Structure and Properties of Metastable β Ti–25Nb–8Sn Alloy following Cold Rolling and Aging Treatments

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Phase Identification

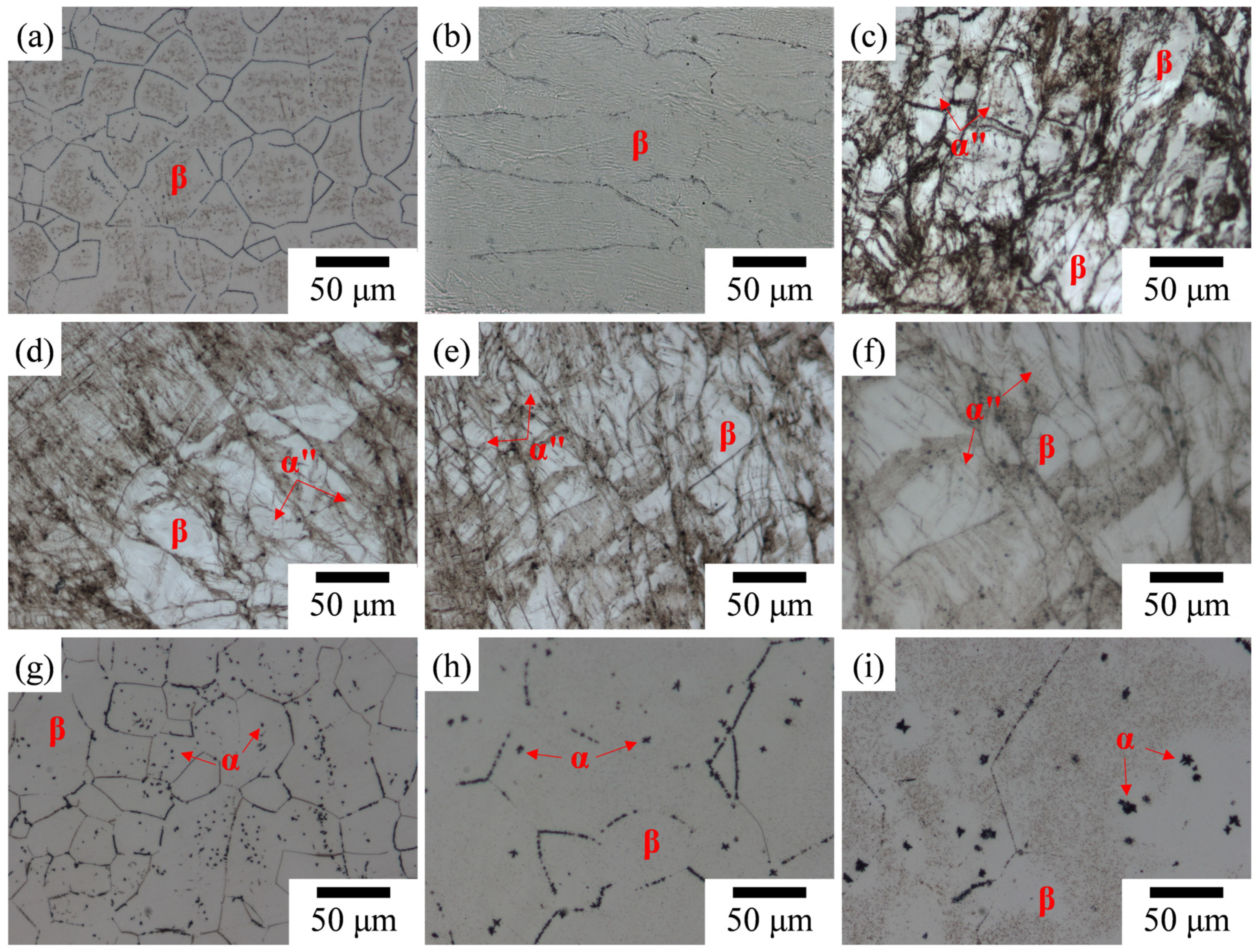

3.2. Microstructure

3.3. Mechanical Properties

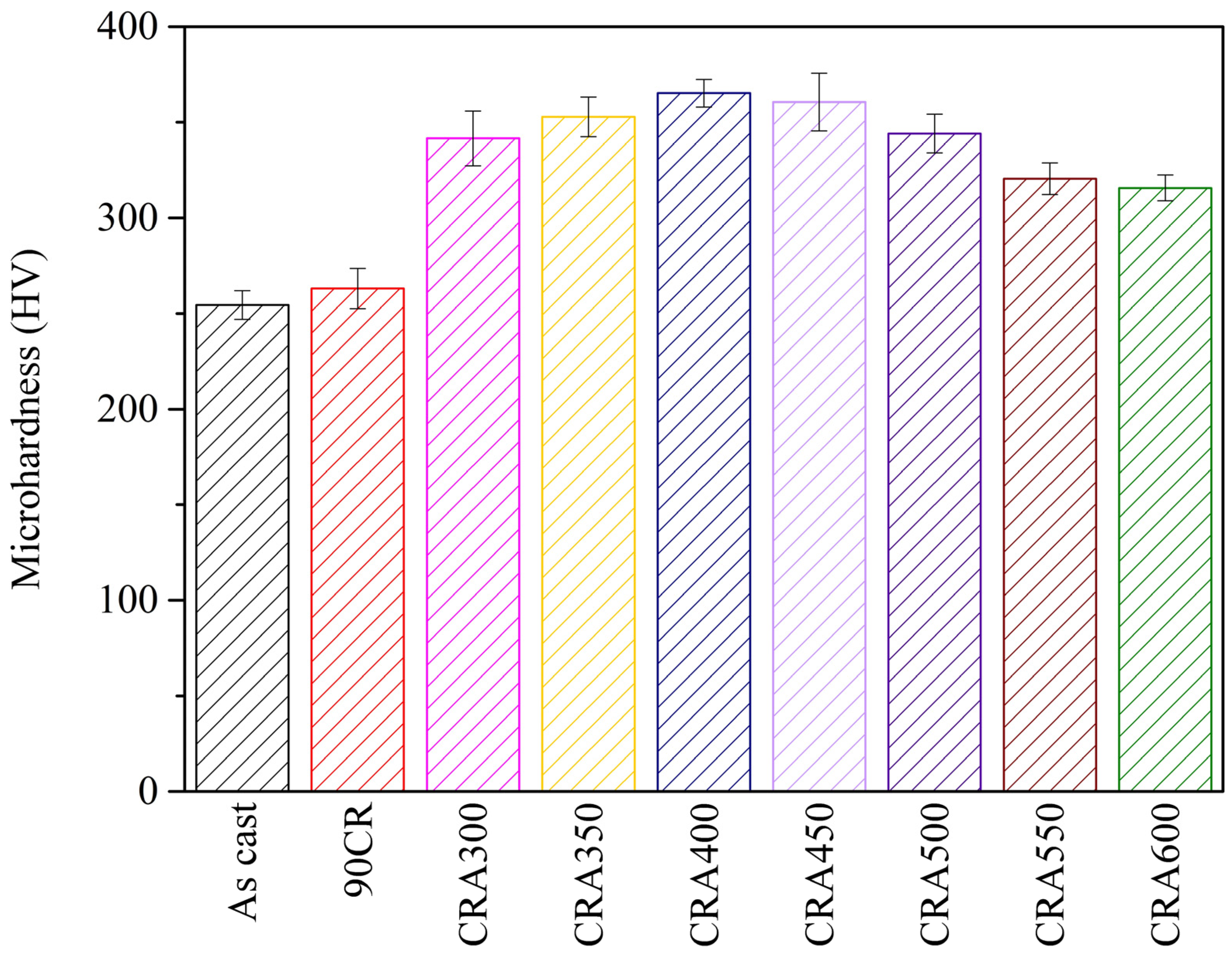

3.3.1. Microhardness

3.3.2. Bending Properties

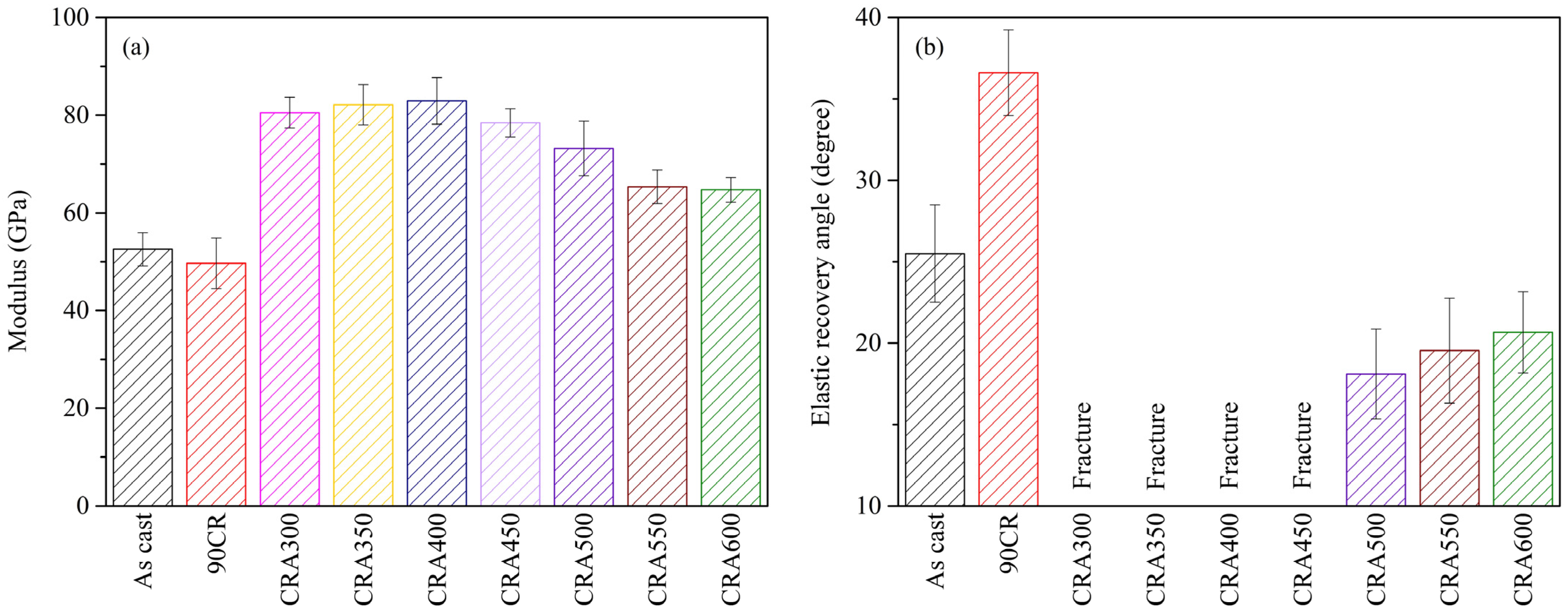

