Effect of Hot-Pressing Process on Mechanical Properties of UHMWPE Fiber Non-Woven Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

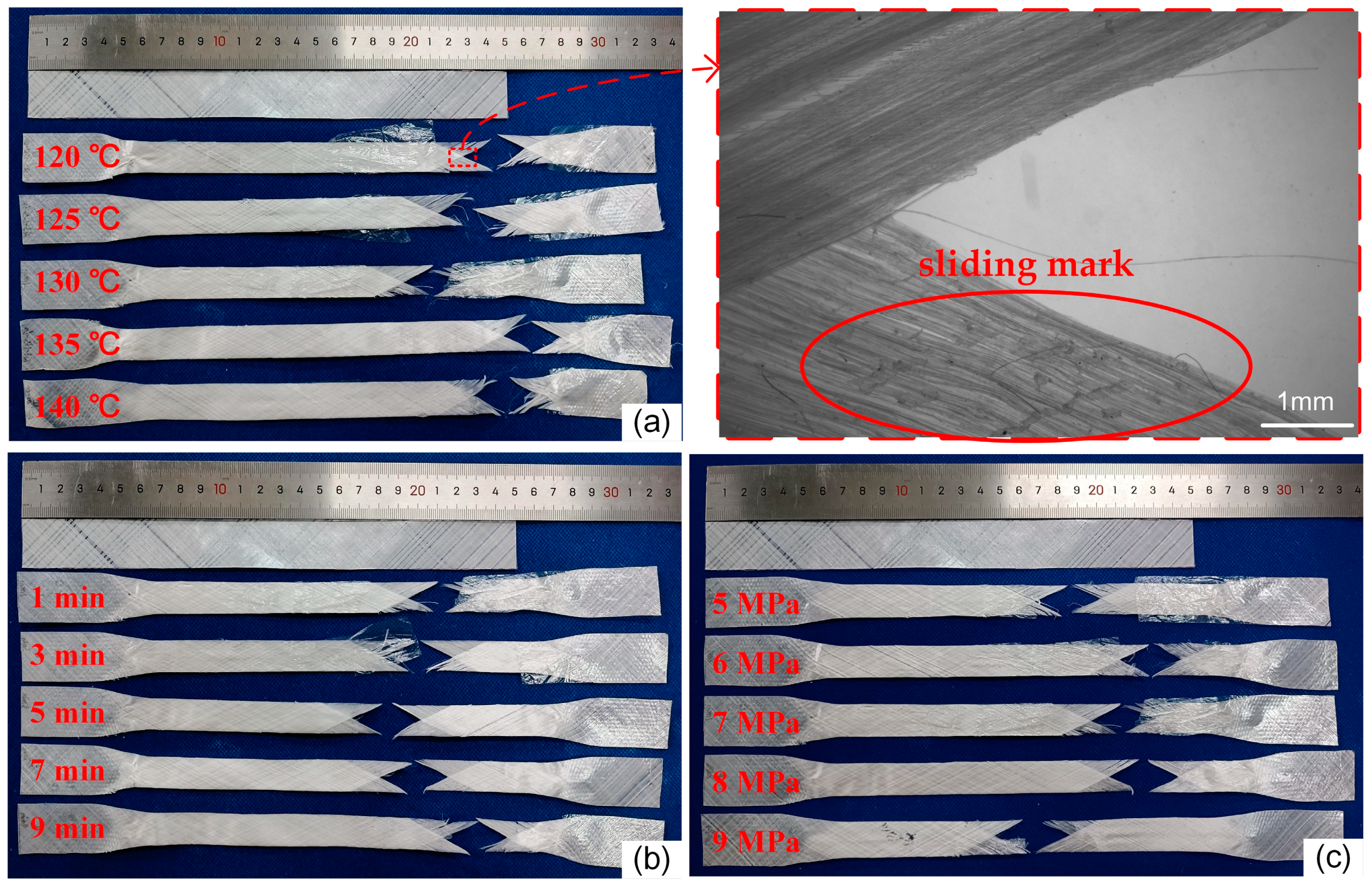

