Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures

Abstract

1. Introduction

2. Experimental Investigations

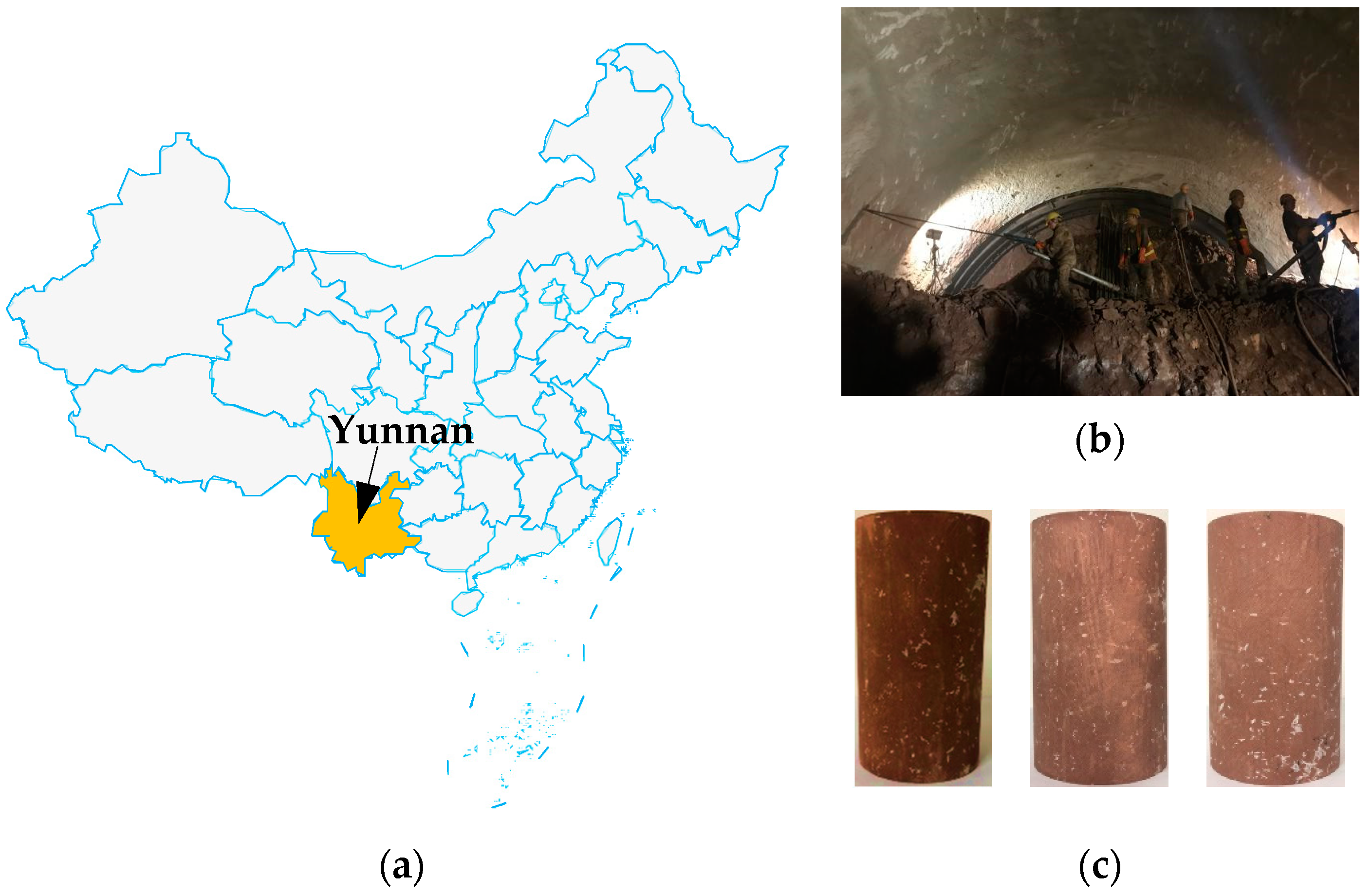

2.1. Description of Specimen

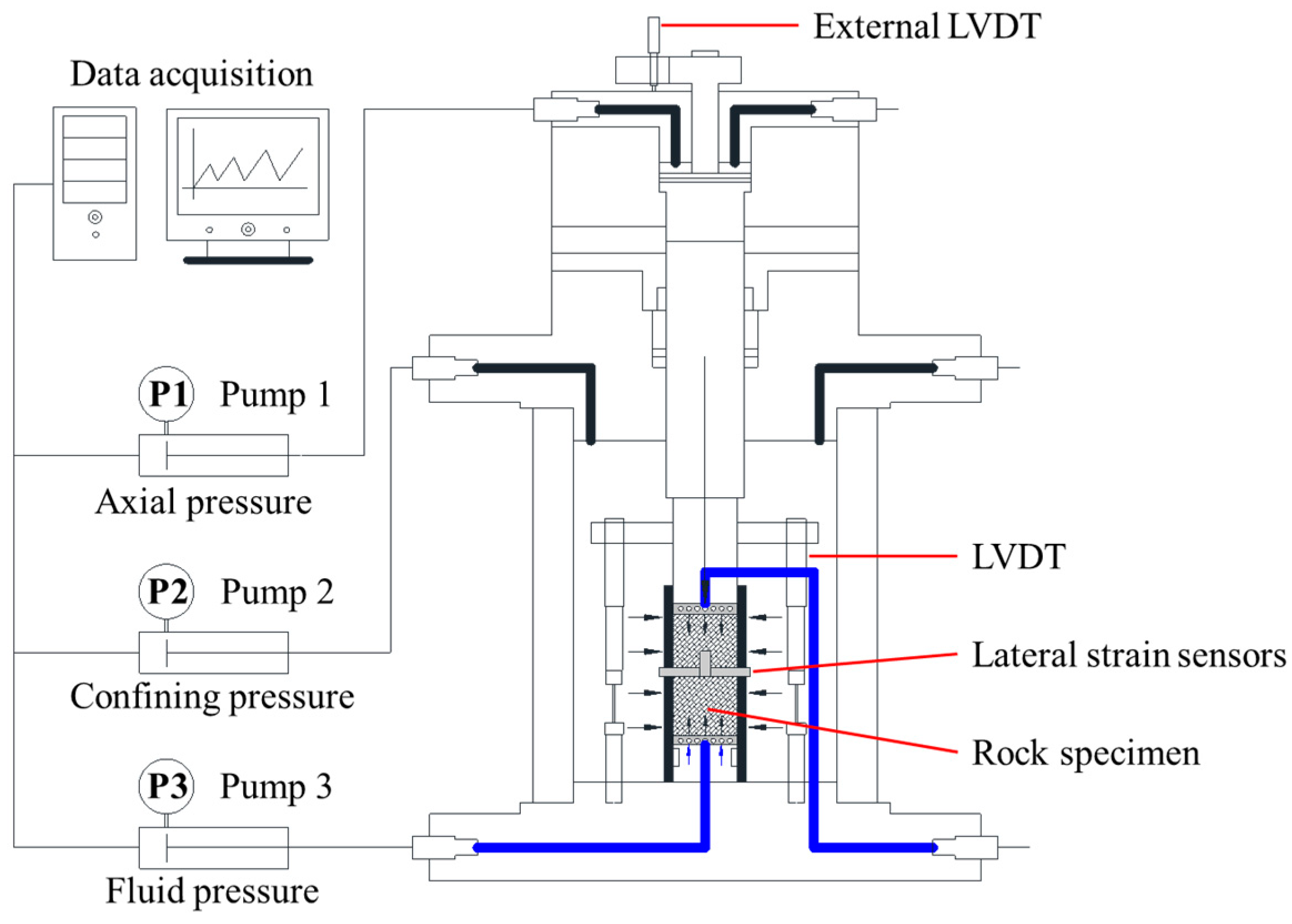

2.2. Test Apparatus and Methods

- Triaxial compression tests without fluid pressure: Natural calcareous mudstone specimens underwent triaxial compression tests at confining pressures of 2, 4, and 6 MPa. First, a natural calcareous mudstone specimen was installed in a triaxial pressure cell. The sensors were then adjusted, and the confining pressure was subsequently applied at a rate of 0.5 MPa/s to the desired value. Once the confining pressure had reached a stable state, axial loading was applied at a rate of 0.02 mm/min until the specimen failed.