3.3.3. Elastic Properties

3.3.4. Fracture Surface Topography

3.3.5. Elastic Admissible Strain (EAS)

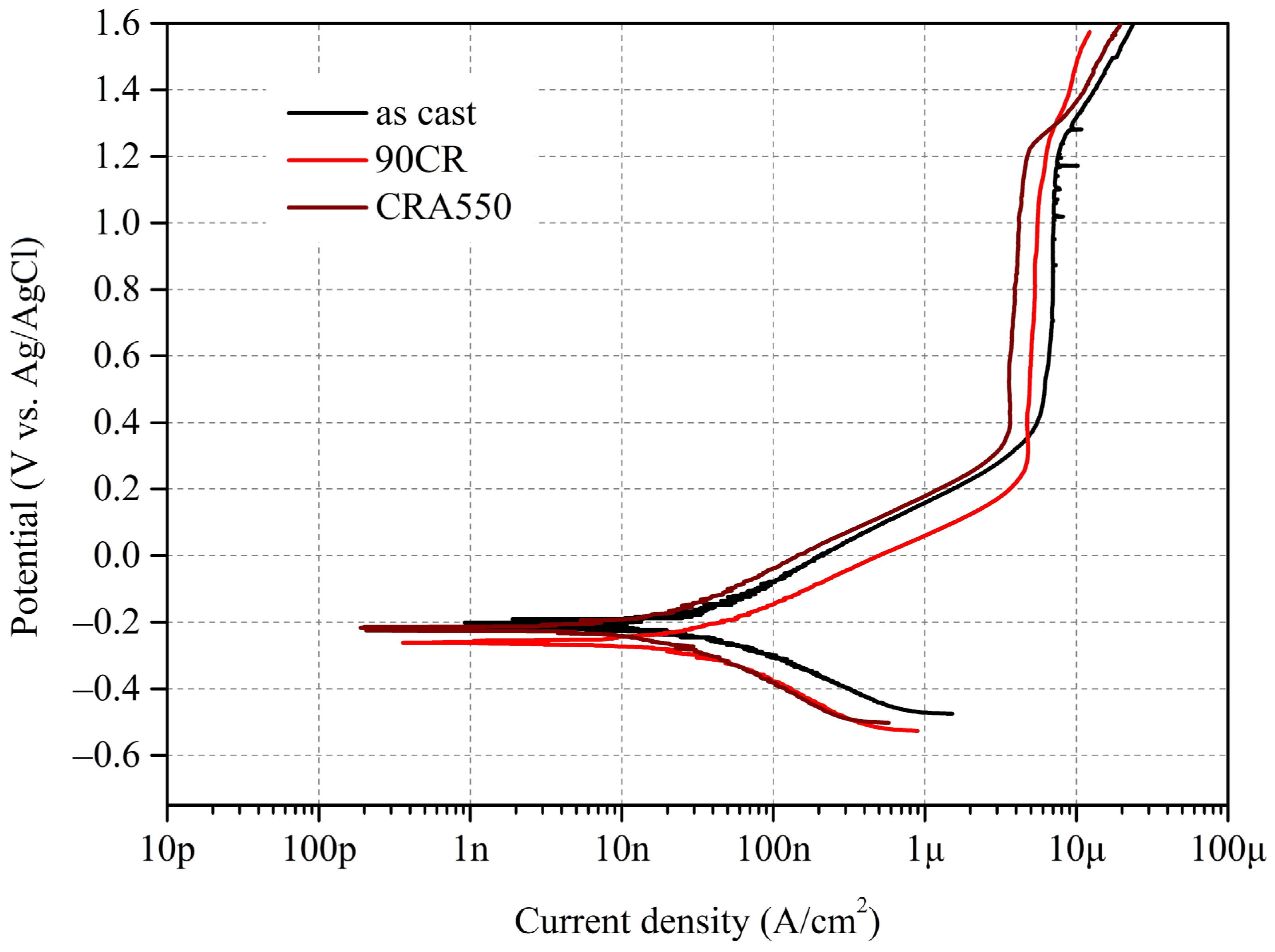

3.4. Corrosion Properties

3.4.1. Potentiodynamic Polarization Tests

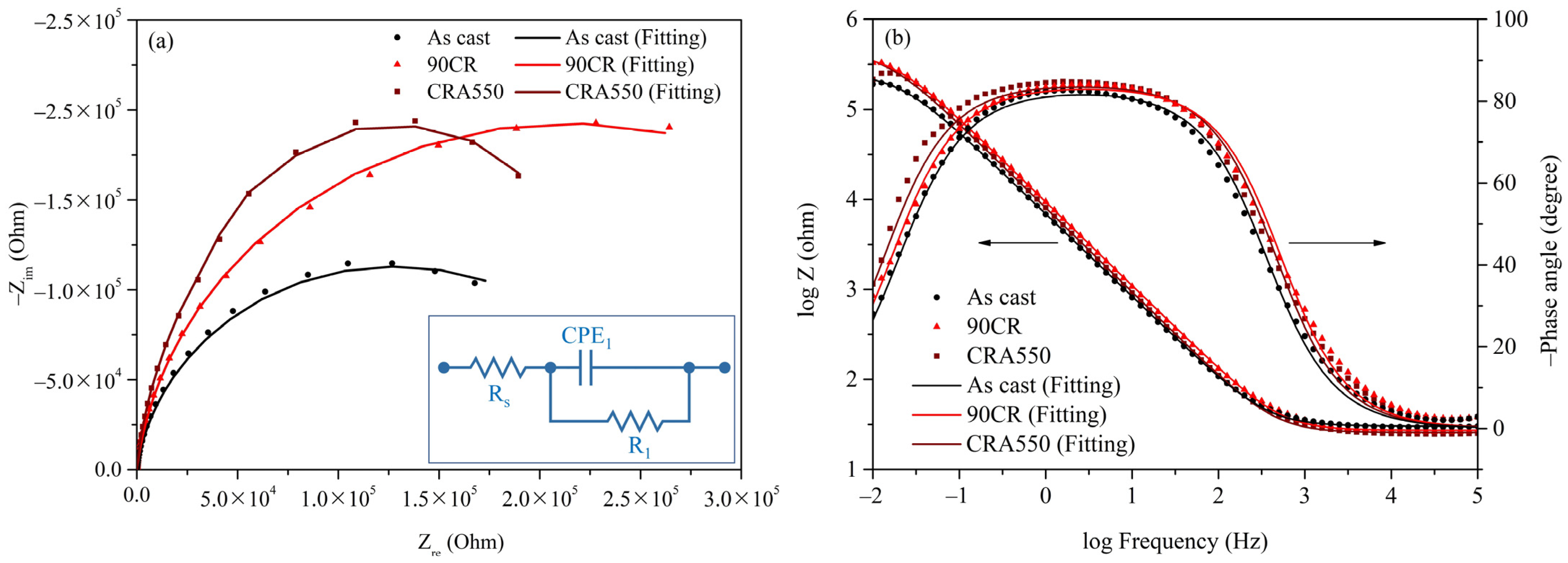

3.4.2. Electrochemical Impedance Spectroscopy (EIS) Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sidhu, S.S.