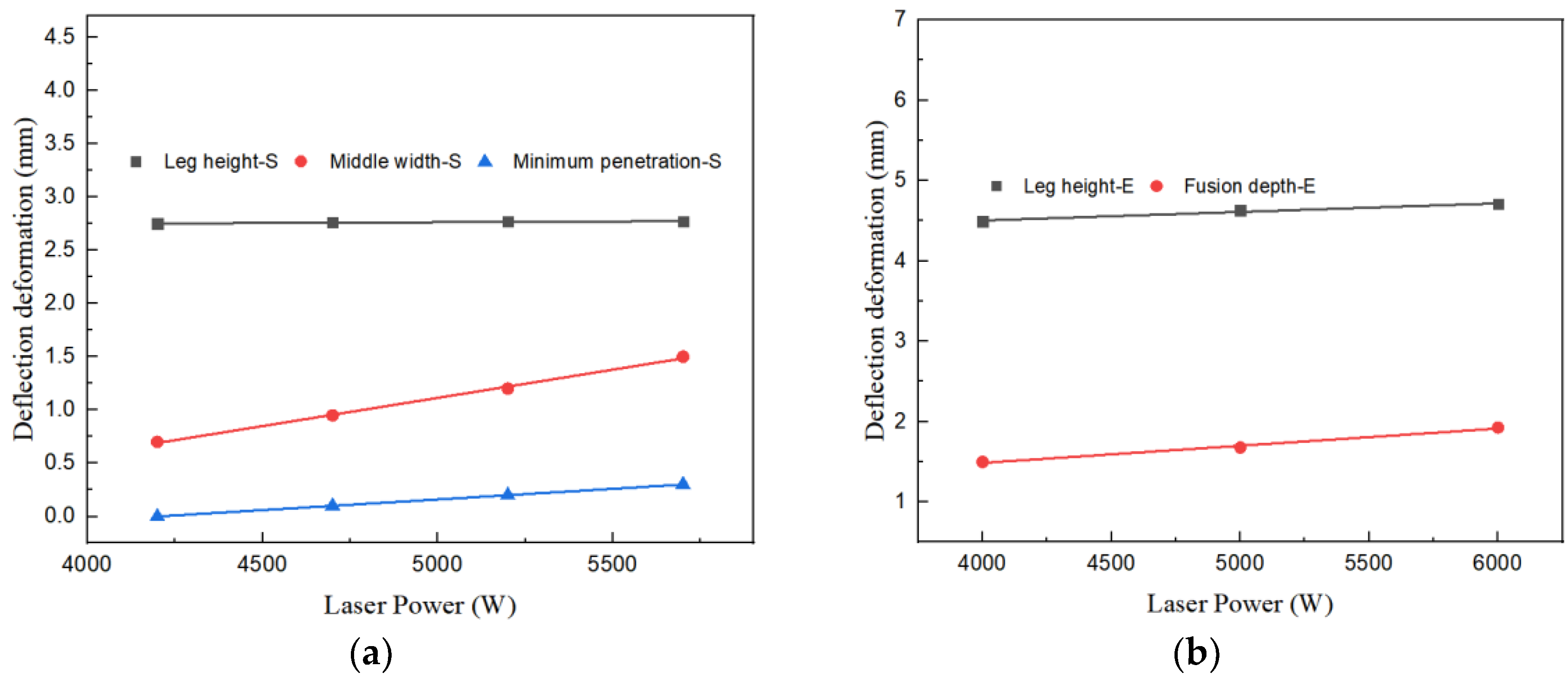

3.3. Effects of Laser Power

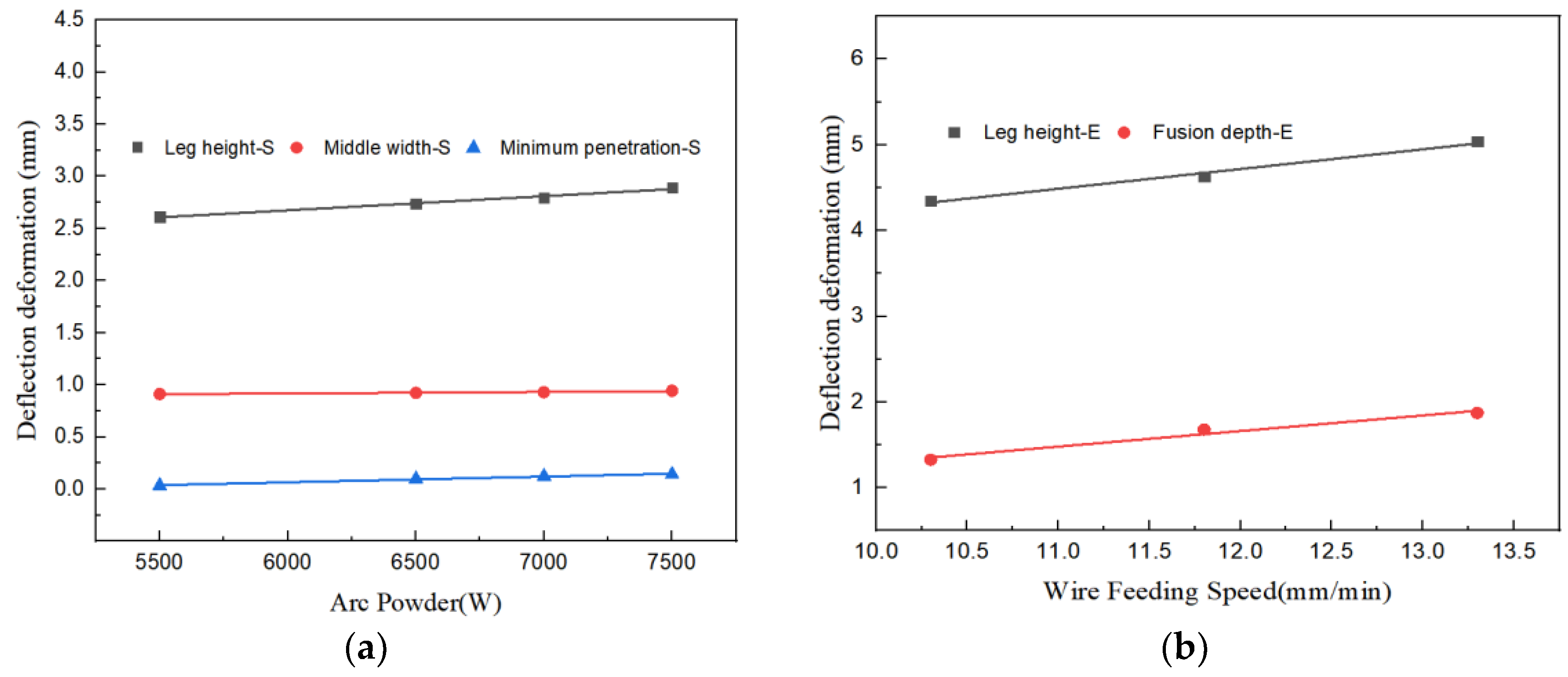

3.4. Effects of Arc Power

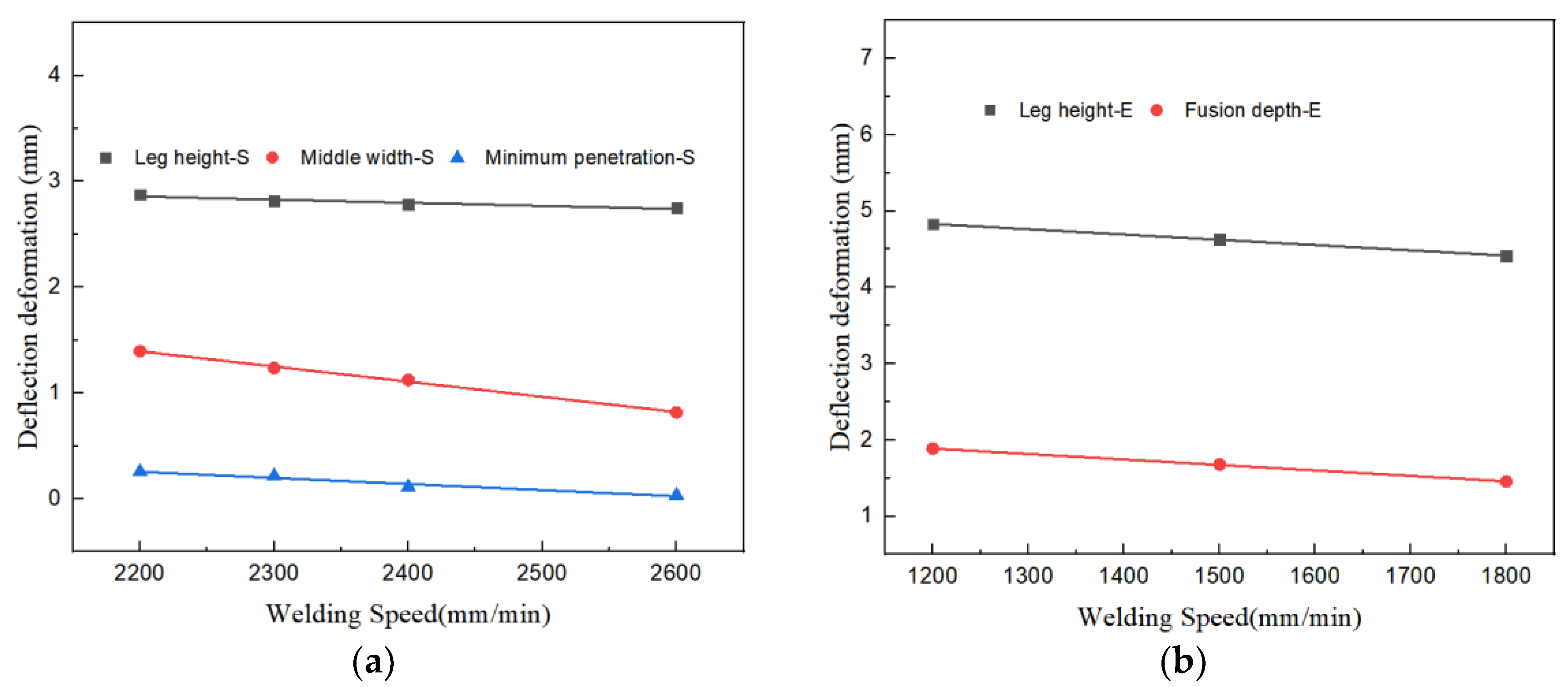

3.5. Effects of Welding Speed

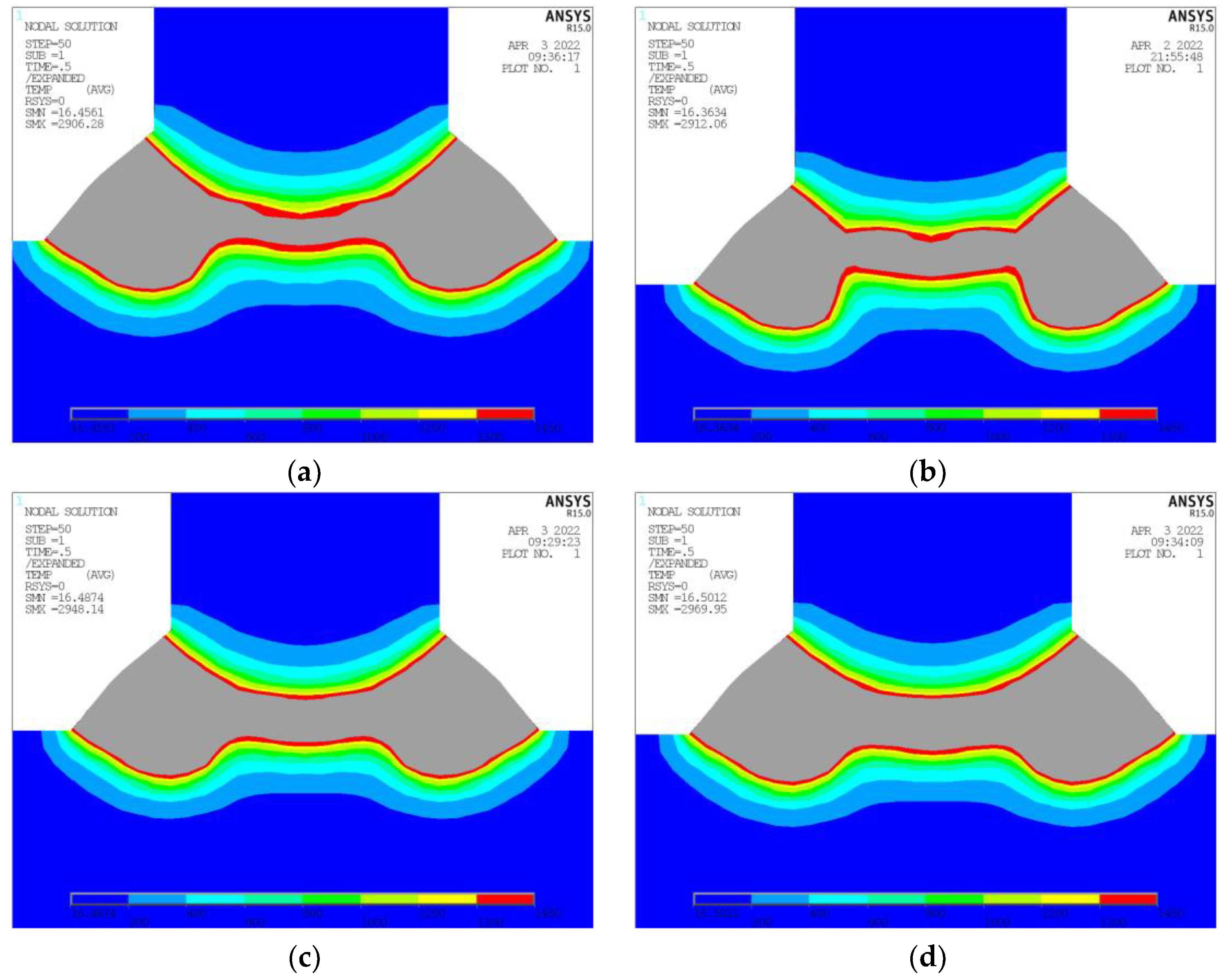

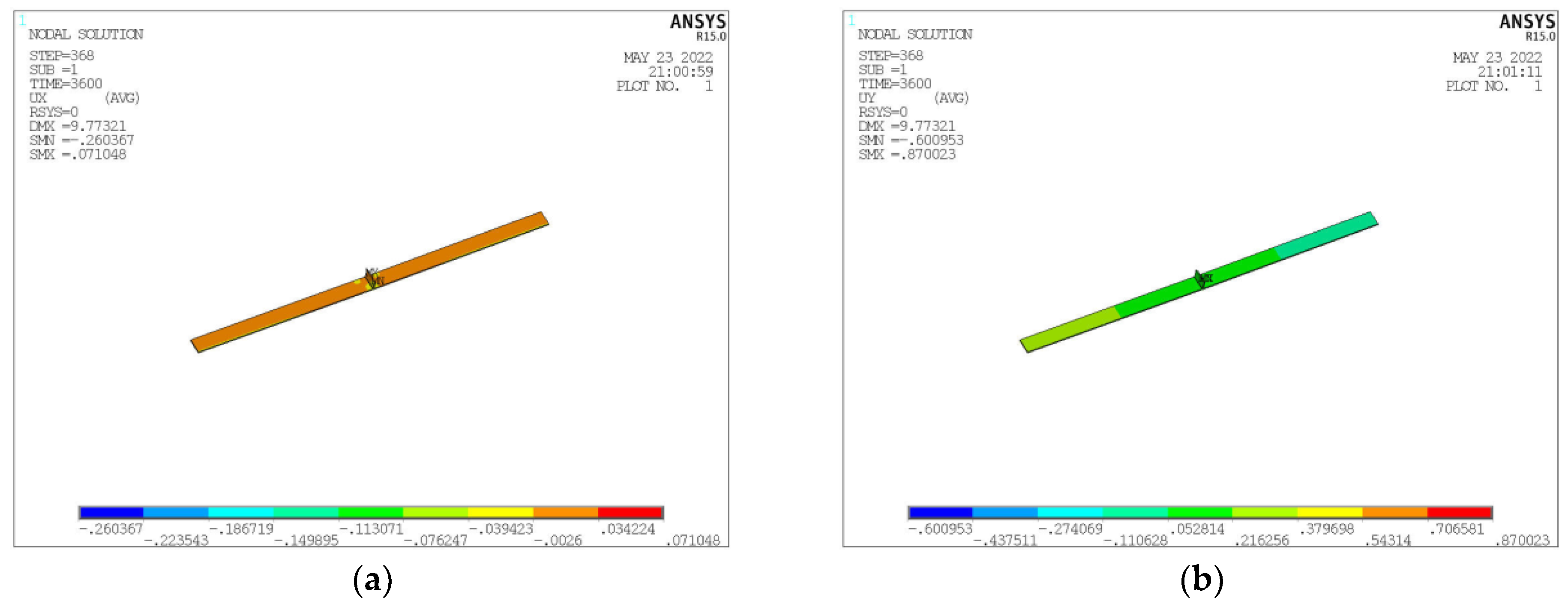

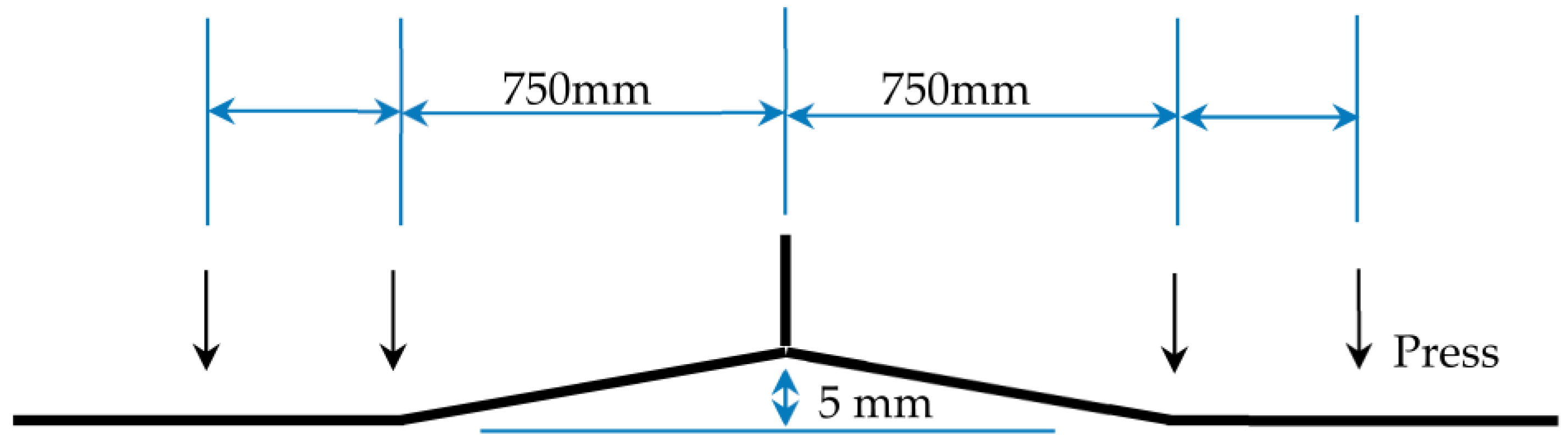

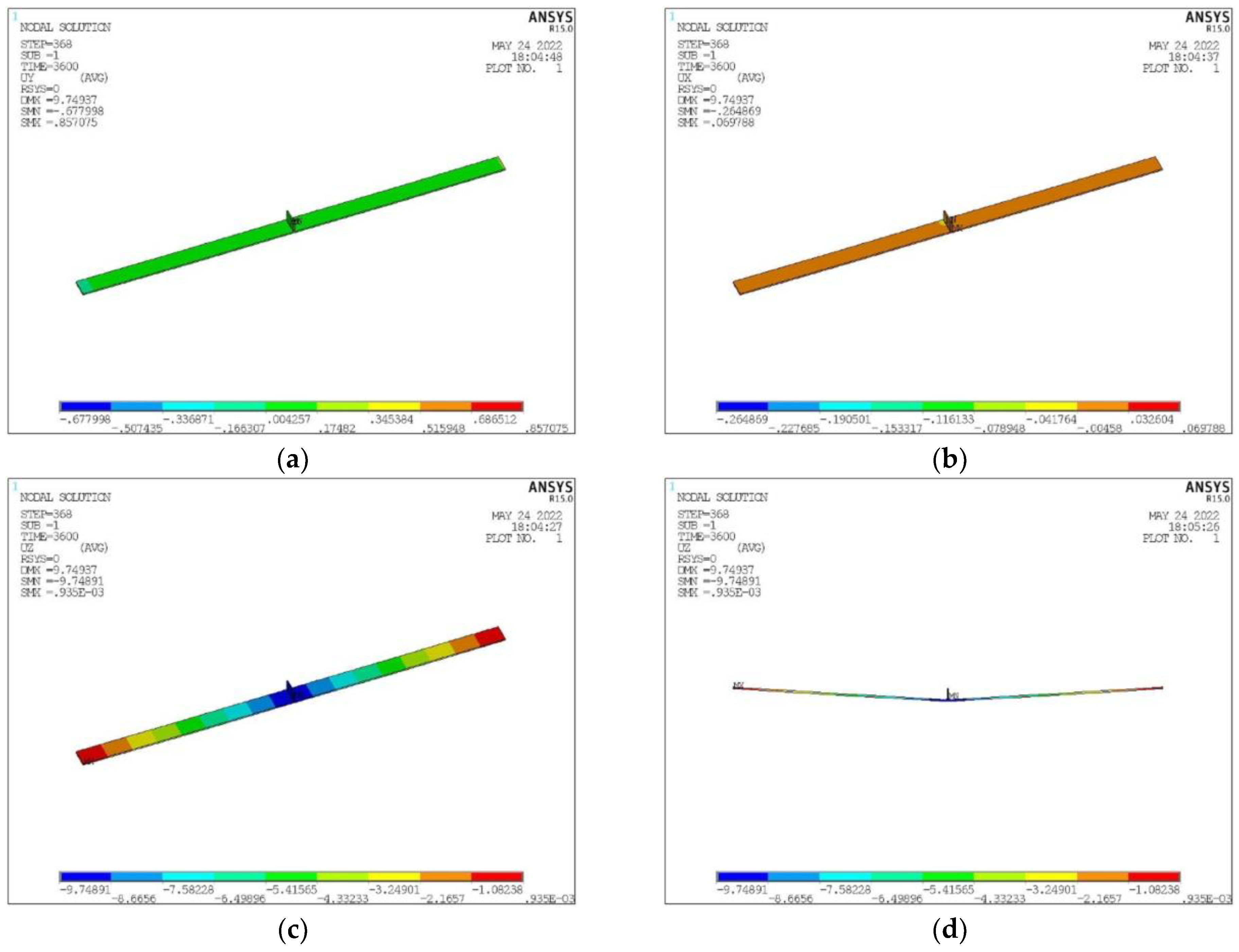

3.6. Deformation Simulation Calculation

4. Conclusions

- The thermodynamics of the 8 mm T-joint laser–GMAW welding were virtually recreated employing the twin-pyramidal heat source model. Subsequently, the resultant empirical welding seam architecture was juxtaposed with the simulated cross-section. The close congruity reinforced the veracity of the heat source model in question.

