Influencing Factors of Porosity and Strength of Plant-Growing Concrete

Abstract

:1. Introduction

2. Experimental Study

2.1. Raw Materials and Experimental Design

2.2. Specimen Preparation

2.2.1. Washing

2.2.2. Mixing

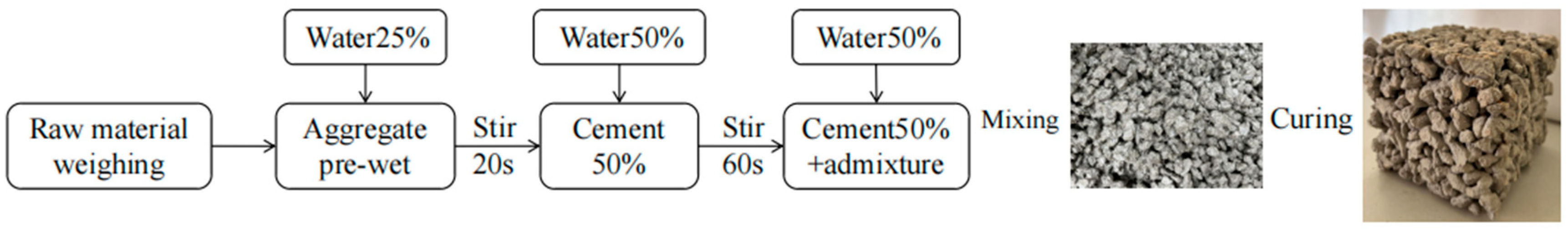

2.2.3. Preparation Process

2.3. Testing Methods

2.3.1. Stress–Strain Curve Test

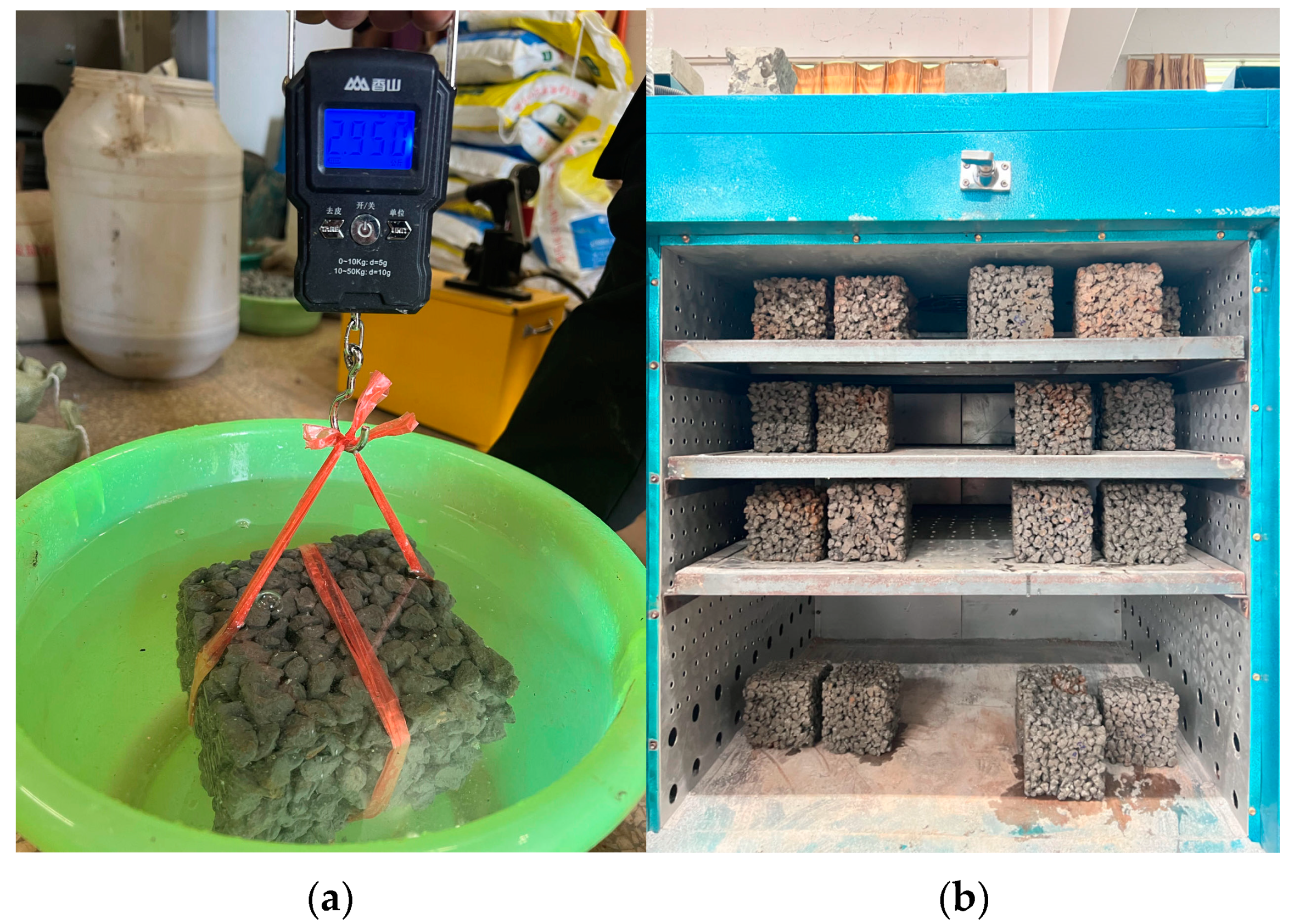

2.3.2. Effective Porosity

3. Test Results and Discussion

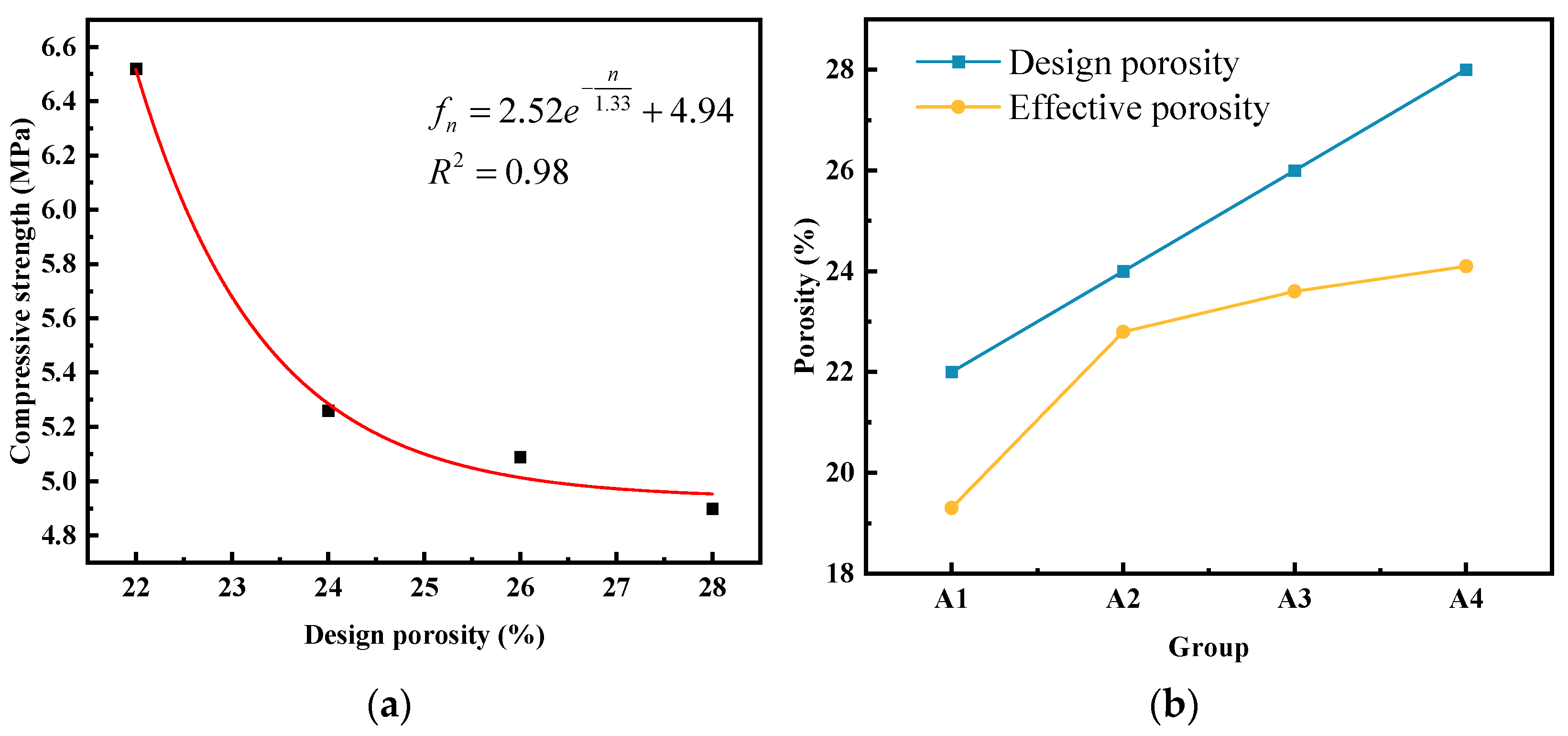

3.1. Impact of Porosity on Mechanical Properties of Vegetated Concrete

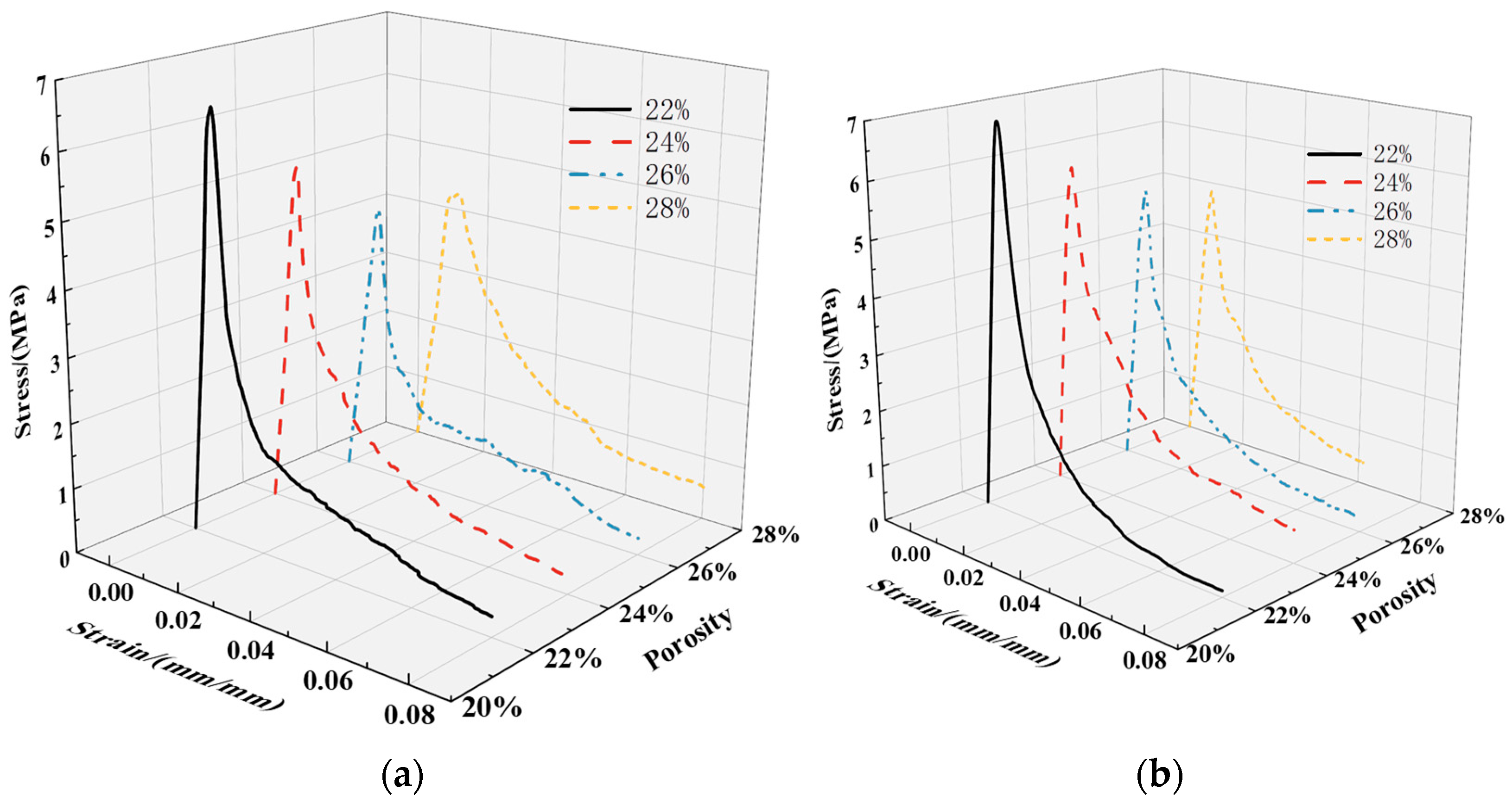

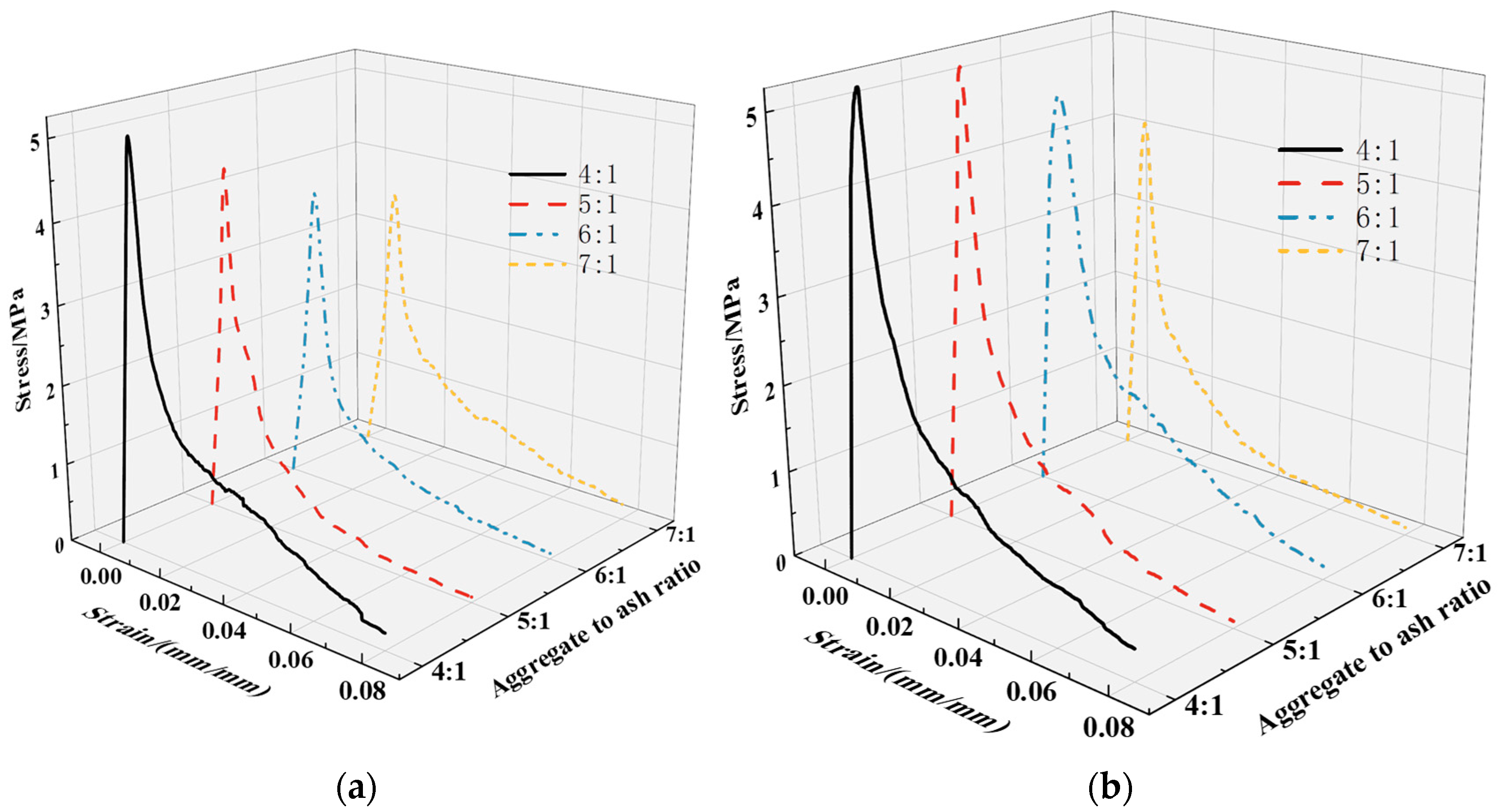