; Singh, H.; Gepreel, M.A.H. A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mater. Sci. Eng. C 2021, 121, 111661. [Google Scholar] [CrossRef] [PubMed]

- Bahl, S.; Suwas, S.; Chatterjee, K. Comprehensive review on alloy design, processing, and performance of β Titanium alloys as biomedical materials. Int. Mater. Rev. 2021, 66, 114–139. [Google Scholar] [CrossRef]

- Tardelli, J.D.C.; Bolfarini, C.; Reis, A.C. Comparative analysis of corrosion resistance between beta titanium and Ti–6Al–4V alloys: A systematic review. J. Trace Elem. Med. Biol. 2020, 62, 126618. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, A.; Neelakantan, S. Enhanced thermo-mechanical processing through stress-induced martensitic transformation and its effect on grain refinement in metastable β titanium alloys. Scr. Mater. 2023, 226, 115222. [Google Scholar] [CrossRef]

- Nunes, A.R.V.; Borborema, S.; Araújo, L.S.; Malet, L.; Dille, J.; Almeida, L.H. Influence of thermo-mechanical processing on structure and mechanical properties of a new metastable β Ti–29Nb–2Mo–6Zr alloy with low Young’s modulus. J. Alloys Compd. 2020, 820, 153078. [Google Scholar] [CrossRef]

