A Comparative Analysis of Low and High SiC Volume Fraction Additively Manufactured SiC/Ti6Al4V(ELI) Composites Based on the Best Process Parameters of Laser Power, Scanning Speed and Hatch Distance

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

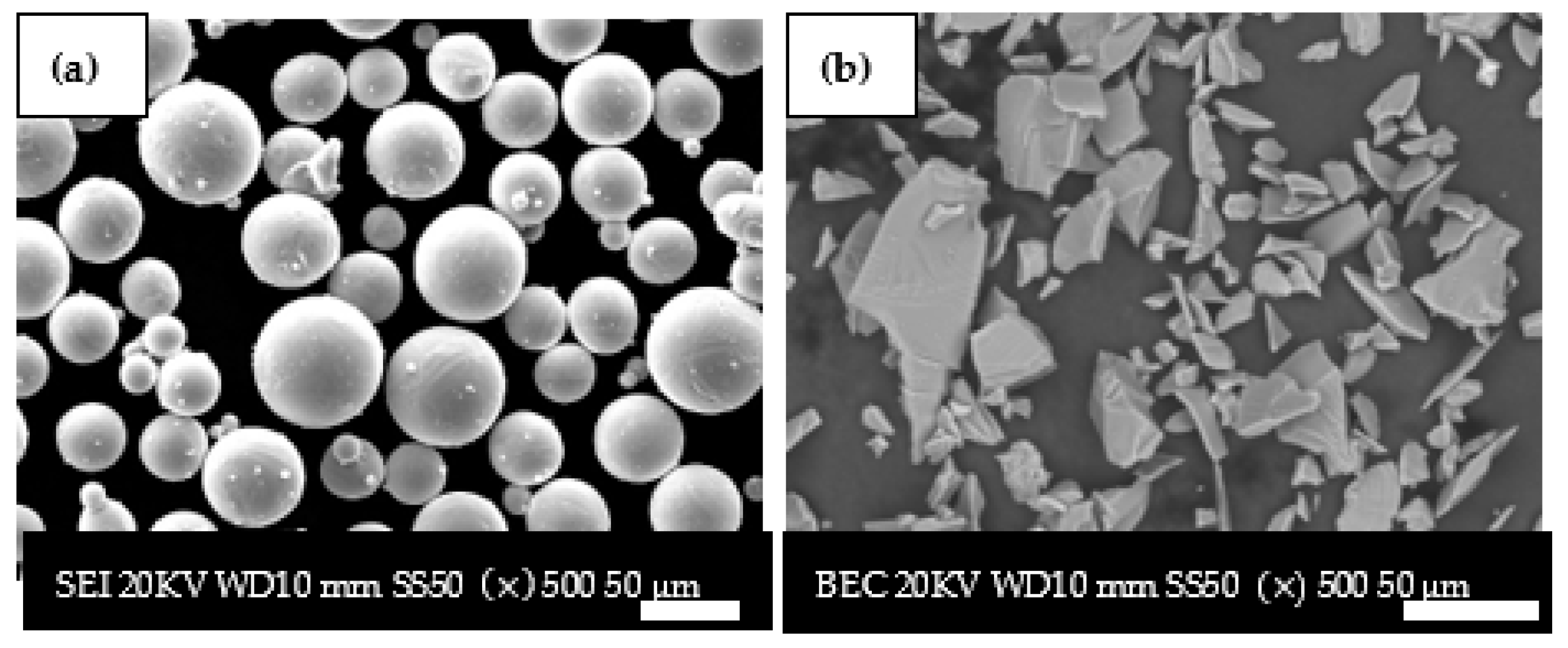

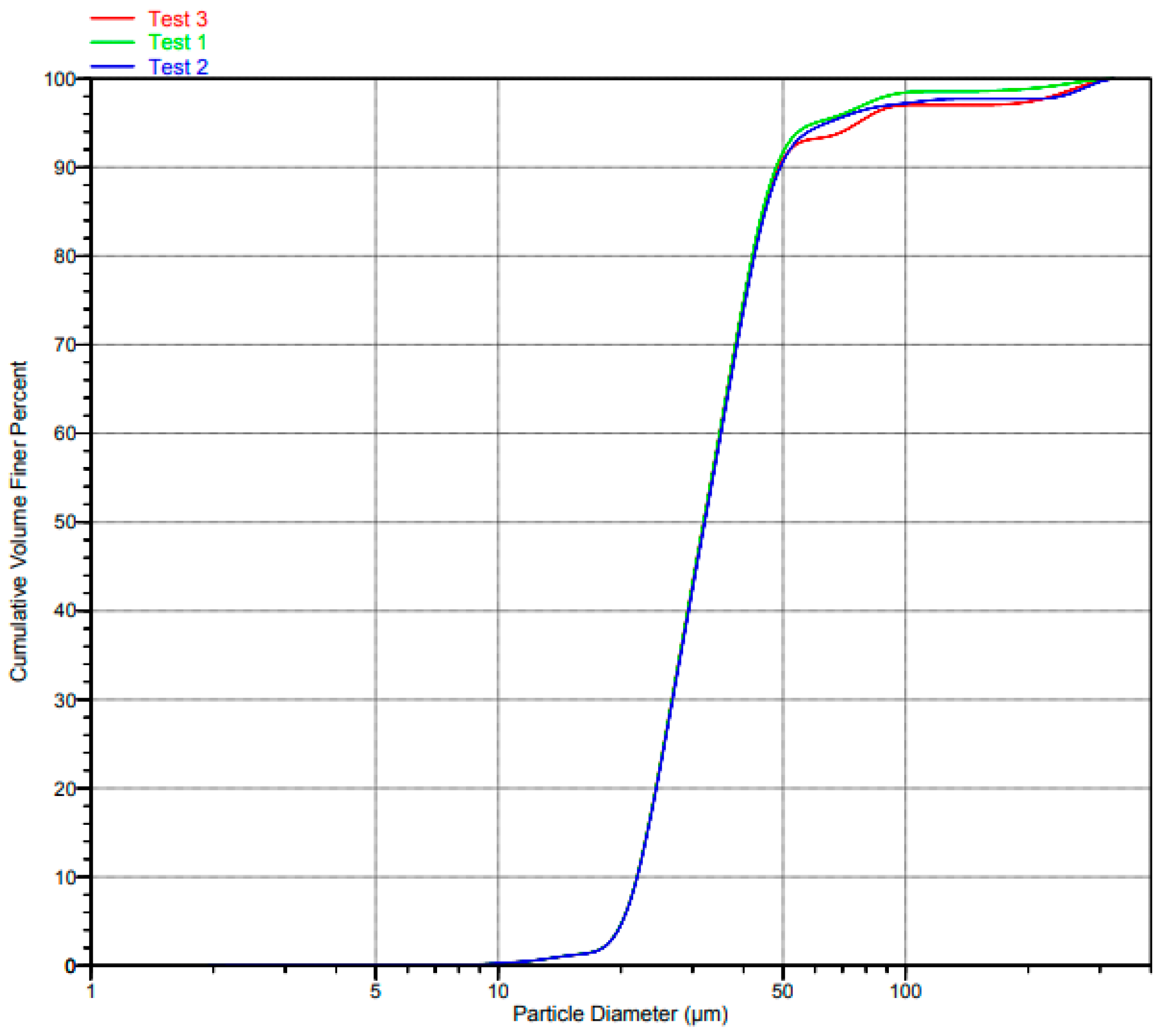

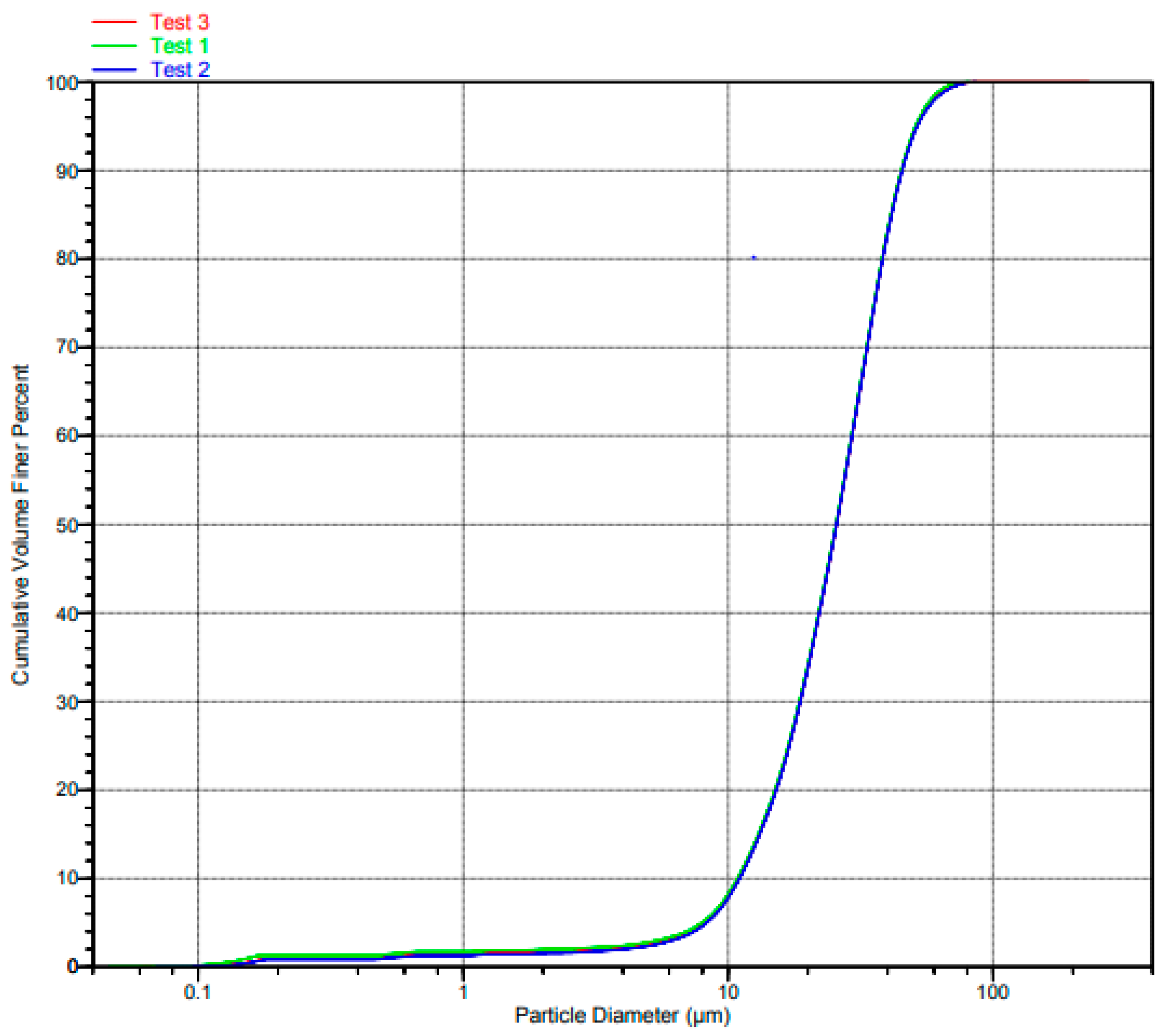

3.1. Particle Size Distribution and Morphology of SiC and Ti6Al4V(ELI) Powders

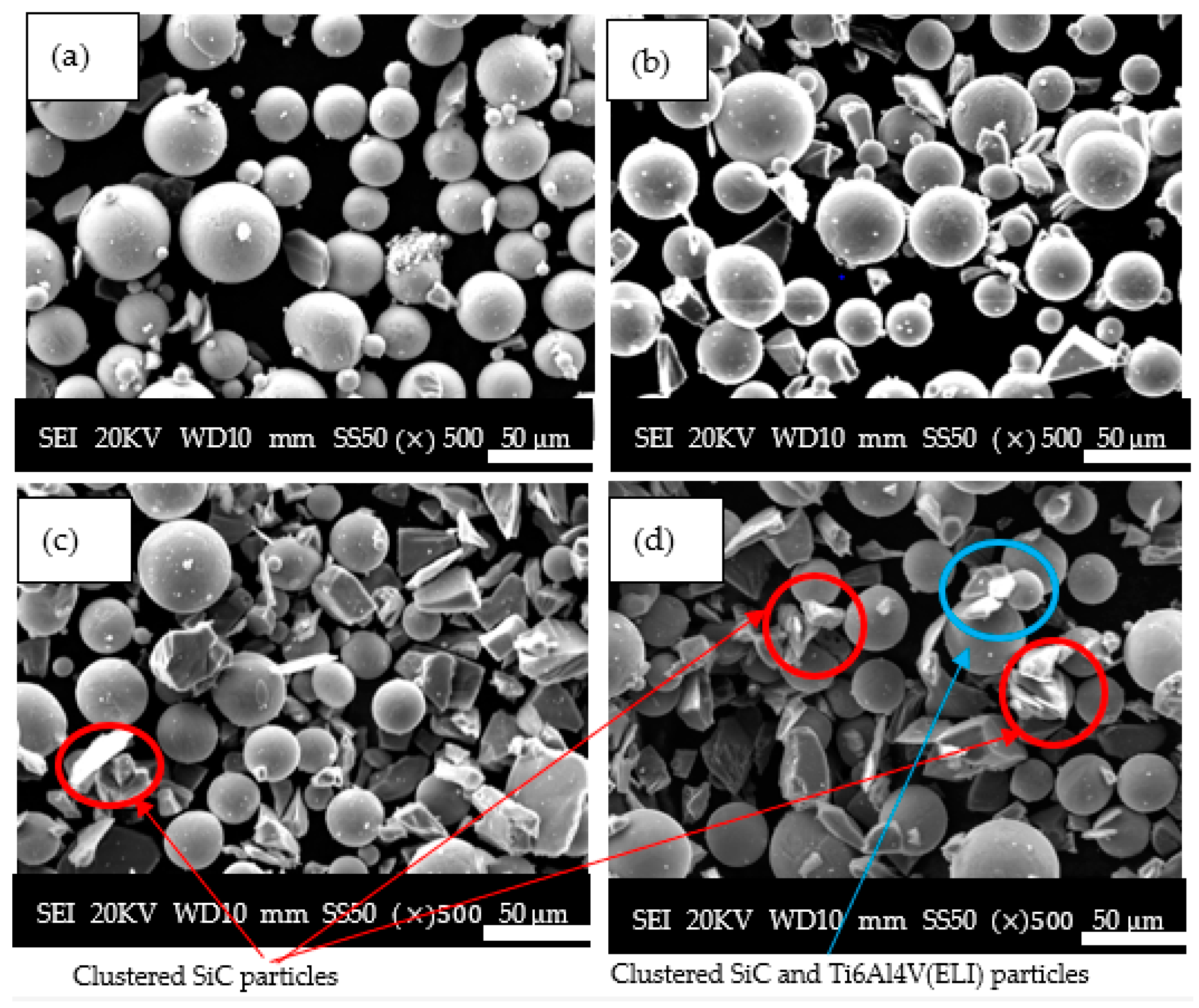

3.2. SEM Micrographs of the Mixed SiC and Ti6Al4V(ELI) Powders

