Mechanical, Durability, and Microstructure Assessment of Wastepaper Fiber-Reinforced Concrete Containing Metakaolin

Abstract

1. Introduction

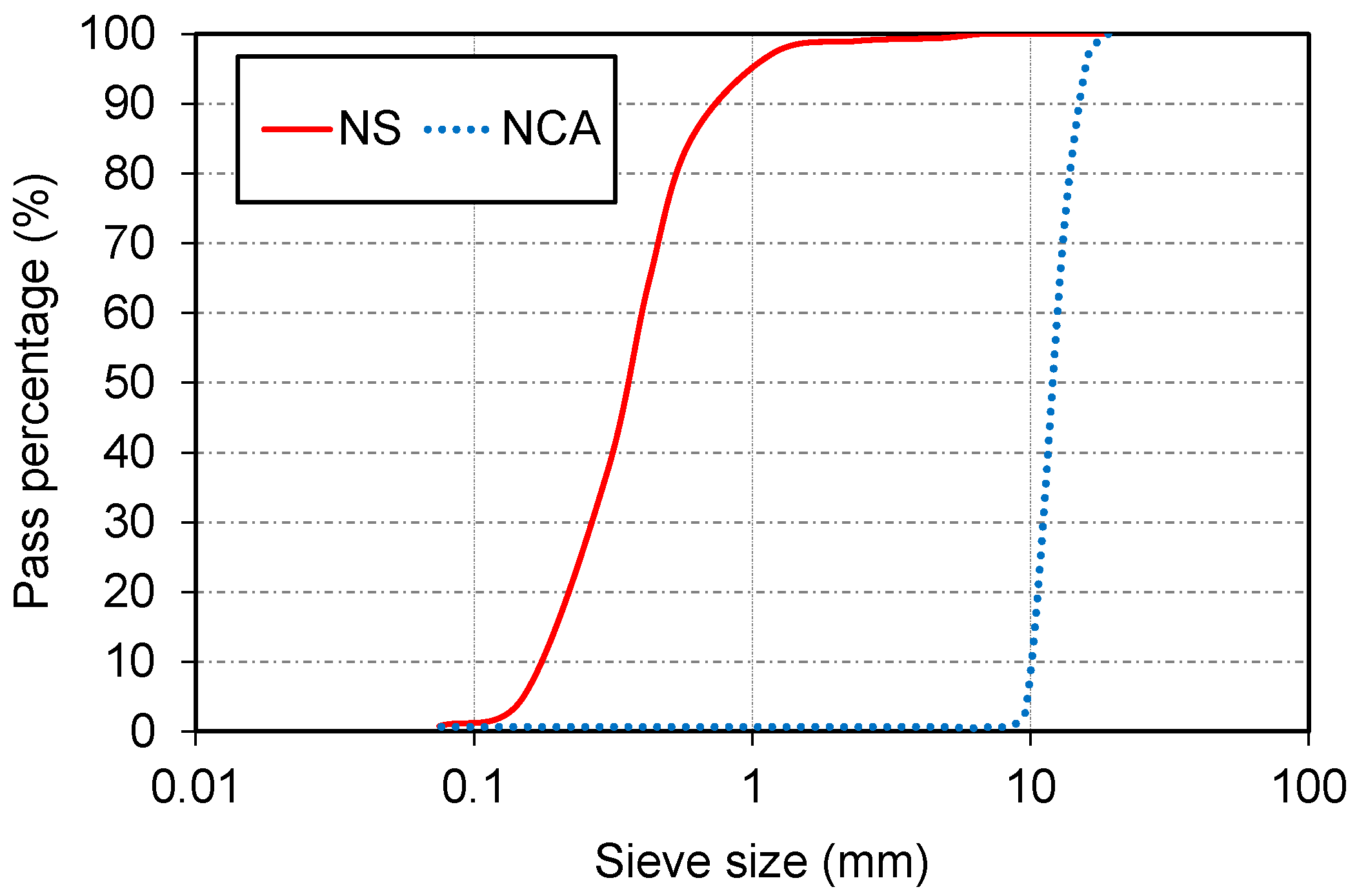

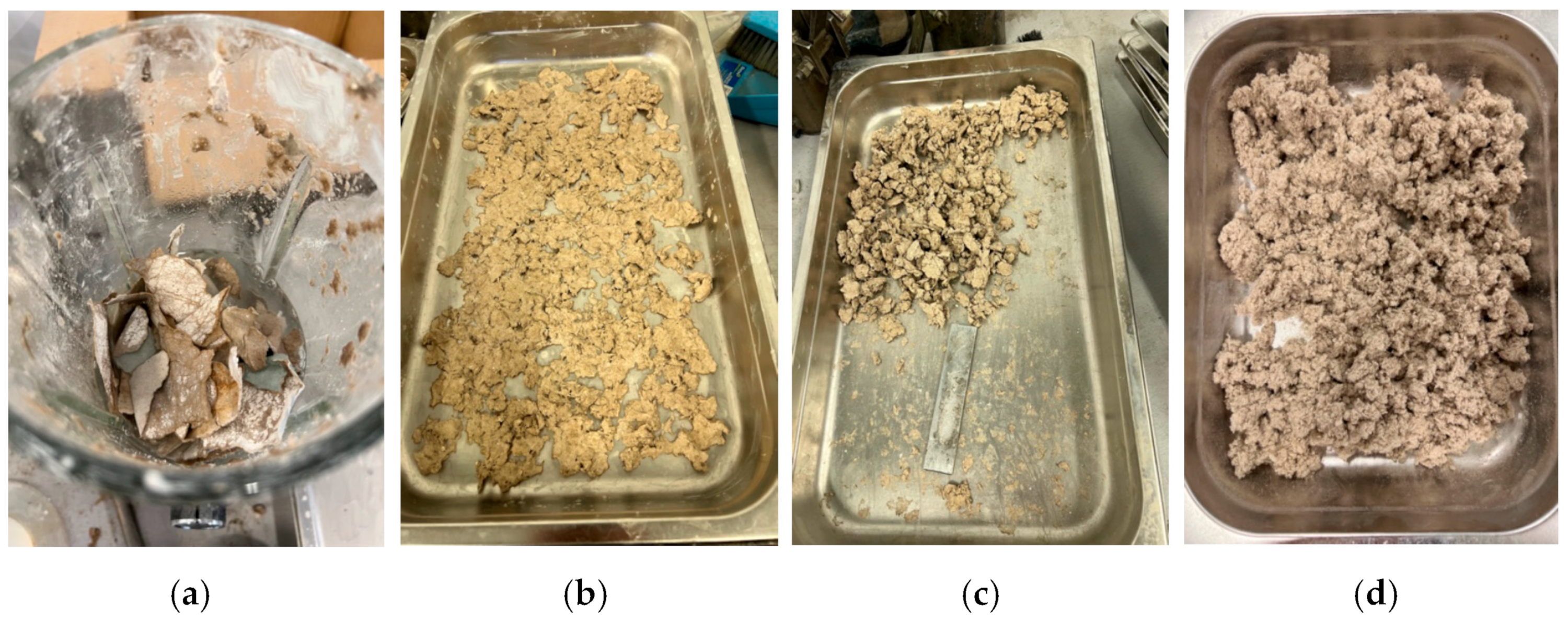

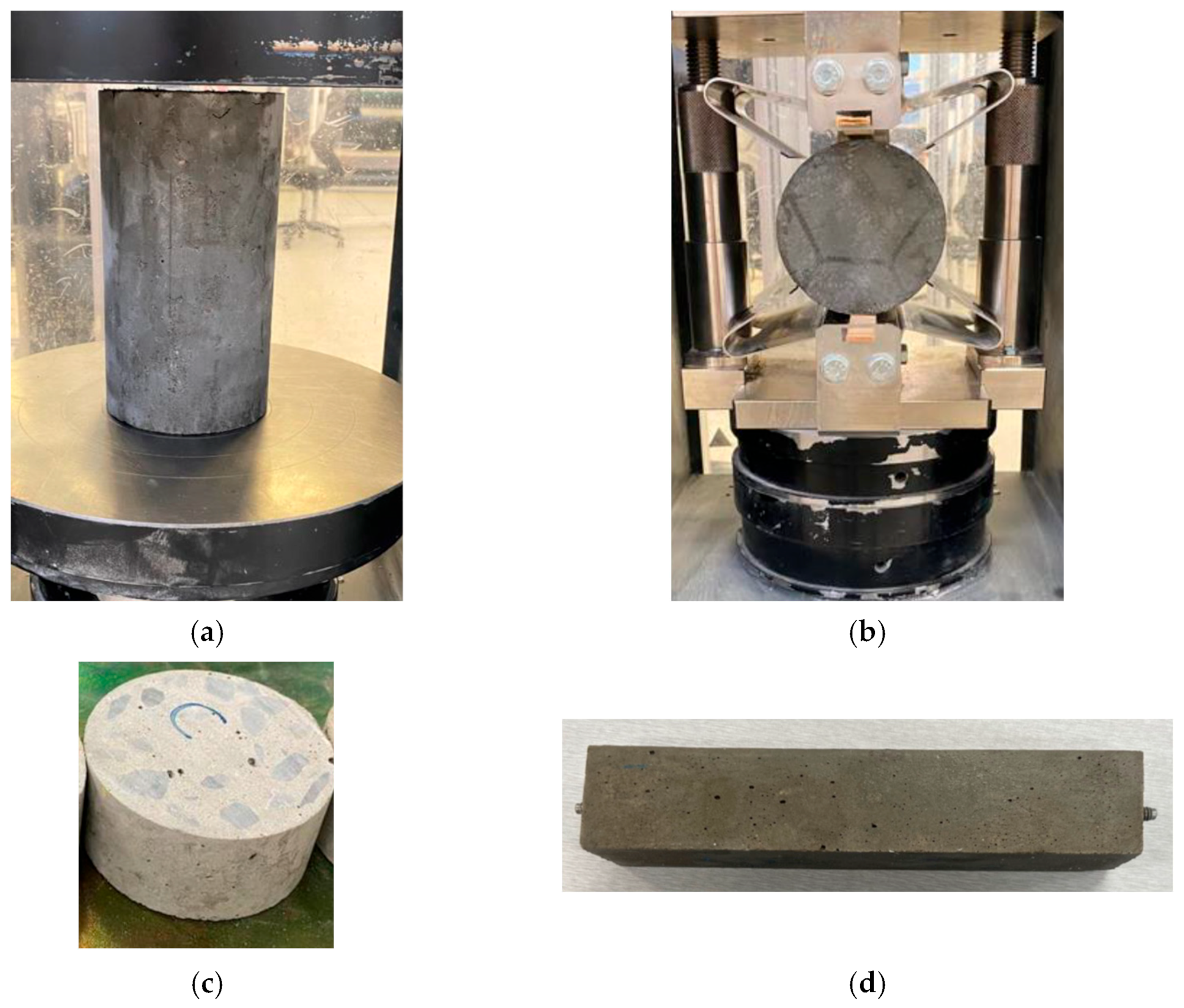

2. Materials and Methods

3. Results

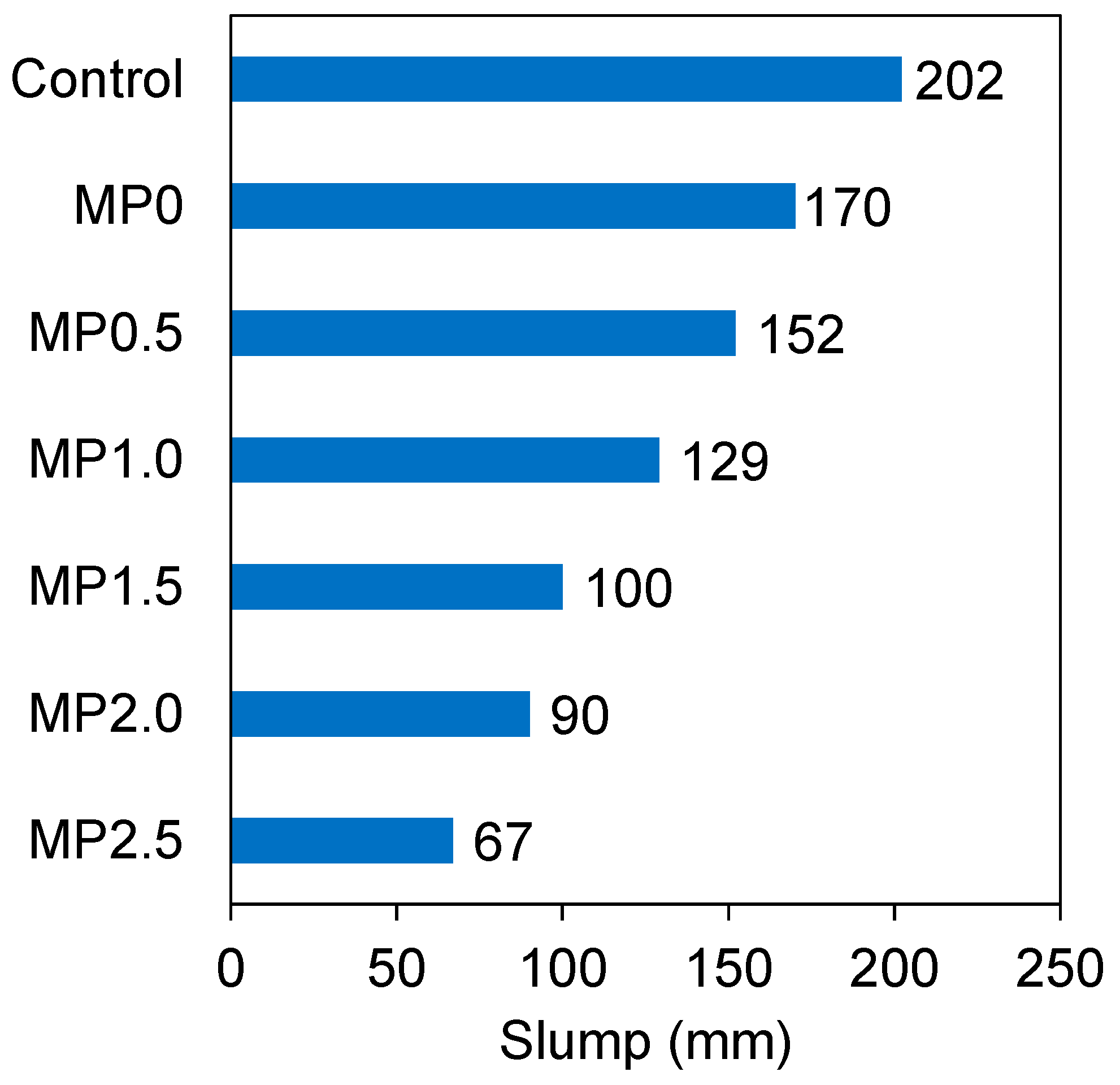

3.1. Slump

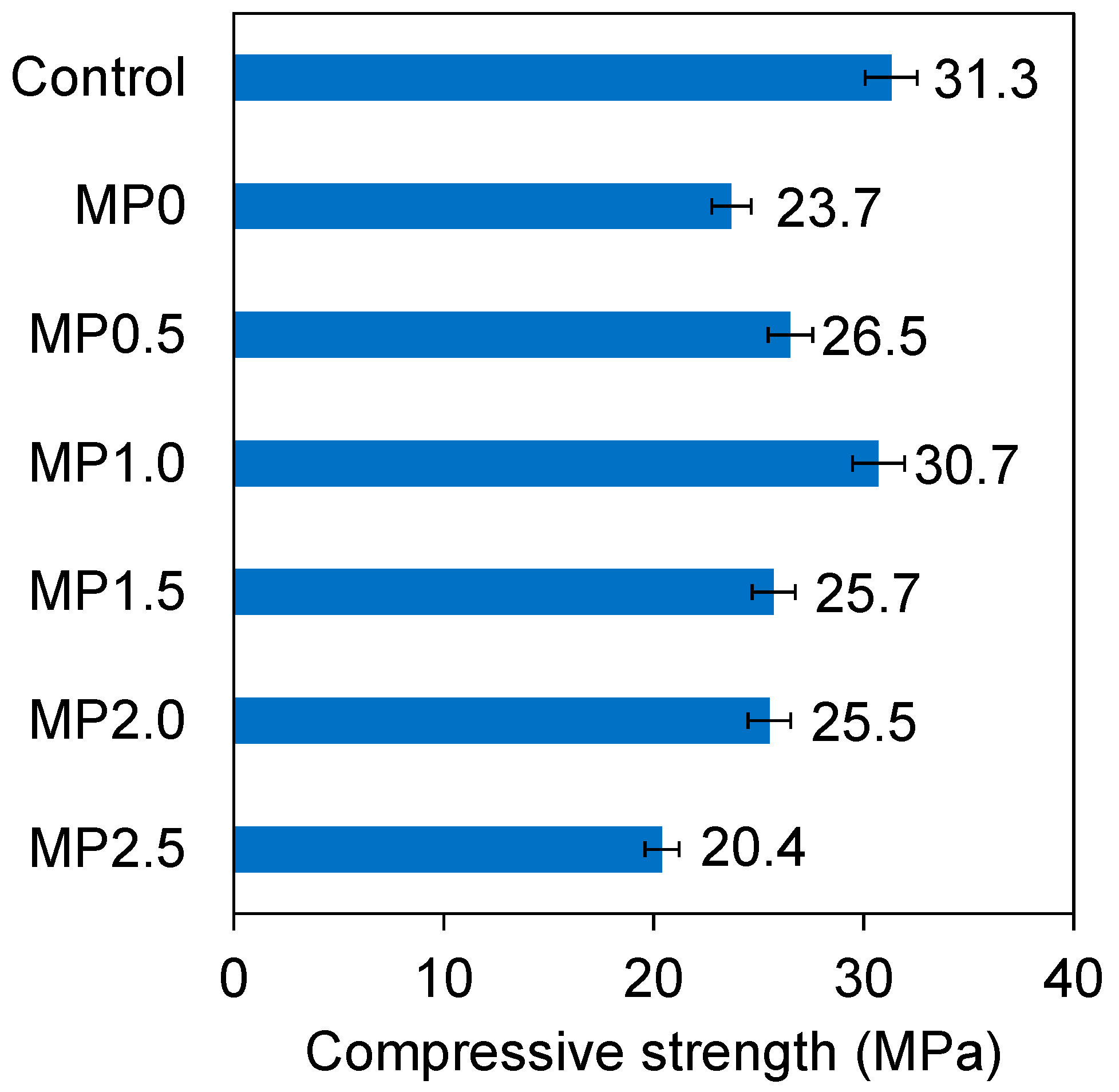

3.2. Compressive Strength

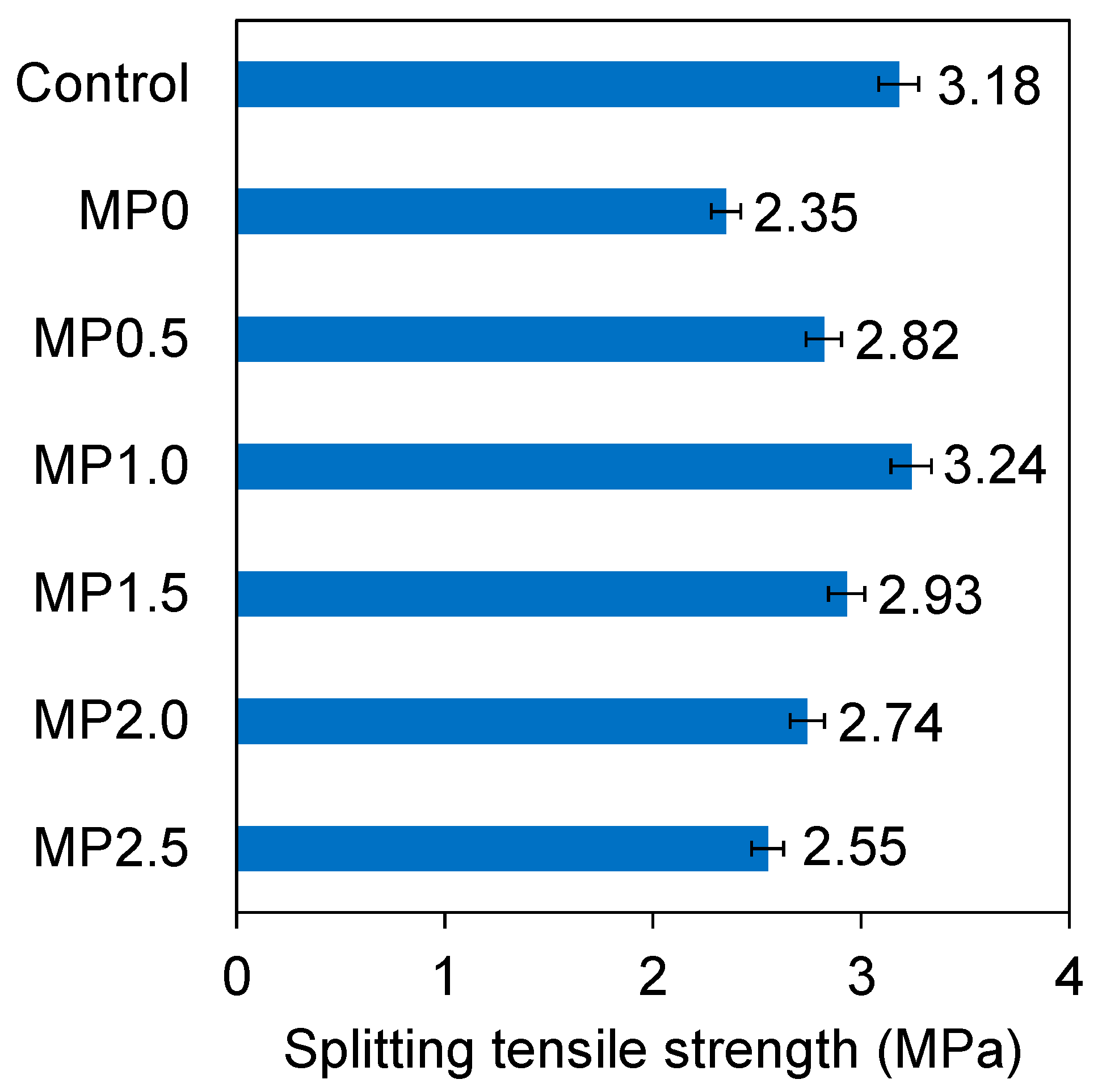

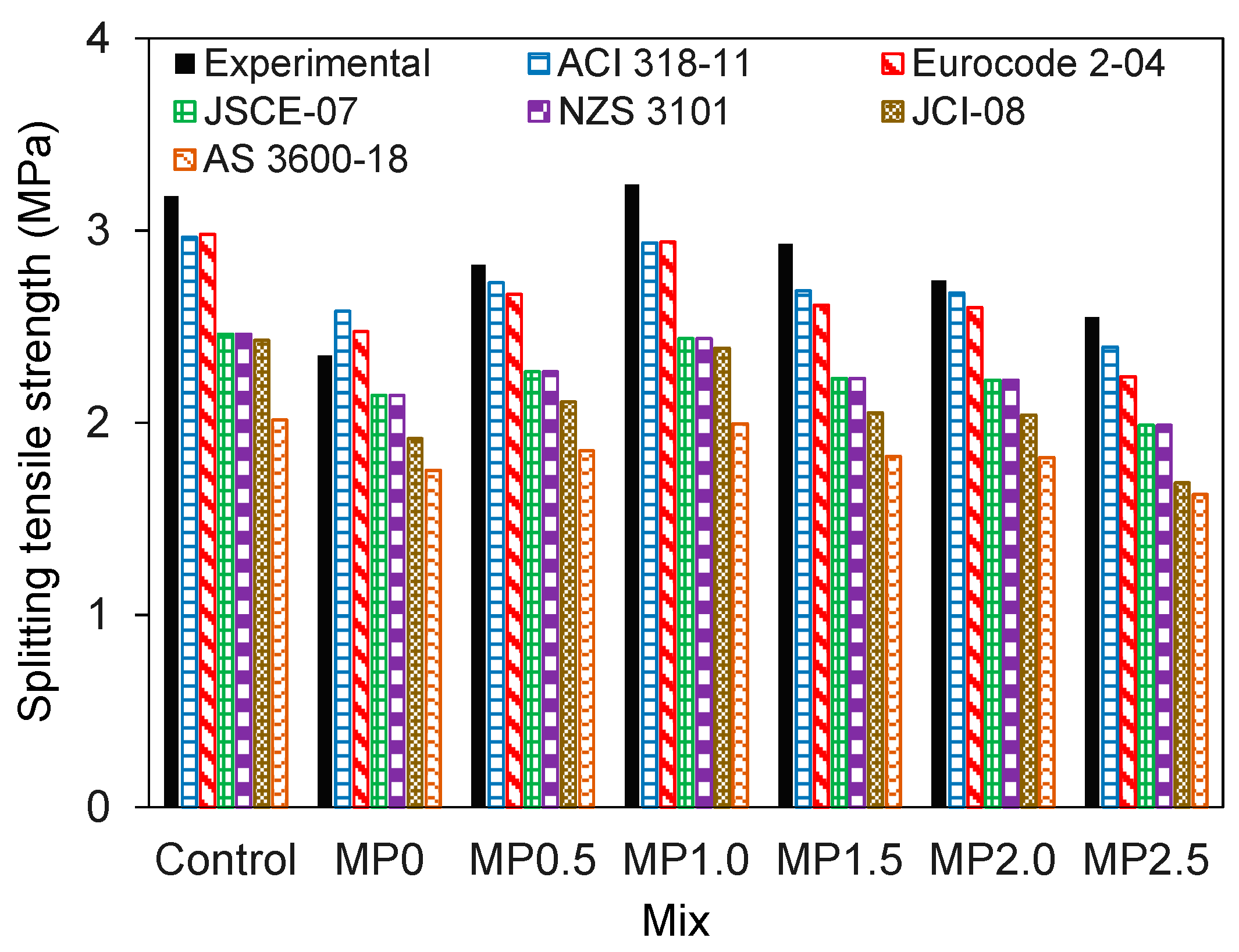

3.3. Splitting Tensile Strength

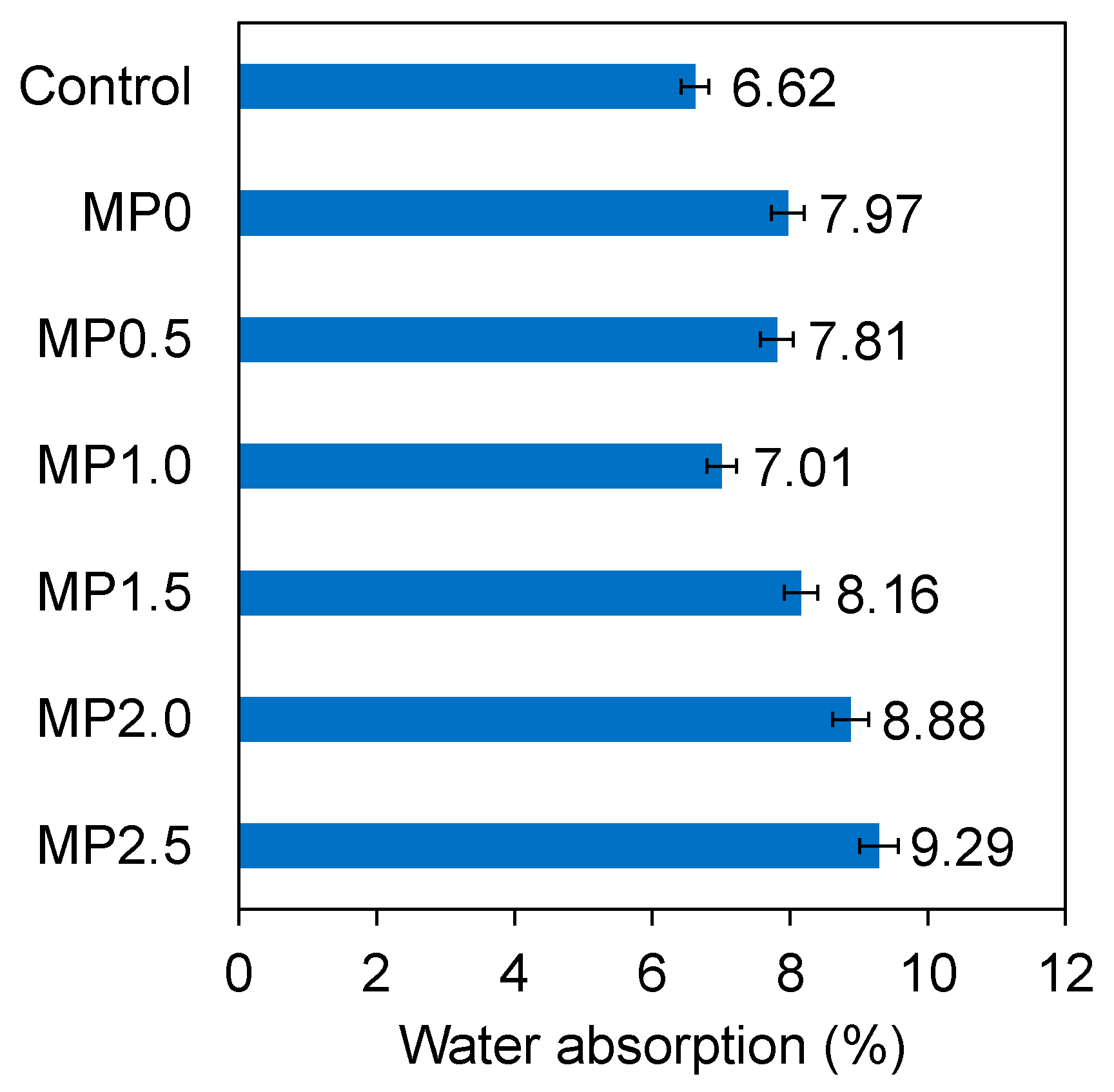

3.4. Water Absorption

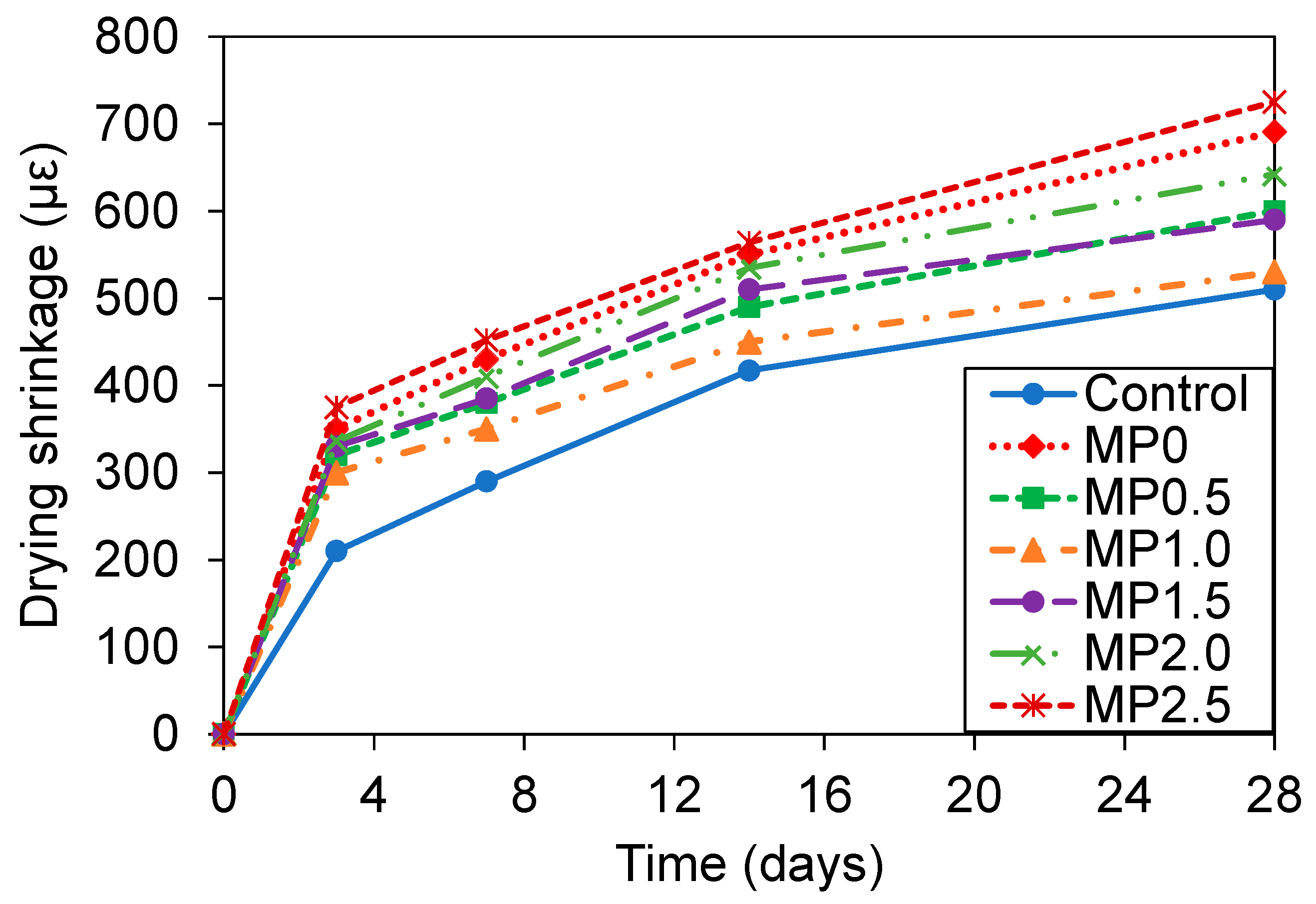

3.5. Drying Shrinkage

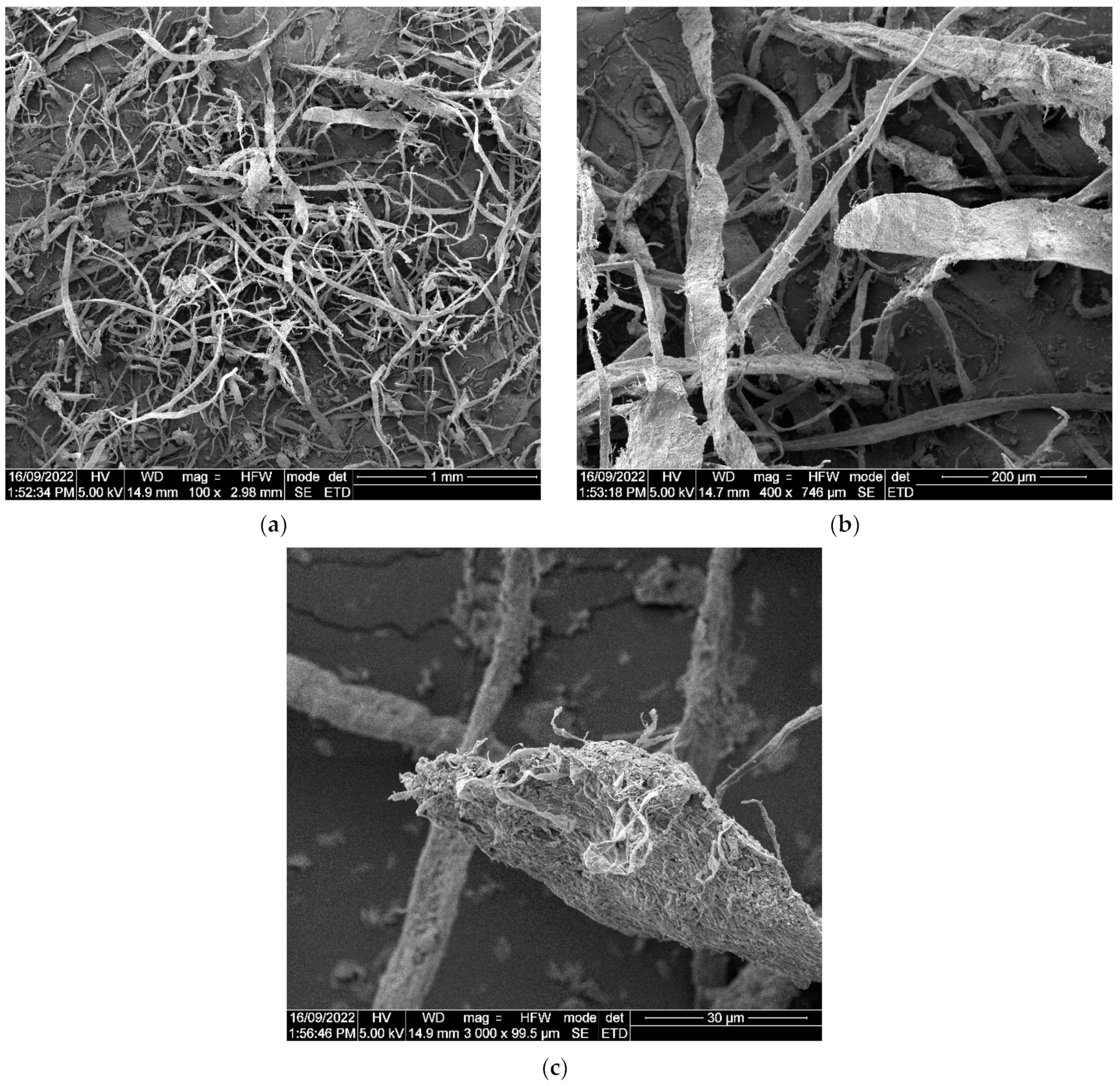

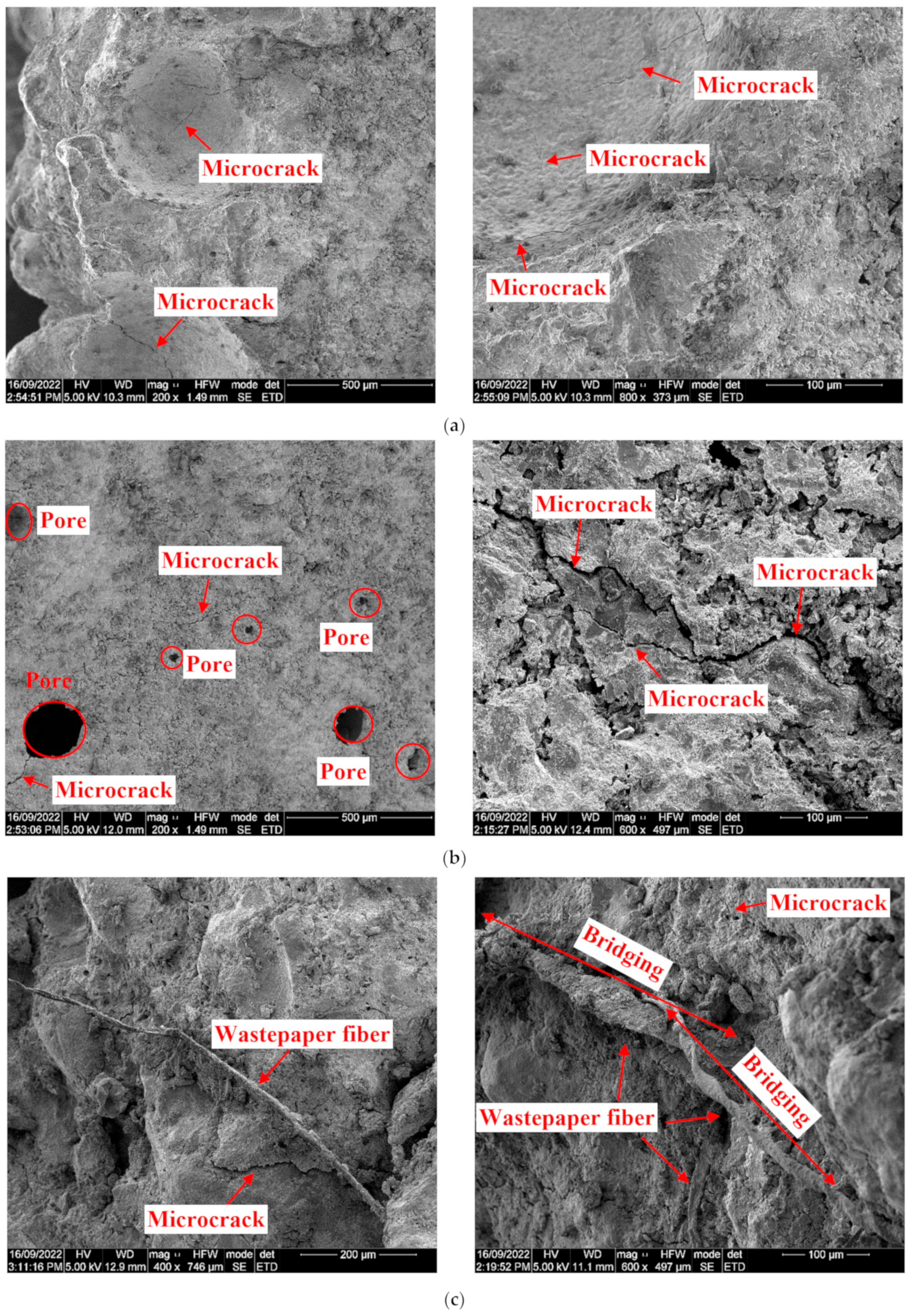

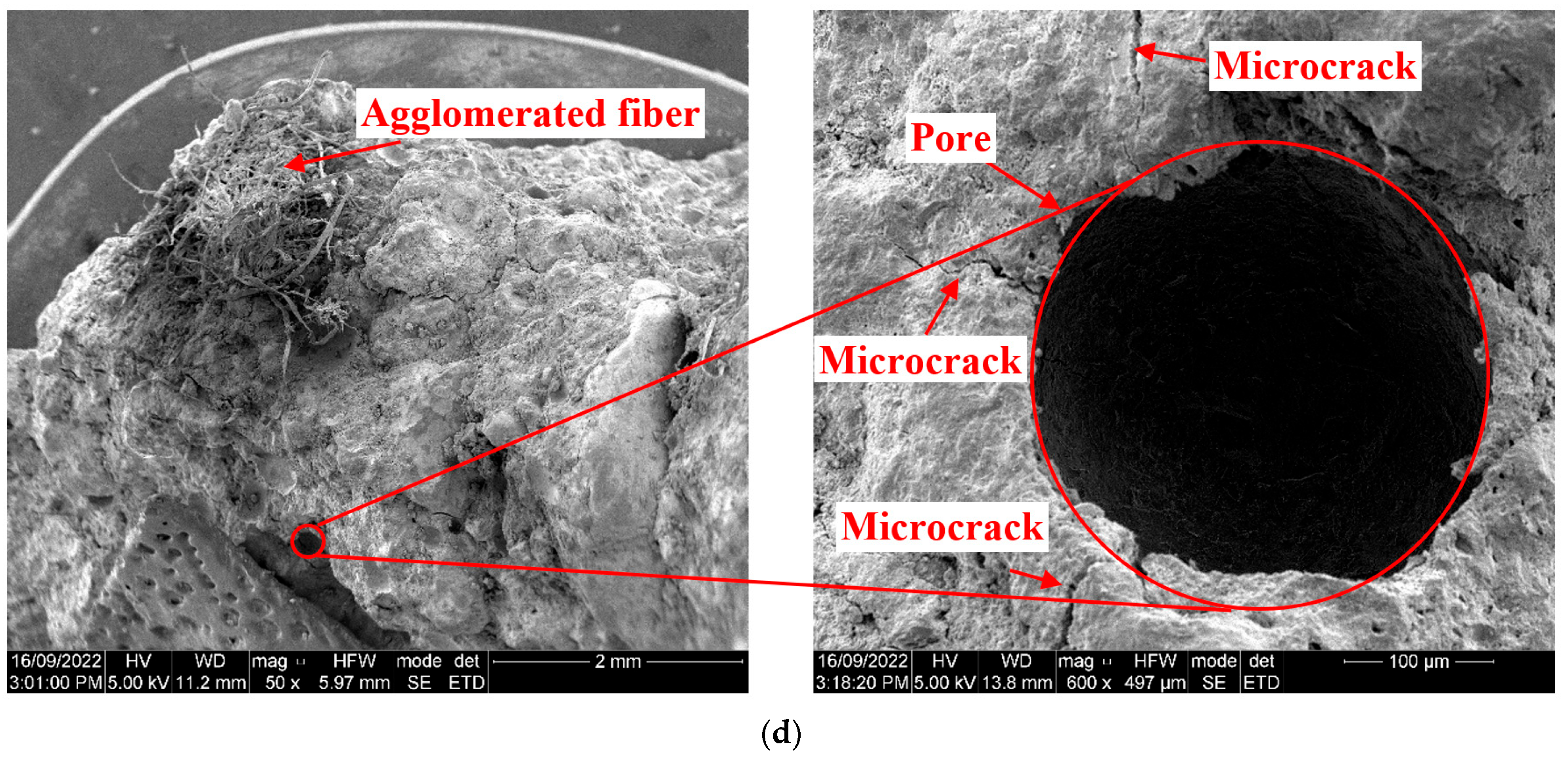

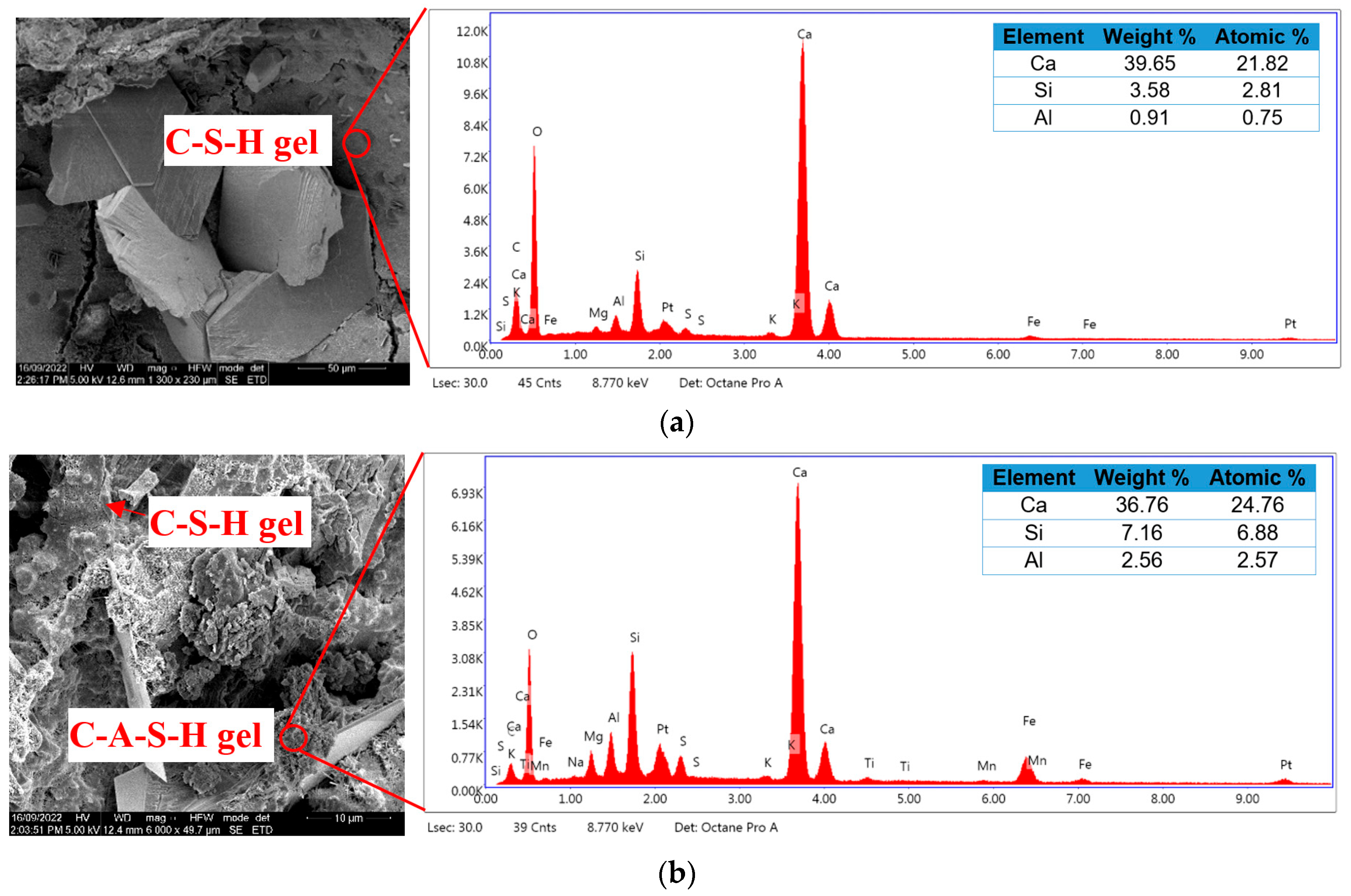

