Influence of Confining Element Stiffness on the In-Plane Seismic Performance of Confined Masonry Walls

Abstract

1. Introduction

2. Methodology

2.1. Experimental Setup and Instrumentation

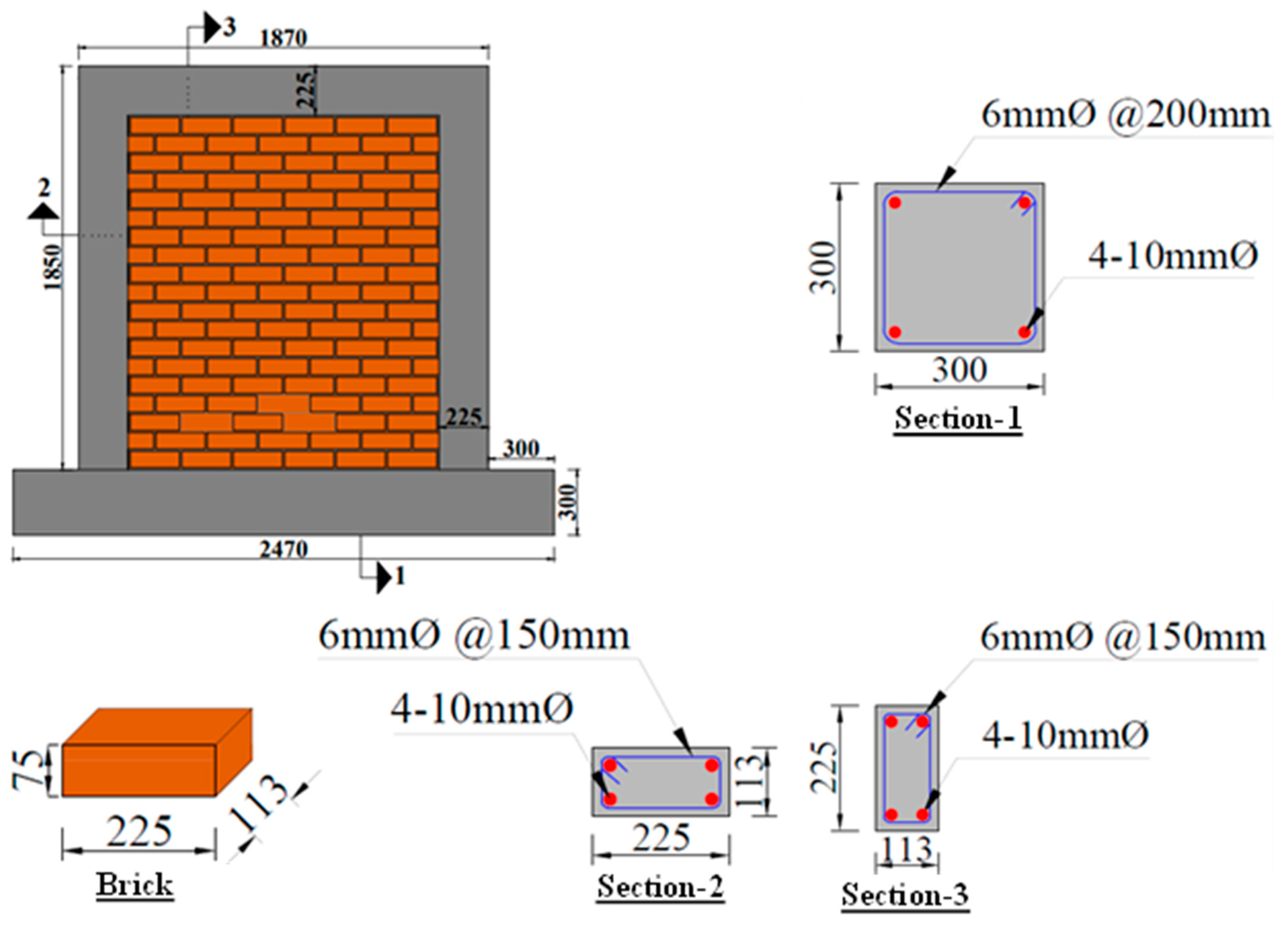

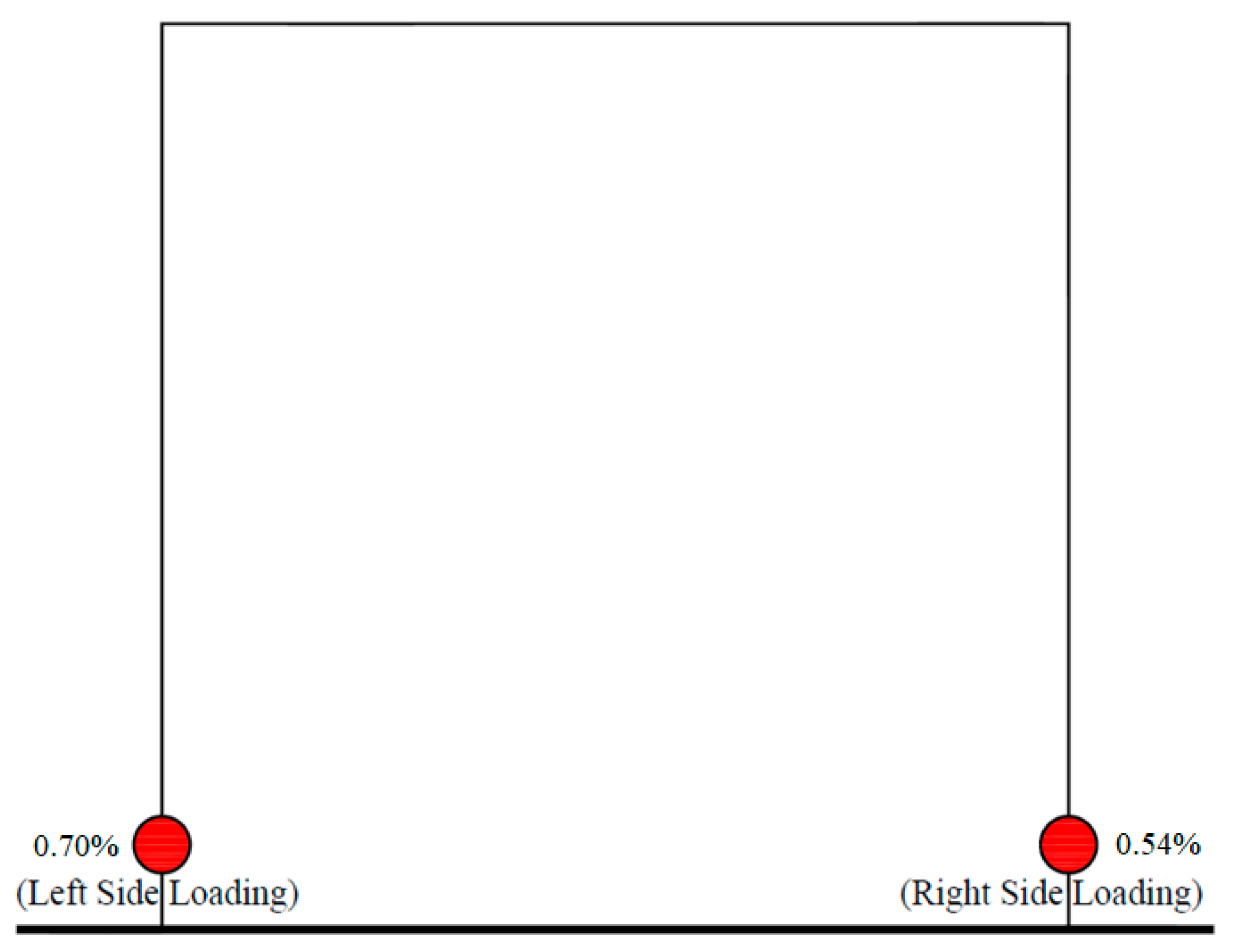

2.1.1. Description of Specimen

2.1.2. Material Characteristics

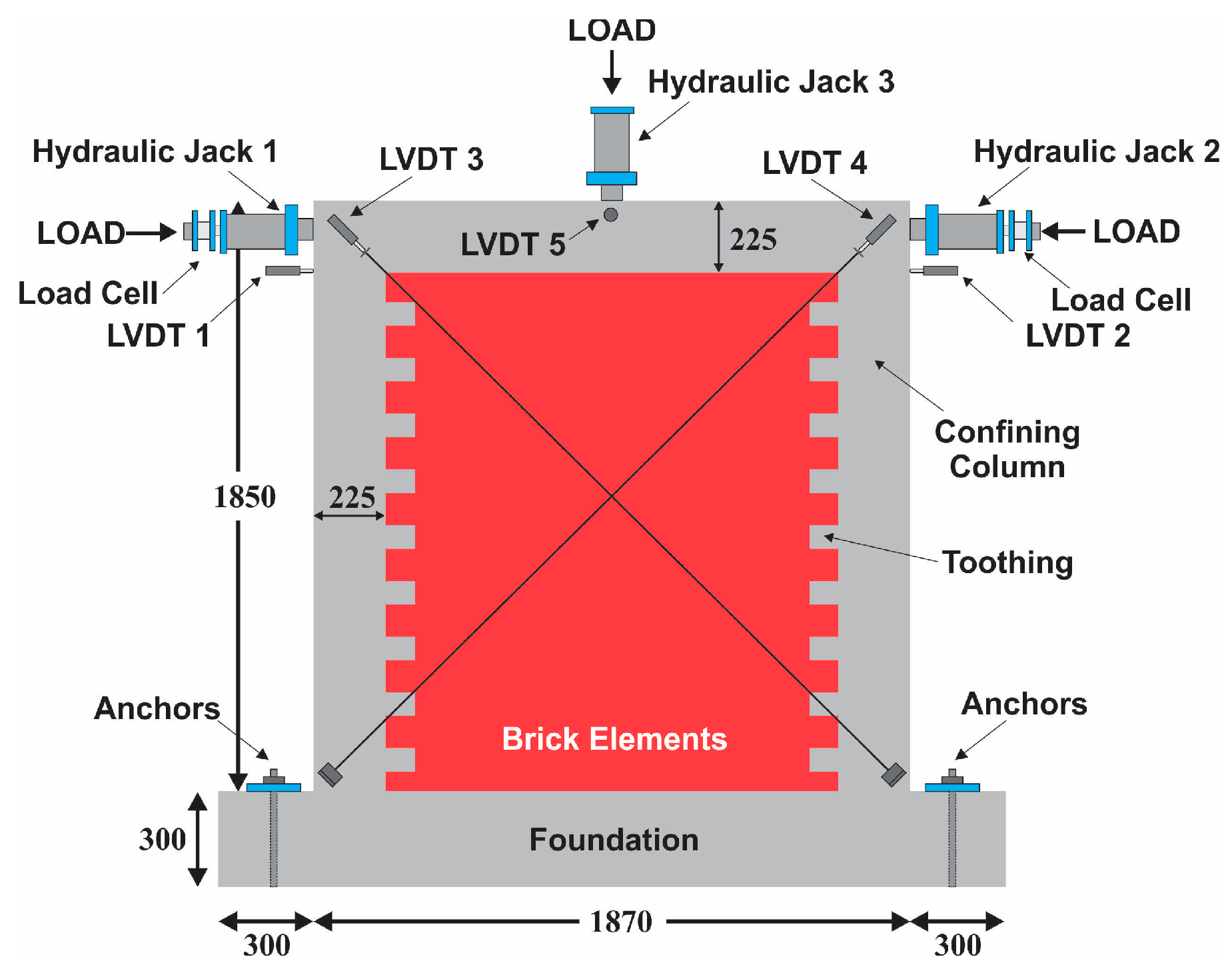

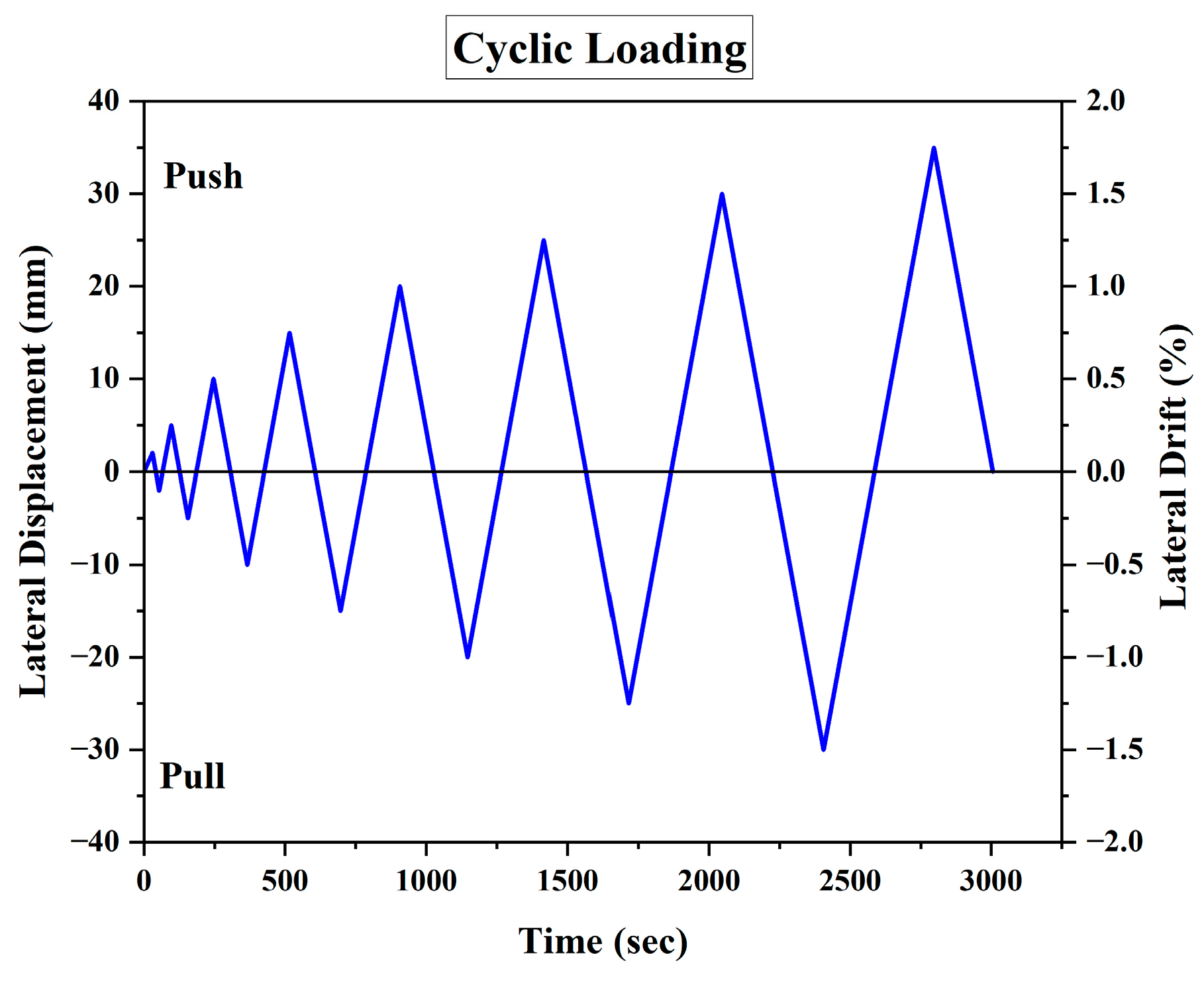

2.1.3. Instrumentation and Test Setup

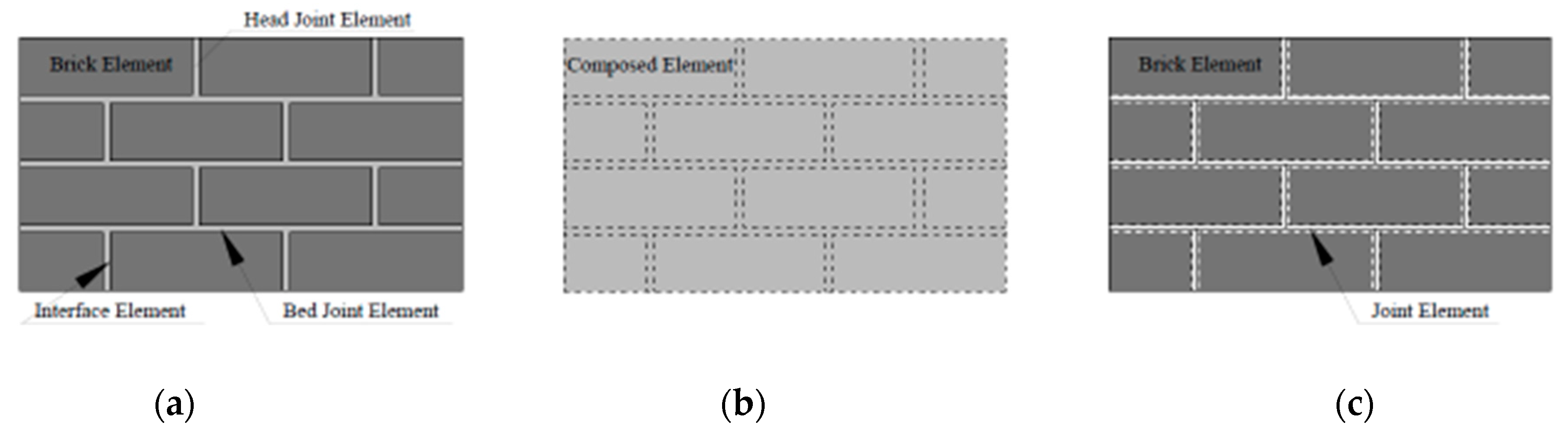

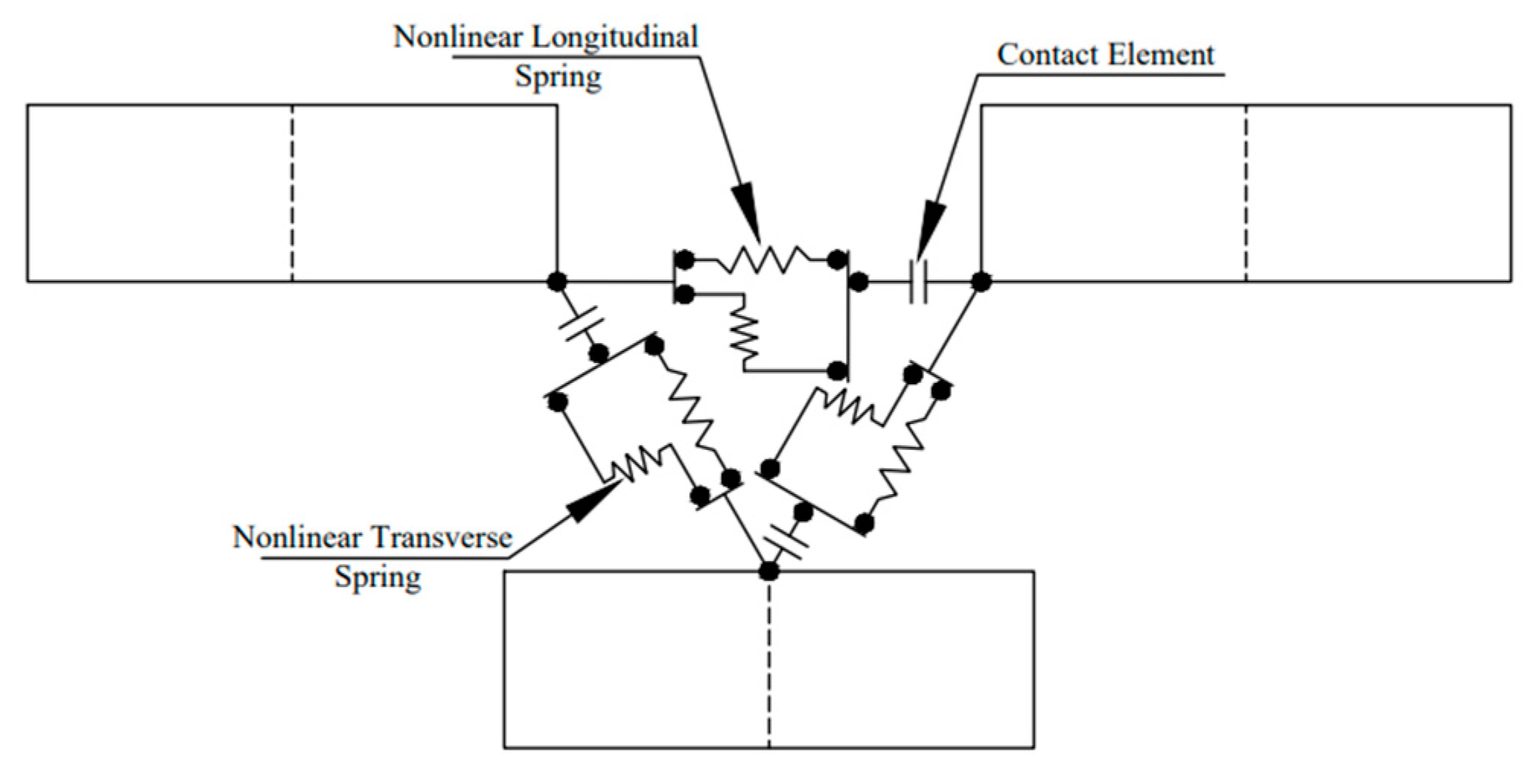

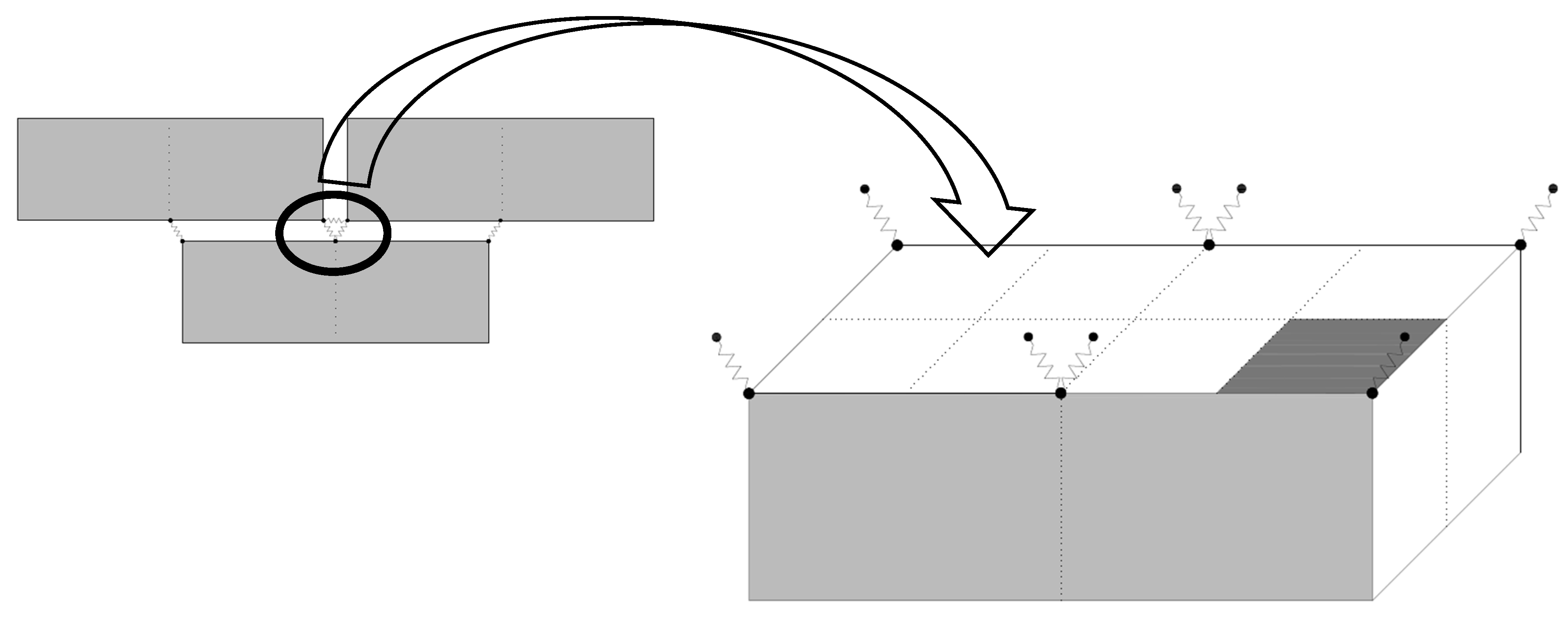

2.2. Numerical Modeling

2.2.1. Modeling Technique

2.2.2. Modeling

3. Results and Discussion

3.1. Experimental Results

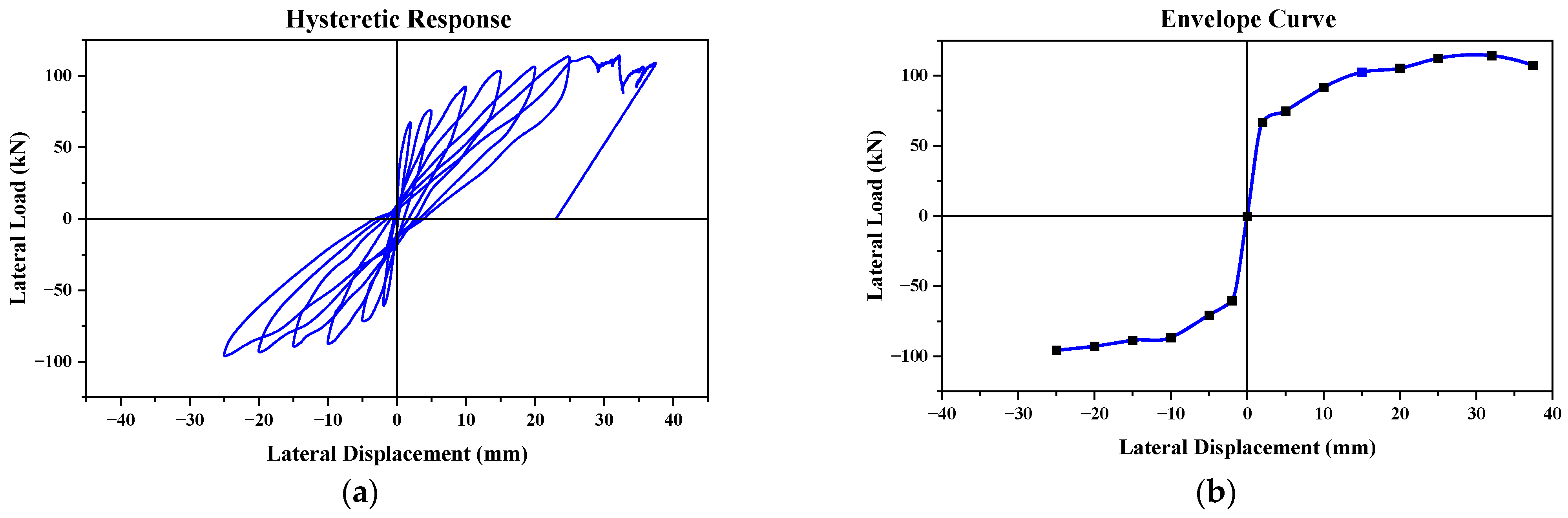

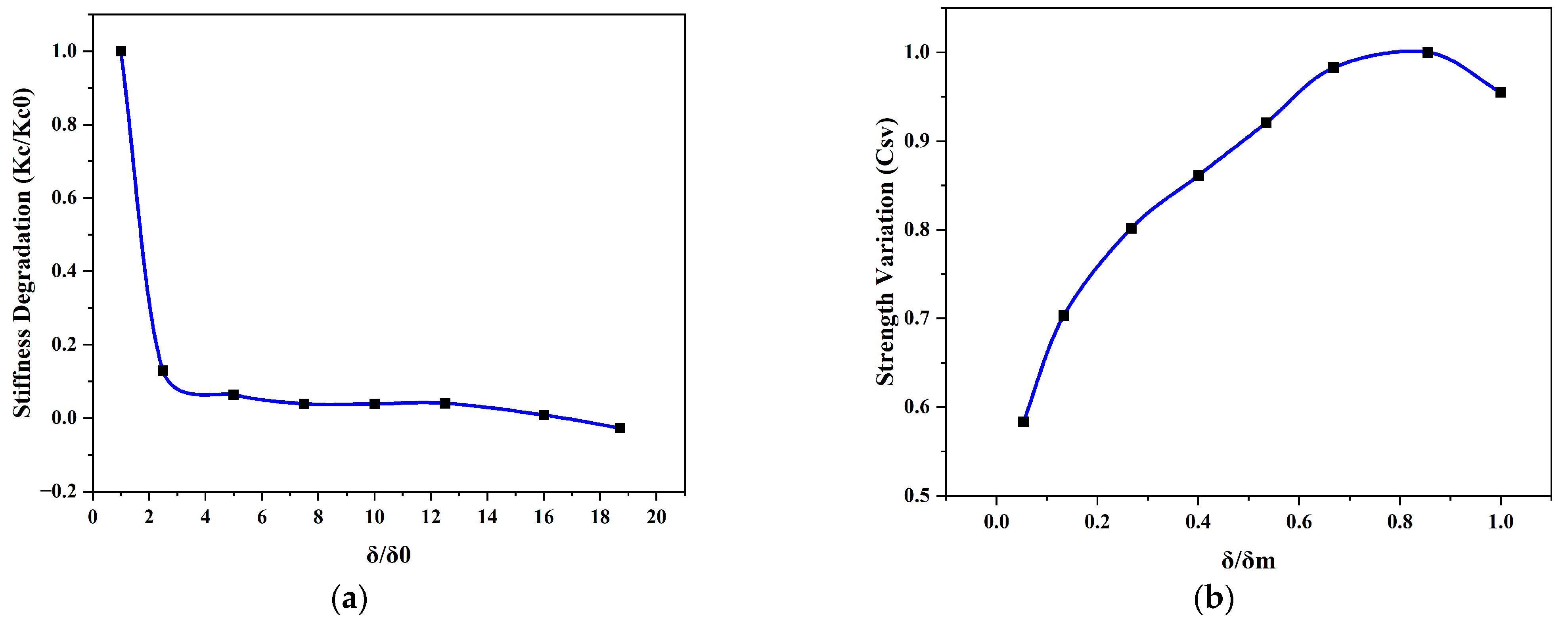

3.1.1. In-Plane Load vs. Deformations

3.1.2. Steel Strain in Longitudinal Bar

3.1.3. Failure Mechanism

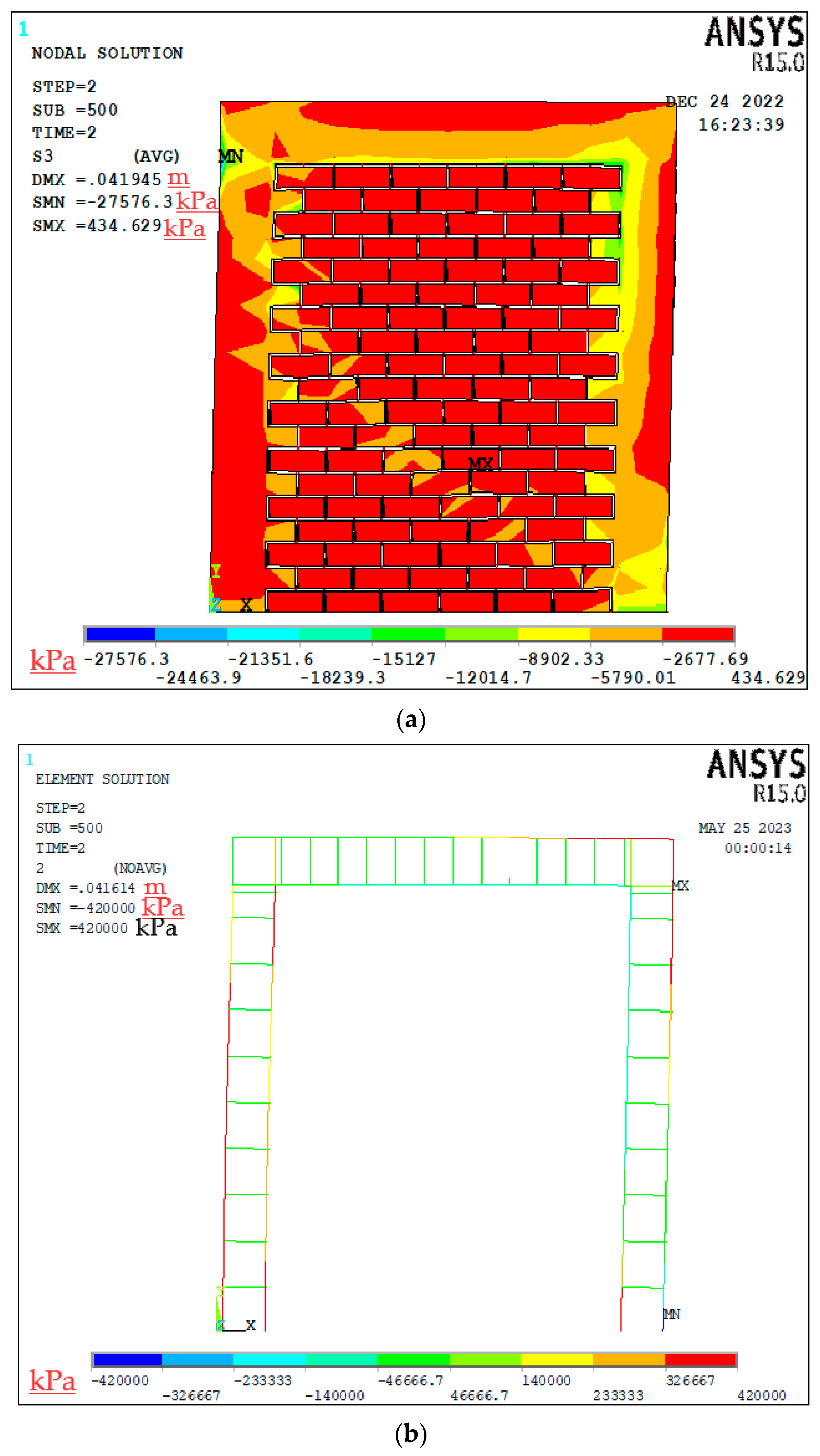

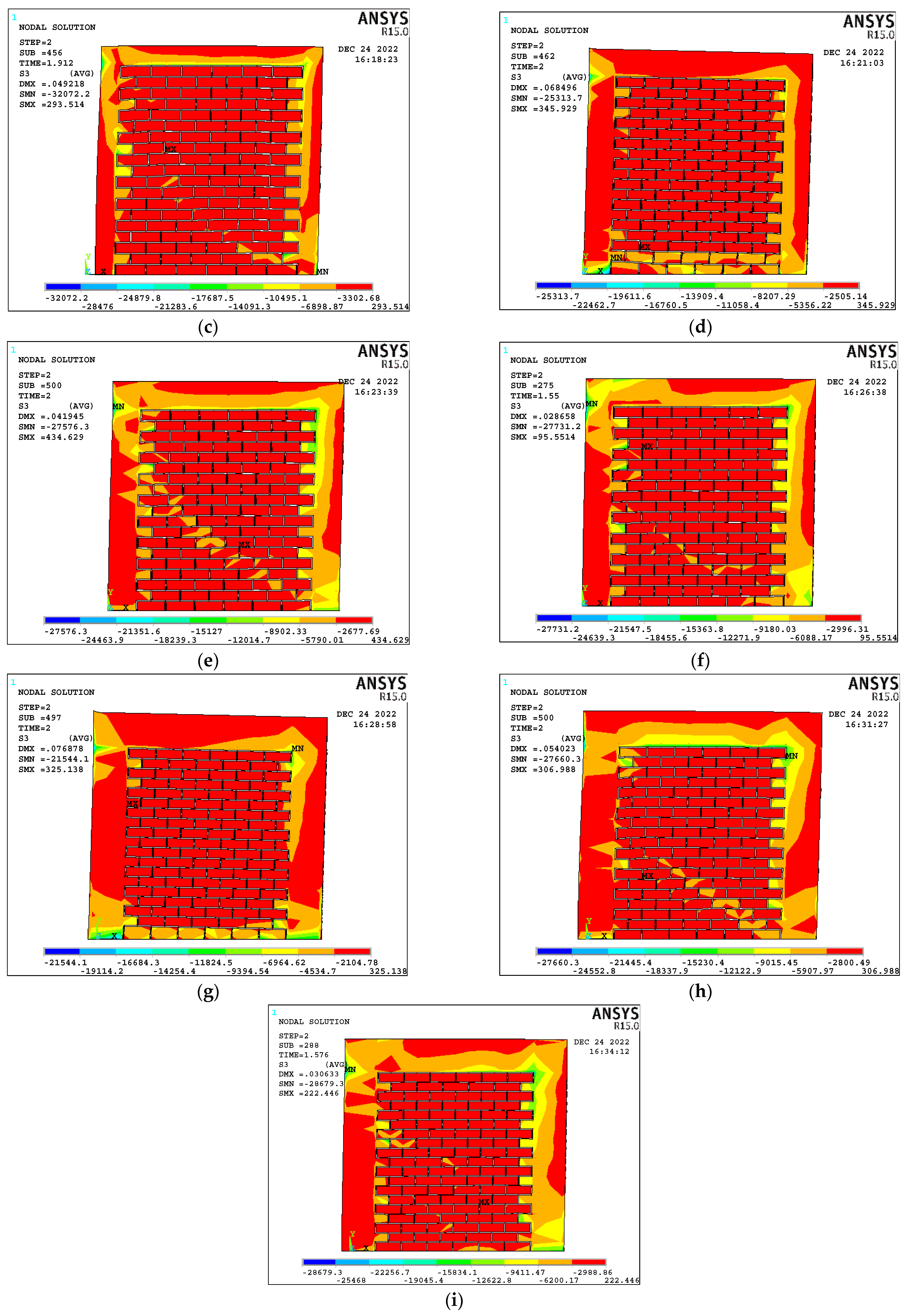

3.2. Numerical Simulation

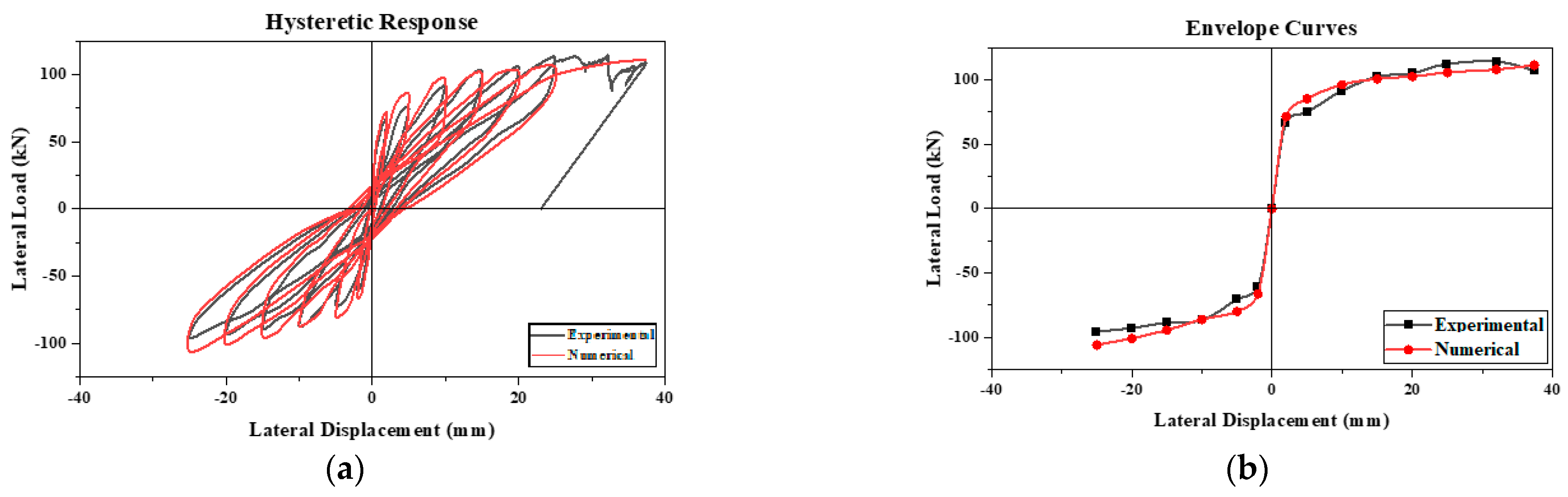

3.2.1. Validation of Numerical Wall Model

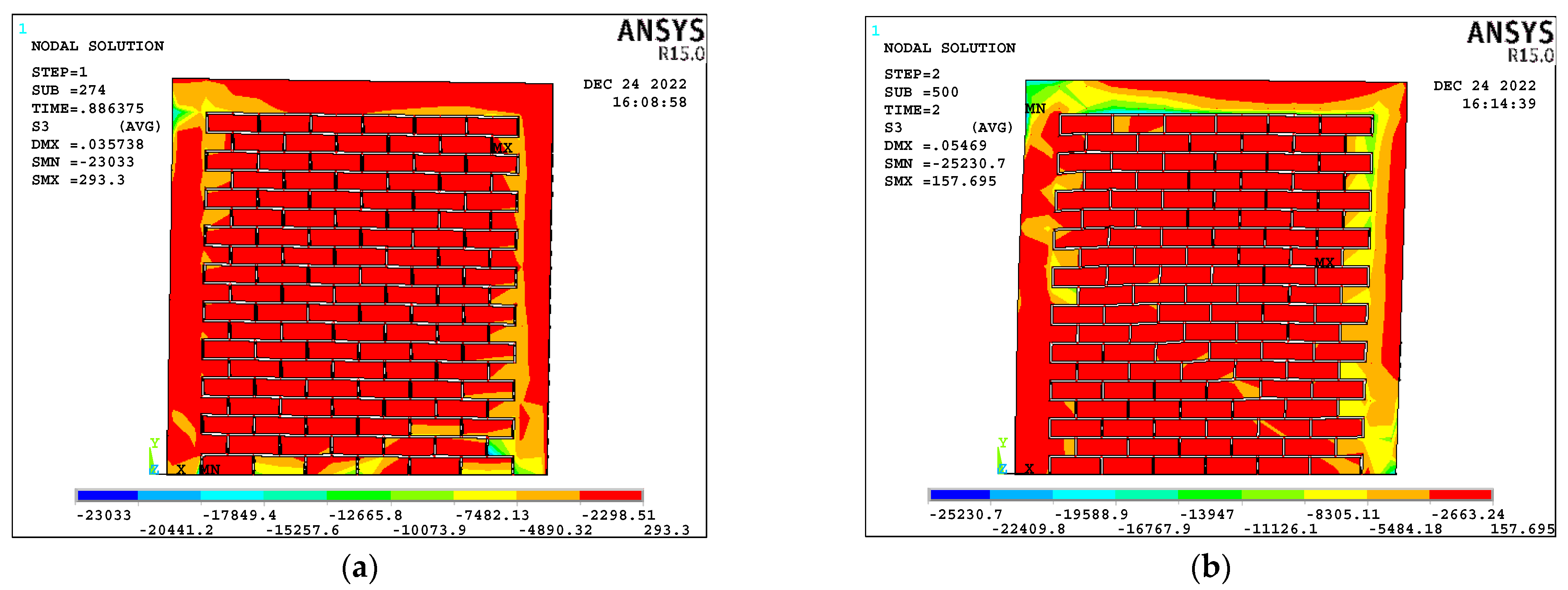

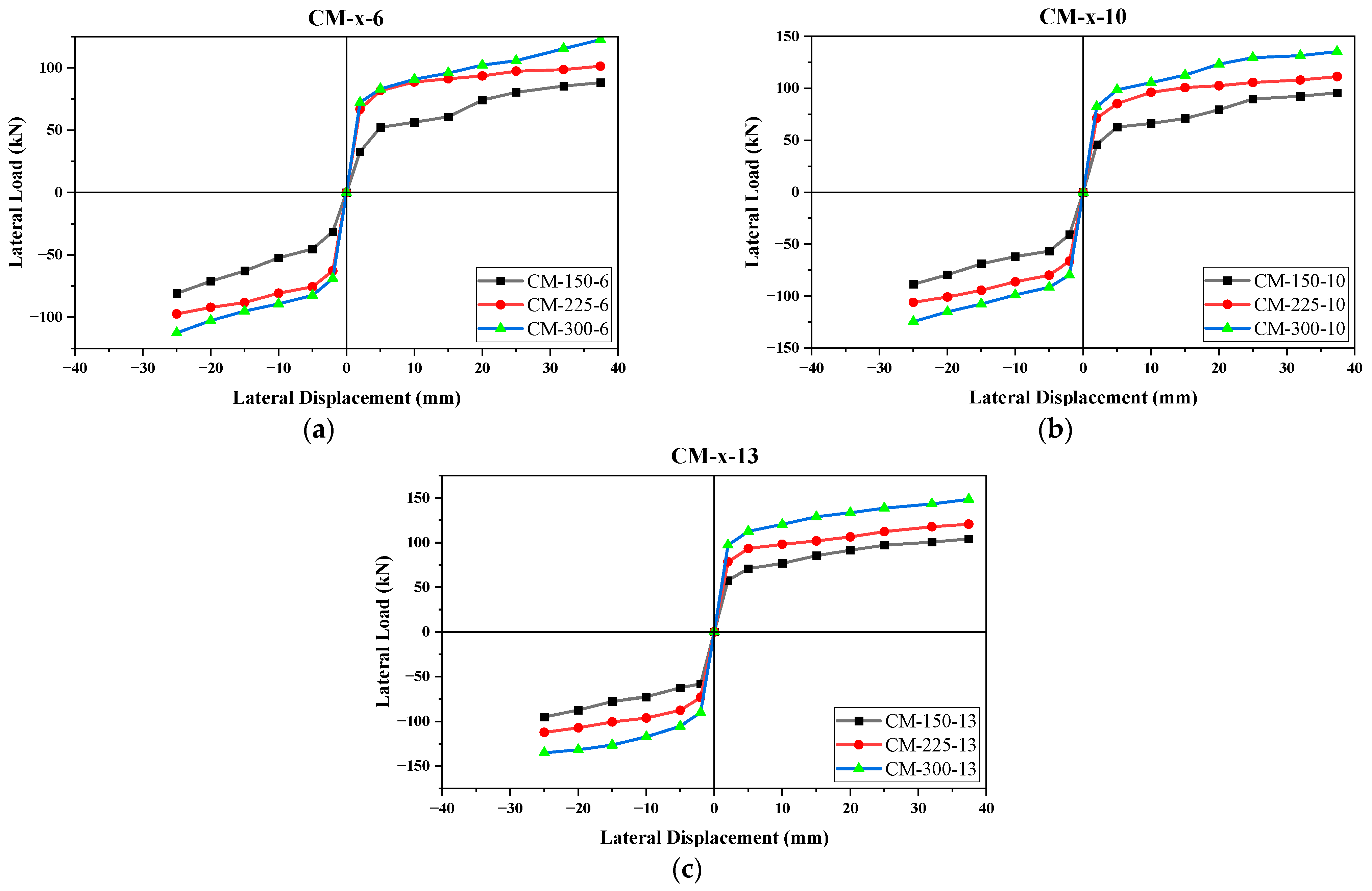

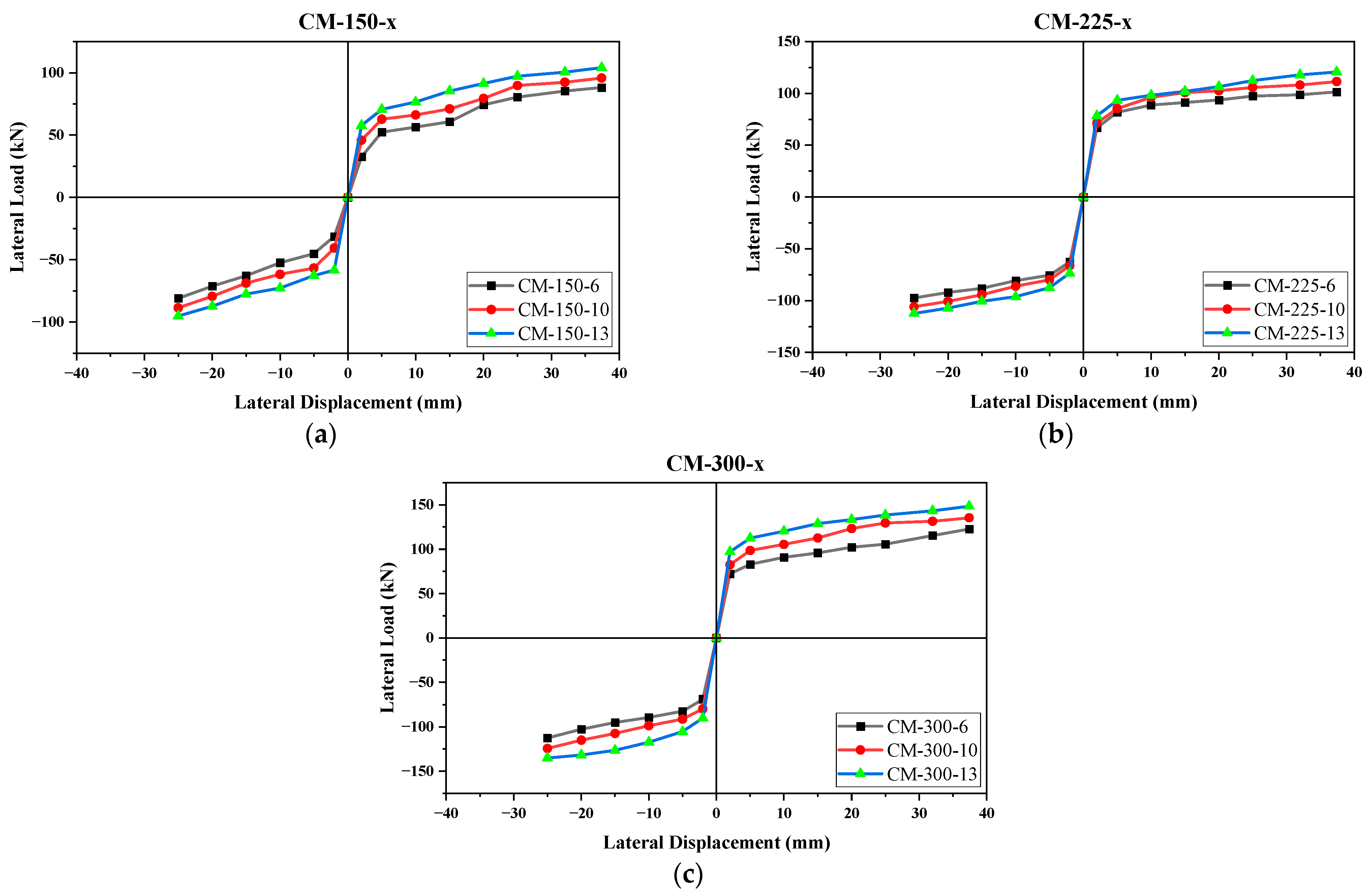

3.2.2. Parametric Study

4. Conclusions

