The Impact of Surface Roughness on Conformal Cooling Channels for Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of the Experiment

2.2. Materials and Equipment

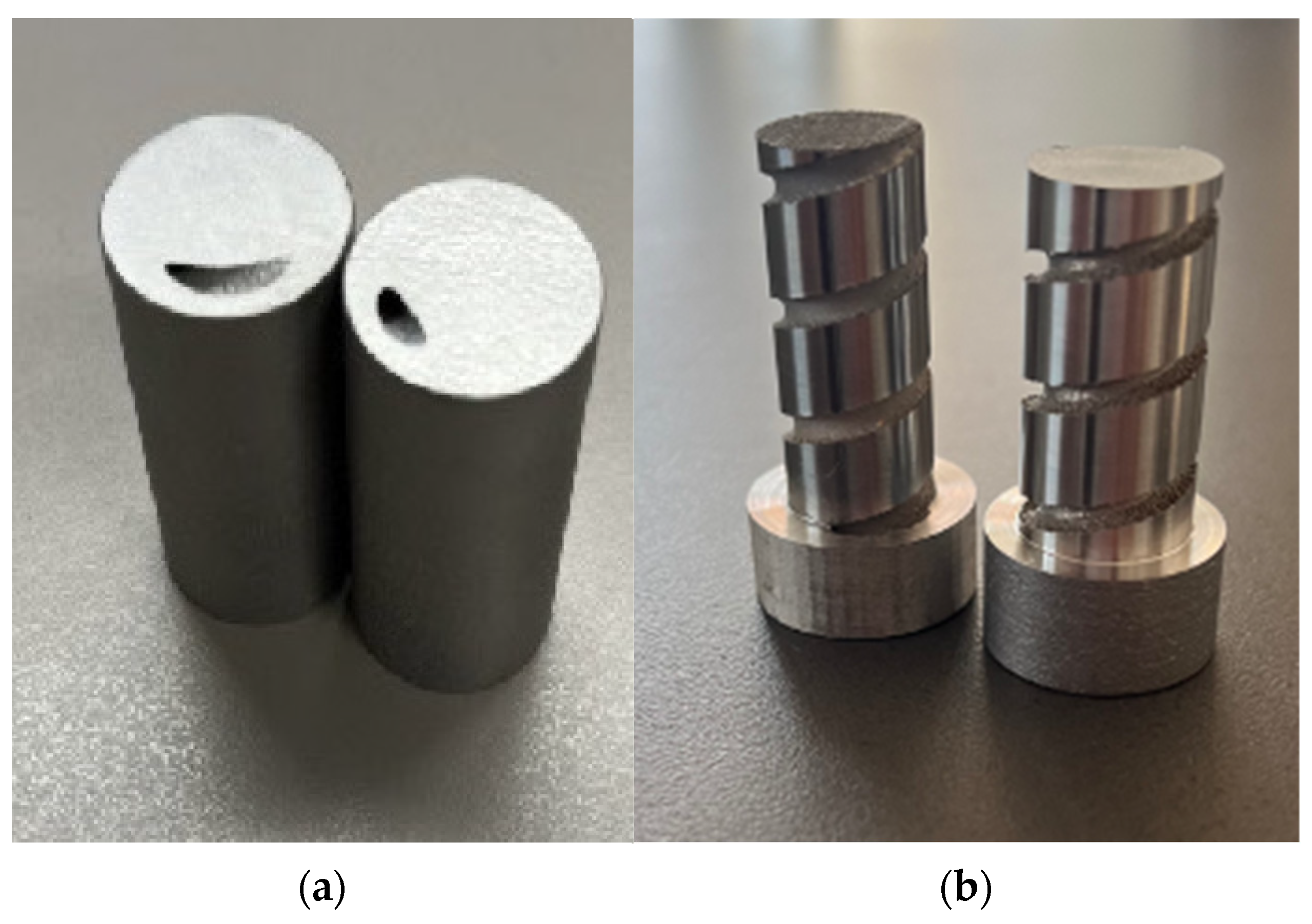

2.3. Test Specimens’ Design

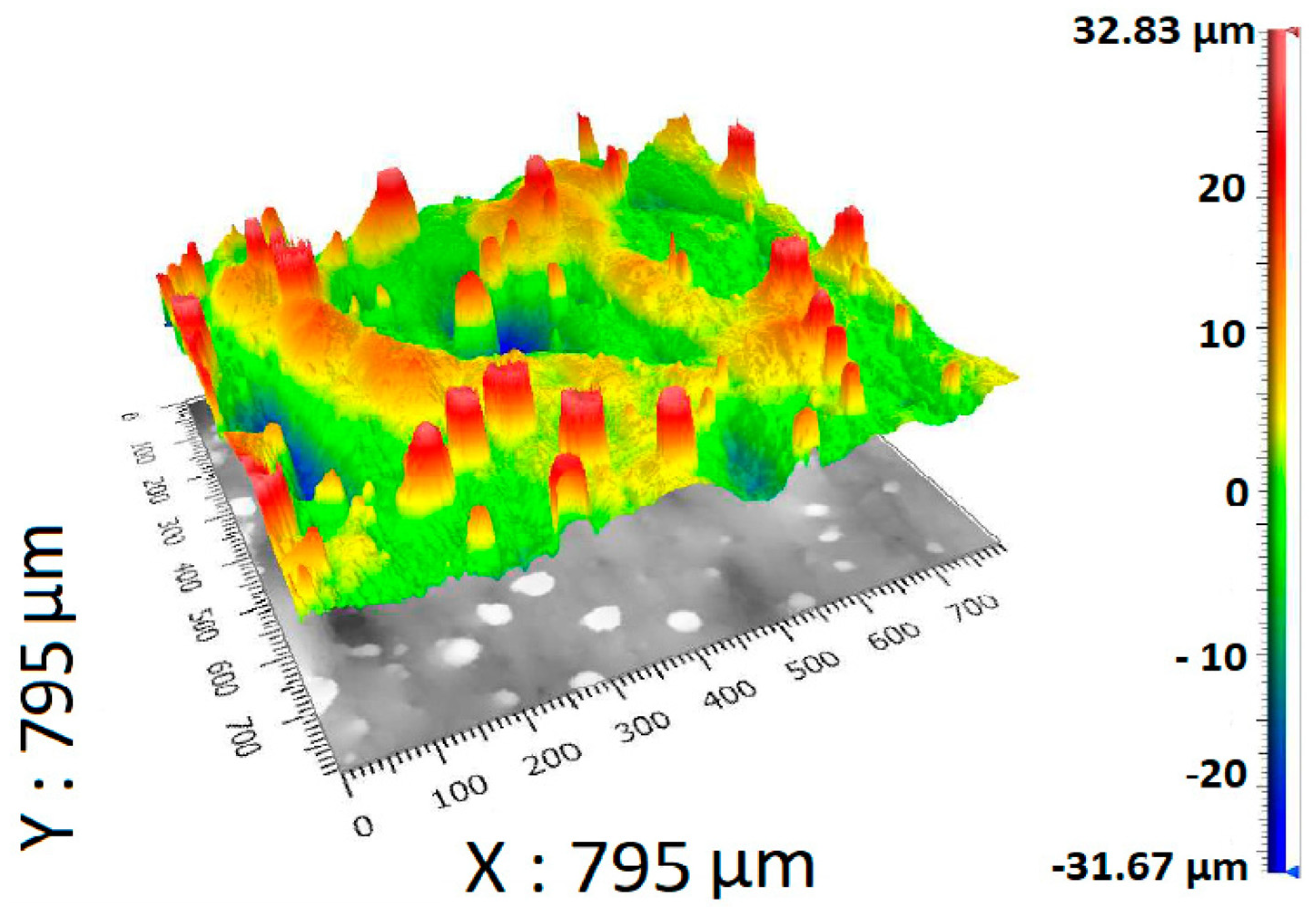

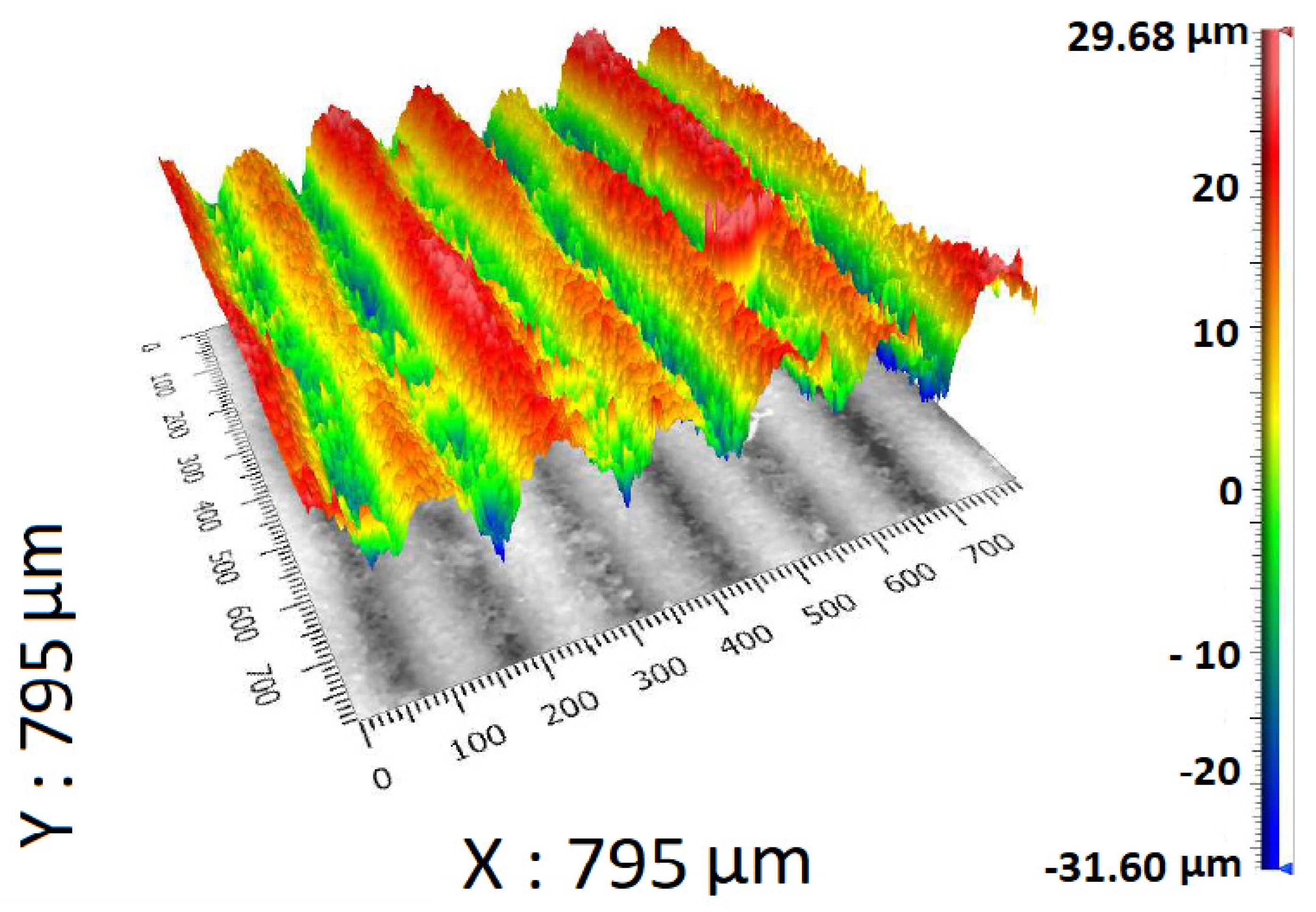

2.4. Internal Surface Roughness Measurement

