Recent Advances in Self-Powered Tactile Sensing for Wearable Electronics

Abstract

:1. Introduction

2. Classification of Self-Powered Tactile Sensors

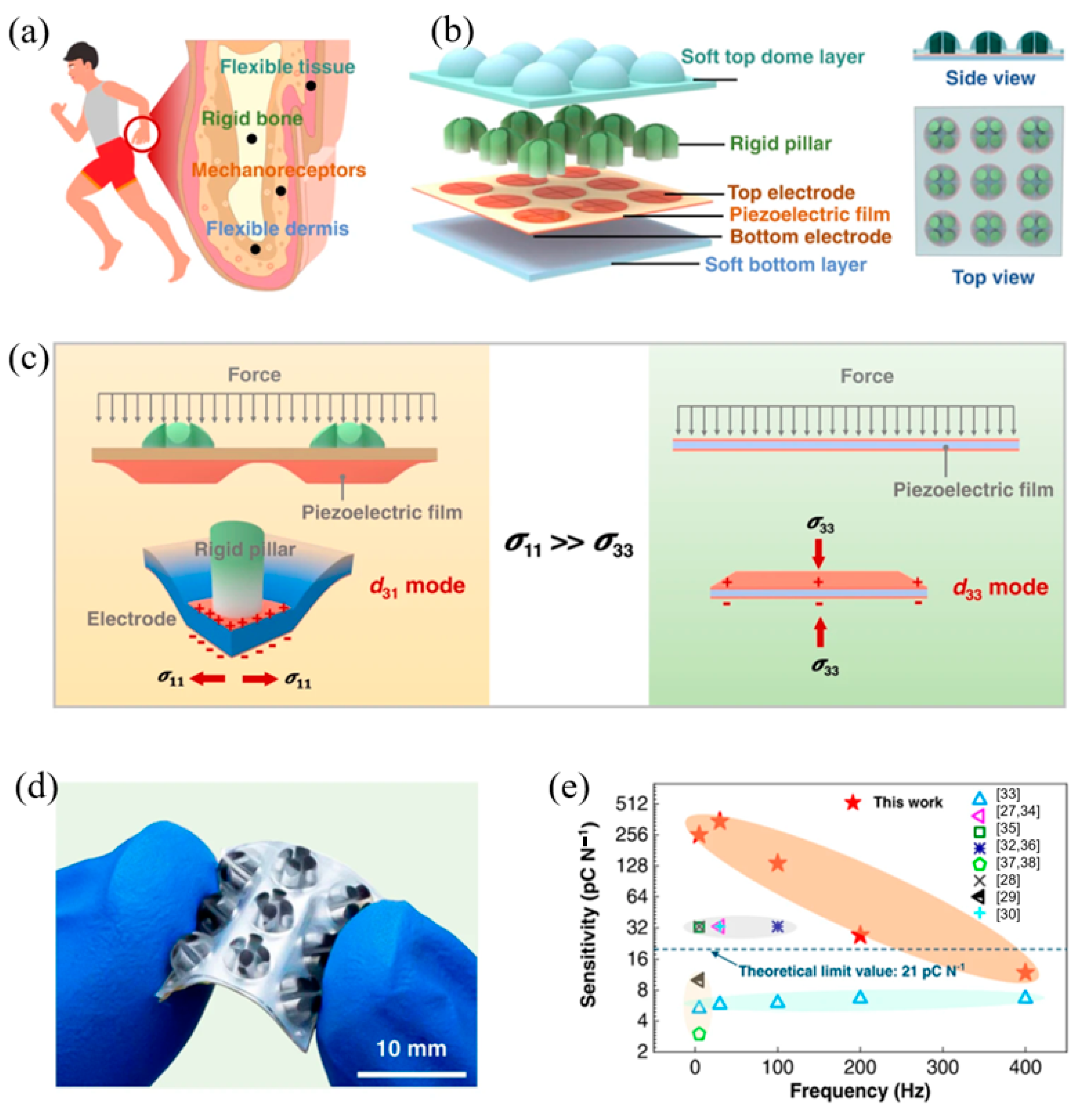

2.1. Piezoelectric-Type

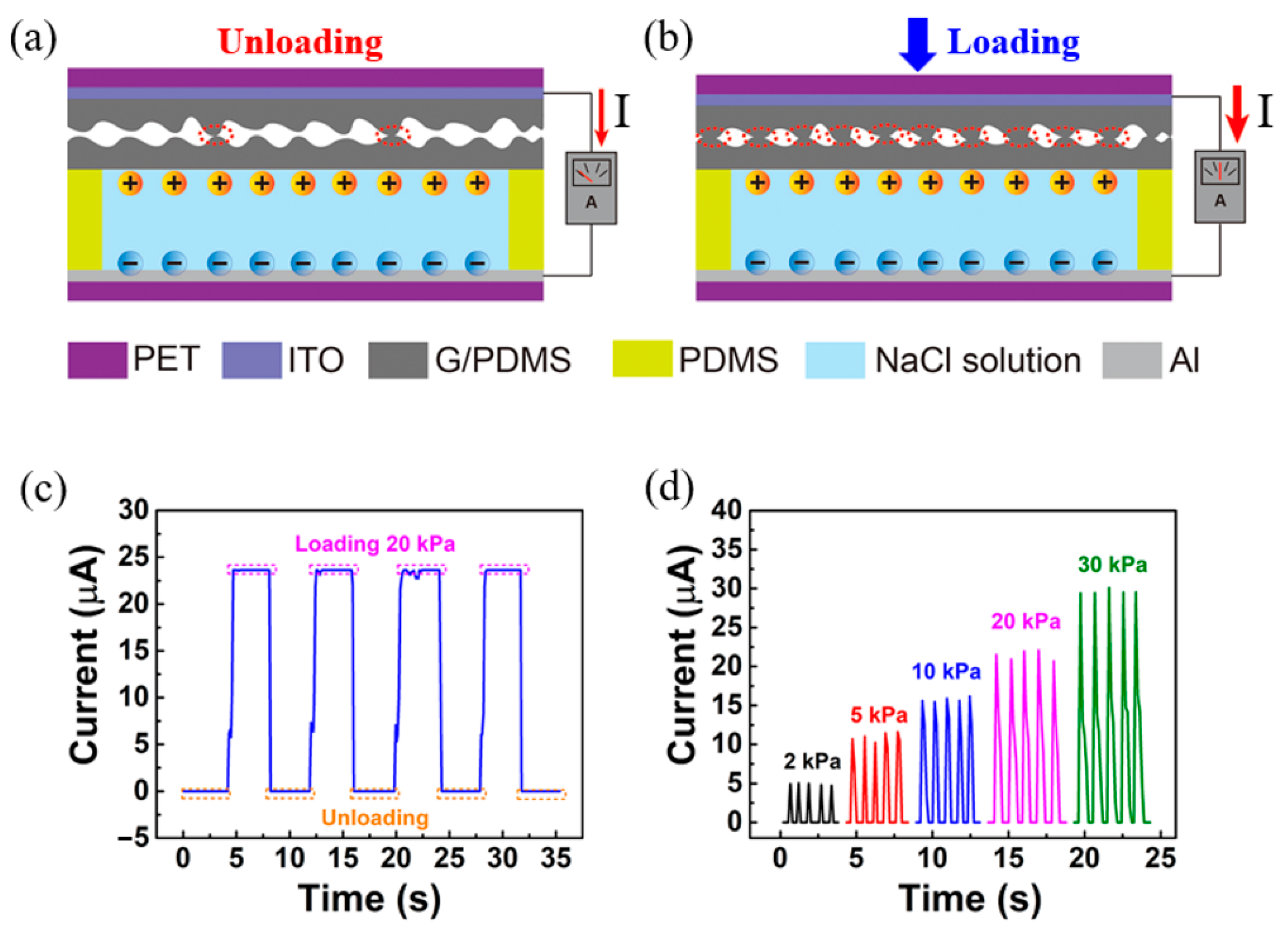

2.2. Triboelectric-Type

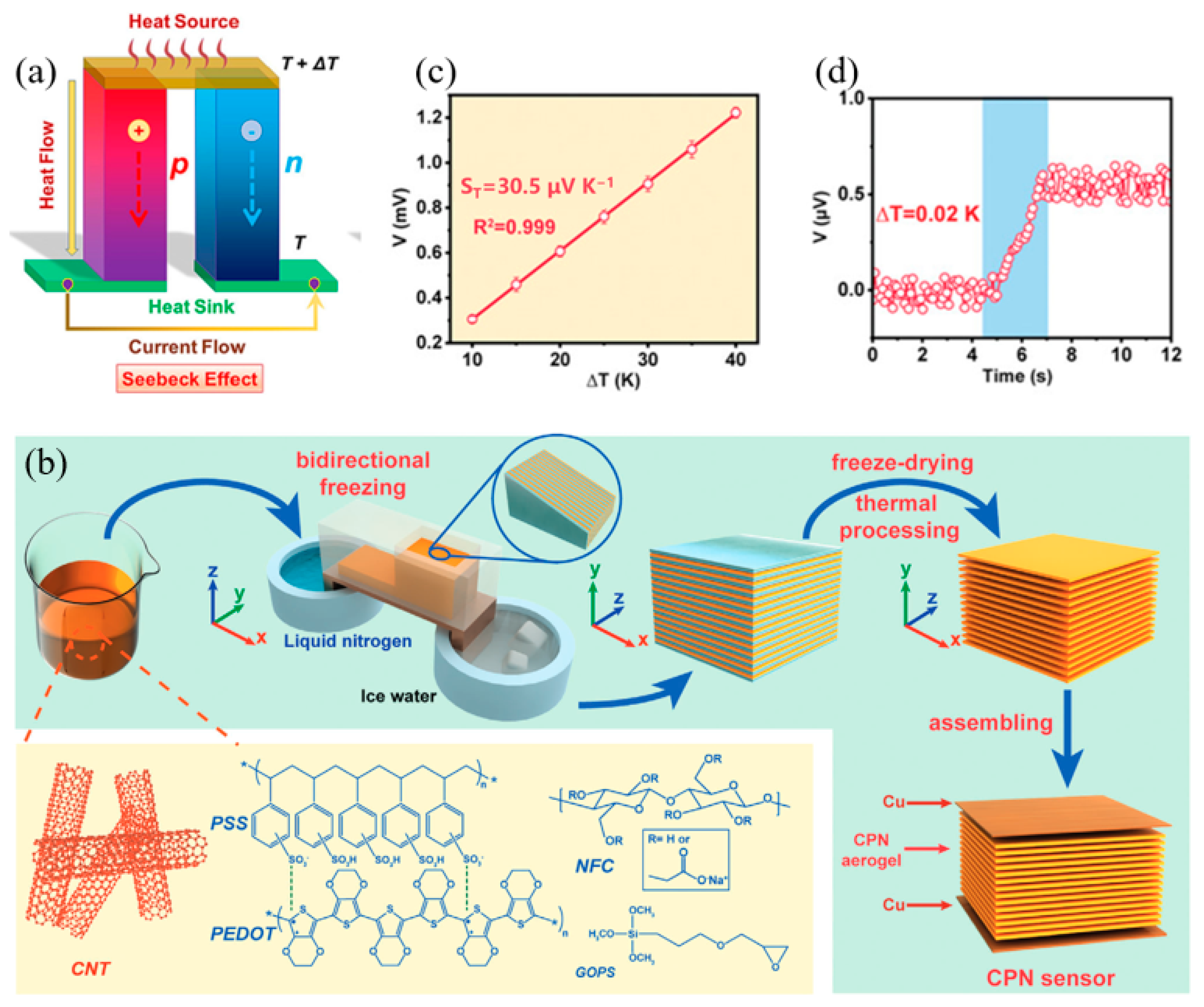

2.3. Thermoelectric Effect Type

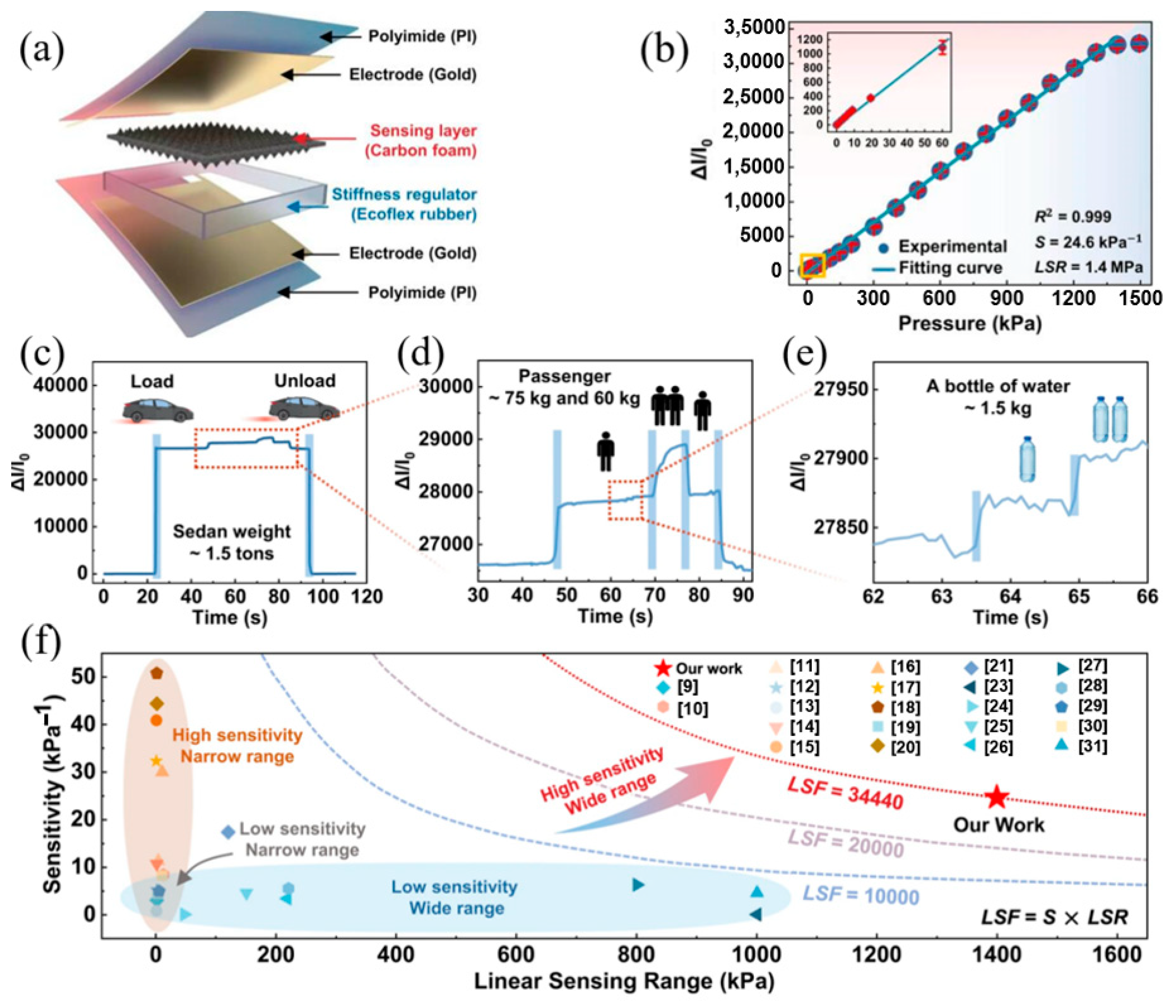

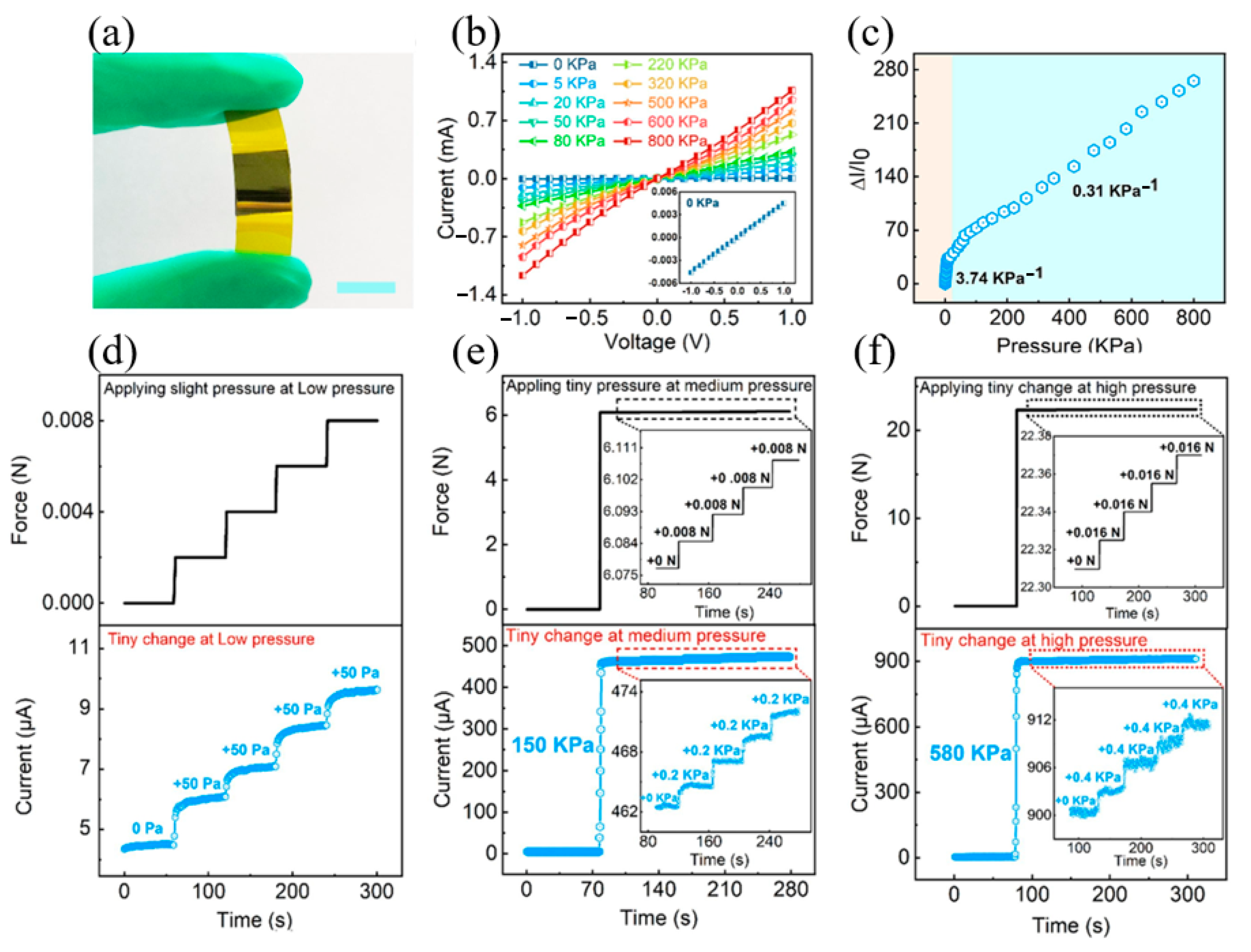

2.4. Piezoresistive-Type

3. Main Performance Indicators

3.1. Sensitivity

3.2. Pressure Detection Range

3.3. Pressure Resolution

4. Practical Applications

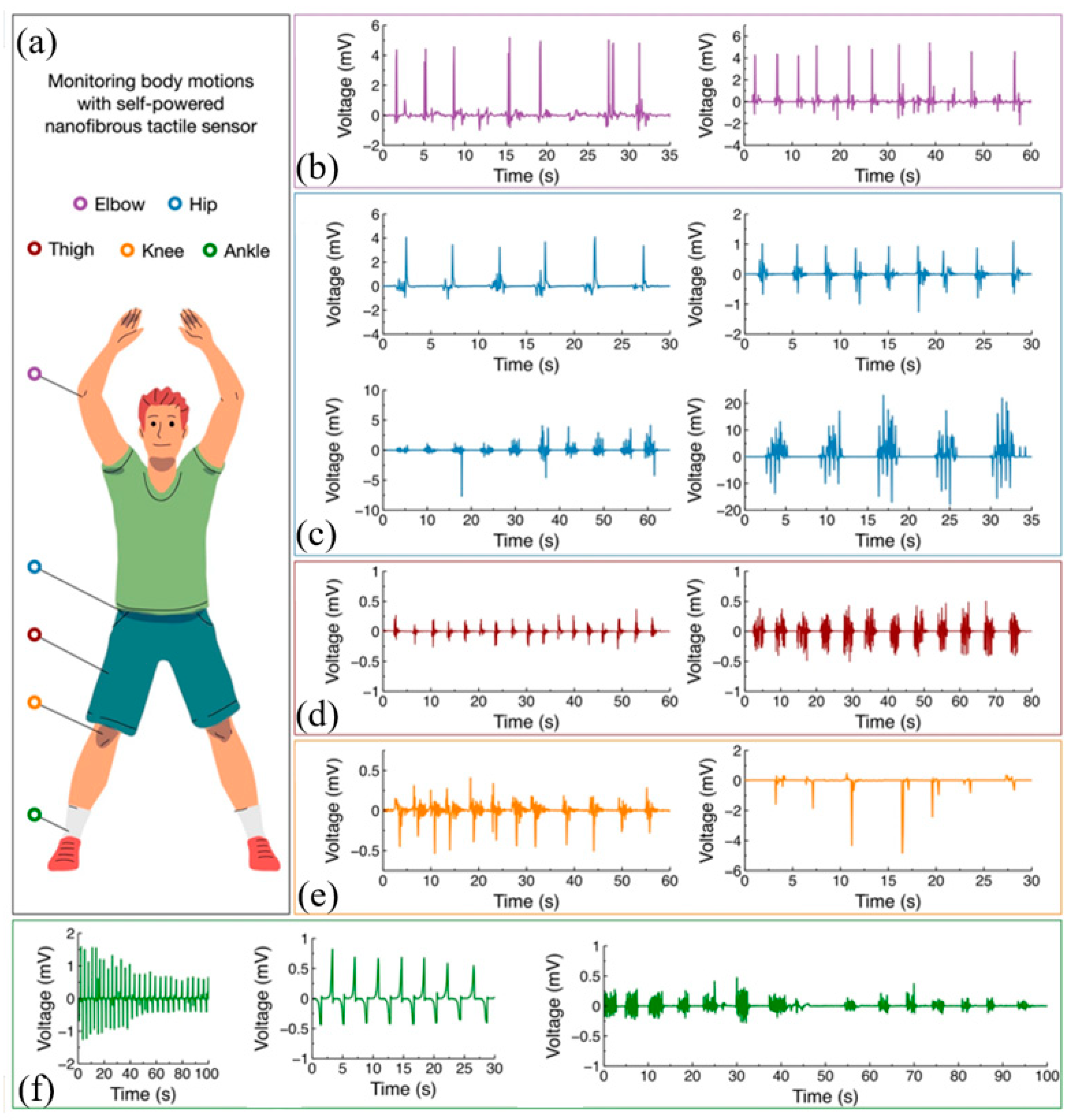

4.1. Human Motion Detection

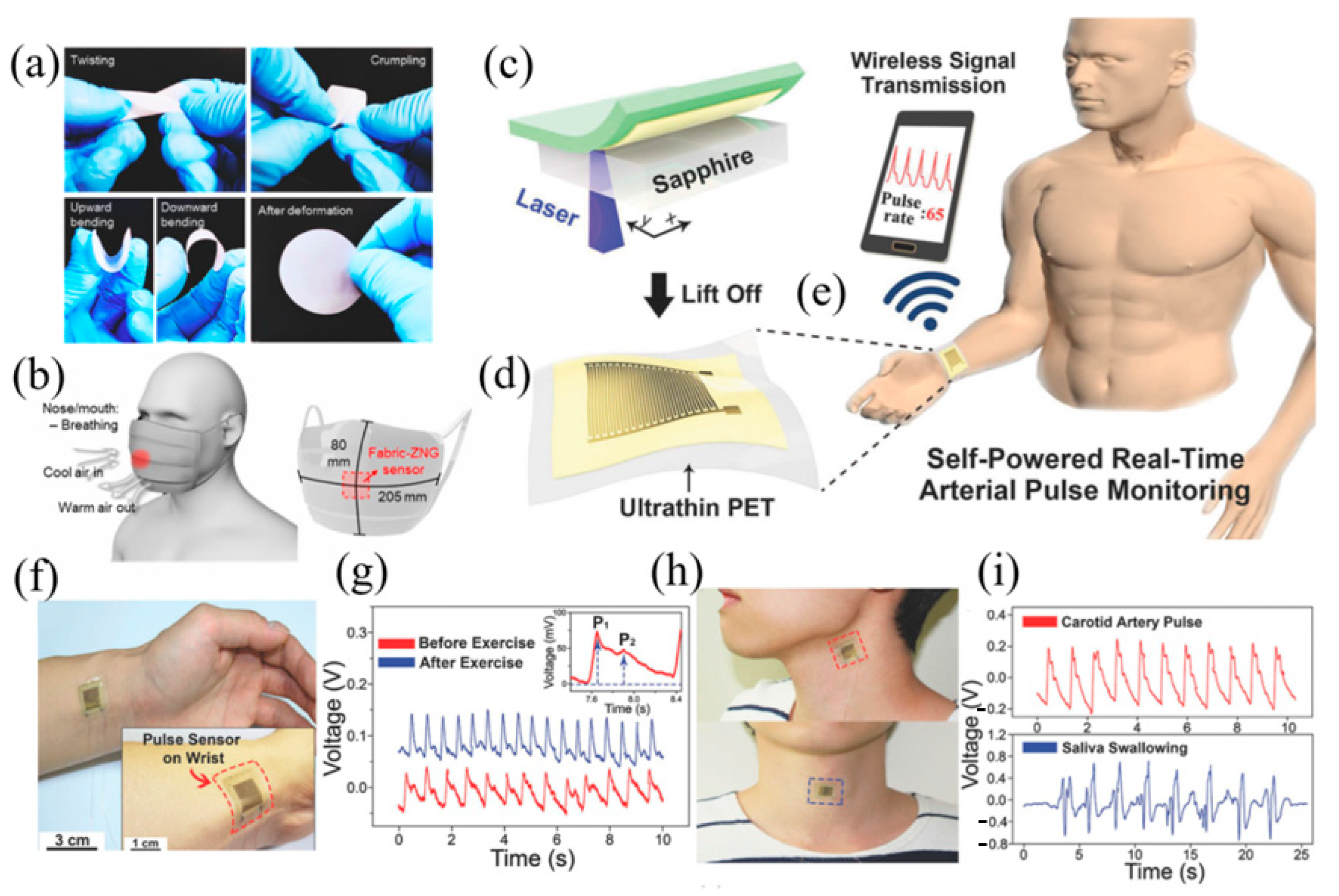

4.2. Health Monitoring

| Materials | Sensing Mechanism | Sensitivity | Low Limit | Up Limit | Response Time | Durability [Cycles] | Ref. |

|---|---|---|---|---|---|---|---|

| TPU/PVDF/ AgNWs | Piezoelectric | 20.3 mVN−1 | NA | NA | 70 ms | >2000 | [37] |

