Influence of Welding Degree on the Meso-Mechanical Anisotropy, Fracture Propagation, and Fracture Surface Roughness of Welded Tuff

Abstract

:1. Introduction

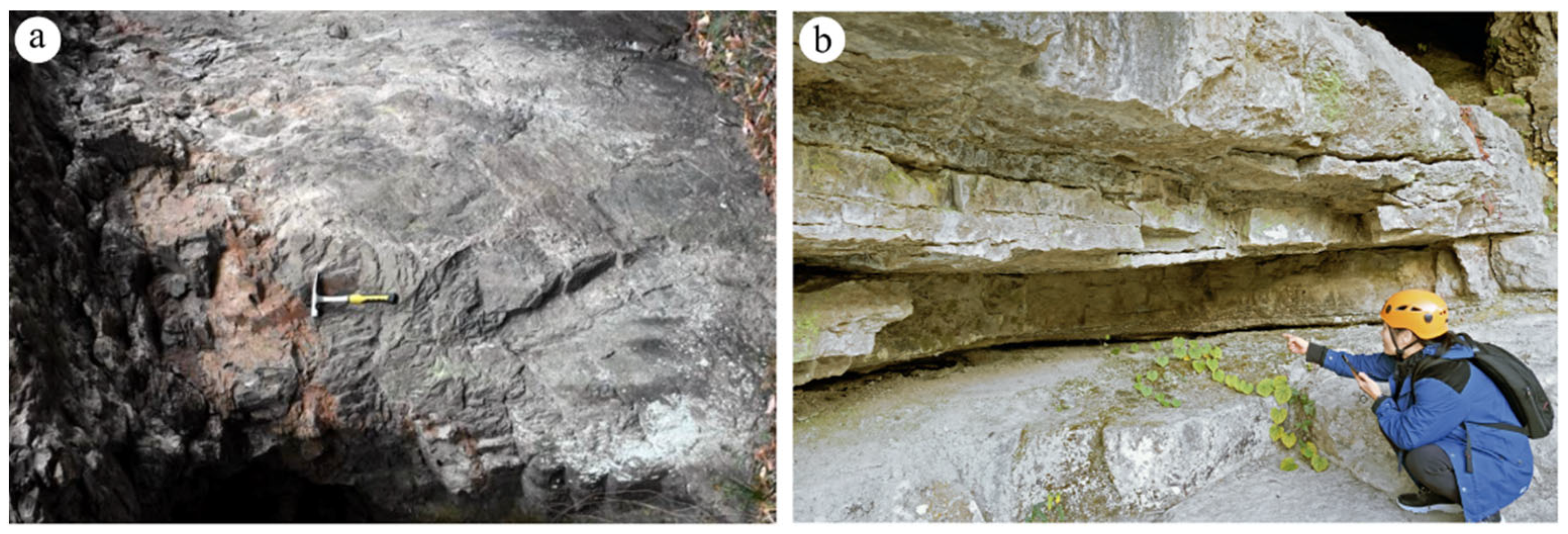

2. Materials and Methods

2.1. Materials

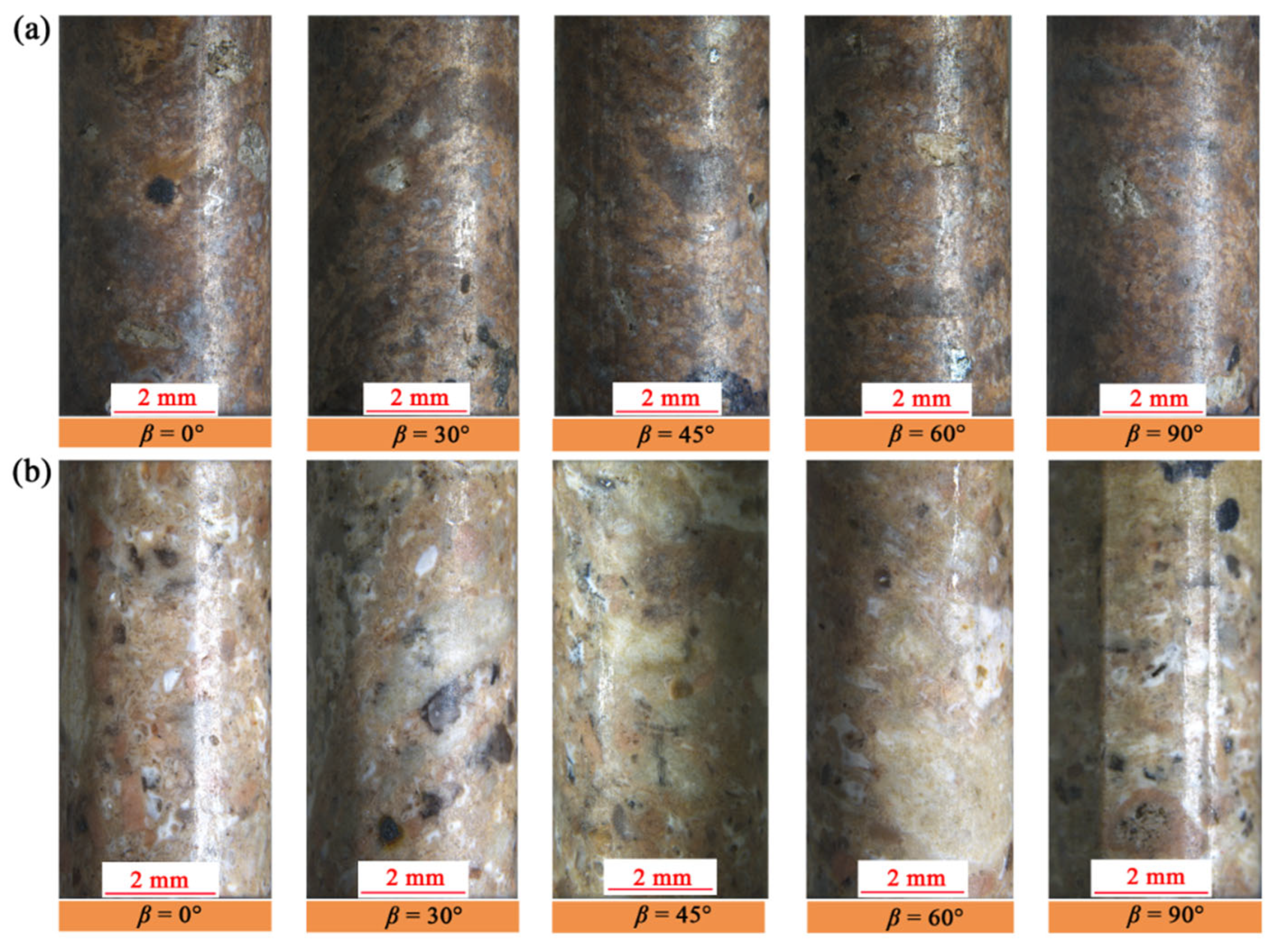

2.2. Methods

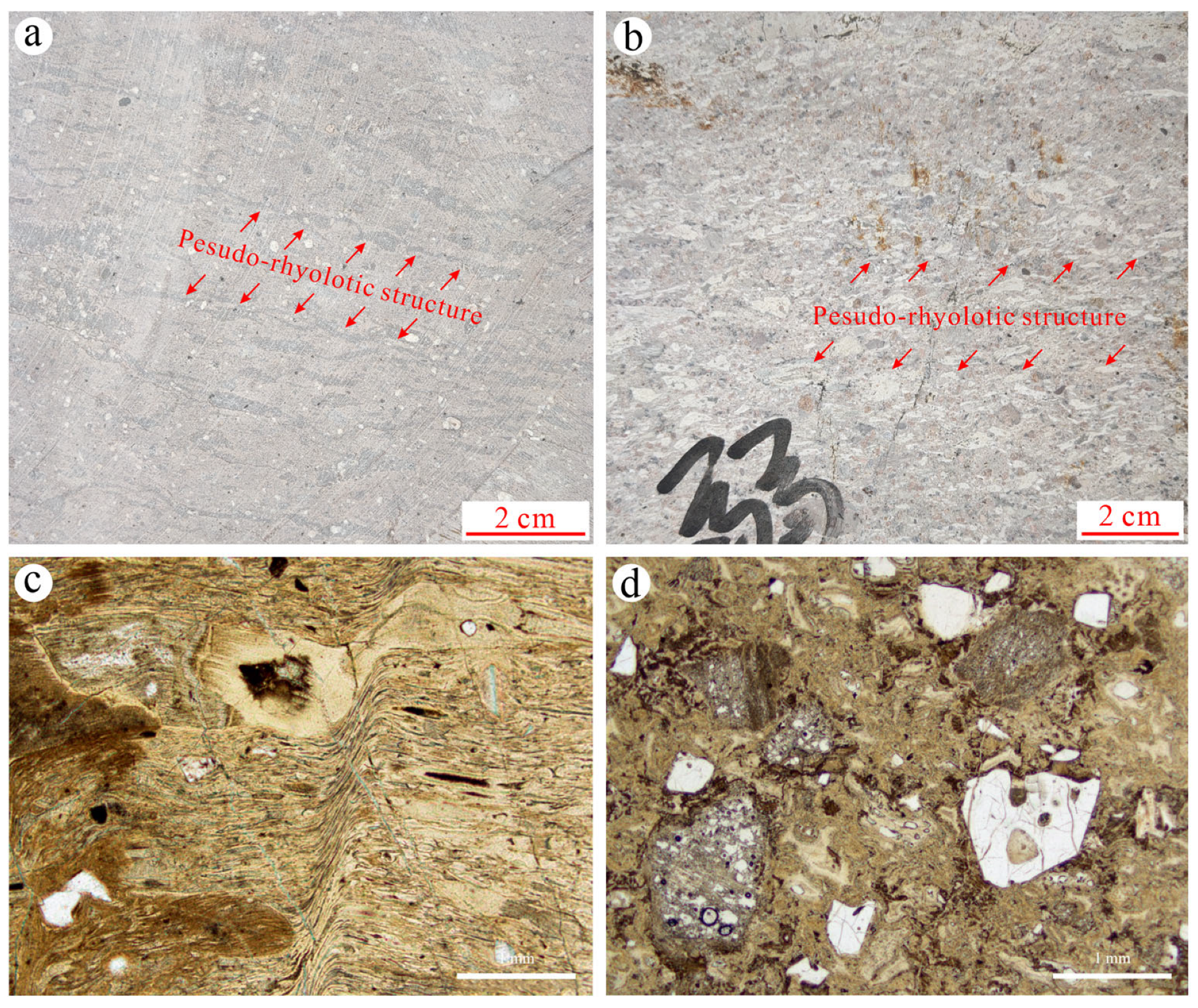