3.1.1. Stress–Strain Full Curves

3.1.2. Effective Porosity

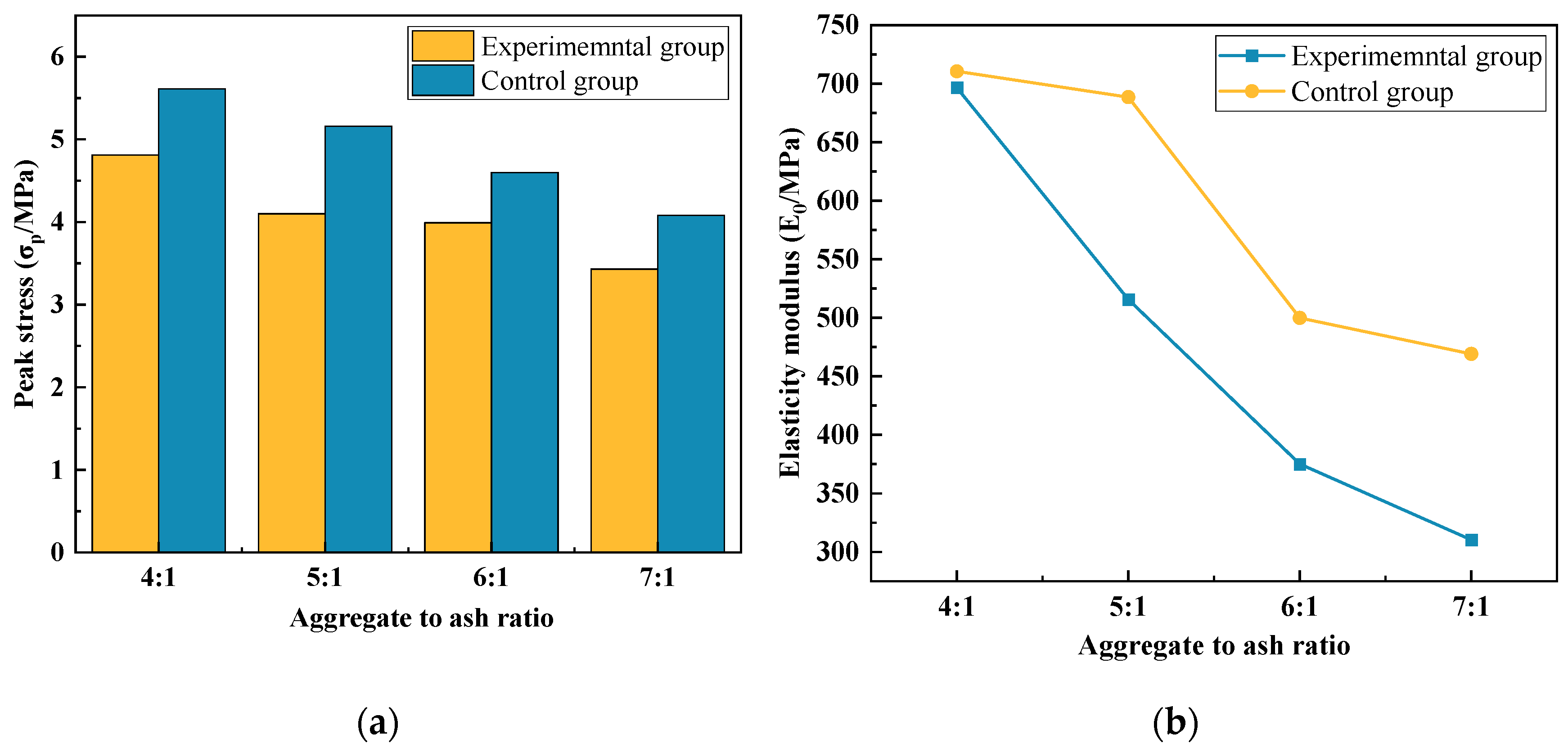

3.2. Influence of Cementitious Material Ratio on Mechanical Properties of Vegetated Concrete

3.2.1. Stress–Strain Curves

3.2.2. Effective Porosity

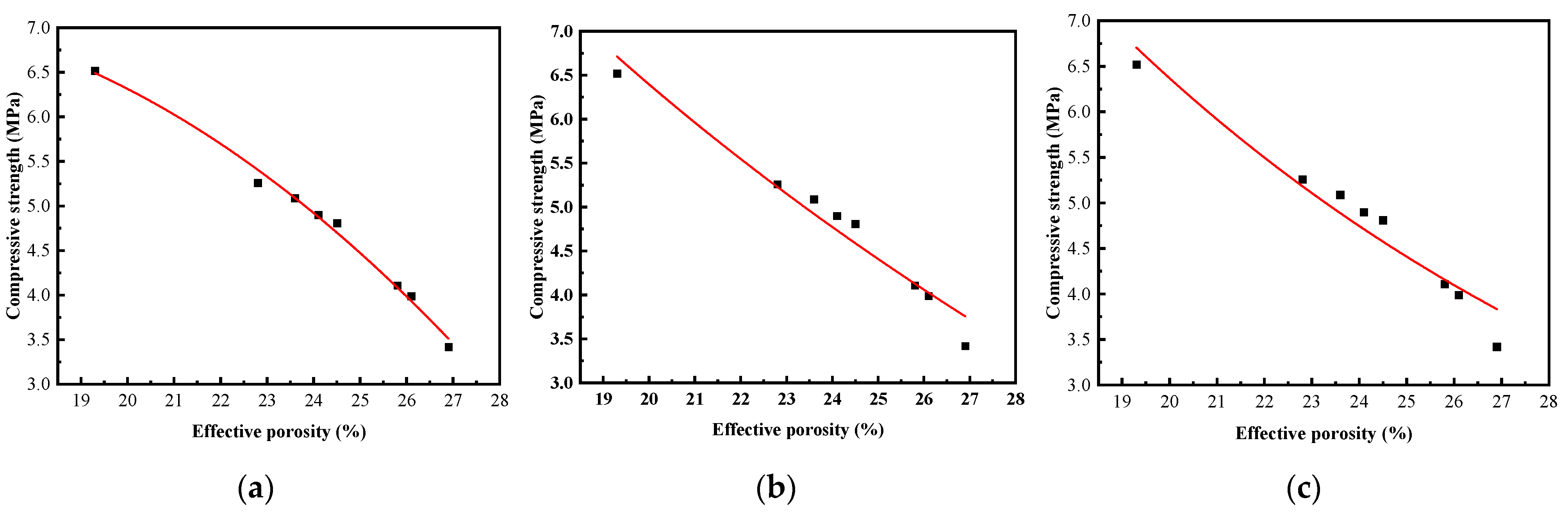

3.3. Correlation between Compressive Strength and Effective Porosity

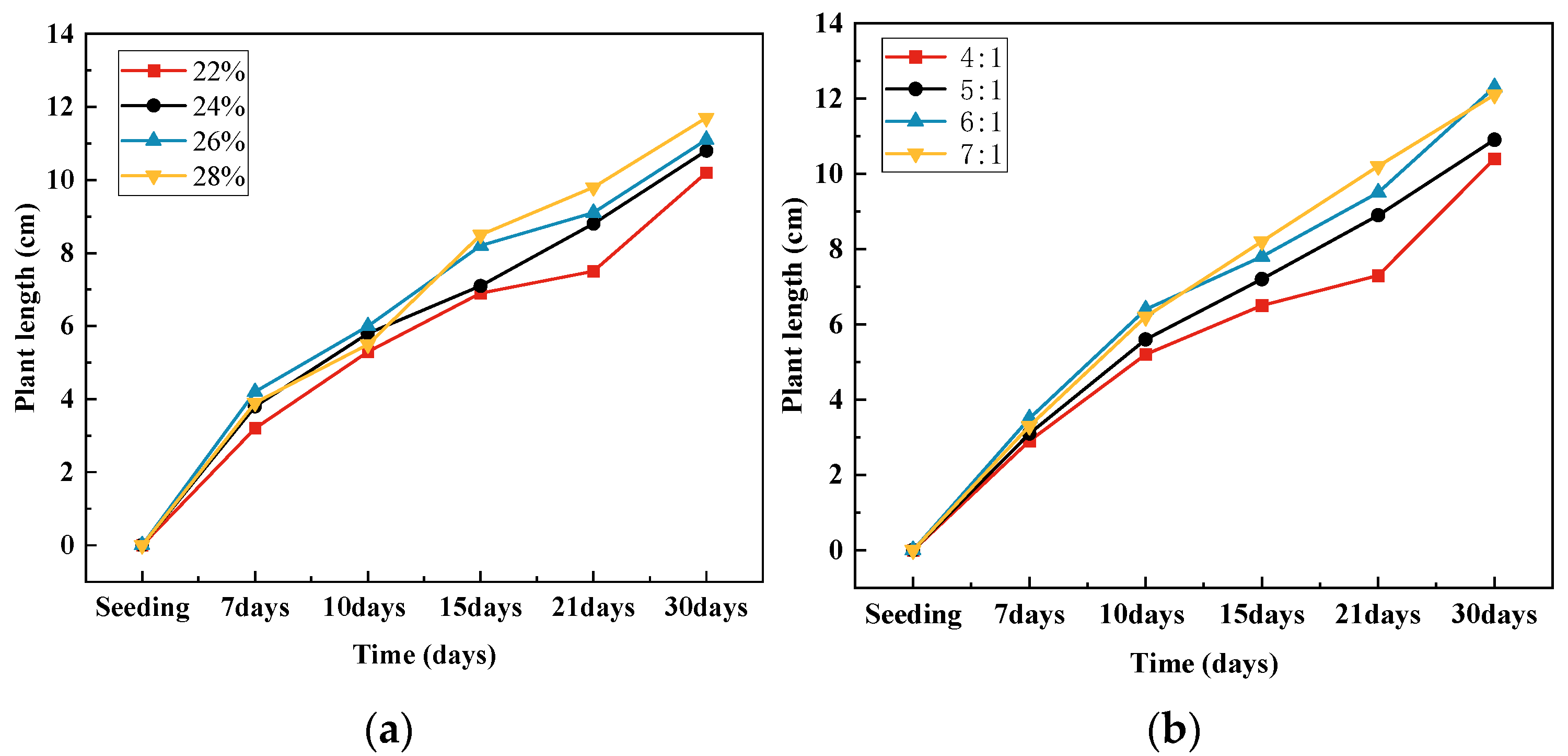

3.4. Vegetative Experiment of Vegetated Concrete

4. Conclusions

- Utilizing aggregate gradation within the range of 10–15 mm and a water–cement ratio ranging from 0.40 to 0.43, a design porosity between 22% and 