Segregated Conductive Polymer Composite with Fe3O4-Decorated Graphite Nanoparticles for Microwave Shielding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

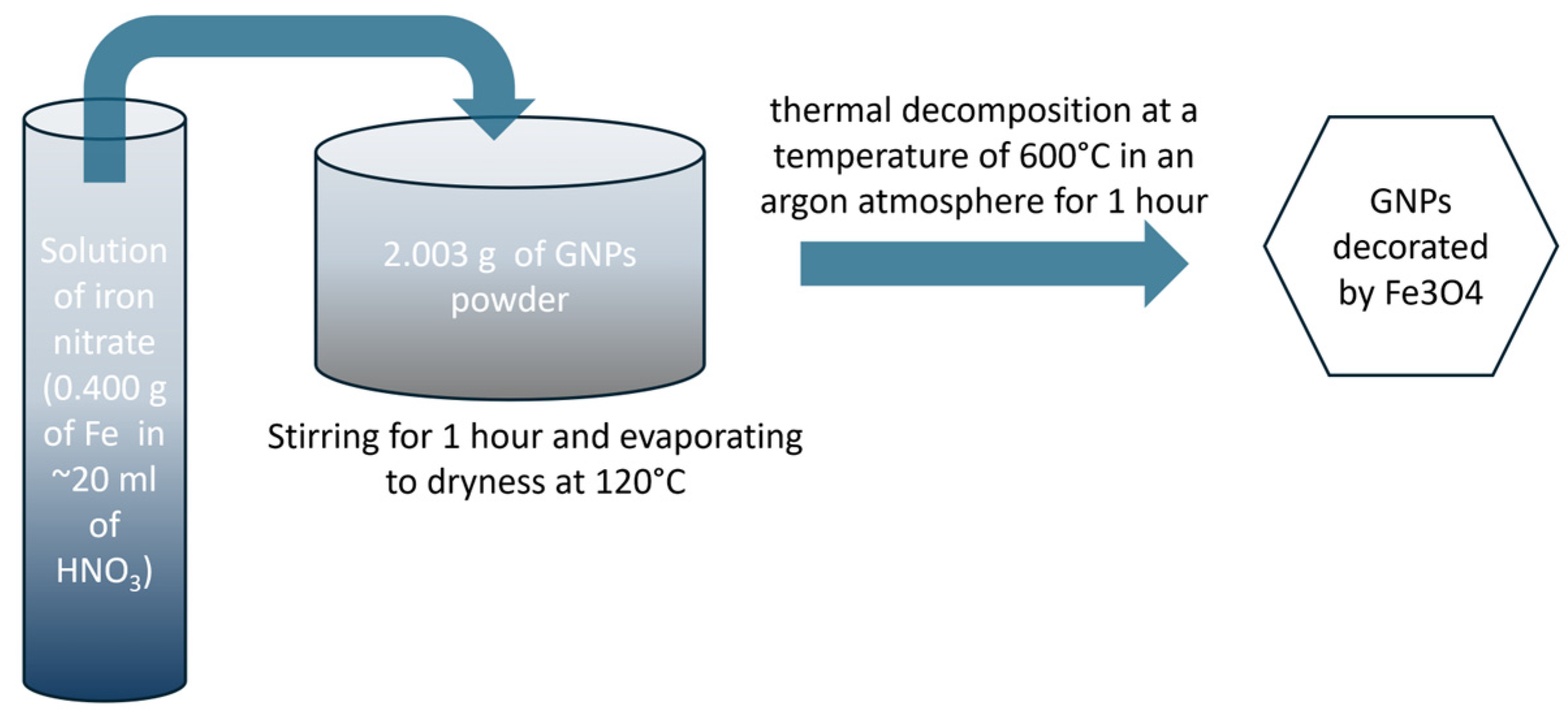

