Optimization of the Shape of Hooked-End Steel Fiber Based on Pulling Out and Reinforcing Cementitious Composites

Abstract

:1. Introduction

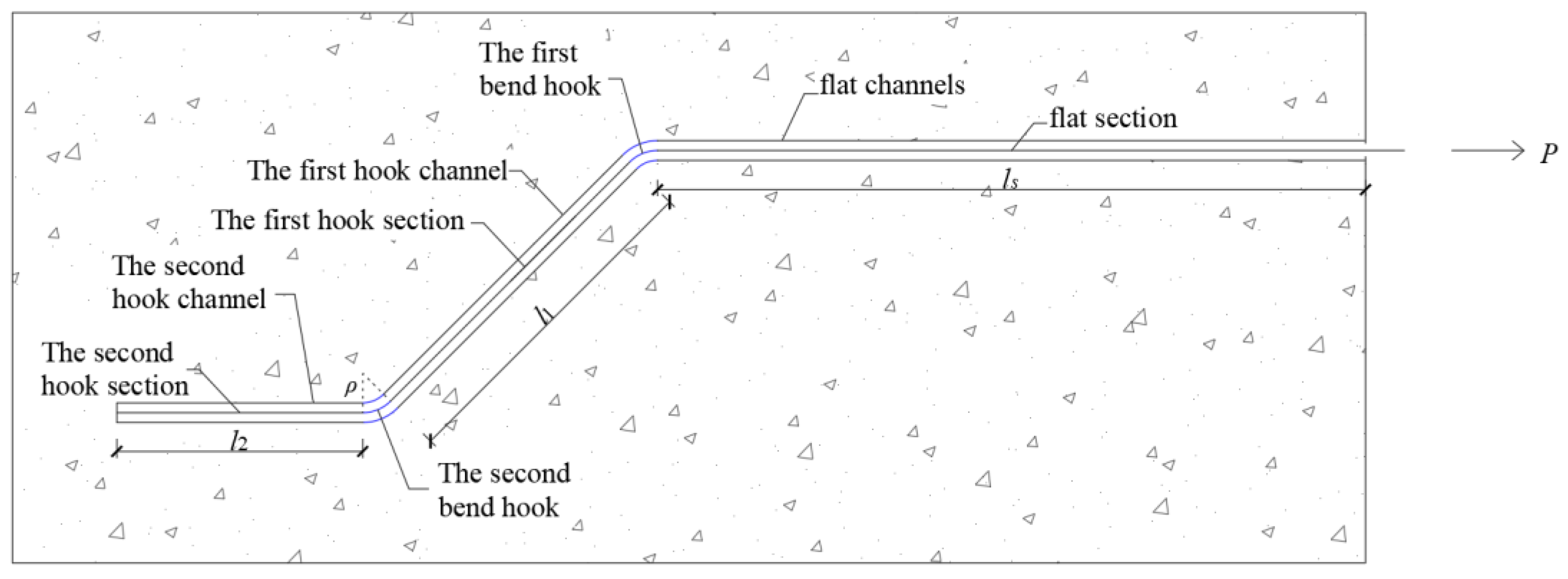

2. Calculation Model of Steel Fiber Pullout Resistance

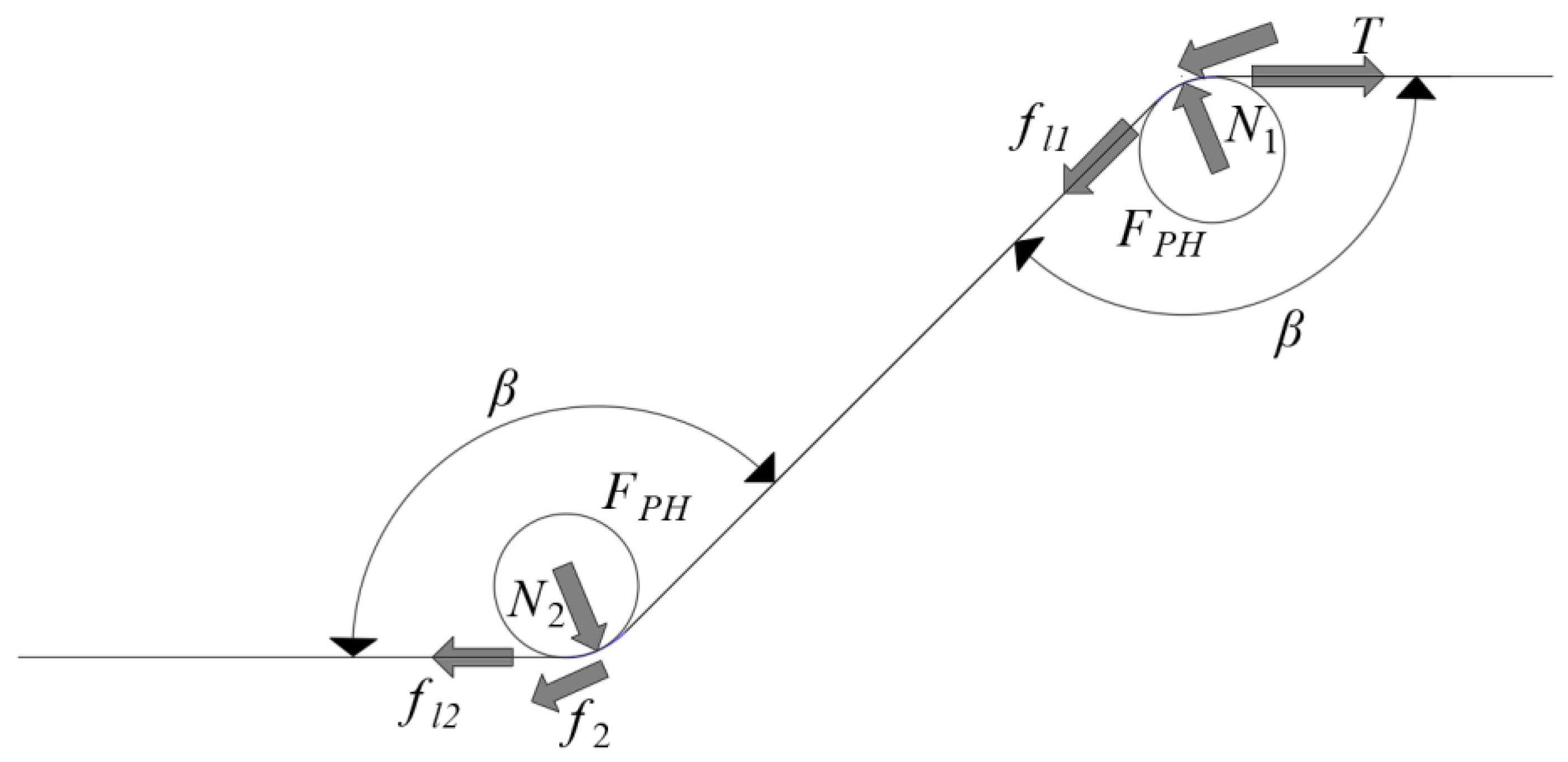