- Triaxial compression tests incorporating fluid pressure: Calcareous mudstone specimens were subjected to triaxial compression tests under a fluid pressure of 1 MPa and confining pressures of 2, 4, and 6 MPa. It was essential to evacuate and saturate the specimen before testing. The procedure followed the aforementioned steps until the confining pressure reached a stable state. Subsequently, fluid pressure was applied at 1 MPa and allowed to stabilize. Thereafter, axial loading was conducted at a rate of 0.02 mm/min until the specimen failed. The permeability of calcareous mudstone was evaluated using a steady-state approach [21].

3. Test Results

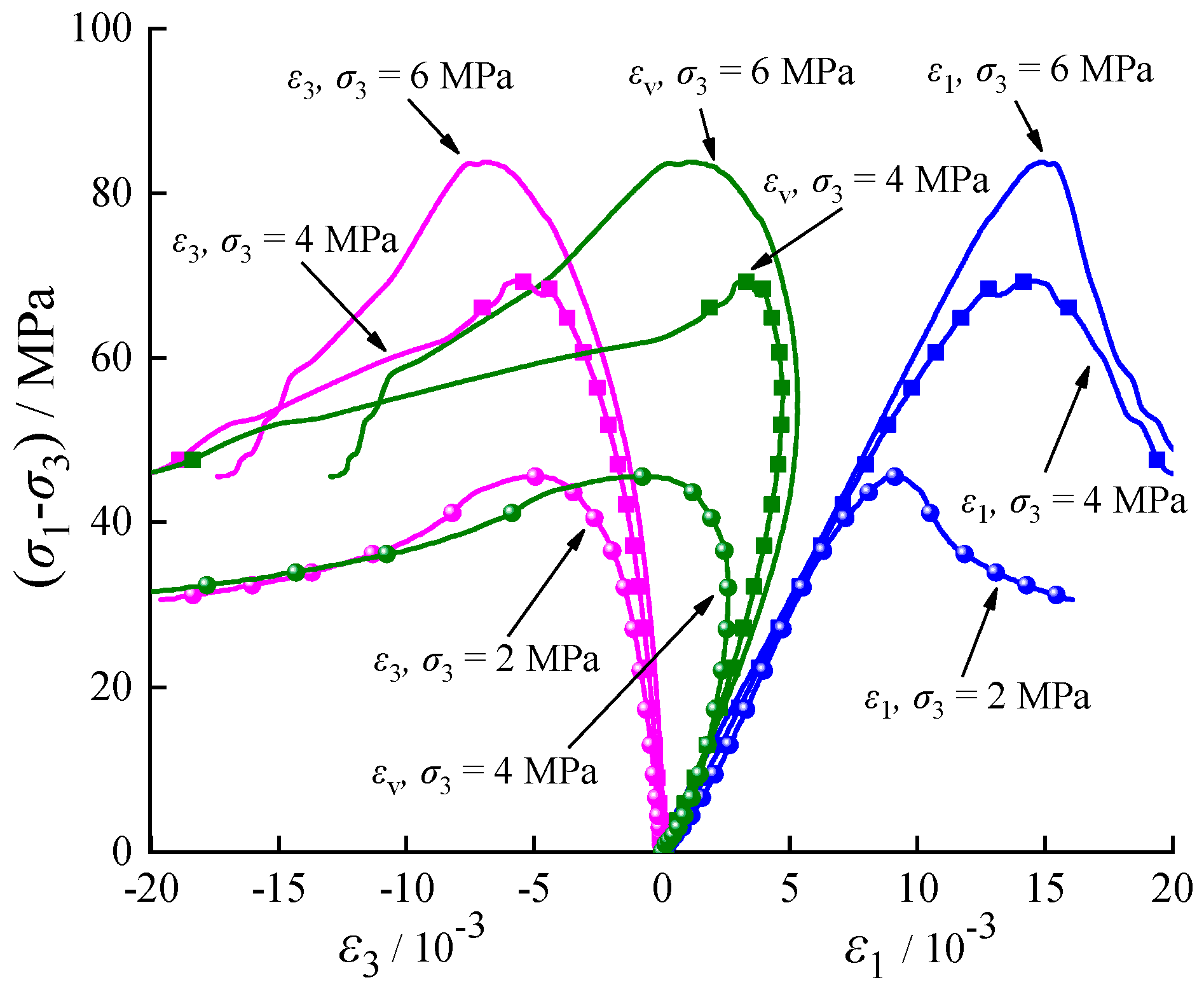

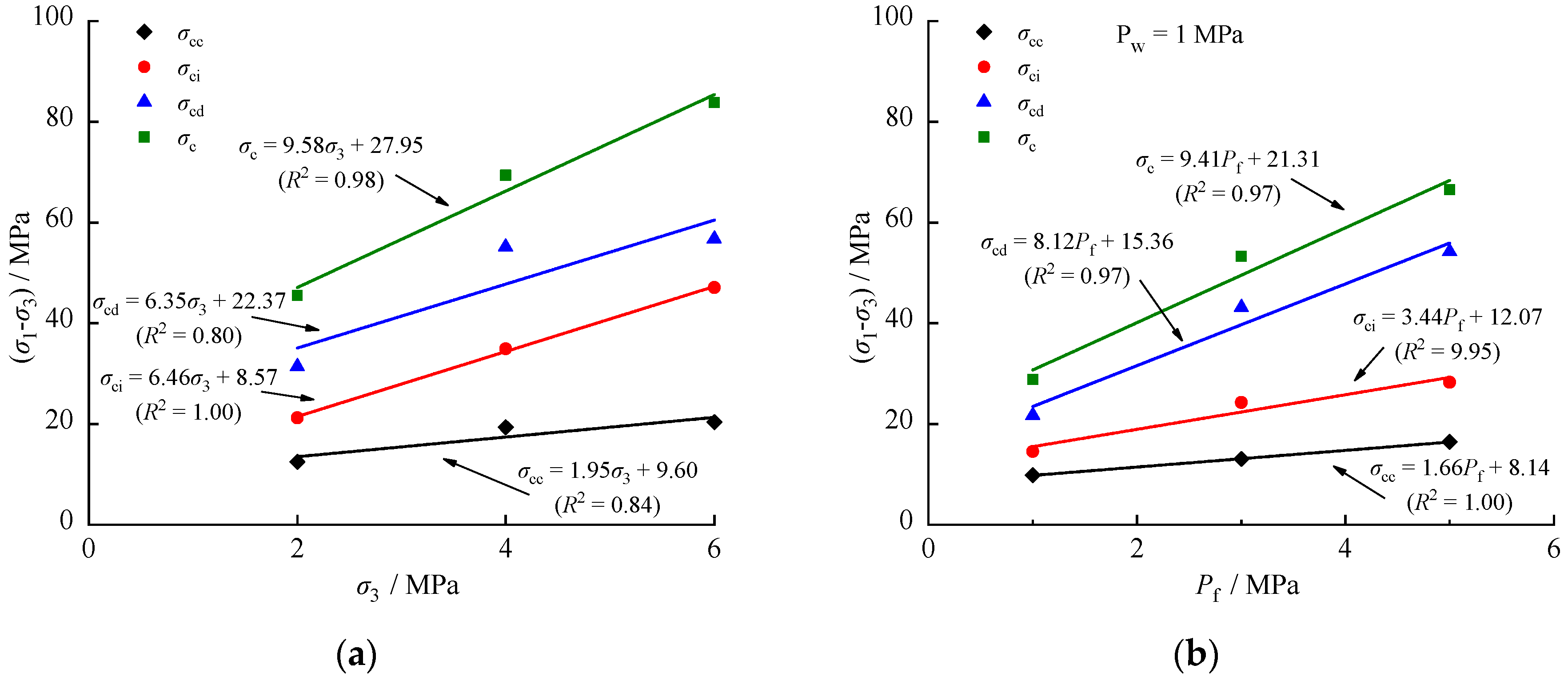

3.1. Stress–Strain Relationships and Crack Propagation Laws