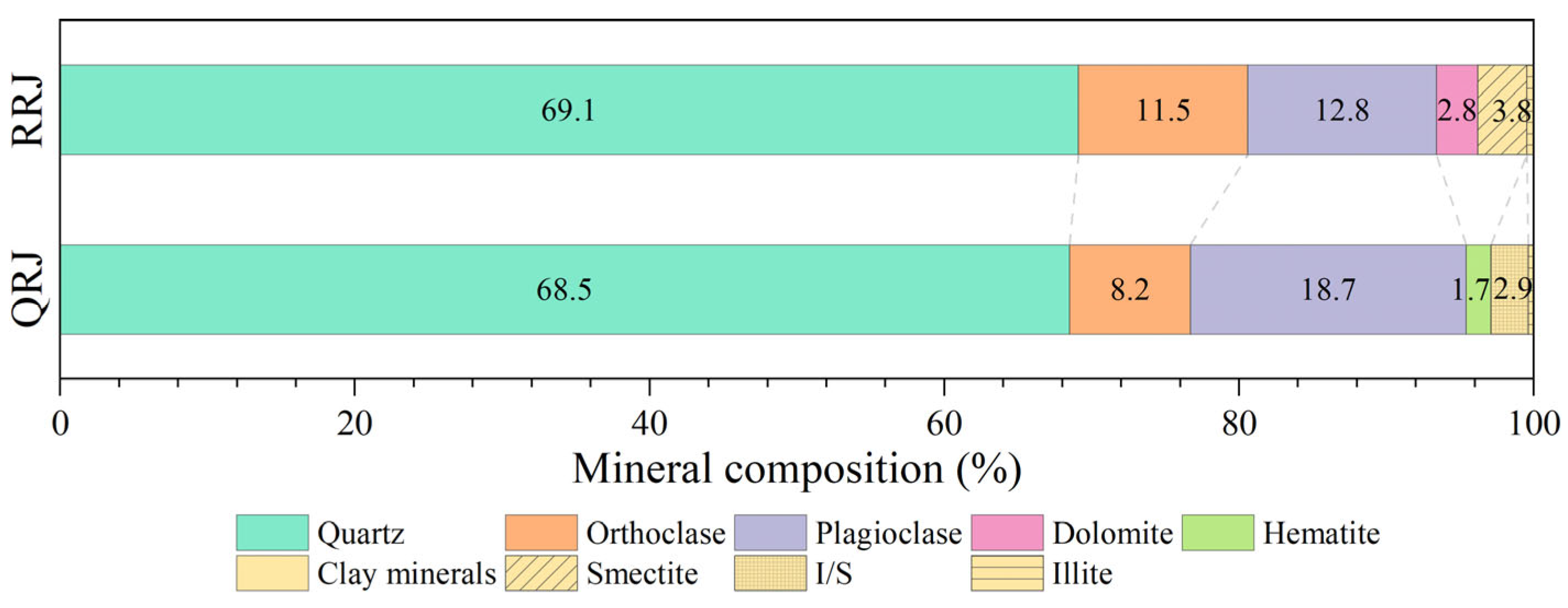

3. Mineralogical and Porosity Features of Welded Tuffs

3.1. Mineral Composition

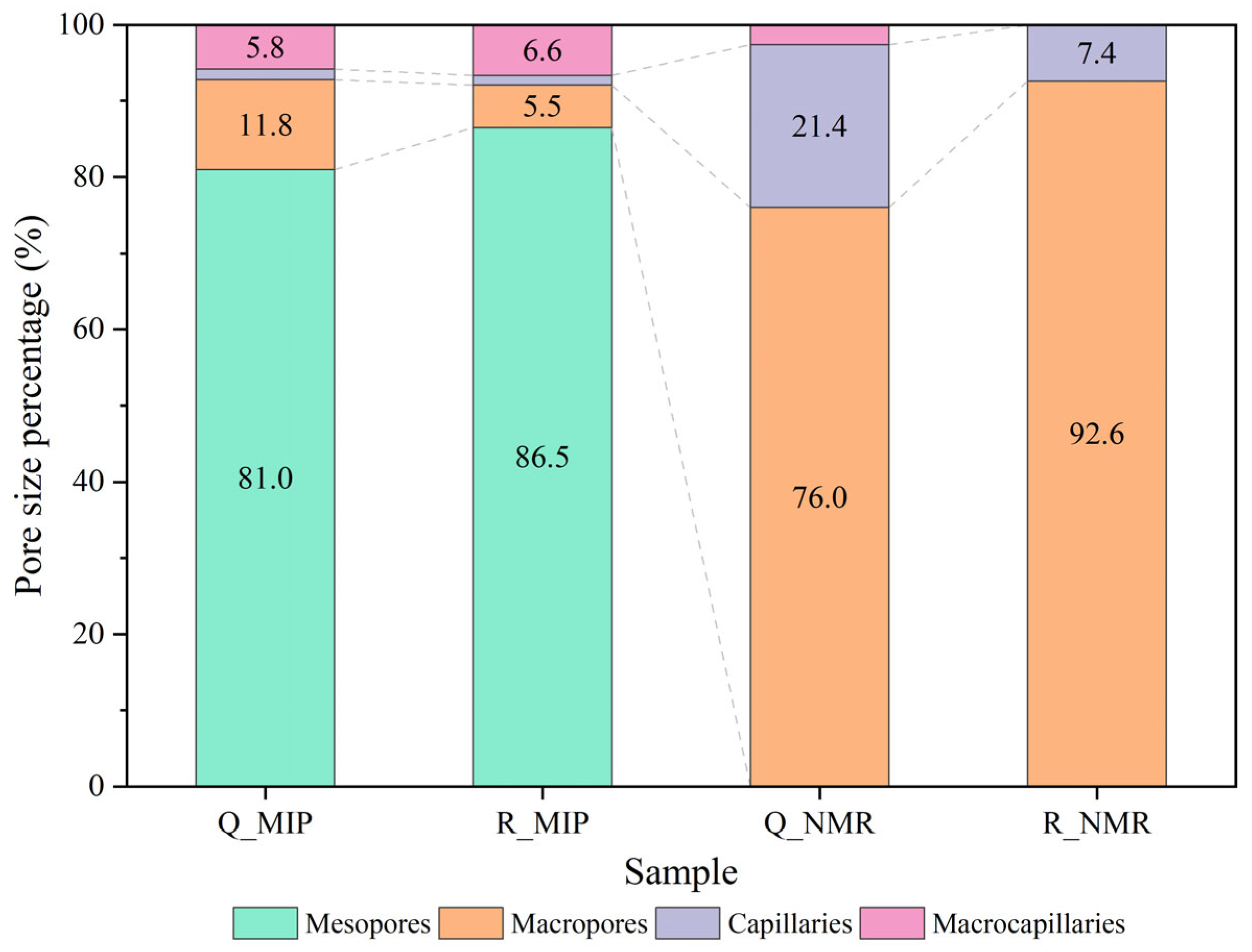

3.2. Pore Structure

4. Meso-Mechanical Properties of Welded Tuffs with Different Welding Degrees

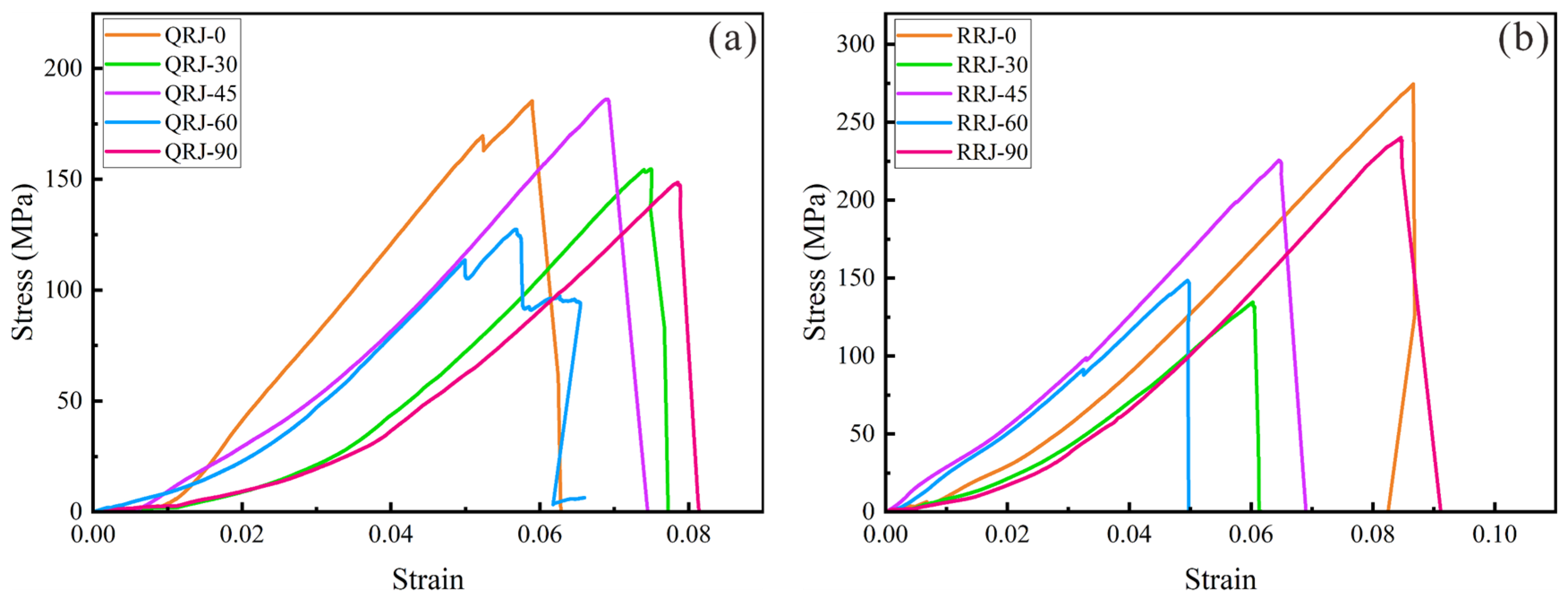

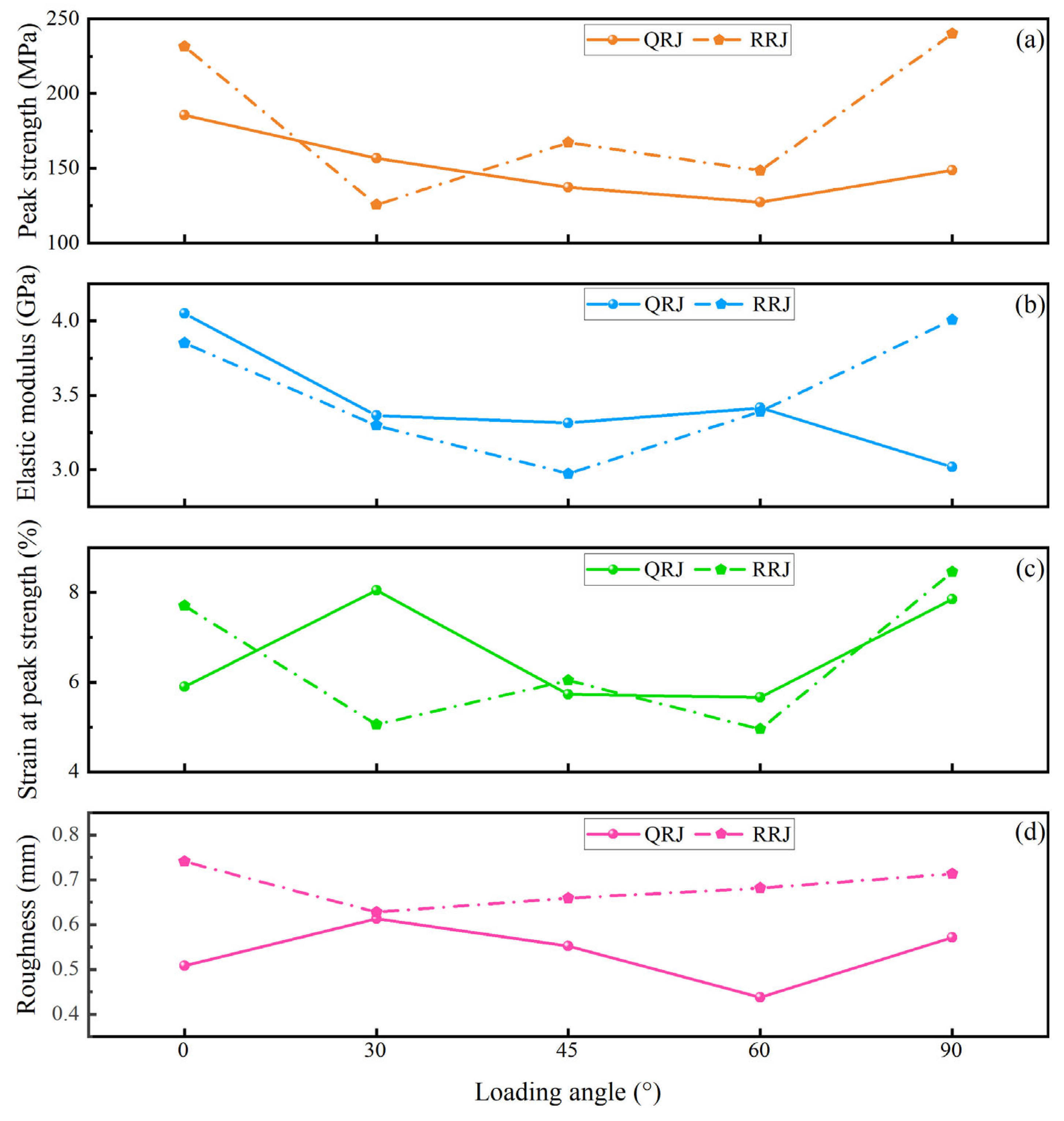

4.1. Meso-Mechanical Anisotropy of Welded Tuffs

