Effect of Inconel 718 Filler on the Microstructure and Mechanical Properties of Inconel 690 Joint by Ultrasonic Frequency Pulse Assisted TIG Welding

Abstract

1. Introduction

2. Experimental Methods

2.1. Welding Material

2.2. Microstructure Characterization

2.3. Mechanical Properties Test

3. Results and Discussion

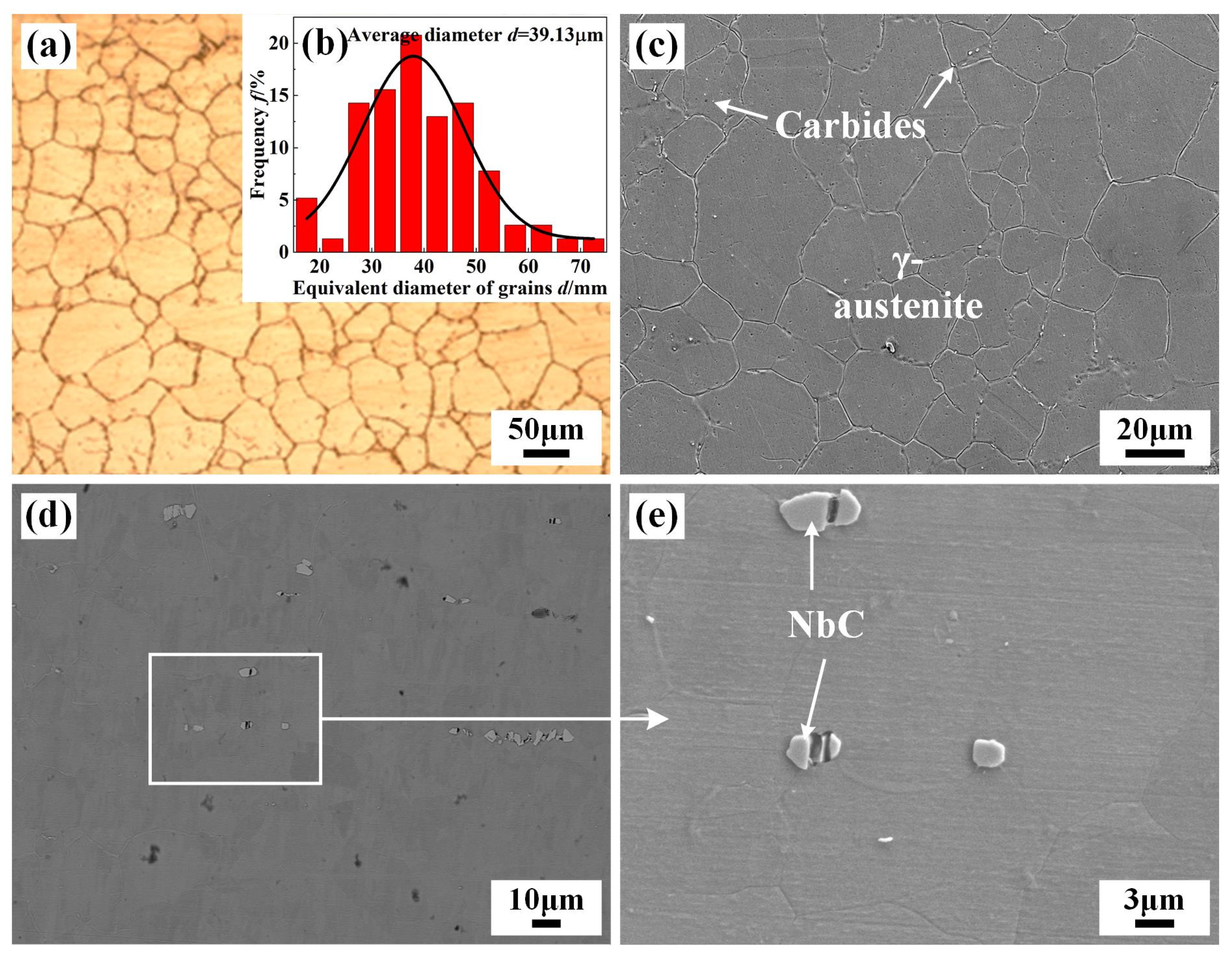

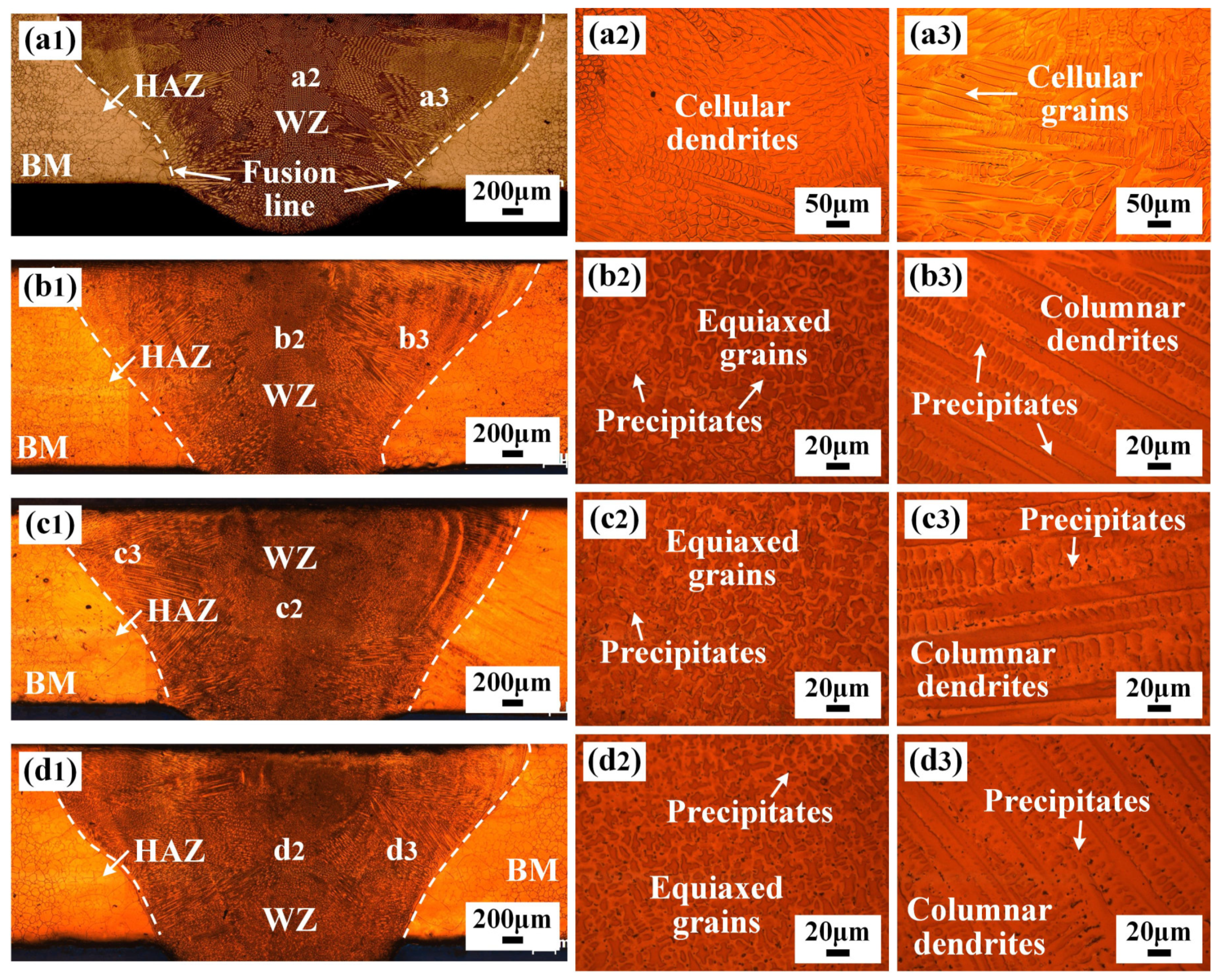

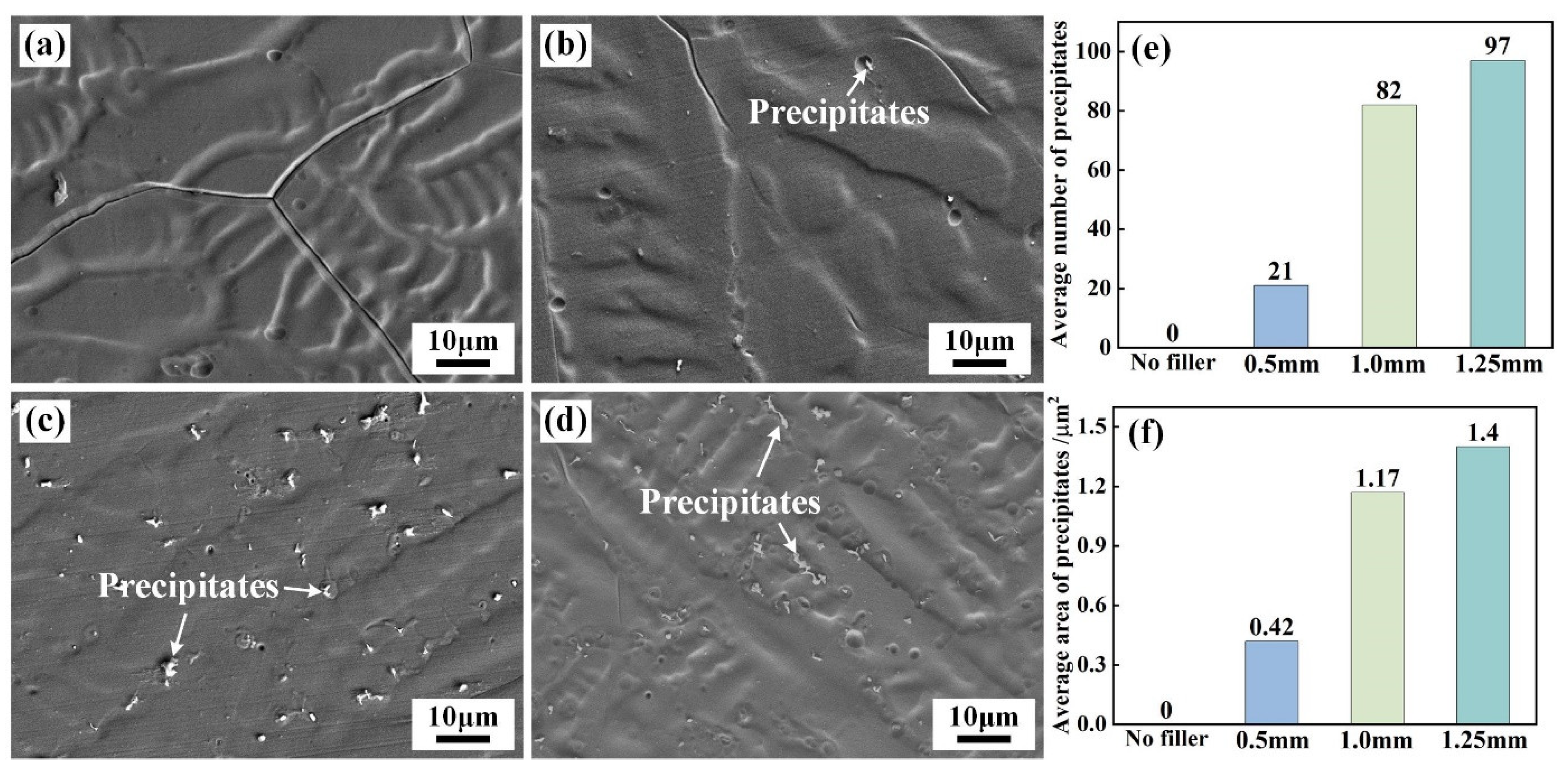