2.2. Preparation Methods for GNPs Decorated by Fe3O4

2.3. CMs Preparation

2.4. Experimental Methods

3. Results

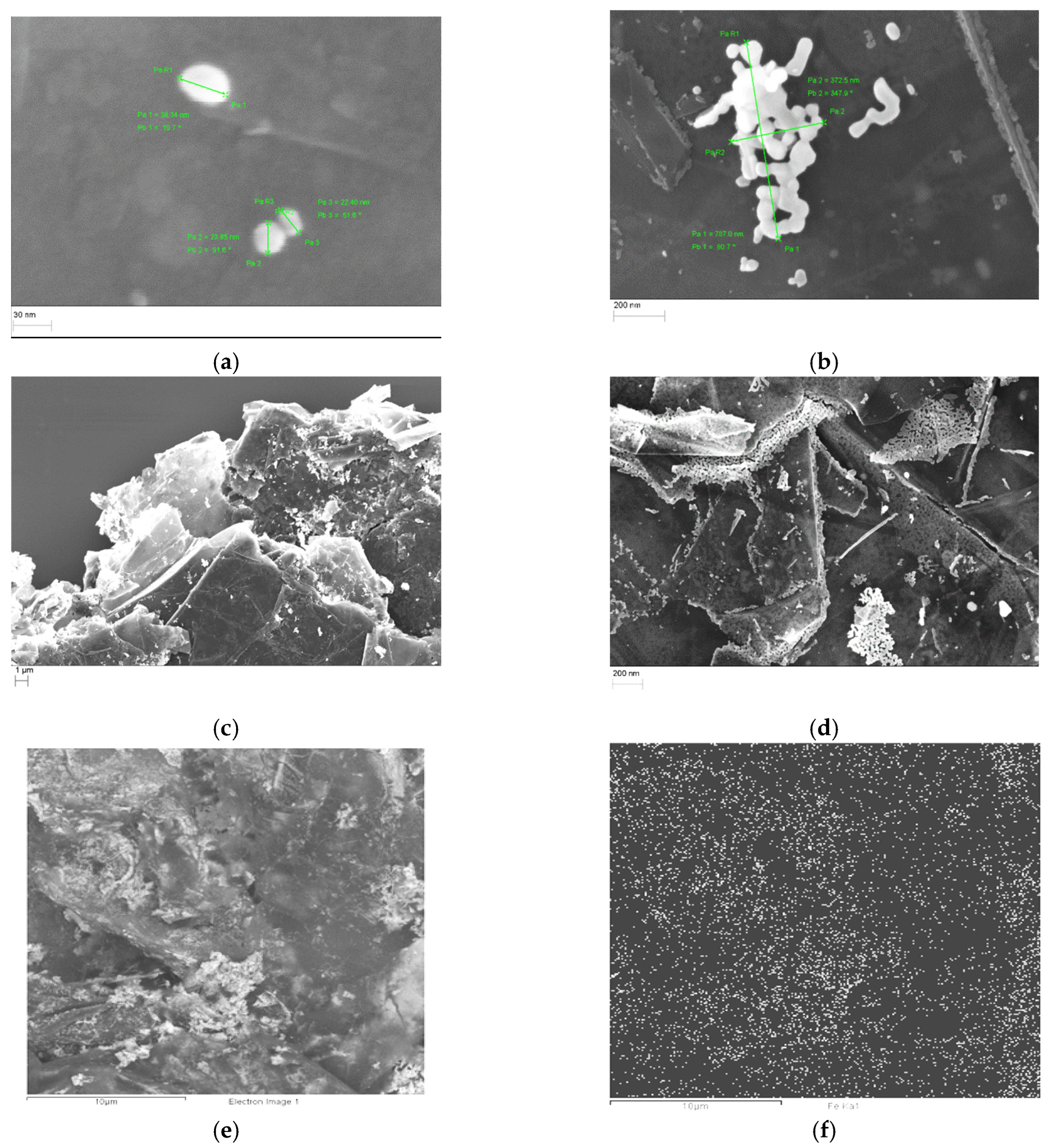

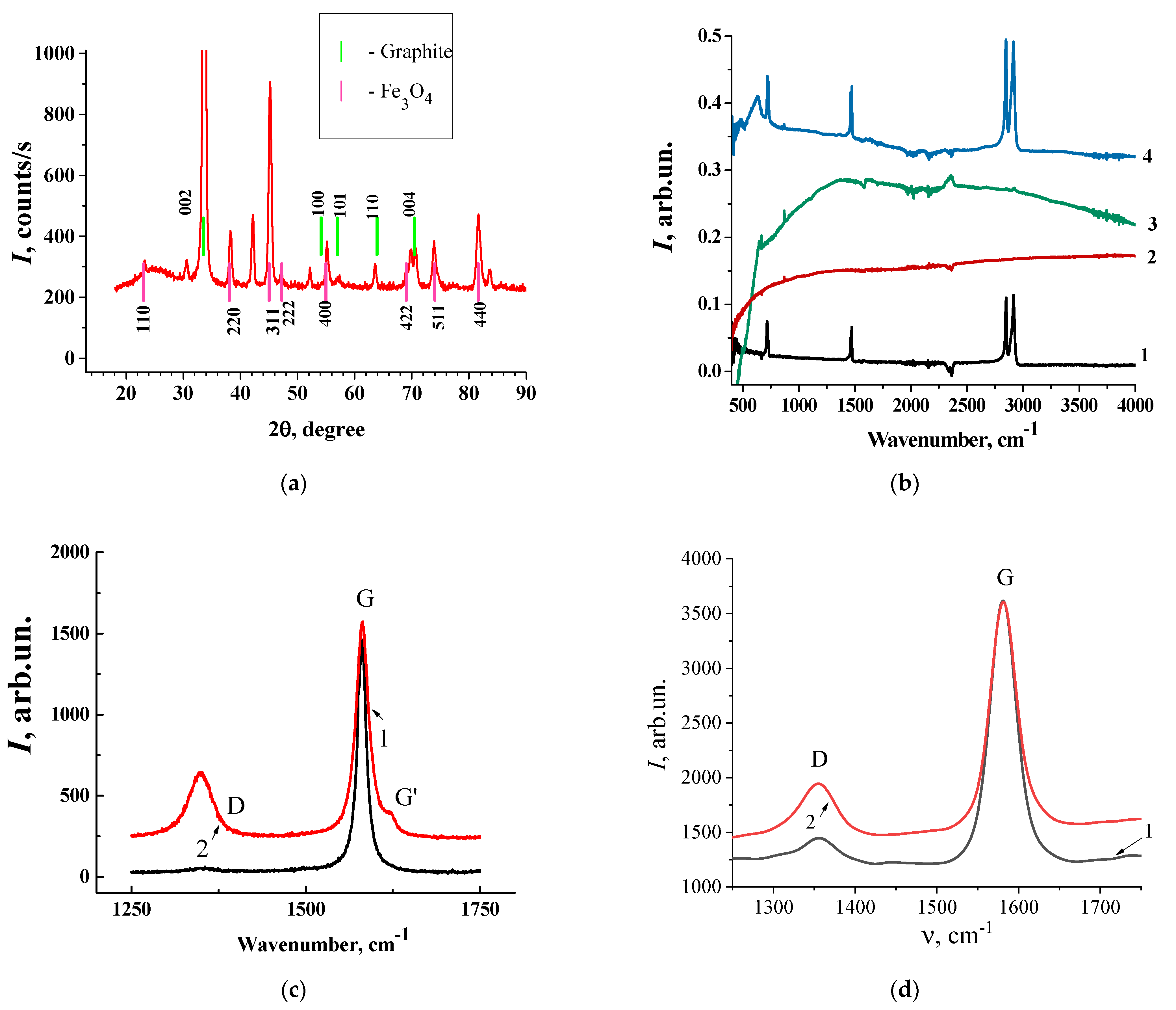

3.1. Material Characterization

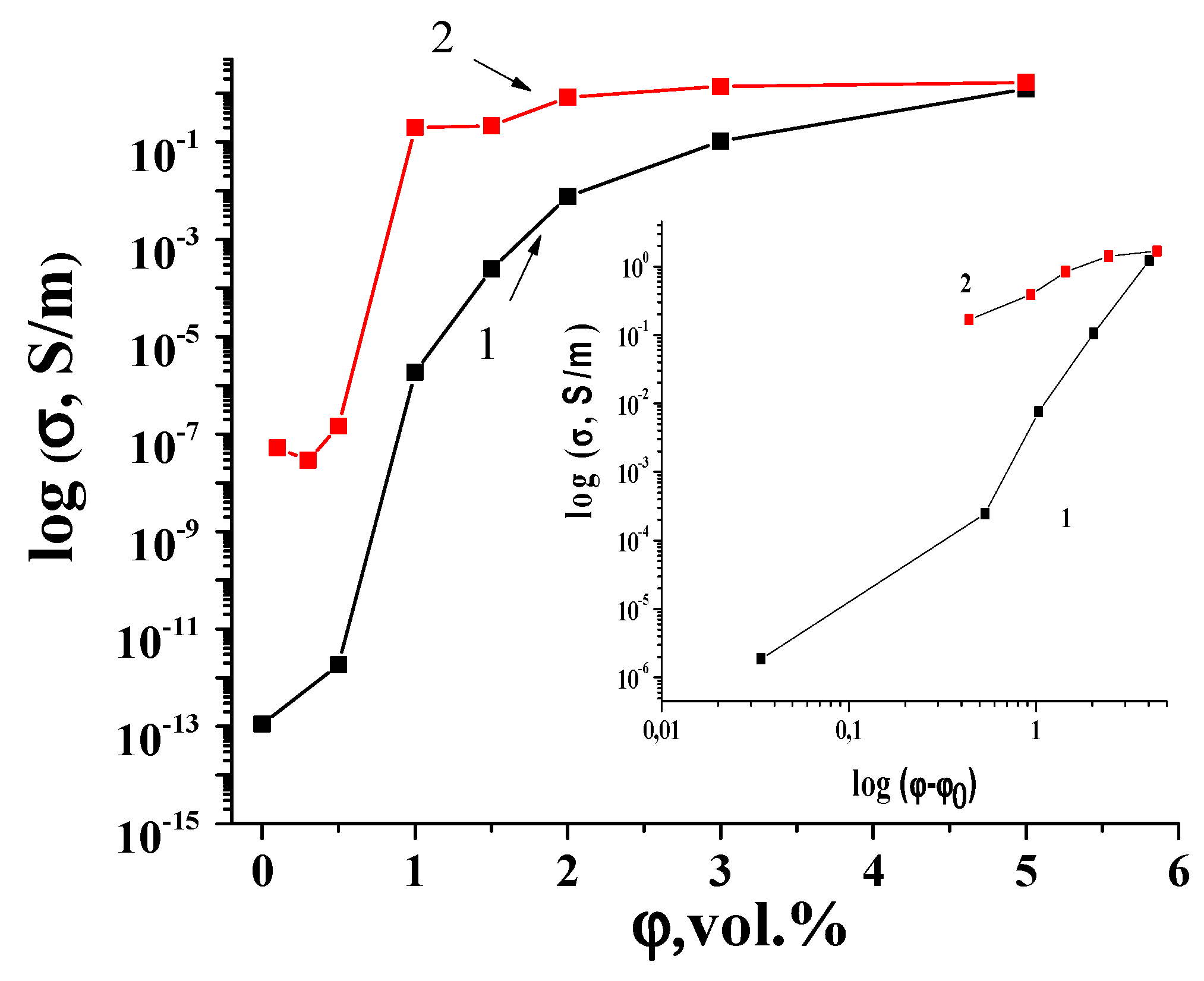