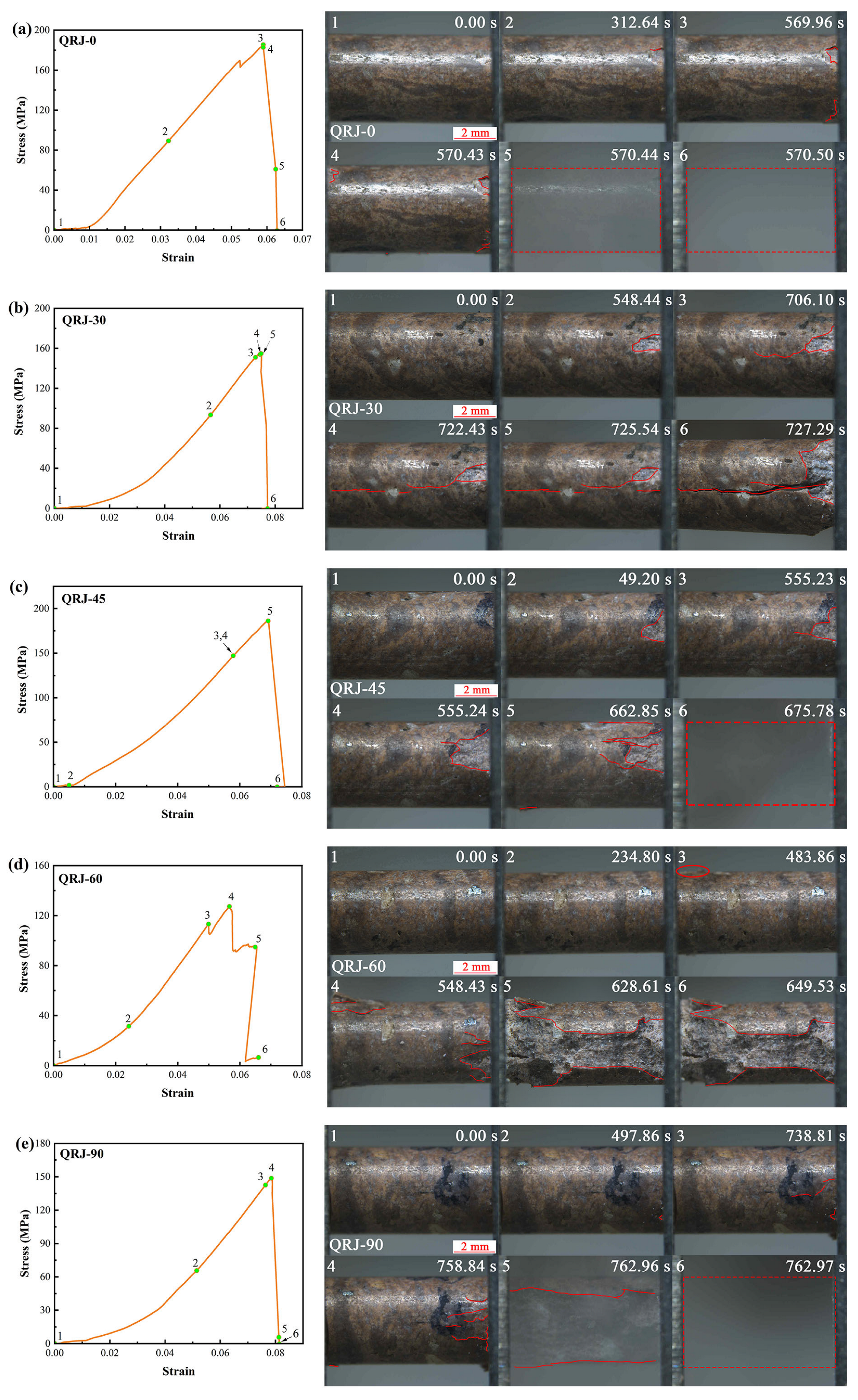

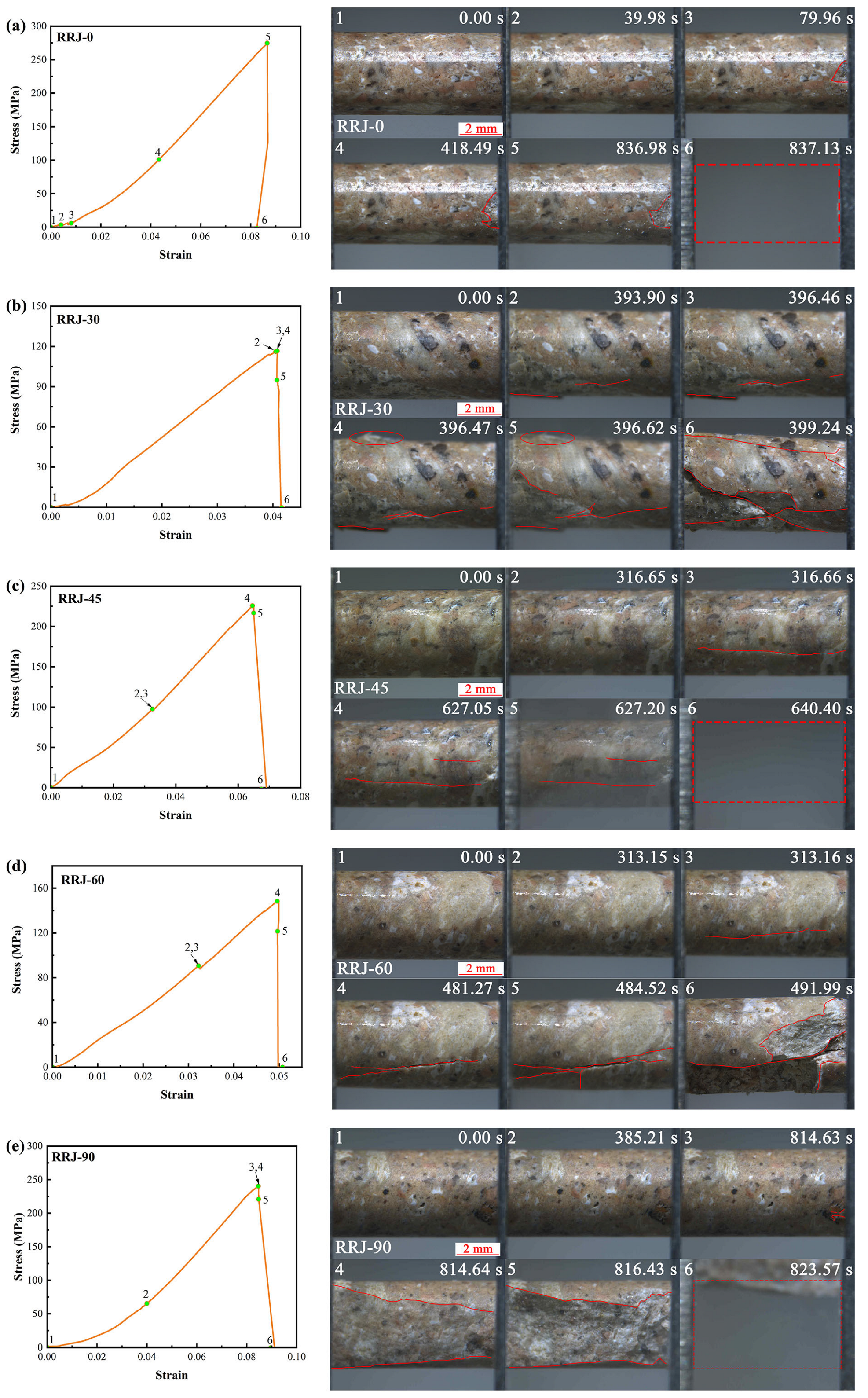

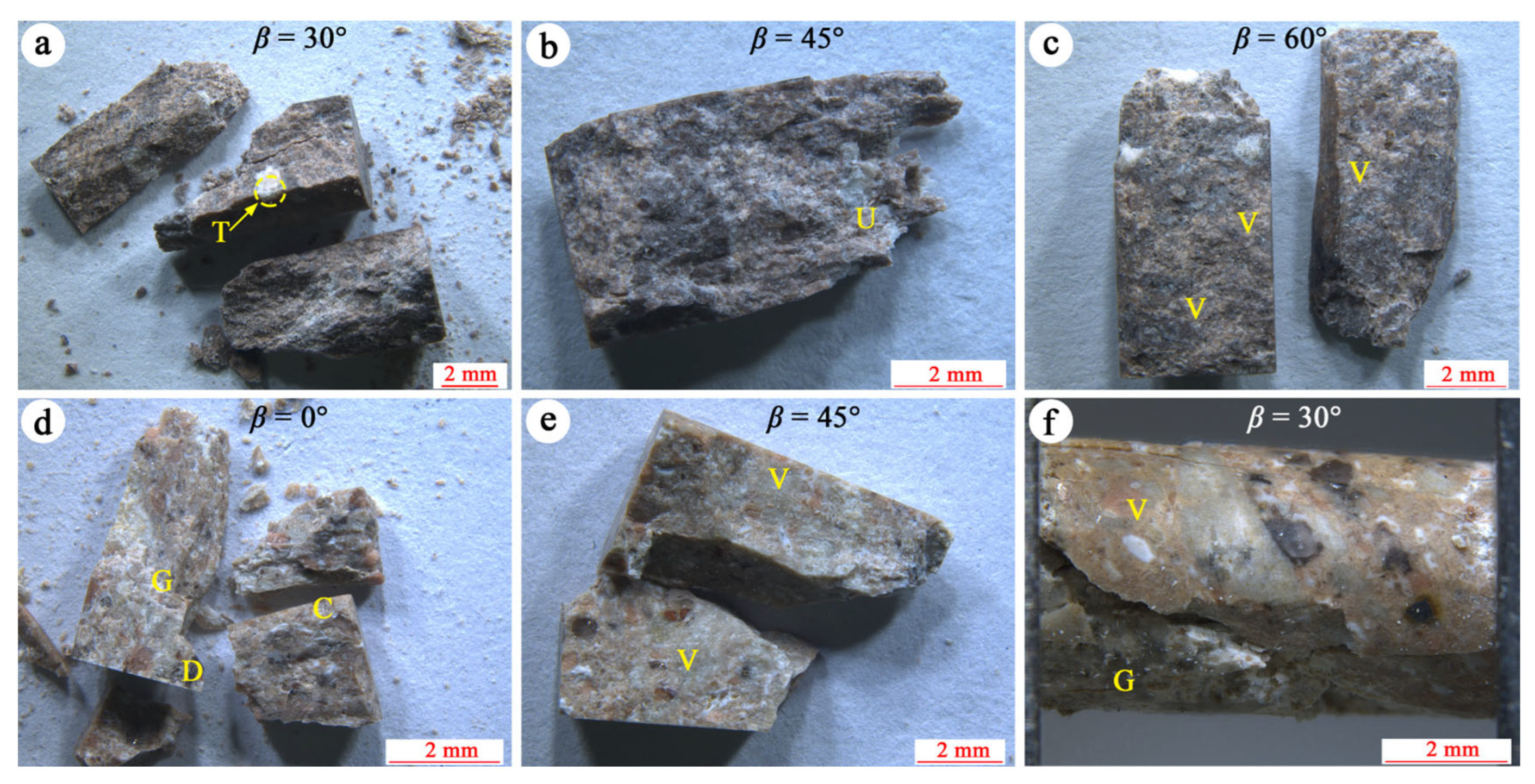

4.2. Fracture Propagation of Welded Tuffs

4.3. Fracture Surface Roughness of Welded Tuffs

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Colella, A.; Di Benedetto, C.; Calcaterra, D.; Cappelletti, P.; D’Amore, M.; Di