Unveiling the Stacking Fault-Driven Phase Transition Delaying Cryogenic Fracture in Fe-Co-Cr-Ni-Mo-C-Based Medium-Entropy Alloy

Abstract

:1. Introduction

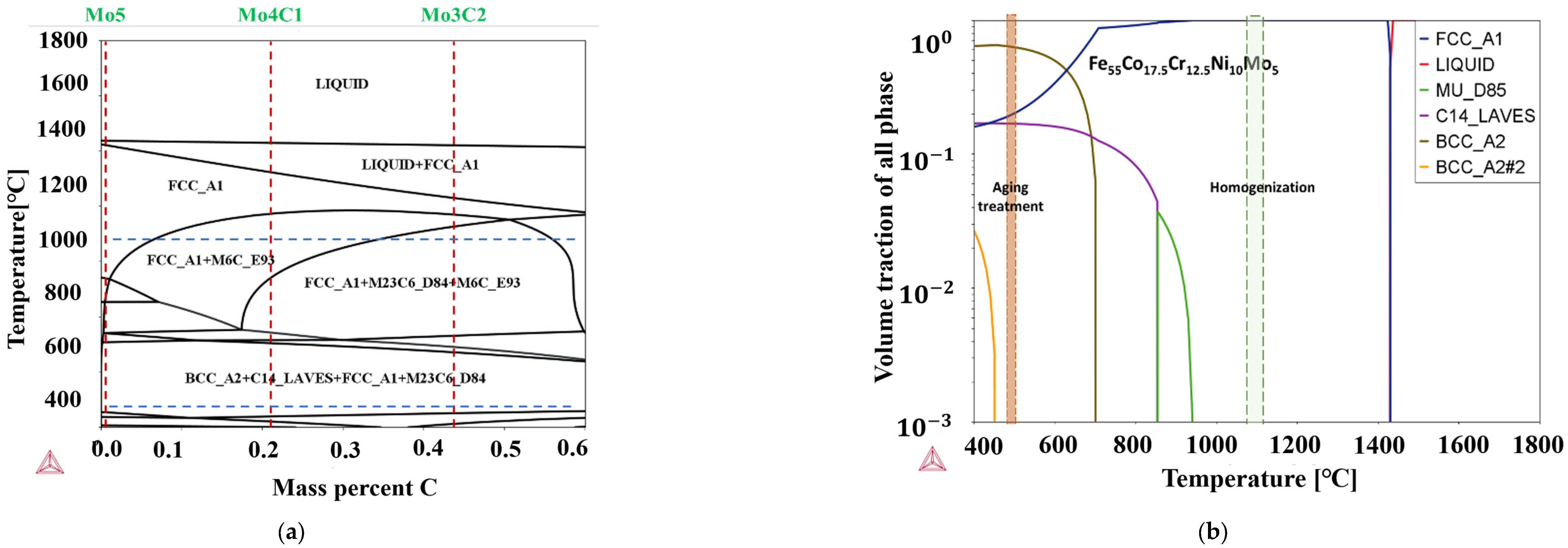

2. Experimental Procedure

3. Experimental Results

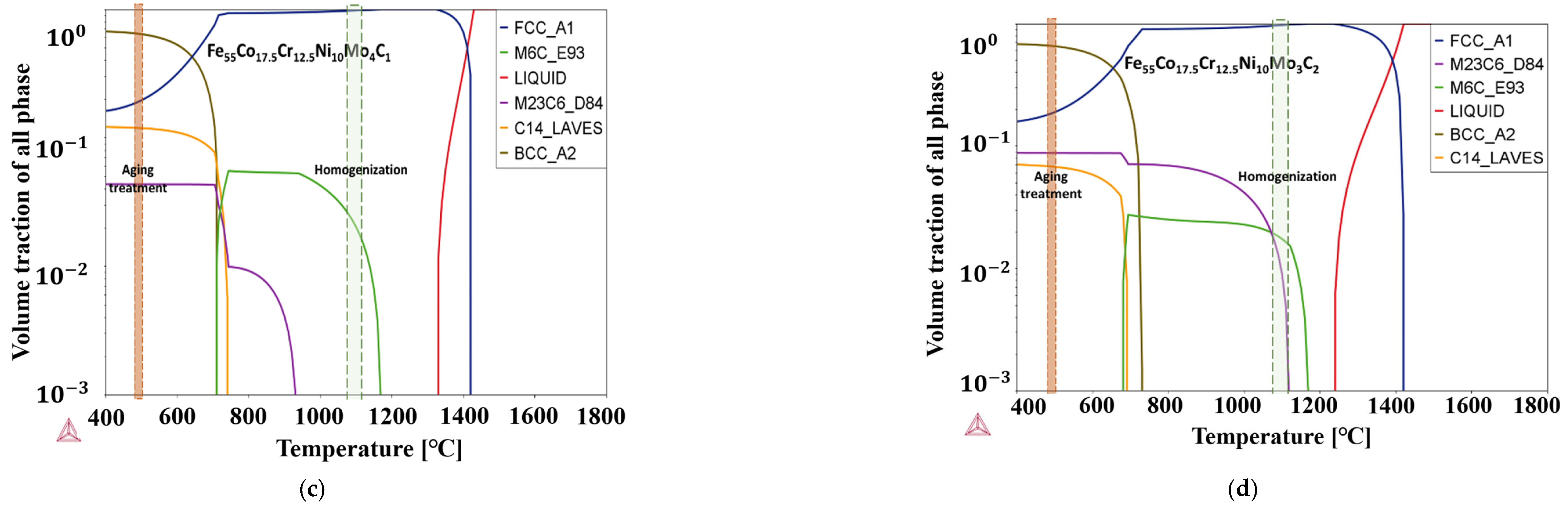

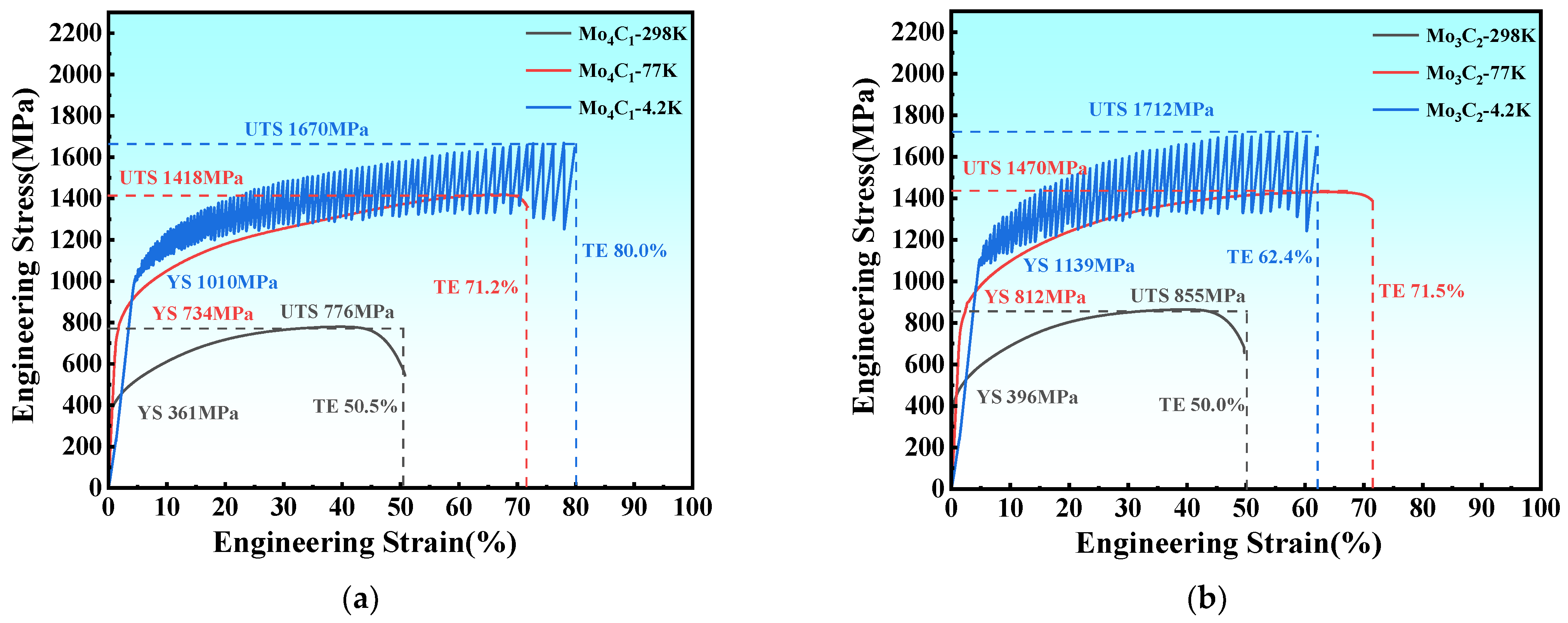

3.1. Mechanical Property of Mo5 Alloy

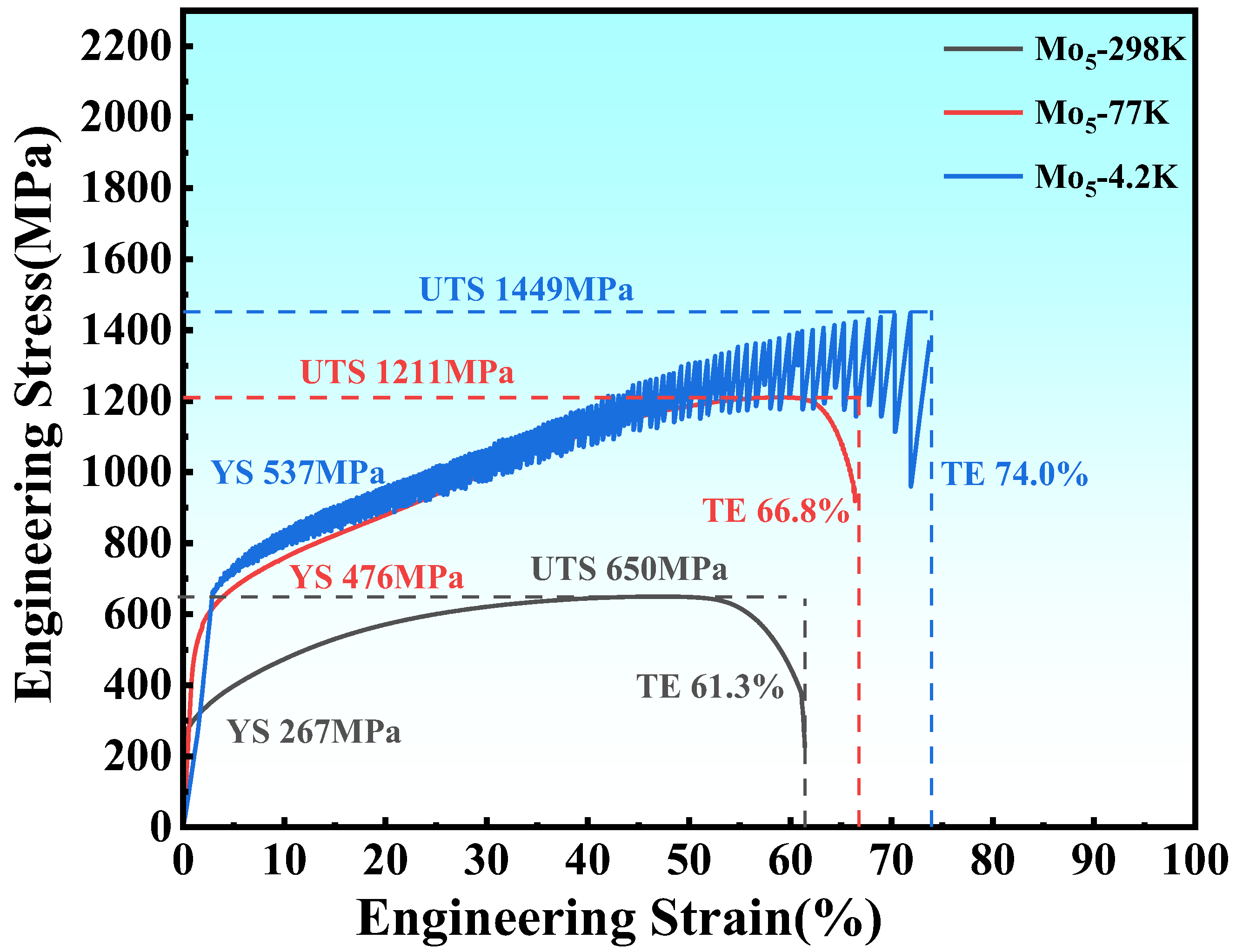

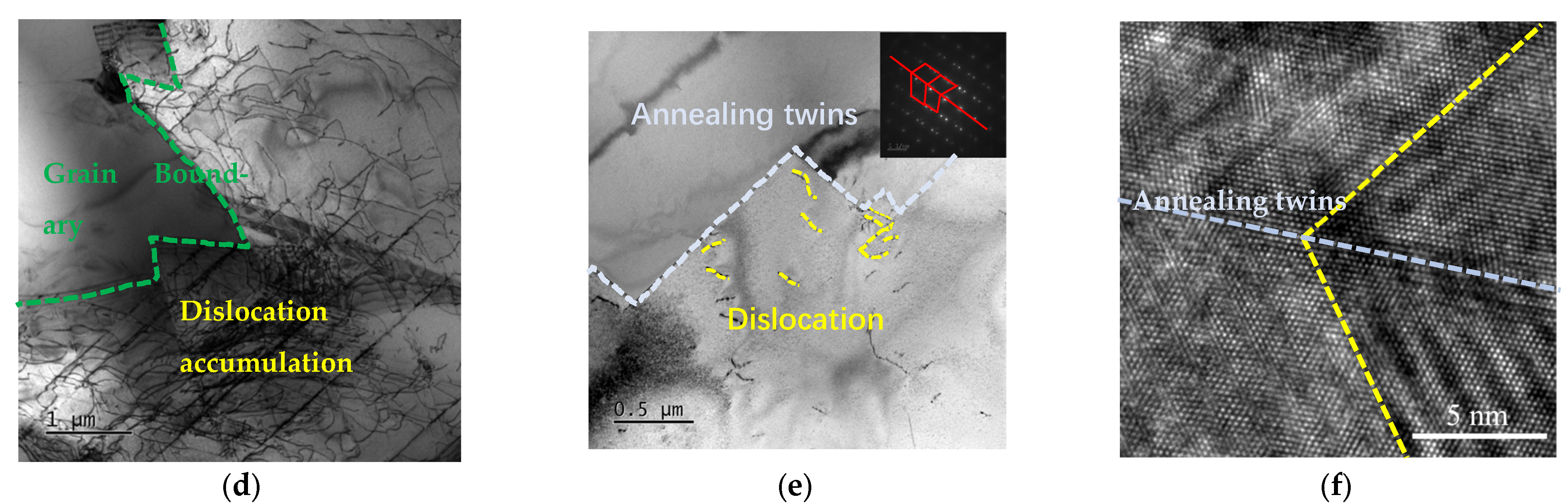

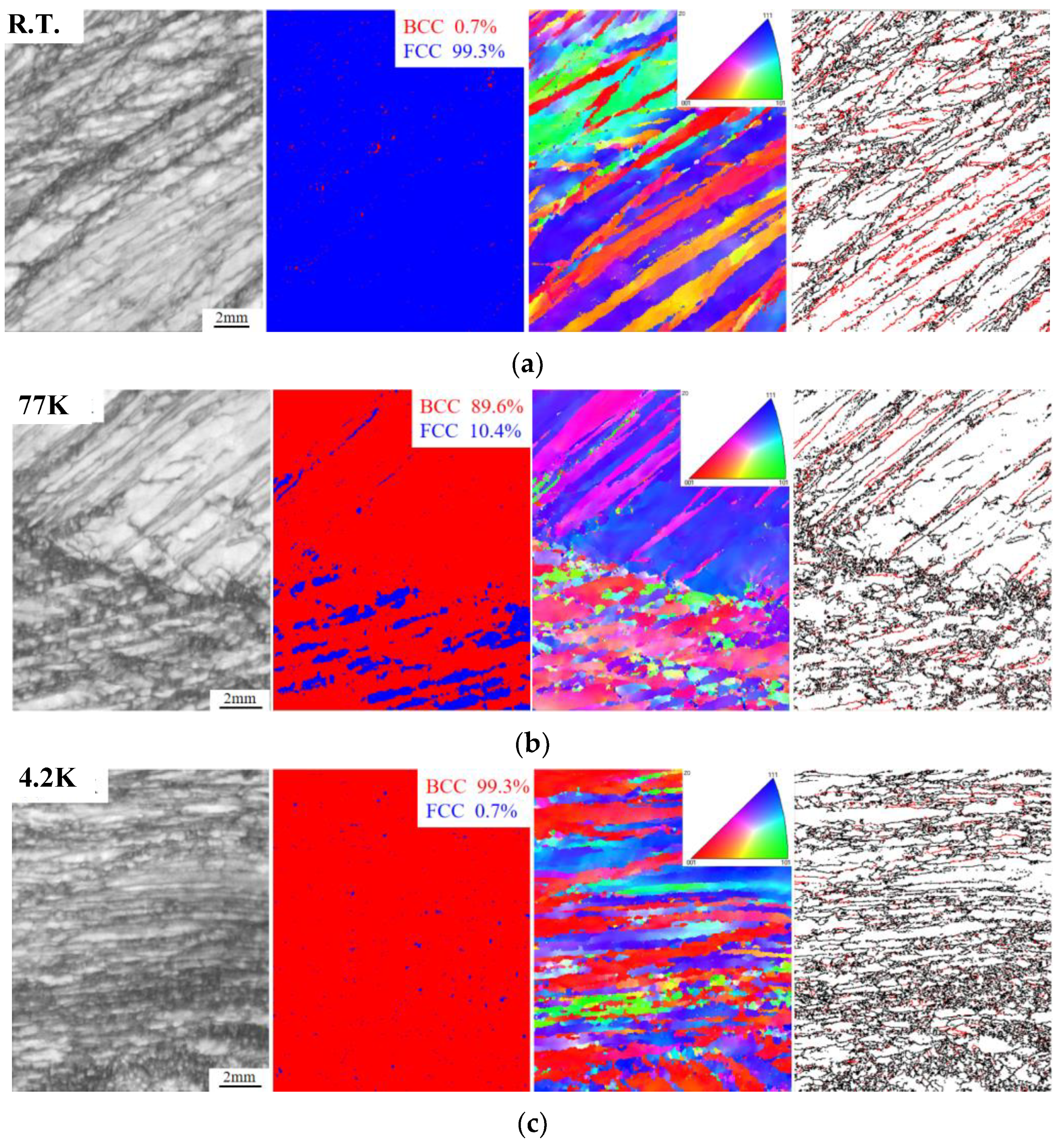

3.2. Microstructure Characterization of Mo5 Alloy

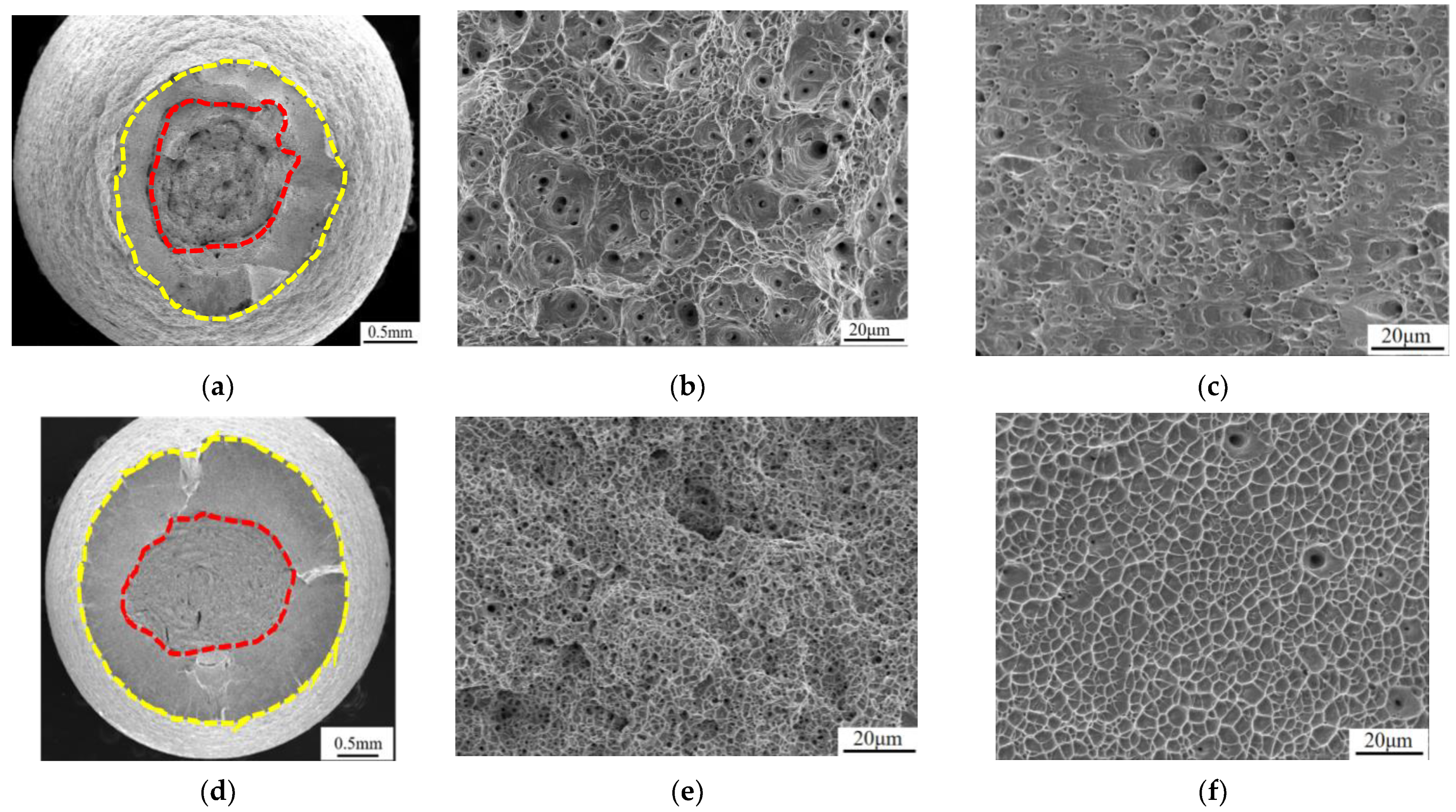

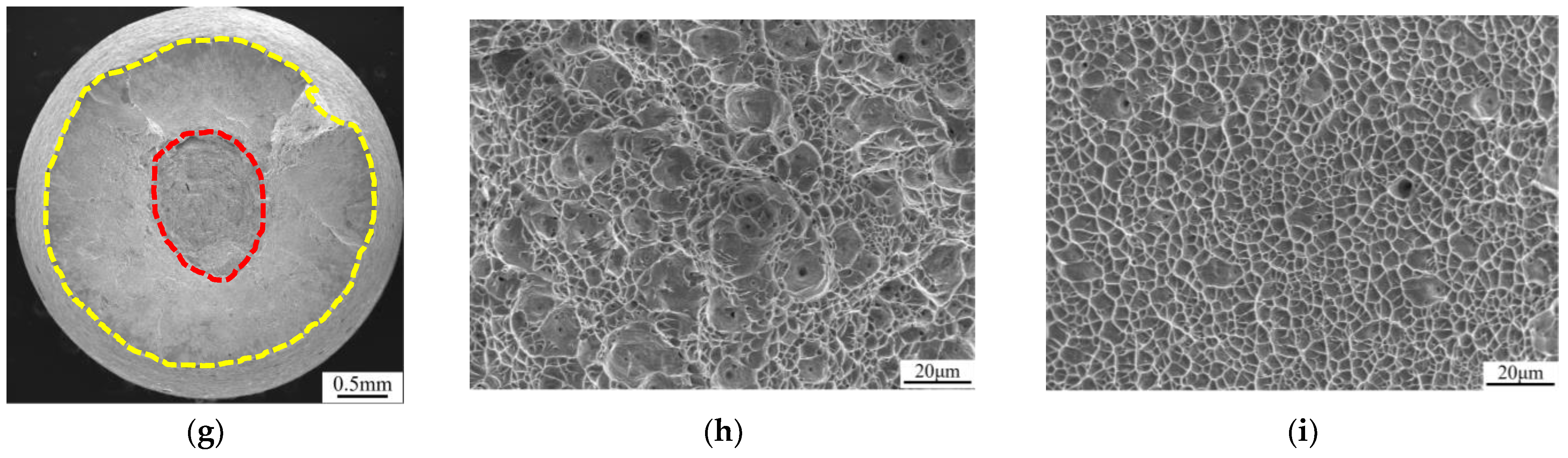

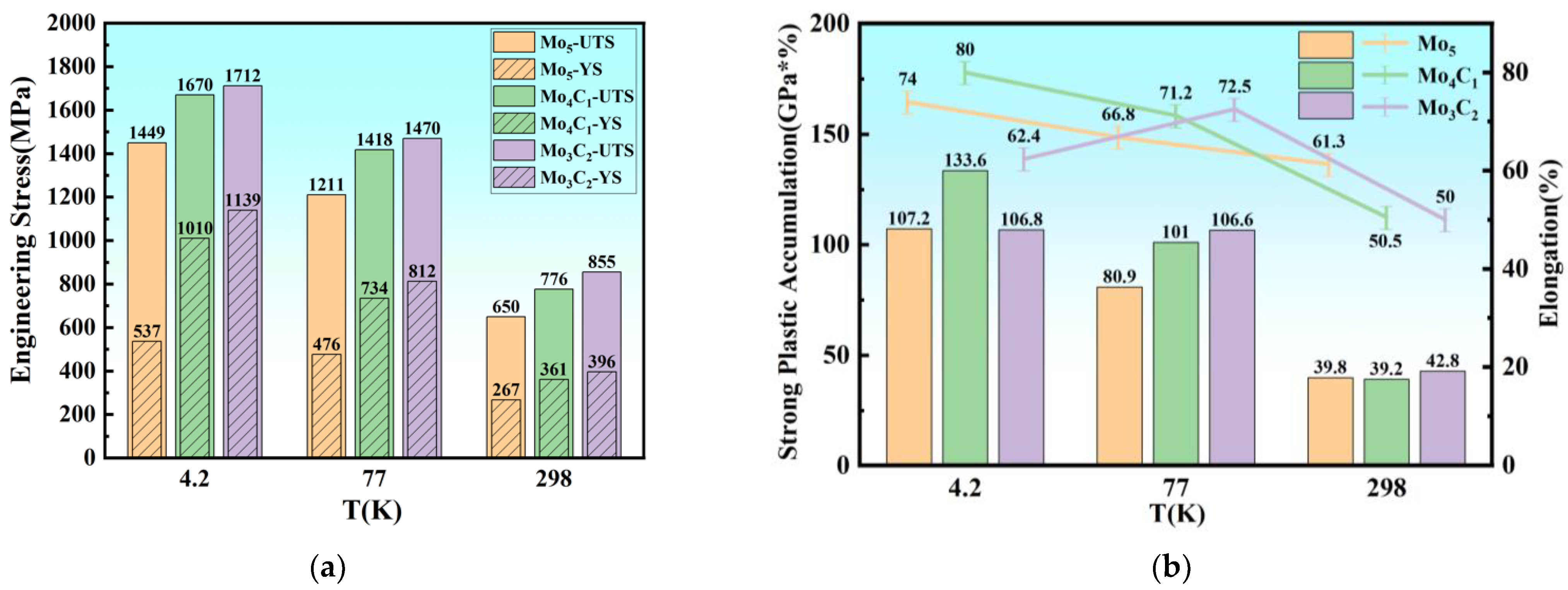

3.3. Effect of Carbon Addition on Mechanical Property and Microstructure

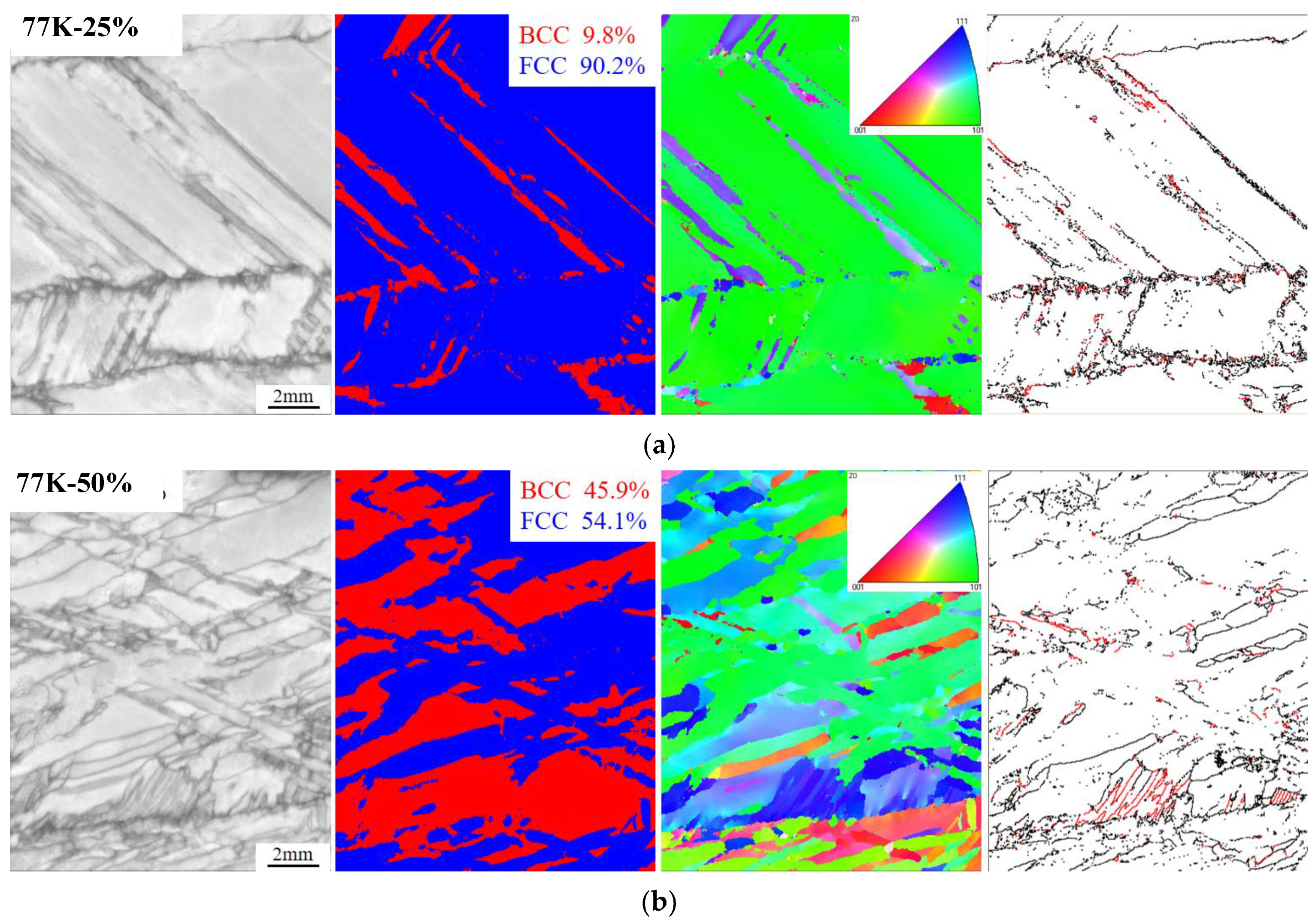