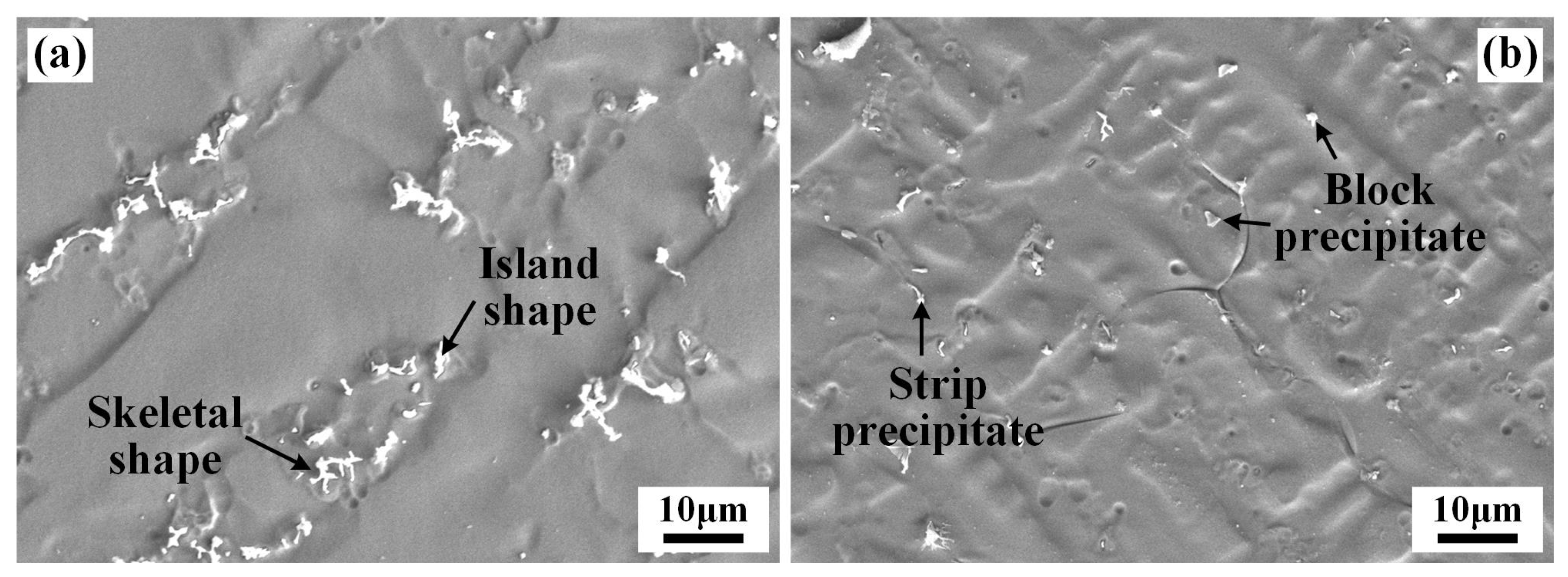

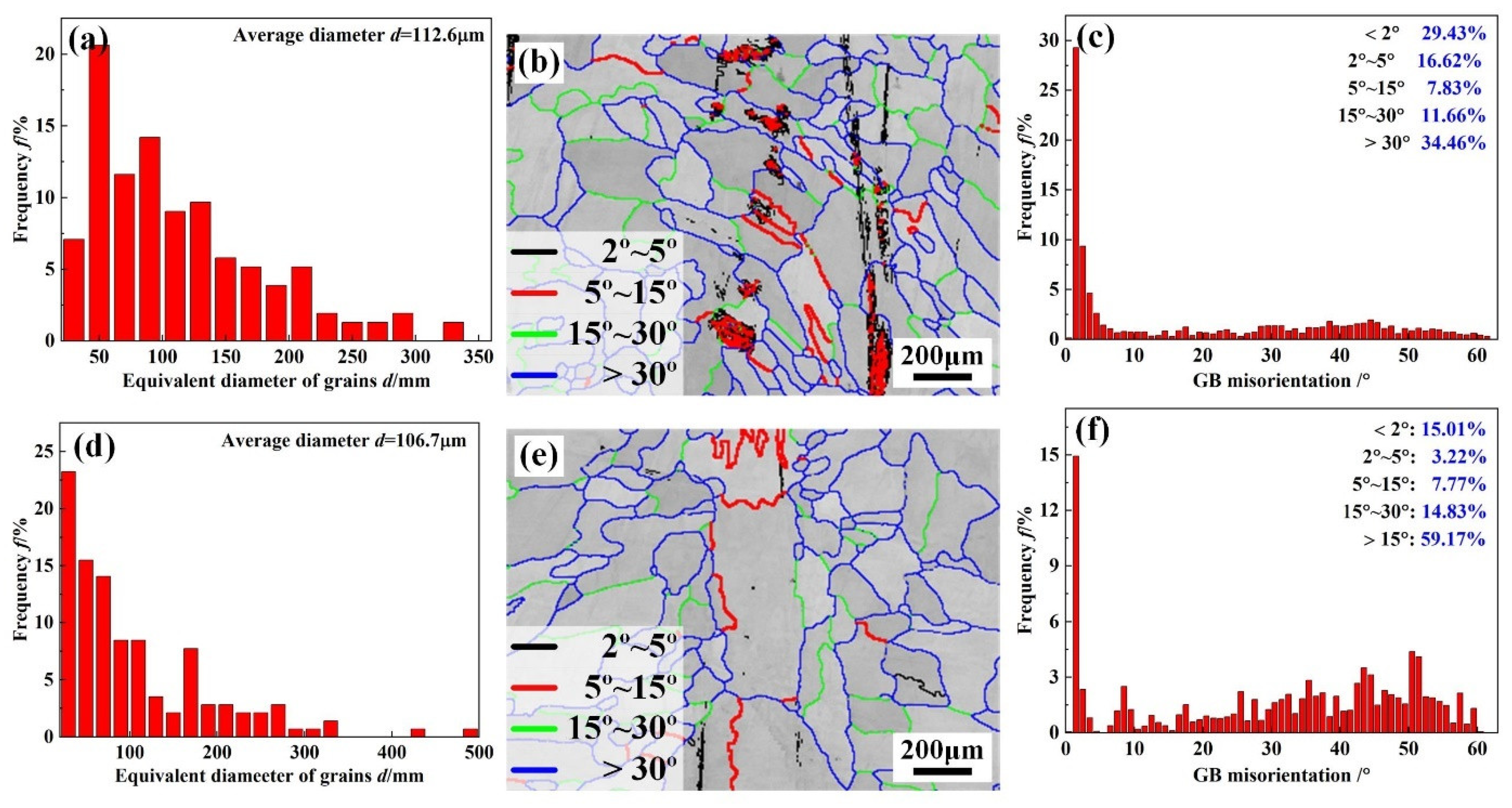

3.1. Effect of IN718 Filler on Microstructure

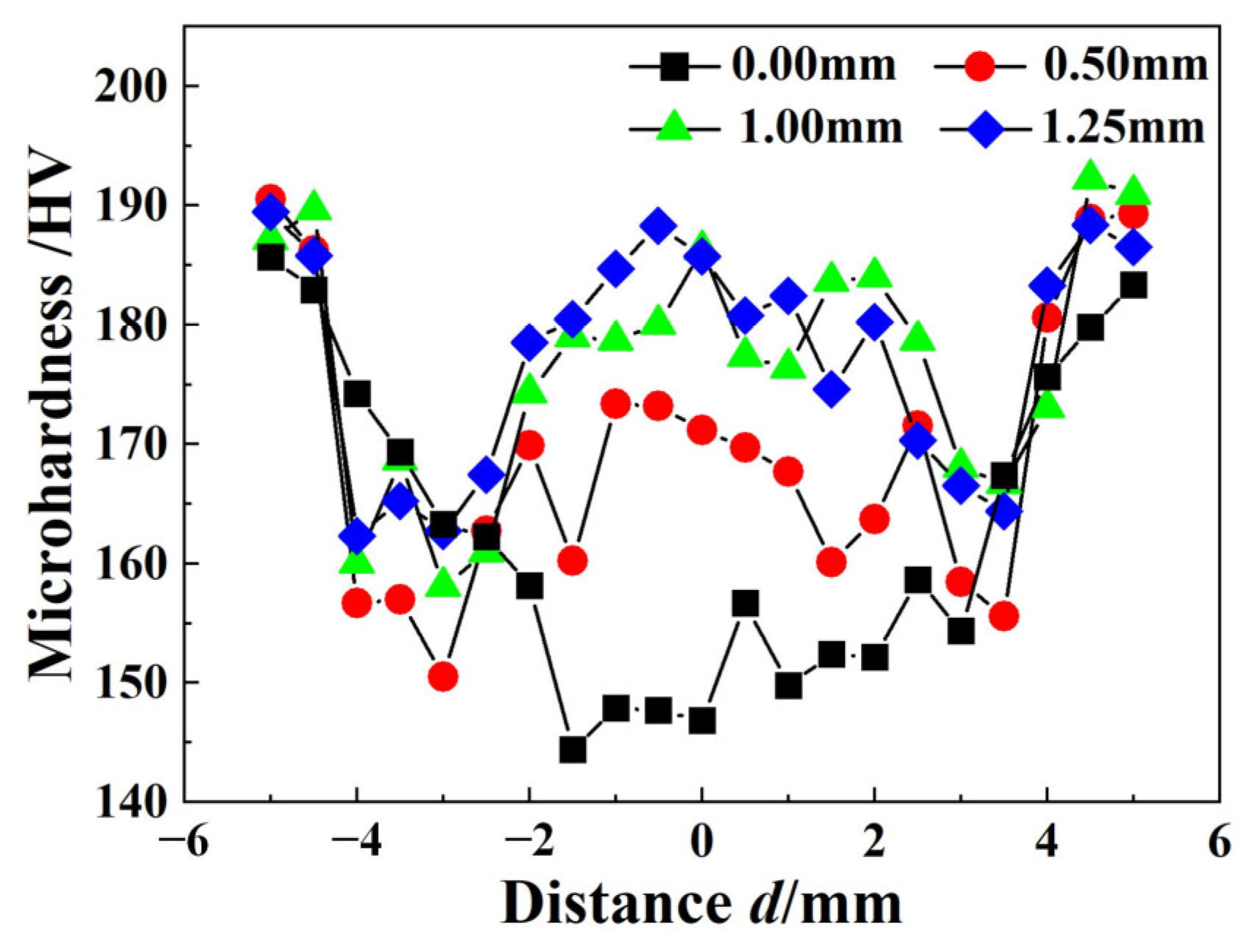

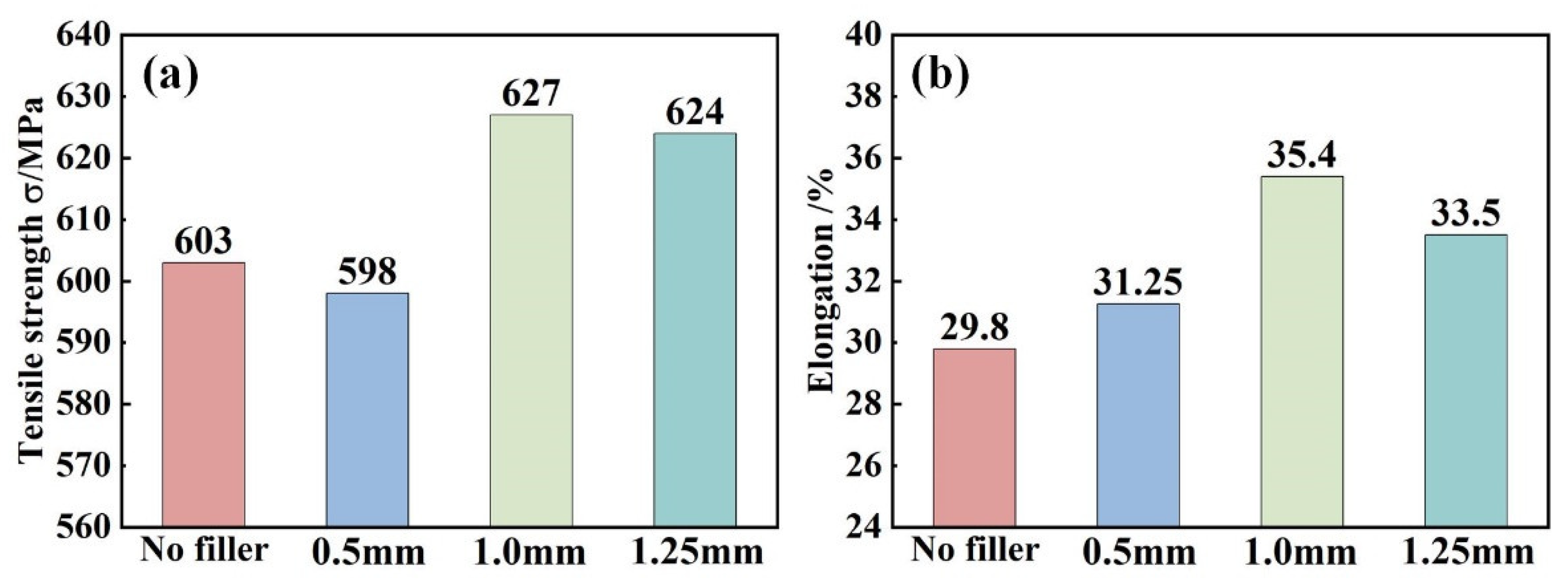

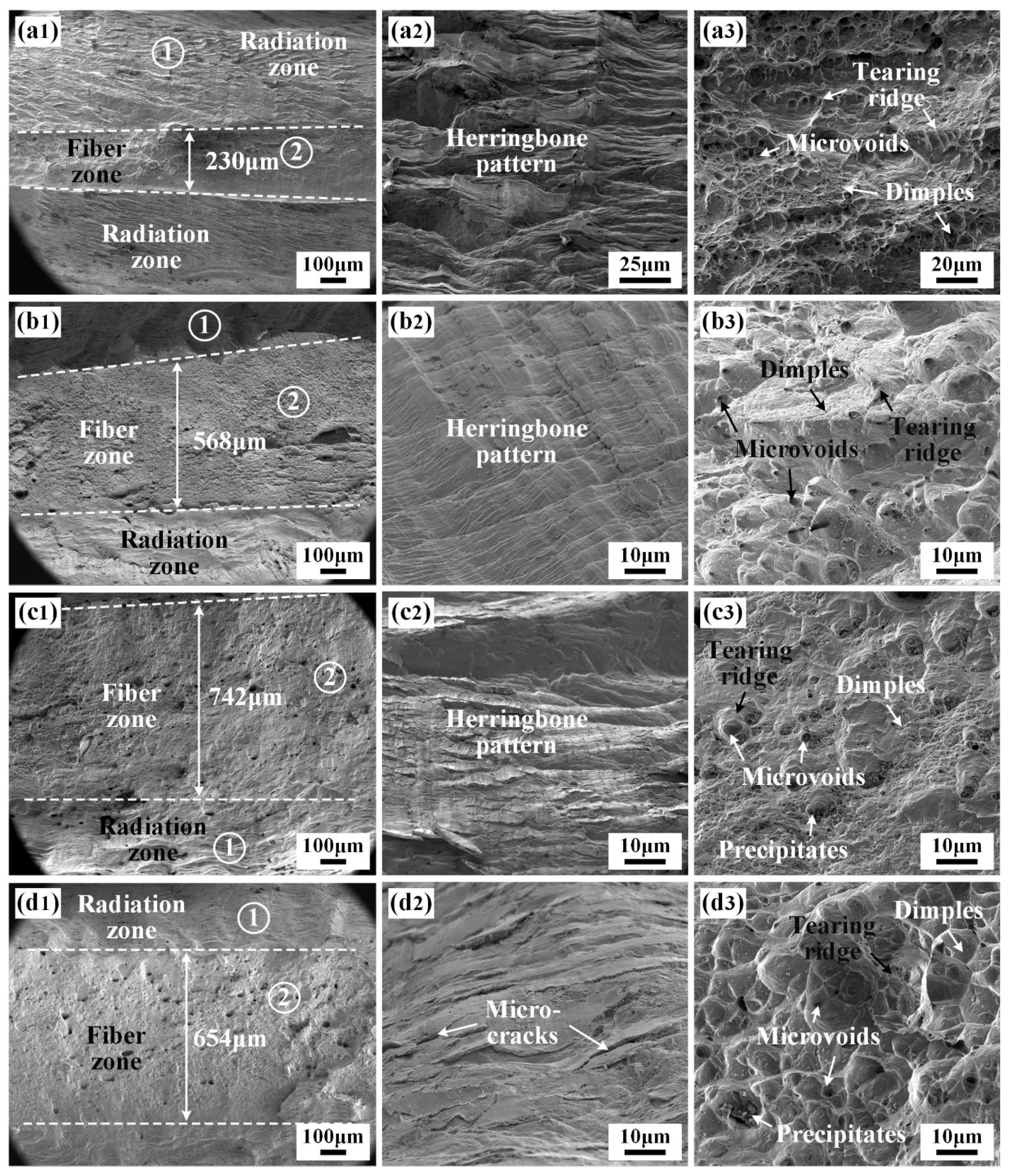

3.2. Effect of IN718 Filler on the Mechanical Properties of IN690 Joints

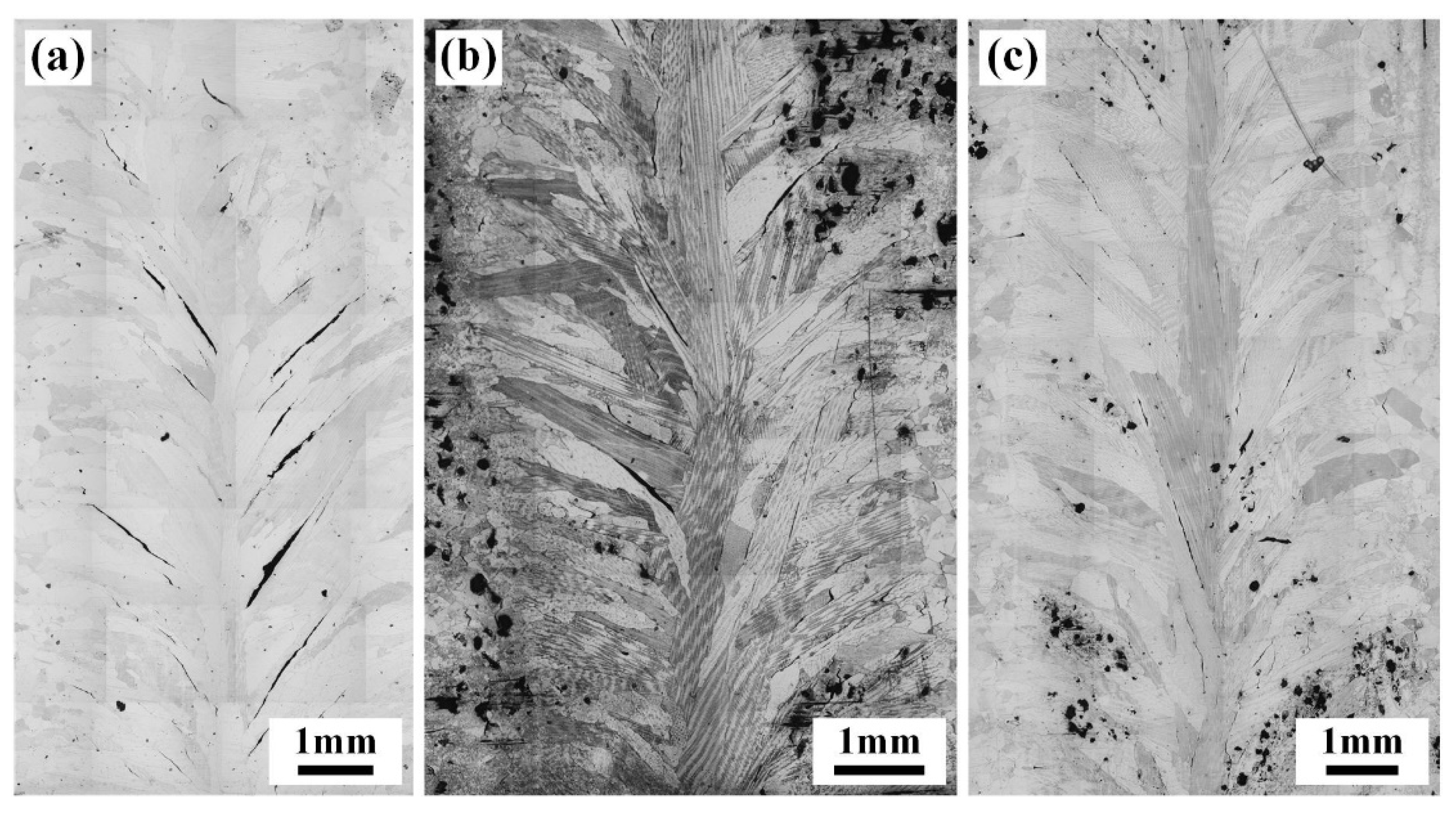

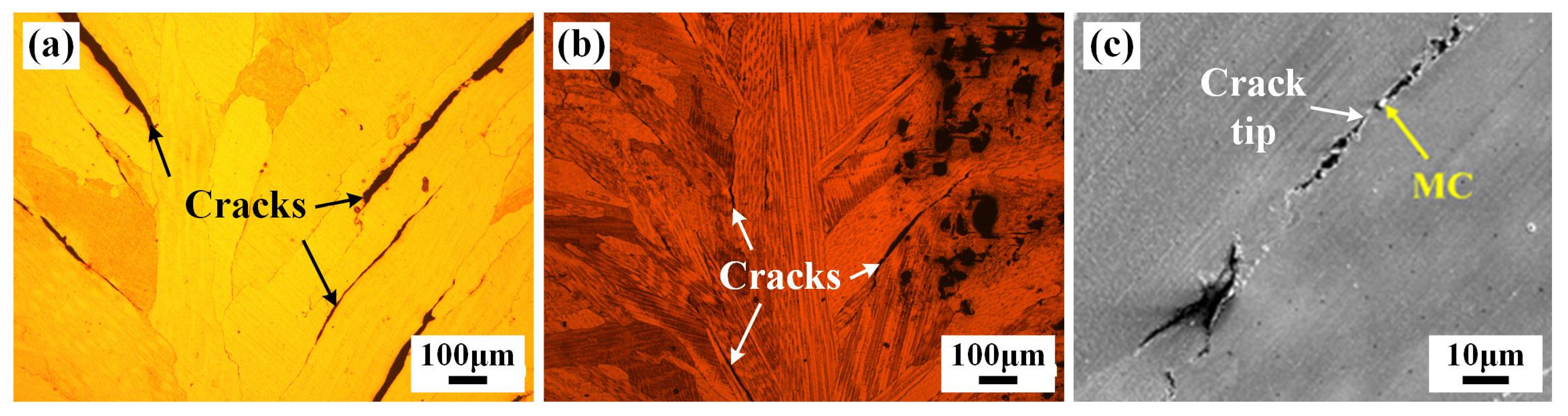