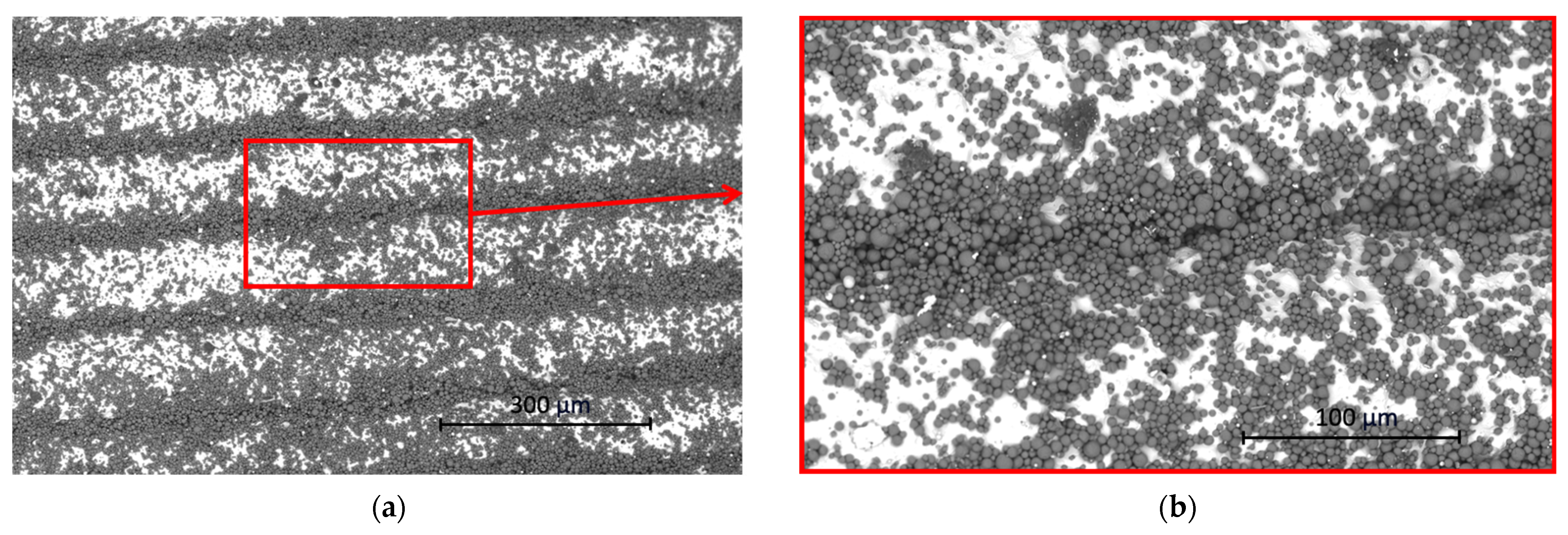

2.5. Scanning Electron Microscopy

2.6. Cooling System Flow Analysis

Analysis Parameters

3. Results

3.1. Internal Surface Roughness Measurement

3.2. Scanning Electron Microscopy

EDAX Analysis

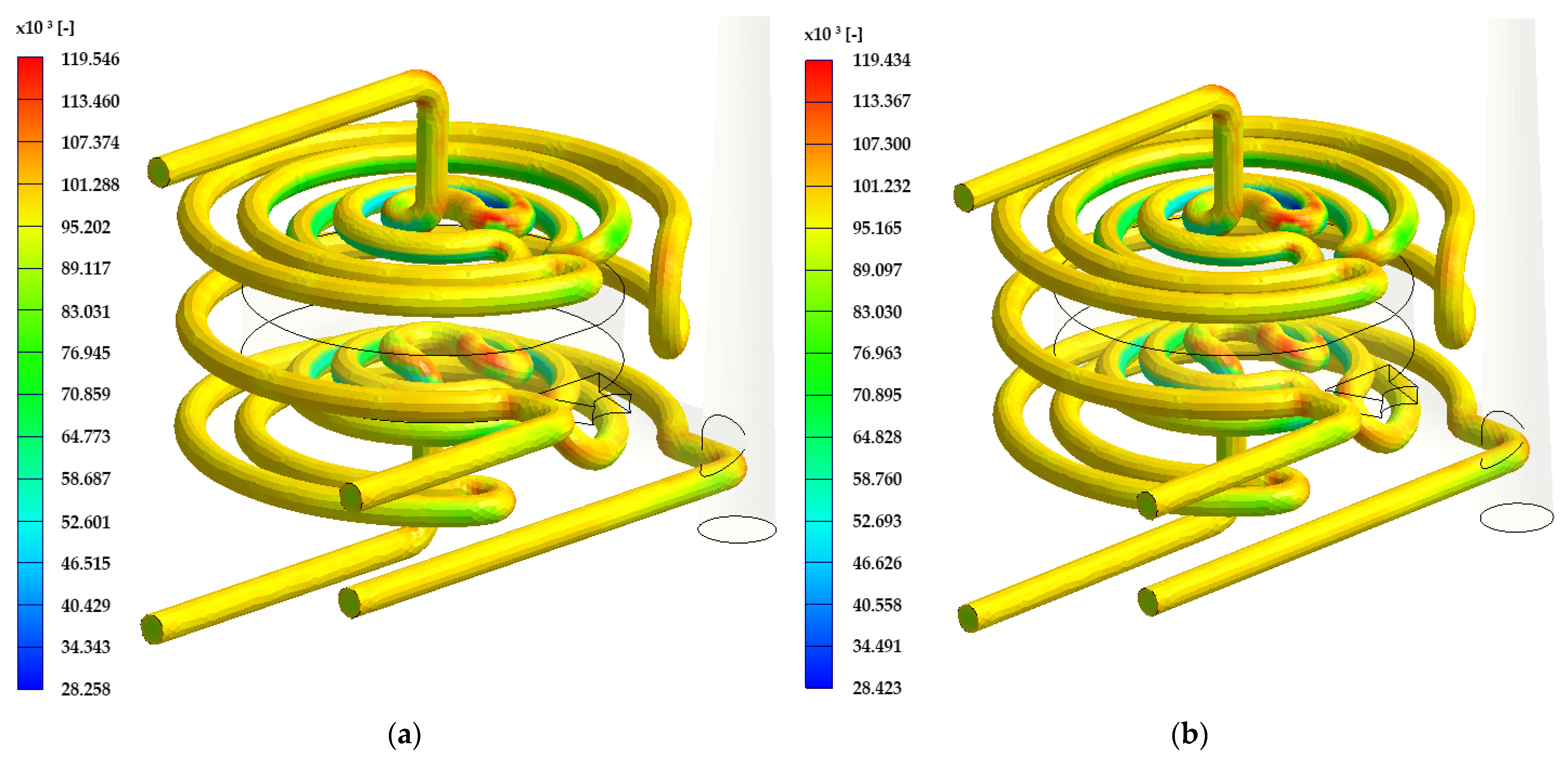

3.3. Cooling System Flow Analysis

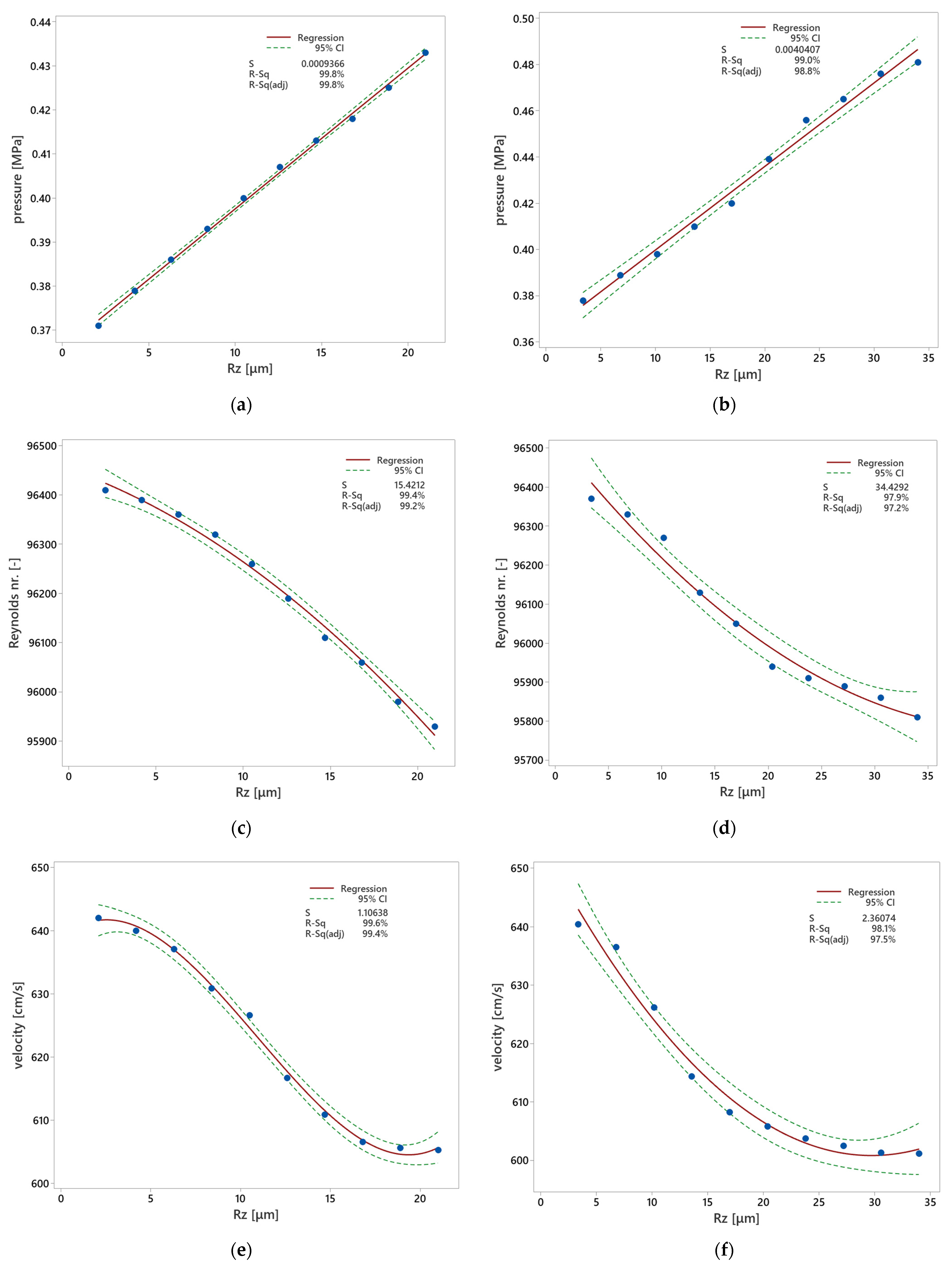

Regression Models