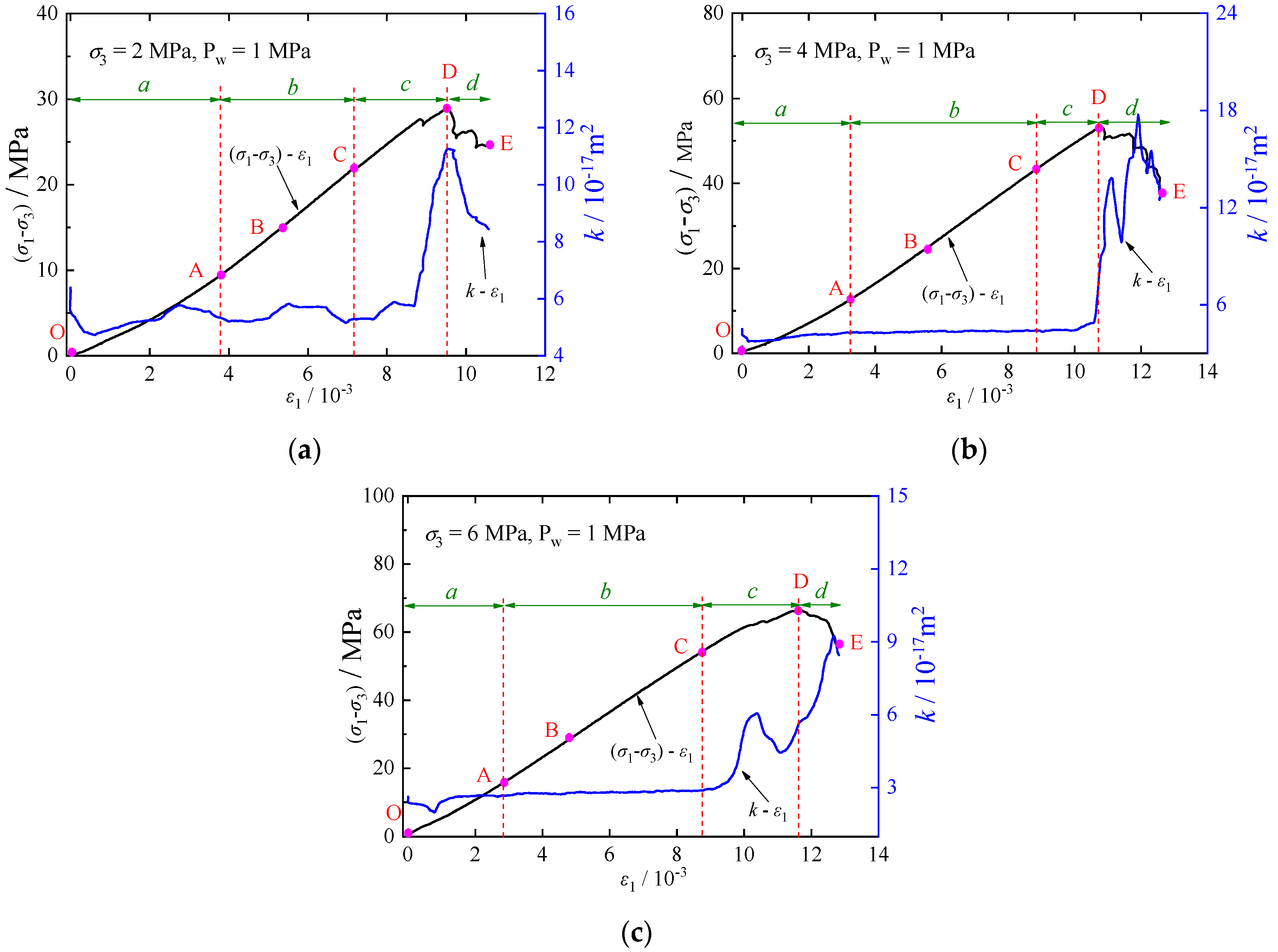

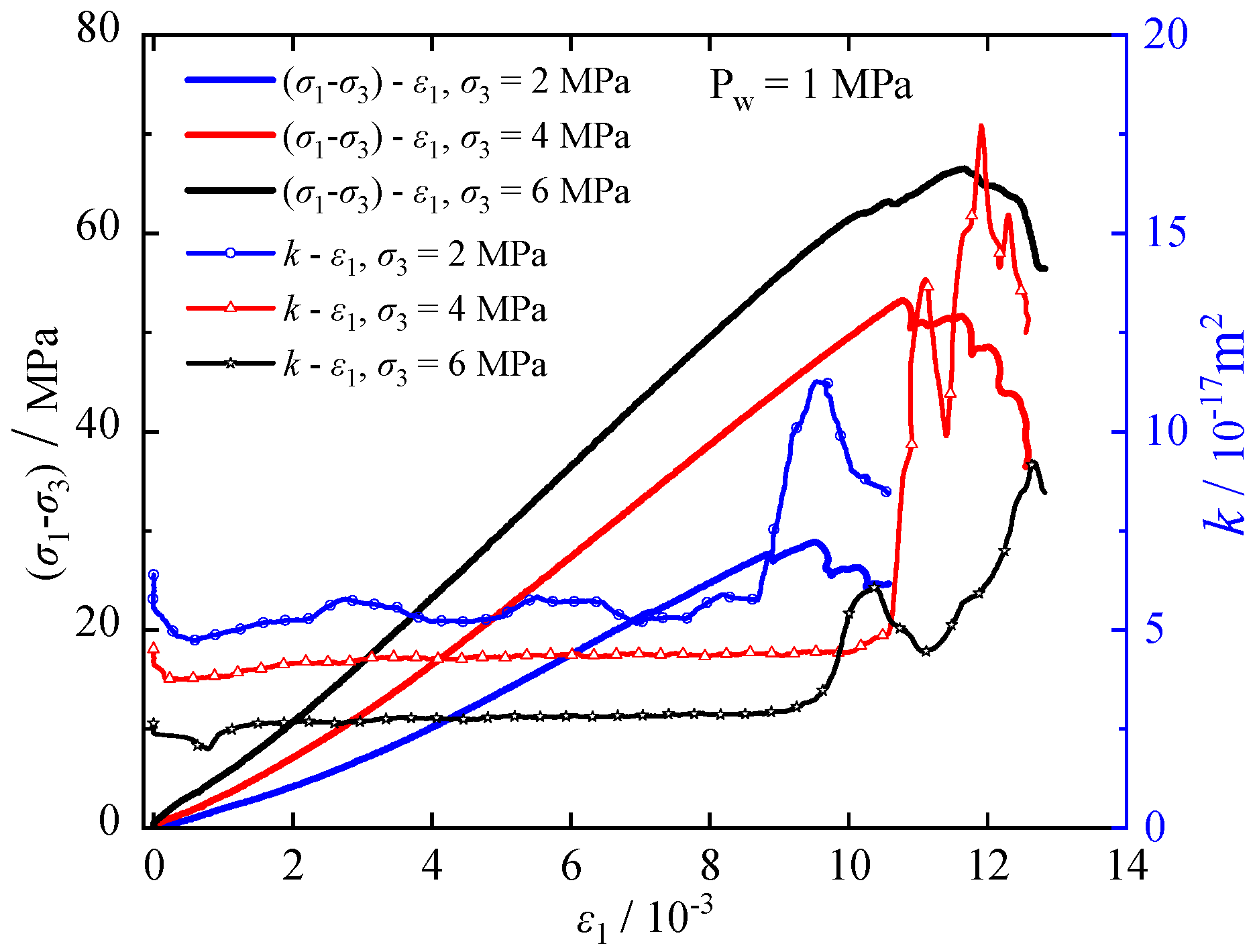

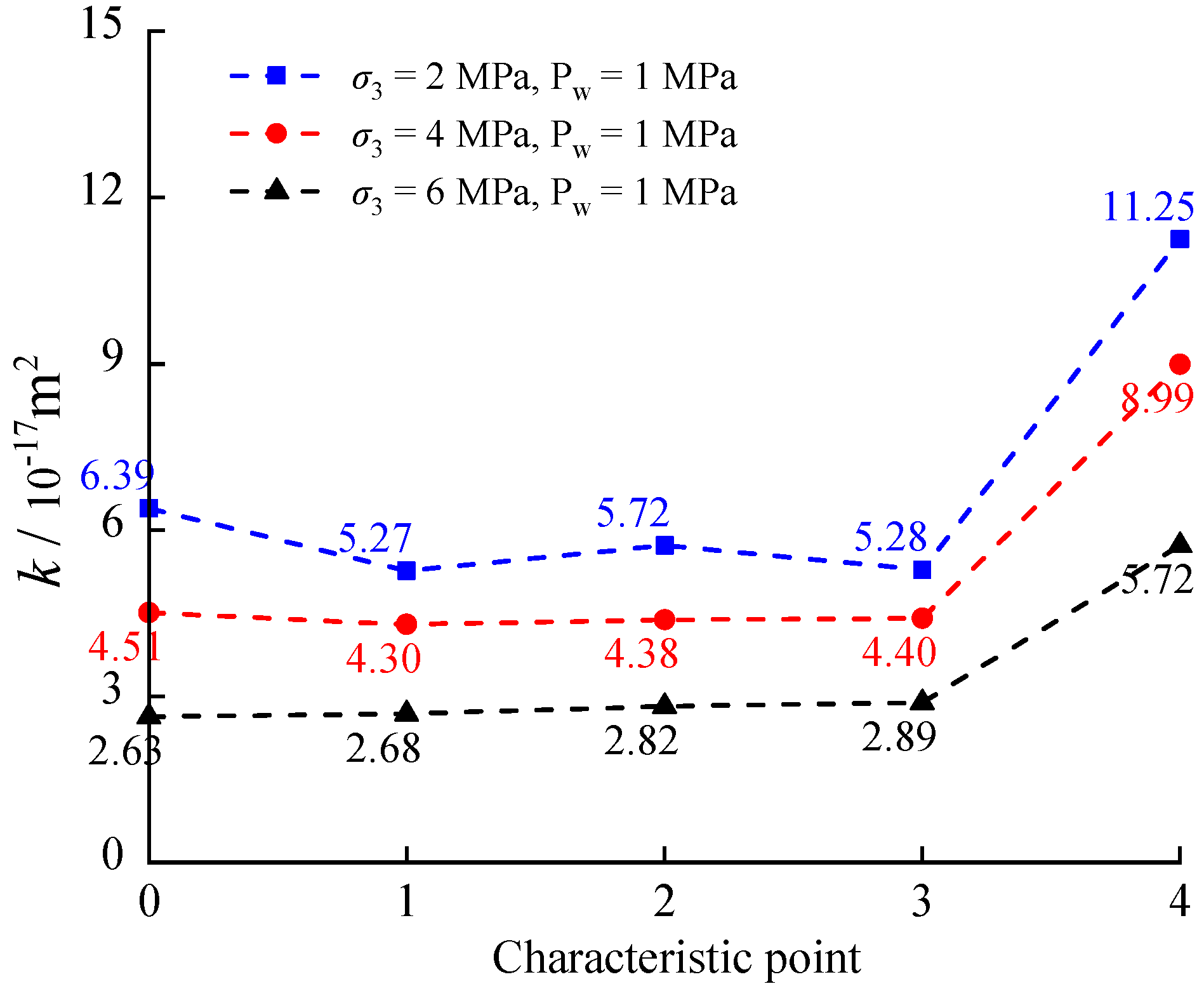

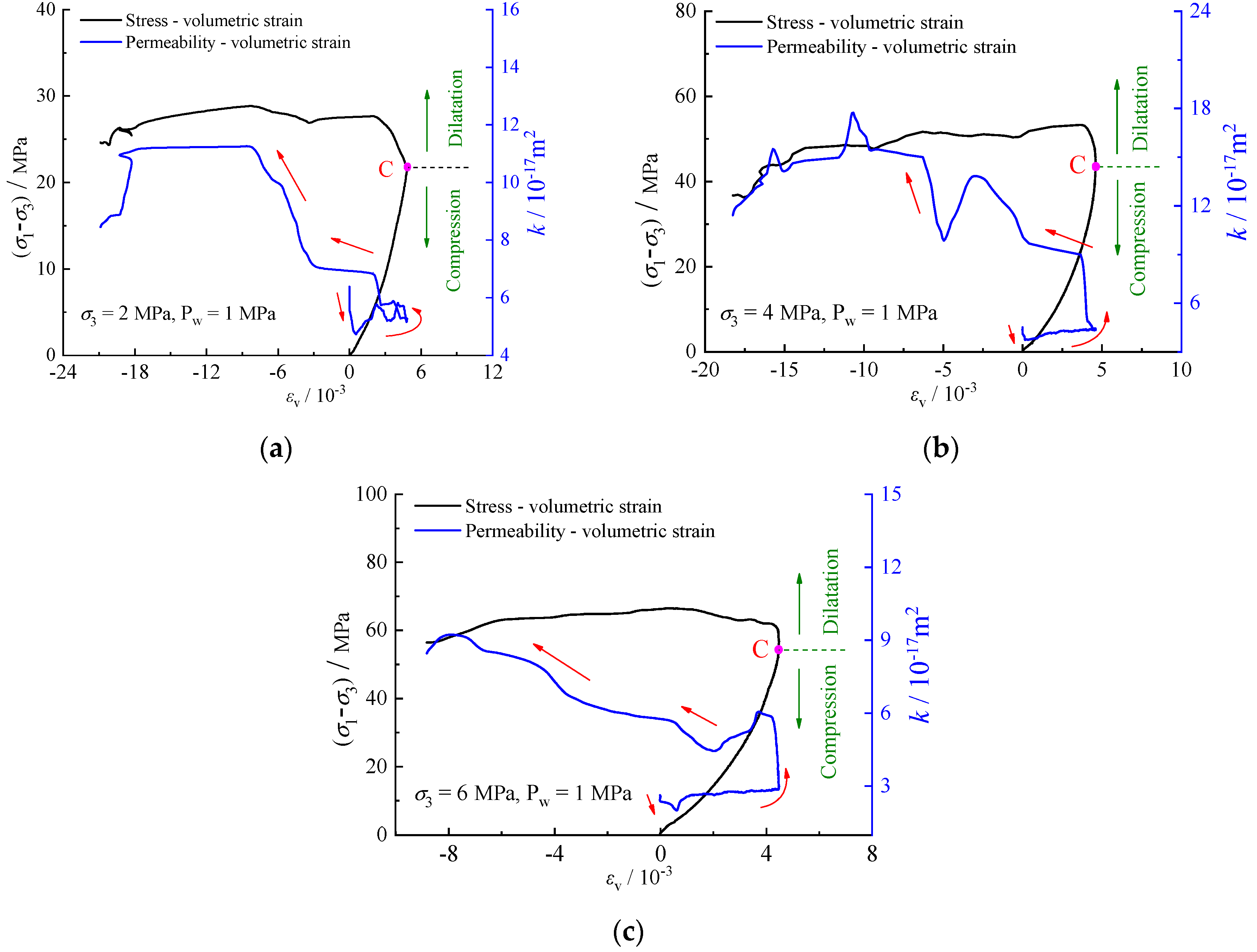

3.2. Permeability Characteristics

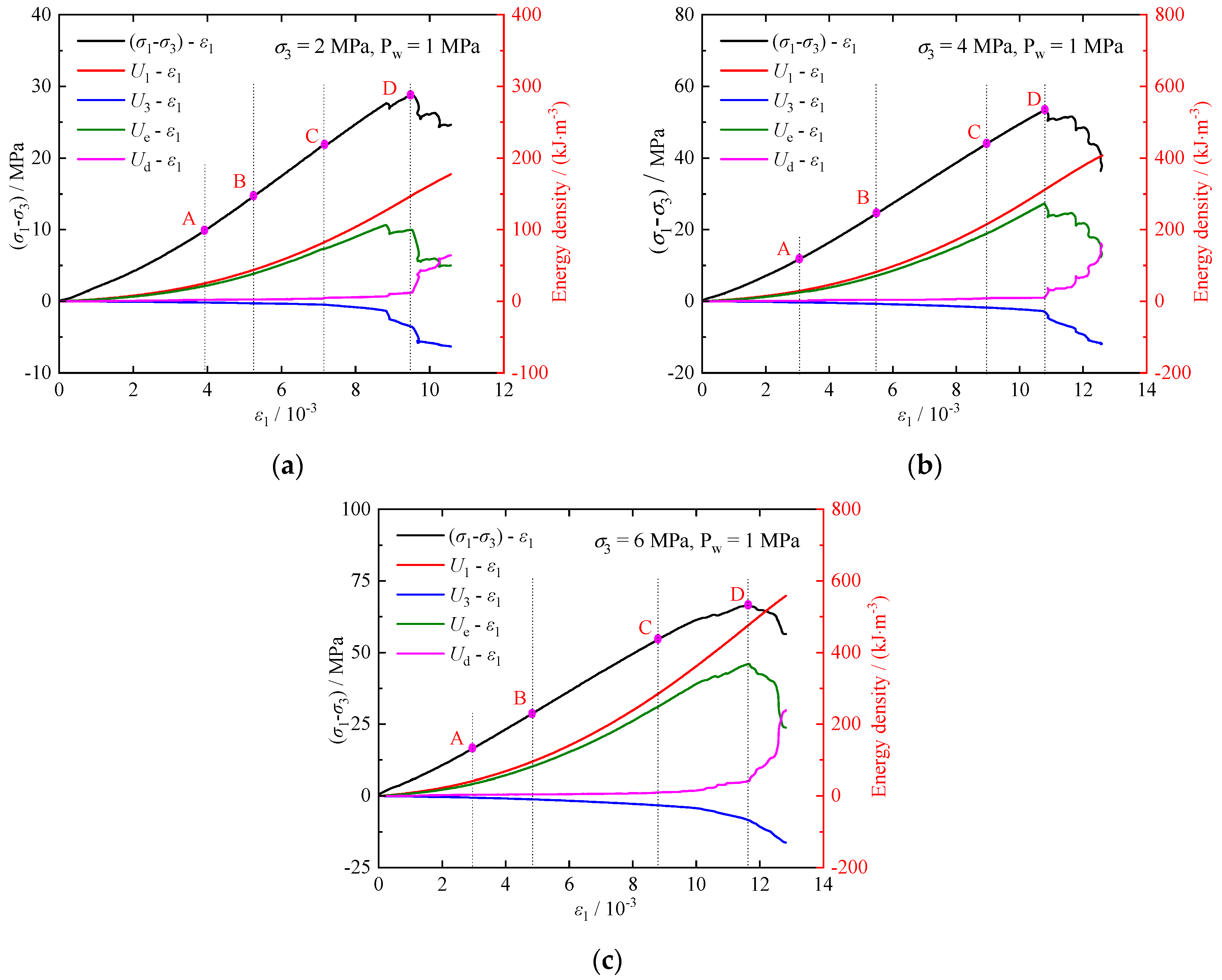

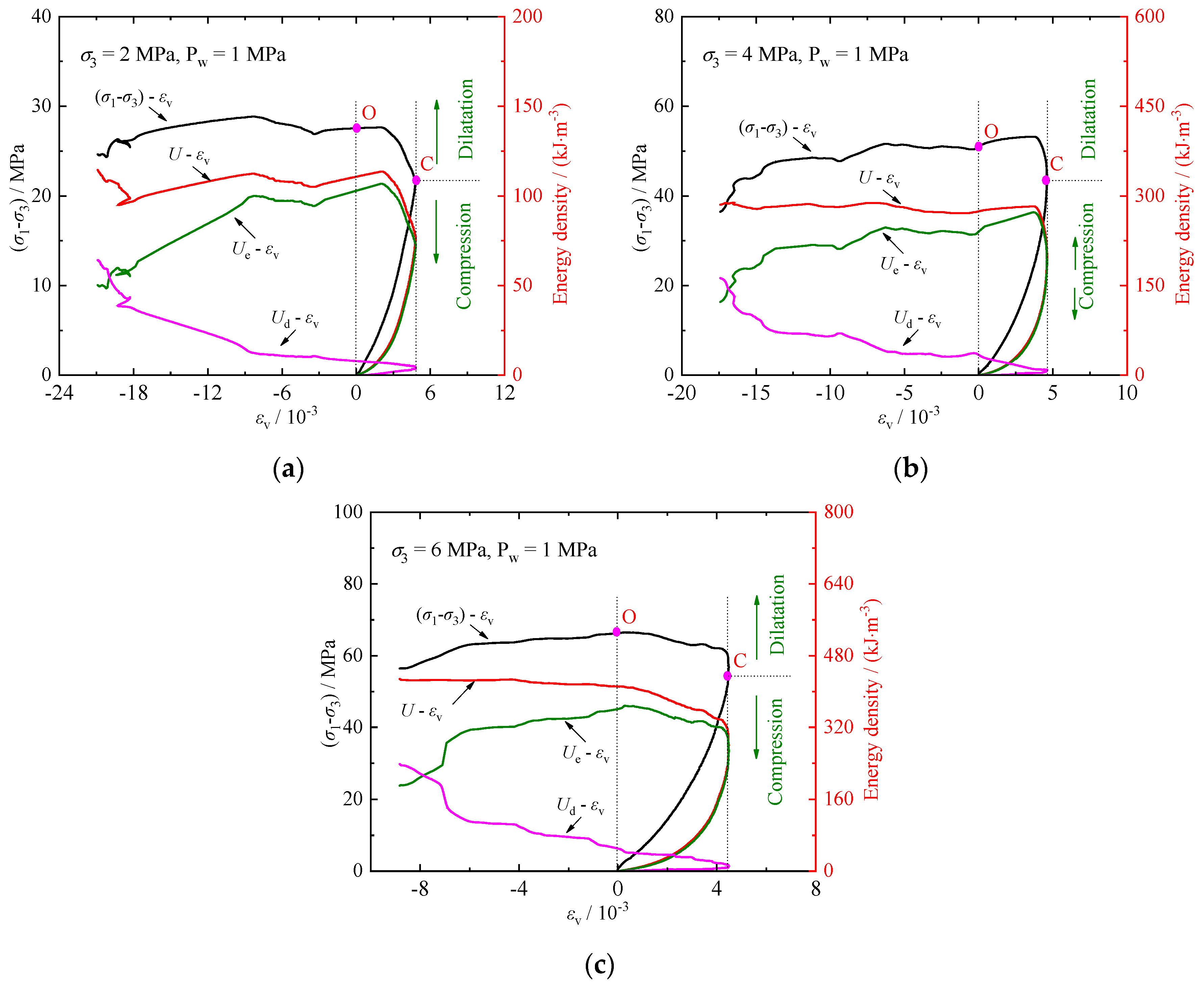

3.3. Mechanism of Energy Evolution

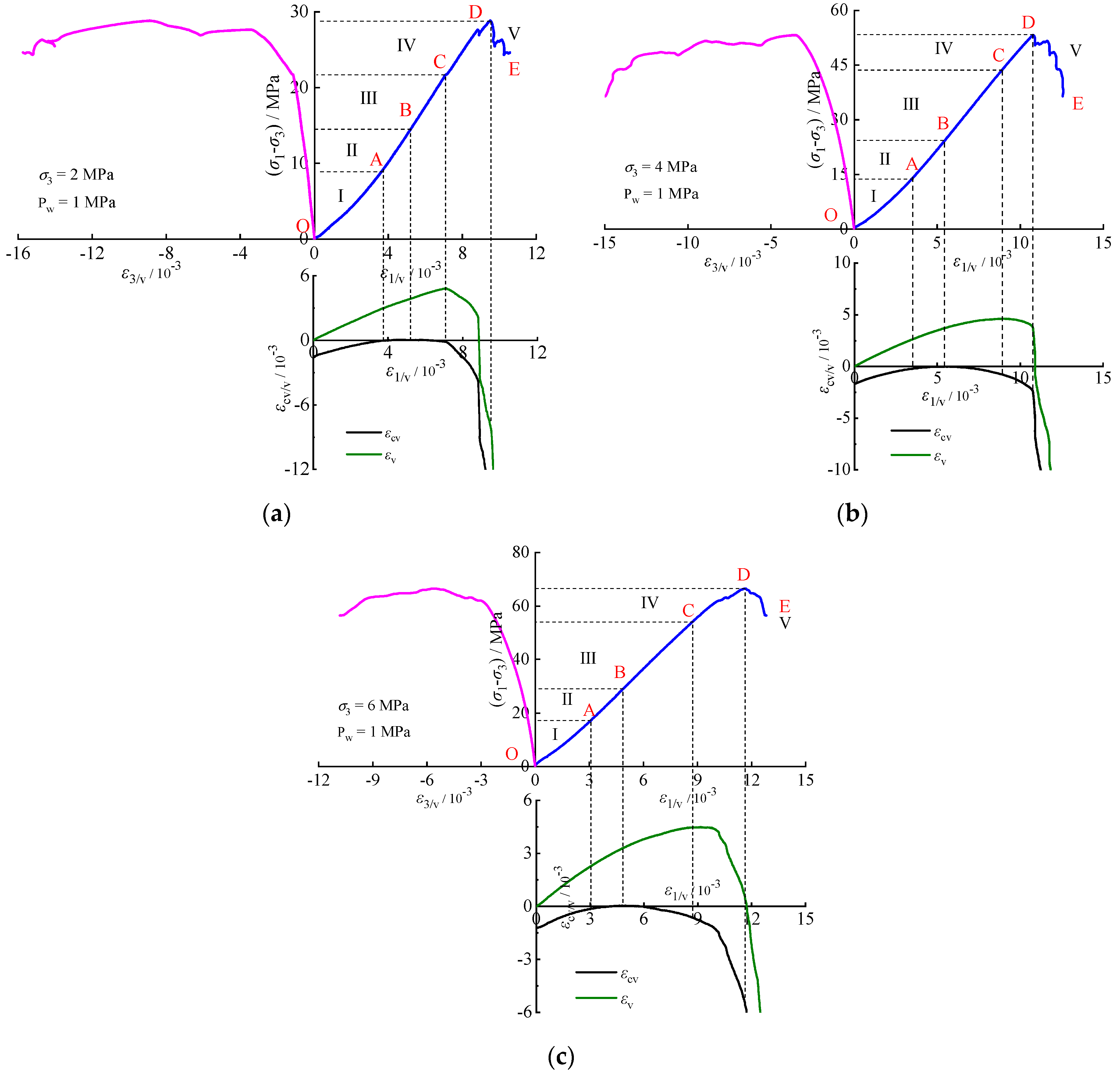

- The crack compression stage (OA): During the initial stage of axial stress loading, most of the deformation is attributed to microcrack compression and closure. The energy density in this stage changes minimally with a slow growth rate, resulting in low energy conversion efficiency. The energy in this phase is predominantly governed by , with the total energy stored as elastic strain energy exceeding the energy dissipated in microcrack closure and grain friction.