3.2. Electrical Conductivity

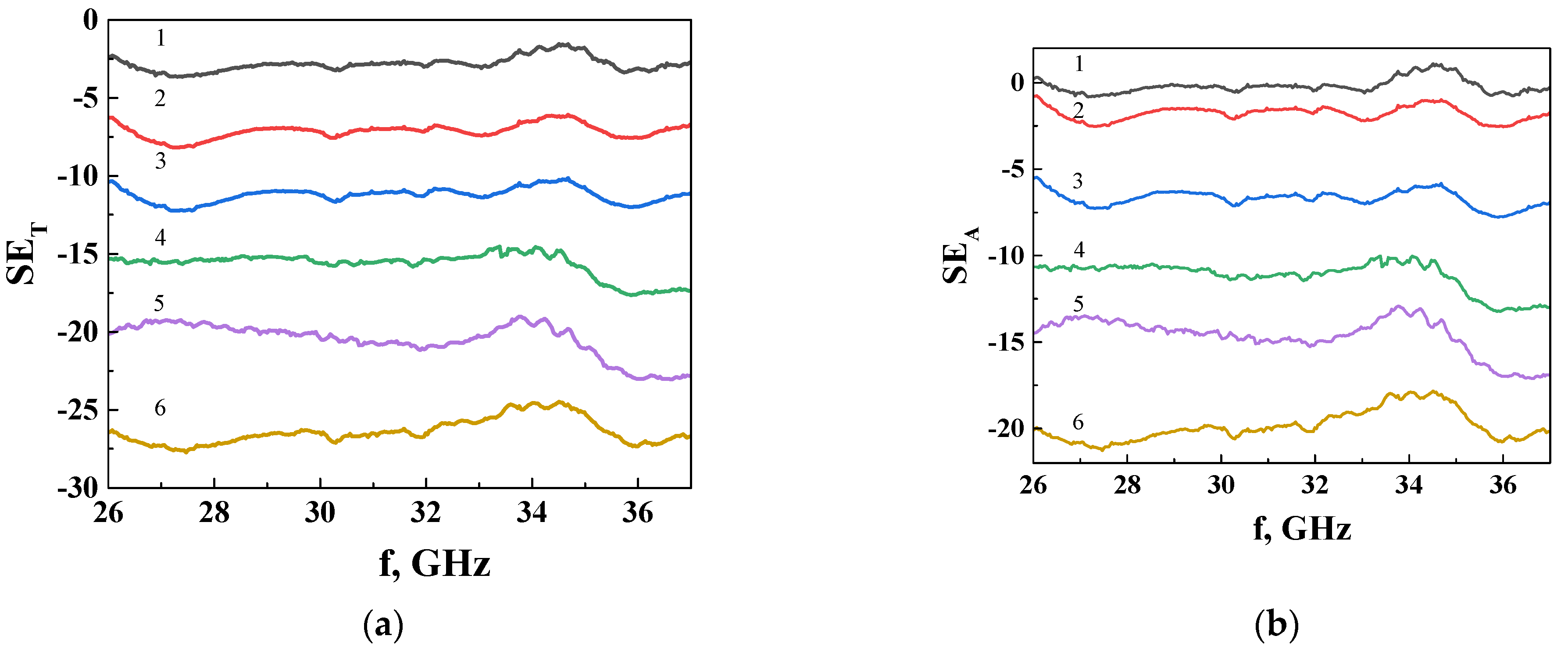

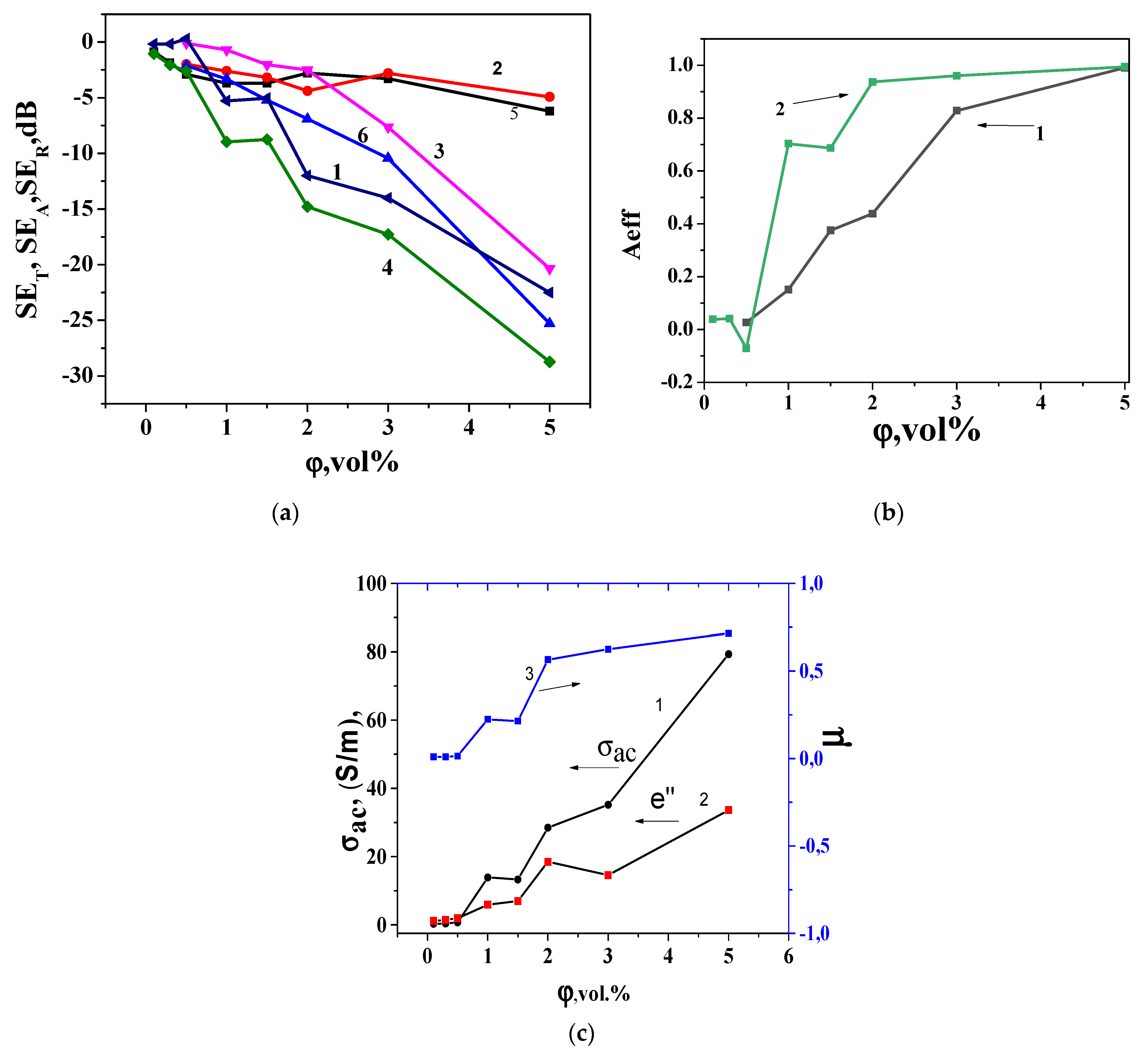

3.3. Microwave Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Tang, X.H.; Cai, J.H.; Wu, H.; Shen, J.B.; Guo, S.Y. Construction, mechanism and prospective of conductive polymer composites with multiple interfaces for electromagnetic interference shielding: A review. Carbon 2021, 177, 377–402. [Google Scholar] [CrossRef]