- The hysteretic response of the masonry panel exhibited approximately symmetric loops in push-and-pull load cycles with an increasing trend of lateral strength except in the last push load, in which the load carrying capacity reached maximum value of 114.3 kN and then decreased to 109.1 kN, corresponding to 1.73% and 2.02% drift index, respectively.

- The shear failure mode observed in the test specimen demonstrated that the toothed contact surface between the masonry panel and the tie-column remained intact, providing evidence of the superior performance of the CM wall compared to the infilled structures.

- The width of the diagonal shear cracks was noted as 24 mm, while the width of the largest flexural crack in the tie-column was measured to be 9 mm.

- The FE model of the experimentally tested wall panel was developed based on a simplified micro-modeling technique, with the same parameter values offered an approximate concordance with the experimental results by a maximum error of 2.6% for ultimate lateral load strength and 5.4% for initial stiffness.

- The parametric study indicated a positive correlation between the seismic strength of confined masonry walls and the size of both the confining components and the longitudinal reinforcement. An increase in the size of the confining elements enhances the moment of inertia, leading to a higher lateral load capacity. Additionally, a greater column stiffness results in reduced deformation transfer to the masonry panel under lateral loads. The tie-columns primarily dissipate energy, with the remaining load transmitted to the masonry panel once the columns reach their capacity.

