17-4 PH Steel Parts Obtained through MEX and PBF-LB/M Technologies: Comparison of the Structural Properties

Abstract

1. Introduction

2. Materials and Methods

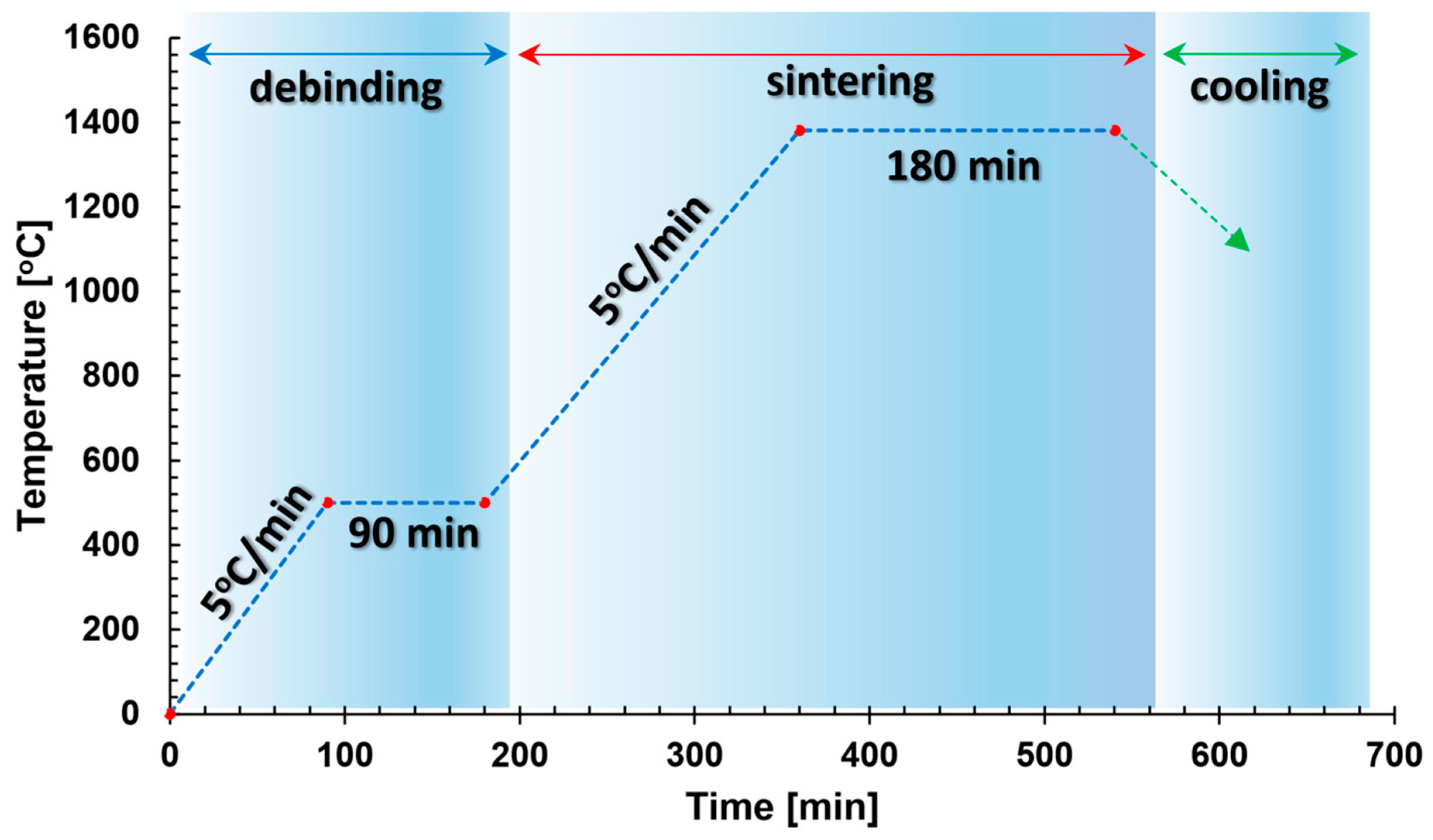

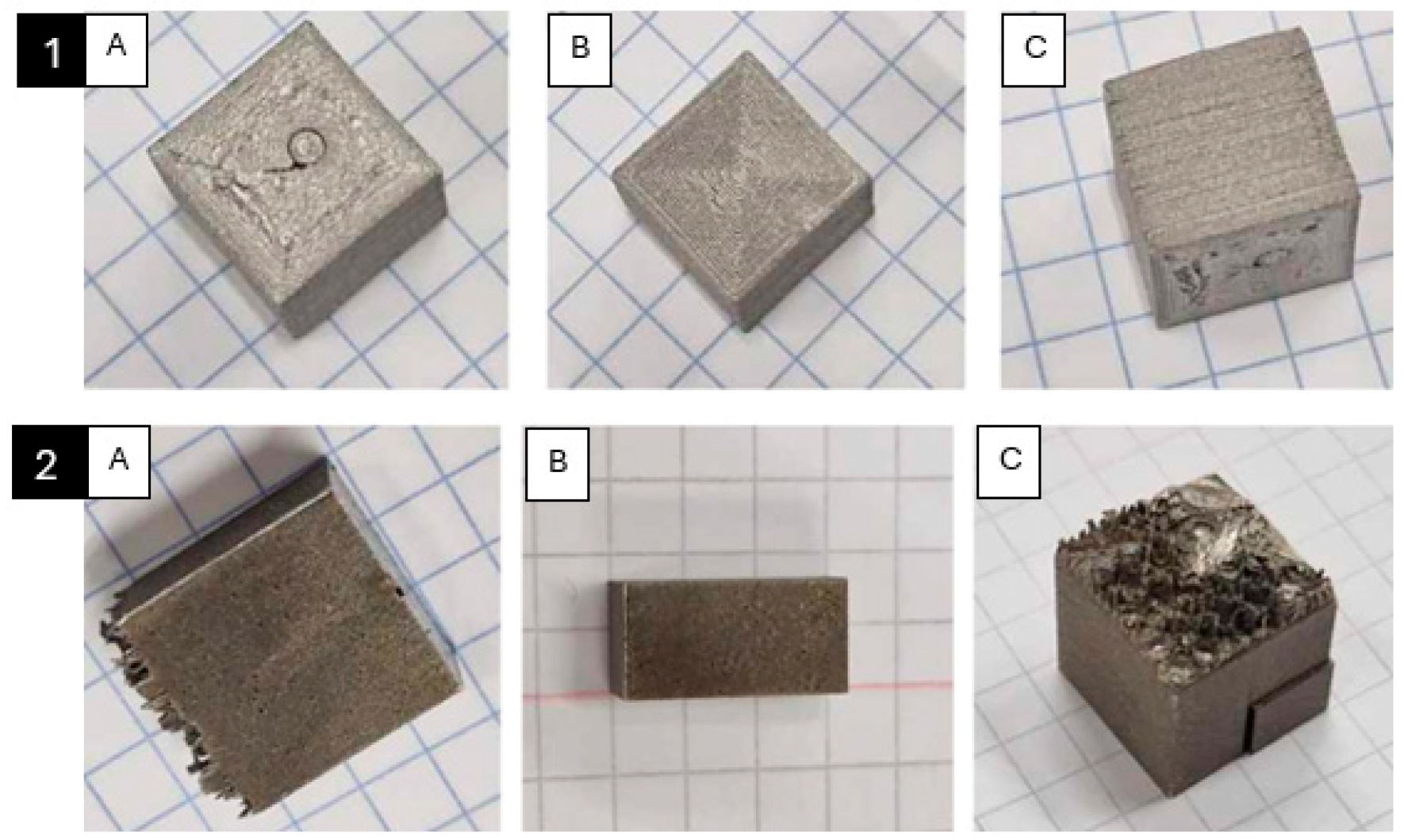

2.1. MEX Manufacturing

2.2. PBF-LB/M Manufacturing

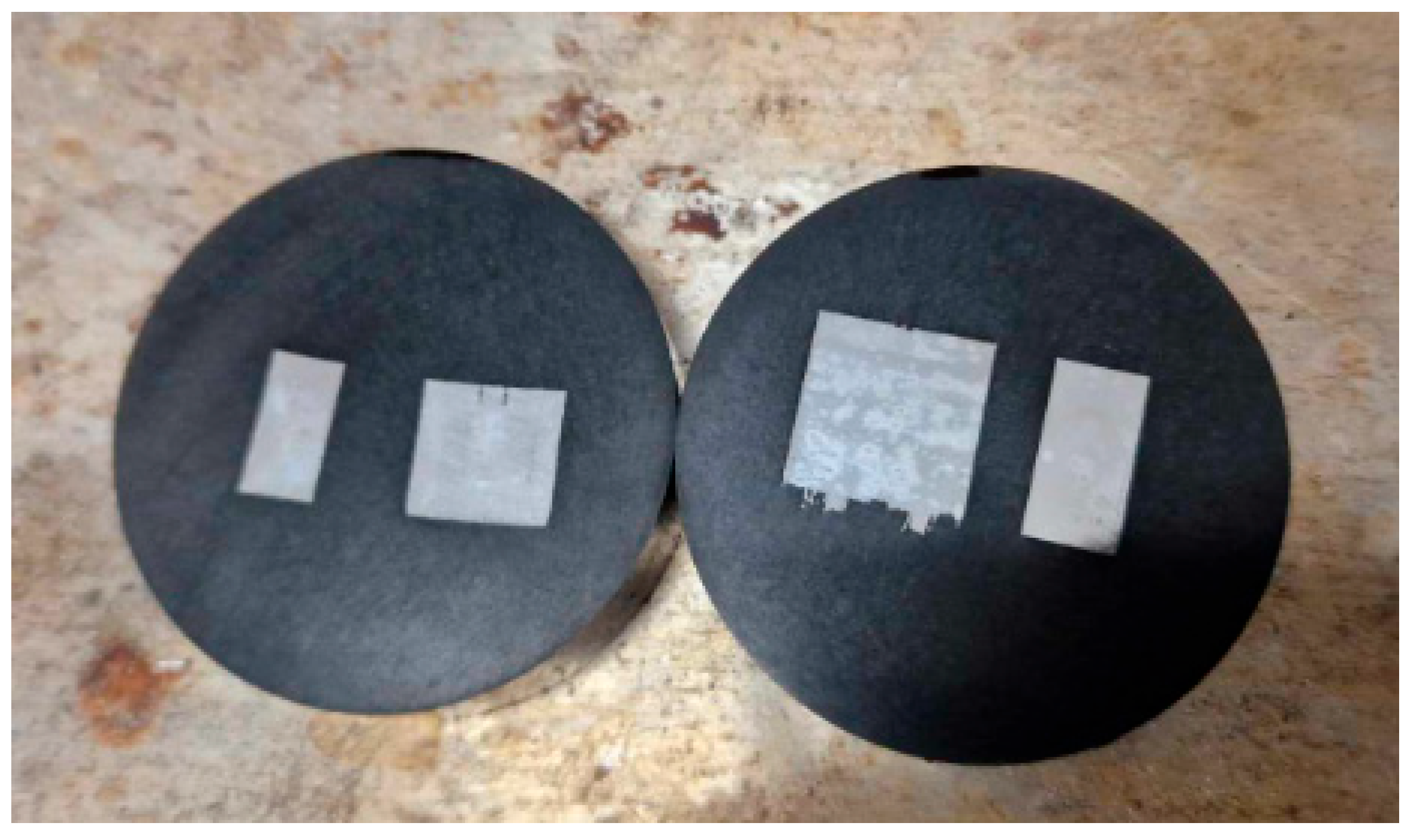

2.3. Preparation of the Printed Samples Involved

2.4. Microstructural Investigation

3. Results and Discussion