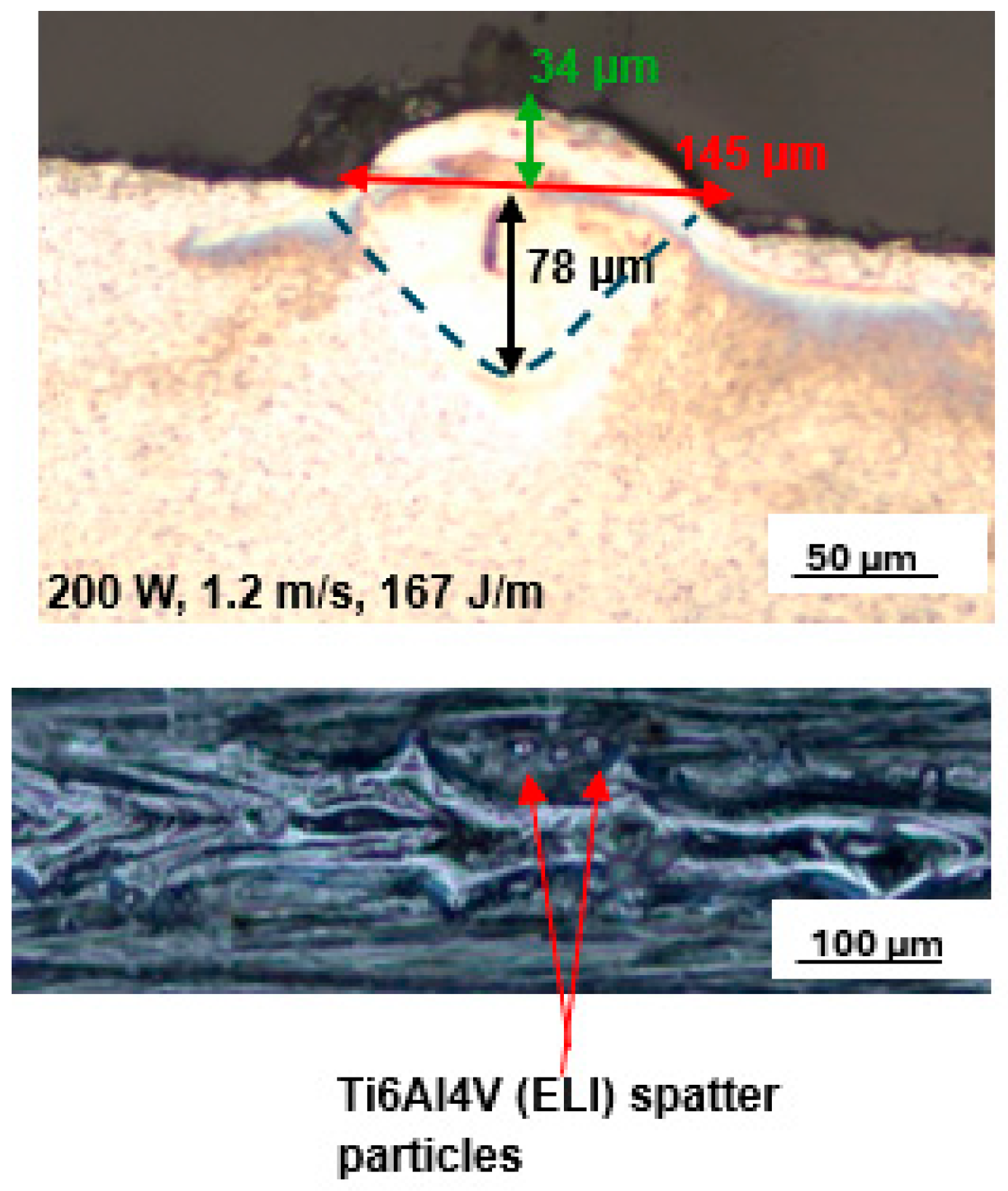

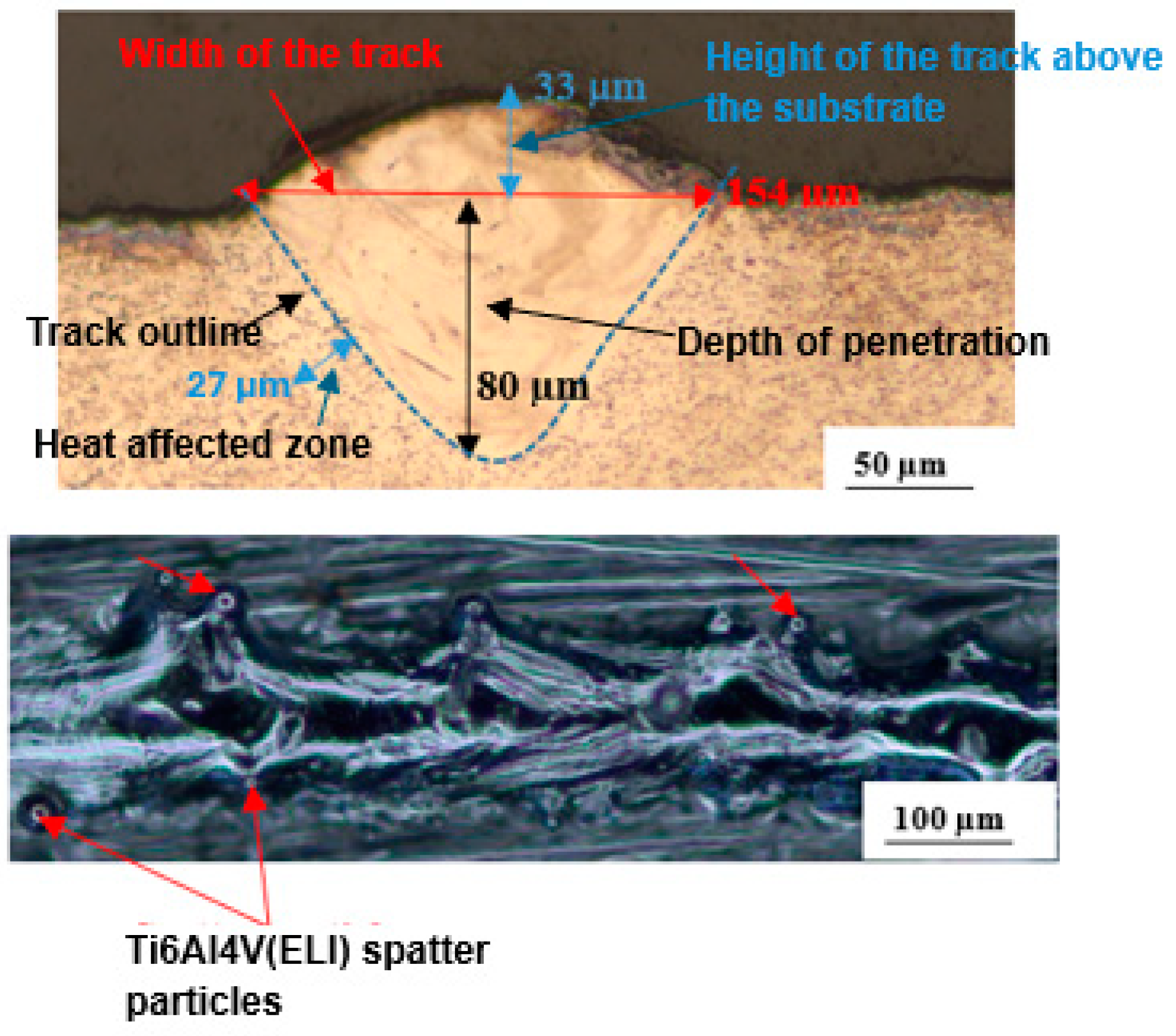

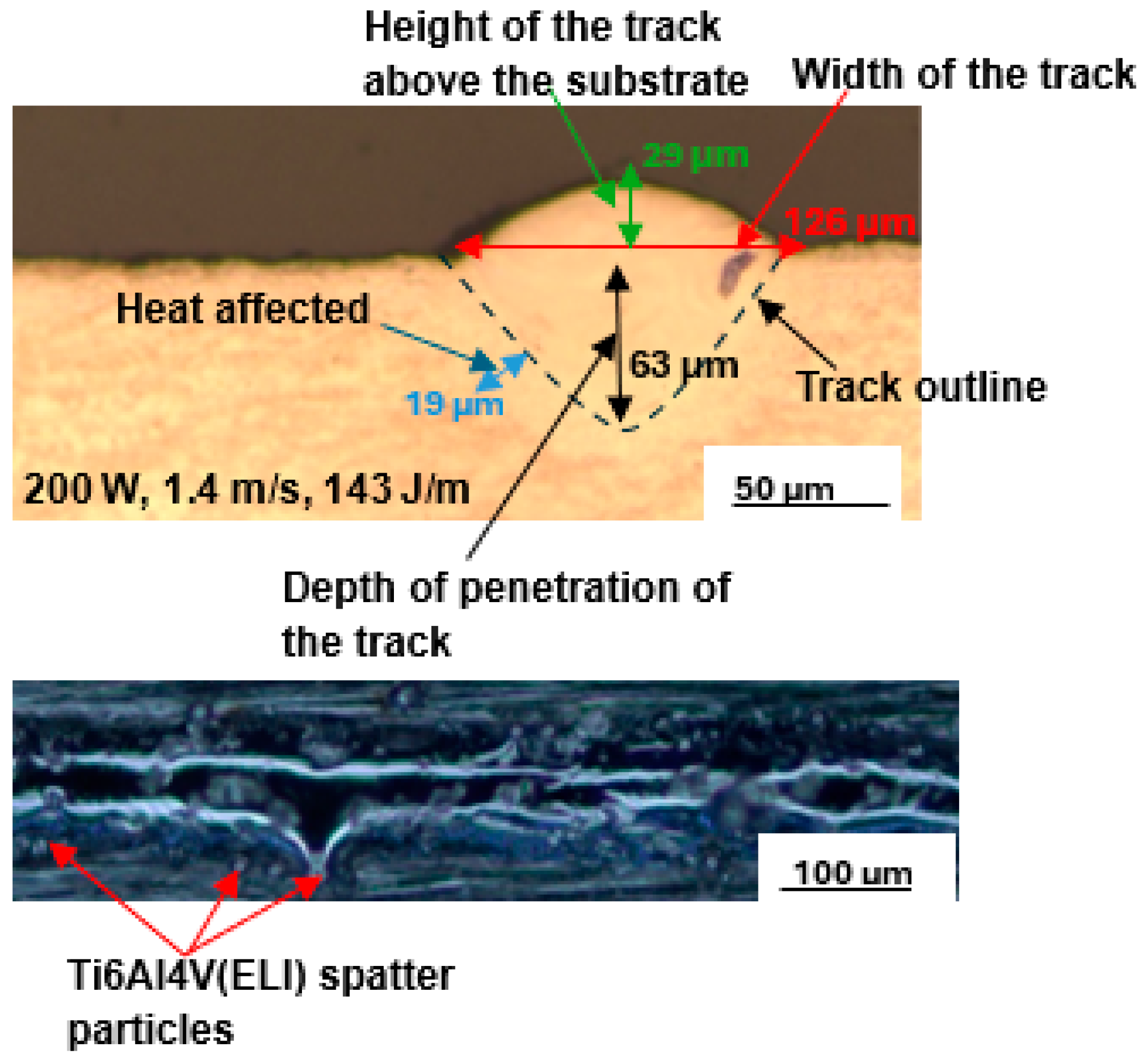

3.3. Top Surface and Cross-Sectional Analysis of Single Tracks at 5% and 10% SiC Volume Fraction in SiC/Ti6Al4V(ELI) Composites