- Fu, Y.; Xiao, W.; Rong, J.; Ren, L.; Peng, H.; Wen, Y.; Zhao, X.; Ma, C. Achieving large near-linear elasticity, low modulus, and high strength in a metastable β-Ti alloy by mild cold rolling. J. Mater. Sci. Technol. 2024, 189, 1–12. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. Effect of Heat Treatment Procedure on Mechanical Properties of Ti–15V–3Al–3Sn–3Cr Metastable β Titanium Alloy. J. Mater. Eng. Perform. 2021, 30, 1066–1074. [Google Scholar] [CrossRef]

- He, F.; Yang, S.; Cao, J. Effect of Cold Rolling and Aging on the Microstructure and Mechanical Properties of Ti–Nb–Zr Alloy. J. Mater. Eng. Perform. 2020, 29, 3411–3419. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanable, S.; Hanada, S. Beta TiNbSn alloys with low Young’s modulus and high strength. Mater. Trans. 2005, 46, 1070–1078. [Google Scholar] [CrossRef]

- Du, Z.; Guo, H.; Liu, J.; Cheng, J.; Zhao, X.; Wang, X.; Liu, F.; Cui, X. Microstructure evolution during aging heat treatment and its effects on tensile properties and dynamic Young’s modulus of a biomedical β titanium alloy. Mater. Sci. Eng. A 2020, 791, 139677. [Google Scholar] [CrossRef]

- Vishnu, J.; Sankar, M.; Rack, H.J.; Rao, N.; Singh, A.K.; Manivasagam, G. Effect of phase transformations during aging on tensile strength and ductility of metastable beta titanium alloy Ti–35Nb–7Zr–5Ta–0.35O for orthopedic applications. Mater. Sci. Eng. A 2020, 779, 139127. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, R.; Niinomi, M.; Kuroda, D.; Zhou, Y.; Fukunaga, K.; Suzuki, A. Aging response of the Young’s modulus and mechanical properties of Ti–29Nb–13Ta–4.6Zr for biomedical applications. Metall. Mater. Trans. A 2003, 34, 1007–1012. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hsu, S.K.; Syu, J.Y.; Ho, W.F. The structure and mechanical properties of as-cast Ti–25Nb–xSn alloys for biomedical applications. Mater. Sci. Eng. A 2013, 568, 1–7. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Fang, W.C.; Ho, W.F. Experimental Investigation of the Impact of Niobium Additions on the Structural Characteristics and Properties of Ti–5Cr–xNb Alloys for Biomedical Applications. Materials 2024, 17, 1667. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Li, Y.; Ipek, R.; Wen, C. Development of Ti–Nb–Zr alloys with high elastic admissible strain for temporary orthopedic devices. Acta Biomater. 2015, 20, 176–187. [Google Scholar] [CrossRef] [PubMed]

- Plaine, A.H.; Silva, M.R.; Bolfarini, C. Tailoring the microstructure and mechanical properties of metastable Ti–29Nb–13Ta–4.6Zr alloy for self-expansible stent applications. J. Alloys Compd. 2019, 800, 35–40. [Google Scholar] [CrossRef]

- Li, C.; Lee, D.G.; Mi, X.; Ye, W.; Hui, S.; Lee, Y. Phase transformation and age hardening behavior of new Ti–9.2Mo–2Fe alloy. J. Alloys Compd. 2013, 549, 152–157. [Google Scholar] [CrossRef]

- He, B.; Li, J.; Cheng, X.; Wang, H.M. Brittle fracture behavior of a laser additive manufactured near-β titanium alloy after low temperature aging. Mater. Sci. Eng. A 2017, 699, 229–238. [Google Scholar] [CrossRef]