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Venkatesh, G.; Kumar, Y.R.; Raghavendra, G. Comparison of Straight Line to Conformal Cooling Channel in Injection Molding. Mater. Today Proc. 2017, 4, 1167–1173. [Google Scholar] [CrossRef]

- Deepika, S.S.; Patil, B.T.; Shaikh, V.A. Plastic Injection Molded Door Handle Cooling Time Reduction Investigation Using Conformal Cooling Channels. Mater. Today Proc. 2020, 27, 519–523. [Google Scholar] [CrossRef]

- Jahan, S.A.; El-Mounayri, H. Optimal Conformal Cooling Channels In 3D Printed Dies for Plastic Injection Molding. Procedia Manuf. 2016, 5, 888–900. [Google Scholar] [CrossRef]

- Dimla, E.; Rull-Trinidad, J.; Garcia-Granada, A.A.; Reyes, G. Thermal Comparison of Conventional and Conformal Cooling Channel Designs For A Non-Constant Thickness Screw Cap. J. Korean Soc. Precis. Eng. 2018, 35, 95–101. [Google Scholar] [CrossRef]

- Park, H.-S.; Dang, X.-P.; Nguyen, D.-S.; Kumar, S. Design of Advanced Injection Mold to Increase Cooling Efficiency. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 319–328. [Google Scholar] [CrossRef]