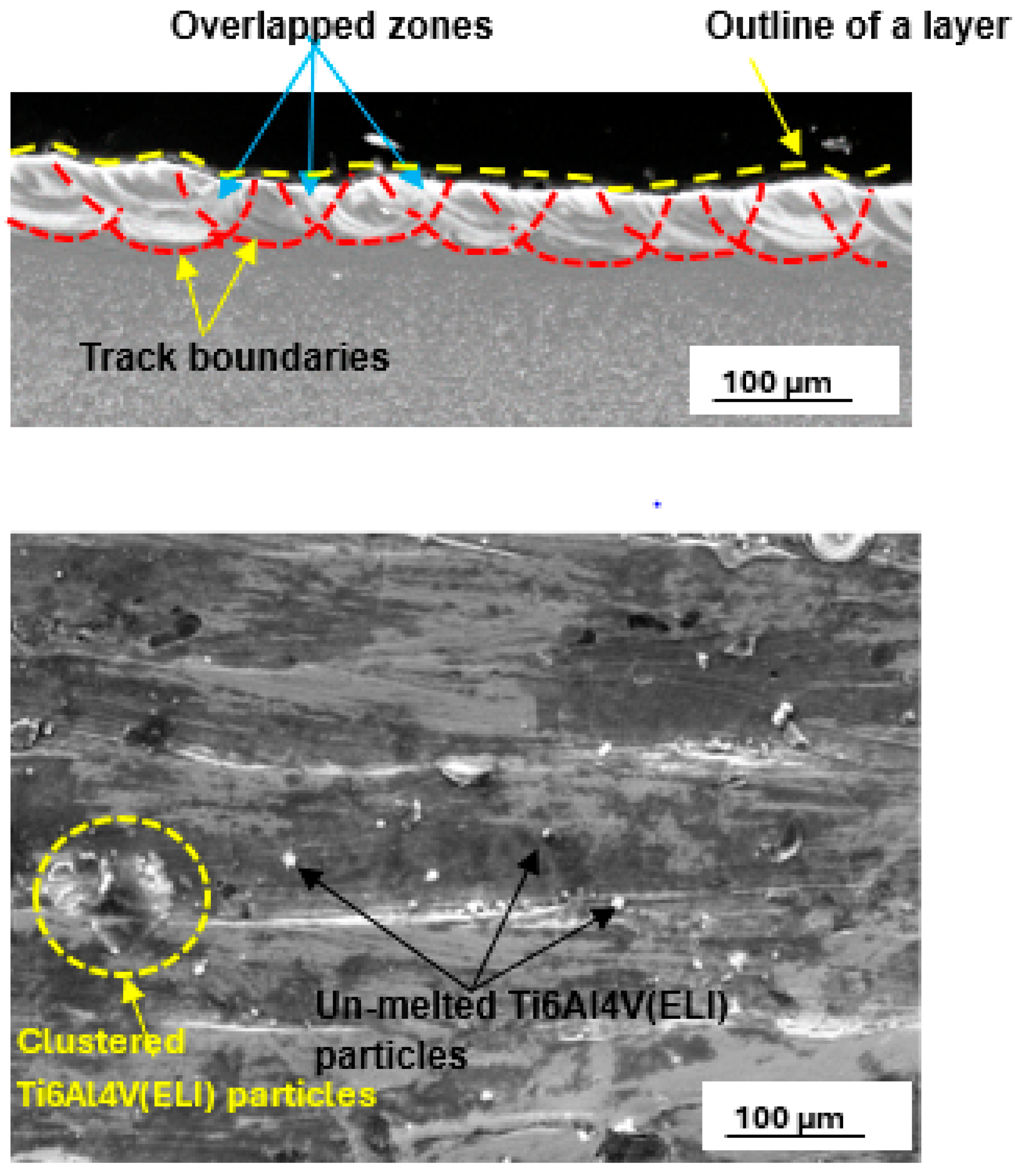

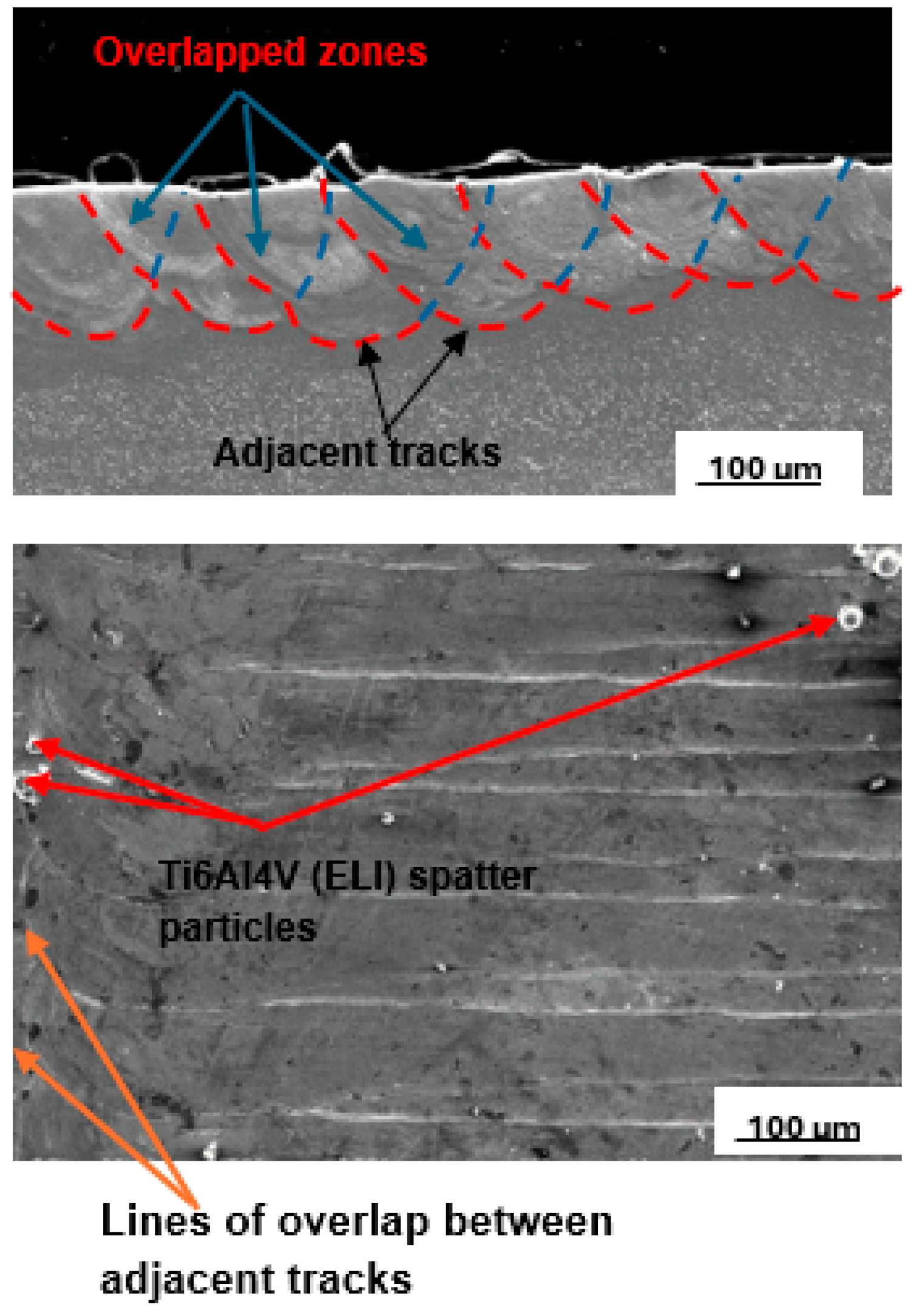

3.4. Top Surface and Cross-Sectional Analysis of SiC/Ti6Al4V(ELI) Single Layers at 5% and 10% SiC Volume Fractions in SiC/Ti6Al4V(ELI) Composites