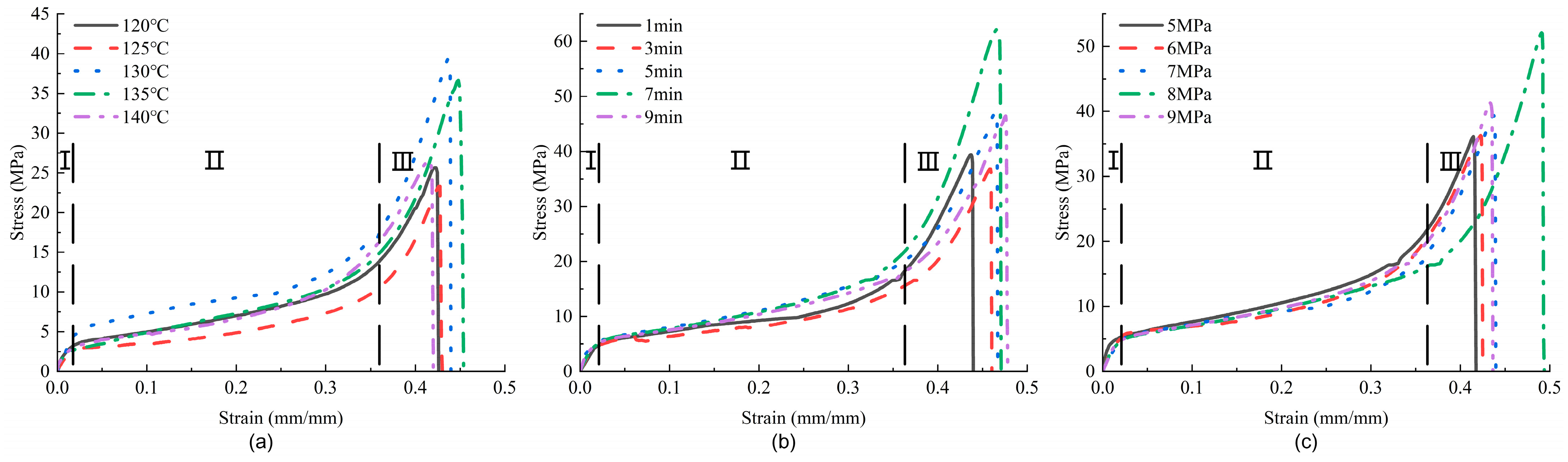

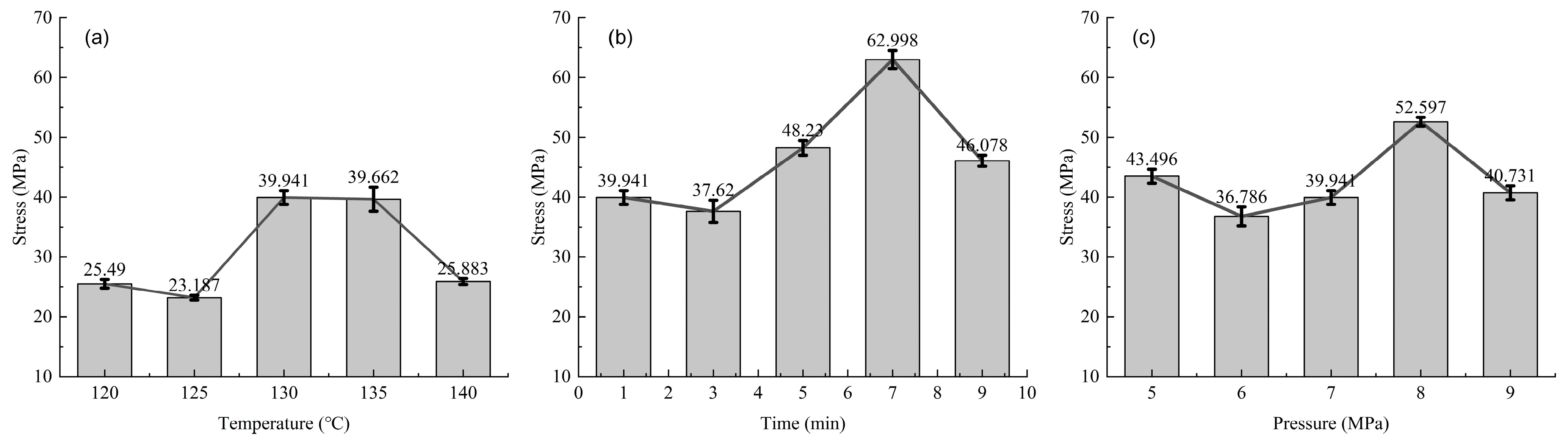

3.1. The Impact of Hot-Pressing Parameters on the In-Plane Shear Properties of 2UD Fabrics