3.3. Effect of IN718 Filler on the DDC Susceptibility of IN690 Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Tian, C.; Liu, L.; Tan, W. Effect of temperature on simulated flow-induced vibration wear behavior of Inconel 690 alloy mated with 304 SS in pressurized steam/water environment. J. Tribol. 2023, 145, 031707. [Google Scholar] [CrossRef]

- Yin, M.; Yin, H.; Zhang, Q.; Long, J. Effect of ultrasonic surface rolling process on the high temperature fretting wear behavior of Inconel 690 alloy. Wear 2022, 500, 204347. [Google Scholar] [CrossRef]

- Lee, H.T.; Kuo, T.Y. Effects of niobium on microstructure, mechanical properties, and corrosion behaviour in weldments of alloy 690. Sci. Technol. Weld. J. 1999, 4, 245–256. [Google Scholar] [CrossRef]

- Rapetti, A.; Christien, F.; Tancret, F.; Todeschini, P.; Hendili, S. Effect of composition on ductility dip cracking of 690 nickel alloy during multipass welding. Mater. Today Commun. 2020, 24, 101163. [Google Scholar] [CrossRef]

- Kadoi, K.; Uegaki, T.; Shinozaki, K.; Yamamoto, M. New measurement technique of ductility curve for ductility-dip cracking susceptibility in Alloy 690 welds. Mat. Sci. Eng. A-Struct. 2016, 672, 59–64. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C. High temperature behavior of Ni-base weld metal Part I. Ductility and microstructural characterization. Mat. Sci. Eng. A-Struct. 2004, 380, 259–271. [Google Scholar] [CrossRef]

- Unfried-Silgado, J.; Ramirez, A.J. Modeling and characterization of as-welded microstructure of solid solution strengthened Ni-Cr-Fe alloys resistant to ductility-dip cracking part I: Numerical modeling. Met. Mater. Int. 2014, 20, 297–305. [Google Scholar] [CrossRef]

- Ahn, H.I.; Jeong, S.H.; Cho, H.H.; Lee, H.W. Ductility-dip cracking susceptibility of Inconel 690 using Nb content. J. Alloys Compd. 2019, 783, 263–271. [Google Scholar] [CrossRef]