- Enhancing the size of the steel reinforcement bars improved the seismic strength of the structure. However, the reinforcement ratio emerged as a critical factor, directly influencing the ductility and tensile resistance. The load–moment interaction curves demonstrated that the moment capacity of the reinforced concrete columns increases substantially with higher reinforcement ratios, a finding corroborated by this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lourenço, P.B. Masonry structures, overview. Encycl. Earthq. Eng. 2014, 1–9. [Google Scholar]

- Delatte, N.J. Lessons from Roman cement and concrete. J. Prof. Issues Eng. Educ. Pract. 2001, 127, 109. [Google Scholar] [CrossRef]

- Hnaihen, K.H. The appearance of bricks in ancient mesopotamia. Athens J. Hist. 2020, 6, 73–96. [Google Scholar] [CrossRef]

- Tomazevic, M. Earthquake-Resistant Design of Masonry Buildings; World Scientific: Singapore, 1999; Volume 1. [Google Scholar]

- Guillaud, H. Characterization of earthen materials. Terra Lit. Rev. 2008, 21–31. [Google Scholar]

- Bhattacharya, S.; Nayak, S.; Dutta, S.C. A critical review of retrofitting methods for unreinforced masonry structures. Int. J. Disaster Risk Reduct. 2014, 7, 51–67. [Google Scholar] [CrossRef]