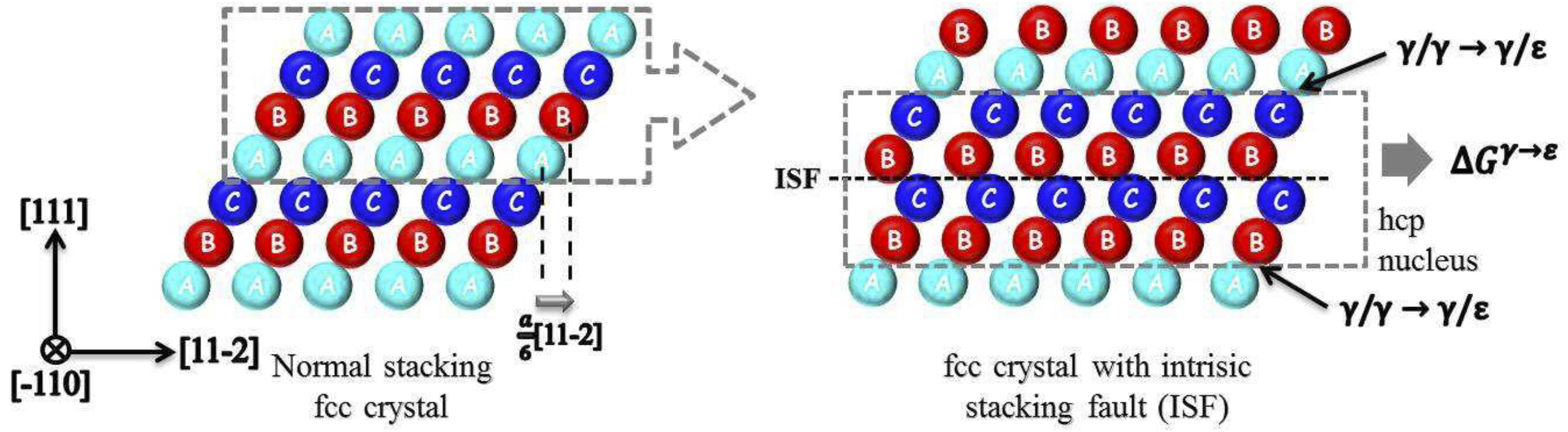

3.4. Phase Transition during Cryogenic Tensile Deformation

4. Discussion

5. Conclusions

- FeCoCrNiMo5−xCx-based alloys exhibit outstanding mechanical properties under cryogenic conditions. Particularly for the Mo4C1 alloy, the strength and ductility increase simultaneously from R.T. to 4.2 K. The tensile strength and elongation of the Mo4C1 alloy are 776 MPa and 50.5% at R.T., 1418 MPa and 71.2% in liquid nitrogen 77 K, and 1670 MPa and 80.0% in liquid helium 4.2 K, respectively.

- Under the R.T. condition, the primary contributing mechanism of strain hardening is twinning-induced plasticity. At 77 K and 4.2 K, the activation of martensitic transformation to partially replace the twining mechanism (TRIP) became the main reason for plasticity improvement during cryogenic tensile deformation.