- Shen, S.; Kanbur, B.B.; Zhou, Y.; Duan, F. Thermal and Mechanical Analysis for Conformal Cooling Channel in Plastic Injection Molding. Mater. Today Proc. 2020, 28, 396–401. [Google Scholar] [CrossRef]

- Chung, C.-Y. Integrated Optimum Layout of Conformal Cooling Channels and Optimal Injection Molding Process Parameters for Optical Lenses. Appl. Sci. 2019, 9, 4341. [Google Scholar] [CrossRef]

- Park, H.-S.; Dang, X.-P. Development of A Smart Plastic Injection Mold with Conformal Cooling Channels. Procedia Manuf. 2017, 10, 48–59. [Google Scholar] [CrossRef]

- Torres-Alba, A.; Mercado-Colmenero, J.M.; Caballero-Garcia, J.d.D.; Martin-Doñate, C. Application of New Triple Hook-Shaped Conformal Cooling Channels for Cores and Sliders in Injection Molding to Reduce Residual Stress and Warping in Complex Plastic Optical Parts. Polymers 2021, 13, 2944. [Google Scholar] [CrossRef]

- Goldsberry, C. Milacron’s DME Partners with Linear AMS to Develop 3D-Printed Conformal Cooling Technology; Plastics Today: Santa Monica, CA, USA, 2017. [Google Scholar]

- Spina, R.; Walach, P.; Schild, J.; Hopmann, C. Analysis of Lens Manufacturing with Injection Molding. Int. J. Precis. Eng. Manuf. 2012, 13, 2087–2095. [Google Scholar] [CrossRef]

- Bensingh, R.J.; Boopathy, S.R.; Jebaraj, C. Minimization of Variation in Volumetric Shrinkage and Deflection on Injection Molding of Bi-Aspheric Lens Using Numerical Simulation. J. Mech. Sci. Technol. 2016, 30, 5143–5152. [Google Scholar] [CrossRef]

- Huang, M.-S.; Chen, J.-Y.; Xiao, Y.-Q. Quality Monitoring of Micro-Shrinkage Defects in Thick-Walled Injection Molded Components. Measurement 2022, 201, 111733. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, C. Design and Optimization of Conformal Cooling Channels for Increasing Cooling Efficiency In Injection Molding. Appl. Sci. 2023, 13, 7437. [Google Scholar] [CrossRef]

- Vanek, J.; Stanek, M.; Martin Ovsik, M.; Chalupa, V. Injection Molding of Polycarbonate Thick-Walled Parts Using a Tool with Variously Designed Gate Inserts. Mater. Tehnol. 2023, 57, 299–305. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Jiang, Z.-F.; Yang, X.-Y.; Chu, S.-X.; Wu, J.-Q. Characterization of A Direct Metal Printed Injection Mold with Different Conformal Cooling Channels. Int. J. Adv. Manuf. Technol. 2020, 107, 1223–1238. [Google Scholar] [CrossRef]

- Simiyu, L.W.; Mutua, J.M.; Muiruri, P.I.; Ikua, B.W. Optimization of Polygonal Cross-Sectioned Conformal Cooling Channels in Injection Molding. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 18, 1593–1609. [Google Scholar] [CrossRef]

- Jahan, S.; El-Mounayri, H. A Thermomechanical Analysis of Conformal Cooling Channels in 3D Printed Plastic Injection Molds. Appl. Sci. 2018, 8, 2567. [Google Scholar] [CrossRef]

- Hensley, C.; Sisco, K.; Beauchamp, S.; Godfrey, A.; Rezayat, H.; McFalls, T.; Galicki, D.; List, F.; Carver, K.; Stover, C.; et al. Qualification Pathways for Additively Manufactured Components for Nuclear Applications. J. Nucl. Mater. 2021, 548, 152846. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive Manufacturing for Energy: A Review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Brennan, M.C.; Keist, J.S.; Palmer, T.A. Defects in Metal Additive Manufacturing Processes. J. Mater. Eng. Perform. 2021, 30, 4808–4818. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The Influence of Porosity on Fatigue Crack Initiation in Addi-tively Manufactured Titanium Components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef] [PubMed]

- Sangid, M.D.; Ravi, P.; Prithivirajan, V.; Miller, N.A.; Kenesei, P.; Park, J.-S. ICME Approach to Determining Critical Pore Size of IN718 Produced by Selective Laser Melting. JOM 2019, 72, 465–474. [Google Scholar] [CrossRef]

- Scott, S.; Chen, W.-Y.; Heifetz, A. Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals. Sensors 2023, 23, 8462. [Google Scholar] [CrossRef] [PubMed]

- Galati, M.; Minetola, P. Analysis of Density, Roughness, and Accuracy of the Atomic Diffusion Additive Manufacturing (Adam) Process for Metal Parts. Materials 2019, 12, 4122. [Google Scholar] [CrossRef] [PubMed]