- Resistance, E.; Housing, L.E. Housing in North-East India Seismic Design and Behaviour of Confined Masonry Buildings Why Confined Masonry? IIT Patna: Dayalpur Daulatpur, India, 2016. [Google Scholar]

- Bruneau, M. State-of-the-art report on seismic performance of unreinforced masonry buildings. J. Struct. Eng. 1994, 120, 230–251. [Google Scholar] [CrossRef]

- So, E.K.M.; Pomonis, A. Derivation of globally applicable casualty rates for use in earthquake loss estimation models. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Asian Development Bank and World Bank (ADB-WB). Preliminary Damage and Needs Assessment-Pakistan 2005 Earthquake; Asian Development Bank and World Bank Islamabad: Islamabad, Pakistan, 2005. [Google Scholar]

- Naseer, A.; Khan, A.N.; Hussain, Z.; Ali, Q. Observed seismic behavior of buildings in northern Pakistan during the 2005 Kashmir earthquake. Earthq. Spectra 2010, 26, 425–449. [Google Scholar] [CrossRef]

- Jain, S.K.; Basu, D.; Ghosh, I.; Rai, D.C.; Brzev, S.; Bhargava, L.K. Application of confined masonry in a major project in India. In Proceedings of the Tenth US National Conference on Earthquake Engineering Frontiers of Earthquake Engineering, Anchorage, Alaska, 21–25 July 2014. [Google Scholar]

- Marques, R.; Lourenço, P.B. A model for pushover analysis of confined masonry structures: Implementation and validation. Bull. Earthq. Eng. 2013, 11, 2133–2150. [Google Scholar] [CrossRef]