- The elastic deformation stage (AB): The microcracks are further compressed and closed, the curves of the and have the same tendency to grow faster, and the changes in the and are very small. The total energy stored during this phase is primarily elastic strain energy.

- The crack stable propagation stage (BC): Microcracks in the rock initiate and propagate, leading to plastic deformation. The rates of and continue to increase rapidly, while the growth rate of and accelerates.

- The crack unstable propagation stage (CD): Cracks extend and develop in the rock unstably, with and continue to increase. However, the rate of increase in decreases. Additionally, as the rate increases, the changes in and become more noticeable, indicating accelerated crack expansion and penetration in the rock, accompanied by increased damage and plastic deformation.

- The post-peak failure stage (DE): Microcracks coalesce and connect to generate a macro-failure plane at the peak stress, leading to rock fails. During this stage, the increase in occurs at a slower rate. There is a reversal of , where stored is converted and released, resulting in sharp changes in and . Most of the energy is dissipated as macro-fractures develop and deform.

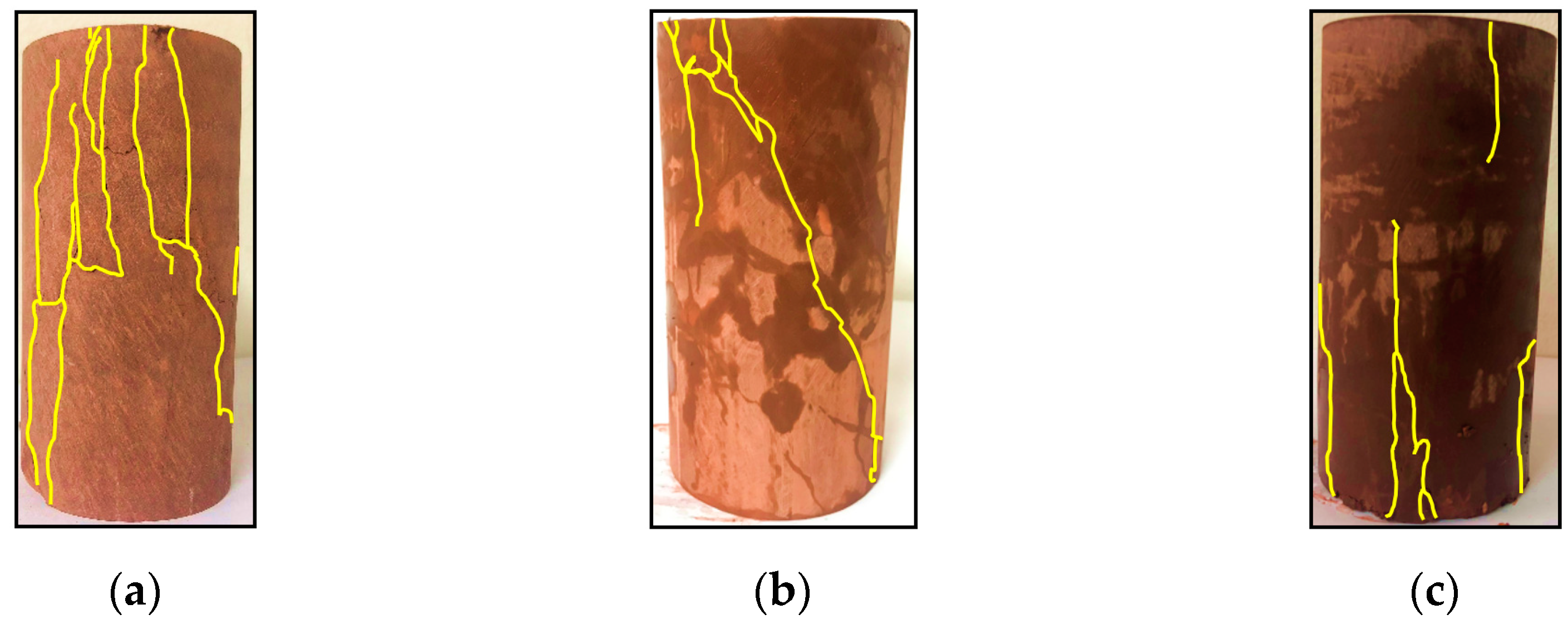

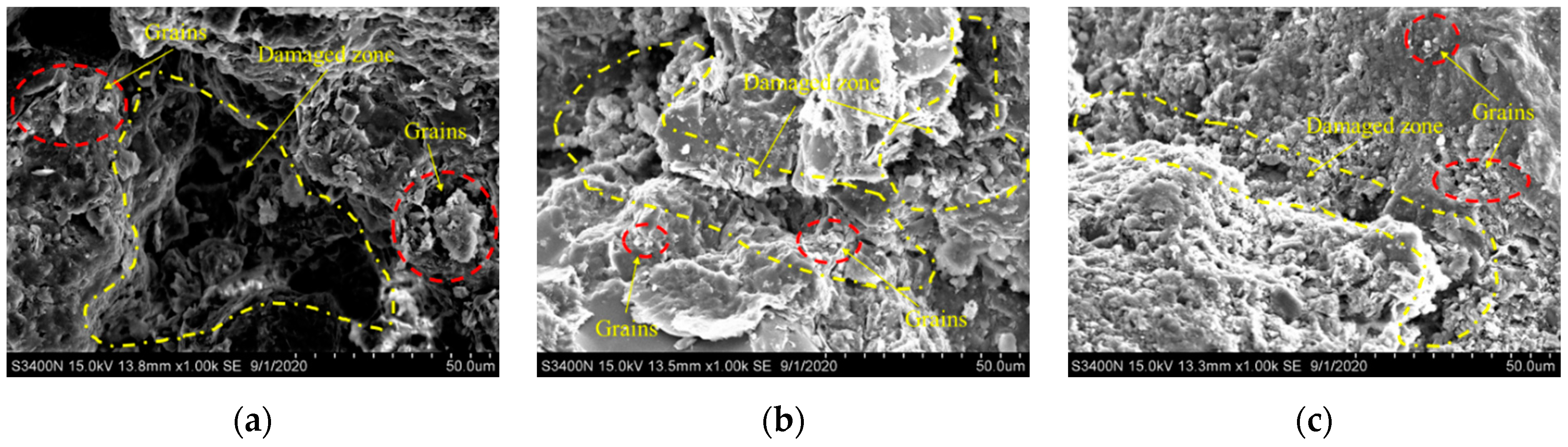

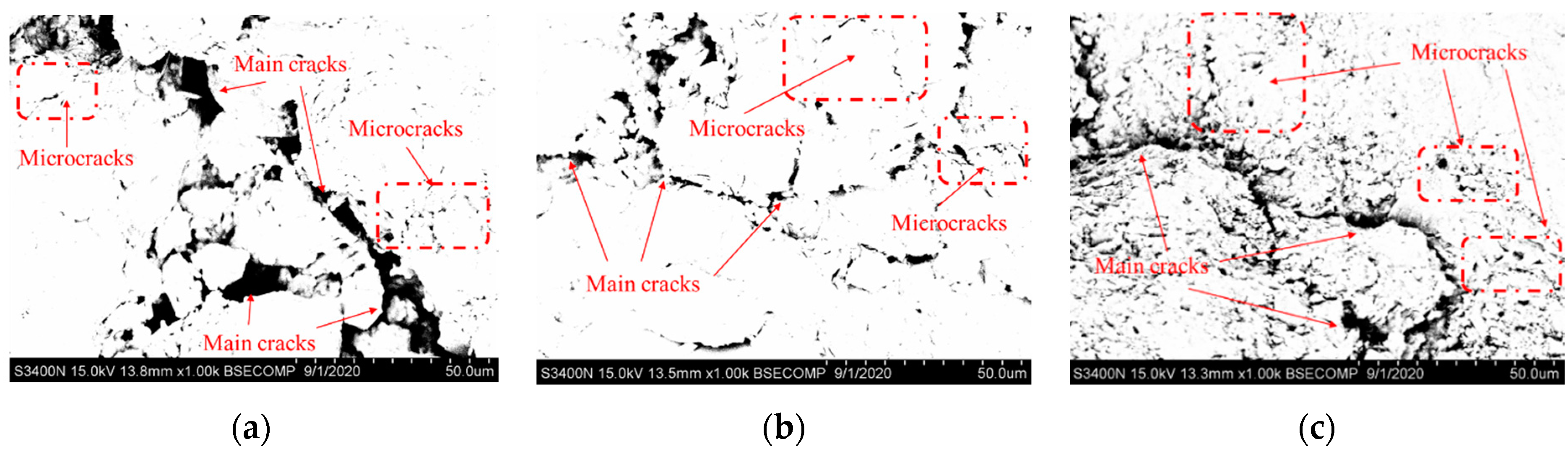

3.4. Failure Characteristics

3.5. Mechanisms Analysis of Deformation Failure, Permeability, and Energy Evolution

4. Conclusions

- The stress–strain relationship of calcareous mudstone under varying confining pressures exhibits five stages based on characteristic stresses. The evolution of cracks effectively illustrates the deformation and failure process of calcareous mudstone. With increasing confining pressure, the characteristic stresses of each stage linearly increase, resulting in enhanced strength and ductility of the rock. For example, the peak stress σc (Pw = 0) increases by 52.35% and 20.85% when the confining pressure σ3 increases from 2 MPa to 4 MPa and 6 MPa, respectively.

- This study explores the hydro-mechanical coupling of water, stress, and rock in the loading of calcareous mudstone. It reveals that fluid pressure weakens the mechanical properties of calcareous mudstone. Specifically, when σ3 = 2 MPa, the values of σcc, σci, σcd, and σc are reduced by 21.60%, 31.37%, 30.70%, and 36.61%, respectively, due to the effect of a fluid pressure of 1 MPa. Additionally, the evolution pattern of permeability in relation to axial/volumetric strain demonstrates significant stage characteristics associated with crack development and characteristic stresses. Permeability decreases with increasing confining pressure.

- The evolution of energy density and stress–strain during loading exhibits similar phase characteristics. The damage stress serves as the turning point of energy dissipation and marks the threshold for delineating stages of the energy density-volumetric strain relationship curve. As an illustrative example, the dissipative energy Ud is considered. The values of Ud at σcc, σcd, and σc for σ3 = 2 MPa are 2.02, 4.09, and 12.39 kJ/m3, respectively. In contrast, the values of Ud at σcc, σcd, and σc for σ3 = 6 MPa are 3.93, 10.31, and 42.51 kJ/m3, respectively. Higher confining pressure correspond to greater energy values at characteristic stresses, necessitating more energy for rock deformation and failure.