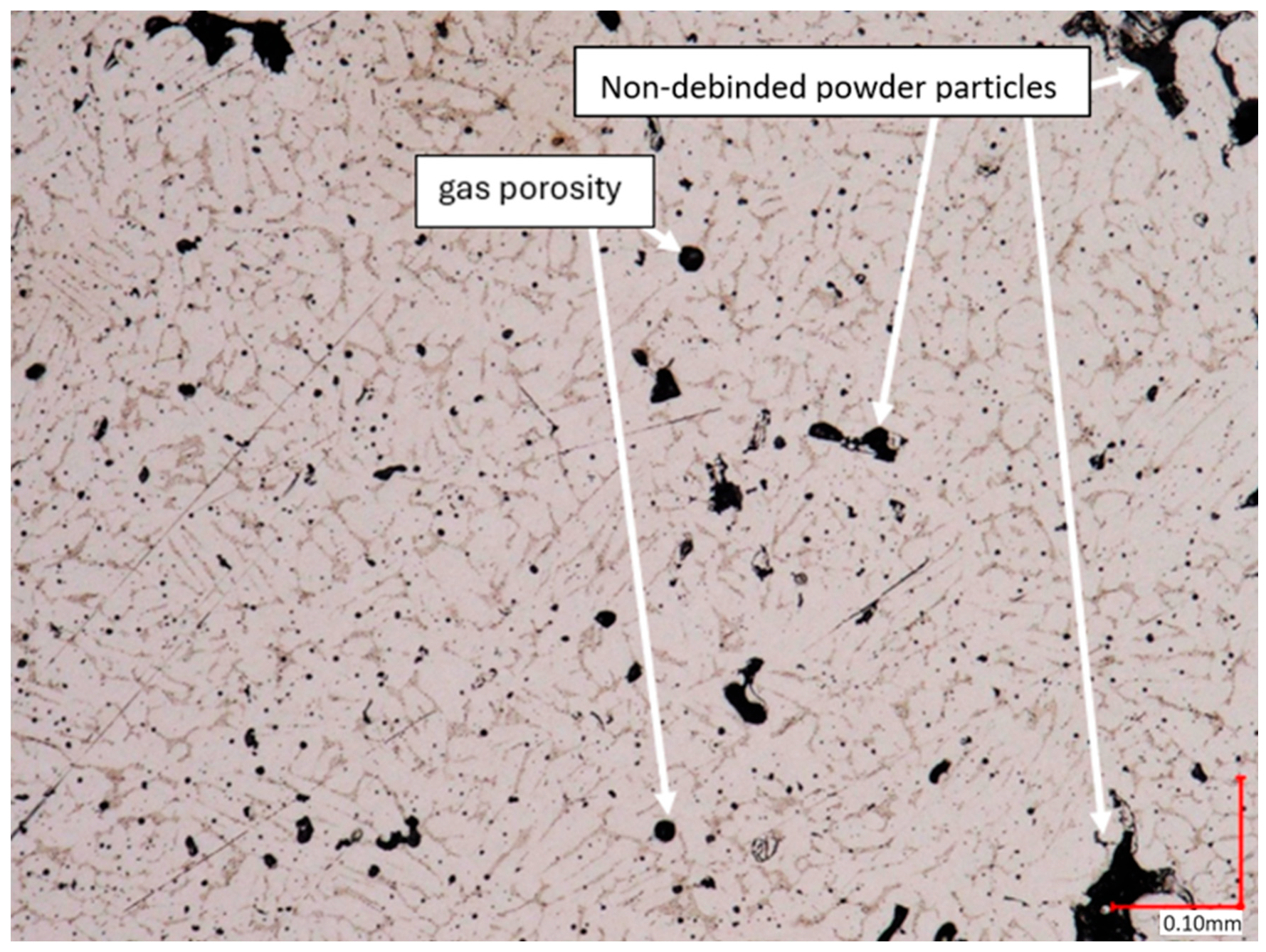

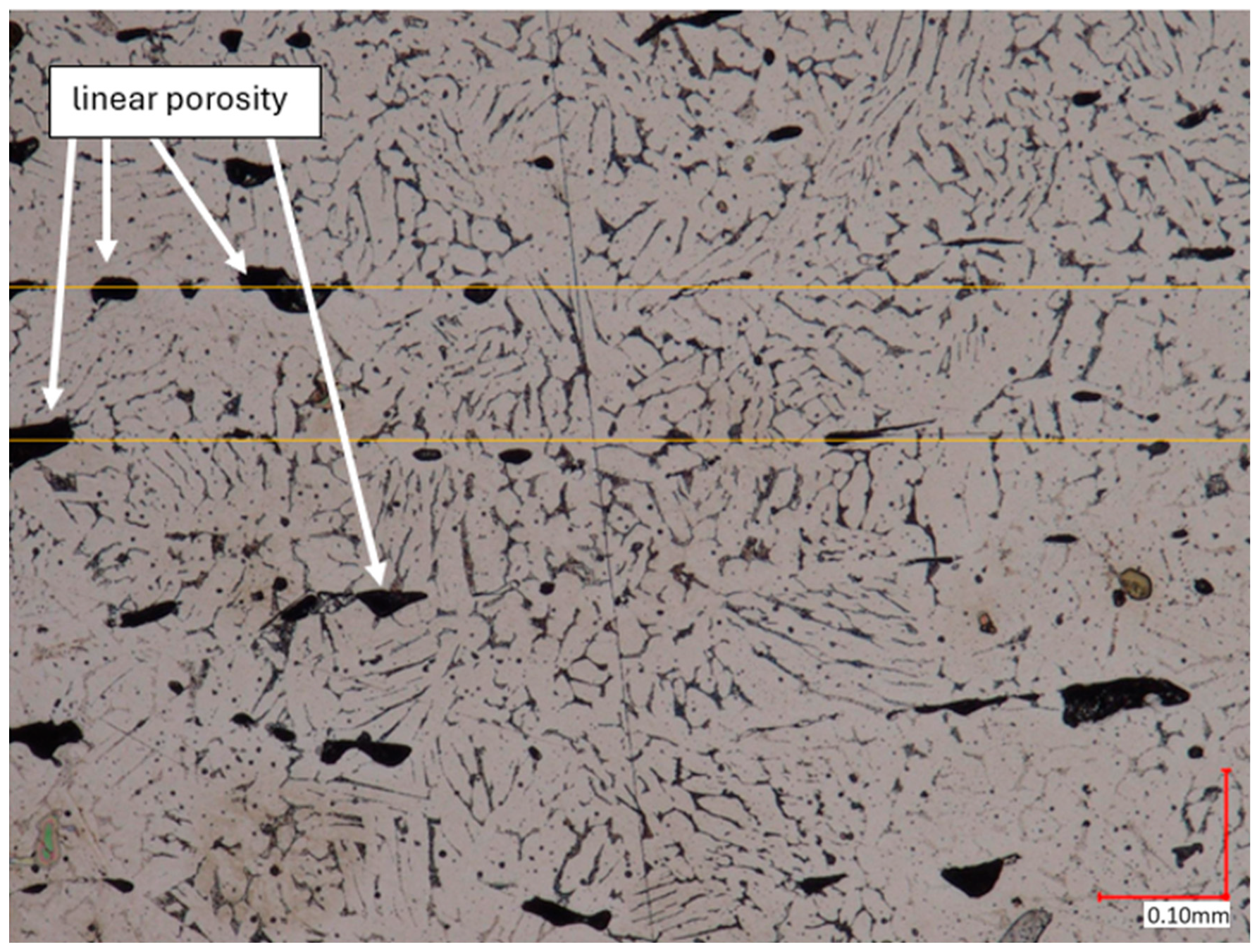

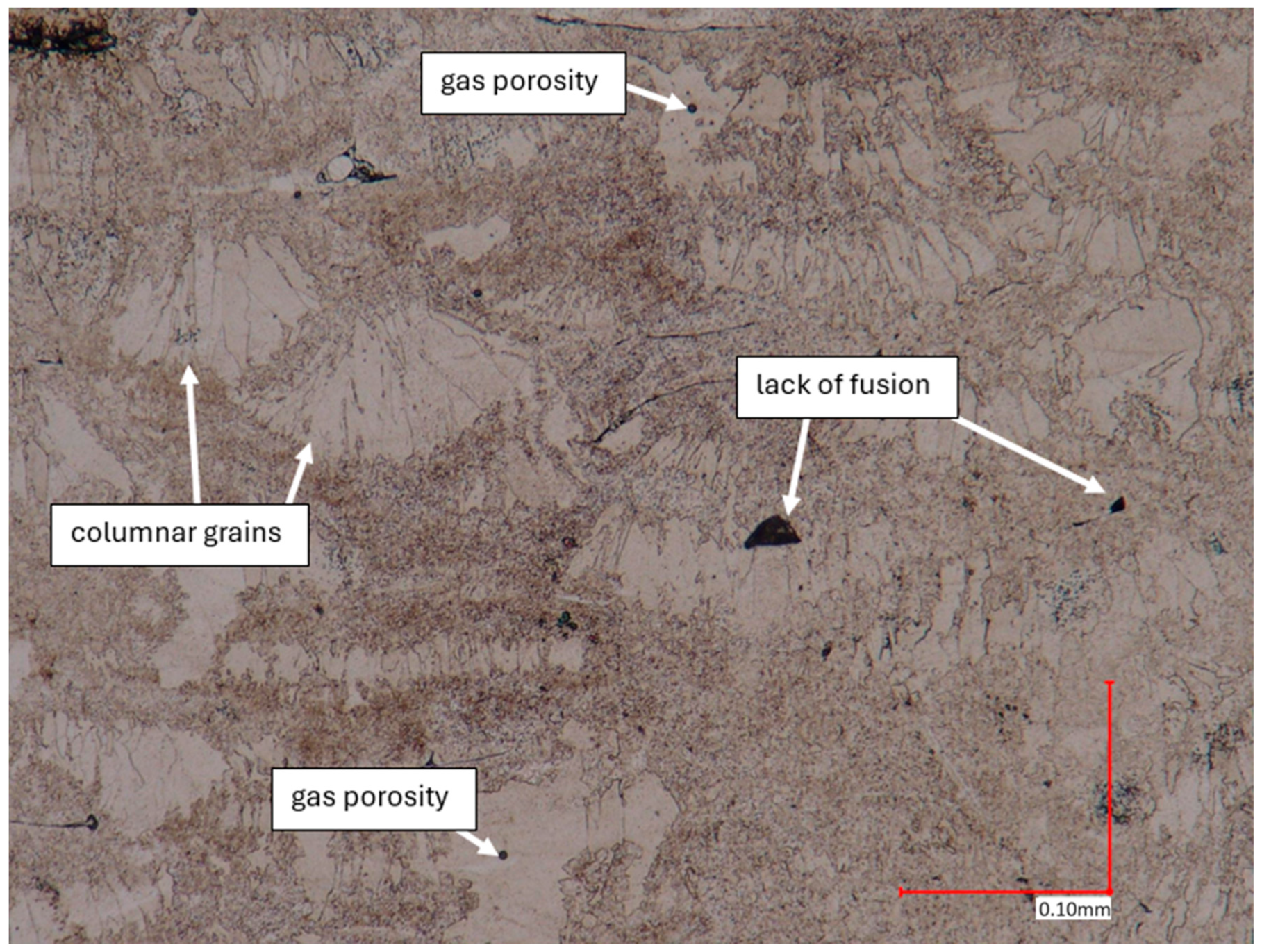

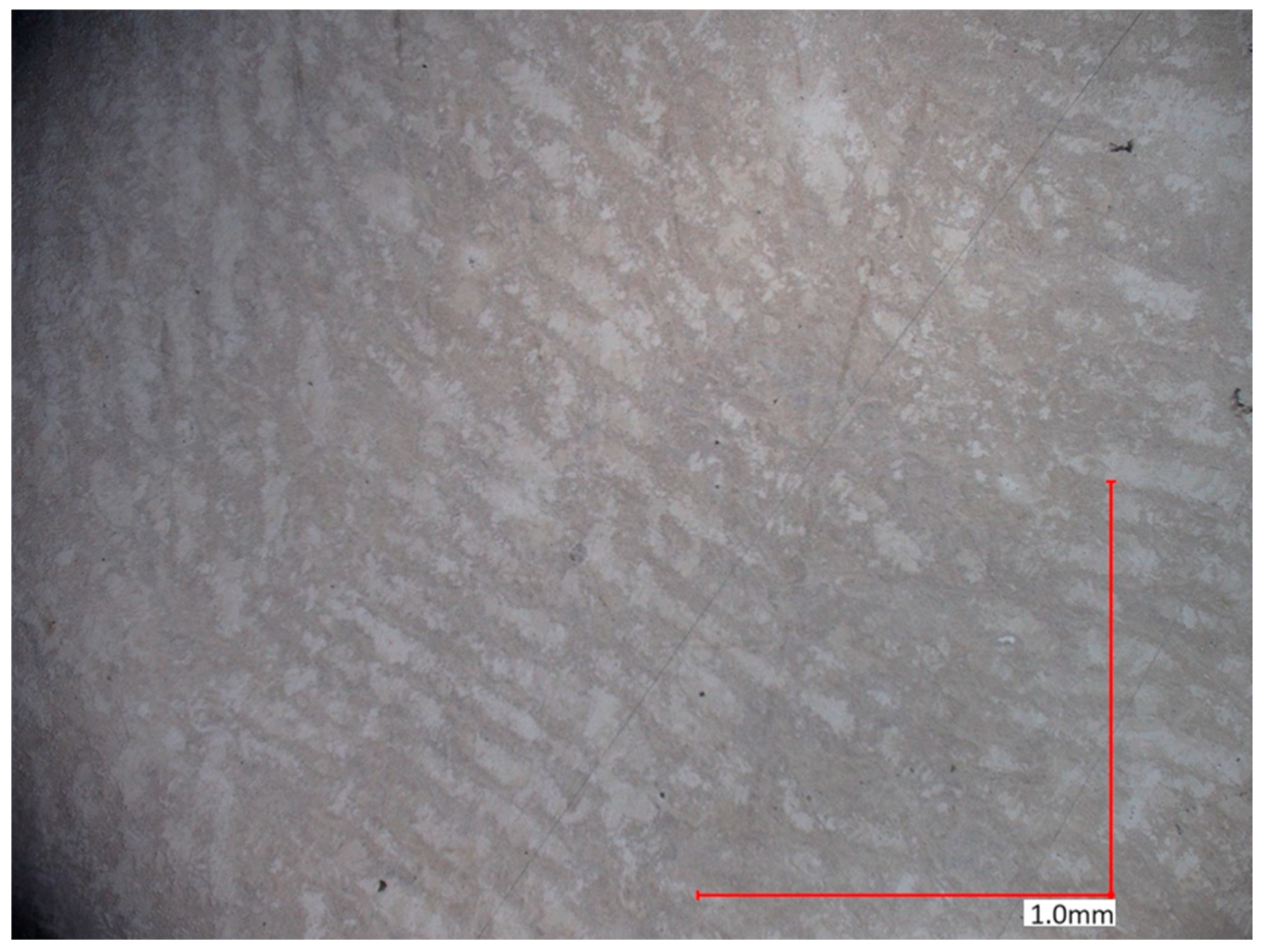

3.1. Microstructural Investigation

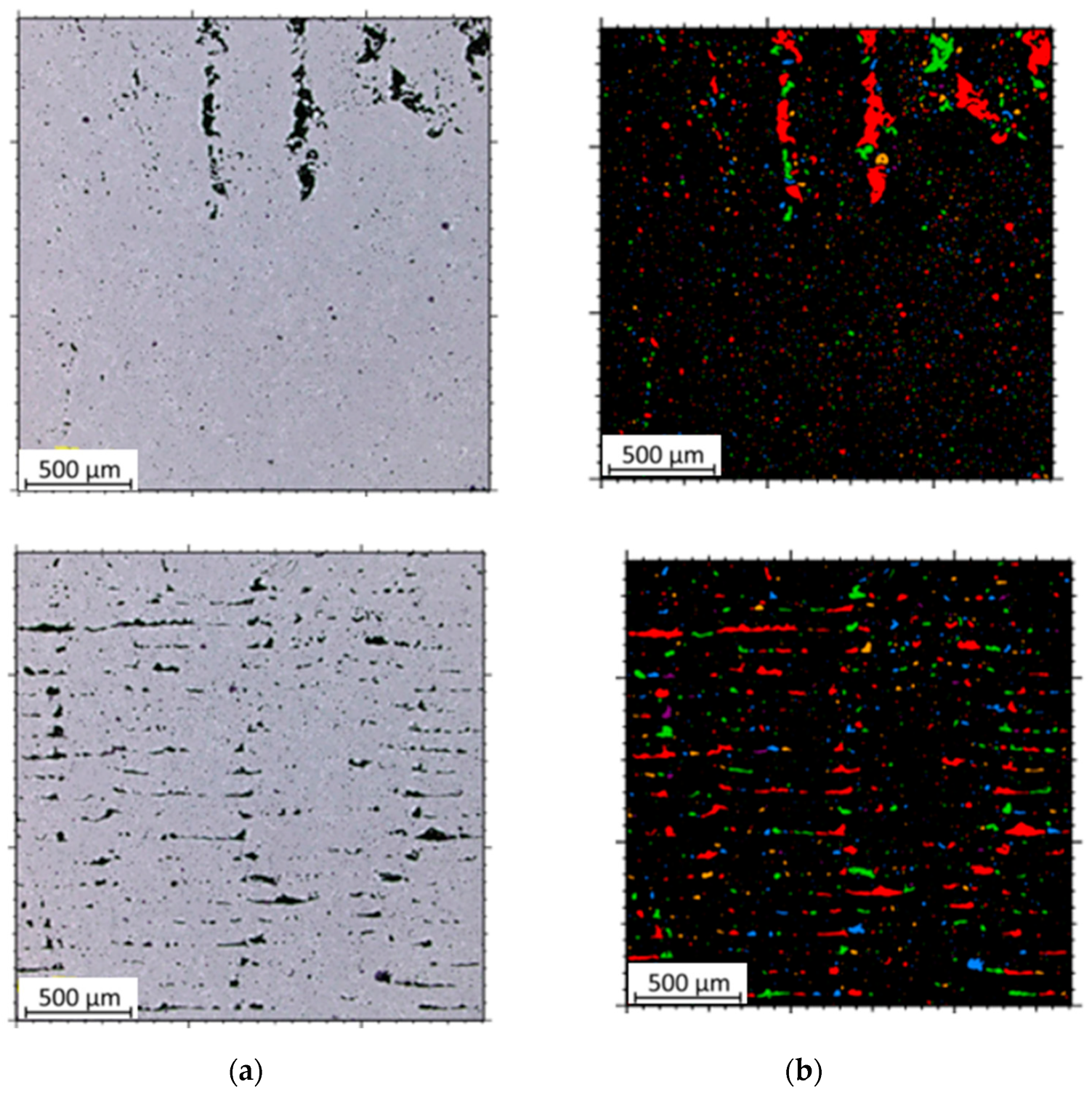

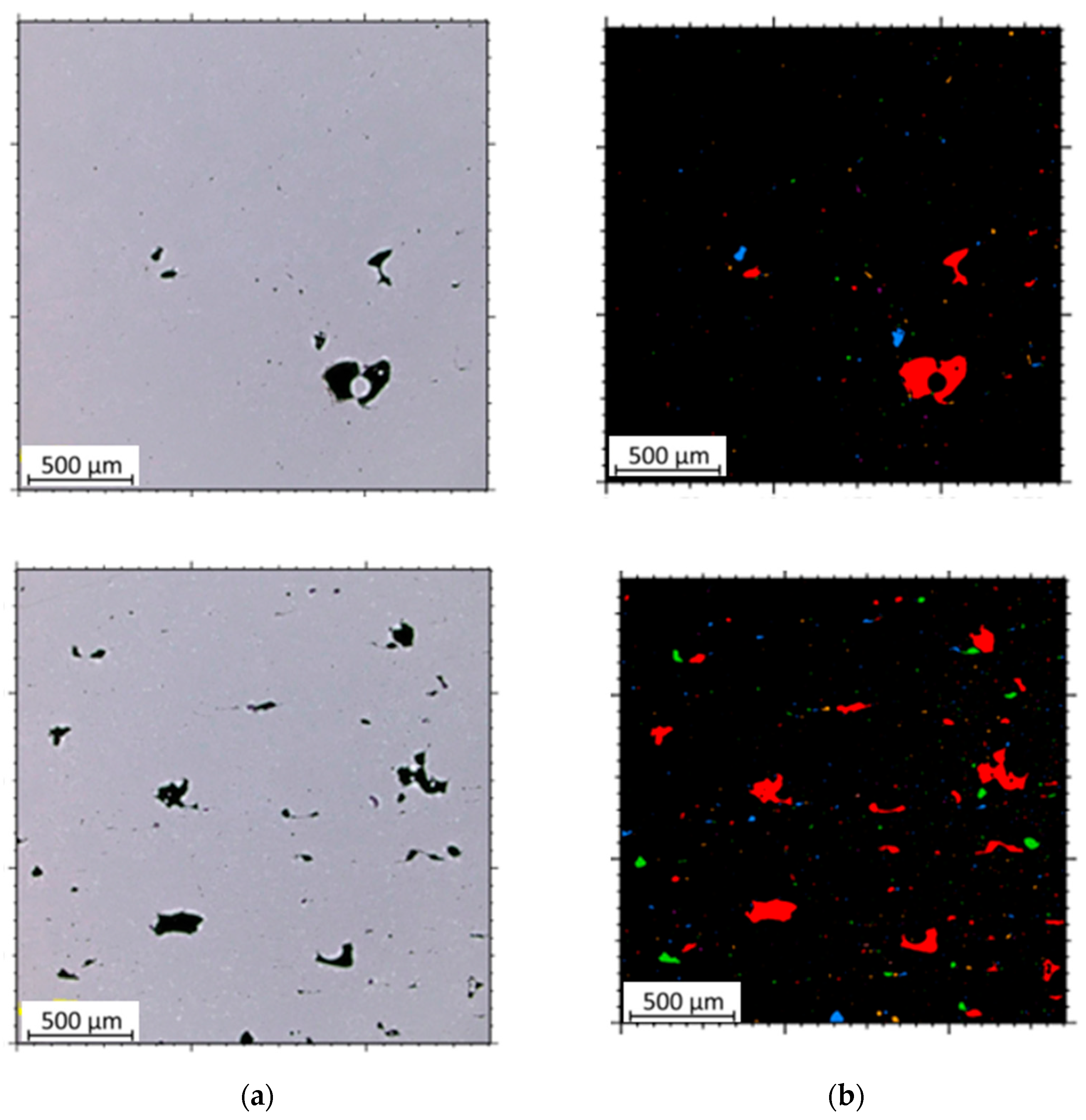

3.2. Porosity

3.3. Archimedes’ Method

3.4. Microhardness Analysis

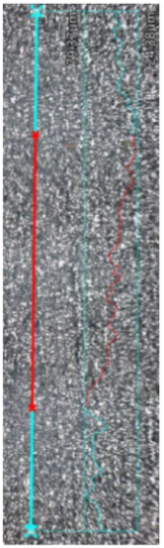

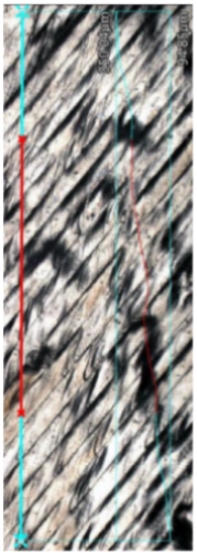