- Borah, B.; Singhal, V.; Kaushik, H.B. Sustainable housing using confined masonry buildings. SN Appl. Sci. 2019, 1, 983. [Google Scholar] [CrossRef]

- Brzev, S. Earthquake-Resistant Confined Masonry Construction; NICEE, National Information Center of Earthquake Engineering, Indian Institute of Technology Kanpur: Uttar Pradesh, India, 2007. [Google Scholar]

- Erberik, M.A.; Citiloglu, C.; Erkoseoglu, G. Seismic performance assessment of confined masonry construction at component and structure levels. Bull. Earthq. Eng. 2019, 17, 867–889. [Google Scholar] [CrossRef]

- Gouveia, J.P.; Lourenço, P.B. Masonry shear walls subjected to cyclic loading: Influence of confinement and horizontal reinforcement. In Proceedings of the Tenth North American Masonry Converence, St. Louis, MO, USA, 3–5 June 2007. [Google Scholar]

- Schacher, T. Confined Masonry for One and Two Storey Buildings in Low-Tech Environments—A Guidebook for Technicians and Artisans; National Information Centre of Earthquake Engineering: Kanpur, India, 2009. [Google Scholar]

- Singhal, V.; Rai, D.C. Role of toothing on in-plane and out-of-plane behavior of confined masonry walls. J. Struct. Eng. 2014, 140, 4014053. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Seismic Design of Buildings. The People’s Republic of China National Standard: Beijing, China, 2010; p. 237.