2.1. Mechanical Anchoring Force of Hooked-End

2.2. Friction between the Fiber and Matrix in a Flat Channel

2.3. Maximum and Residual Pullout Resistance

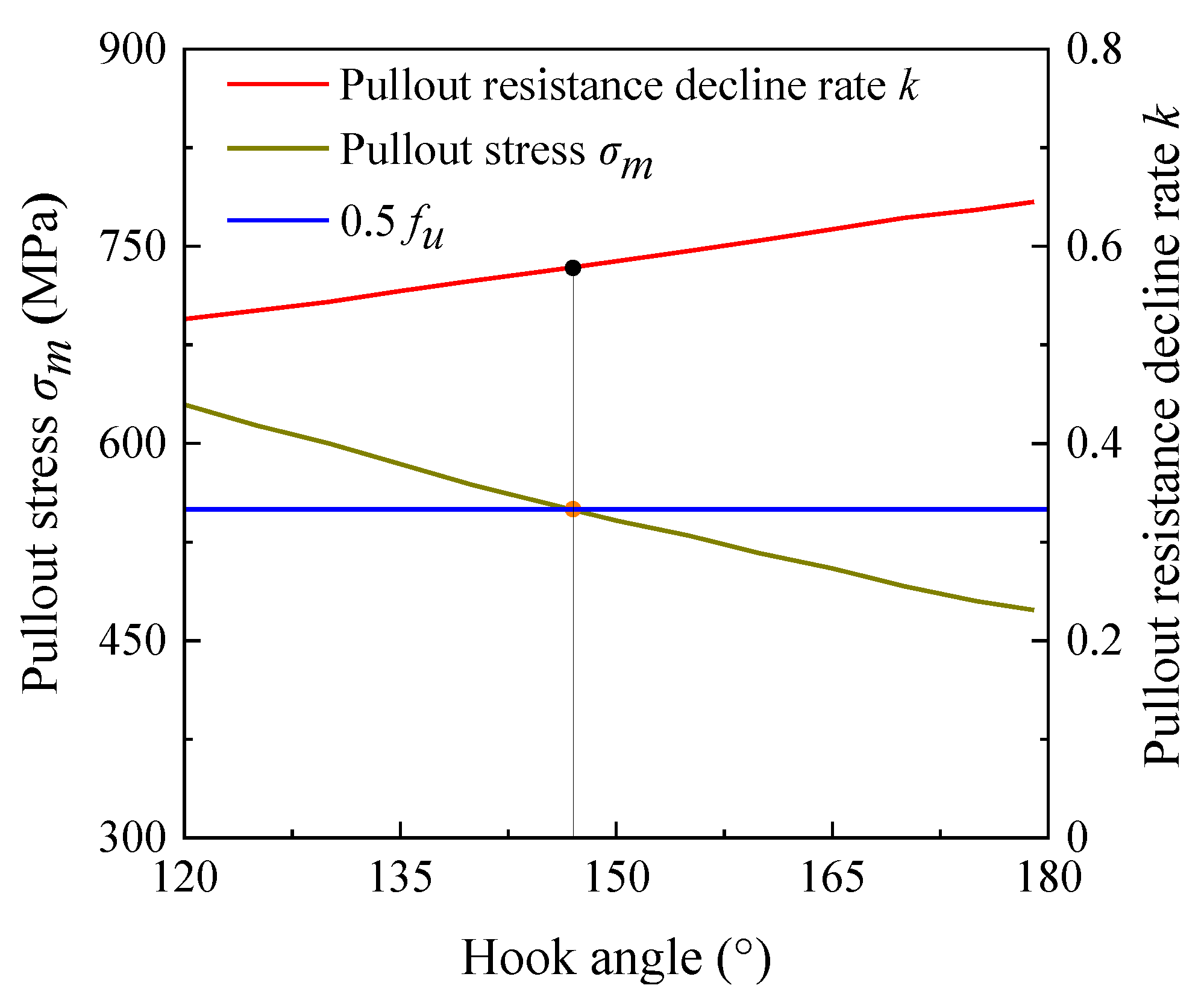

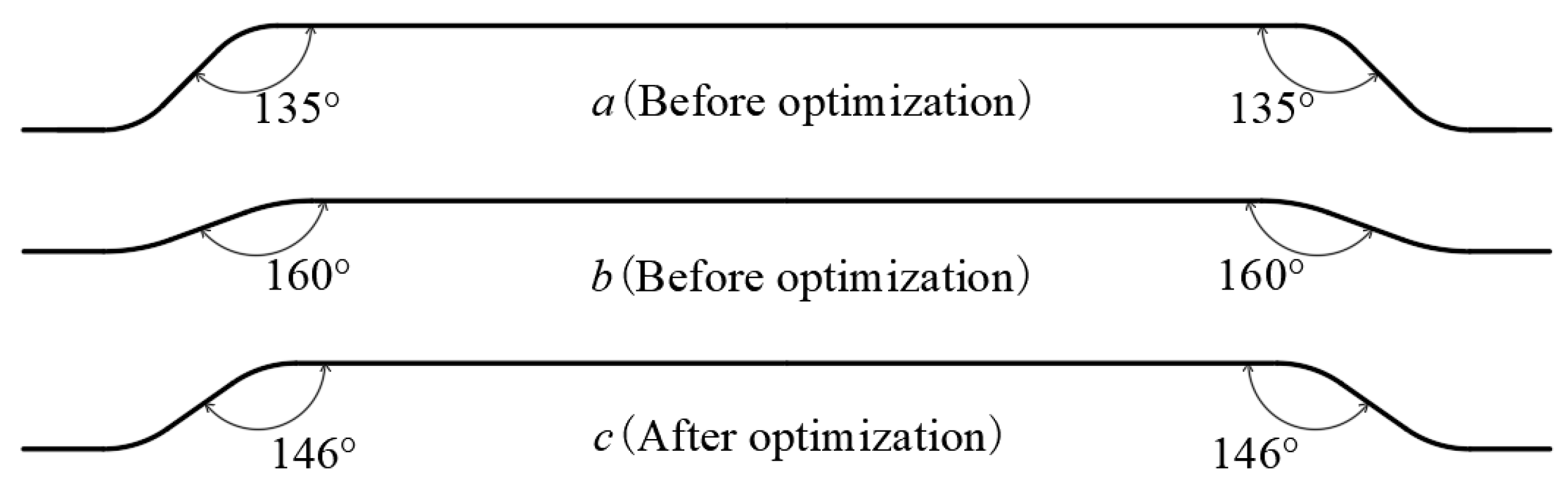