- Calcareous mudstone specimens exhibit different macroscopic failure modes due to variations in confining pressure. Furthermore, SEM and BSE tests reveal that with increasing confining pressure, the size and width of cracks diminish, and the mineral grains on crack surfaces reduce in size. These findings serve as a valuable reference for comprehending the microcrack response mechanism of calcareous mudstone to variations in confining pressure under hydro-mechanical coupling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, L.; Xu, W.; Wang, R.; Wang, H.; Xie, W.-C. Mechanical and Permeability Characteristics of Basalt During Unloading Confining Pressure Creep Tests Under Coupled Hydro-Mechanical Conditions. Rock Mech. Rock Eng. 2021, 54, 6091–6103. [Google Scholar] [CrossRef]

- Zhao, J.; Tan, Z.; Wang, X.; Zhou, Z.; Li, G. Engineering Characteristics of Water-Bearing Weakly Cemented Sandstone and Dewatering Technology in Tunnel Excavation. Tunn. Undergr. Space Technol. 2022, 121, 104316. [Google Scholar] [CrossRef]

- Gao, R.; Wu, F.; Chen, J.; Zhu, C.; Ji, C. Study on Creep Characteristics and Constitutive Model of Typical Argillaceous Salt Rock in Energy Storage Caverns in China. J. Energy Storage 2022, 50, 104248. [Google Scholar] [CrossRef]

- Lu, C.; Yu, H.; Li, H.; Chen, W. Experimental Study on the Physico-Mechanical Properties of Tamusu Mudstone—A Potential Host Rock for High-Level Radioactive Waste in Inner Mongolia of China. J. Rock Mech. Geotech. Eng. 2022, 14, 1901–1909. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Heiland, J. Laboratory Testing of Coupled Hydro-Mechanical Processes during Rock Deformation. Hydrogeol. J. 2003, 11, 122–141. [Google Scholar] [CrossRef]

- Martin, C.; Chandler, N. The Progressive Fracture of Lac Du Bonnet Granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.; Tasaka, Y.; Maejima, T.; Morioka, H.; Minami, M. Generalized Crack Initiation and Crack Damage Stress Thresholds of Brittle Rock Masses near Underground Excavations. Int. J. Rock Mech. Min. Sci. 2004, 41, 833–847. [Google Scholar] [CrossRef]

- Martin, C.D.; Christiansson, R. Estimating the Potential for Spalling around a Deep Nuclear Waste Repository in Crystalline Rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 219–228. [Google Scholar] [CrossRef]

- Everitt, R.A.; Lajtai, E.Z. The Influence of Rock Fabric on Excavation Damage in the Lac Du Bonnett Granite. Int. J. Rock Mech. Min. Sci. 2004, 41, 1277–1303. [Google Scholar] [CrossRef]

- Zong, Y.; Han, L.; Wei, J.; Wen, S. Mechanical and Damage Evolution Properties of Sandstone under Triaxial Compression. Int. J. Min. Sci. Technol. 2016, 26, 601–607. [Google Scholar] [CrossRef]

- Katz, O.; Reches, Z. Microfracturing, Damage, and Failure of Brittle Granites. J. Geophys. Res. Solid Earth 2004, 109, B01206. [Google Scholar] [CrossRef]

- Diederichs, M.S. The 2003 Canadian Geotechnical Colloquium: Mechanistic Interpretation and Practical Application of Damage and Spalling Prediction Criteria for Deep Tunnelling. Can. Geotech. J. 2007, 44, 1082–1116. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B. Quantifying Progressive Pre-Peak Brittle Fracture Damage in Rock during Uniaxial Compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 361–380. [Google Scholar] [CrossRef]

- Xue, L.; Qin, S.; Sun, Q.; Wang, Y.; Lee, L.M.; Li, W. A Study on Crack Damage Stress Thresholds of Different Rock Types Based on Uniaxial Compression Tests. Rock Mech. Rock Eng. 2014, 47, 1183–1195. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B.; Read, R. Identifying Crack Initiation and Propagation Thresholds in Brittle Rock. Can. Geotech. J. 1998, 35, 222–233. [Google Scholar] [CrossRef]

- Yao, Q.; Chen, T.; Ju, M.; Liang, S.; Liu, Y.; Li, X. Effects of Water Intrusion on Mechanical Properties of and Crack Propagation in Coal. Rock Mech. Rock Eng. 2016, 49, 4699–4709. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Tang, C.; Li, H.; Wang, S. Experimental and Numerical Investigation of Permeability Evolution with Damage of Sandstone under Triaxial Compression. Rock Mech. Rock Eng. 2017, 50, 1529–1549. [Google Scholar] [CrossRef]