| PDMS/PVDF | Piezoelectric | 346.5 pCN−1 | 0.009 N | 4.3 N | NA | NA | [74] |

| BTO@PVDF | Piezoelectric | 116 mV kPa−1 within pressure range 0–10 N | NA | NA | 82.7 ms | >12,000 | [94] |

| PZT | Piezoelectric | 0.018 kPa−1 | NA | NA | 60 ms | >5000 | [103] |

| PDMS | Triboelectric | 1305 mV kPa−1 | 40 Pa | 1200 kPa | NA | NA | [79] |

| Organic-based ferrofluid | Triboelectric | 21.48 kPa−1 | 1.25 Pa | 390 kPa | 90 ms | NA | [49] |

| graphite/PDMS | Piezoresistive | 4.2 × 103 kPa–1 | 20 Pa | 30 kPa | 8 ms | >4000 | [61] |

| Ecoflex rubber/ melamine foam | Piezoresistive | 24.6 kPa−1 | 200 Pa | 1.2 MPa | 8.4 ms | >5000 | [78] |

| PDMS/CNTs | Piezoresistive | 3.74 kPa−1 | 1.65 Pa | 800 kPa | 15 ms | >5000 | [80] |

| CNT/PEDO:PSS /NFC | Thermoelectric | 30.5 μVK−1 | 0.02 K | NA | NA | NA | [55] |

4.3. Intelligent Robot