- Fink, C. An investigation on ductility-dip cracking in the base metal heat-affected zone of wrought nickel base alloys—Part I: Metallurgical effects and cracking mechanism. Weld. World 2016, 60, 939–950. [Google Scholar] [CrossRef]

- Hua, C.; Lu, H.; Yu, C.; Chen, J.; Wei, X.; Xu, J. Reduction of ductility-dip cracking susceptibility by ultrasonic-assisted GTAW. J. Mater. Process. Technol. 2017, 239, 240–250. [Google Scholar] [CrossRef]

- Blecher, J.J.; Palmer, T.A.; DebRoy, T. Solidification Map of a Nickel-Base Alloy. Metall. Mater. Trans. A 2014, 45, 2142–2151. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, Y.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mat. Sci. Eng. A-Struct. 2021, 819, 141507. [Google Scholar] [CrossRef]

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. An overview on welding of Inconel 718 alloy-Effect of welding processes on microstructural evolution and mechanical properties of joints. Mater. Charact. 2021, 174, 110997. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, X.; Zou, Y.; Wang, J.; Cao, L. Effect of Nb Content on Microstructure and Mechanical Properties of K4169-Type Superalloy. J. Mater. Eng. Perform. 2022, 31, 4204–4213. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, Y.; Xiao, H.; Li, S.; Song, L. Investigation of the Nb element segregation for laser additive manufacturing of nickel-based superalloys. Int. J. Heat. Mass. Tran. 2021, 180, 121800. [Google Scholar] [CrossRef]

- Han, K.; Wang, H.; Shen, L.; Zhang, B. Analysis of cracks in the electron beam welded joint of K465 nickel-base superalloy. Vacuum 2018, 157, 21–30. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, L.; Wang, B.; Yao, L.; Jiang, B.; Luo, L.; Chen, R.; Su, Y.; Guo, J. Microstructure evolution and mechanical properties of wire-fed electron beam directed energy deposition repaired GH4169 superalloy. J. Mater. Res. Technol. 2023, 27, 7259–7270. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Ming, X.; Zhang, S.; Lin, X.; Huang, W. The failure mechanism of 50% laser additive manufactured Inconel 718 and the deformation behavior of Laves phases during a tensile process. Int. J. Adv. Manuf. Technol. 2017, 91, 2733–2740. [Google Scholar] [CrossRef]

- Han, K.; Wang, H.; Zhang, B.; Zhao, J.; Lei, J.; Zhao, X. Microstructural/mechanical characterizations of electron beam welded IN738LC joint after post-weld heat treatment. J. Mater. Res. Technol. 2022, 17, 1030–1042. [Google Scholar] [CrossRef]

- Qin, X.; Wang, J.; Cheng, S.; Wu, Y.; Zhou, L. Evolution of microstructure and 800 °C/294 MPa stress rupture property of cast Ni-based superalloys during long-term thermal exposure: Role and behavior of primary MC carbide. Mat. Sci. Eng. A-Struct. 2023, 881, 145416. [Google Scholar] [CrossRef]

- Liu, G.; Winwood, S.; Rhodes, K.; Birosca, S. The effects of grain size, dendritic structure and crystallographic orientation on fatigue crack propagation in IN713C nickel-based superalloy. Int. J. Plast. 2020, 125, 150–168. [Google Scholar] [CrossRef]

- Schneider, J.; Farris, L.; Nolze, G.; Reinsch, S.; Cios, G.; Tokarski, T.; Thompson, S. Microstructure Evolution in Inconel 718 Produced by Powder Bed Fusion Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 20. [Google Scholar] [CrossRef]

- Brewer, L.; Othon, M.; Young, L.; Angeliu, T. Misorientation mapping for visualization of plastic deformation via electron back-scattered diffraction. Microsc. Microanal. 2006, 12, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Chinh, N.Q.; Olasz, D.; Ahmed, A.Q.; Sáfrán, G.; Lendvai, J.; Langdon, T.G. Modification of the Hall-Petch relationship for submicron-grained fcc metals. Mat. Sci. Eng. A-Struct. 2023, 862, 144419. [Google Scholar] [CrossRef]

- Song, X.; Wang, Y.; Zhao, X.; Zhang, J.; Li, Y.; Wang, Y.; Chen, Z. Analysis of carbide transformation in MC-M23C6 and its effect on mechanical properties of Ni-based superalloy. J. Alloys Compd. 2022, 911, 164959. [Google Scholar] [CrossRef]

- Ye, M.; Wang, Z.; Butt, H.A.; Yang, M.; Chen, H.; Han, K.; Cui, M.; Lei, Y. Enhancing the joint of dissimilar aluminum alloys through MIG welding approach assisted by ultrasonic frequency pulse. Mater. Lett. 2023, 330, 133289. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Z.; Yu, L.; Dong, J.; Liu, Y. The simultaneous improvements of strength and ductility in additive manufactured Ni-based superalloy via controlling cellular subgrain microstructure. J. Mater. Sci. Technol. 2021, 68, 184–190. [Google Scholar] [CrossRef]

- Yonezawa, T.; Hänninen, H.; Hashimoto, A. Weld Cracking Susceptibility of High-Cr Ni-Base Fe Alloys and Its Improvement—Development of Novel Test Method for Ductility-Dip Cracking and New Alloy. Metall. Mater. Trans. A 2024, 55, 1878–1893. [Google Scholar] [CrossRef]

- Wei, X.; Xu, M.; Chen, J.; Yu, C.; Chen, J.; Lu, H.; Xu, J. Fractal analysis of Mo and Nb effects on grain boundary character and hot cracking behavior for Ni-Cr-Fe alloys. Mater. Charact. 2018, 145, 65–76. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Sowards, J.W.; Lippold, J.C. Improving the ductility-dip cracking resistance of Ni-base alloys. J. Mater. Process. Technol. 2006, 179, 212–218. [Google Scholar] [CrossRef]

| Alloy | Alloy Element | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Fe | Mo | Nb | Al | Ti | C | Mn | Si | Cu | S | |

| IN 690 | 60.02 | 30.39 | 8.88 | - | - | 0.2 | 0.21 | 0.02 | 0.197 | 0.07 | 0.01 | 0.002 |

| IN 718 | 53.90 | 18.01 | 17.99 | 3.07 | 5.32 | 0.42 | 1.02 | 0.08 | 0.07 | 0.09 | 0.02 | 0.001 |

| Welding Number | Thickness of Filler (mm) | Welding Current (A) | Voltage (V) | Welding Velocity (mm·min−1) | Shield Gas Flow (L·min−1) | Excitation Voltage (V) | Excitation Frequency (kHz) | |