28% yielded a 30-day compressive strength ranging from 4.9 to 6.52 MPa, effective porosity ranging from 19.3% to 24.1%, and a density ranging from 1748.14 to 2062.22 kg/m3. Notably, specimens with higher effective porosity exhibited uneven deformation in the descending segment of the stress–strain curve;

- Under the same aggregate gradation and water–cement ratio, incorporating a fly ash ratio ranging from 4% to 7% resulted in a 30-day compressive strength ranging from 3.42 to 4.81 MPa, effective porosity ranging from 24.5% to 26.9%, and a density ranging from 1694.81 to 1866.67 kg/m3;

- The investigation of stress–strain curve characteristics for vegetation concrete revealed positive correlations between compressive strength and the elastic modulus with cement content. In contrast, negative correlations were observed with porosity. Peak strain exhibited a positive correlation with porosity and a negative correlation with cement content. Notably, the peak strain for vegetation concrete was 3–5 times greater than ordinary concrete. A fitting analysis was conducted on the relationship between the compressive strength and effective porosity of vegetation-type concrete after 30 days, revealing that a polynomial function adequately captures the correlation between compressive strength and effective porosity;

- Based on the vegetation effects observed at the 30-day mark, ryegrass demonstrated faster growth than other grass species and exhibited some adaptability to alkaline soil conditions. Within 10 days, the plant height reached 3–4 cm, while the root length measured approximately 1 cm. After 30 days, the root length extended to 4 cm, capable of penetrating a 3-centimeter-thick vegetation concrete specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbier, E.B. Valuing ecosystem services for coastal wetland protection and restoration: Progress and challenges. Resources 2013, 2, 213–230. [Google Scholar] [CrossRef]

- Weston, N.B. Declining sediments and rising seas: An unfortunate convergence for tidal wetlands. Estuaries Coasts 2014, 37, 1–23. [Google Scholar] [CrossRef]

- Castillo, M.E.; Baldwin, E.M.; Casarin, R.S.; Vanegas, G.P.; Juaréz, M.A. Characterization of risks in coastal zones: A review. Clean Soil Air Water 2012, 40, 894–905. [Google Scholar] [CrossRef]

- Liu, C.; Xia, Y.; Chen, J.; Huang, K.; Wang, J.; Wang, C.; Huang, Z.; Wang, X.; Rao, C.; Shi, M. Research and Application Progress of Vegetation Porous Concrete. Materials 2023, 16, 7039. [Google Scholar] [CrossRef] [PubMed]