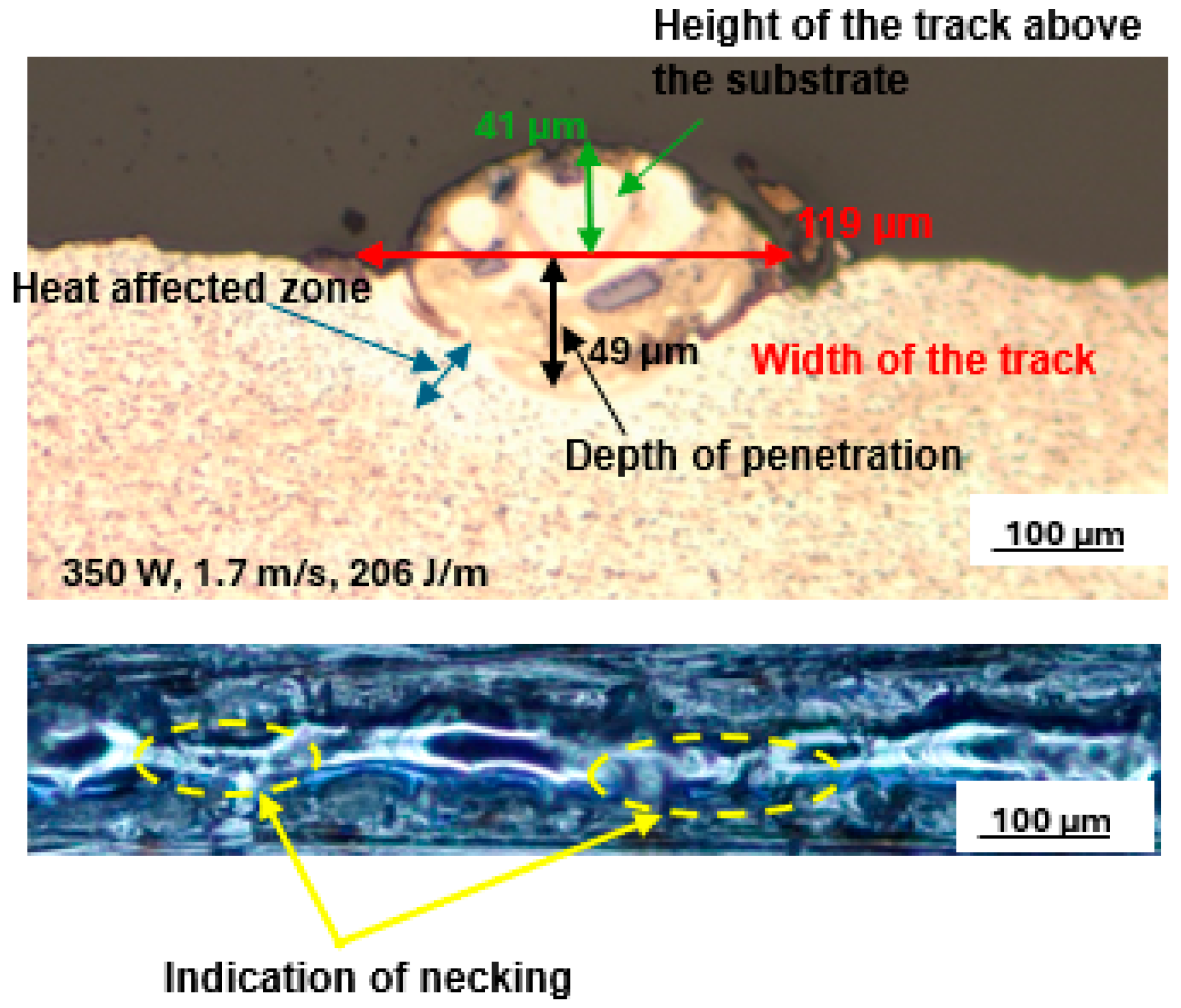

3.5. Top Surface and Cross-Sectional Analysis of SiC/Ti6Al4V(ELI) Single Tracks at 25% and 30% SiC Volume Fractions in SiC/Ti6Al4V(ELI) Composites