- Jia, X.; Li, Y.; Shen, B.; Zheng, W. Evaluation, fabrication and dynamic performance regulation of green EMI-shielding materials with low reflectivity: A review. Compos. Part B 2022, 233, 109652. [Google Scholar] [CrossRef]

- Baan, R.; Grosse, Y.; Lauby-Secretan, B.; Ghissassi, F.E.; Bouvard, V.; Benbrahim-Tallaa, L.; Islami, F.; Galichet, L.; Straif, K. Carcinogenicity of radiofrequency electromagnetic fields. Lancet Oncol. 2011, 12, 624–626. [Google Scholar] [CrossRef] [PubMed]

- Russell, C.L. 5G wireless telecommunications expansion: Public health and environmental implications. Env. Res. 2018, 165, 484–495. [Google Scholar] [CrossRef] [PubMed]

- Maruthi, N.; Faisa, M.; Raghavendra, N. Conducting polymer based composites as efficient EMI shielding materials: A comprehensive review and future. Synth. Met. 2021, 272, 116664. [Google Scholar] [CrossRef]

- Iqbal, S.; Ahmad, S. Conducting polymer composites: An efficient EMI shielding material. In Materials for Potential EMI Shielding Applications: Processing, Properties and Current Trends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 257–266, Chapter 16. [Google Scholar] [CrossRef]

- Kausa, A. Nanocarbon Nanocomposites of Polyaniline and Shielding: Design and Effectiveness. Polym.-Plast. Technol. Mater. 2022, 61, 1988–2000. [Google Scholar] [CrossRef]

- Liu, S.; Qin, S.; Jiang, Y.; Song, P.; Wang, H. Lightweight high-performance carbon-polymer nanocomposites for electromagnetic interference shielding. Compos. Part. A Appl. Sci. Manuf. 2021, 145, 106376. [Google Scholar] [CrossRef]

- Yakovenko, O.; Matzui, L.; Danylova, G.; Zadorozhnii, V.; Vovchenko, L.; Perets, Y.; Lazarenko, O. Electrical Properties of Composite Materials with Electric Field-Assisted Alignment of Nanocarbon Fillers. Nanoscale Res. Lett. 2017, 12, 471. [Google Scholar] [CrossRef] [PubMed]

- Zeranska-Chudek, K.; Wróblewska, A.; Kowalczyk, S.; Plichta, A.; Zdrojek, M. Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management. Appl. Mater. 2021, 14, 2856. [Google Scholar] [CrossRef]

- Vovchenko, L.; Matzui, L.; Oliynyk, V.; Launetz, V.; Lazarenko, A. Nanocarbon-Epoxy Composites as Electromagnetic Shielding Materials. Mol. Cryst. Liq. Cryst. 2008, 497, 46/[378]–54/[386]. [Google Scholar] [CrossRef]

- Li, Y.; Shang, Y.; Li, M.; Zhang, X.; He, J. High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method. Materials 2022, 15, 6430. [Google Scholar] [CrossRef] [PubMed]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic shielding effectiveness of carbon fibre reinforced composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Zecchi, S.; Cristoforo, G.; Bartoli, M.; Tagliaferro, A.; Torsello, D.; Rosso, C.; Boccaccio, M.; Acerra, F. A Comprehensive Review of Electromagnetic Interference Shielding Composite Materials. Micromachines 2024, 15, 187. [Google Scholar] [CrossRef] [PubMed]

- Yuan, M.; Zhou, M.; Fu, H. Synergistic microstructure of sandwich-like NiFe2O4@SiO2@MXene nanocomposites for enhancement of microwave absorption in the whole Ku-band. Compos. Part B Eng. 2021, 224, 109178. [Google Scholar] [CrossRef]

- Zhang, M.; Ling, H.; Ding, S.; Xie, Y.; Cheng, T.; Zhao, L.; Wang, T.; Bian, H.; Lin, H.; Li, Z.; et al. Synthesis of CF@PANI hybrid nanocomposites decorated with Fe3O4 nanoparticles towards excellent lightweight microwave absorber. Carbon 2021, 174, 248–259. [Google Scholar] [CrossRef]

- Siengchin, S. A review on lightweight materials for defence applications: Present and future developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Arief, I.; Biswas, S.; Bose, S. Fe-Co-Anchored Reduced Graphene Oxide Framework-Based Soft Composites Containing Carbon Nanotubes as Highly Efficient Microwave Absorbers with Excellent Heat Dissipation Ability. ASC Appl. Mater. Interfaces 2017, 9, 9202–19214. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, I.R.; Matori, K.A.; Ismail, I.; Awang, Z.; Rusly, S.N.A.; Nazlan, R.; Idris, F.M.; Zulkimi, M.M.M.; Abdullah, N.H.; Mustaffa, M.S.; et al. A Study on Microwave Absorption Properties of Carbon Black and Ni0.6Zn0.4Fe2O4 Nanocomposites by Tuning the Matching, Absorbing Layer Structures. Sci. Rep. 2020, 10, 3135. [Google Scholar] [CrossRef] [PubMed]