Martire, D.; Graziano, S.F.; Papa, L.; de Gennaro, M.; Langella, A. The Neapolitan Yellow Tuff: An outstanding example of heterogeneity. Constr. Build. Mater. 2017, 136, 361–373. [Google Scholar] [CrossRef]

- Heap, M.J.; Lavallée, Y.; Laumann, A.; Hess, K.-U.; Meredith, P.G.; Dingwell, D.B. How tough is tuff in the event of fire? Geology 2012, 40, 311–314. [Google Scholar] [CrossRef]

- Deniz, B.E.; Topal, T. Durability assessment of some Cappadocian tuffs using factor analysis, multiple regression analysis, and analytical hierarchy process. Bull. Eng. Geol. Environ. 2021, 81, 6. [Google Scholar] [CrossRef]

- Kiani, M.; Hashemi, M.; Ajalloeian, R.; Benavente, D. Investigating the geological and geomechanical characteristics governing the weathering behavior of Meymand tuff. Environ. Earth Sci. 2022, 81, 45. [Google Scholar] [CrossRef]

- Germinario, L.; Török, Á. Variability of technical properties and durability in volcanic tuffs from the same quarry region—Examples from Northern Hungary. Eng. Geol. 2019, 262, 105319. [Google Scholar] [CrossRef]