5. Summary and Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Liu, C.; Shang, F.; Niu, S.; Ke, L.; Zhang, N.; Ma, B.; Li, R.; Sun, X.; Zhang, S. Tactile Sensing Technology in Bionic Skin: A Review. Biosens. Bioelectron. 2023, 220, 114882. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Hong, I.; Kim, M.; Im, S.; Roh, Y.; Kim, C.; Lim, J.; Kim, D.; Park, J.; Lee, S.; et al. Ultra-Stable and Tough Bioinspired Crack-Based Tactile Sensor for Small Legged Robots. NPJ Flex. Electron. 2023, 7, 22. [Google Scholar] [CrossRef]

- Yang, J.-H.; Kim, S.-Y.; Lim, S.-C. Effects of Sensing Tactile Arrays, Shear Force, and Proprioception of Robot on Texture Recognition. Sensors 2023, 23, 3201. [Google Scholar] [CrossRef] [PubMed]

- Si, Z.; Yu, T.C.; Morozov, K.; McCann, J.; Yuan, W. RobotSweater: Scalable, Generalizable, and Customizable Machine-Knitted Tactile Skins for Robots. In Proceedings of the 2023 IEEE International Conference on Robotics and Automation (ICRA), London, UK, 29 May–2 June 2023; IEEE: London, UK, 2023; pp. 10352–10358. [Google Scholar]

- Chefchaouni Moussaoui, S.; Cisneros-Limón, R.; Kaminaga, H.; Benallegue, M.; Nobeshima, T.; Kanazawa, S.; Kanehiro, F. Spatial Calibration of Humanoid Robot Flexible Tactile Skin for Human–Robot Interaction. Sensors 2023, 23, 4569. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.-J.; Zhao, X.-H.; Zhou, Y.; Yeung, C.-C.; Wu, W.; Venkatesh, S.; Xu, Z.-X.; Wylie, J.J.; Li, W.-J.; Roy, V.A.L. Fingertip-Skin-Inspired Highly Sensitive and Multifunctional Sensor with Hierarchically Structured Conductive Graphite/Polydimethylsiloxane Foams. Adv. Funct. Mater. 2019, 29, 1808829. [Google Scholar] [CrossRef]

- Mu, Y.; Cheng, J.; Wu, X.; Yang, W.; Jin, N.; Xing, Y.; Liu, W.; Yue, C.; Wang, H.; Wu, J.; et al. All-Printed Flexible Capacitive Array Tactile Force Sensors with Tunable Sensitivity and Low Crosstalk for Micro Motion Detection. Sens. Actuators A Phys. 2023, 356, 114337. [Google Scholar] [CrossRef]