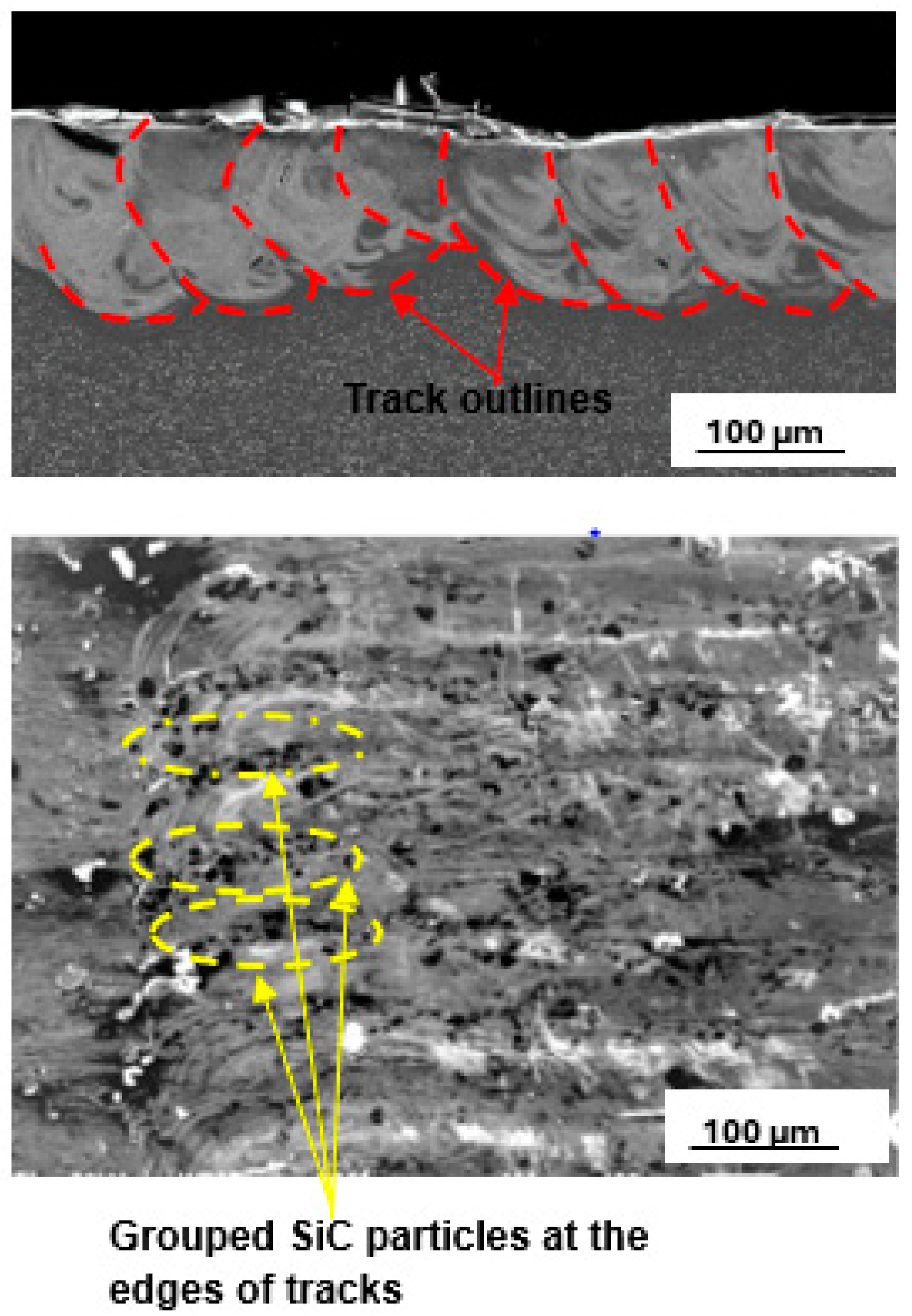

3.6. Top Surface and Cross-Sectional Analysis of SiC/Ti6Al4V(ELI) Single Layers at 25% and 30% SiC Volume Fractions in SiC/Ti6Al4V(ELI) Composites

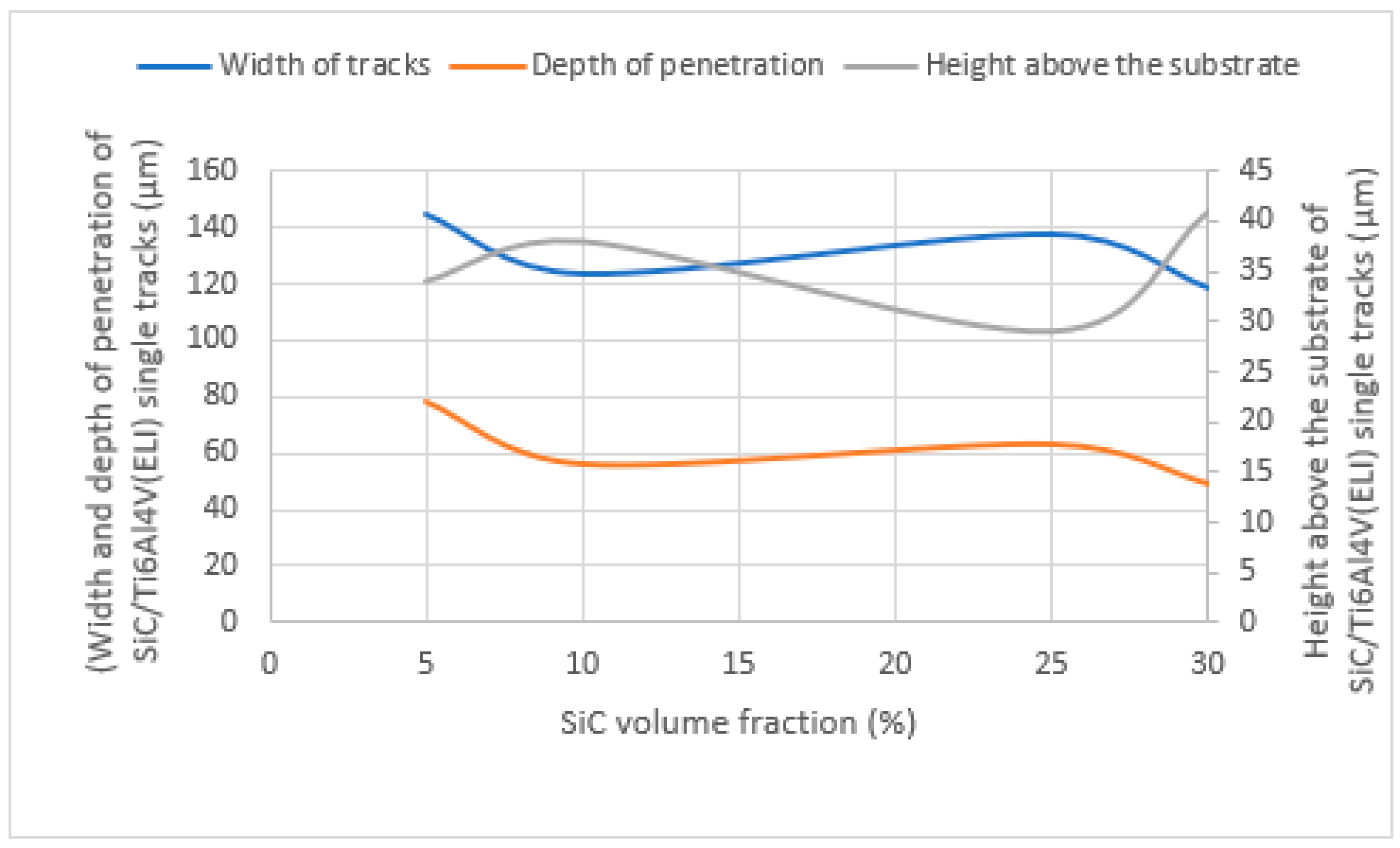

4. Comparative Analysis of Geometrical Characteristics of Low and High SiC Volume Fractions

5. Conclusions

- Experiments performed in this study indicated the possibility of producing parts with improved mechanical properties for volume fractions of SiC in SiC/Ti6Al4V(ELI) composites ranging from 5% to 25%.

- From the qualitative analysis of surface roughness by observing clustering of SiC particles at the edges of tracks as well as surface imperfections and their variation with the volume fraction of SiC, it was confirmed in this study that the surface roughness of layers increased with rising SiC volume fractions from 25% to 30% due to clusters of SiC particles at the edges of the tracks, and at lower volume fractions, due to an increased number of spatter particles at the edges of tracks.