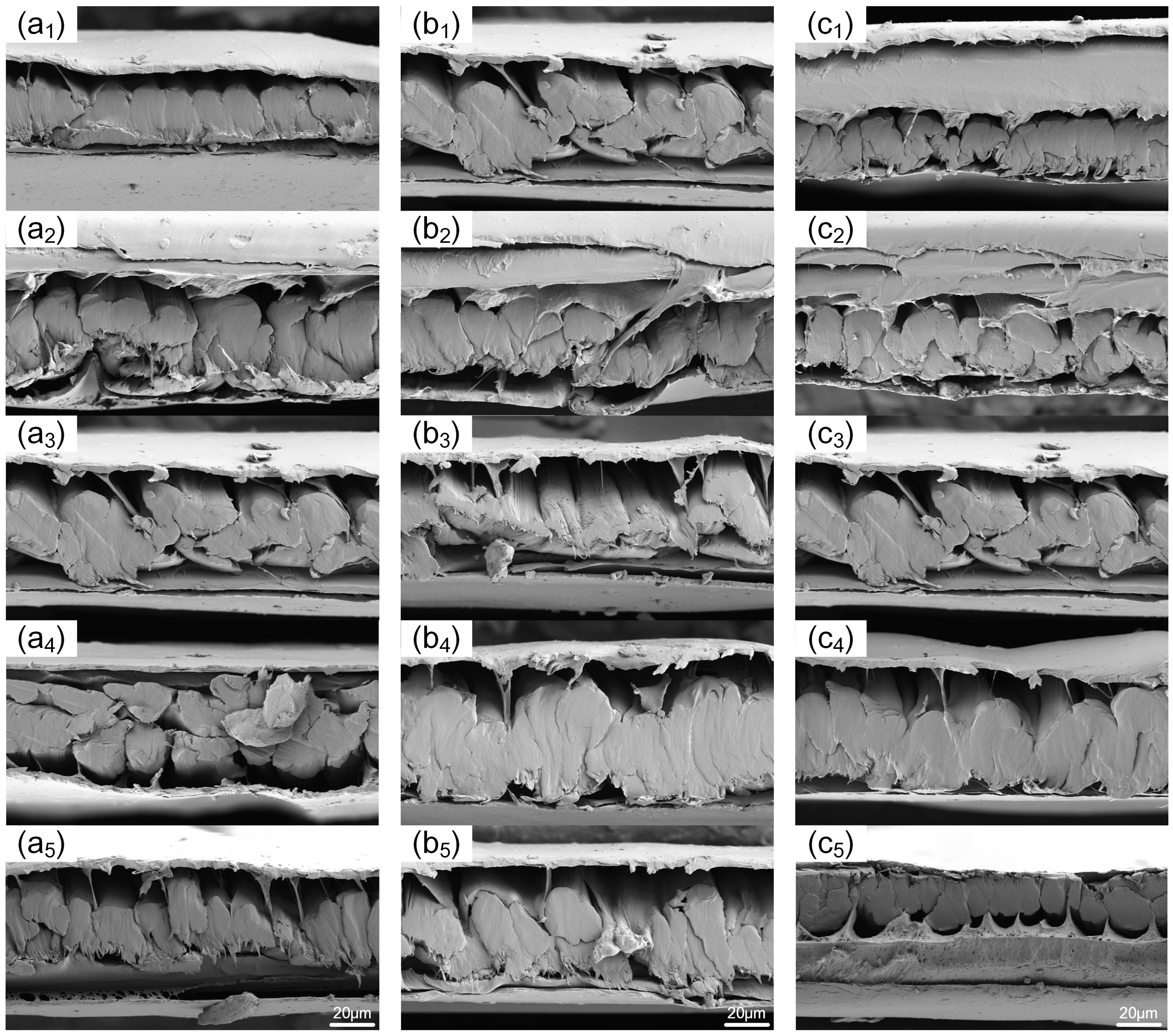

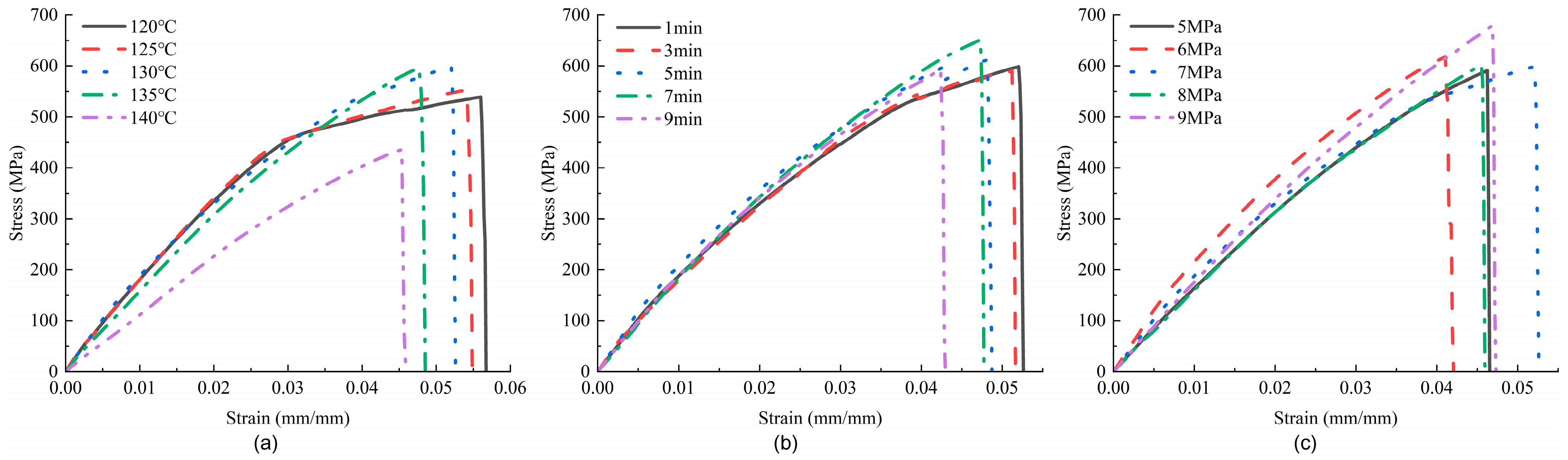

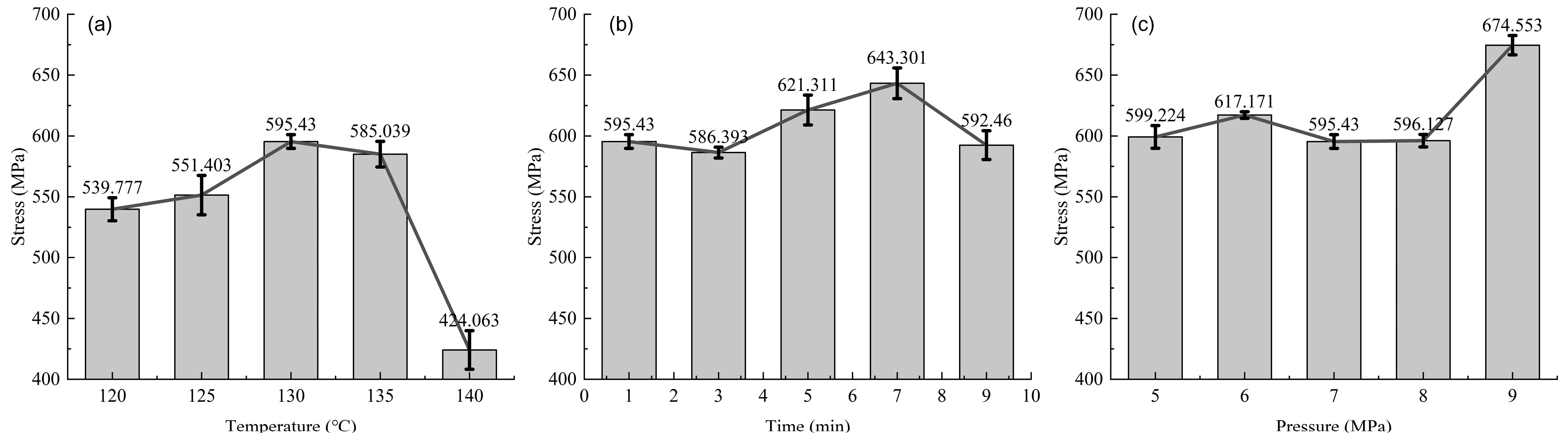

3.2. The Impact of Hot-Pressing Parameters on the Tensile Properties of 2UD Fabric

4. Discussion

4.1. The Impact of Hot-Pressing Parameters on In-Plane Shear Properties

4.2. The Impact of Hot-Pressing Parameters on Tensile Properties

5. Conclusions

- (a)