- In the context of T-joint laser–GMAW welding, the incident angle and altitude are vital for determining the fidelity of the welding. As the incident angle escalates, the entire melt pool is displaced towards the base-plate lateral, thereby enhancing the molten expanse of the base plate. An excessive angle could pose a threat of partial welding on the flipside. An unduly high incident altitude would be susceptible to inadequate penetration of the interstitial joint surface.

- The force of the arc and the feeding of the wire subtly influence the proportionality of the welding leg in the context of laser–GMAW welding; however, their perturbation over the deepest penetration and mid-width is diminutive. As the laser strength surges, the welding leg parameters remain irrevocably stable while the middle breadth and halcyon penetration register growth. Rising welding speed is observed to constrict the dimensions of the welding leg, middle-width, and minimal penetration recess.

- The implementation of arched deformation mitigation in the middle of the T-joint laser–GMAW welding and confining the repositioning of the base plate at the optimal positions bilaterally can significantly curtail the welding deformation while bolstering the welding quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Selvaperumal, S.; Thangaraju, D.B.K. Experimental studies and optimization of process parameters in laser welding of stainless steel 304 H. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 95440892211391. [Google Scholar] [CrossRef]

- Yang, X.; Chen, H.; Zhu, Z.; Cai, C.; Zhang, C. Effect of shielding gas flow on welding process of laser-arc hybrid welding and MIG welding. J. Manuf. Process. 2019, 38, 530–542. [Google Scholar] [CrossRef]

- Unt, A.; Lappalainen, E.; Salminen, A. Autogeneous laser and hybrid laser arc welding of T-joint low alloy steel with fiber laser systems. Phys. Procedia 2013, 41, 140–143. [Google Scholar] [CrossRef]