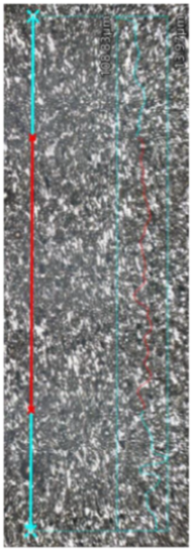

3.5. Roughness

4. Conclusions

- Samples produced using the PBF-LB/M method had significantly lower porosity than MEX samples in both the XY and YZ planes.

- The density of PBF-LB/M samples was much higher than that of MEX samples, indicating better structural homogeneity and fewer defects.

- MEX specimens showed higher microhardness values than PBF-LB/M specimens.

- MEX samples had lower surface roughness compared to PBF-LB/M samples, suggesting differences in surface quality between the two manufacturing methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1–27. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of leakage prediction in gasketed flange joints at pipeline deformations. Materials 2022, 15, 4354. [Google Scholar] [CrossRef]

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of pretension in bolts for structural health monitoring of multi-bolted connection: FEM approach. Lubricants 2022, 10, 75. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A Review on 3D Micro-Additive Manufacturing Technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Stefaniak, K.; Masek, A. Green Copolymers Based on Poly(Lactic Acid)—Short Review. Materials 2021, 14, 5254. [Google Scholar] [CrossRef] [PubMed]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the Fused Deposition (FDM) Printing Process on Polylactic Acid (PLA) Chemistry and Structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef]

- Mazurkiewicz, M.; Kluczyński, J.; Jasik, K.; Sarzyński, B.; Szachogłuchowicz, I.; Łuszczek, J.; Torzewski, J.; Śnieżek, L.; Grzelak, K.; Małek, M. Bending Strength of Polyamide-Based Composites Obtained during the Fused Filament Fabrication (FFF) Process. Materials 2022, 15, 5079. [Google Scholar] [CrossRef] [PubMed]