- The single tracks and single layers produced at the highest SiC volume fraction of 30% used in the present work had unacceptable geometrical and surface features; therefore, this indicated that the building of parts at the high volume fraction of 30% would lead to unacceptable mechanical qualities.

- Additionally, it can be concluded that the thermal properties of SiC particles have a negative effect at high volume fractions on the penetration of single tracks and single layers and will lead to a reduction in the mechanical properties of parts. It is concluded that the building of multiple layers and 3D parts can be pursued based on the optimal process parameter sets of hatch distance, laser power, and scanning speed found for single tracks and layers for volume fractions of SiC at and below 25%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dilip, J.J.S.; Zhang, S.S.; Teng, C.; Zeng, K.; Robinson, C.; Pal, D.; Stucker, B. Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog. Addit. Manuf. 2017, 2, 157–167. [Google Scholar] [CrossRef]

- Bhong, M.; Khan, T.K.; Devade, K.; Krishna, B.V.; Sura, S.; Eftikhaar, H.K.; Thethi, H.P.; Gupta, N. Review of composite materials and applications. Mater. Today. Proc. 2023. [Google Scholar] [CrossRef]

- Mashabela, M.; Maringa, M.; Dzogbewu, T. Nano particulate reinforced composites and their application to additively manufactured TI6AL4V for use in the aerospace sector. Manuf. Rev. 2022, 9, 29. [Google Scholar]

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R.; Pinca-Bretotean, C. A study of advancement in application opportunities of aluminum metal matrix composites. Mater. Today. Proc. 2020, 26, 2419–2424. [Google Scholar] [CrossRef]

- Patel, M.; Kumar, A.; Sahu, S.K.; Singh, M.K. Mechanical behaviors of ceramic particulate reinforced aluminium metal matrix composites–A review. Int. Res. J. Eng. Technol. 2020, 7, 201–204. [Google Scholar]

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Min. Mater. Character. Eng. 2009, 8, 455. [Google Scholar] [CrossRef]

- Rohatgi, P.K. Metal matrix composites. Def. Sci. J. 1993, 43, 323. [Google Scholar] [CrossRef]

- Thamae, M.; Maringa, M.; Du Preez, W. Influence of Selective Laser Melting Process Parameters on the Characteristics of SiC/Ti6Al4V(ELI) Single Tracks. In Proceedings of the RAPDASA-RobMech-PRASA-CoSAAMI Conference—Digital Technology in Product Development—23rd Annual International RAPDASA Conference, Somerset West, South Africa, 9–11 November 2022; pp. 1–15. [Google Scholar]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and additive manufacturing with metal matrix composites: A perspective. Procedia Manuf. 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; Du Preez, W.B. Producing Ti5Mo-fused tracks and layers via laser powder bed fusion. Metals 2022, 12, 950. [Google Scholar] [CrossRef]

- Gospodinov, D.; Ferdinandov, N.; Dimitrov, S. Classification, properties and application of titanium and its alloys. Proc. Univ. Ruse 2016, 55, 27–32. [Google Scholar]

- Salihu, S.A.; Suleiman, Y.I.; Eyinavi, A.I. Classification, Properties and Applications of titanium and its alloys used in automotive industry—A Review. Am. J. Eng. Res. 2019, 4, 92–98. [Google Scholar]

- De Rojas Candela, C.S.; Riquelme, A.; Bonache, V.; Rodrigo, P.; Rams, J. Ti6Al4V/SiC metal matrix composites additively manufactured by direct laser deposition. Met. Mater. Int. 2022, 28, 3120–3144. [Google Scholar] [CrossRef]

- Li, J.; Xu, Y.; Xiao, W.; Ma, C.; Huang, X. Development of Ti-Al-Ta-Nb-(Re) near-α high temperature titanium alloy: Microstructure, thermal stability, and mechanical properties. J. Mater. Sci. Tech. 2022, 109, 1–11. [Google Scholar] [CrossRef]

- Mukerji, J. Ceramic Matrix Composites. Def. Sci. J. 1993, 43, 385. [Google Scholar] [CrossRef]

- Misra, S.; Hussain, M.; Gupta, A.; Kumar, V.; Kumar, S.; Das, A.K. Fabrication and characteristic evaluation of direct metal laser sintered SiC particulate reinforced Ti6Al4V metal matrix composites. J. Laser Appl. 2019, 31, 012005. [Google Scholar] [CrossRef]

- ASTM-F2792 -12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012; pp. 1–3.

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for sustainable additive manufacturing: A review. Sustain. Mater. Tech. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Bhatia, A.; Sehgal, A.K. Additive manufacturing materials, methods and applications: A review. Mater. Today. Proc. 2023, 81, 1060–1067. [Google Scholar] [CrossRef]

- Pupo, Y.; Delgado, J.; Sereno, L.; Ciurana, J. Scanning space analysis in selective laser melting for CoCrMo powder. Procedia Eng. 2013, 63, 370–378. [Google Scholar] [CrossRef]

- Nandhakumar, R.; Venkatesan, K. A process parameters review on selective laser melting-based additive manufacturing of single and multi-material: Microstructure, physical properties, tribological, and surface roughness. Mater. Today. Comm. 2023, 35, 105538. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc-and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Bineli, A.R.R.; Peres, A.P.G.; Jardini, A.L.; Maciel Filho, R. Direct metal laser sintering (DMLS): Technology for design and construction of micro-reactors. In Proceedings of the 6th Brazilian Conference on Manufacturing Engineering, Caxias do Sul, Brazil, 11–15 April 2011; Volume 11. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I.; Du Plessis, A. Basics of laser powder bed fusion. In Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021; pp. 15–38. [Google Scholar]

- Dzogbewu, T.C.; Du Preez, W.B. Laser Powder Bed Fusion of Ti15Mo Fused Tracks and Layers. JOM 2023, 75, 3183–3196. [Google Scholar] [CrossRef]

- Dursun, G.; Ibekwe, S.; Li, G.; Mensah, P.; Joshi, G.; Jerro, D. Influence of laser processing parameters on the surface characteristics of 316L stainless steel manufactured by selective laser melting. Mater. Today Proc. 2020, 26, 387–393. [Google Scholar] [CrossRef]

- Newby, E.B. Investigation of in-situ alloying grade 23 Titanium with Copper by Selective Laser Melting Process for biomedical applications. Master’s Dissertation, Central University of Technology, Bloemfontein, South Africa, 2018. [Google Scholar]

- Min, S.O.N.G. Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites. Trans. Nonferrous Met. Soc. China 2009, 19, 1400–1404. [Google Scholar]

- Aigbodion, V.S.; Hassan, S.B. Effects of silicon carbide reinforcement on microstructure and properties of cast Al–Si–Fe/SiC particulate composites. Mater. Sci. Eng. A 2007, 447, 355–360. [Google Scholar] [CrossRef]

- Shen, X.J.; Zhang, C.; Yang, Y.G.; Liu, L. On the microstructure, mechanical properties and wear resistance of an additively manufactured Ti64/metallic glass composite. Addit. Manuf. 2019, 25, 499–510. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Xue, Y.; Zhao, Z.; Ye, Z.; Cao, W.; Zhu, J.; Jiang, F. Microstructure, and properties of (diamond+ TiC) reinforced Ti6Al4V titanium matrix composites manufactured by directed energy deposition. J. Mater. Res. Technol. 2024, 28, 3110–3120. [Google Scholar] [CrossRef]

- Poletti, C.; Balog, M.; Schubert, T.; Liedtke, V.; Edtmaier, C. Production of titanium matrix composites reinforced with SiC particles. Compos. Sci. Technol. 2008, 68, 2171–2177. [Google Scholar] [CrossRef]