- Phani Babu, V.V.; GB, V.K. A Review On 3D Printing Process on Metals and Their Surface Roughness and Dimensional Accuracy. Mater. Today Proc. 2022, 64, 523–530. [Google Scholar] [CrossRef]

- Abbès, B.; Abbès, F.; Abdessalam, H.; Upganlawar, A. Finite Element Cooling Simulations of Conformal Cooling Hybrid Injection Molding Tools Manufactured by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2019, 103, 2515–2522. [Google Scholar] [CrossRef]

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J.; Courbon, J. Effect of Abrasive Flow Machining (Afm) Finish of Selective Laser Melting (Slm) Internal Channels on Fatigue Performance. J. Manuf. Process. 2020, 59, 248–257. [Google Scholar] [CrossRef]

- Günther, J.; Leuders, S.; Koppa, P.; Tröster, T.; Henkel, S.; Biermann, H.; Niendorf, T. On the Effect of Internal Channels and Surface Roughness on the High-Cycle Fatigue Performance of Ti-6Al-4V Processed by Slm. Mater. Des. 2018, 143, 1–11. [Google Scholar] [CrossRef]

- Dumas, M.; Cabanettes, F.; Kaminski, R.; Valiorgue, F.; Picot, E.; Lefebvre, F.; Grosjean, C.; Rech, J. Influence of the Finish Cutting Operations on the Fatigue Performance of Ti-6Al-4V Parts Produced by Selective Laser Melting. Procedia CIRP 2018, 71, 429–434. [Google Scholar] [CrossRef]

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J. Abrasive Flow Machining (Afm) Finishing of Conformal Cooling Channels Created by Selective Laser Melting (Slm). Precis. Eng. 2020, 64, 20–33. [Google Scholar] [CrossRef]

- Chawla, G.; Mittal, V.K.; Mittal, S. Design and Development of Fixture and Modification Of Existing Afm Setup to Magnetic Abrasive Flow Machining (Mafm) Process Setup. J. Phys. Conf. Ser. 2019, 1240, 012009. [Google Scholar] [CrossRef]

- François, M.; Han, S.; Segonds, F.; Dupuy, C.; Rivette, M.; Turpault, S.; Mimouna, M.; Salvatore, F.; Rech, J.; Peyre, P. Electromagnetic Performance of Ti6Al4V and Alsi7Mg0.6 Waveguides with Laser Beam Melting (Lbm) Produced and Abrasive Flow Machining (Afm) Finished Internal Surfaces. J. Electromagn. Waves Appl. 2021, 35, 2510–2526. [Google Scholar] [CrossRef]

- Bílek, O.; Pata, V.; Kubišová, M.; Řezníček, M. Mathematical Methods of Surface Roughness Evaluation of Areas with a Distinctive Inclination. Manuf. Technol. 2018, 18, 363–368. [Google Scholar] [CrossRef]

- Meloun, M.; Militky, J. A Compendium of Statistical Data Processing; Karolinum: Prague, Czech Republic, 2013; p. 984. ISBN 978-80-246-2196-8. [Google Scholar]