3.6. Microstructural Analysis

4. Conclusions

- Incorporating wastepaper fiber into metakaolin-based concrete leads to a decrease in the workability of the concrete, with a 67% decrease observed at a 2.5% fiber content. This workability decrease can be attributed to the ability of the fiber to absorb water and its rough texture.

- Replacing 20% of cement with metakaolin results in a 24% decrease in the compressive strength, a 26% decrease in the splitting tensile strength, a 20% increase in the water absorption, and a 35% increase in the drying shrinkage of the concrete at 28 days. These changes are primarily caused by the increased porosity and the promotion of crack initiation and propagation within the metakaolin-based concrete.

- The addition of wastepaper fiber to metakaolin concrete up to an optimal content of 1% fiber causes a 29% increase in the compressive strength, a 38% increase in the splitting tensile strength, a 12% decrease in the water absorption, and a 23% decrease in the drying shrinkage of the concrete at 28 days. According to microstructural analyses, these improvements in the mechanical and durability properties of the metakaolin concrete are attributed to the uniform dispersion of the fibers within the concrete matrix when they are used at up to an optimal level, thereby effectively serving as bridges to obstruct the propagation of microcracks.

- Increasing the wastepaper fiber content from 1 to 2.5% results in a 33% decrease in the compressive strength and a 21% decrease in the splitting tensile strength, along with a 32% increase in the water absorption and a 37% increase in the drying shrinkage of the metakaolin concrete at 28 days. This can be explained by the