- Aslam, M.; Sahoo, C.K. Finite element analysis and experimental investigation of moving heat source model for GMAW deposited mild steel weld bead. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 2218–2228. [Google Scholar] [CrossRef]

- Yan, J.; Gao, M.; Zeng, X. Study on microstructure and mechanical properties of 304 stainless steel joints by TIG, laser and laser-TIG hybrid welding. Opt. Lasers Eng. 2010, 48, 512–517. [Google Scholar] [CrossRef]

- Pan, Q.; Mizutani, M.; Kawahito, Y.; Katayama, S. High power disk laser-metal active gas arc hybrid welding of thick high tensile strength steel plates. J. Laser Appl. 2016, 28, 012004. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yang, G.; Kovacevic, R. Hybrid laser-arc welding of advanced high-strength steel. J. Mater. Process. Technol. 2014, 214, 2823–2833. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Ma, J.; Liu, W.; Kovacevic, R. Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel. Mater. Des. 2015, 67, 509–521. [Google Scholar] [CrossRef]

- Ming, G.; Xiaoyan, Z.; Qianwu, H. Effects of gas shielding parameters on weld penetration of CO2 laser-TIG hybrid welding. J. Mater. Process. Technol. 2007, 184, 177–183. [Google Scholar] [CrossRef]

- Mazar Atabaki, M.; Yazdian, N.; Kovacevic, R. Hybrid laser/arc welding of thick high-strength steel in different configurations. Adv. Manuf. 2018, 6, 176–188. [Google Scholar] [CrossRef]