- Vinnik, D.A.; Starikov, A.Y.; Zhivulin, V.E.; Astapovich, K.A.; Turchenko, V.A.; Zuba, T.I.; Trukhanov, S.V.; Kohout, J.; Kmječ, T.; Yakovenko, O.; et al. Structure and magnetodielectric properties of titanium substituted barium hexaferrites. Ceram. Int. 2021, 47, 17293–17306. [Google Scholar] [CrossRef]

- Yakovenko, O.S.; Matzui, L.Y.; Vovchenko, L.L.; Oliynyk, V.V.; Zagorodni, V.V.; Trukhanov, S.V.; Trukhanov, A.V. Electromagnetic Properties of Carbon Nanotube/BaFe12−xGaxO19/Epoxy Composites with Random and Oriented Filler Distributions. Nanomaterials 2021, 11, 2873. [Google Scholar] [CrossRef]

- Yakovenko, O.S.; Matzui, L.Y.; Syvolozhskyi, O.A.; Vovchenko, L.L.; Lazarenko, O.A.; Ischenko, O.V.; Dyachenko, A.G.; Vakaliuk, A.V.; Oliynyk, V.V.; Zagorodnii, V.V.; et al. Epoxy composites filled with graphite nanoplatelets modified by FeNi nanoparticles: Structure and microwave properties. Mater. Sci. Eng. B. 2022, 283, 115776. [Google Scholar] [CrossRef]

- Manjappa, P.; Krishna Rajan, H.; Gowdaru Mahesh, M.; Gulur Sadananda, K. Electromagnetic Waves by Synergetic Effect of α-Fe2O3 and MWCNT/Graphene in LDPE-Based Composites for EMI Applications. Materials 2022, 15, 9006. [Google Scholar] [CrossRef] [PubMed]

- Vovchenko, L.L.; Oliynyk, V.V.; Zagorodnii, V.V.; Matzui, L.Y.; Milovanov, Y.S. Dielectric and microwave shielding properties of three-phase composites graphite nanoplatelets/carbonyl iron/epoxy resin. Appl. Nanosci. 2020, 10, 4781–4790. [Google Scholar] [CrossRef]

- Song, W.-L.; Guan, X.-T.; Fan, L.-Z.; Cao, L.-Z.; Zhao, Q.-L.; Wang, C.-Y.; Cao, M.-S. Tuning broadband microwave absorption via highly conductive Fe3O4/graphenen heterostructural nanofillers. Mater. Res. Bull. 2015, 72, 316–323. [Google Scholar] [CrossRef]

- Zong, M.; Huang, Y.; Zhao, Y.; Sun, X.; Qu, C.; Luo, D.; Zheng, J. Facile preparation, high microwave absorption and microwave absorbing mechanism of RGO–Fe3O4 composites. RSC Adv. 2013, 3, 23638. [Google Scholar] [CrossRef]

- Chai, J.; Cheng, J.; Zhang, D.; Xiong, Y.; Yang, X.; Ba, X.; Ullah, S.; Zheng, G.; Yan, M.; Cao, M. Enhancing electromagnetic wave absorption performance of Co3O4 nanoparticles functionalized MoS2 nanosheets. J. Alloys Compd. 2020, 829, 15453. [Google Scholar] [CrossRef]

- Liang, C.; Gu, Z.; Zhang, Y.; Ma, Z.; Qiu, H.; Cu, J. Structural Design Strategies of Polymer Matrix Composites for Electromagnetic Interference Shielding: A Review. Nano-Micro Lett. 2021, 13, 181. [Google Scholar] [CrossRef] [PubMed]

- Jia, Z.; Zhang, M.; Liu, B.; Wang, F.; Wei, G. Graphene foams for electromagnetic interference shielding: A review. ACS Appl. Nano Mater. 2020, 3, 6140–6155. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, N.; He, C. The superior mechanical and physical properties of nanocarbon reinforced bulk composites achieved by architecture design: A review. Prog. Mater. Sci. 2020, 113, 100672. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Liu, M.; Li, J.; Zhou, X. Review on Shielding Mechanism and Structural Design of Electromagnetic Interference Shielding Composites. Macromol. Mater. Eng. 2021, 306, 2100032. [Google Scholar] [CrossRef]

- Wang, T.; Kong, W.-W.; Yu, W.-C.; Gao, J.-F.; Dai, K.; Yan, D.-X.; Li, Z.-M. A Healable and Mechanically Enhanced Composite with Segregated Conductive Network Structure for High-Efficient Electromagnetic Interference Shielding. Nano-Micro Lett. 2021, 13, 162. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.C.; Yan, D.X.; Jiang, X.; Pang, H.; Gao, J.F. Synergistic effect of graphite and carbon nanotubes on improved electromagnetic interference shielding performance in segregated composites. Ind. Eng. Chem. Res. 2018, 57, 11929–11938. [Google Scholar] [CrossRef]

- Vovchenko, L.; Matzui, L.; Oliynyk, V.; Launets, V.; Mamunya, Y. Nanocarbon/polyethylene composites with segregated conductive network for electromagnetic interference shielding. Mol. Cryst. Liq. Cryst. 2018, 672, 186–198. [Google Scholar] [CrossRef]

- Mamunya, Y.; Matzui, L.; Vovchenko, L.; Maruzhenko, O.; Oliynyk, V.; Pusz, S.; Szeluga, U.; Kumanek, B. Influence of conductive filler distribution on electrical conductivity and EMI shielding properties of nanocarbon composites. Compos. Sci. Technol. 2019, 170, 51–59. [Google Scholar] [CrossRef]