- Sumanasooriya, M.S.; Neithalath, N. Pore structure features of pervious concretes proportioned for desired porosities and their performance prediction. Cem. Concr. Compos. 2011, 33, 778–787. [Google Scholar] [CrossRef]

- Deo, O.; Neithalath, N. Compressive response of pervious concretes proportioned for desired porosities. Constr. Build. Mater. 2011, 25, 4181–4189. [Google Scholar] [CrossRef]

- Kim, H.H.; Park, C.G. Plant growth and water purification of porous vegetation concrete formed of blast furnace slag, natural jute fiber and styrene butadiene latex. Sustainability 2016, 8, 386. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, Y. Performance Evaluation and Field Application of Prefabricated Grass-Planting Concrete Blocks with Concave-Convex Construction for Mid-Sized and Small River Revetment Projects. Pol. J. Environ. Stud. 2022, 31, 99–110. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Wu, H.; Dong, Q.; Burdette, E.G. Performance comparison of laboratory and field produced pervious concrete mixtures. Constr. Build. Mater. 2011, 25, 3187–3192. [Google Scholar] [CrossRef]

- Fan, J.C.; Huang, C.L.; Yang, C.H.; Liao, K.-W.; Liao, W.-W. Effect evaluation of shotcrete vegetation mulching technique applied to steep concrete-face slopes on a highway of Taiwan. Paddy Water Environ. 2013, 11, 145–159. [Google Scholar] [CrossRef]

- JC/T 2557-2020; Green-Growing Concrete. Ministry of Industry and Information Technology: Beijing, China, 2020.

- Liu, D.; Zhang, B.; Yang, Y.; Xu, W.; Ding, Y.; Xia, Z. Effect of organic material type and proportion on the physical and mechanical properties of vegetation-concrete. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Wang, F.; Sun, C. Effect of pore structure on compressive strength and permeability of planting recycled concrete. Constr. Build. Mater. 2023, 394, 132167. [Google Scholar] [CrossRef]

- Seifeddine, K.; Amziane, S.; Toussaint, E. State of the art on the mechanical properties of pervious concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 7727–7755. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Jang, J.G.; Ahn, Y.B.; Souri, H.; Lee, H.K. A novel eco-friendly porous concrete fabricated with coal ash and geopolymeric binder: Heavy metal leaching characteristics and compressive strength. Constr. Build. Mater. 2015, 79, 173–181. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y. Optimum mix design of enhanced permeable concrete–an experimental investigation. Constr. Build. Mater. 2010, 24, 2664–2671. [Google Scholar] [CrossRef]

- Corapcioglu, M.Y. Advances in Porous Media; Elsevier: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Xiong, D.; Chen, F.; Lv, K.; Tan, X.; Huang, Y. The performance and temporal dynamics of vegetation concretes comprising three herbaceous species in soil stabilization and slope protection. Ecol. Eng. 2023, 188, 106873. [Google Scholar] [CrossRef]

- Horiguchi, I.; Mimura, Y.; Monteiro, P.J.M. Plant-growing performance of pervious concrete containing crushed oyster shell aggregate. Clean. Mater. 2021, 2, 100027. [Google Scholar] [CrossRef]

- GB/T 3183-2017; Masonry Cement. Standardization Administration of China: Beijing, China, 2017.

- Liu, Q.; Su, L.; Xiao, H.; Xu, W.; Yan, W.M.; Xia, Z. Preparation of shale ceramsite vegetative porous concrete and its performance as a planting medium. Eur. J. Environ. Civ. Eng. 2021, 25, 2111–2126. [Google Scholar] [CrossRef]

- National Ready Mixed Concrete Association. National Ready Mixed Concrete Association Excellence in Safety Awards; Office of Safety; National Ready Mixed Concrete Association: Alexandria, VA, USA, 2014. [Google Scholar]

- NeithAlAth, N.; Bentz, D.P.; Sumanasooriya, M.S. Predicting the permeability of pervious concrete. Concr. Int. 2010, 32, 35–40. [Google Scholar]

- Luck, J.D.; Workman, S.R.; Higgins, S.F. Hydrologic properties of pervious concrete. In Proceedings of the 2006 ASAE Annual Meeting, Boston, MA, USA, 19–22 August 2006; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006; Volume 1. [Google Scholar]

- Fairey, N.A.; Lefkovitch, L.P. Crop density and seed production of tall fescue (Festuca arundinacea Schreber). 1. Yield and plant development. Can. J. Plant Sci. 1999, 79, 535–541. [Google Scholar] [CrossRef]

- SL 352-2006; Test Code for Hydraulic Concrete. Ministry of Water Resources: Beijing, China, 2006.