- Eagar, T.W.; Tsai, N.S. Temperature fields produced by traveling distributed heat sources. Weld. J. 1983, 62, 346–355. [Google Scholar]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Papynov, E.K.; Shichalin, O.O.; Kolesnikov, A.F.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Study of the thermal behavior of wedge-shaped samples of HfB 2–45 vol% SiC ultra-high-temperature composite in a high-enthalpy air flow. Russ. J. Inorg. Chem. 2018, 63, 421–432. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Gordeev, A.N.; Simonenko, N.P.; Vasilevskii, S.A.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Behavior of HfB 2-SiC (10, 15, and 20 vol%) ceramic materials in high-enthalpy air flows. Russ. J. Inorg. Chem. 2016, 61, 1203–1218. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Tal’skikh, K.Y.; Gridasova, E.A.; Avramenko, V.A.; Sevastyanov, V.G.; et al. Impact of a supersonic dissociated air flow on the surface of HfB 2–30 vol% SiC UHTC produced by the Sol–Gel method. Russ. J. Inorg. Chem. 2018, 63, 1484–1493. [Google Scholar] [CrossRef]

- Rahman, K.M.; Vorontsov, V.A.; Flitcroft, S.M.; Dye, D. A high strength Ti–SiC metal matrix composite. Adv. Eng. Mater. 2017, 19, 1700027. [Google Scholar] [CrossRef]

- Li, N.; Liu, W.; Xiong, H.; Qin, R.; Huang, S.; Zhang, G.; Gao, C. In-situ reaction of Ti-Si-C composite powder and formation mechanism of laser deposited Ti6Al4V/(TiC+ Ti3SiC2) system functionally graded material. Mater. Design 2019, 183, 108155. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Spurling, R.A. Fiber-matrix reaction zone growth kinetics in SiC-reinforced Ti-6Al-4V as studied by transmission electron microscopy. In Recent Advances in Composites in the United States and Japan; ASTM International: West Conshohocken, PA, USA, 1985. [Google Scholar]

- Ramosena, L.A.; Parker, B.S.; Dzogbewu, T.C.; Du Preez, W.B.; Blaine, D.C. Optimum Process parameters for DMLS IN-SITU Alloying of a Ti10(60Al40V) powder blend. In Proceedings of the 20th International Conference of the Rapid Product Development Association of South Africa, Bloemfontein, South Africa, 6–8 November 2019. [Google Scholar]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Leitz, K.H.; Grohs, C.; Singer, P.; Tabernig, B.; Plankensteiner, A.; Kestler, H.; Sigl, L.S. Fundamental analysis of the influence of powder characteristics in Selective Laser Melting of molybdenum based on a multi-physical simulation model. Int. J. Refract. Hard Met. 2018, 72, 1–8. [Google Scholar] [CrossRef]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure, and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2020, 770, 138455. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt pool and as-built quality during selective laser melting of stainless steel: Modelling and experimental approaches. J. Mater. 2018, 12, 50. [Google Scholar] [CrossRef]

- Karimi, P.; Sadeghi, E.; Ålgårdh, J.; Andersson, J. EBM-manufactured single tracks of Alloy 718: Influence of energy input and focus offset on geometrical and microstructural characteristics. Mater. Charact. 2019, 148, 88–99. [Google Scholar] [CrossRef]

- Ren, X.; Liu, H.; Lu, F.; Huang, L.; Yi, X. Effects of processing parameters on the densification, microstructure and mechanical properties of pure tungsten fabricated by optimized selective laser melting: From single and multiple scan tracks to bulk parts. Int. J. Refract. Hard Meter. 2021, 96, 105490. [Google Scholar] [CrossRef]

- Ramosena, L.A.; Dzogbewu, T.C.; du Preez, W. Direct Metal Laser Sintering of the Ti6Al4V Alloy from a Powder Blend. J. Mater. 2022, 15, 8193. [Google Scholar] [CrossRef]

- Bobel, A.; Anam, M.A.; Lorenzo-Martin, C.; Gould, B.; Hector, L.G., Jr.; Greco, A. Additive manufacturing process parameter determination for a new Fe-C-Cu alloy. J. Manuf. Process. 2023, 101, 311–321. [Google Scholar] [CrossRef]

- Du, X.; Chen, J.; She, Y.; Liu, Y.; Yang, Y.; Yang, J.; Dong, S. Effect of process parameter optimization on morphology and mechanical properties of Ti6Al4V alloy produced by selective laser melting. Prog. Nat. Sci. Mater. Int. 2023, 33, 911–917. [Google Scholar] [CrossRef]

- Zhang, H.; Vallabh, C.K.P.; Zhao, X. Influence of spattering on in-process layer surface roughness during laser powder bed fusion. J. Manuf. Process. 2023, 104, 289–306. [Google Scholar] [CrossRef]

- Tang, C.; Tan, J.L.; Wong, C.H. A numerical investigation on the physical mechanisms of single- track defects in selective laser melting. Int. J. Heat Mass Transf. 2018, 126, 957–968. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.; Liu, S.; Gao, Q. Study on overlap rate and machinability of selected laser melting of maraging steel. Mater. Sci. 2023, 41, 368–382. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, X.; Ma, F.; Jiang, J.; Yang, W. Research on deposited tracks and microstructures of AlSi10Mg alloy produced by selective laser melting. Appl. Phys. A 2020, 126, 1–10. [Google Scholar] [CrossRef]

| 100 W | Scanning speed (m/s) | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 |

| Linear energy density (J/m) | 333 | 250 | 200 | 167 | 143 | 125 | 111 | |

| 150 W | Scanning speed (m/s) | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.1 | 1.2 |

| Linear energy density (J/m) | 250 | 214 | 188 | 167 | 150 | 136 | 125 | |

| 200 W | Scanning speed (m/s) | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 1.5 | 1.6 |

| Linear energy density (J/m) | 250 | 222 | 200 | 167 | 143 | 133 | 125 | |

| 250 W | Scanning speed (m/s) | 1.1 | 1.2 | 1.3 | 1.5 | 1.7 | 1.8 | 1.9 |

| Linear energy density (J/m) | 227 | 208 | 192 | 167 | 147 | 139 | 132 | |

| 300 W | Scanning speed (m/s) | 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.2 | 2.4 |

| Linear energy density (J/m) | 250 | 214 | 188 | 167 | 150 | 136 | 125 | |

| 350 W | Scanning speed (m/s) | 1.5 | 1.7 | 1.9 | 2.1 | 2.3 | 2.5 | 2.7 |

| Linear energy density (J/m) | 233 | 206 | 184 | 167 | 152 | 140 | 130 |

| Ti6Al4V(ELI) | Elements | Ti | Al | V | Fe | O | N | H |

| Composition (%) | 89.56 | 6.35 | 3.73 | 0.17 | 0.13 | 0.05 | 0.012 | |

| SiC | Elements | Al | Ca | Ti | Fe | Y | SIC | |

| Composition (%) | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | 99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thamae, M.; Maringa, M.; du Preez, W. A Comparative Analysis of Low and High SiC Volume Fraction Additively Manufactured SiC/Ti6Al4V(ELI) Composites Based on the Best Process Parameters of Laser Power, Scanning Speed and Hatch Distance. Materials 2024, 17, 2606. https://doi.org/10.3390/ma17112606

Thamae M, Maringa M, du Preez W. A Comparative Analysis of Low and High SiC Volume Fraction Additively Manufactured SiC/Ti6Al4V(ELI) Composites Based on the Best Process Parameters of Laser Power, Scanning Speed and Hatch Distance. Materials. 2024; 17(11):2606. https://doi.org/10.3390/ma17112606

Chicago/Turabian StyleThamae, Masenate, Maina Maringa, and Willie du Preez. 2024. "A Comparative Analysis of Low and High SiC Volume Fraction Additively Manufactured SiC/Ti6Al4V(ELI) Composites Based on the Best Process Parameters of Laser Power, Scanning Speed and Hatch Distance" Materials 17, no. 11: 2606. https://doi.org/10.3390/ma17112606