- Kim, K.H.; Jang, J.-U.; Yoo, G.Y.; Kim, S.H.; Oh, M.J.; Kim, S.Y. Enhanced Electrical and Thermal Conductivities of Polymer Composites with a Segregated Network of Graphene Nanoplatelets. Materials 2023, 16, 5329. [Google Scholar] [CrossRef]

- Vovchenko, L.; Matzui, L.; Oliynyk, V.; Milovanov, Y.; Mamunya, Y.; Volynets, N.; Plyushch, A.; Kuzhir, P. Polyethylene Composites with Segregated Carbon Nanotubes Network: Low Frequency Plasmons and High Electromagnetic Interference Shielding Efficiency. Materials 2020, 13, 1118. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Xu, Y.; Yan, D.-X.; Yang, Y.; Zhao, G.; Liu, Y. Ultrahigh molecular weight polyethylene composites with segregated nickel conductive network for highly efficient electromagnetic interference shieldinging. Mater. Lett. 2017, 209, 353–356. [Google Scholar] [CrossRef]

- Iqbal, A.; Sambyal, P.; Koo, C.M. 2D MXenes for Electromagnetic Shielding: A Review. Adv. Funct. Mater. 2020, 30, 2000883. [Google Scholar] [CrossRef]

- Liang, C.; Song, P.; Qiu, H.; Huangfu, Y.; Lu, Y. Superior electromagnetic interference shielding performances of epoxy composites by introducing highly aligned reduced graphene oxide flms. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105512. [Google Scholar] [CrossRef]

- Xu, D.; Chen, W.; Liu, P. Enhanced electromagnetic interference shielding and mechanical properties of segregated polymer/carbon nanotube composite via selective microwave sintering. Compos. Sci. Technol. Vol. 2020, 199, 108355. [Google Scholar] [CrossRef]

- Yan, D.-X.; Pang, H.; Vajtai, B.; Li, R.; Xu, L. Structured reduced graphene oxide/polymer composites for ultra-efficient electromagnetic interference shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Cui, C.-H.; Yan, D.-X.; Pang, H.; Jia, L.-C.; Bao, Y.; Jiang, X.; Li, Z.-M. Towards efficient electromagnetic interference shielding performance for polyethylene composites by structuring segregated carbon black/graphite networks. Chin. J. Polym. Sci. 2016, 34, 1490–1499. [Google Scholar] [CrossRef]

- Anjaneyalu, A.M.; Shayesteh, A.; Sundararaj, U. Enhanced electromagnetic interference shielding effectiveness of hybrid fillers by segregated structure. AIP Conf. Proc. 2019, 2065, 040009. [Google Scholar] [CrossRef]

- Matzui, L.Y.; Syvolozhskyi, O.A.; Vovchenko, L.L.; Yakovenko, O.S.; Lazarenko, O.A.; Len, T.; Ischenko, O.V.; Dyachenko, A.G.; Vakaliuk, A.V.; Oliynyk, V.V.; et al. Electrical and electromagnetic interference shielding properties of GNP-NiFe hybrid composite with segregate structure of conductive networks. J. Appl. Phys. 2022, 131, 055110. [Google Scholar] [CrossRef]

- Zhan, Y.; Wang, J.; Zhang, K.; Li, Y.; Meng, Y.; Yan, N.; Wei, W.; Peng, F.; Xia, H. Fabrication of a flexible electromagnetic interference shielding Fe3O4@reduced graphene oxide/natural rubber composite. Chem. Eng. J. 2018, 344, 184–193. [Google Scholar] [CrossRef]

- Yakovenko, O.; Matzui, L.; Perets, Y.; Ovsiienko, I.; Brusylovets, O.; Vovchenko, L.; Szroeder, P. Effects of Dispersion and Ultraviolet/Ozonolysis Functionalization of Graphite Nanoplatelets on the Electrical Properties of Epoxy Nanocomposites. In Nanophysics, Nanophotonics, Surface Studies and Applications; Fesenko, O., Yatsenko, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; Volume 183, pp. 477–491. [Google Scholar] [CrossRef]

- Vovchenko, L.; Matzui, L.; Oliynyk, V.; Launetz, V. The effect of filler morphology and distribution on electrical and shielding properties of graphite-epoxy composites. Mol. Cryst. Liq. Cryst. 2011, 535, 179–188. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Tian, Z.; Dai, J.; Li, J.; Zhu, G.; Lu, J.; Xu, C.; Wang, Y.; Shi, Z. Tailored Fabrication of -Fe2O3 Nanocrystals/Reduced Graphene Oxide Nanocomposites with Excellent Electromagnetic Absorption Property. J. Nanosci. Nanotechnol. 2016, 16, 12590–12601. [Google Scholar] [CrossRef]

- Ayachi, A.A.; Mechakra, H.; Silvan, M.M.; Boudjaadar, S.; Achour, S. Monodisperse α-Fe2O3 nanoplatelets: Synthesis and characterization. Ceram. Int. 2015, 41, 2228–2233. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Geng, S.; Zhou, C.; Jia, X.; Yang, F.; Zhang, L.; Ren, X.; Yang, H. Preparation of flexible reduced graphene oxide/poly(vinyl alcohol) film with superior microwave absorption properties. RSC Adv. 2015, 5, 88958. [Google Scholar] [CrossRef]

- Lin, Z.; Yao, Y.; Li, Z.; Liu, Y.; Li, Z.; Wong, C.-P. Solvent-Assisted Thermal Reduction of Graphite Oxide. J. Phys. Chem. C 2010, 114, 14819–14825. [Google Scholar] [CrossRef]