- Wang, P.; Li, G.; Liu, J.; Hou, Z.; Meng, C.; Guo, S.; Liu, C.; Fan, S. Tailorable Capacitive Tactile Sensor Based on Stretchable and Dissolvable Porous Silver Nanowire/Polyvinyl Alcohol Nanocomposite Hydrogel for Wearable Human Motion Detection. Adv. Mater. Inter. 2021, 8, 2100998. [Google Scholar] [CrossRef]

- Chang, K.; Meng, J.; Guo, M.; Li, L.; Liu, T.; Huang, Y. Flexible and Breathable MXene Fabrics for Highly Sensitive Human Motion Monitoring. Chem. Eng. J. 2023, 474, 145532. [Google Scholar] [CrossRef]

- Firouzeh, A.; Mizutani, A.; Groten, J.; Zirkl, M.; Shea, H. PopTouch: A Submillimeter Thick Dynamically Reconfigured Haptic Interface with Pressable Buttons. Adv. Mater. 2024, 36, 2307636. [Google Scholar] [CrossRef]

- Lai, Q.; Zhao, X.; Sun, Q.; Tang, Z.; Tang, X.; Roy, V.A.L. Emerging MXene-Based Flexible Tactile Sensors for Health Monitoring and Haptic Perception. Small 2023, 19, 2300283. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z.; Zhou, H.; Guo, X.; Zhang, Y.; Wang, Y.; Liu, P.; Liu, C.; Ma, Y.; Zhang, Y. Highly Sensitive Pressure Sensor Based on Structurally Modified Tissue Paper for Human Physiological Activity Monitoring. J. Appl. Polym. Sci. 2020, 137, 48973. [Google Scholar] [CrossRef]

- Sun, Q.; Lai, Q.; Tang, Z.; Tang, X.; Zhao, X.; Roy, V.A.L. Advanced Functional Composite Materials toward E-Skin for Health Monitoring and Artificial Intelligence. Adv. Mater. Technol. 2023, 8, 2201088. [Google Scholar] [CrossRef]

- Lee, D.; Chung, J.; Yong, H.; Lee, S.; Shin, D. A Deformable Foam-Layered Triboelectric Tactile Sensor with Adjustable Dynamic Range. Int. J. Precis. Eng. Manuf.-Green. Tech. 2019, 6, 43–51. [Google Scholar] [CrossRef]

- Wang, J.; Cui, P.; Zhang, J.; Ge, Y.; Liu, X.; Xuan, N.; Gu, G.; Cheng, G.; Du, Z. A Stretchable Self-Powered Triboelectric Tactile Sensor with EGaIn Alloy Electrode for Ultra-Low-Pressure Detection. Nano Energy 2021, 89, 106320. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, B.; Tan, D.; Li, M.; Wang, Y.; Yang, Y. Asymmetric-Elastic-Structure Fabric-Based Triboelectric Nanogenerators for Wearable Energy Harvesting and Human Motion Sensing. Chem. Eng. J. 2023, 466, 143079. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Deng, Y.; Zhu, P.; Yu, Y.; Hu, S.; Zhang, R. High-Sensitivity Self-Powered Temperature/Pressure Sensor Based on Flexible Bi-Te Thermoelectric Film and Porous Microconed Elastomer. J. Mater. Sci. Technol. 2022, 103, 1–7. [Google Scholar] [CrossRef]

- Zhao, X.J.; Kuang, S.Y.; Wang, Z.L.; Zhu, G. Highly Adaptive Solid–Liquid Interfacing Triboelectric Nanogenerator for Harvesting Diverse Water Wave Energy. ACS Nano 2018, 12, 4280–4285. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiang, J.; Zhang, C.; Sun, M.; Han, S.; Zhang, R.; Liang, N.; Sun, D.; Liu, H. Energy-Efficient, Fully Flexible, High-Performance Tactile Sensor Based on Piezotronic Effect: Piezoelectric Signal Amplified with Organic Field-Effect Transistors. Nano Energy 2020, 76, 105050. [Google Scholar] [CrossRef]

- Wang, F.; Ye, R.; Song, Y.; Chen, Y.; Jiang, Y.; Lv, S.; Li, M. Modeling Analysis and 3D Force Prediction of a Novel Piezoelectric Tactile Sensor. J. Sens. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Mao, A.; Lu, W.; Jia, Y.; Wang, R.; Sun, J. Flexible Piezoelectric Devices and Their Wearable Applications. J. Inorg. Mater. 2023, 38, 717. [Google Scholar] [CrossRef]

- Li, J.; Wei, X.; Sun, X.; Li, R.; Wu, C.; Liao, J.; Zheng, T.; Wu, J. A Novel Strategy for Excellent Piezocatalytic Activity in Lead-Free BaTiO3-Based Materials via Manipulating the Multiphase Coexistence. ACS Appl. Mater. Interfaces 2022, 14, 46765–46774. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Xia, H.; Ni, Q.-Q. Study on Material Performances of Lead Zirconate Titanate/Shape Memory Polyurethane Composites Combining Shape Memory and Piezoelectric Effect. Compos. Part. A Appl. Sci. Manuf. 2018, 110, 183–189. [Google Scholar] [CrossRef]

- He, J.; Guo, X.; Yu, J.; Qian, S.; Hou, X.; Cui, M.; Yang, Y.; Mu, J.; Geng, W.; Chou, X. A High-Resolution Flexible Sensor Array Based on PZT Nanofibers. Nanotechnology 2020, 31, 155503. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Zhang, H.; Zhu, M.; Wei, X.; Cao, J.; Murtaza, I.; Ali, M.U.; Meng, H.; Xu, J. Lead Zirconate Titanate (a Piezoelectric Ceramic)-Based Thermal and Tactile Bimodal Organic Transistor Sensors. Org. Electron. 2020, 80, 105673. [Google Scholar] [CrossRef]

- Du, X.; Zhou, Z.; Zhang, Z.; Yao, L.; Zhang, Q.; Yang, H. Porous, Multi-Layered Piezoelectric Composites Based on Highly Oriented PZT/PVDF Electrospinning Fibers for High-Performance Piezoelectric Nanogenerators. J. Adv. Ceram. 2022, 11, 331–344. [Google Scholar] [CrossRef]

- Jo, E.-B.; Lee, Y.-A.; Cho, Y.-A.; Günther, P.A.; Gebhardt, S.E.; Neubert, H.; Kim, H.-S. The 0–3 Lead Zirconate-Titanate (PZT)/Polyvinyl-Butyral (PVB) Composite for Tactile Sensing. Sensors 2023, 23, 1649. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Qin, Q.; Wang, X.; Xiang, H.; Zheng, J.; Lu, Y.; Lv, C.; Wu, K.; Yan, L.; Wang, N.; et al. Piezoelectric Nanogenerator for Highly Sensitive and Synchronous Multi-Stimuli Sensing. ACS Nano 2021, 15, 19783–19792. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.-J.; Hahn, B.-D.; Ryu, J.; Yoon, W.-H.; Lee, B.-K.; Park, D.-S. Preparation and Characterization of Piezoelectric Ceramic–Polymer Composite Thick Films by Aerosol Deposition for Sensor Application. Sens. Actuators A Phys. 2009, 153, 89–95. [Google Scholar] [CrossRef]

- Ma, S.; Kumaresan, Y.; Dahiya, A.S.; Lorenzelli, L.; Dahiya, R.S. Flexible Tactile Sensors Using AlN and MOSFETs Based Ultra-Thin Chips. IEEE Sens. J. 2023, 23, 23988–23994. [Google Scholar] [CrossRef]

- Kumaresan, Y.; Ma, S.; Shakthivel, D.; Dahiya, R. AlN Ultra-Thin Chips Based Flexible Piezoelectric Tactile Sensors. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Manchester, UK, 20–23 June 2021; IEEE: Manchester, UK, 2021; pp. 1–4. [Google Scholar]

- Jiang, J.; Tu, S.; Fu, R.; Li, J.; Hu, F.; Yan, B.; Gu, Y.; Chen, S. Flexible Piezoelectric Pressure Tactile Sensor Based on Electrospun BaTiO3/Poly(Vinylidene Fluoride) Nanocomposite Membrane. ACS Appl. Mater. Interfaces 2020, 12, 33989–33998. [Google Scholar] [CrossRef]