- Within a certain range, as the hot-pressing parameters increase, the fiber–resin bond strength of the non-woven fabric also increases. The in-plane shear performance of the samples is mainly related to this bond strength, while the tensile performance is influenced by both the bond strength and the fibers’ intrinsic properties. Changes in hot-pressing parameters create significant differences in the neatness of the tensile sample fractures and the extent of fiber pull-out from the matrix.

- (b)

- When the hot-pressing time is set to 1 min and pressure to 7 MPa, with temperatures varying between 120 °C and 140 °C, both the tensile and in-plane shear strengths of the non-woven fabric initially increase and then decrease, peaking at 130 °C. The in-plane shear strength changes by 72.3%, and the tensile strength changes by 40.4%.

- (c)

- With a hot-pressing temperature of 130 °C, a pressure of 7 MPa, and time varying from 1 to 9 min, both the tensile and in-plane shear strengths of the non-woven fabric first decrease, then increase and decrease again, reaching their maximum at 7 min. The in-plane shear strength changes by 67.5%, and the tensile strength changes by 9.7%.

- (d)

- At a hot-pressing temperature of 130 °C, time of 1 min, and pressure varying from 5 to 9 MPa, the in-plane shear strength of the non-woven fabric initially decreases, then increases, and decreases again, peaking at 8 MPa. The tensile strength shows no significant change within the range from 5 to 8 MPa but reaches its maximum at 9 MPa. The in-plane shear strength changes by 43%, and the tensile strength changes by 13.3%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, W.; Li, R.; Li, C.; Chen, Z.R.; Zhang, L. Mechanical properties of surface-modified ultra-high molecular weight polyethylene fiber reinforced natural rubber composites. Polym. Compos. 2017, 38, 1215–1220. [Google Scholar] [CrossRef]

- Zheng, Z.; Tang, X.Z.; Shi, M.W.; Zhou, G.T. Surface modification of ultrahigh-molecular-weight polyethylene fibers. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 463–472. [Google Scholar] [CrossRef]

- Zhamu, A.; Wingert, M.; Jana, S.; Zhong, W.H.; Stone, J. Treatment of functionalized graphitic nanofibers (GNFs) and the adhesion of GNFs-reinforced-epoxy with ultra high molecular weight polyethylene fiber. Compos. Part A 2006, 38, 699–709. [Google Scholar] [CrossRef]

- Coline, R.; Eric, L.; JeanClaude, G.; Nicolas, G.; Cathie, V.G. A review of the mechanical and physical properties of polyethylene fibers. Textiles 2021, 1, 86–151. [Google Scholar] [CrossRef]

- Vidushi, S.; Sheetal, C.; Nandita, K.; Bikramjit, B. Six decades of UHMWPE in reconstructive surgery. Int. Mater. Rev. 2023, 68, 46–81. [Google Scholar] [CrossRef]

- Pragati, B.; Amit, K.; Alok, K.; Prabhat, K.D. Optimization of surface treatments for improving adhesion of UHMWPE nonwoven composite with dissimilar materials. Fibers Polym. 2023, 24, 1431–1440. [Google Scholar] [CrossRef]

- Yixuan, W.; Ruixiang, H. Research progress on surface modification and application status of UHMWPE fiber. J. Phys. Conf. Ser. 2022, 2263, 012–016. [Google Scholar] [CrossRef]

- Jena, P.; Ramanjeneyulu, K.; Kumar, S.K.; Bhat, T.B. Ballistic studies on layered structures. Mater. Des. 2009, 30, 1922–1929. [Google Scholar] [CrossRef]

- Zhang, T.G.; Satapathy, S.S.; Vargas-Gonzalez, L.R.; Walsh, S.M. Ballistic impact response of Ultra-High-Molecular-Weight Polyethylene (UHMWPE). Compos. Struct. 2015, 133, 191–201. [Google Scholar] [CrossRef]