- López-Doncel, R.; Wedekind, W.; Aguillón-Robles, A.; Dohrmann, R.; Molina-Maldonado, S.; Leiser, T.; Wittenborn, A.; Siegesmund, S. Thermal expansion on volcanic tuff rocks used as building stones: Examples from Mexico. Environ. Earth Sci. 2018, 77, 338. [Google Scholar] [CrossRef]

- Ma, L.; Daemen, J.J.K. An experimental study on creep of welded tuff. Int. J. Rock Mech. Min. Sci. 2006, 43, 282–291. [Google Scholar] [CrossRef]

- Zimmerman, R.M.; Nimick, F.B.; Board, M.P. Geoengineering characterization of welded tuffs from laboratory and field investigations. In Proceedings of the Materials Research Society Annual Meeting, Boston, MA, USA, 26–29 November 1984; Volume 44, pp. 547–554. [Google Scholar]

- Tsang, Y.W. A field study for understanding thermally driven coupled processes in partially saturated fractured welded tuff. Int. J. Rock Mech. Min. Sci. 2000, 37, 337–356. [Google Scholar] [CrossRef]

- Price, R.H.; Boyd, P.J.; Noel, J.S.; Martin, R.J., III. Relation between Static and Dynamic Rock Properties in Welded and Nonwelded Tuff; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 1994; p. 9. [Google Scholar] [CrossRef]

- Manley, C.R. In situ formation of welded tuff-like textures in the carapace of a voluminous silicic lava flow, Owyhee County, SW Idaho. Bull. Volcanol. 1996, 57, 672–686. [Google Scholar] [CrossRef]

- Bao, Y. Characteristics of ignimbrites in Zhejiang province. Reg. Geol. China 1986, 3, 228–238. [Google Scholar]

- Branney, M.J.; Kokelaar, B.P.; McConnell, B.J. The Bad Step Tuff: A lava-like rheomorphic ignimbrite in a calc-alkaline piecemeal caldera, English Lake District. Bull. Volcanol. 1992, 54, 187–199. [Google Scholar] [CrossRef]

- Branney, M.J.; Sparks, R.S.J. Fiamme formed by diagenesis and burial-compaction in soils and subaqeuous sediments. J. Geol. Soc. 1990, 147, 919–922. [Google Scholar] [CrossRef]

- Kaçmaz, H.; Köktürk, U. Geochemistry and mineralogy of zeolitic tuffs from the Alaçatı (Çeşme) area, Turkey. Clay. Clay Miner. 2004, 52, 705–713. [Google Scholar] [CrossRef]

- Zhu, S.; Zhu, X.; Liu, J.; Yao, Y.; Xiao, B.; Niu, H.; Zhao, C. Genesis and hydrocarbon significance of vesicular welded tuffs: A case study from the Fengcheng Formation, Wu-Xia area, Junggar Basin, NW China. Pet. Explor. Dev. 2012, 39, 173–183. [Google Scholar] [CrossRef]

- Hudyma, N.; Avar, B.B.; Karakouzian, M. Compressive strength and failure modes of lithophysae-rich Topopah Spring Tuff specimens and analog models containing cavities. Eng. Geol. 2004, 73, 179–190. [Google Scholar] [CrossRef]

- Zhu, W.; Baud, P.; Vinciguerra, S.; Wong, T.-F. Micromechanics of brittle faulting and cataclastic flow in Alban Hills tuff. J. Geophys. Res. Solid Earth 2011, 116, B06209. [Google Scholar] [CrossRef]

- Schultz, R.A.; Li, Q. Uniaxial strength testing of non-welded Calico Hills tuff, Yucca Mountain, Nevada. Eng. Geol. 1995, 40, 287–299. [Google Scholar] [CrossRef]

- Heap, M.J.; Kushnir, A.R.L.; Griffiths, L.; Wadsworth, F.; Marmoni, G.M.; Fiorucci, M.; Martino, S.; Baud, P.; Gilg, H.; Reuschlé, T. Fire resistance of the Mt. Epomeo Green Tuff, a widely-used building stone on Ischia Island (Italy). Volcanica 2018, 1, 33–48. [Google Scholar] [CrossRef]

- Wedekind, W.; López-Doncel, R.; Dohrmann, R.; Kocher, M.; Siegesmund, S. Weathering of volcanic tuff rocks caused by moisture expansion. Environ. Earth Sci. 2013, 69, 1203–1224. [Google Scholar] [CrossRef]

- Ofoegbu, G.I.; Painter, S.; Chen, R.; Fedors, R.W.; Ferrill, D.A. Geomechanical and thermal effects on moisture flow at the proposed Yucca Mountain nuclear waste repository. Nucl. Technol. 2001, 134, 241–262. [Google Scholar] [CrossRef]

- Siegesmund, S.; Gross, C.J.; Dohrmann, R.; Marler, B.; Ufer, K.; Koch, T. Moisture expansion of tuff stones and sandstones. Environ. Earth Sci. 2023, 82, 146. [Google Scholar] [CrossRef]

- Li, L.; Tan, Y.; Huang, B.; Deng, X. Pore property as an indicator of macro-deterioration in slightly weathered tuffs. Eng. Geol. 2020, 267, 105492. [Google Scholar] [CrossRef]

- Pötzl, C.; Siegesmund, S.; Dohrmann, R.; Koning, J.M.; Wedekind, W. Deterioration of volcanic tuff rocks from Armenia: Constraints on salt crystallization and hydric expansion. Environ. Earth Sci. 2018, 77, 660. [Google Scholar] [CrossRef]

- Togashi, Y.; Kikumoto, M.; Tani, K.; Hosoda, K.; Ogawa, K. Detection of deformation anisotropy of tuff by a single triaxial test on a single specimen. Int. J. Rock Mech. Min. Sci. 2018, 108, 23–36. [Google Scholar] [CrossRef]

- Osada, M. Drying-induced deformation characteristics of rocks. In Proceedings of the ISRM International Symposium—8th Asian Rock Mechanics Symposium, Sapporo, Japan, 14–16 October 2014. [Google Scholar]

- Togashi, Y.; Imano, T.; Osada, M.; Hosoda, K.; Ogawa, K. Principal strain rotation of anisotropic tuff due to continuous water-content variation. Int. J. Rock Mech. Min. Sci. 2021, 138, 104646. [Google Scholar] [CrossRef]

- Quane, S.L.; Russell, J.K. Ranking welding intensity in pyroclastic deposits. Bull. Volcanol. 2005, 67, 129–143. [Google Scholar] [CrossRef]