- Tomaževič, M.; Klemenc, I. Seismic behaviour of confined masonry walls. Earthq. Eng. Struct. Dyn. 1997, 26, 1059–1071. [Google Scholar] [CrossRef]

- Tu, Y.-H.; Chuang, T.-H.; Liu, P.-M.; Yang, Y.-S. Out-of-plane shaking table tests on unreinforced masonry panels in RC frames. Eng. Struct. 2010, 32, 3925–3935. [Google Scholar] [CrossRef]

- Yoshimura, K.; Kikuchi, K.; Kuroki, M.; Nonaka, H.; Kim, K.T.; Wangdi, R.; Oshikata, A. Experimental study for developing higher seismic performance of brick masonry walls. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Standard, B. Eurocode 6—Design of Masonry Structures—; British Standard Institution: London, UK, 2005. [Google Scholar]

- Colegio Federado de Ingenieros y de Arquitectos de Costa Rica. Seismic Code of Costa Rica; Colegio Federado de Ingenieros y de Arquitectos de Costa Rica: San Jose, CA, USA, 1986. [Google Scholar]

- Asociación Colombiana de Ingeniería Sísmica. NSR-98: Normas Colombianas de Diseño y Construcción Sismo-Resistente; Asociación Colombiana de Ingeniería Sísmica: Bogota, Colombia, 1999. [Google Scholar]

- Code, A.S. INPRES CIRSOC 103: Normas Argentinas Para Construcciones Sismor Resistentes, Part III Construcciones de Mampostería; The National Institute for Seismic Prevention: San Juan, Argentina, 1983. [Google Scholar]

- Instituto Nacional de Normalización. NCh2123.Of1997 Mod.2003: Albañilería Confinada—Requisitos de Diseño y Cálculo; Norma Chilena Oficial: Santiago, Chile, 2003.