- Ma, X.L.; Wen, L.H.; Wang, S.Y. The optimization of thermo-compression process parameters of continuous carbon fiber reinforced PEEK composites. J. Phys. Conf. Ser. 2023, 2587, 012014. [Google Scholar] [CrossRef]

- Cline, J.; Love, B. The effect of in-plane shear properties on the ballistic performance of polyethylene composites. Int. J. Impact Eng. 2020, 143, 103592. [Google Scholar] [CrossRef]

- Ogawa, T.; Mukai, H.; Osawa, S. Mechanical properties of ultrahigh-molecular-weight polyethylene fiber-reinforced PE composites. J. Appl. Polym. Sci. 1998, 68, 1431–1439. [Google Scholar] [CrossRef]

- Karbalaie, M.; Yazdanirad, M.; Mirhabibi, A. High performance Dyneema~R fiber laminate for impact resistance/ macro structural composites. J. Thermoplast. Compos. Mater. 2012, 25, 403–414. [Google Scholar] [CrossRef]

- Cao, M.J.; Chen, L.; Xu, R.Z.; Fang, Q. Effect of the temperature on ballistic performance of UHMWPE laminate with limited thickness. Compos. Struct. 2021, 277, 114638. [Google Scholar] [CrossRef]

- Zeng, Z.; Guo, B.B.; Li, M.; Li, J.; Zhou, X.D. Experimental and simulated investigation of temperature distribution of UHMWPE laminated composites during hot pressing process. J. Appl. Polym. Sci. 2018, 135, 45874. [Google Scholar] [CrossRef]

- Zheng, Z.; Huang, X.C.; Li, Y.; Yang, N.C.; Wang, X.L.; Shi, M.W. Influence factors of internal structure and interfacial compatibility of UHMWPE fiber/SEBS resin composites: Processing parameters, structure of fiber and nature of resin. Compos. Part B 2012, 43, 1538–1544. [Google Scholar] [CrossRef]

- Comte, E.; Merhi, D.; Michaud, V.; Månson, J.A.E. Void formation and transport during SMC manufacturing: Effect of the glass fiber sizing. Polym. Compos. 2006, 27, 239–322. [Google Scholar] [CrossRef]

- Lässig, R.T.; May, M.; Heisserer, U.; Riedel, W.; Bagusat, F.; Werff, H.; Hiermaier, S.J. Effect of consolidation pressure on the impact behavior of UHMWPE composites. Compos. Part B 2018, 147, 47–55. [Google Scholar] [CrossRef]

- Forster, A.L.; Forster, A.M.; Chin, J.W.; Peng, J.S.; Lin, C.C.; Petit, S.; Kang, K.L.; Paulter, N.; Riley, M.A.; Rice, K.D.; et al. Long-term stability of UHMWPE fibers. Polym. Degrad. Stab. 2015, 114, 45–51. [Google Scholar] [CrossRef]

- GB/T 1447—2005; Test conditions for isotropic and orthotropic fiber-reinforced plastics composites. National Standard: Beijing, China, 2005.

- Xu, Z.P.; Zhang, M.; Gao, S.H.; Wang, G.B.; Zhang, S.L.; Luan, J.S. Study on mechanical properties of unidirectional continuous carbon fiber-reinforced PEEK composites fabricated by the wrapped yarn method. Polym. Compos. 2019, 40, 56–69. [Google Scholar] [CrossRef]

- Deplancke, T.; Lame, O.; Rousset, F.; Aguili, I.; Seguela, R.; Vigier, G. Diffusion versus cocrystallization of very long polymer chains at interfaces: Experimental study of sintering of uhmwpe nascent powder. Macromolecules 2013, 47, 197–207. [Google Scholar] [CrossRef]

- Hu, S.S.; Yuan, X.Y.; Ma, Y.J.; Zhang, G.G.; Wang, C.Y.; Pang, X.L.; Xiong, F. Temperature-influenced cutting mechanism of UHMWPE fibres. J. Manuf. Process 2024, 113, 183–196. [Google Scholar] [CrossRef]

- Lessard, H.; Lebrun, G.; Benkaddour, A.; Pham, X.T. Influence of process parameters on the thermostamping of a [0/90]12 carbon/polyether ether ketone laminate. Compos. Part A Appl. Sci. Manuf. 2015, 70, 59–68. [Google Scholar] [CrossRef]