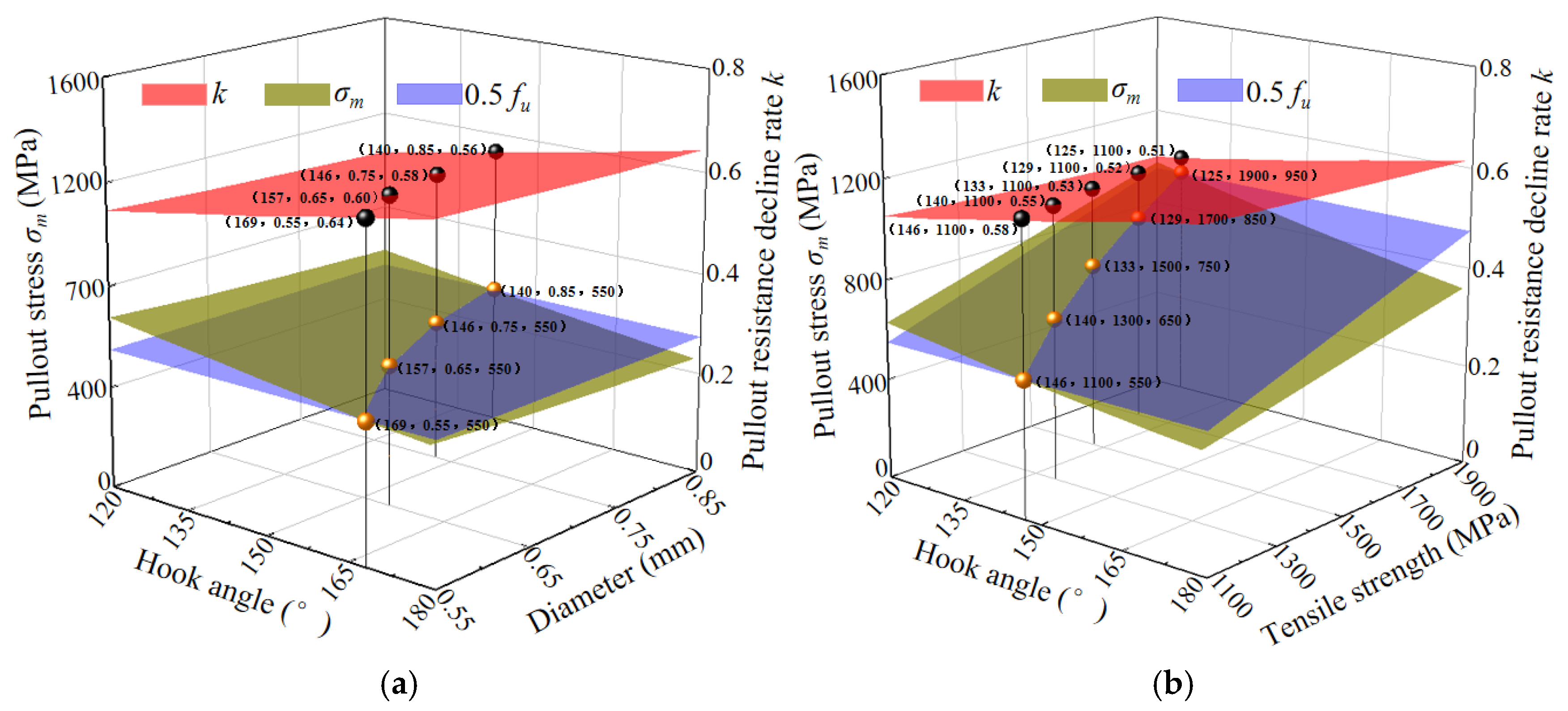

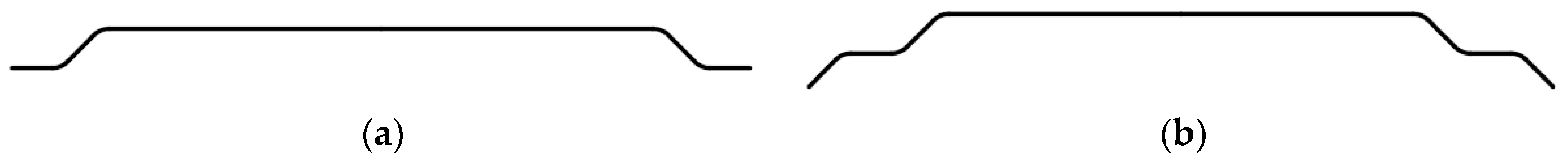

3. Optimization of Hooked-End Steel Fiber Shape

4. Steel Fiber Pulling out Behavior Test

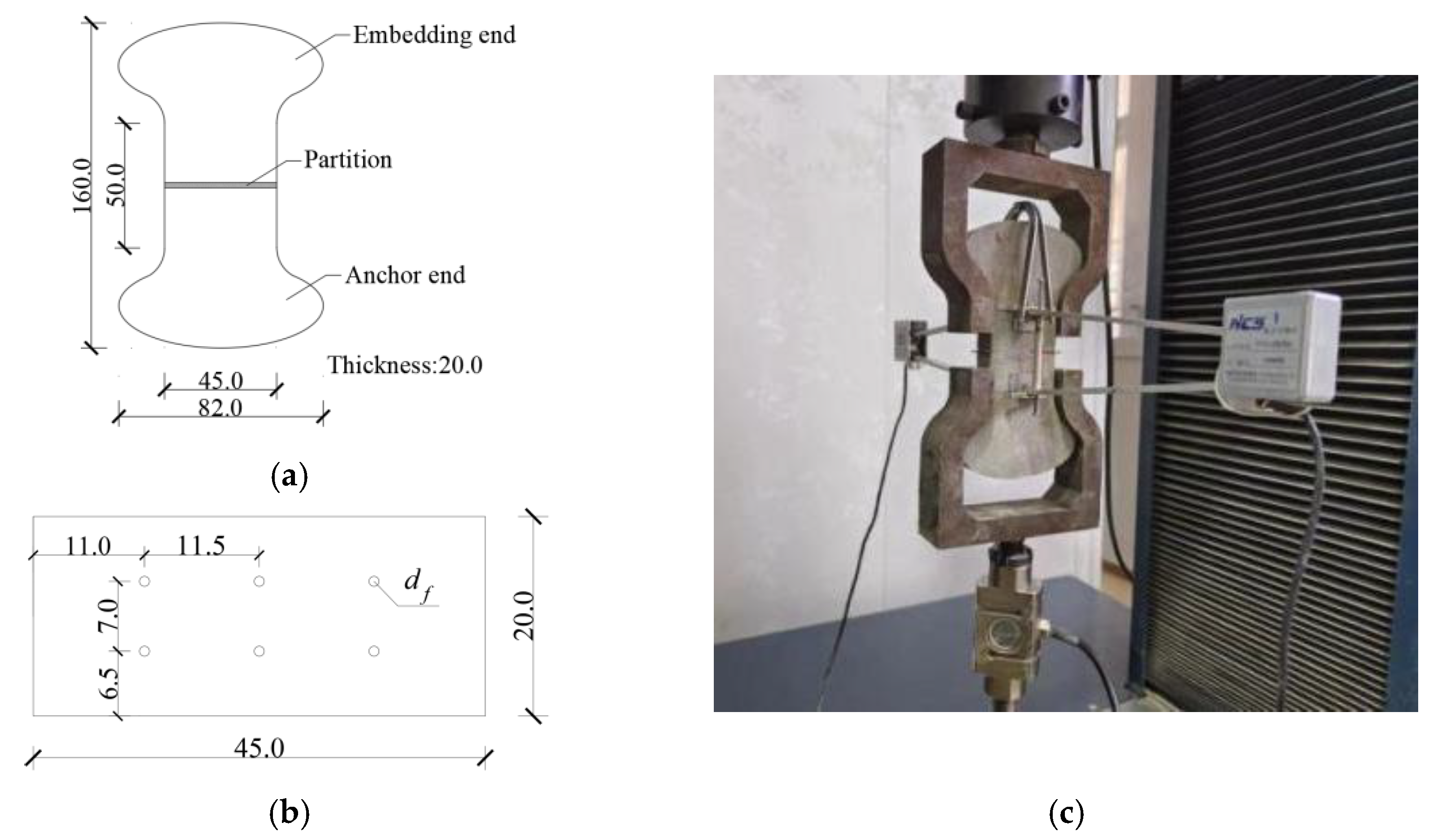

4.1. Specimen Preparation and Testing