clumping of the fibers and their uneven distribution within the concrete matrix as observed in the microstructural analyses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yao, C.; Shen, A.; Wang, W.; Guo, Y.; Dai, X.; Ren, G. Review on autogenous self-healing technologies and multi-dimension mechanisms for cement concrete. Arch. Civ. Mech. Eng. 2023, 24, 15. [Google Scholar] [CrossRef]

- Praburanganathan, S.; Sudharsan, N.; Bharath Simha Reddy, Y.; Naga Dheeraj Kumar Reddy, C.; Natrayan, L.; Paramasivam, P. Force-deformation study on glass fiber reinforced concrete slab incorporating waste paper. Adv. Civ. Eng. 2022, 2022, 5343128. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Yuan, H.; Zillante, G.; Wang, J. Investigation of the social and economic impacts of cross-regional mobility of construction and demolition waste in Australia. Resour. Conserv. Recycl. 2023, 190, 106814. [Google Scholar] [CrossRef]

- El-Haggar, S.; Samaha, A.; El-Haggar, S.; Samaha, A. Sustainable Utilization of Construction and Demolition Waste. In Roadmap for Global Sustainability—Rise of the Green Communities; Springer: Berlin/Heidelberg, Germany, 2019; pp. 169–188. [Google Scholar]

- D’Angelo, A.; Dal Poggetto, G.; Piccolella, S.; Leonelli, C.; Catauro, M. Characterisation of white metakaolin-based geopolymers doped with synthetic organic dyes. Polymers 2022, 14, 3380. [Google Scholar] [CrossRef] [PubMed]

- Salino, R.E.; Catai, R.E. A study of polyurethane waste composite (PUR) and recycled plasterboard sheet cores with polyurethane foam for acoustic absorption. Constr. Build. Mater. 2023, 387, 131201. [Google Scholar] [CrossRef]

- Suárez, S.; Roca, X.; Gasso, S. Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: Application to the Spanish context. J. Clean. Prod. 2016, 117, 150–159. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Weimann, K.; Adam, C.; Buchert, M.; Sutter, J. Environmental evaluation of gypsum plasterboard recycling. Minerals 2021, 11, 101. [Google Scholar] [CrossRef]

- Solahuddin, B. A comprehensive review on waste paper concrete. Results Eng. 2022, 16, 100740. [Google Scholar] [CrossRef]

- Aciu, C.; Iluţiu–Varvara, D.A.; Cobirzan, N.; Balog, A. Recycling of paper waste in the composition of plastering mortars. Procedia Technol. 2014, 12, 295–300. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, X.; Li, W.; Chen, Q. Self-shrinkage behaviors of waste paper fiber reinforced cement paste considering its self-curing effect at early-ages. Int. J. Polym. Sci. 2016, 2016, 8690967. [Google Scholar] [CrossRef]