- Ryu, C.; Hajra, S.; Sahu, M.; Jung, S.I.; Jang, I.R.; Kim, H.J. PVDF-Bismuth Titanate Based Self-Powered Flexible Tactile Sensor for Biomechanical Applications. Mater. Lett. 2022, 309, 131308. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, L.; Luo, G.; Li, M.; Han, X.; Xia, Y.; Li, Z.; Lin, Q.; Yang, P.; Dai, L.; et al. All Electrospun Fabrics Based Piezoelectric Tactile Sensor. Nanotechnology 2022, 33, 415502. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhu, L.; Xiang, Y.; Li, M. Sensitivity Enhancement of the Tactile Sensor Based on Hydrothermally Grown ZnO Nanorods Modified by Catalytic Au Nanoparticles. Mater. Res. Express 2022, 9, 045004. [Google Scholar] [CrossRef]

- Yu, J.; Hou, X.; Cui, M.; Zhang, S.; He, J.; Geng, W.; Mu, J.; Chou, X. Highly Skin-Conformal Wearable Tactile Sensor Based on Piezoelectric-Enhanced Triboelectric Nanogenerator. Nano Energy 2019, 64, 103923. [Google Scholar] [CrossRef]

- Wei, C.; Zhou, H.; Zheng, B.; Zheng, H.; Shu, Q.; Du, H.; Ma, A.; Liu, H. Fully Flexible and Mechanically Robust Tactile Sensors Containing Core–Shell Structured Fibrous Piezoelectric Mat as Sensitive Layer. Chem. Eng. J. 2023, 476, 146654. [Google Scholar] [CrossRef]

- Pan, S.; Zhang, Z. Fundamental Theories and Basic Principles of Triboelectric Effect: A Review. Friction 2019, 7, 2–17. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric Nanogenerators as Self-Powered Active Sensors. Nano Energy 2015, 11, 436–462. [Google Scholar] [CrossRef]

- Lin, L.; Xie, Y.; Wang, S.; Wu, W.; Niu, S.; Wen, X.; Wang, Z.L. Triboelectric Active Sensor Array for Self-Powered Static and Dynamic Pressure Detection and Tactile Imaging. ACS Nano 2013, 7, 8266–8274. [Google Scholar] [CrossRef] [PubMed]

- Ruth, S.R.A.; Feig, V.R.; Tran, H.; Bao, Z. Microengineering Pressure Sensor Active Layers for Improved Performance. Adv. Funct. Mater. 2020, 30, 2003491. [Google Scholar] [CrossRef]

- Yao, G.; Xu, L.; Cheng, X.; Li, Y.; Huang, X.; Guo, W.; Liu, S.; Wang, Z.L.; Wu, H. Bioinspired Triboelectric Nanogenerators as Self-Powered Electronic Skin for Robotic Tactile Sensing. Adv. Funct. Mater. 2020, 30, 1907312. [Google Scholar] [CrossRef]

- Shin, Y.; Park, Y.; Ghosh, S.K.; Lee, Y.; Park, J.; Ko, H. Ultrasensitive Multimodal Tactile Sensors with Skin-Inspired Microstructures through Localized Ferroelectric Polarization. Adv. Sci. 2022, 9, 2105423. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Xie, Z.; Yao, K.; Li, D.; Liu, Y.; Gao, Z.; Lu, W.; Chang, L.; Yu, X. Trampoline Inspired Stretchable Triboelectric Nanogenerators as Tactile Sensors for Epidermal Electronics. Nano Energy 2021, 81, 105590. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Dong, L.; Han, X.; Du, W.; Zhai, J.; Pan, C.; Wang, Z.L. Self-Powered High-Resolution and Pressure-Sensitive Triboelectric Sensor Matrix for Real-Time Tactile Mapping. Adv. Mater. 2016, 28, 2896–2903. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.; Zhang, X.; Huo, Z.; Li, X.; Que, M.; Peng, Z.; Wang, H.; Pan, C. A Highly Stretchable Transparent Self-Powered Triboelectric Tactile Sensor with Metallized Nanofibers for Wearable Electronics. Adv. Mater. 2018, 30, 1706738. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Zhou, T.; Yin, Y.; Cao, R.; Li, C.; Wang, Z.L. Transparent and Flexible Triboelectric Sensing Array for Touch Security Applications. ACS Nano 2017, 11, 8364–8369. [Google Scholar] [CrossRef]

- Zhu, X.X.; Li, Z.B.; Li, X.S.; Su, L.; Wei, X.Y.; Kuang, S.Y.; Su, B.W.; Yang, J.; Wang, Z.L.; Zhu, G. Triboelectrification-Enabled Thin-Film Tactile Matrix for Self-Powered High-Resolution Imaging. Nano Energy 2018, 50, 497–503. [Google Scholar] [CrossRef]

- Liu, J.; Wen, Z.; Lei, H.; Gao, Z.; Sun, X. A Liquid–Solid Interface-Based Triboelectric Tactile Sensor with Ultrahigh Sensitivity of 21.48 kPa−1. Nano-Micro Lett. 2022, 14, 88. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Zheng, Y.; Xing, L.; Hou, B. Recent Progress of Thermoelectric Applications for Cooling/Heating, Power Generation, Heat Flux Sensor and Potential Prospect of Their Integrated Applications. Therm. Sci. Eng. Prog. Progress. 2023, 45, 102064. [Google Scholar] [CrossRef]

- DiSalvo, F.J. Thermoelectric Cooling and Power Generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef]

- Liu, G.; Wang, T. Research Progress in Thermoelectric Materials for Sensor Application. Acta Chim. Sin. 2017, 75, 1029. [Google Scholar] [CrossRef]

- Samanian, M.; Ghatee, M.H. Study of the Molybdenum Dichalcogenide Crystals: Recent Developments and Novelty of the P-MoS2 Structure. J. Mol. Model. 2021, 27, 268. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Chou, T.-M.; Yang, W.; He, M.; Zhao, Y.; Li, N.; Lin, Z.-H. Flexible Thermoelectric Nanogenerator Based on the MoS2/Graphene Nanocomposite and Its Application for a Self-Powered Temperature Sensor. Semicond. Sci. Technol. 2017, 32, 044003. [Google Scholar] [CrossRef]

- Gao, F.; Min, P.; Ma, Q.; Zhang, T.; Yu, Z.; Shang, J.; Li, R.; Li, X. Multifunctional Thermoelectric Temperature Sensor for Noncontact Information Transfer and Tactile Sensing in Human-Machine Interaction. Adv. Funct. Mater. 2024, 34, 2309553. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, Y.; Wang, Y.; Mao, H.; Zhang, Q.; Deng, Y. Flexible 3D Architectured Piezo/Thermoelectric Bimodal Tactile Sensor Array for E-Skin Application. Adv. Energy Mater. 2020, 10, 2001945. [Google Scholar] [CrossRef]

- Gao, F.-L.; Liu, J.; Li, X.-P.; Ma, Q.; Zhang, T.; Yu, Z.-Z.; Shang, J.; Li, R.-W.; Li, X. Ti3C2Tx MXene-Based Multifunctional Tactile Sensors for Precisely Detecting and Distinguishing Temperature and Pressure Stimuli. ACS Nano 2023, 17, 16036–16047. [Google Scholar] [CrossRef] [PubMed]

- Gidts, M.; Hsu, W.-F.; Payo, M.R.; Kushwaha, S.; Wang, C.; Ceyssens, F.; Reynaerts, D.; Locquet, J.-P.; Kraft, M. A Novel Piezoresistive Pressure Sensor Based on Cr-Doped V2O3 Thin Film. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems (MEMS), Munich, Germany, 15–19 January 2023; IEEE: Munich, Germany, 2023; pp. 901–904. [Google Scholar]