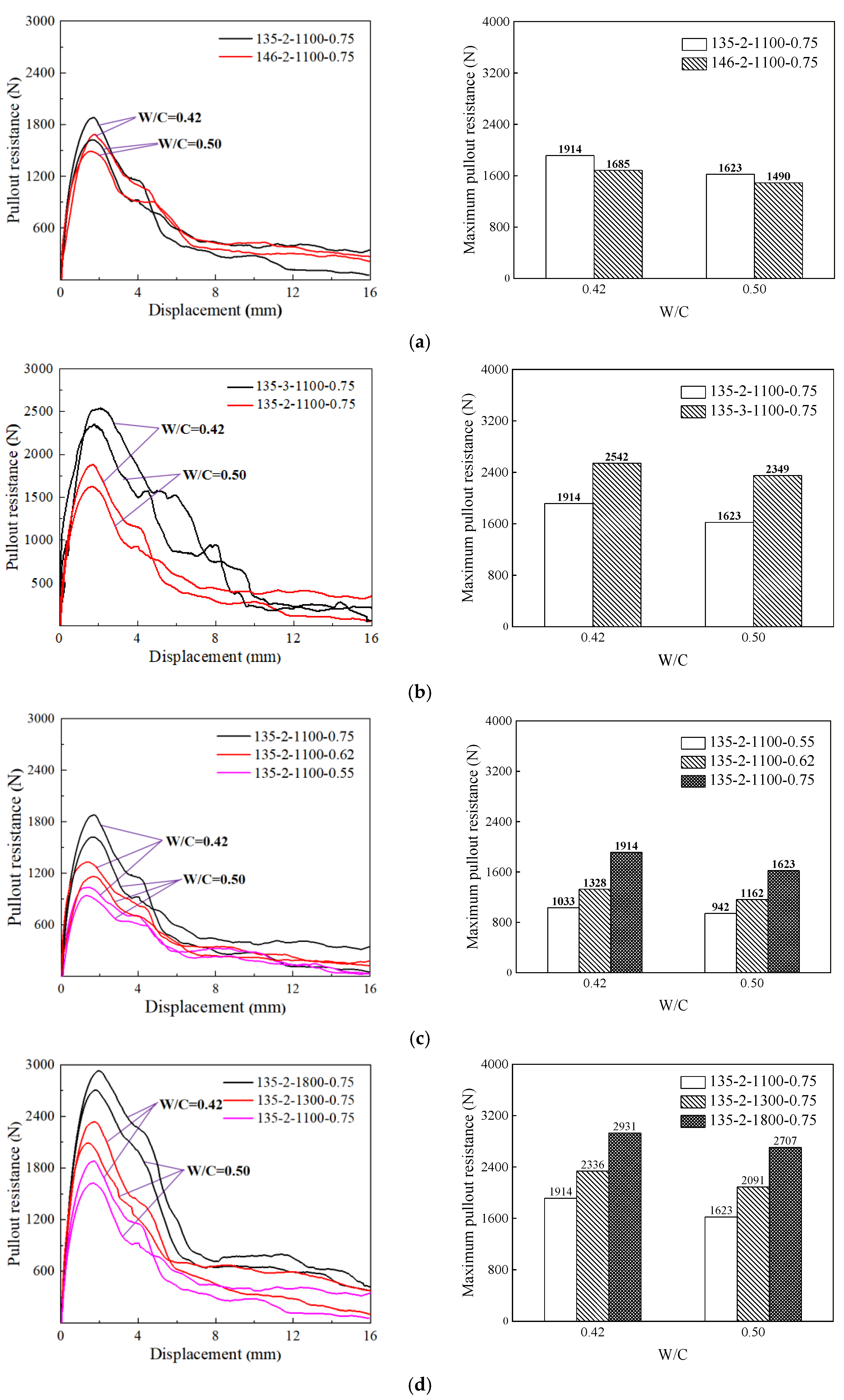

4.2. Test Results

5. Analysis and Discussion

6. Conclusions

- (1)

- An optimization method for the steel fiber shape was proposed to change the hook angle and number of hooks to slow down the decrease in pullout resistance under a certain diameter and tensile strength.

- (2)

- The maximum pullout resistance of the hooked end steel fibers increased with decreasing hook angle, increasing number of hooks, increasing diameter, increasing tensile strength, and increasing matrix strength.

- (3)