- The precipitated carbides, namely M₆C and M₂₃C₆, along with increased dislocation density can significantly improve yield and tensile strength. As the temperature freezes to 4.2 K, the plasticity of the Mo3C2 alloy deteriorates, identifying the reason why the carbides hinder the dislocation slip and twin growth.

- The significant decrease in stacking fault energy (SFE) observed at cryogenic temperatures can facilitate processes like twinning and martensitic transformations, which play a crucial role in improving ductility under extreme conditions. The addition of carbon increases the stacking fault energy to some degree. However, the primary impact of carbon addition on the determination of cryogenic properties remains the reinforcement of precipitation mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anoop, C.R.; Singh, R.K.; Kumar, R.R.; Jayalakshmi, M.; Antony Prabhu, T.; Thomas Tharian, K.; Narayana Murty, S.V.S. A Review on Steels for Cryogenic Applications. Mater. Perform. Charact. 2021, 10, 16–88. [Google Scholar] [CrossRef]

- Guo, L.; Ou, X.; Ni, S.; Liu, Y.; Song, M. Effects of Carbon on the Microstructures and Mechanical Properties of Fecocrnimn High Entropy Alloys. Mater. Sci. Eng. A 2019, 746, 356–362. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, R.D.; Wu, F.F.; Lin, S.B.; Jiang, S.S.; Huang, Y.J.; Chen, S.H.; Eckert, J. Transformation-Enhanced Strength and Ductility in a Fecocrnimn Dual Phase High-Entropy Alloy. Mater. Sci. Eng. A 2020, 780, 139182. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Q.; Lu, J.; Liu, C.; Yang, Y. High-Entropy Alloy: Challenges and Prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Li, W.; Xie, D.; Li, D.; Zhang, Y.; Gao, Y.; Liaw, P.K. Mechanical Behavior of High-Entropy Alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile Properties of High- and Medium-Entropy Alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The Influences of Temperature and Microstructure on the Tensile Properties of a Cocrfemnni High-Entropy Alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical Properties and Stacking Fault Energies of Nifecrcomn High-Entropy Alloy. JOM 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- Naeem, M.; He, H.; Harjo, S.; Kawasaki, T.; Zhang, F.; Wang, B.; Lan, S.; Wu, Z.; Wu, Y.; Lu, Z.; et al. Extremely High Dislocation Density and Deformation Pathway of Crmnfeconi High Entropy Alloy at Ultralow Temperature. Scr. Mater. 2020, 188, 21–25. [Google Scholar] [CrossRef]

- Jo, Y.H.; Jung, S.; Choi, W.M.; Sohn, S.S.; Kim, H.S.; Lee, B.J.; Kim, N.J.; Lee, S. Cryogenic Strength Improvement by Utilizing Room-Temperature Deformation Twinning in a Partially Recrystallized Vcrmnfeconi High-Entropy Alloy. Nat. Commun. 2017, 8, 15719. [Google Scholar] [CrossRef] [PubMed]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure Evolution and Critical Stress for Twinning in the Crmnfeconi High-Entropy Alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Feng, H.; Fang, Q.H.; Liu, B.; Liu, Y.; Liu, Y.W.; Wen, P.H. Nucleation and Growth Mechanisms of Nanoscale Deformation Twins in Hexagonal-Close-Packed Metal Magnesium. Mech. Mater. 2017, 109, 26–33. [Google Scholar] [CrossRef]

- He, H.; Naeem, M.; Zhang, F.; Zhao, Y.; Harjo, S.; Kawasaki, T.; Wang, B.; Wu, X.; Lan, S.; Wu, Z.; et al. Stacking Fault Driven Phase Transformation in Crconi Medium Entropy Alloy. Nano Lett. 2021, 21, 1419–1426. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, S.; MacDonald, B.E.; Rupert, T.J.; Hahn, H.; Lavernia, E.J.; Apelian, D. Recent Progress in the Cocrni Alloy System. Materialia 2022, 24, 101476. [Google Scholar] [CrossRef]

- Moon, J.; Tabachnikova, E.; Shumilin, S.; Hryhorova, T.; Estrin, Y.; Brechtl, J.; Liaw, P.K.; Wang, W.; Dahmen, K.A.; Zargaran, A.; et al. Deformation Behavior of a Co-Cr-Fe-Ni-Mo Medium-Entropy Alloy at Extremely Low Temperatures. Mater. Today 2021, 50, 55–68. [Google Scholar] [CrossRef]