- Hu, B.; Richardson, I. Microstructure and mechanical properties of AA7075 (T6) hybrid laser/GMA welds. Mater. Sci. Eng. A 2007, 459, 94–100. [Google Scholar] [CrossRef]

- Moore, P.; Howse, D.; Wallach, E. Microstructures and properties of laser/arc hybrid welds and autogenous laser welds in pipeline steels. Sci. Technol. Weld. Join. 2004, 9, 314–322. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Liu, W.; Kovacevic, R. Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt. Laser Technol. 2014, 59, 68–92. [Google Scholar] [CrossRef]

- Campana, G.; Fortunato, A.; Ascari, A.; Tani, G.; Tomesani, L. The influence of arc transfer mode in hybrid laser-MIG welding. J. Mater. Process. Technol. 2007, 191, 111–113. [Google Scholar] [CrossRef]

- Tani, G.; Campana, G.; Fortunato, A.; Ascari, A. The influence of shielding gas in hybrid LASER–MIG welding. Appl. Surf. Sci. 2007, 253, 8050–8053. [Google Scholar] [CrossRef]

- Siddique, M.; Abid, M. Finite element simulation of mechanical stress relieving in welded pipe—Flange joint. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2006, 220, 17–30. [Google Scholar] [CrossRef]

- Abid, M.; Qarni, M. Numerical investigation of residual stresses and distortions due to multi-pass welding in a pipe-flange joint. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2010, 224, 253–267. [Google Scholar] [CrossRef]

- Farrokhi, F.; Endelt, B.; Kristiansen, M. A numerical model for full and partial penetration hybrid laser welding of thick-section steels. Opt. Laser Technol. 2019, 111, 671–686. [Google Scholar] [CrossRef]

- Zhan, X.; Zhao, Y.; Liu, Z.; Gao, Q.; Bu, H. Microstructure and porosity characteristics of 5A06 aluminum alloy joints using laser-MIG hybrid welding. J. Manuf. Process. 2018, 35, 437–445. [Google Scholar] [CrossRef]

- Rao, Z.; Liao, S.; Tsai, H.-L. Modelling of hybrid laser–GMA welding: Review and challenges. Sci. Technol. Weld. Join. 2011, 16, 300–305. [Google Scholar] [CrossRef]

- Lindgren, L.-E. Numerical modelling of welding. Comput. Methods Appl. Mech. Eng. 2006, 195, 6710–6736. [Google Scholar] [CrossRef]

- Dal, M.; Fabbro, R. An overview of the state of art in laser welding simulation. Opt. Laser Technol. 2016, 78, 2–14. [Google Scholar] [CrossRef]

- Deng, D. Fem Prediction of Welding Residual Stress and Distortion in Carbon Steel Considering Phase Transformation Effects. Mater. Des. 2009, 30, 359–366. [Google Scholar] [CrossRef]

- Nguyen, N.; Mai, Y.; Simpson, S.; Ohta, A. Analytical Approximate Solution for Double Ellipsoidal Heat Source in Finite Thick Plate. Weld. J. 2004, 83, 82. [Google Scholar]

- Wang, Y. Experiment and numerical simulation of AH36 laser arc hybrid welding process. Electr. Weld. Mach. 2021, 118, 105–110. [Google Scholar]

| Chemical Composition | C | Mn | Si | S | P | Nb | Cu |

|---|---|---|---|---|---|---|---|

| AH36 | 0.15~0.18 | 1.20~1.45 | 0.15~0.50 | 0.015 | 0.025 | 0.015~0.025 | / |

| ER70S-6 | 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.035 | 0.025 | / | <0.5 |

| No. | Laser Power (W) | Wire Feeding Speed (mm/min) | Welding Speed (m/min) | Incident Position (mm) |

|---|---|---|---|---|

| 1 | 5000 | 11.8 | 1.5 | 0.5 |

| 2 | 6000 | 11.8 | 1.5 | 0.5 |

| 3 | 4000 | 11.8 | 1.5 | 0.5 |

| 4 | 5000 | 13.3 | 1.5 | 0.5 |

| 5 | 5000 | 10.3 | 1.5 | 0.5 |

| 6 | 5000 | 11.8 | 1.8 | 0.5 |

| 7 | 5000 | 11.8 | 1.2 | 0.5 |

| 8 | 5000 | 11.8 | 1.5 | 0 |

| 9 | 5000 | 11.8 | 1.5 | 1.5 |

| No. | Type | Laser Power (W) | Arc Power (W) | Wire Feeding Speed (mm/min) | Welding Speed (mm/min) | Incident Position (mm) | Incident Angle (°) |