- Ballor, J.; Li, T.; Prima, F.; Boehlert, C.J.; Devaraj, A. A review of the metastable omega phase in beta titanium alloys: The phase transformation mechanisms and its effect on mechanical properties. Int. Mater. Rev. 2023, 68, 26–45. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.K.; Li, H.P.; Zhao, X.Q. Direct evidence for competition between metastable ω and equilibrium α phases in aged β-type Ti alloys. Rare Met. 2014, 33, 390–393. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Dai, S.; Chen, F.; Yu, X.; Zhang, Y. Influence of cold rolling and ageing treatment on microstructure and mechanical properties of Ti–30Nb–5Ta–6Zr alloy. J. Mech. Behav. Biomed. Mater. 2013, 27, 33–42. [Google Scholar] [CrossRef]

- Yi, R.W.; Liu, H.Q.; Yi, D.Q.; Wan, W.F. Precipitation hardening and microstructure evolution of the Ti–7Nb–10Mo alloy during aging. Mater. Sci. Eng. C 2016, 63, 577–586. [Google Scholar] [CrossRef] [PubMed]

- Tane, M.; Akita, S.; Nakano, T.; Hagihara, K.; Umakoshi, Y.; Niinomi, M.; Nakajima, H. Peculiar elastic behavior of Ti–Nb–Ta–Zr single crystals. Acta Mater. 2008, 56, 2856–2863. [Google Scholar] [CrossRef]

- Lan, C.; Chen, F.; Chen, H.; Wu, Y.; Wu, X. Influence of oxygen content on the microstructure and mechanical properties of cold rolled Ti–32.5Nb–6.8Zr–2.7Sn–xO alloys after aging treatment. J. Mater. Sci. Technol. 2018, 34, 2100–2106. [Google Scholar] [CrossRef]

- Costa, F.H.; Salvador, C.A.F.; Mello, M.G.; Caram, R. Alpha phase precipitation in Ti–30Nb–1Fe alloys—Phase transformations in continuous heating and aging heat treatments. Mater. Sci. Eng. A 2016, 677, 222–229. [Google Scholar] [CrossRef]

- Lu, S.; Ma, F.; Liu, P.; Li, W.; Liu, X.; Chen, X.; Zhang, K.; Han, Q.; Zhang, L.C. Recrystallization Behavior and Super-Elasticity of a Metastable β-Type Ti–21Nb–7Mo–4Sn Alloy During Cold Rolling and Annealing. J. Mater. Eng. Perform. 2018, 27, 4100–4106. [Google Scholar] [CrossRef]

- Azevedo, T.F.; Lima, T.N.; Blas, J.G.; Pereira, L.C.; Griza, S. The mechanical behavior of Ti–Nb–Sn alloys according to alloying contents, cold rolling and aging. J. Mech. Behav. Biomed. Mater. 2017, 75, 33–40. [Google Scholar] [CrossRef]

- Wong, K.K.; Hsu, H.C.; Wu, S.C.; Ho, W.F. Structure and properties of Ti-rich Ti–Zr–Nb–Mo medium-entropy alloys. J. Alloys Compd. 2021, 868, 159137. [Google Scholar] [CrossRef]

- Li, G.; Pan, X.; Jiang, J.; Li, J.; Xie, L.; Liu, H.; Zhang, M. Achieving ultra-fine grains and high corrosion resistance of Al–Zn–Mg–Cu alloy by ECAP and post cold rolling. J. Mater. Res. Technol. 2023, 26, 7354–7368. [Google Scholar] [CrossRef]

- Wang, P.; Ma, L.; Cheng, X.; Li, X. Effect of grain size and crystallographic orientation on the corrosion behaviors of low alloy steel. J. Alloys Compd. 2021, 857, 158258. [Google Scholar] [CrossRef]

- Xu, W.; Chen, M.; Lu, X.; Zhang, D.; Singh, H.; Yu, J.; Pan, Y.; Qu, X.; Liu, C. Effects of Mo content on corrosion and tribocorrosion behaviours of Ti−Mo orthopaedic alloys fabricated by powder metallurgy. Corros. Sci. 2020, 168, 108557. [Google Scholar] [CrossRef]