- Sommereyns, A.; Hupfeld, T.; Gökce, B.; Barcikowski, S.; Schmidt, M. Evaluation of essential powder properties through complementary particle size analysis methods for laser powder bed fusion of polymers. Procedia CIRP 2020, 94, 116–121. [Google Scholar] [CrossRef]

- Hupfeld, T.; Doñate-Buendía, C.; Krause, M.; Sommereyns, A.; Wegner, A.; Sinnemann, T.; Schmidt, M.; Gökce, B.; Barcikowski, S. Scaling up colloidal surface additivation of polymer powders for laser powder bed fusion. Procedia CIRP 2020, 94, 110–115. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical Property of FDM Printed ABS: Influence of Printing Parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Jasik, K.; Kluczyński, J.; Miedzińska, D.; Popławski, A.; Łuszczek, J.; Zygmuntowicz, J.; Piotrkiewicz, P.; Perkowski, K.; Wachowski, M.; Grzelak, K. Comparison of Additively Manufactured Polymer-Ceramic Parts Obtained via Different Technologies. Materials 2024, 17, 240. [Google Scholar] [CrossRef]

- Vorndran, E.; Moseke, C.; Gbureck, U. 3D printing of ceramic implants. MRS Bull. 2015, 40, 127–136. [Google Scholar] [CrossRef]

- Vidal, L.; Kampleitner, C.; Krissian, S.; Brennan, M.A.; Hoffmann, O.; Raymond, Y.; Maazouz, Y.; Ginebra, M.-P.; Rosset, P.; Layrolle, P. Regeneration of segmental defects in metatarsus of sheep with vascularized and customized 3D-printed calcium phosphate scaffolds. Sci. Rep. 2020, 10, 7068. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed]

- Hur, H.; Jin Park, Y.; Kim, D.H.; Wan Ko, J. Material Extrusion for Ceramic Additive Manufacturing with Polymer-Free Ceramic Precursor Binder. Mater. Des. 2022, 221, 110930. [Google Scholar] [CrossRef]

- Papazoglou, E.L.; Karkalos, N.E.; Karmiris-Obratański, P.; Markopoulos, A.P. On the Modeling and Simulation of SLM and SLS for Metal and Polymer Powders: A Review; Springer: Dordrecht, The Netherlands, 2022; Volume 29, ISBN 0123456789. [Google Scholar]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Carvalho, O.; Silva, F.S.; Miranda, G. 316L Stainless Steel Mechanical and Tribological Behavior—A Comparison between Selective Laser Melting, Hot Pressing and Conventional Casting. Addit. Manuf. 2017, 16, 81–89. [Google Scholar] [CrossRef]

- Abattouy, M.; Ouardouz, M.; Azzouzi, H. Toward SLM Cost Model Estimation: Stainless Steels Case Study. Int. J. Eng. Appl. Phys. 2022, 2, 381–393. [Google Scholar]

- Tian, C.; Li, X.; Zhang, S.; Guo, G.; Wang, L.; Rong, Y. Study on Design and Performance of Metal-Bonded Diamond Grinding Wheels Fabricated by Selective Laser Melting (SLM). Mater. Des. 2018, 156, 52–61. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Ramazani, H.; Kami, A. Metal FDM, a New Extrusion-Based Additive Manufacturing Technology for Manufacturing of Metallic Parts: A Review. Prog. Addit. Manuf. 2022, 7, 609–626. [Google Scholar] [CrossRef]

- Kurose, T.; Abe, Y.; Santos, M.V.A.; Kanaya, Y.; Ishigami, A.; Tanaka, S.; Ito, H. Influence of the Layer Directions on the Properties of 316l Stainless Steel Parts Fabricated through Fused Deposition of Metals. Materials 2020, 13, 2493. [Google Scholar] [CrossRef] [PubMed]

- Quarto, M.; Carminati, M.; D’Urso, G.; Giardini, C.; Maccarini, G. Processability of Metal-Filament through Polymer FDM Machine. In Proceedings of the ESAFORM 2021—24th International Conference on Material Forming, Liège, Belgium, 14–16 April 2021; Volume 13, pp. 1–11. [Google Scholar] [CrossRef]

- Kedziora, S.; Decker, T.; Museyibov, E.; Morbach, J.; Hohmann, S.; Huwer, A.; Wahl, M. Strength Properties of 316L and 17-4 PH Stainless Steel Produced with Additive Manufacturing. Materials 2022, 15, 6278. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. Jom 2019, 71, 880–885. [Google Scholar] [CrossRef]

- Fazzini, F.; Boschetto, A.; Bottini, L.; Diez, A.C.; Cini, A. Correlation between Metal Fused Filament Fabrication Parameters and Material Properties of Sintered 17-4 PH. Procedia Struct. Integr. 2023, 49, 59–66. [Google Scholar] [CrossRef]

- Atatreh, S.; Alyammahi, M.S.; Vasilyan, H.; Alkindi, T.; Susantyoko, R.A. Evaluation of the Infill Design on the Tensile Properties of Metal Parts Produced by Fused Filament Fabrication. Results Eng. 2023, 17, 100954. [Google Scholar] [CrossRef]

- Kluczyński, J.; Jasik, K.; Łuszczek, J.; Sarzyński, B.; Grzelak, K.; Dražan, T.; Joska, Z.; Szachogłuchowicz, I.; Płatek, P.; Małek, M. A Comparative Investigation of Properties of Metallic Parts Additively Manufactured through MEX and PBF-LB/M Technologies. Materials 2023, 16, 5200. [Google Scholar] [CrossRef] [PubMed]

- Łuszczek, J.; Śnieżek, L.; Grzelak, K.; Kluczyński, J.; Torzewski, J.; Szachogłuchowicz, I.; Wachowski, M.; Karpiński, M. Processability of 21NiCrMo2 Steel Using the Laser Powder Bed Fusion: Selection of Process Parameters and Resulting Mechanical Properties. Materials 2022, 15, 8972. [Google Scholar] [CrossRef]

- PN-EN ISO 6507-1; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- Kluczyński, J.; Śniezek, L.; Grzelak, K.; Oziebło, A.; Perkowski, K.; Torzewski, J.; Szachogłuchowicz, I.; Gocman, K.; Wachowski, M.; Kania, B. Comparison of Different Heat Treatment Processes of Selective Laser Melted 316L Steel Based on Analysis of Mechanical Properties. Materials 2020, 13, 3805. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Gorantla, S.; Popp, U.; Okolo, B.; Schulze, V. Process Porosity and Mechanical Performance of Fused Filament Fabricated 316L Stainless Steel. Rapid Prototyp. J. 2019, 25, 1319–1327. [Google Scholar] [CrossRef]