|---|---|---|---|---|---|---|---|

| 1 | Simulation | 4700 | 7000 | / | 2500 | 0.5 | 12 |

| 2 | Simulation | 4700 | 7000 | / | 2500 | 1 | 12 |

| 3 | Simulation | 4700 | 7000 | / | 2500 | 1.5 | 12 |

| 4 | Experiment | 5000 | / | 11.8 | 1500 | 0.5 | 12 |

| 5 | Experiment | 5000 | / | 11.8 | 1500 | 0 | 12 |

| 6 | Experiment | 5000 | / | 11.8 | 1500 | 1.5 | 12 |

| No. | Type | Laser Power (W) | Leg Height (mm) | Middle Width (mm) | Minimum Penetration (mm) | Fusion Depth (mm) |

|---|---|---|---|---|---|---|

| 1 | Simulation | 4200 | 2.752 | 0.721 | 0.021 | / |

| 2 | Simulation | 4700 | 2.761 | 0.951 | 0.112 | / |

| 3 | Simulation | 5200 | 2.768 | 1.212 | 0.212 | / |

| 4 | Simulation | 5700 | 2.772 | 1.523 | 0.322 | / |

| 5 | Experiment | 5000 | 4.628 | / | / | 1.678 |

| 6 | Experiment | 6000 | 4.708 | / | / | 1.926 |

| 7 | Experiment | 4000 | 4.494 | / | / | 1.498 |

| No. | Type | Arc Power (W) | Wire Feeding Speed (mm/min) | Leg Height (mm) | Middle Width (mm) | Minimum Penetration (mm) | Fusion Depth (mm) |

|---|---|---|---|---|---|---|---|

| 1 | Simulation | 5500 | / | 2.612 | 0.912 | 0.035 | / |

| 2 | Simulation | 6500 | / | 2.738 | 0.924 | 0.098 | / |

| 3 | Simulation | 7000 | / | 2.795 | 0.929 | 0.124 | / |

| 4 | Simulation | 7500 | / | 2.891 | 0.943 | 0.143 | / |

| 5 | Experiment | / | 11.8 | 4.628 | / | / | 1.678 |

| 6 | Experiment | / | 13.3 | 5.038 | / | / | 1.872 |

| 7 | Experiment | / | 10.3 | 4.349 | / | / | 1.327 |

| No. | Type | Welding Speed (mm/min) | Leg Height (mm) | Middle Width (mm) | Minimum Penetration (mm) | Fusion Depth (mm) |

|---|---|---|---|---|---|---|

| 1 | Simulation | 2200 | 2.876 | 1.397 | 0.257 | / |

| 2 | Simulation | 2300 | 2.814 | 1.236 | 0.216 | / |

| 3 | Simulation | 2400 | 2.783 | 1.125 | 0.112 | / |

| 4 | Simulation | 2600 | 2.751 | 0.816 | 0.035 | / |

| 5 | Experiment | 1500 | 4.628 | / | / | 1.678 |

| 6 | Experiment | 1800 | 4.414 | / | / | 1.457 |

| 7 | Experiment | 1200 | 4.829 | / | / | 1.886 |

| Laser Power (W) | Wire Feeding Speed (mm/min) | Welding Speed (m/min) | Incident Position (mm) |

|---|---|---|---|

| 5000–6000 | 10.3–13.3 | 1.2–1.8 | 0–0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, N.-K.; Shi, J.; Yang, R.-D.; Xi, J.-T.; Luo, X.-M.; Yin, X.-Y.; Zhang, R.-X. Numerical Simulation and Experimental Analysis on Seam Feature Size and Deformation for T-Joint Laser–GMAW Hybrid Welding. Materials 2024, 17, 228. https://doi.org/10.3390/ma17010228

Wei N-K, Shi J, Yang R-D, Xi J-T, Luo X-M, Yin X-Y, Zhang R-X. Numerical Simulation and Experimental Analysis on Seam Feature Size and Deformation for T-Joint Laser–GMAW Hybrid Welding. Materials. 2024; 17(1):228. https://doi.org/10.3390/ma17010228

Chicago/Turabian StyleWei, Nai-Kun, Jin Shi, Run-Dang Yang, Jun-Tong Xi, Xiao-Meng Luo, Xu-Yue Yin, and Rui-Xue Zhang. 2024. "Numerical Simulation and Experimental Analysis on Seam Feature Size and Deformation for T-Joint Laser–GMAW Hybrid Welding" Materials 17, no. 1: 228. https://doi.org/10.3390/ma17010228