- Qu, W.; Pan, B.; Gong, H.; Yang, Z.; Ma, Y. Electrochemical corrosion and impedance studies of Ti–30Zr–xNb (x = 7, 10, 13 at.%) alloy in simulated downhole environment. J. Solid State Electrochem. 2023, 27, 1155–1164. [Google Scholar] [CrossRef]

| Code Name | Processing Condition |

|---|---|

| As cast | As cast |

| 90CR | 90% cold rolling |

| CRA300 | 90% cold rolling + aging at 300 °C for 60 min |

| CRA350 | 90% cold rolling + aging at 350 °C for 60 min |

| CRA400 | 90% cold rolling + aging at 400 °C for 60 min |

| CRA450 | 90% cold rolling + aging at 450 °C for 60 min |

| CRA500 | 90% cold rolling + aging at 500 °C for 60 min |

| CRA550 | 90% cold rolling + aging at 550 °C for 60 min |

| CRA600 | 90% cold rolling + aging at 600 °C for 60 min |

| Alloy | Phase Volume Fractions (%) | ||

|---|---|---|---|

| β | α″ | α | |

| As cast | 100 | 0 | 0 |

| 90CR | 56 | 44 | 0 |

| CRA300 | 68 | 32 | 0 |

| CRA350 | 70 | 30 | 0 |

| CRA400 | 71 | 29 | 0 |

| CRA450 | 90 | 5 | 5 |

| CRA500 | 93 | 0 | 7 |

| CRA550 | 93 | 0 | 7 |

| CRA600 | 91 | 0 | 9 |

| Alloy Conditions | Ecorr (V) | icorr (A/cm2) | Epass (V) | ipass (A/cm2) | βa (V/dec) | βc (V/dec) | Rp (MΩ·cm2) | Corrosion Rate (mm/year) |

|---|---|---|---|---|---|---|---|---|

| As cast | −0.21 | 1.08 × 10−8 | 0.36 | 4.85 × 10−6 | 0.10 | 0.07 | 1.66 | 8.72 × 10−5 |

| 90CR | −0.25 | 7.50 × 10−9 | 0.22 | 3.94 × 10−6 | 0.06 | 0.07 | 1.87 | 6.07 × 10−5 |

| CRA550 | −0.21 | 3.77 × 10−9 | 0.33 | 3.23 × 10−6 | 0.06 | 0.06 | 3.46 | 4.39 × 10−5 |

| Alloy Conditions | Rs (Ω·cm2) | CPE1 (10−5 F·cm2) | R1 (kΩ·cm2) | n1 | Ceff (10−5 F·cm2) | χ2 (10−4) |

|---|---|---|---|---|---|---|

| As cast | 30.3 | 26.7 | 256 | 0.920 | 3.145 | 1.2022 |

| 90CR | 27.3 | 19.2 | 429 | 0.931 | 2.256 | 1.4815 |

| CRA550 | 25.6 | 22.5 | 386 | 0.935 | 2.639 | 5.4953 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, H.-C.; Wu, S.-C.; Jian, Z.-L.; Ho, W.-F. Structure and Properties of Metastable β Ti–25Nb–8Sn Alloy following Cold Rolling and Aging Treatments. Materials 2024, 17, 3062. https://doi.org/10.3390/ma17133062

Hsu H-C, Wu S-C, Jian Z-L, Ho W-F. Structure and Properties of Metastable β Ti–25Nb–8Sn Alloy following Cold Rolling and Aging Treatments. Materials. 2024; 17(13):3062. https://doi.org/10.3390/ma17133062

Chicago/Turabian StyleHsu, Hsueh-Chuan, Shih-Ching Wu, Zhong-Lin Jian, and Wen-Fu Ho. 2024. "Structure and Properties of Metastable β Ti–25Nb–8Sn Alloy following Cold Rolling and Aging Treatments" Materials 17, no. 13: 3062. https://doi.org/10.3390/ma17133062