Evaluation of Localized Spallation of TBCs via a Combination of Conjugate Heat Transfer Numerical and Experimental Analysis

Abstract

1. Introduction

2. Experimental Setup

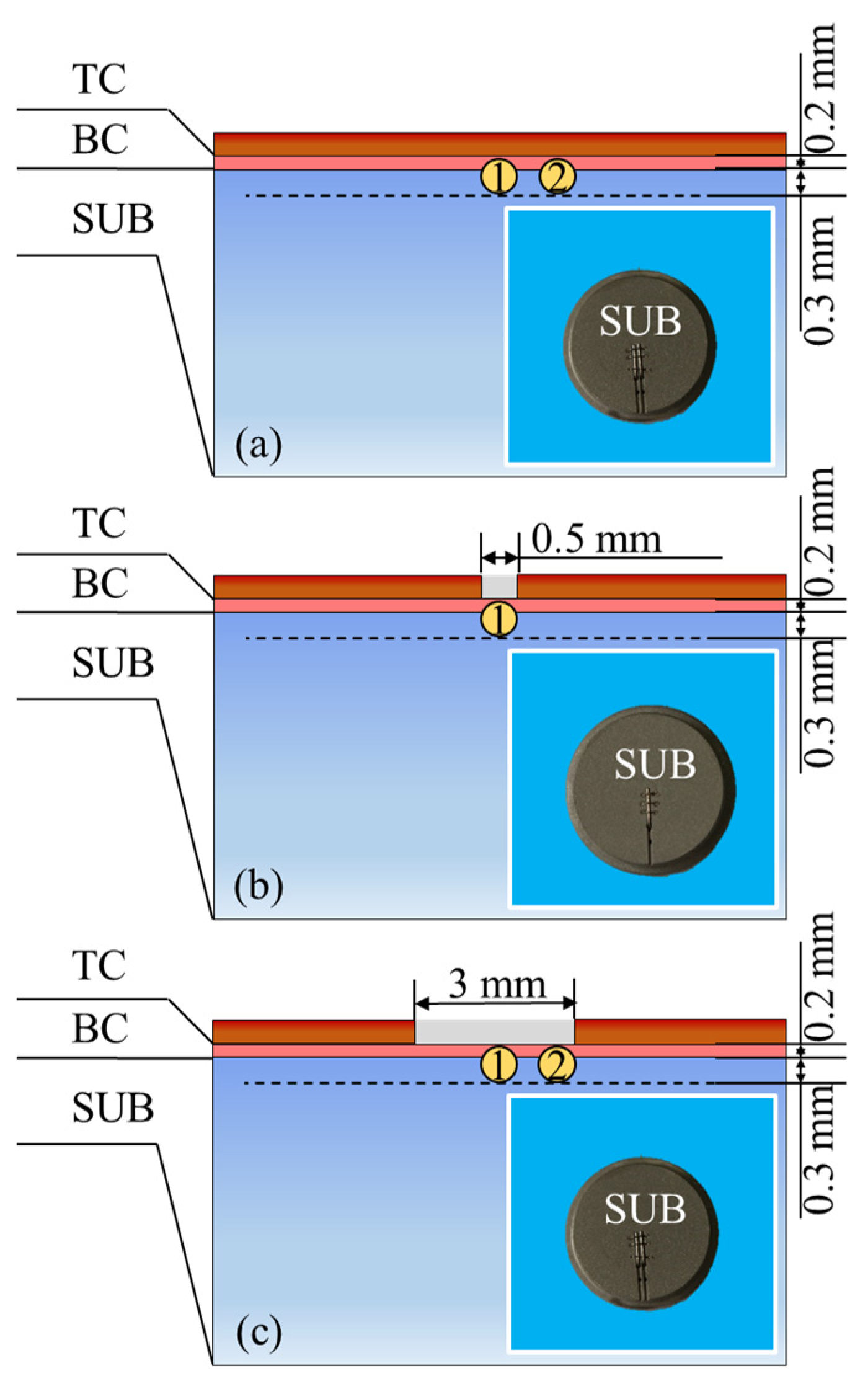