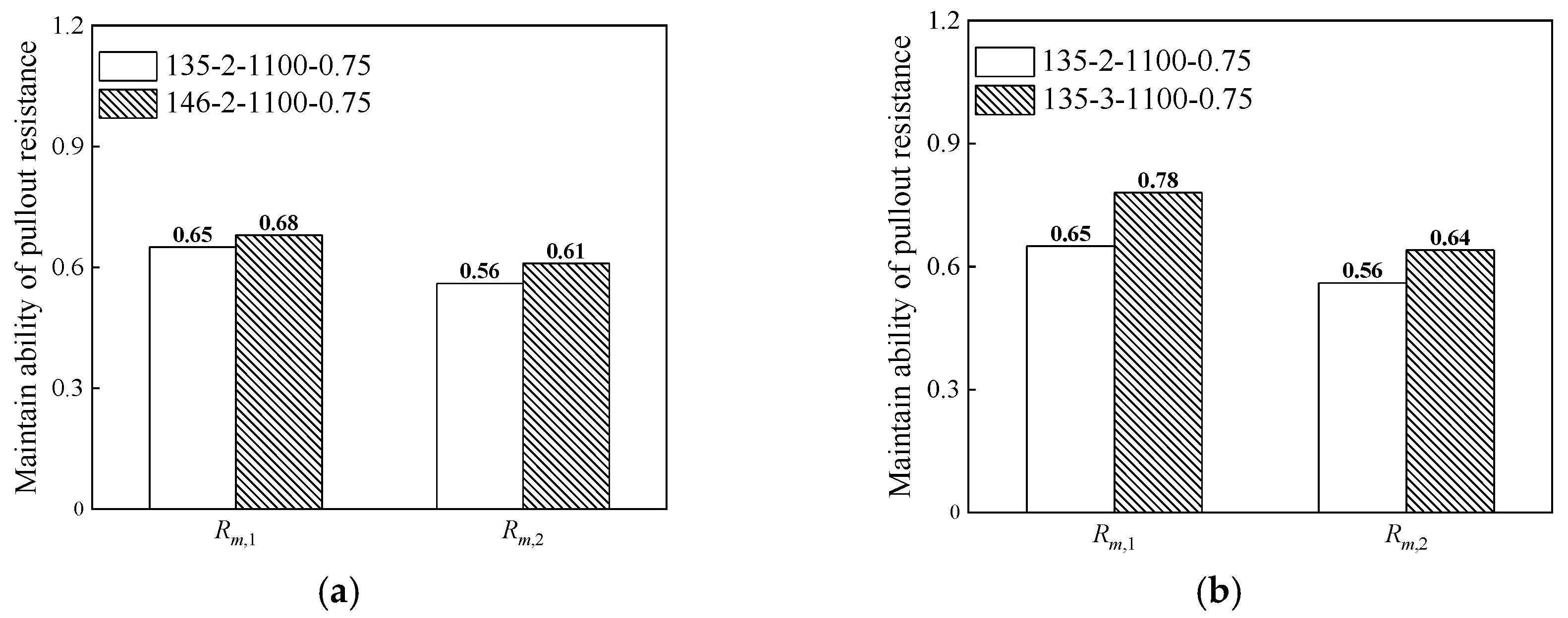

- Optimized steel fibers have a stronger ability to maintain pullout resistance than preoptimized steel fibers. When the water-cement ratio of the cementitious matrix is 0.5, and the steel fiber diameter is 0.75 mm with a tensile strength of 1100 MPa, the ability of the steel fiber to maintain pullout resistance (Rm,1 and Rm,2) increases by 5% and 9% after adjusting the hook angle from 135° to 146° (optimized), respectively.

- (4)

- Compared with the residual flexural-tensile strength of steel-fiber concrete notched beams calculated using the geometric L/D ratio, which is calculated using the equivalent L/D ratio is closer to the test value, indicating that the equivalent L/D ratio can more accurately reflect the reinforcing effect of steel fibers.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nnaaman, A.E.; Homrich, J.R. Tensile stress-strain properties of SIFCON. ACI Mater. J. 1989, 86, 244–251. [Google Scholar]

- Stang, H.; Shah, S.P. Failure of fibre-reinforced composites by pull-out fracture. J. Mater. Sci. 1986, 21, 953–957. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Je, J.; Choi, H.; Sukontasukkul, P. Influence of embedment length on the pullout behavior of steel fibers from ultra-high-performance concrete. Mater. Lett. 2020, 276, 128233. [Google Scholar] [CrossRef]

- Dupont, D.; Vandewalle, L. Distribution of steel fibres in rectangular sections. Cem. Concr. Compos. 2005, 27, 391–398. [Google Scholar] [CrossRef]

- Atik, S.; Hikaru, N.; Taito, M. Mesoscale modelling of SFRC based on 3D RBSM considering the effects of fiber shape and orientation. Cem. Concr. Compos. 2023, 139, 105039. [Google Scholar]

- Woo, S.; Kim, K.; Han, S. Tensile cracking constitutive model of steel fiber reinforced concrete (SFRC). KSCE J. Civ. Eng. 2014, 18, 1446–1454. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Shi, C.; Chen, X. Experimental and numerical study on tensile strength and failure pattern of high performance steel fiber reinforced concrete under dynamic splitting tension. Constr. Build. Mater. 2020, 259, 119796. [Google Scholar] [CrossRef]