- Ghafoori, N.; Dutta, S. Laboratory investigation of compacted no-fines concrete for paving materials. J. Mater. Civ. Eng. 1995, 7, 183–191. [Google Scholar] [CrossRef]

- Faiz, H.; Ng, S.; Rahman, M. A state-of-the-art review on the advancement of sustainable vegetation concrete in slope stability. Constr. Build. Mater. 2022, 326, 126502. [Google Scholar] [CrossRef]

- Chen, J.G.; Du, W.L.; Zhao, G.Q.; Shi, M.; Xue, B. Effect of Aggregate Size and Water Cement on Compressive Strength and Physiological Performance of Planting Concrete. Materials 2022, 15, 6685. [Google Scholar] [CrossRef]

- Hasselman, D.P.H.; Fulrath, R.M. The effect of a small fraction of spherical porosity on the elastic moduli of glass. J. Am. Ceram. Soc. 1963. [Google Scholar] [CrossRef]

- Schiller, K.K. Strength of porous materials. Cem. Concr. Res. 1971, 1, 419–422. [Google Scholar] [CrossRef]

- Ryshkewitch, E. Compression strength of porous sintered alumina and zirconia: 9th communication to ceramography. J. Am. Ceram. Soc. 1953, 36, 65–68. [Google Scholar] [CrossRef]

| Test Indicators | SO3/% | Cl−/% | Ignition Loss/% | Retained on the 80 μm Sieve/% |

|---|---|---|---|---|

| Test results | 3.44 | 0.04 | 4.37 | 3.5 |

| Industry standards | >3.5 | >0.06 | — | <10.0% |

| Sample Number | Factors | Mix Proportions | |||

|---|---|---|---|---|---|

| Design Porosity | Aggregate Cement Ratio | Aggregate kg/m3 | Cementitious Material kg/m3 | Water kg/m3 | |

| Group1 (Design porosity) | |||||

| 1–1 | 22% | 4.2:1 | 1460 | 345 | 124 |

| 1–2 | 24% | 4.6:1 | 1460 | 316 | 114 |

| 1–3 | 26% | 5.1:1 | 1460 | 287 | 103 |

| 1–4 | 28% | 5.7:1 | 1460 | 258 | 93 |

| Group (Aggregate cement ratio) | |||||

| 2–1 | 26% | 4:1 | 1336 | 334 | 134 |

| 2–2 | 26% | 5:1 | 1430 | 286 | 114 |

| 2–3 | 26% | 6:1 | 1500 | 250 | 100 |

| 2–4 | 26% | 7:1 | 1561 | 223 | 89 |

| Group | Number | Design Porosity | Compressive Strength/MPa | Modulus of Elasticity/MPa | Peak Strain |

|---|---|---|---|---|---|

| Experimental group | A1–1 | 22% | 6.52 | 915.67 | 0.00742 |

| A1–2 | 24% | 5.26 | 679.32 | 0.00759 | |

| A1–3 | 26% | 5.09 | 509.64 | 0.00876 | |

| A1–4 | 28% | 4.90 | 417.06 | 0.01164 | |

| Control group | A2–1 | 22% | 7.01 | 1087.54 | 0.00661 |

| A2–2 | 24% | 6.14 | 989.25 | 0.00765 | |

| A2–3 | 26% | 5.36 | 775.15 | 0.00781 | |

| A2–4 | 28% | 4.45 | 665.26 | 0.00989 |

| Group | Group | Aggregate-to-Cement Ratio | Compressive Strength/MPa | Modulus of Elasticity/MPa | Peak Strain |

|---|---|---|---|---|---|

| Experimental group | B1–1 | 4 | 4.81 | 696.55 | 0.00819 |

| B1–2 | 5 | 4.11 | 515.56 | 0.00831 | |

| B1–3 | 6 | 3.99 | 375.08 | 0.00852 | |

| B1–4 | 7 | 3.43 | 310.34 | 0.00928 | |

| Control group | B2–1 | 4 | 5.61 | 710.52 | 0.00622 |

| B2–2 | 5 | 5.16 | 688.50 | 0.00716 | |

| B2–3 | 6 | 4.60 | 499.84 | 0.00928 | |

| B2–4 | 7 | 4.08 | 469.08 | 0.00944 |

| Category | Equation | The Fitted Equation | R2 |

|---|---|---|---|

| Polynomial function | 0.99 | ||

| Logarithmic function | 0.95 | ||

| Exponential function | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, J.; Shen, C.; Ye, M.; Huang, S.; He, J.; Cui, D. Influencing Factors of Porosity and Strength of Plant-Growing Concrete. Materials 2024, 17, 31. https://doi.org/10.3390/ma17010031

Cai J, Shen C, Ye M, Huang S, He J, Cui D. Influencing Factors of Porosity and Strength of Plant-Growing Concrete. Materials. 2024; 17(1):31. https://doi.org/10.3390/ma17010031

Chicago/Turabian StyleCai, Jiashi, Chunying Shen, Ming Ye, Siyang Huang, Jinxing He, and Ding Cui. 2024. "Influencing Factors of Porosity and Strength of Plant-Growing Concrete" Materials 17, no. 1: 31. https://doi.org/10.3390/ma17010031

APA StyleCai, J., Shen, C., Ye, M., Huang, S., He, J., & Cui, D. (2024). Influencing Factors of Porosity and Strength of Plant-Growing Concrete. Materials, 17(1), 31. https://doi.org/10.3390/ma17010031