- Godec, D.; Cano, S.; Holzer, C.; Gonzalez-Gutierrez, J. Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials 2020, 13, 774. [Google Scholar] [CrossRef]

- Rane, K.; Cataldo, S.; Parenti, P.; Sbaglia, L.; Mussi, V.; Annoni, M.; Giberti, H.; Strano, M. Rapid Production of Hollow SS316 Profiles by Extrusion Based Additive Manufacturing. In Proceedings of the 21st International ESAFORM Conference on Material Forming: ESAFORM, Palermo, Italy, 23–25 April 2018; AIP Conference Proceedings 1960. Fratini, L., di Lorenzo, R., Buffa, G., Ingarao, G., Eds.; AIP Publishing LLC: Melville, NY, USA, 2018; p. 140014. [Google Scholar]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused Filament Fabrication, Debinding and Sintering as a Low Cost Additive Manufacturing Method of 316L Stainless Steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Grzelak, K.; Kluczyński, J.; Szachogłuchowicz, I.; Łuszczek, J.; Śnieżek, L.; Torzewski, J. Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting. Materials 2020, 13, 5662. [Google Scholar] [CrossRef]

- Meana, V.; Cuesta, E.; Álvarez, B.J. Testing the Sandblasting Process in the Manufacturing of Reference Spheres for Non-Contact Metrology Applications. Materials 2021, 14, 5187. [Google Scholar] [CrossRef]

| Filament Diameter [mm] | Layer Thickness [mm] | Nozzle Diameter [mm] | Nozzle Temperature [°C] | Print Bed Temperature [°C] | Feed Rate [mm/s] | Infill [%] | Number of Contours | Infill Pattern | Cooling Speed [mm/s] | Printing Time for 3 Samples [h] |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.75 | 0.1 | 0.2 | 250 | 100 | 35 | 100 | 5 | concentric | 0 | 3 |

| Elements | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Cu | Mn | Si | Nb + Ta | C | N | O | P | S |

| Weight (%) | |||||||||||

| Bal. | 15.00–17.50 | 3.00–5.00 | 3.00–5.00 | 1.00 | 0.07 | 0.15–0.45 | 0.07 | 0.10 | 0.04 | 0.040 | 0.015 |

| Layer Thickness [mm] | Hatch Distance [mm] | Scanning Speed [mm/s] | Power [W] | Energy Density [J/mm3] | Printing Time for 3 Samples [h] |

|---|---|---|---|---|---|

| 0.03 | 0.12 | 800 | 200 | 69.4 | 4.5 |

| Reagent | HCl | HNO3 | CH3COOH | glycerol |

|---|---|---|---|---|

| Quantity [mL] | 6 | 4 | 4 | 0.2 |

| Sample | Number of Grain Pores | Pore Volume (mm2) | Pore Volume (%) | The Average Size of an Individual Grain (mm2) |

|---|---|---|---|---|

| MEX (XY) | 2388 ± 733 | 5726 ± 1835 | 7.8 ± 2.5 | 4.5 ± 3.6 |

| PBF-LB/M (XY) | 1709 ± 582 | 2073 ± 1998 | 2.8 ± 2.7 | 1.6 ± 1.1 |

| MEX (YZ) | 2211 ± 868 | 4733 ± 1257 | 6.4 ± 1.7 | 2.4 ± 1.1 |

| PBF-LB/M (YZ) | 890 ± 364 | 1988 ± 294 | 2.7 ± 0.4 | 2.7 ± 0.8 |

| Type of Test Sample | Density (g/cm3) | Porosity (%) |

|---|---|---|

| Conventional | 7.746 ± 0.180 | ~0 |

| PBF-LB/M | 7.397 ± 0.139 | 4.51 |

| MEX | 7.356 ± 0.059 | 5.03 |

| Type of Test Sample | HV0.1 (XY) | HV0.1 (YZ) |

|---|---|---|

| MEX | 303 ± 2 | 328 ± 8 |

| PBF-LB/M | 285 ± 19 | 267 ± 11 |

| Sample Type | MEX—Upper Plane | MEX—Lateral Plane | PBF-LB/M—Upper Plane | PBF-LB/M—Lateral Plane |

|---|---|---|---|---|

| Surface image with the indicated profile line |  |  |  |  |

| Measured profile length [μm] | 4673.66 | 4751.61 | 4819.71 | 4718.80 |

| Measured profile height [μm] | 103.75 | 54.98 | 255.19 | 94.86 |

| Rz [μm] | 15.20 | 24.02 | 33.05 | 32.10 |

| Ra [μm] | 2.71 | 4.24 | 8.27 | 5.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasik, K.; Śnieżek, L.; Kluczyński, J.; Łuszczek, J.; Grzelak, K.; Sarzyński, B.; Szachogłuchowicz, I. 17-4 PH Steel Parts Obtained through MEX and PBF-LB/M Technologies: Comparison of the Structural Properties. Materials 2024, 17, 2801. https://doi.org/10.3390/ma17122801

Jasik K, Śnieżek L, Kluczyński J, Łuszczek J, Grzelak K, Sarzyński B, Szachogłuchowicz I. 17-4 PH Steel Parts Obtained through MEX and PBF-LB/M Technologies: Comparison of the Structural Properties. Materials. 2024; 17(12):2801. https://doi.org/10.3390/ma17122801

Chicago/Turabian StyleJasik, Katarzyna, Lucjan Śnieżek, Janusz Kluczyński, Jakub Łuszczek, Krzysztof Grzelak, Bartłomiej Sarzyński, and Ireneusz Szachogłuchowicz. 2024. "17-4 PH Steel Parts Obtained through MEX and PBF-LB/M Technologies: Comparison of the Structural Properties" Materials 17, no. 12: 2801. https://doi.org/10.3390/ma17122801

APA StyleJasik, K., Śnieżek, L., Kluczyński, J., Łuszczek, J., Grzelak, K., Sarzyński, B., & Szachogłuchowicz, I. (2024). 17-4 PH Steel Parts Obtained through MEX and PBF-LB/M Technologies: Comparison of the Structural Properties. Materials, 17(12), 2801. https://doi.org/10.3390/ma17122801