- Lu, J.; Yin, G.; Deng, B.; Zhang, W.; Li, M.; Chai, X.; Liu, C.; Liu, Y. Permeability Characteristics of Layered Composite Coal-Rock under True Triaxial Stress Conditions. J. Nat. Gas Sci. Eng. 2019, 66, 60–76. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Pei, J.; Xu, H.; Bian, Y. Mechanical and Permeability Characteristics of Rock under Hydro-Mechanical Coupling Conditions. Environ. Earth Sci. 2015, 73, 5987–5996. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W.; Jia, C.; Cai, M.; Meng, Q. Experimental Research on Permeability Evolution with Microcrack Development in Sandstone under Different Fluid Pressures. J. Geotech. Geoenviron. Eng. 2016, 142, 04016014. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Z.; Zhong, N.; Connell, L.D.; Down, D.I.; Lin, W.; Zhang, Y. Experimental Study of Anisotropic Gas Permeability and Its Relationship with Fracture Structure of Longmaxi Shales, Sichuan Basin, China. Fuel 2016, 180, 106–115. [Google Scholar] [CrossRef]

- Yang, F.; Wang, G.; Hu, D.; Zhou, H.; Tan, X. Influence of Water-Rock Interaction on Permeability and Heat Conductivity of Granite under High Temperature and Pressure Conditions. Geothermics 2022, 100, 102347. [Google Scholar] [CrossRef]

- Yu, J.; Xu, W.; Jia, C.; Wang, R.; Wang, H. Experimental Measurement of Permeability Evolution in Sandstone during Hydrostatic Compaction and Triaxial Deformation. Bull. Eng. Geol. Environ. 2019, 78, 5269–5280. [Google Scholar] [CrossRef]

- Wang, H.; Chu, W.; He, M. Anisotropic Permeability Evolution Model of Rock in the Process of Deformation and Failure. J. Hydrodyn. 2012, 24, 25–31. [Google Scholar] [CrossRef]

- Zou, L.; Tarasov, B.G.; Dyskin, A.V.; Adhikary, D.P.; Pasternak, E.; Xu, W. Physical Modelling of Stress-Dependent Permeability in Fractured Rocks. Rock Mech. Rock Eng. 2013, 46, 67–81. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W. Permeability Evolution Laws and Equations during the Course of Deformation and Failure of Brittle Rock. J. Eng. Mech. 2013, 139, 1621–1626. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Shao, S.S. Energy Monitoring and Analysis during Deformation of Bedded-Sandstone: Use of Acoustic Emission. Ultrasonics 2014, 54, 217–226. [Google Scholar] [CrossRef]

- Chen, Z.; He, C.; Wu, D.; Xu, G.; Yang, W. Fracture Evolution and Energy Mechanism of Deep-Buried Carbonaceous Slate. Acta Geotech. 2017, 12, 1243–1260. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, W.H.; Liu, D.Q.; Hou, Z.Q.; Li, C.H. On Anisotropic Fracture Evolution and Energy Mechanism During Marble Failure Under Uniaxial Deformation. Rock Mech. Rock Eng. 2019, 52, 3567–3583. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.-T.; Yang, C.; Han, Q.; Wang, Z.; Kong, R. Evaluation Method of Rock Brittleness under True Triaxial Stress States Based on Pre-Peak Deformation Characteristic and Post-Peak Energy Evolution. Rock Mech. Rock Eng. 2021, 54, 1277–1291. [Google Scholar] [CrossRef]

- Zhou, H.W.; Wang, Z.H.; Wang, C.S.; Liu, J.F. On Acoustic Emission and Post-Peak Energy Evolution in Beishan Granite Under Cyclic Loading. Rock Mech. Rock Eng. 2019, 52, 283–288. [Google Scholar] [CrossRef]

- Peng, R.; Ju, Y.; Wang, J.G.; Xie, H.; Gao, F.; Mao, L. Energy Dissipation and Release During Coal Failure Under Conventional Triaxial Compression. Rock Mech. Rock Eng. 2015, 48, 509–526. [Google Scholar] [CrossRef]

- Zhang, J.; Du, R.; Chen, Y.; Huang, Z. Experimental Investigation of the Mechanical Properties and Energy Evolution of Layered Phyllite Under Uniaxial Multilevel Cyclic Loading. Rock Mech. Rock Eng. 2023, 56, 4153–4168. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, M.; Han, L.; Pu, H.; Nie, T. Effects of Acoustic Emission and Energy Evolution of Rock Specimens Under the Uniaxial Cyclic Loading and Unloading Compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, H.; Zhang, R.; Zhang, Z.; Gao, M.; Jia, Z.; Xie, J. Deformation Damage and Energy Evolution Characteristics of Coal at Different Depths. Rock Mech. Rock Eng. 2019, 52, 1491–1503. [Google Scholar] [CrossRef]

- Chen, Z.; He, C.; Ma, G.; Xu, G.; Ma, C. Energy Damage Evolution Mechanism of Rock and Its Application to Brittleness Evaluation. Rock Mech. Rock Eng. 2019, 52, 1265–1274. [Google Scholar] [CrossRef]

- Xia, B.; Li, Y.; Hu, H.; Luo, Y.; Peng, J. Effect of Crack Angle on Mechanical Behaviors and Damage Evolution Characteristics of Sandstone Under Uniaxial Compression. Rock Mech. Rock Eng. 2022, 55, 6567–6582. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W.; Shao, J.-F. Experimental Researches on Hydro-Mechanical Properties of Altered Rock under Confining Pressures. Rock Mech. Rock Eng. 2014, 47, 485–493. [Google Scholar] [CrossRef]

- Wang, H.; Xu, W.; Lui, Z.; Chao, Z.; Meng, Q. Dependency of Hydromechanical Properties of Monzonitic Granite on Confining Pressure and Fluid Pressure under Compression. Int. J. Mod. Phys. B 2016, 30, 1650086. [Google Scholar] [CrossRef]

- Fairhurst, C.E.; Hudson, J.A. Draft ISRM Suggested Method for the Complete Stress-Strain Curve for Intact Rock in Uniaxial Compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 279–289. [Google Scholar]

- Mogi, K. Fracture and Flow of Rocks under High Triaxial Compression. J. Geophys. Res. 1971, 76, 1255–1269. [Google Scholar] [CrossRef]

- Yu, M.; Liu, B.; Liu, K.; Sun, J.; Deng, T.; Wang, Q. Creep Behavior of Carbonaceous Mudstone under Triaxial Hydraulic Coupling Condition and Constitutive Modelling. Int. J. Rock Mech. Min. Sci. 2023, 164, 105357. [Google Scholar] [CrossRef]

- Huang, K.; Yu, F.; Zhang, W.; Tong, K.; Guo, J.; Li, S.; Chen, S.; Dai, Z. Relationship between Capillary Water Absorption Mechanism and Pore Structure and Microfracture of Red-Layer Mudstone in Central Sichuan. Bull. Eng. Geol. Env. 2023, 82, 100. [Google Scholar] [CrossRef]

- Huang, K.; Yu, F.; Zhang, W.; Tong, K.; Li, S.; Guo, J.; Chen, S.; Dai, Z. Experimental and Numerical Simulation Study on the Influence of Gaseous Water on the Mechanical Properties of Red-Layer Mudstone in Central Sichuan. Rock Mech. Rock Eng. 2023, 56, 3159–3178. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.; Zheng, H.; Zheng, Y.; Wang, G. Microfracture Behavior and Energy Evolution of Heterogeneous Mudstone Subjected to Moisture Diffusion. Comput. Geotech. 2022, 150, 104918. [Google Scholar] [CrossRef]

| Sample No. | Confining Pressure (MPa) | Fluid Pressure (MPa) | Crack Damage Stress (MPa) | Peak Stress (MPa) | Peak Axial Strain (×10−3) |

|---|---|---|---|---|---|

| DZ-1 | 2 | / | 31.38 | 45.53 | 8.91 |

| DZ-2 | 4 | / | 55.17 | 69.38 | 14.23 |

| DZ-3 | 6 | / | 55.34 | 83.84 | 14.93 |

| DZ-4 | 2 | 1 | 21.75 | 28.87 | 9.52 |

| DZ-5 | 4 | 1 | 43.10 | 53.26 | 10.78 |

| DZ-6 | 6 | 1 | 54.21 | 66.51 | 11.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Qu, X.; Yan, L.; Ning, Y. Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures. Materials 2024, 17, 2731. https://doi.org/10.3390/ma17112731

Xu W, Qu X, Yan L, Ning Y. Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures. Materials. 2024; 17(11):2731. https://doi.org/10.3390/ma17112731

Chicago/Turabian StyleXu, Wei, Xiao Qu, Long Yan, and Yu Ning. 2024. "Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures" Materials 17, no. 11: 2731. https://doi.org/10.3390/ma17112731

APA StyleXu, W., Qu, X., Yan, L., & Ning, Y. (2024). Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures. Materials, 17(11), 2731. https://doi.org/10.3390/ma17112731