- Wu, H.; Seguin, F.; Koncar, V.; Cochrane, C.; Dupont, L.; Lahuec, C.; Khaldi, A. Stretchable Piezoresistive Textile Yarn Strain Transducer for Low Deformation Detection. Sens. Actuators A Phys. 2023, 363, 114755. [Google Scholar] [CrossRef]

- Yu, C.; Xu, J.; Yang, L.; Ye, M.; Ye, Y.; Li, T.; Zhang, Y.; Zhang, Z.; Xu, H.; Tan, H.; et al. Self-Driving Flexible Piezoresistive Sensors Integrated with Enhanced Energy Harvesting Sensor of ZnO/Ti3C2Tx Nanocomposite Based on 3D Structure. J. Alloys Compd. 2023, 956, 170358. [Google Scholar] [CrossRef]

- Sun, Q.-J.; Zhao, X.-H.; Yeung, C.-C.; Tian, Q.; Kong, K.-W.; Wu, W.; Venkatesh, S.; Li, W.-J.; Roy, V.A.L. Bioinspired, Self-Powered, and Highly Sensitive Electronic Skin for Sensing Static and Dynamic Pressures. ACS Appl. Mater. Interfaces 2020, 12, 37239–37247. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.-C.; Tang, X.-G.; Sun, Q.-J.; Jiang, Y.-P.; Li, W.-H.; Liu, Q.-X. Low-Cost Composite Film Triboelectric Nanogenerators for a Self-Powered Touch Sensor. Nanoscale 2023, 15, 6263–6272. [Google Scholar] [CrossRef]

- Yan, L.; Mi, Y.; Lu, Y.; Qin, Q.; Wang, X.; Meng, J.; Liu, F.; Wang, N.; Cao, X. Weaved Piezoresistive Triboelectric Nanogenerator for Human Motion Monitoring and Gesture Recognition. Nano Energy 2022, 96, 107135. [Google Scholar] [CrossRef]

- Khuje, S.; Islam, A.; Yu, J.; Ren, S. Printing Conformal and Flexible Copper Networks for Multimodal Pressure and Flow Sensing. Nanoscale 2023, 15, 18660–18666. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Liu, G.; Li, Z.; Zhang, W.; Meng, Q. Flexible Tactile Sensors with Biomimetic Microstructures: Mechanisms, Fabrication, and Applications. Adv. Colloid. Interface Sci. 2023, 320, 102988. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Cui, X.; Yang, Y. Oblique Pyramid Microstructure-Patterned Flexible Sensors for Pressure and Visual Temperature Sensing. ACS Appl. Mater. Interfaces 2023, 15, 59760–59767. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Cen, Y.; Zeng, X. Highly Sensitive Flexible Tactile Sensor Mimicking the Microstructure Perception Behavior of Human Skin. ACS Appl. Mater. Interfaces 2021, 13, 28538–28545. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.P.; Kim, Y.-R.; Ko, H. Anisotropic Silver Nanowire Dielectric Composites for Self-Healable Triboelectric Sensors with Multi-Directional Tactile Sensitivity. Nano Energy 2022, 92, 106704. [Google Scholar] [CrossRef]

- Ning, C.; Dong, K.; Cheng, R.; Yi, J.; Ye, C.; Peng, X.; Sheng, F.; Jiang, Y.; Wang, Z.L. Flexible and Stretchable Fiber-Shaped Triboelectric Nanogenerators for Biomechanical Monitoring and Human-Interactive Sensing. Adv. Funct. Mater. 2021, 31, 2006679. [Google Scholar] [CrossRef]

- Shao, D.; Wang, C.; Li, W.; Lu, L.; Lu, J.; Yang, W. Natural Ginkgo Tree Leaves as Piezo-Energy Harvesters. J. Mater. Chem. C 2022, 10, 15016–15027. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Y.; Qu, C.; Liu, H.; Zhang, S.; Lin, F.; Wu, W.; Song, G. Micro-Crack Assisted Wrinkled PEDOT: PSS to Detect and Distinguish Tensile Strain and Pressure Based on a Triboelectric Nanogenerator. Adv. Mater. Technol. 2022, 7, 2100423. [Google Scholar] [CrossRef]

- Chen, L.; Feng, J.; Li, T.; Li, X.; Zhang, J. High-Tactile Sensitivity of Piezoresistive Sensors with a Micro-Crack Structure Induced by Thin Film Tension. IEEE Electron. Device Lett. 2019, 40, 1519–1521. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.; Choi, M. Ultrasensitive Mechanical Crack-Based Sensor Inspired by the Spider Sensory System. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, H.; Mo, J.; Chen, S.; Xie, Y.; Ma, S.; Chen, R.; Luo, T.; Ling, W.; Qin, L.; et al. Finger-Inspired Rigid-Soft Hybrid Tactile Sensor with Superior Sensitivity at High Frequency. Nat. Commun. 2022, 13, 5076. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.-H.; Lai, Q.-T.; Guo, W.-T.; Liang, Z.-H.; Tang, Z.; Tang, X.-G.; Roy, V.A.L.; Sun, Q.-J. Skin-Inspired Highly Sensitive Tactile Sensors with Ultrahigh Resolution over a Broad Sensing Range. ACS Appl. Mater. Interfaces 2023, 15, 30486–30494. [Google Scholar] [CrossRef] [PubMed]

- Saraf, R.; Tsui, T.; Maheshwari, V. Modulation of Mechanical Properties and Stable Light Energy Harvesting by Poling in Polymer Integrated Perovskite Films: A Wide Range, Linear and Highly Sensitive Tactile Sensor. J. Mater. Chem. A 2019, 7, 14192–14198. [Google Scholar] [CrossRef]

- Parida, K.; Bhavanasi, V.; Kumar, V.; Bendi, R.; Lee, P.S. Self-Powered Pressure Sensor for Ultra-Wide Range Pressure Detection. Nano Res. 2017, 10, 3557–3570. [Google Scholar] [CrossRef]

- Chen, R.; Luo, T.; Wang, J.; Wang, R.; Zhang, C.; Xie, Y.; Qin, L.; Yao, H.; Zhou, W. Nonlinearity Synergy: An Elegant Strategy for Realizing High-Sensitivity and Wide-Linear-Range Pressure Sensing. Nat. Commun. 2023, 14, 6641. [Google Scholar] [CrossRef]

- Zhou, S.; Li, H.; Mao, D.; Pan, Z.; Chen, H. A Brushed Hemicylindrical Pressure Sensor Based on Triboelectricity Exhibits High Sensitivity, a Low Detection Limit and a Wide Detection Range. J. Mater. Chem. C 2023, 11, 3644–3651. [Google Scholar] [CrossRef]

- Wang, S.; Gao, F.; Hu, Y.; Zhang, S.; Shang, H.; Ge, C.; Tan, B.; Zhang, X.; Zhang, J.; Hu, P. Skin-Inspired Tactile Sensor Based on Gradient Pore Structure Enable Broad Range Response and Ultrahigh Pressure Resolution. Chem. Eng. J. 2022, 443, 136446. [Google Scholar] [CrossRef]

- Yu, A.; Chen, L.; Chen, X.; Zhang, A.; Fan, F.; Zhan, Y.; Wang, Z.L. Triboelectric Sensor as Self-Powered Signal Reader for Scanning Probe Surface Topography Imaging. Nanotechnology 2015, 26, 165501. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, H.L.; Li, H.Y.; Wei, X.Y.; Wang, Z.L.; Zhu, G. Enhanced High-Resolution Triboelectrification-Induced Electroluminescence for Self-Powered Visualized Interactive Sensing. ACS Appl. Mater. Interfaces 2019, 11, 13796–13802. [Google Scholar] [CrossRef]

- Wang, J.; Qian, S.; Yu, J.; Zhang, Q.; Yuan, Z.; Sang, S.; Zhou, X.; Sun, L. Flexible and Wearable PDMS-Based Triboelectric Nanogenerator for Self-Powered Tactile Sensing. Nanomaterials 2019, 9, 1304. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Adhikary, P.; Jana, S.; Biswas, A.; Sencadas, V.; Gupta, S.D.; Tudu, B.; Mandal, D. Electrospun Gelatin Nanofiber Based Self-Powered Bio-e-Skin for Health Care Monitoring. Nano Energy 2017, 36, 166–175. [Google Scholar] [CrossRef]