- Ministerio de Vivienda. Construcción y Saneamiento. Norma E.070 Albañilería; Ministerio de Vivienda, Construcción y Saneamiento, Servicio Nacional de Capacitación para la Industria de la Construcción—SENCICO: Lima, Peru, 2019. Available online: https://www.cip.org.pe/publicaciones/2021/enero/portal/e.070-alba-ileria-sencico.pdf (accessed on 1 June 2024).

- Gaceta Oficial del Distrito Federal. Normas Técnicas Complementarias Sobre Criterios y Acciones Para el Diseño Estructural de las Edificaciones; Gobierno del Distrito Federal: México City, México, 2004; pp. 88–194. Available online: http://paot.org.mx/centro/gaceta/2004/octubre04/06octubre04_ter.pdf (accessed on 1 June 2024).

- BCP. Building Code of Pakistan (Seismic Provisions 2007). In Ministry of Housing and Works; Government of Pakistan: Islamabad, Pakistan, 2007. [Google Scholar]

- Cai, G.; Su, Q.; Tsavdaridis, K.D.; Degée, H. Simplified density indexes of walls and tie-columns for confined masonry buildings in seismic zones. J. Earthq. Eng. 2020, 24, 447–469. [Google Scholar] [CrossRef]

- Baker, J.W. Measuring bias in structural response caused by ground motion scaling. In Proceedings of the 8th Pacific Conference on Earthquake Engineering, Singapore, 5–7 December 2007; Volume 8. [Google Scholar]

- Cazarín, E.F.E.; Terán-Gilmore, A. Seismic Performance of Confined Masonry Buildings Designed with the Mexico City Building Code. In Proceedings of the 13th North American Masonry Conference, Salt Lake, UT, USA, 16–19 June 2019. [Google Scholar]

- Marques, R.; Lourenço, P.B. Structural behaviour and design rules of confined masonry walls: Review and proposals. Constr. Build. Mater. 2019, 217, 137–155. [Google Scholar] [CrossRef]

- Brzev, S.; Reiter, M.; Pérez Gavilán, J.J.; Quiun, D.; Membreño, M.; Hart, T.; Sommer, D. Confined Masonry The Current Design Standards 13NAMC 20190224. In Proceedings of the 13 North American Masonry Conference, Salt Lake City, UT, USA, 16–19 June 2019. [Google Scholar]

- Pérez-Gavilán, J.J. The effect of shear-moment interaction on the shear strength of confined masonry walls. Constr. Build. Mater. 2020, 263, 120087. [Google Scholar] [CrossRef]

- Ajmal, M.M.; Qazi, A.U.; Ahmed, A.; Mughal, U.A.; Abbas, S.; Kazmi, S.M.S.; Munir, M.J. Structural Performance of Energy Efficient Geopolymer Concrete Confined Masonry: An Approach towards Decarbonization. Energies 2023, 16, 3579. [Google Scholar] [CrossRef]

- Al-Ata, B.A.; Alkloub, A.; Allouzi, R. Development of Backbone Curve for Reinforced Concrete Frames with Confined Masonry Walls. Pract. Period. Struct. Des. Constr. 2023, 28, 4023035. [Google Scholar] [CrossRef]

- Meli, R.; Svetlana, B.; Yamin, L.; Astroza, M.; Boen, T.; Crisafulli, F.; Dai, J.; Farsi, M.; Hart, T.; Mebarki, A.; et al. Seismic Design Guide for Low-Rise Confined Masonry Buildings; EERI-WHE World Housing Encyclopedia: Oakland, CA, USA, 2011. [Google Scholar]

- Galvis, F.A.; Miranda, E.; Heresi, P.; Dávalos, H.; Ruiz-García, J. Overview of collapsed buildings in Mexico City after the 19 September 2017 (Mw7. 1) earthquake. Earthq. Spectra 2020, 36, 83–109. [Google Scholar] [CrossRef]

- Marques, R.; Pereira, J.M.; Lourenço, P.B. Lateral in-plane seismic response of confined masonry walls: From numerical to backbone models. Eng. Struct. 2020, 221, 111098. [Google Scholar] [CrossRef]

- Yoshimura, K.; Kikuchi, K.; Kuroki, M.; Liu, L.; Ma, L. Effect of vertical axial loads and repeated lateral forces on seismic behavior of confined concrete masonry walls. Shock Vib. Dig. 2000, 32, 48–49. [Google Scholar]

- Riahi, Z.; Elwood, K.J.; Alcocer, S.M. Backbone model for confined masonry walls for performance-based seismic design. J. Struct. Eng. 2009, 135, 644–654. [Google Scholar] [CrossRef]

- Zabala, F.; Bustos, J.L.; Masanet, A.; Santalucia, J. Experimental behaviour of masonry structural walls used in Argentina. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Gavilan, J.J.P.; Flores, L.E.; Alcocer, S.M. An experimental study of confined masonry walls with varying aspect ratios. Earthq. Spectra 2015, 31, 945–968. [Google Scholar] [CrossRef]

- Bartolomé, A.S.; Quiun, D.; Torrealva, D. Seismic behaviour of a three-story half scale confined masonry structure. In Proceedings of the Tenth World Conference on Earthquake Engineering, Madrid, Spain, 19–24 July 1992; pp. 3527–3531. [Google Scholar]

- Escalante, J.J.P.G.; Brzev, S.; Cazarin, E.F.E.; Ganzerli, S.; Quiun, D.; Reiter, M.T. Experimental research studies on seismic behaviour of confined masonry structures: Current status and future needs. Buildings 2023, 13, 1776. [Google Scholar] [CrossRef]

- Chourasia, A.; Bhattacharyya, S.K.; Bhandari, N.M.; Bhargava, P. Seismic performance of different masonry buildings: Full-scale experimental study. J. Perform. Constr. Facil. 2016, 30, 4016006. [Google Scholar] [CrossRef]

- Marinilli, A.; Castilla, E. Experimental evaluation of confined masonry walls with several confining-columns. Proceedings of 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Kato, H.; Goto, T.; Minzuno, H. Cyclic loading tests of confined masonry wall elements for structural design development of apartment houses in the third world. Proceeding of the Tenth World Conference on Earthquake Engineering, Madrid, Spain, 19–24 July 1992; pp. 3539–3544. [Google Scholar]

- Okail, H.; Abdelrahman, A.; Abdelkhalik, A.; Metwaly, M. Experimental and analytical investigation of the lateral load response of confined masonry walls. HBRC J. 2016, 12, 33–46. [Google Scholar] [CrossRef]

- Ashraf, M.; Khan, A.N.; Naseer, A.; Ali, Q.; Alam, B. Seismic behavior of unreinforced and confined brick masonry walls before and after ferrocement overlay retrofitting. Int. J. Archit. Herit. 2012, 6, 665–688. [Google Scholar] [CrossRef]

- Varela-Rivera, J.; Fernandez-Baqueiro, L.; Gamboa-Villegas, J.; Prieto-Coyoc, A.; Moreno-Herrera, J. Flexural behavior of confined masonry walls subjected to in-plane lateral loads. Earthq. Spectra 2019, 55, 405–422. [Google Scholar] [CrossRef]

- Matošević, Ɖ.; Sigmund, V.; Guljaš, I. Cyclic testing of single bay confined masonry walls with various connection details. Bull. Earthq. Eng. 2015, 13, 565–586. [Google Scholar] [CrossRef]

- Ahmed, A.; Ahmad, I.; Shahzada, K.; Naqash, M.T.; Alam, B.; Fahad, M.; Wali Khan, S. Seismic Capacity Assessment of Confined Brick Masonry Building: An Experimental Approach. Shock Vib. 2018, 2018, 4756352. [Google Scholar] [CrossRef]

- Gentile, C.; Saisi, A.; Borlenghi, P. FE modelling for seismic assessment of an ancient tower from ambient vibration survey. In Proceedings of the Eighth International Operational Modal Analysis Conference, Copenhagen, Denmark, 13–15 May 2019; pp. 295–305. [Google Scholar]

- Quiroz, L.G.; Maruyama, Y.; Zavala, C. Cyclic behavior of Peruvian confined masonry walls and calibration of numerical model using genetic algorithms. Eng. Struct. 2014, 75, 561–576. [Google Scholar] [CrossRef]

- Ibrar, M.; Naseer, A.; Ashraf, M.; Badshah, E.; Ullah, S. Evaluation of confined masonry walls with varying sizes of confining elements and reinforcement ratios against cyclic loading. J. Build. Eng. 2022, 50, 104094. [Google Scholar] [CrossRef]

- ACI CODE-318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute Committee: Farmington Hills, MI, USA, 2019.

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2006; pp. 1–5.

- ASTM C109; ASTM C109/C109M—20b. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2020; Volume 4, p. 9.

- ASTM C67-07; Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. ASTM International: West Conshohocken, PA, USA, 2007; Volume i, pp. 1–12.

- Masonry Standards Joint Committee. Building code requirements for masonry structures (TMS 402-11/ACI 530-11/ASCE 6-11) and specification for masonry structures (TMS 602-11/ACI 530.1-11/ASCE 5-11) and companion commentaries. Farmingt. Hills MI Am. Concr. Inst. 2011. [Google Scholar]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens 1. ASTM International: West Conshohocken, PA, USA, 2003; pp. 1–5.

- ASTM C469/C469M-10; Standard Test method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2010; Volume 469.

- ASTM A615; Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM E519-02; Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages. ASTM International: West Conshohocken, PA, USA, 2002; Volume 5.

- BS EN 1052-3; Methods of Test for Masonry—Part 3: Determination of Initial Shear Strength. BSI: London, UK, 2002.

- ACI 374.1-05; Acceptance Criteria for Moment Frames Based on Structural Testing and Commentary. ACI Committee: Farmington Hills, MI, USA, 2014. Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=374105&Format=DOWNLOAD&Language=English&Units=US_Units (accessed on 1 June 2024).