|---|---|---|---|---|---|---|---|---|

| Top Surface | Back Surface | |||||||

| 1# | 0 (without filler) | 52 | 12~12.5 | 100 | 15 | 18 | 60 | 60 |

| 2# | 0.5 | |||||||

| 3# | 1.0 | |||||||

| 4# | 1.25 | |||||||

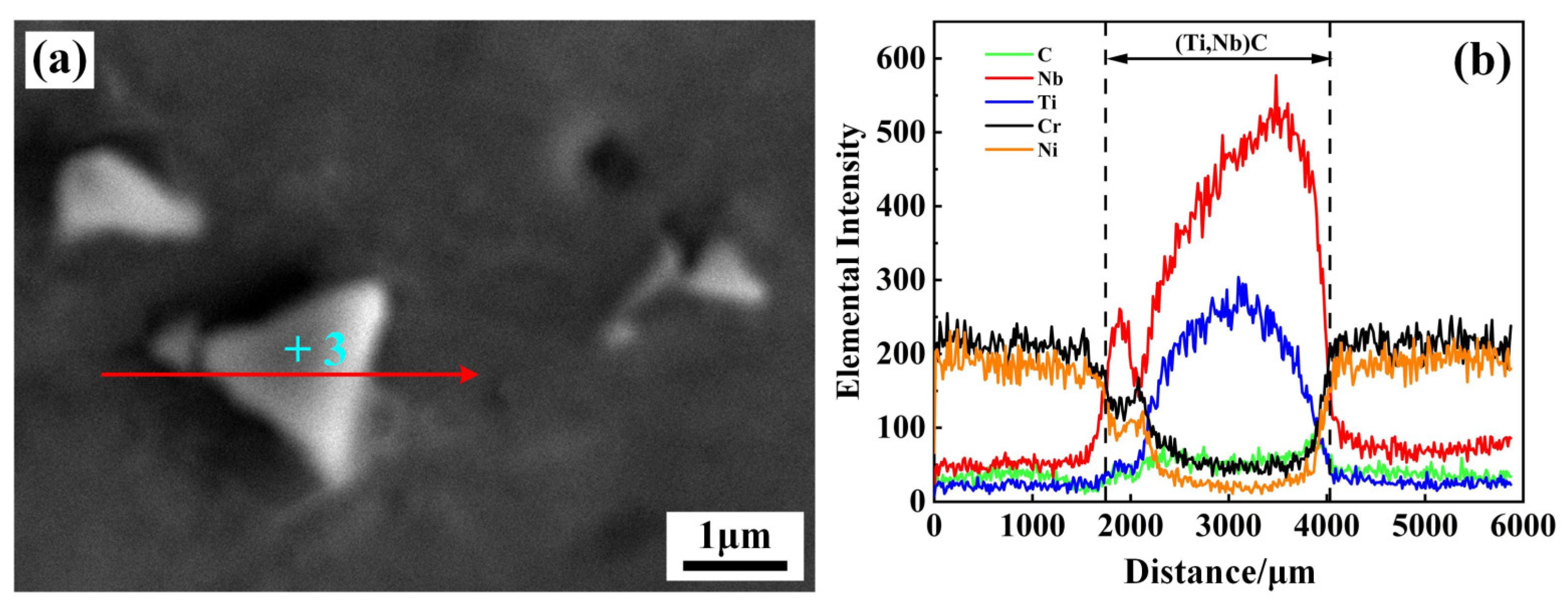

| Regions | Alloy Elements (%) | Possible Phases | ||||||

|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Fe | Nb | Ti | C | Mo | ||

| +1 | 34.13 | 20.76 | 7.52 | 25.86 | 5.99 | 0 | 5.74 | Laves phases |

| +2 | 9.18 | 7.22 | 3.53 | 32.25 | 9.67 | 36.84 | 1.31 | γ-Ni matrix |

| +3 | 4.68 | 5.88 | 2.70 | 21.61 | 28.55 | 35.08 | 0.68 | MC-type carbide |

| Group | Strain/% | Number | Total Length/µm | Average Length/µm | Maximum Length/µm |

|---|---|---|---|---|---|

| Joint 1# | 3.8% | 29 | 33,973.49 | 1171.50 | 3666.80 |

| Joint 3# | 3.8% | 19 | 11,385.00 | 599.21 | 1612.13 |

| 6% | 20 | 21,723.50 | 1068.18 | 2599.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, K.; Hu, X.; Zhang, X.; Chen, H.; Liu, J.; Zhang, X.; Chen, P.; Li, H.; Lei, Y.; Xi, J. Effect of Inconel 718 Filler on the Microstructure and Mechanical Properties of Inconel 690 Joint by Ultrasonic Frequency Pulse Assisted TIG Welding. Materials 2024, 17, 2857. https://doi.org/10.3390/ma17122857

Han K, Hu X, Zhang X, Chen H, Liu J, Zhang X, Chen P, Li H, Lei Y, Xi J. Effect of Inconel 718 Filler on the Microstructure and Mechanical Properties of Inconel 690 Joint by Ultrasonic Frequency Pulse Assisted TIG Welding. Materials. 2024; 17(12):2857. https://doi.org/10.3390/ma17122857

Chicago/Turabian StyleHan, Ke, Xin Hu, Xinyue Zhang, Hao Chen, Jinping Liu, Xiaodong Zhang, Peng Chen, Hongliang Li, Yucheng Lei, and Jinhui Xi. 2024. "Effect of Inconel 718 Filler on the Microstructure and Mechanical Properties of Inconel 690 Joint by Ultrasonic Frequency Pulse Assisted TIG Welding" Materials 17, no. 12: 2857. https://doi.org/10.3390/ma17122857

APA StyleHan, K., Hu, X., Zhang, X., Chen, H., Liu, J., Zhang, X., Chen, P., Li, H., Lei, Y., & Xi, J. (2024). Effect of Inconel 718 Filler on the Microstructure and Mechanical Properties of Inconel 690 Joint by Ultrasonic Frequency Pulse Assisted TIG Welding. Materials, 17(12), 2857. https://doi.org/10.3390/ma17122857