| Parameter | |

|---|---|

| Channel diameter | 4 mm |

| Coolant medium | Water (90 °C) |

| Defined flow rate | 6 L/min |

| Mesh type | Volumetric |

| Element type | Tetra |

| Number of elements | 172,374 |

| Bad element | 0 |

| Solver | Standard |

| Analysis type | 3D solid cooling channel |

| Turbulence modeling | Yes |

| Cooling channel mesh aspect ratio range | 0.7–1 |

| Parameter | Specimen A (DMLS) | Specimen B (ADAM) |

|---|---|---|

| Rz [μm] | 21 | 34 |

| Element | Atomic Concentration [%] | Weight Concentration [%] |

|---|---|---|

| C | 31.65 | 11.01 |

| O | 20.08 | 9.31 |

| Al | 2.31 | 1.80 |

| Si | 2.09 | 1.70 |

| Ca | 2.50 | 2.90 |

| Fe | 29.63 | 47.95 |

| Ni | 10.23 | 21.12 |

| Mo | 1.51 | 4.20 |

| Element | Atomic Concentration [%] | Weight Concentration [%] |

|---|---|---|

| C | 10.69 | 5.39 |

| O | 41.33 | 27.77 |

| Al | 36.95 | 41.86 |

| V | 2.19 | 4.70 |

| Cr | 2.74 | 5.99 |

| Fe | 6.09 | 14.29 |

| Rz [μm] | Pressure [MPa] | Reynolds nr. [-] | Flow Velocity [cm/s] |

|---|---|---|---|

| 21 | 0.433 | 95,930 | 605.3 |

| 18.9 | 0.425 | 95,980 | 605.6 |

| 16.8 | 0.418 | 96,060 | 606.6 |

| 14.7 | 0.413 | 96,110 | 610.9 |

| 12.6 | 0.407 | 96,190 | 616.7 |

| 10.5 | 0.400 | 96,260 | 626.6 |

| 8.4 | 0.393 | 96,320 | 630.9 |

| 6.3 | 0.386 | 96,360 | 637.1 |

| 4.2 | 0.379 | 96,390 | 640.0 |

| 2.1 | 0.371 | 96,410 | 642.0 |

| Rz [μm] | Pressure [MPa] | Reynolds nr. [-] | Flow Velocity [cm/s] |

|---|---|---|---|

| 34 | 0.481 | 95,810 | 601.2 |

| 30.6 | 0.476 | 95,860 | 601.3 |

| 27.2 | 0.465 | 95,890 | 602.5 |

| 23.8 | 0.456 | 95,910 | 603.8 |

| 20.4 | 0.439 | 95,940 | 605.8 |

| 17 | 0.420 | 96,050 | 608.3 |

| 13.6 | 0.410 | 96,130 | 614.4 |

| 10.2 | 0.398 | 96,270 | 626.2 |

| 6.8 | 0.389 | 96,330 | 636.5 |

| 3.4 | 0.378 | 96,370 | 640.4 |

| Type of AM Technology | Tested Parameter | Estimations of Regression Parameters | |||

|---|---|---|---|---|---|

| b0 | b1 | b2 | b3 | ||

| DMLS | Pressure [MPa] | 3.656 × 10−1 | 3.195 × 10−3 | - | - |

| Reynolds nr. [-] | 9.645 × 104 | −1.262 × 101 | −6.270 × 10−1 | - | |

| Flow velocity [cm/s] | 9.640 × 104 | 1.153 × 101 | –3.120 × 100 | 7.194 × 10−2 | |

| ADAM | Pressure [MPa] | 3.673 × 10−1 | 3.472 × 10−3 | - | - |

| Reynolds nr. [-] | 9.652 × 104 | −3.456 × 101 | 3.998 × 10–1 | - | |

| Flow velocity [cm/s] | 6.546 × 102 | −3.614 × 100 | 6.078 × 10–2 | - | |

| Parameters | DMLS | ADAM | ||||

|---|---|---|---|---|---|---|

| Pressure | Reynolds nr. | Flow Velocity | Pressure | Reynolds nr. | Flow Velocity | |

| Coefficient of Multiple Correlation | 9.989 × 10−1 | 9.969 × 10−1 | 9.979 × 10−1 | 9.915 × 10−1 | 9.892 × 10−1 | 9.958 × 10−1 |

| Coefficient of Determination | 9.979 × 10−1 | 9.938 × 10−1 | 9.958 × 10−1 | 9.831 × 10−1 | 9.785 × 10−1 | 9.916 × 10−1 |

| Predicted Correlation Coefficient | 9.926 × 10−1 | 9.999 × 10−1 | 9.665 × 10−1 | 9.518 × 10−1 | 9.999 × 10−1 | 9.147 × 10−1 |

| Mean Squared Error of Prediction | 1.374 × 10−6 | 3.749 × 10–1 | 3.358 × 100 | 3.071 × 10−5 | 1.242 × 100 | 8.781 × 100 |

| Testing of Regression Triplet | ||||||

| Fisher–Snedecor Test of Model Significance | Model is significant | |||||

| Scott’s Criteria of Multicollinearity | Model is correct | |||||

| Cook–Weisberg Score Test for Heteroskedasticity | Residue demonstrating homoskedasticity | |||||

| Jarque–Berra Test of Normality | Residue has a normal distribution | |||||

| Wald Test of Auto Correlation | Autocorrelation is insignificant | |||||

| Durbin–Watson Test of Auto Correlation | Negative autocorrelation of residues not demonstrated | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanzlik, J.; Vanek, J.; Pata, V.; Senkerik, V.; Polaskova, M.; Kruzelak, J.; Bednarik, M. The Impact of Surface Roughness on Conformal Cooling Channels for Injection Molding. Materials 2024, 17, 2477. https://doi.org/10.3390/ma17112477

Hanzlik J, Vanek J, Pata V, Senkerik V, Polaskova M, Kruzelak J, Bednarik M. The Impact of Surface Roughness on Conformal Cooling Channels for Injection Molding. Materials. 2024; 17(11):2477. https://doi.org/10.3390/ma17112477

Chicago/Turabian StyleHanzlik, Jan, Jiri Vanek, Vladimir Pata, Vojtech Senkerik, Martina Polaskova, Jan Kruzelak, and Martin Bednarik. 2024. "The Impact of Surface Roughness on Conformal Cooling Channels for Injection Molding" Materials 17, no. 11: 2477. https://doi.org/10.3390/ma17112477

APA StyleHanzlik, J., Vanek, J., Pata, V., Senkerik, V., Polaskova, M., Kruzelak, J., & Bednarik, M. (2024). The Impact of Surface Roughness on Conformal Cooling Channels for Injection Molding. Materials, 17(11), 2477. https://doi.org/10.3390/ma17112477