- Prakash, A.; Chandra, S.; Bahadur, D. Structural, magnetic, and textural properties of iron oxide-reduced graphene oxide hybrids and their use for the electrochemical detection of chromium. Carbon 2012, 50, 4209–4219. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.A. Jorio, Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47. [Google Scholar] [CrossRef]

- Reich, S.; Thomsen, C. Raman spectroscopy of graphite. Phil. Trans. R. Soc. Lond. A 2004, 362, 2271–2288. [Google Scholar] [CrossRef]

- Naumenko, A.P.; Korniyenko, N.E.; Yashchuk, V.M.; Bliznyuk, V.N.; Singamaneni, S. Phonon-like light scattering in polycrystalline carbon structures. Ukr. J. Phys. 2012, 57, 197–207. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Naumenko, A.; Yashchuk, V.; Bliznyuk, V.; Singamaneni, S. Peculiarities of Raman spectra of polyurethane/carbon nanotube composite. Eur. Phys. J. B 2012, 85, 120. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction to Percolation Theory; Taylor & Francis: London, UK, 1992. [Google Scholar] [CrossRef]

- Ovsienko, I.V.; Len, T.A.; Matzui, L.Y.; Golub, O.A.; Prylutskyy, Y.I.; Eklund, P. The effect of thermal and chemical treatment on the structural and phase composition of nanocarbon materials. Mater. Sci. Eng. C 2006, 26, 1180–1184. [Google Scholar] [CrossRef]

- Ovsiienko, I.; Lzarenko, O.; Matzui, L.; Brusylovets, O.; Le Normand, F.A. Influence of chemical treatment on the microstruc-ture of nanographite. Phys. Status Solidi (A) 2014, 211, 2765–2772. [Google Scholar] [CrossRef]

- Lazarenko, O.; Vovchenko, L.; Matzui, L.; Perets, Y. The electronic transport properties of the composites with nanosized carbon fillers. Mol. Cryst. Liq. Cryst. 2011, 536, 72–80. [Google Scholar] [CrossRef]

- Vovchenko, L.L.; Vovchenko, V.Y. Simulation of percolation threshold in composites filled with conducting particles of various morphology. Mat.-Wiss. Und Werkstofftech. 2011, 41, 1015–1020. [Google Scholar] [CrossRef]

- Lisunova, M.O.; Mamunya, Y.P.; Lebovka, N.I.; Melezhyk, A.V. Percolation behavior of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur. Polym. J. 2007, 43, 949–958. [Google Scholar] [CrossRef]

- Yu, W.-C.; Xu, J.-Z.; Wang, Z.-G.; Huang, Y.-F.; Yin, H.-M.; Xu, L.; Chen, Y.-W.; Yan, D.-X.; Li, Z.-M. Constructing highly oriented segregated structure towards high-strength carbon nanotube/ultrahigh-molecular-weight polyethylene composites for electromagnetic interference shielding. Compos. Part A 2018, 110, 237–245. [Google Scholar] [CrossRef]

- Luo, J.C.; Wang, L.; Huang, X.W.; Li, B.; Guo, Z.; Song, X.; Lin, L.; Tang, L.-C.; Xue, H.; Gao, J. Mechanically durable, highly conductive, and anticorrosive composite fabrics with excellent self-cleaning performance for high-efficiency electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2019, 11, 10883–10894. [Google Scholar] [CrossRef] [PubMed]

| Place in Sample | xD, cm−1 | xG, cm−1 | IG/ID |

|---|---|---|---|

| GNPs | |||

| 1 | 1348.9 | 1582.0 | 1.64 |

| 2 | 1348.9 | 1582.0 | 11.11 |

| GNPs/Fe3O4 | |||

| 1 | 1368 | 1579 | 3.2 |

| 2 | 1355.15 | 1581.16 | 2.38 |

| Composite | vol.% | t | , S/m |

|---|---|---|---|

| SCMs with GNPs/UHMWPE | 0.97 | 2.78 | 9.78 |

| SCMs with (GNPs/Fe3O4)/UHMWPE | 0.56 | 1.63 | 4.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matzui, L.Y.; Syvolozhskyi, O.A.; Vovchenko, L.L.; Yakovenko, O.S.; Len, T.A.; Ischenko, O.V.; Vakaliuk, A.V.; Oliynyk, V.V.; Zagorodnii, V.V.; Naumenko, A.; et al. Segregated Conductive Polymer Composite with Fe3O4-Decorated Graphite Nanoparticles for Microwave Shielding. Materials 2024, 17, 2808. https://doi.org/10.3390/ma17122808

Matzui LY, Syvolozhskyi OA, Vovchenko LL, Yakovenko OS, Len TA, Ischenko OV, Vakaliuk AV, Oliynyk VV, Zagorodnii VV, Naumenko A, et al. Segregated Conductive Polymer Composite with Fe3O4-Decorated Graphite Nanoparticles for Microwave Shielding. Materials. 2024; 17(12):2808. https://doi.org/10.3390/ma17122808

Chicago/Turabian StyleMatzui, Ludmila Yu., Oleksii A. Syvolozhskyi, Ludmila L. Vovchenko, Olena S. Yakovenko, Tetyana A. Len, Olena V. Ischenko, Anna V. Vakaliuk, Victor V. Oliynyk, Volodymyr V. Zagorodnii, Antonina Naumenko, and et al. 2024. "Segregated Conductive Polymer Composite with Fe3O4-Decorated Graphite Nanoparticles for Microwave Shielding" Materials 17, no. 12: 2808. https://doi.org/10.3390/ma17122808