- Mynarz, M.; Mynarzova, L. Non-linear approaches to the response of brick masonry wall to lateral loading. Int. J. GEOMATE 2018, 14, 76–82. [Google Scholar] [CrossRef]

- Kömürcü, S.; Gedikli, A. Macro and Micro Modelling of the Unreinforced Masonry Shear Walls. Eur. J. Eng. Nat. Sci. 2019, 3, 116–123. Available online: https://dergipark.org.tr/en/pub/ejens/issue/49410/369461 (accessed on 1 June 2024).

- Kanıt, R.; Döndüren, M.S. Investıgatıon of usıng ansys software ın the determınatıon of stress behavıours of masonry walls under out of plane cyclıng load. Int. J. Phys. Sci. 2010, 5, 97–108. [Google Scholar]

- Lourenço, P.B.; Silva, L.C. Computational Strategies for Masonry Structures; Technische Universiteit Delft: Delft, The Netherlands, 1996. [Google Scholar]

- Vindhyashree, H.S.; Rahamath, A.; Kumar, W.P.; Kumar, M.T. IJERT-Numerical Simulation of Masonry Prism Test using ANSYS and ABAQUS. IJERT J. Int. J. Eng. Res. Technol. 2015. [Google Scholar]

- Mughal, U.A.; Qazi, A.U.; Ahmed, A.; Abbass, W.; Abbas, S.; Salmi, A.; Sayed, M.M. Impact of Openings on the In-Plane Strength of Confined and Unconfined Masonry Walls: A Sustainable Numerical Study. Sustainability 2022, 14, 7467. [Google Scholar] [CrossRef]

- Basit, A.; Abbas, S.; Ajmal, M.M.; Mughal, U.A.; Kazmi, S.M.S.; Munir, M.J. Joint Behavior of Full-Scale Precast Concrete Pipe Infrastructure: Experimental and Numerical Analysis. Infrastructures 2024, 9, 69. [Google Scholar] [CrossRef]

- Naseer, M.A.; Qazi, A.U.; Mughal, U.A.; Ajmal, M.M.; Ahmed, A. Characteristics of unconfined masonry walls under in-plane static and reverse-cyclic loading: A comparative numerical study. Eur. J. Environ. Civ. Eng. 2023, 1–26. [Google Scholar] [CrossRef]

- Magenes, G.; Della Fontana, A. Simplified non-linear seismic analysis of masonry buildings. Proc. Br. Masonry Soc. 1998, 8, 190–195. [Google Scholar]

- Vanin, A.; Foraboschi, P. Journal-Modelling of Masonry Panels by Truss Analogy—Part 1. Mason. Int. 2009, 22, 1–10. [Google Scholar]

- Tomaževič, M.; Gams, M. Shaking table study and modelling of seismic behaviour of confined AAC masonry buildings. Bull. Earthq. Eng. 2012, 10, 863–893. [Google Scholar] [CrossRef]

- Lagomarsino, S.; Penna, A.; Galasco, A.; Cattari, S. TREMURI program: An equivalent frame model for the nonlinear seismic analysis of masonry buildings. Eng. Struct. 2013, 56, 1787–1799. [Google Scholar] [CrossRef]

- Caliò, I.; Marletta, M.; Pantò, B. A new discrete element model for the evaluation of the seismic behaviour of unreinforced masonry buildings. Eng. Struct. 2012, 40, 327–338. [Google Scholar] [CrossRef]

- Mughal, U.A.; Qazi, A.U.; Ahmed, A.; Ajmal, M.M.; Danish, M. Investigation of torsion in confined masonry structures originating due to unsymmetric openings. Eur. J. Environ. Civ. Eng. 2023, 1, 1–20. [Google Scholar] [CrossRef]

- Mughal, U.A.; Qazi, A.U.; Ahmed, A.; Sahar, U.U.; Ajmal, M.M. Comparative analysis of mechanical characteristics in masonry walls: Impact of aspect ratios and opening percentages. Eur. J. Environ. Civ. Eng. 2024, 1, 1–22. [Google Scholar] [CrossRef]

- Ansys Inc. Element Reference. 2010. Available online: https://www.ansys.com (accessed on 1 June 2024).

- Borah, B.; Kaushik, H.B.; Singhal, V. Analysis and Design of Confined Masonry Structures: Review and Future Research Directions. Buildings 2023, 13, 1282. [Google Scholar] [CrossRef]

- El-Diasity, M.; Okail, H.; Kamal, O.; Said, M. Structural performance of confined masonry walls retrofitted using ferrocement and GFRP under in-plane cyclic loading. Eng. Struct. 2015, 94, 54–69. [Google Scholar] [CrossRef]

- ASCE/SEI 41-06; Supplement to Seismic Rehabilitation of Existing Buildings. ASTM International: West Conshohocken, PA, USA, 2007.

- Hejazi, F.; Karimzadeh, K. Analysis Procedure for Earthquake Resistant Structures; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Jin, L.; Yu, W.; Su, X.; Zhang, S.; Du, X.; Han, J.; Li, D. Effect of cross-section size on the flexural failure behavior of RC cantilever beams under low cyclic and monotonic lateral loadings. Eng. Struct. 2018, 156, 567–586. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, S.; Han, J.; Li, D.; Du, X. Effect of cross-section size on flexural compressive failure of RC columns: Monotonic and cyclic tests. Eng. Struct. 2019, 186, 456–470. [Google Scholar] [CrossRef]

- Tajzadah, J.A.; Agrawal, V.V. Effect of Column Size, Shape and Orientation on Seismic Performance of RC Building. J. Emerg. Technol. Innov. Res. (JETIR) 2019, 6, 1–6. [Google Scholar]

- Smith, B.S. Methods for predicting the lateral stiffness and strength of multi-storey infilled frames. Build. Sci. 1967, 2, 247–257. [Google Scholar] [CrossRef]

- Wight, J.K.; McGregor, J.G. Reinforced Concrete Mechanics & Design, 6th ed.; Pearson: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Wang, X.; Zhang, Y.; Su, Y.; Feng, Y. Experimental investigation on the effect of reinforcement ratio to capacity of RC column to resist lateral impact loading. Syst. Eng. Procedia 2011, 1, 35–41. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Elchalakani, M.; Do, T.V.; Hao, H. Sensitivity of lateral impact response of RC columns reinforced with GFRP bars and stirrups to concrete strength and reinforcement ratio. Eng. Struct. 2021, 242, 112512. [Google Scholar] [CrossRef]

- Chrysanidis, T. Influence of elongation degree on transverse buckling of confined boundary regions of R/C seismic walls. Constr. Build. Mater. 2019, 211, 703–720. [Google Scholar] [CrossRef]

- Chrysanidis, T.A. Evaluation of out-of-plane response of R/C structural wall boundary edges detailed with maximum code-prescribed longitudinal reinforcement ratio. Int. J. Concr. Struct. Mater. 2020, 14, 3. [Google Scholar] [CrossRef]

- Chrysanidis, T. The effect of longitudinal reinforcement ratio on the lateral buckling behavior of R/C walls modelled using prism elements. J. Build. Eng. 2021, 42, 102456. [Google Scholar] [CrossRef]

| Properties | Assigned Values |

|---|---|

| Poisson’s ratio for bricks: νb | 0.20 |

| Poisson’s ratio for mortar: νm | 0.15 |

| Poisson’s ratio for concrete: νc | 0.16 |

| Normal stiffness of CONTA178 element: Kn | 13,967,223 kN/m |

| Tangential stiffness of CONTA178 element: Ks | 6,072,705 kN/m |

| Vcr (kN) | Vmax (kN) | Vmax/Aw (MPa) | δm (%) | Ed (kN-mm) | ||||

|---|---|---|---|---|---|---|---|---|

| Push | Pull | Avg | Push | Pull | Avg | |||

| 75.7 | 114.3 | 98.2 | 106.2 | 0.67 | 2.0 | 1.4 | 1.7 | 5861 |

| Specimen Name | Nomenclature of CM Walls | In-Plane Dimension of Confining Elements (mm) | Size of Longitudinal Rebar (mm) | Steel Reinforcement Ratio (%) |

|---|---|---|---|---|

| 1 | CM-150-6 | 150 | 6 | 0.17 |

| 2 | CM-150-10 | 150 | 10 | 0.46 |

| 3 | CM-150-13 | 150 | 13 | 0.78 |

| 4 | CM-225-6 | 225 | 6 | 0.11 |

| 5 | CM-225-10 | 225 | 10 | 0.31 |

| 6 | CM-225-13 | 225 | 13 | 0.52 |

| 7 | CM-300-6 | 300 | 6 | 0.08 |

| 8 | CM-300-10 | 300 | 10 | 0.23 |

| 9 | CM-300-13 | 300 | 13 | 0.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajmal, M.M.; Qazi, A.U.; Ahmed, A.; Mughal, U.A.; Kazmi, S.M.S.; Munir, M.J. Influence of Confining Element Stiffness on the In-Plane Seismic Performance of Confined Masonry Walls. Materials 2024, 17, 3100. https://doi.org/10.3390/ma17133100

Ajmal MM, Qazi AU, Ahmed A, Mughal UA, Kazmi SMS, Munir MJ. Influence of Confining Element Stiffness on the In-Plane Seismic Performance of Confined Masonry Walls. Materials. 2024; 17(13):3100. https://doi.org/10.3390/ma17133100

Chicago/Turabian StyleAjmal, Muhammad Mubashir, Asad Ullah Qazi, Ali Ahmed, Ubaid Ahmad Mughal, Syed Minhaj Saleem Kazmi, and Muhammad Junaid Munir. 2024. "Influence of Confining Element Stiffness on the In-Plane Seismic Performance of Confined Masonry Walls" Materials 17, no. 13: 3100. https://doi.org/10.3390/ma17133100

APA StyleAjmal, M. M., Qazi, A. U., Ahmed, A., Mughal, U. A., Kazmi, S. M. S., & Munir, M. J. (2024). Influence of Confining Element Stiffness on the In-Plane Seismic Performance of Confined Masonry Walls. Materials, 17(13), 3100. https://doi.org/10.3390/ma17133100