- Nieuwoudt, P.D.; Babafemi, A.J.; Boshoff, W.P. The response of cracked steel fibre reinforced concrete under various sustained stress levels on both the macro and single fibre level. Constr. Build. Mater. 2017, 156, 828–843. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C.; Liao, L.; Wang, C.; Zhao, R. Investigation into the effect of fibre distribution on the post-cracking tensile strength of SFRC through physical experimentation and numerical simulation. Constr. Build. Mater. 2020, 248, 118433. [Google Scholar] [CrossRef]

- Naaman, A.E.; Najm, H. Bond-Slip Mechanisms of Steel Fibers in Concrete. ACI Mater. J. 1991, 88, 135–145. [Google Scholar]

- Abdallah, S.; Fan, M.; Rees, D.W.A. Analysis and modelling of mechanical anchorage of 4D/5D hooked end steel fibres. Mater. Design. 2016, 112, 539–552. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 139–201. [Google Scholar] [CrossRef]

- Zhan, Y.; Meschke, G. Analytical model for the pullout behavior of straight and hooked-end steel fibers. J. Eng. Mech. 2014, 140, 04014091. [Google Scholar] [CrossRef]

- Soetens, T.; Gysel, V.A.; Matthys, S.; Taerwe, L. A semi-analytical model to predict the pull-out behaviour of inclined hooked-end steel fibres. Constr. Build. Mater. 2013, 43, 253–265. [Google Scholar] [CrossRef]

- Alwan, J.M.; Naaman, A.E.; Guerrero, P. Effect of mechanical clamping on the pull-out response of hooked steel fibers embedded in cementitious matrices. Concr. Sci. Eng. 1999, 1, 15–25. [Google Scholar]

- Wang, Z.; Bi, J.; He, R.; Zhao, Y.; Huo, L.; Duan, Y. A meso-mechanical model for post-cracking tensile constitutive behavior of steel fiber reinforced concrete. Constr. Build. Mater. 2021, 296, 123625. [Google Scholar] [CrossRef]