- Khattar, N.; Jagriti; Ahlawat, V.; Sharma, P.; Berar, U.; Diwan, P.K. Optimization of compression parameters of UHMWPE through thermal stability. Mater. Chem. Phys. 2023, 307, 128220. [Google Scholar] [CrossRef]

| Hot-Pressing Parameters | Group Number | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Temperature/°C | 120 | 125 | 130 | 135 | 140 |

| Time/min | 1 | 1 | 1 | 1 | 1 |

| Pressure/MPa | 7 | 7 | 7 | 7 | 7 |

| Temperature/°C | 130 | 130 | 130 | 130 | 130 |

| Time/min | 1 | 3 | 5 | 7 | 9 |

| Pressure/MPa | 7 | 7 | 7 | 7 | 7 |

| Temperature/°C | 130 | 130 | 130 | 130 | 130 |

| Time/min | 1 | 1 | 1 | 1 | 1 |

| Pressure/MPa | 5 | 6 | 7 | 8 | 9 |

| Group | Number | Average/MPa | Variance | F | p-Value | F-Crit |

|---|---|---|---|---|---|---|

| 120 °C | 3 | 25.490 | 0.764 | 108.068 | 3.479 × 10−8 | 3.478 |

| 125 °C | 3 | 23.187 | 0.231 | |||

| 130 °C | 3 | 39.940 | 1.961 | |||

| 135 °C | 3 | 39.662 | 6.140 | |||

| 140 °C | 3 | 25.883 | 0.358 | |||

| 1 min | 3 | 39.940 | 1.961 | 104.738 | 4.051 × 10−8 | 3.478 |

| 3 min | 3 | 37.620 | 5.247 | |||

| 5 min | 3 | 48.230 | 2.325 | |||

| 7 min | 3 | 62.998 | 3.420 | |||

| 9 min | 3 | 46.078 | 1.229 | |||

| 5 MPa | 3 | 43.496 | 2.077 | 50.731 | 1.317 × 10−6 | 3.478 |

| 6 MPa | 3 | 36.786 | 3.789 | |||

| 7 MPa | 3 | 39.940 | 1.961 | |||

| 8 MPa | 3 | 52.597 | 0.825 | |||

| 9 MPa | 3 | 40.731 | 2.070 |

| Group | Number | Average/MPa | Variance | F | p-Value | F-Crit |

|---|---|---|---|---|---|---|

| 120 °C | 3 | 539.777 | 178.939 | 47.028 | 1.883 × 10−6 | 3.478 |

| 125 °C | 3 | 551.403 | 520.797 | |||

| 130 °C | 3 | 595.430 | 64.203 | |||

| 135 °C | 3 | 585.039 | 221.563 | |||

| 140 °C | 3 | 424.063 | 503.129 | |||

| 1 min | 3 | 595.430 | 64.203 | 8.562 | 0.00287 | 3.478 |

| 3 min | 3 | 586.393 | 39.714 | |||

| 5 min | 3 | 621.312 | 302.242 | |||

| 7 min | 3 | 643.301 | 317.986 | |||

| 9 min | 3 | 592.459 | 278.659 | |||

| 5 MPa | 3 | 599.224 | 174.976 | 39.251 | 4.388 × 10−6 | 3.478 |

| 6 MPa | 3 | 617.171 | 14.732 | |||

| 7 MPa | 3 | 595.430 | 64.203 | |||

| 8 MPa | 3 | 596.127 | 52.817 | |||

| 9 MPa | 3 | 674.554 | 125.879 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Zhang, X.; Gu, T.; Zhang, F.; Niu, Y.; Liu, S. Effect of Hot-Pressing Process on Mechanical Properties of UHMWPE Fiber Non-Woven Fabrics. Materials 2024, 17, 2611. https://doi.org/10.3390/ma17112611

Huang J, Zhang X, Gu T, Zhang F, Niu Y, Liu S. Effect of Hot-Pressing Process on Mechanical Properties of UHMWPE Fiber Non-Woven Fabrics. Materials. 2024; 17(11):2611. https://doi.org/10.3390/ma17112611

Chicago/Turabian StyleHuang, Jiaxiang, Xiaoping Zhang, Tianyi Gu, Fubao Zhang, Yanfeng Niu, and Susu Liu. 2024. "Effect of Hot-Pressing Process on Mechanical Properties of UHMWPE Fiber Non-Woven Fabrics" Materials 17, no. 11: 2611. https://doi.org/10.3390/ma17112611