- Fu, J.; Cao, C.; Tong, W.; Hao, Y.; Peng, L. The Tensile Properties and Serrated Flow Behavior of a Thermomechanically Treated Cocrfenimn High-Entropy Alloy. Mater. Sci. Eng. A 2017, 690, 418–426. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, S.; Lee, C.; Shi, Y.; Feng, R.; Xie, X.; Hamblin, D.; Coleman, A.M.; Straka, B.; Shortt, H. A Review of the Serrated-Flow Phenomenon and Its Role in the Deformation Behavior of High-Entropy Alloys. Metals 2020, 10, 1101. [Google Scholar] [CrossRef]

- Bae, J.W.; Park, J.M.; Moon, J.; Choi, W.M.; Lee, B.-J.; Kim, H.S. Effect of Μ-Precipitates on the Microstructure and Mechanical Properties of Non-Equiatomic Cocrfenimo Medium-Entropy Alloys. J. Alloys Compd. 2019, 781, 75–83. [Google Scholar] [CrossRef]

- An, Q.; Wang, J.; Liu, Y.; Liu, B.; Guo, W.; Fang, Q.; Nie, Y. Effects of C and Mo on Microstructures and Mechanical Properties of Dual-Phase High Entropy Alloys. Intermetallics 2019, 110, 106471. [Google Scholar] [CrossRef]

- Fan, Z.; Gao, F. Grain Initiation and Grain Refinement: An Overview. Metals 2022, 12, 1728. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-Induced Plasticity (Twip) Steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Zaefferer, S.; Ohlert, J.; Bleck, W. A Study of Microstructure, Transformation Mechanisms and Correlation between Microstructure and Mechanical Properties of a Low Alloyed Trip Steel. Acta Mater. 2004, 52, 2765–2778. [Google Scholar] [CrossRef]

- Achmad, T.L.; Fu, W.; Chen, H.; Zhang, C.; Yang, Z.G. Effects of Alloying Elements Concentrations and Temperatures on the Stacking Fault Energies of Co-Based Alloys by Computational Thermodynamic Approach and First-Principles Calculations. J. Alloys Compd. 2017, 694, 1265–1279. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. A General Mechanism of Martensitic Nucleation: Part I. General Concepts and the Fcc → Hcp Transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

| Alloy | Co-wt% | Cr-wt% | Mo-wt% | Ni-wt% | C-wt% | H- wt% | N-wt% | O-wt% | Fe-wt% |

|---|---|---|---|---|---|---|---|---|---|

| Mo5—Nominal Composition | 17.72 | 11.17 | 8.24 | 10.08 | Bal. | ||||

| Mo5—Measured composition | 17.80 | 11.0 | 8.25 | 10.12 | 0.014 | 0.00008 | 0.0020 | 0.0058 | Bal. |

| Mo4C1—Nominal Composition | 17.98 | 11.33 | 6.69 | 10.23 | 0.21 | Bal. | |||

| Mo4C1—Measured composition | 18.09 | 11.26 | 6.72 | 10.27 | 0.21 | 0.00010 | 0.0016 | 0.0025 | Bal. |

| Mo3C2—Nominal Composition | 18.25 | 11.50 | 5.09 | 10.38 | 0.42 | Bal. | |||

| Mo3C2—Measured composition | 18.27 | 11.45 | 5.05 | 10.41 | 0.44 | 0.00010 | 0.0015 | 0.0014 | Bal. |

| Alloys | Temperature (K) | Rm (MPa) | Rp0.2 (MPa) | A (%) | Z (%) |

|---|---|---|---|---|---|

| Mo5 | R.T. | 650 | 267 | 61.3 | 83.5 |

| 77 K | 1211 | 476 | 66.8 | 74.0 | |

| 4.2 K | 1449 | 537 | 74.0 | 64.0 |

| Alloys | Mo5 | Mo4C1 | Mo3C2 |

|---|---|---|---|

| Dislocation density (cm−2) | 8.60 × 108 | 1.82 × 109 | 3.97 × 1011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, H.; Du, Z.; Zhang, H.; Liu, Y.; Zhao, S.; Yang, Y.; Wang, C.; Lei, S.; Geng, R.; Wang, C. Unveiling the Stacking Fault-Driven Phase Transition Delaying Cryogenic Fracture in Fe-Co-Cr-Ni-Mo-C-Based Medium-Entropy Alloy. Materials 2024, 17, 2502. https://doi.org/10.3390/ma17112502

Ding H, Du Z, Zhang H, Liu Y, Zhao S, Yang Y, Wang C, Lei S, Geng R, Wang C. Unveiling the Stacking Fault-Driven Phase Transition Delaying Cryogenic Fracture in Fe-Co-Cr-Ni-Mo-C-Based Medium-Entropy Alloy. Materials. 2024; 17(11):2502. https://doi.org/10.3390/ma17112502

Chicago/Turabian StyleDing, Hui, Zhenhang Du, Haifeng Zhang, Yu Liu, Shiteng Zhao, Yonggang Yang, Changjun Wang, Simin Lei, Ruming Geng, and Chunxu Wang. 2024. "Unveiling the Stacking Fault-Driven Phase Transition Delaying Cryogenic Fracture in Fe-Co-Cr-Ni-Mo-C-Based Medium-Entropy Alloy" Materials 17, no. 11: 2502. https://doi.org/10.3390/ma17112502

APA StyleDing, H., Du, Z., Zhang, H., Liu, Y., Zhao, S., Yang, Y., Wang, C., Lei, S., Geng, R., & Wang, C. (2024). Unveiling the Stacking Fault-Driven Phase Transition Delaying Cryogenic Fracture in Fe-Co-Cr-Ni-Mo-C-Based Medium-Entropy Alloy. Materials, 17(11), 2502. https://doi.org/10.3390/ma17112502