- Zhao, D.; Khoshnazar, R. Microstructure of cement paste incorporating high volume of low-grade metakaolin. Cem. Concr. Compos. 2020, 106, 103453. [Google Scholar] [CrossRef]

- De Azevedo, A.R.; Alexandre, J.; Xavier, G.d.C.; Pedroti, L.G. Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar] [CrossRef]

- Ilakkiya, R.; Dhanalakshmi, G. Experimental investigation on concrete using waste paper. Int. Res. J. Eng. Technol. 2018, 5, 1995–1999. [Google Scholar]

- Solahuddin, B.; Yahaya, F. Effect of shredded waste paper on properties of concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 682, 012006. [Google Scholar] [CrossRef]

- Solahuddin, B.; Yahaya, F. Properties of concrete containing shredded waste paper as an additive. Mater. Today Proc. 2022, 51, 1350–1354. [Google Scholar] [CrossRef]

- Solahuddin, B.; Yahaya, F. Load-strain behaviour of shredded waste paper reinforced concrete beam. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1092, 012063. [Google Scholar] [CrossRef]

- Hospodarova, V.; Stevulova, N.; Briancin, J.; Kostelanska, K. Investigation of waste paper cellulosic fibers utilization into cement based building materials. Buildings 2018, 8, 43. [Google Scholar] [CrossRef]

- Zaki, H.; Gorgis, I.; Salih, S. Mechanical Properties of Papercrete Matec Web Conf; EDP Sciences: Sharm El-Shiekh, Egypt, 2018. [Google Scholar]

- Chung, J.-H.; Kim, B.-H.; Choi, H.-K.; Choi, C.-S. Development of Papercrete Due to Paper Mixing Ratio; Hanyang University: Seoul, Republic of Korea, 2015; pp. 133–791. [Google Scholar]

- Jung, H.-S. An experimental study on development of construction concrete products using wastepaper. J. Ceram. Process. Res. 2015, 16 (Suppl. S1), 104–109. [Google Scholar]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Schabowicz, K.; Jóźwiak-Niedźwiedzka, D.; Ranachowski, Z.; Kudela, S.; Dvorak, T. Microstructural characterization of cellulose fibres in reinforced cement boards. Arch. Civ. Mech. Eng. 2018, 18, 1068–1078. [Google Scholar] [CrossRef]

- Biswal, U.S.; Dinakar, P. Influence of metakaolin and silica fume on the mechanical and durability performance of high-strength concrete made with 100% coarse recycled aggregate. J. Hazard. Toxic Radioact. Waste 2022, 26, 04022004. [Google Scholar] [CrossRef]

- Jackowski, M.; Małek, M. A multi-site study of a new cement composite brick with partial cement substitutes and waste materials. Case Stud. Constr. Mater. 2023, 18, e01992. [Google Scholar] [CrossRef]

- Zaid, O.; Martínez-García, R.; Abadel, A.A.; Fraile-Fernández, F.J.; Alshaikh, I.M.H.; Palencia-Coto, C. To determine the performance of metakaolin-based fiber-reinforced geopolymer concrete with recycled aggregates. Arch. Civ. Mech. Eng. 2022, 22, 114. [Google Scholar] [CrossRef]

- Zhang, P.; Han, X.; Hu, S.; Wang, J.; Wang, T. High-temperature behavior of polyvinyl alcohol fiber-reinforced metakaolin/fly ash-based geopolymer mortar. Compos. Part B Eng. 2022, 244, 110171. [Google Scholar] [CrossRef]

- Raheem, A.A.; Abdulwahab, R.; Kareem, M.A. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete- A review. J. Clean. Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Majstorović, F.; Sebera, V.; Mrak, M.; Dolenec, S.; Wolf, M.; Marrot, L. Impact of metakaolin on mechanical performance of flax textile-reinforced cement-based composites. Cem. Concr. Compos. 2022, 126, 104367. [Google Scholar] [CrossRef]

- AS 3972; Standards Australia 2010, Portland and Blended Cements. Standards Association of Australia: Sydney, Australia, 2010.

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Compos. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Olalusi, O.B.; Babagbale, D.P. Production of lightweight mortar using recycled waste papers and pulverized ceramics: Mechanical and microscale properties. J. Build. Eng. 2021, 39, 102233. [Google Scholar] [CrossRef]

- C143/C143M-15a; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- C39/C39M-17a; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM-C157/C157M; Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete. ASTM International: West Conshohocken, PA, USA, 2014.

- Hassan, A.A.; Lachemi, M.; Hossain, K.M. Effect of metakaolin and silica fume on the durability of self-consolidating concrete. Cem. Concr. Compos. 2012, 34, 801–807. [Google Scholar] [CrossRef]

- Akcay, B.; Tasdemir, M.A. Performance evaluation of silica fume and metakaolin with identical finenesses in self compacting and fiber reinforced concretes. Constr. Build. Mater. 2018, 185, 436–444. [Google Scholar] [CrossRef]

- Cassagnabère, F.; Diederich, P.; Mouret, M.; Escadeillas, G.; Lachemi, M. Impact of metakaolin characteristics on the rheological properties of mortar in the fresh state. Cem. Concr. Compos. 2013, 37, 95–107. [Google Scholar] [CrossRef]

- Barkat, A.; Kenai, S.; Menadi, B.; Kadri, E.; Soualhi, H. Effects of local metakaolin addition on rheological and mechanical performance of self-compacting limestone cement concrete. J. Adhes. Sci. Technol. 2019, 33, 963–985. [Google Scholar] [CrossRef]

- Singh, H.; Gupta, R. Influence of cellulose fiber addition on self-healing and water permeability of concrete. Case Stud. Constr. Mater. 2020, 12, e00324. [Google Scholar] [CrossRef]

- Salem, R.; Al-Salami, A. Preparation of waste paper fibrous cement and studying of some physical properties. Civ. Environ. Res. 2016, 8, 42–54. [Google Scholar]

- Lee, J.-I.; Kim, C.-Y.; Yoon, J.-H.; Choi, S.-J. Mechanical Properties of Cement Mortar Containing Ground Waste Newspaper as Cementitious Material. Materials 2023, 16, 1374. [Google Scholar] [CrossRef] [PubMed]

- Cardinale, T.; D’Amato, M.; Sulla, R.; Cardinale, N. Mechanical and physical characterization of papercrete as new eco-friendly construction material. Appl. Sci. 2021, 11, 1011. [Google Scholar] [CrossRef]

- Balwaik, S.A.; Raut, S. Utilization of waste paper pulp by partial replacement of cement in concrete. Int. J. Eng. Res. Appl. 2011, 1, 300–309. [Google Scholar]

- Vejmelkova, E.; Pavlikova, M.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Ondráček, M.; Sedlmajer, M.; Černý, R. High performance concrete with Czech metakaolin: Experimental analysis of strength, toughness and durability characteristics. Constr. Build. Mater. 2010, 24, 1404–1411. [Google Scholar] [CrossRef]

- Lapeyre, J.; Kumar, A. Influence of pozzolanic additives on hydration mechanisms of tricalcium silicate. J. Am. Ceram. Soc. 2018, 101, 3557–3574. [Google Scholar] [CrossRef]

- Guo, M.; Gong, G.; Yue, Y.; Xing, F.; Zhou, Y.; Hu, B. Performance evaluation of recycled aggregate concrete incorporating limestone calcined clay cement (LC3). J. Clean. Prod. 2022, 366, 132820. [Google Scholar] [CrossRef]

- Paiva, H.; Velosa, A.; Cachim, P.; Ferreira, V. Effect of metakaolin dispersion on the fresh and hardened state properties of concrete. Cem. Concr. Res. 2012, 42, 607–612. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.K.; Raza, A.; Hussain, U.; Rahman, M.L.; Nazari, S.; Chandan, V.; Muller, M.; Choteborsky, R. Natural cellulosic fiber reinforced concrete: Influence of fiber type and loading percentage on mechanical and water absorption performance. Materials 2022, 15, 874. [Google Scholar] [CrossRef] [PubMed]

- Gadag, P.R.; Somasekharaiah, H.; Ghorpade, V.; Rao, H.S. Evaluation of strength parameters of metakaolin and nanosilica incorporated high-performance concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 822, 012029. [Google Scholar] [CrossRef]

- Poon, C.-S.; Lam, L.; Kou, S.; Wong, Y.-L.; Wong, R. Rate of pozzolanic reaction of metakaolin in high-performance cement pastes. Cem. Concr. Res. 2001, 31, 1301–1306. [Google Scholar] [CrossRef]

- Weng, T.-L.; Lin, W.-T.; Cheng, A. Effect of metakaolin on strength and efflorescence quantity of cement-based composites. Sci. World J. 2013, 2013, 606524. [Google Scholar] [CrossRef] [PubMed]