- Soden, A.M.; Shipton, Z.K. Dilational fault zone architecture in a welded ignimbrite: The importance of mechanical stratigraphy. J. Struct. Geol. 2013, 51, 156–166. [Google Scholar] [CrossRef]

- Soden, A.M.; Lunn, R.J.; Shipton, Z.K. Impact of mechanical heterogeneity on joint density in a welded ignimbrite. J. Struct. Geol. 2016, 89, 118–129. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Huang, B.; Wang, M.; Bai, Z.; Qi, S. Influence of the welding degree on the strength and failure modes of tuff. Materials 2022, 15, 8757. [Google Scholar] [CrossRef]

- National Energy Administration of the People’s Republic of China. Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. In SY/T 5163-2018; Petroleum Industry Press: Beijing, China, 2018. [Google Scholar]

- Brown, E. Rock Characterization Testing and Monitoring: ISRM Suggested Methods; Pergamon: Oxford, UK, 1981. [Google Scholar]

- Huang, B.; Li, L.; Tan, Y.; Hu, R.; Li, X. Investigating the meso-mechanical anisotropy and fracture surface roughness of continental shale. J. Geophys. Res. Solid Earth 2020, 125, e2019JB017828. [Google Scholar] [CrossRef]

- Keller, J.U.; Staudt, R. Gas Adsorption Equilibria: Experimental Methods and Adsorptive Isotherms; Springer: New York, NY, USA, 2005. [Google Scholar]

- Saroglou, H.; Tsiambaos, G. A modified Hoek–Brown failure criterion for anisotropic intact rock. Int. J. Rock Mech. Min. Sci. 2008, 45, 223–234. [Google Scholar] [CrossRef]

- Saroglou, C.; Qi, S.; Guo, S.; Wu, F. ARMR, a new classification system for the rating of anisotropic rock masses. Bull. Eng. Geol. Environ. 2019, 78, 3611–3626. [Google Scholar] [CrossRef]

- Avar, B.B.; Hudyma, N.W. Observations on the influence of lithophysae on elastic (Young’s) modulus and uniaxial compressive strength of Topopah Spring Tuff at Yucca Mountain, Nevada, USA. Int. J. Rock Mech. Min. Sci. 2007, 44, 266–270. [Google Scholar] [CrossRef]

- Martin, R.J.; Price, R.H.; Boyd, P.J.; Noel, J.S. The influence of strain rate and sample inhomogeneity on the moduli and strength of welded tuff. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1507–1510. [Google Scholar] [CrossRef]

- Moon, V.G. Microstructural controls on the geomechanical behaviour of ignimbrite. Eng. Geol. 1993, 35, 19–31. [Google Scholar] [CrossRef]

- Pola, A.; Crosta, G.B.; Fusi, N.; Castellanza, R. General characterization of the mechanical behaviour of different volcanic rocks with respect to alteration. Eng. Geol. 2014, 169, 1–13. [Google Scholar] [CrossRef]

- Moon, V.G. Geotechnical characteristics of ignimbrite: A soft pyroclastic rock type. Eng. Geol. 1993, 35, 33–48. [Google Scholar] [CrossRef]

- Crawford, B.R.; DeDontney, N.L.; Alramahi, B.; Ottesen, S. Shear strength anisotropy in fine-grained rocks. In Proceedings of the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; p. 12. [Google Scholar]

- Tien, Y.M.; Kuo, M.C.; Juang, C.H. An experimental investigation of the failure mechanism of simulated transversely isotropic rocks. Int. J. Rock Mech. Min. Sci. 2006, 43, 1163–1181. [Google Scholar] [CrossRef]

- Binal, A. Prediction of mechanical properties of non-welded and moderately welded ignimbrite using physical properties, ultrasonic pulse velocity, and point load index tests. Q. J. Eng. Geol. Hydrogeol. 2009, 42, 107–122. [Google Scholar] [CrossRef]

- Avar, B.B.; Hudyma, N.; Karakouzian, M. Porosity dependence of the elastic modulus of lithophysae-rich tuff: Numerical and experimental investigations. Int. J. Rock Mech. Min. Sci. 2003, 40, 919–928. [Google Scholar] [CrossRef]

| Loading Angle (°) | Strongly Welded Tuffs | Weakly Welded Tuffs | ||||||

|---|---|---|---|---|---|---|---|---|

| Peak Strength (MPa) | Average Strength (MPa) | Elastic Modulus (GPa) | Average Modulus (GPa) | Peak Strength (MPa) | Average Strength (MPa) | Elastic Modulus (GPa) | Average Modulus (GPa) | |

| 0 | 185.38 | 151.09 | 4.05 | 3.43 | 231.44 | 182.55 | 3.85 | 3.50 |

| 30 | 156.81 | 3.36 | 125.57 | 3.30 | ||||

| 45 | 137.21 | 3.31 | 167.15 | 2.97 | ||||

| 60 | 127.37 | 3.42 | 148.46 | 3.39 | ||||

| 90 | 148.66 | 3.02 | 240.15 | 4.01 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.; Li, L.; Li, C.; Qiao, S.; Ranjith, P.G. Influence of Welding Degree on the Meso-Mechanical Anisotropy, Fracture Propagation, and Fracture Surface Roughness of Welded Tuff. Materials 2024, 17, 2573. https://doi.org/10.3390/ma17112573

Huang B, Li L, Li C, Qiao S, Ranjith PG. Influence of Welding Degree on the Meso-Mechanical Anisotropy, Fracture Propagation, and Fracture Surface Roughness of Welded Tuff. Materials. 2024; 17(11):2573. https://doi.org/10.3390/ma17112573

Chicago/Turabian StyleHuang, Beixiu, Lihui Li, Chenglong Li, Sijia Qiao, and Pathegama Gamage Ranjith. 2024. "Influence of Welding Degree on the Meso-Mechanical Anisotropy, Fracture Propagation, and Fracture Surface Roughness of Welded Tuff" Materials 17, no. 11: 2573. https://doi.org/10.3390/ma17112573

APA StyleHuang, B., Li, L., Li, C., Qiao, S., & Ranjith, P. G. (2024). Influence of Welding Degree on the Meso-Mechanical Anisotropy, Fracture Propagation, and Fracture Surface Roughness of Welded Tuff. Materials, 17(11), 2573. https://doi.org/10.3390/ma17112573