- Zīle, E.; Zīle, O. Effect of the fiber geometry on the pullout response of mechanically deformed steel fibers. Cem. Concr. Res. 2013, 44, 18–24. [Google Scholar] [CrossRef]

- Chanvillard, G. Modeling the pullout of wire-drawn steel fibers. Cem. Concr. Res. 1999, 29, 1027–1037. [Google Scholar] [CrossRef]

- Ding, C.; Gao, D.; Guo, A. Analytical methods for stress-crack width relationship and residual flexural strengths of 3D/4D/5D steel fiber reinforced concrete. Constr. Build. Mater. 2022, 346, 128438. [Google Scholar] [CrossRef]

- Isla, F.; Argaaraz, P.; Luccioni, B. Numerical modelling of steel fibers pull-out from cementitious matrixes. Constr. Build. Mater. 2022, 332, 127373. [Google Scholar] [CrossRef]

- CECS 13-2009; Standard Test Methods for Fiber Reinforced Concrete. China Planning Press: Beijing, China, 2010.

- Parviz, S.; Ziad, B. Fiber Type Effects on the Performance of Steel Fiber Reinforced Concrete. ACI Mater. J. 1991, 88, 129–134. [Google Scholar]

- EN 14651-2005; Test Method for Metallic Fibered Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). European Committee for Standardization: Brussels, Belgium, 2005.

| Hook Angle (°) | Number of Hooks | Maximum Pullout Resistance (N) | Pullout Stress (MPa) | 0.5 fu (MPa) | Residual Pullout Resistance (N) | Pullout Resistance Decline Rate k | |

|---|---|---|---|---|---|---|---|

| Before optimized steel fiber a | 135 | 2 | 259 | 587 | 550 | 143 | 0.55 |

| Before optimized steel fiber b | 160 | 2 | 228 | 516 | 550 | 138 | 0.61 |

| After optimized steel fiber c | 146 | 2 | 244 | 553 | 550 | 141 | 0.58 |

| Steel Fiber Types | Hook Angle (°) | Number of Hooks | Diameter (mm) | Length (mm) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 135-2-1100-0.55 | 135 | 2 | 0.55 | 60 | 1100 |

| 135-2-1100-0.62 | 135 | 2 | 0.62 | 60 | 1100 |

| 135-2-1100-0.75 | 135 | 2 | 0.75 | 60 | 1100 |

| 135-2-1300-0.75 | 135 | 2 | 0.75 | 60 | 1300 |

| 135-2-1800-0.75 | 135 | 2 | 0.75 | 60 | 1800 |

| 146-2-1100-0.75 | 146 | 2 | 0.75 | 60 | 1100 |

| 135-3-1100-0.75 | 135 | 3 | 0.75 | 60 | 1100 |

| W/C | Steel Fiber Types | Maximum Pullout Resistance (Single) (N) | Geometric L/D Ratio | Equivalent L/D Ratio |

|---|---|---|---|---|

| 0.50 | 135-2-1100-0.55 | 157 | 109 | 150 |

| 135-2-1100-0.62 | 194 | 97 | 146 | |

| 135-2-1100-0.75 | 271 | 80 | 139 | |

| 135-2-1300-0.75 | 349 | 80 | 180 | |

| 135-2-1800-0.75 | 451 | 80 | 232 | |

| 146-2-1100-0.75 | 248 | 80 | 128 | |

| 135-3-1100-0.75 | 392 | 80 | 202 |

| W/C | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | Pebble (kg/m3) | Steel Fiber Volume Fraction (kg/m3) |

|---|---|---|---|---|---|

| 0.50 | 175 | 350 | 890 | 965 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xu, B.; Luan, K.; Mu, R.; Chen, J. Optimization of the Shape of Hooked-End Steel Fiber Based on Pulling Out and Reinforcing Cementitious Composites. Materials 2024, 17, 47. https://doi.org/10.3390/ma17010047

Wang X, Xu B, Luan K, Mu R, Chen J. Optimization of the Shape of Hooked-End Steel Fiber Based on Pulling Out and Reinforcing Cementitious Composites. Materials. 2024; 17(1):47. https://doi.org/10.3390/ma17010047

Chicago/Turabian StyleWang, Xiaowei, Bo Xu, Kuiliang Luan, Ru Mu, and Jiao Chen. 2024. "Optimization of the Shape of Hooked-End Steel Fiber Based on Pulling Out and Reinforcing Cementitious Composites" Materials 17, no. 1: 47. https://doi.org/10.3390/ma17010047

APA StyleWang, X., Xu, B., Luan, K., Mu, R., & Chen, J. (2024). Optimization of the Shape of Hooked-End Steel Fiber Based on Pulling Out and Reinforcing Cementitious Composites. Materials, 17(1), 47. https://doi.org/10.3390/ma17010047