- Khatib, J.M.; Clay, R.M. Absorption characteristics of metakaolin concrete. Cem. Concr. Res. 2004, 34, 19–29. [Google Scholar] [CrossRef]

- Khatib, J.; Wild, S. Pore size distribution of metakaolin paste. Cem. Concr. Res. 1996, 26, 1545–1553. [Google Scholar] [CrossRef]

- Larbi, J.; Bijen, J. Influence of pozzolans on the Portland cement paste–aggregate interface in relation to diffusion of ions and water absorption in concrete. Cem. Concr. Res 1992, 22, 551–562. [Google Scholar]

- Zhang, B.; Ji, T.; Ma, Y.; Zhang, Q. Effect of metakaolin and magnesium oxide on flexural strength of ultra-high performance concrete. Cem. Concr. Compos. 2022, 131, 104582. [Google Scholar] [CrossRef]

- Rahimi, M.; Hisseine, O.A.; Tagnit-Hamou, A. Effectiveness of treated flax fibers in improving the early age behavior of high-performance concrete. J. Build. Eng. 2022, 45, 103448. [Google Scholar] [CrossRef]

- Raghuwanshi, S.; Singh, V.; Mishra, P. A review on use of waste paper pulp by partial replacement of cement in concrete. Int. J. Sci. Res. Dev. 2018, 5, 1023–1027. [Google Scholar]

- Seyyedalipour, S.F.; Kebria, D.Y.; Malidarreh, N.R.; Norouznejad, G. Study of utilization of pulp and paper industry wastes in production of concrete. Int. J. Eng. Res. Appl. 2014, 4, 115–122. [Google Scholar]

- Alomayri, T.; Ali, B. Investigating the load-deflection behaviour and drying shrinkage resistance of HPC reinforced using different cellulose fibres. J. Build. Eng. 2023, 73, 106714. [Google Scholar] [CrossRef]

- ACI 318-11; Building Code Requirements for Structural Concrete and Commentary, PCA Notes on ACI 318-11: With Design Applications. ACI International: Farmington Hills, MI, USA, 2011.

- Eurocode-2-04; Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings. British Standards Institution: London, UK, 2004.

- JSCE No. 15; Standard Specification for Concrete Structure. Japan Society of Civil Engineers: Tokyo, Japan, 2007.

- NZS-3101; Concrete Structures Standard. Standards New Zealand: Wellington, New Zealand, 2017.

- Japanese Civil Institute. Guidelines for Control of Cracking of Mass Concrete; Japan Concrete Institute: Tokyo, Japan, 2008. [Google Scholar]

- A.S. AS3600; Concrete Structures. Standards Australia: Sydney, Australia, 2018.

- Ahmedizat, S.R.; Al-Zubaidi, A.B.; Al-Tabbakh, A.A. Fabrication green concrete by Recycled wastepaper. IOP Conf. Ser. Mater. Sci. Eng. 2010, 870, 012146. [Google Scholar] [CrossRef]

- Gorgis, I.N.; Zaki, H.M.; Salih, S.A. Properties of papercrete. ARPN J. Eng. Appl. Sci 2017, 12, 7401–7411. [Google Scholar]

- Kou, S.-c.; Poon, C.-s.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Arnaud, K.N.; Bock, C.H.; Emmanuel, Y.; Billong, N. Characterization of cementitious mortar with addition of fibers from waste paper. J. Build. Pathol. Rehabil. 2022, 7, 55. [Google Scholar] [CrossRef]

- Gwon, S.; Choi, Y.C.; Shin, M. Effect of plant cellulose microfibers on hydration of cement composites. Constr. Build. Mater. 2021, 267, 121734. [Google Scholar] [CrossRef]

- Chen, Y.; Wan, J.; Zhang, X.; Ma, Y.; Wang, Y. Effect of beating on recycled properties of unbleached eucalyptus cellulose fiber. Carbohydr. Polym. 2012, 87, 730–736. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Belgacem, M.N.; Siqueira, G.; Bras, J.; Savastano, H., Jr.; Lahr, F.R. Processing and dimensional changes of cement based composites reinforced with surface-treated cellulose fibres. Cem. Concr. Compos. 2013, 37, 68–75. [Google Scholar] [CrossRef]

- Kawashima, S.; Shah, S.P. Early-age autogenous and drying shrinkage behavior of cellulose fiber-reinforced cementitious materials. Cem. Concr. Compos. 2011, 33, 201–208. [Google Scholar] [CrossRef]

- Zaki, S.I. Application of Ultra Cellulose Fiber for the Enhancement of the Durability and Shrinkage of Cement Pastes Exposed to Normal and Aggressive Curing Condition. Nanotechnologies Constr. 2015, 7, 121–142. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, Y.; Pel, L.; Sun, Z.; Smeulders, D. Early-age hydration and shrinkage of cement paste with coir fibers as studied by Nuclear Magnetic Resonance. Constr. Build. Mater. 2022, 336, 127460. [Google Scholar] [CrossRef]

- Solahuddin, B.; Yahaya, F. Properties of Concrete and Structural Behaviour of Reinforced Concrete Beam Containing Shredded Waste Paper as An Additive. Int. J. Concr. Struct. Mater. 2023, 17, 26. [Google Scholar] [CrossRef]

- Xu, H.; Shao, Z.; Wang, Z.; Cai, L.; Li, Z.; Jin, H.; Chen, T. Experimental study on mechanical properties of fiber reinforced concrete: Effect of cellulose fiber, polyvinyl alcohol fiber and polyolefin fiber. Constr. Build. Mater. 2020, 261, 120610. [Google Scholar] [CrossRef]

- dos Santos, A.C.; Cardoso, F.G.; da Silva, R.J.; de Fátima Gorgulho, H.; Panzera, T.H. Modification of short sugarcane bagasse fibres for application in cementitious composites: A statistical approach to mechanical and physical properties. Constr. Build. Mater. 2022, 353, 129072. [Google Scholar] [CrossRef]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Constr. Build. Mater. 2012, 34, 451–456. [Google Scholar] [CrossRef]

- Kavitha, O.; Shanthi, V.; Arulraj, G.P.; Sivakumar, P. Fresh, micro-and macrolevel studies of metakaolin blended self-compacting concrete. Appl. Clay Sci. 2015, 114, 370–374. [Google Scholar] [CrossRef]

| Composition | Cement | Metakaolin |

|---|---|---|

| SiO2 | 19.9 | 59.0 |

| Al2O3 | 4.79 | 25.4 |

| Fe2O3 | 3.14 | 1.10 |

| CaO | 63.3 | 0.10 |

| MgO | 2.03 | 1.00 |

| Na2O | 0.29 | 0.03 |

| K2O | 0.40 | 3.00 |

| SO3 | 2.69 | – |

| P2O5 | 0.04 | – |

| LOI | 3.42 | – |

| Mix ID | Wastepaper Fiber (% wt) | Binder | Sand (kg/m3) | Coarse Aggregate (kg/m3) | Superplasticizer (% wt) | w/b | |

|---|---|---|---|---|---|---|---|

| Cement (kg/m3) | Metakaolin (kg/m3) | ||||||

| Control | 0 | 330 | 0 | 1030 | 525 | 0.75 | 0.6 |

| MP0 | 0 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

| MP0.5 | 0.5 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

| MP1.0 | 1.0 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

| MP1.5 | 1.5 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

| MP2.0 | 2.0 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

| MP2.5 | 2.5 | 264 | 79 | 1030 | 525 | 0.75 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valizadeh Kiamahalleh, M.; Gholampour, A.; Rezaei Shahmirzadi, M.; Ngo, T.D.; Ozbakkaloglu, T. Mechanical, Durability, and Microstructure Assessment of Wastepaper Fiber-Reinforced Concrete Containing Metakaolin. Materials 2024, 17, 2608. https://doi.org/10.3390/ma17112608

Valizadeh Kiamahalleh M, Gholampour A, Rezaei Shahmirzadi M, Ngo TD, Ozbakkaloglu T. Mechanical, Durability, and Microstructure Assessment of Wastepaper Fiber-Reinforced Concrete Containing Metakaolin. Materials. 2024; 17(11):2608. https://doi.org/10.3390/ma17112608

Chicago/Turabian StyleValizadeh Kiamahalleh, Mohammad, Aliakbar Gholampour, Mohsen Rezaei Shahmirzadi, Tuan D. Ngo, and Togay Ozbakkaloglu. 2024. "Mechanical, Durability, and Microstructure Assessment of Wastepaper Fiber-Reinforced Concrete Containing Metakaolin" Materials 17, no. 11: 2608. https://doi.org/10.3390/ma17112608

APA StyleValizadeh Kiamahalleh, M., Gholampour, A., Rezaei Shahmirzadi, M., Ngo, T. D., & Ozbakkaloglu, T. (2024). Mechanical, Durability, and Microstructure Assessment of Wastepaper Fiber-Reinforced Concrete Containing Metakaolin. Materials, 17(11), 2608. https://doi.org/10.3390/ma17112608