- Zhao, Y.; Shen, S.; Cao, R.; Wu, H.; Yu, H.; Li, X.; Zhang, W.; Pan, C. Flexible Stretchable Tribo-Negative Films with Exceptional Output Performance for High-Temperature Energy Harvesting and Self-Powered Sensor. Nano Energy 2023, 114, 108654. [Google Scholar] [CrossRef]

- Su, C.; Huang, X.; Zhang, L.; Zhang, Y.; Yu, Z.; Chen, C.; Ye, Y.; Guo, S. Robust Superhydrophobic Wearable Piezoelectric Nanogenerators for Self-Powered Body Motion Sensors. Nano Energy 2023, 107, 108095. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Zhao, L.; Yao, K.; Xie, Z.; Zi, Y.; Yu, X. Thin, Skin-Integrated, Stretchable Triboelectric Nanogenerators for Tactile Sensing. Adv. Elect. Mater. 2020, 6, 1901174. [Google Scholar] [CrossRef]

- Liu, Q.; Jin, L.; Zhang, P.; Zhang, B.; Li, Y.; Xie, S.; Li, X. Nanofibrous Grids Assembled Orthogonally from Direct-Written Piezoelectric Fibers as Self-Powered Tactile Sensors. ACS Appl. Mater. Interfaces 2021, 13, 10623–10631. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Jiang, Q.; Wei, G. A Two-Range Tactile Sensor Integrated in Three-Layer Elastomer Based on FBG. Smart Mater. Struct. 2021, 30, 065011. [Google Scholar] [CrossRef]

- Smith, M.; Cacucciolo, V.; Shea, H. Fiber Pumps for Wearable Fluid-ic Systems. Science 2023, 379, 1327–1332. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Jang, S.; Lee, D.; Ra, Y.; Kam, D.; Kim, J.W.; Shin, D.; Seo, K.D.; Choi, D. Self-Powered Hybrid Triboelectric–Piezoelectric Electronic Skin Based on P(VDF-TrFE) Electrospun Nanofibers for Artificial Sensory System. Funct. Compos. Struct. 2022, 4, 045005. [Google Scholar] [CrossRef]

- Fu, Y.; He, H.; Liu, Y.; Wang, Q.; Xing, L.; Xue, X. Self-Powered, Stretchable, Fiber-Based Electronic-Skin for Actively Detecting Human Motion and Environmental Atmosphere Based on a Triboelectrification/Gas-Sensing Coupling Effect. J. Mater. Chem. C 2017, 5, 1231–1239. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, T.; Ho, D.; Qin, S.; Yang, X.; Cho, J.H.; Sun, Q.; Wang, Z.L. Transparent and Self-Powered Multistage Sensation Matrix for Mechanosensation Application. ACS Nano 2018, 12, 254–262. [Google Scholar] [CrossRef]

- Li, J.; Yin, J.; Wee, M.G.V.; Chinnappan, A.; Ramakrishna, S. A Self-Powered Piezoelectric Nanofibrous Membrane as Wearable Tactile Sensor for Human Body Motion Monitoring and Recognition. Adv. Fiber Mater. 2023, 5, 1417–1430. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, H.; Zhang, J.; Hu, Z. High-Sensitivity RGO-TiO2 Humidity Sensor Driven by Triboelectric Nanogenerators for Non-Contact Monitoring of Human Respiration. J. Alloys Compd. 2023, 935, 168006. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, Y.; Tai, H.; Liu, B.; Duan, Z.; Yuan, Z.; Pan, H.; Xie, G.; Du, X.; Su, Y. An Integrated Flexible Self-Powered Wearable Respiration Sensor. Nano Energy 2019, 63, 103829. [Google Scholar] [CrossRef]

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-Powered Respiration Monitoring Enabled By a Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 2101262. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-J.; Song, Z.; Yun, T.G.; Kang, M.-J.; Son, D.H.; Pyun, J.-C. Wearable Fabric-Based ZnO Nanogenerator for Biomechanical and Biothermal Monitoring. Biosens. Bioelectron. 2023, 242, 115739. [Google Scholar] [CrossRef] [PubMed]

- Yi, Q.; Pei, X.; Das, P.; Qin, H.; Lee, S.W.; Esfandyarpour, R. A Self-Powered Triboelectric MXene-Based 3D-Printed Wearable Physiological Biosignal Sensing System for on-Demand, Wireless, and Real-Time Health Monitoring. Nano Energy 2022, 101, 107511. [Google Scholar] [CrossRef]

- Sadri, B.; Abete, A.M.; Martinez, R.V. Simultaneous Electrophysiological Recording and Self-Powered Biosignal Monitoring Using Epidermal, Nanotexturized, Triboelectronic Devices. Nanotechnology 2019, 30, 274003. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.; Zhong, J.; Liu, H.; Liu, N.; Song, Y.; Zang, X.; Dong, Y.; Wang, X.; Lin, L. Self-Powered Pulse Sensors with High Sensitivity to Reveal Sinus Arrhythmia. In 2018 IEEE Micro Electro Mechanical Systems (MEMS); IEEE: Belfast, UK, 2018; pp. 404–407. [Google Scholar]

- Marasco, I.; Niro, G.; Demir, S.M.; Marzano, L.; Fachechi, L.; Rizzi, F.; Demarchi, D.; Motto Ros, P.; D’Orazio, A.; Grande, M.; et al. Wearable Heart Rate Monitoring Device Communicating in 5G ISM Band for IoHT. Bioengineering 2023, 10, 113. [Google Scholar] [CrossRef] [PubMed]

- Park, D.Y.; Joe, D.J.; Kim, D.H.; Park, H.; Han, J.H.; Jeong, C.K.; Park, H.; Park, J.G.; Joung, B.; Lee, K.J. Self-Powered Real-Time Arterial Pulse Monitoring Using Ultrathin Epidermal Piezoelectric Sensors. Adv. Mater. 2017, 29, 1702308. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Ma, Z.; Wang, S.; Xie, G.; Xu, M. A Bio-Inspired Whisker Sensor Based on Triboelectric Nanogenerators. In 2020 35th Youth Academic Annual Conference of Chinese Association of Automation (YAC); IEEE: Zhanjiang, China, 2020; pp. 105–109. [Google Scholar]

- Liu, W.; Duo, Y.; Chen, X.; Chen, B.; Bu, T.; Li, L.; Duan, J.; Zuo, Z.; Wang, Y.; Fang, B.; et al. An Intelligent Robotic System Capable of Sensing and Describing Objects Based on Bimodal, Self-Powered Flexible Sensors. Adv. Funct. Mater. 2023, 33, 2306368. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.-F.; Li, T.; Lai, Q.-T.; Tang, G.; Sun, Q.-J. Recent Advances in Self-Powered Tactile Sensing for Wearable Electronics. Materials 2024, 17, 2493. https://doi.org/10.3390/ma17112493

Liu L-F, Li T, Lai Q-T, Tang G, Sun Q-J. Recent Advances in Self-Powered Tactile Sensing for Wearable Electronics. Materials. 2024; 17(11):2493. https://doi.org/10.3390/ma17112493

Chicago/Turabian StyleLiu, Ling-Feng, Tong Li, Qin-Teng Lai, Guowu Tang, and Qi-Jun Sun. 2024. "Recent Advances in Self-Powered Tactile Sensing for Wearable Electronics" Materials 17, no. 11: 2493. https://doi.org/10.3390/ma17112493

APA StyleLiu, L.-F., Li, T., Lai, Q.-T., Tang, G., & Sun, Q.-J. (2024). Recent Advances in Self-Powered Tactile Sensing for Wearable Electronics. Materials, 17(11), 2493. https://doi.org/10.3390/ma17112493