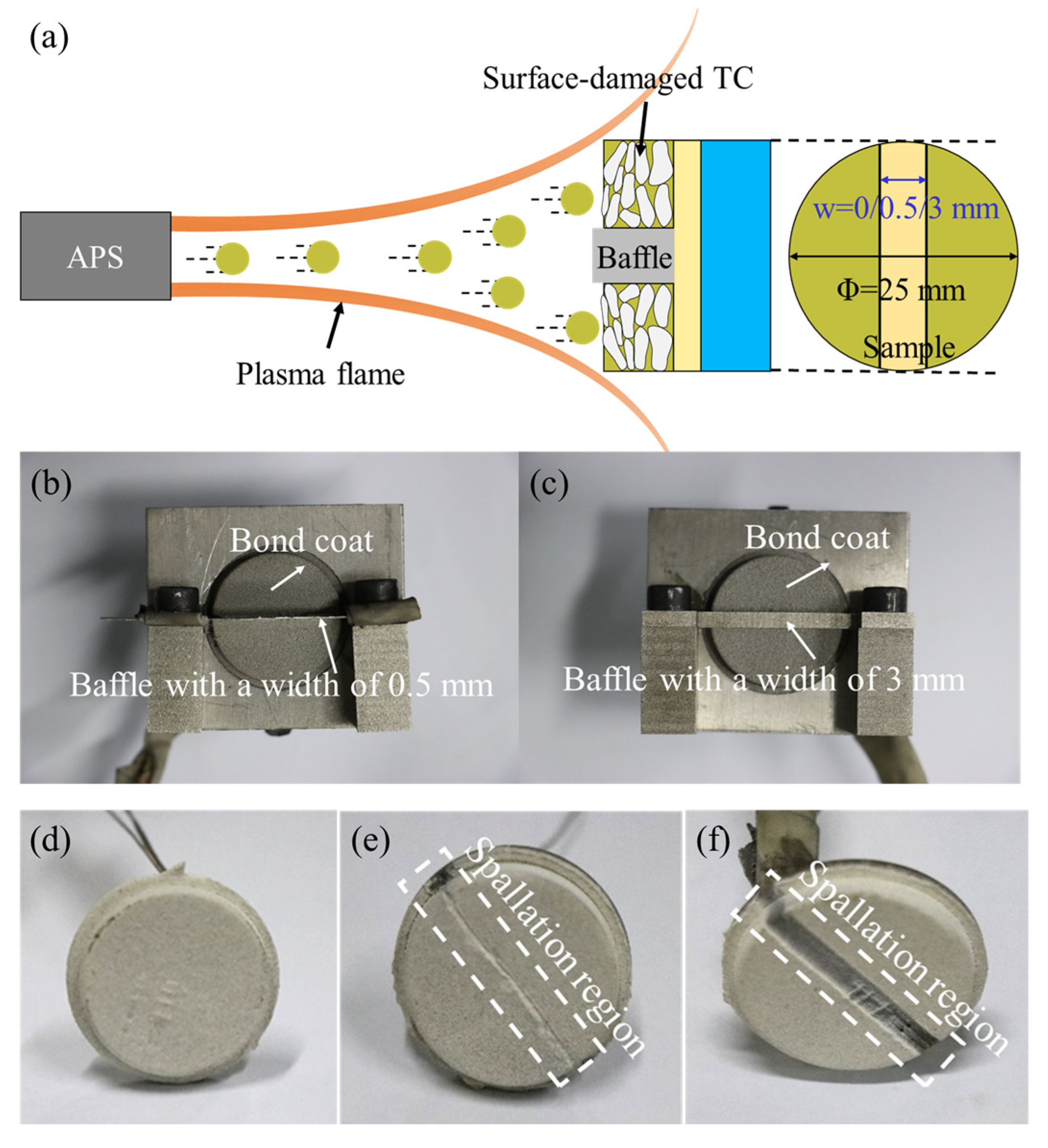

2.1. Preparation of TBC Samples with Different Spallation Widths

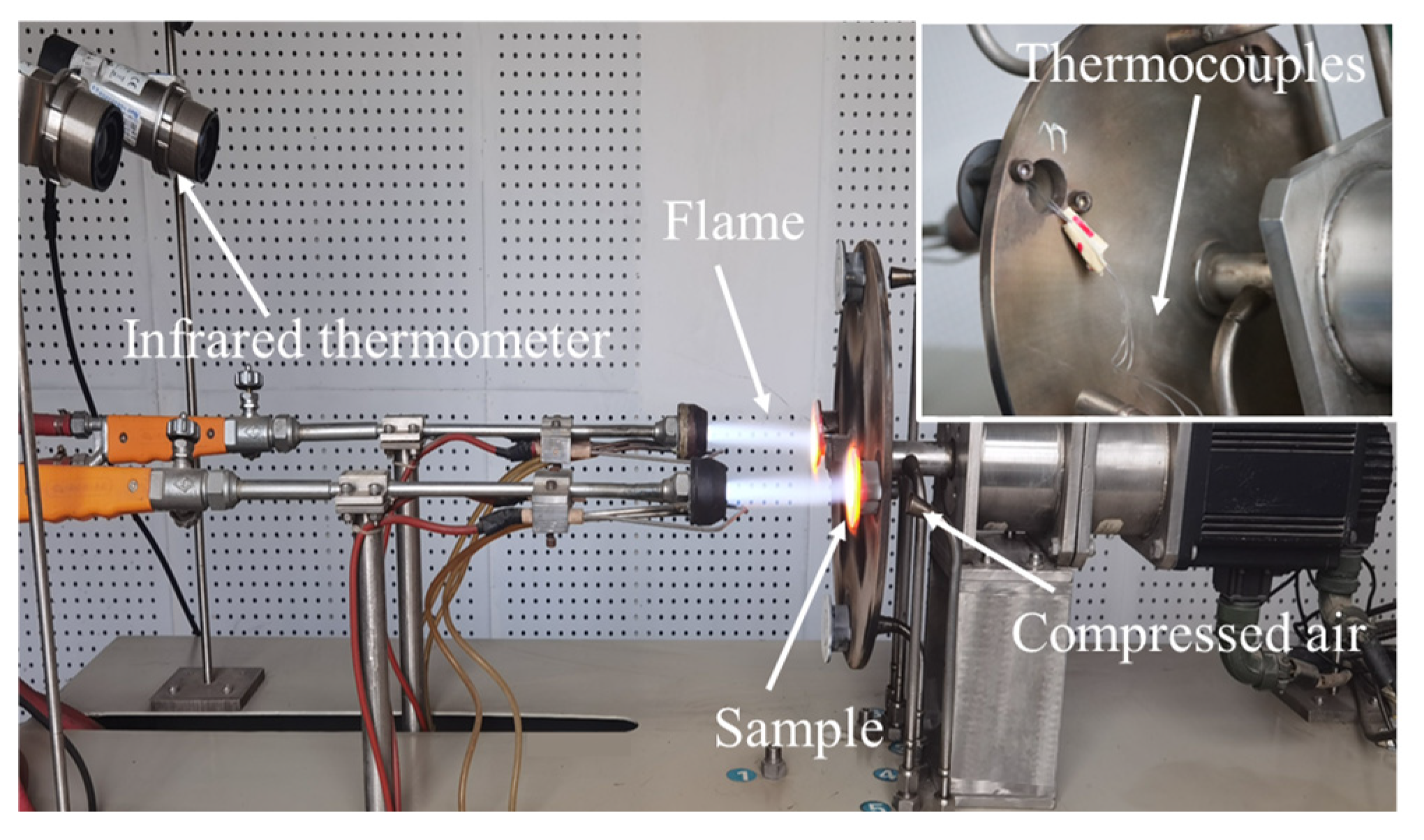

2.2. Thermal Insulation Tests and Temperature Measurements

3. Numerical Model

3.1. Geometry and Meshed Model

3.2. The Conjugate Heat Transfer Numerical Method

3.3. Material Parameters and Boundary Conditions

4. Results and Discussions

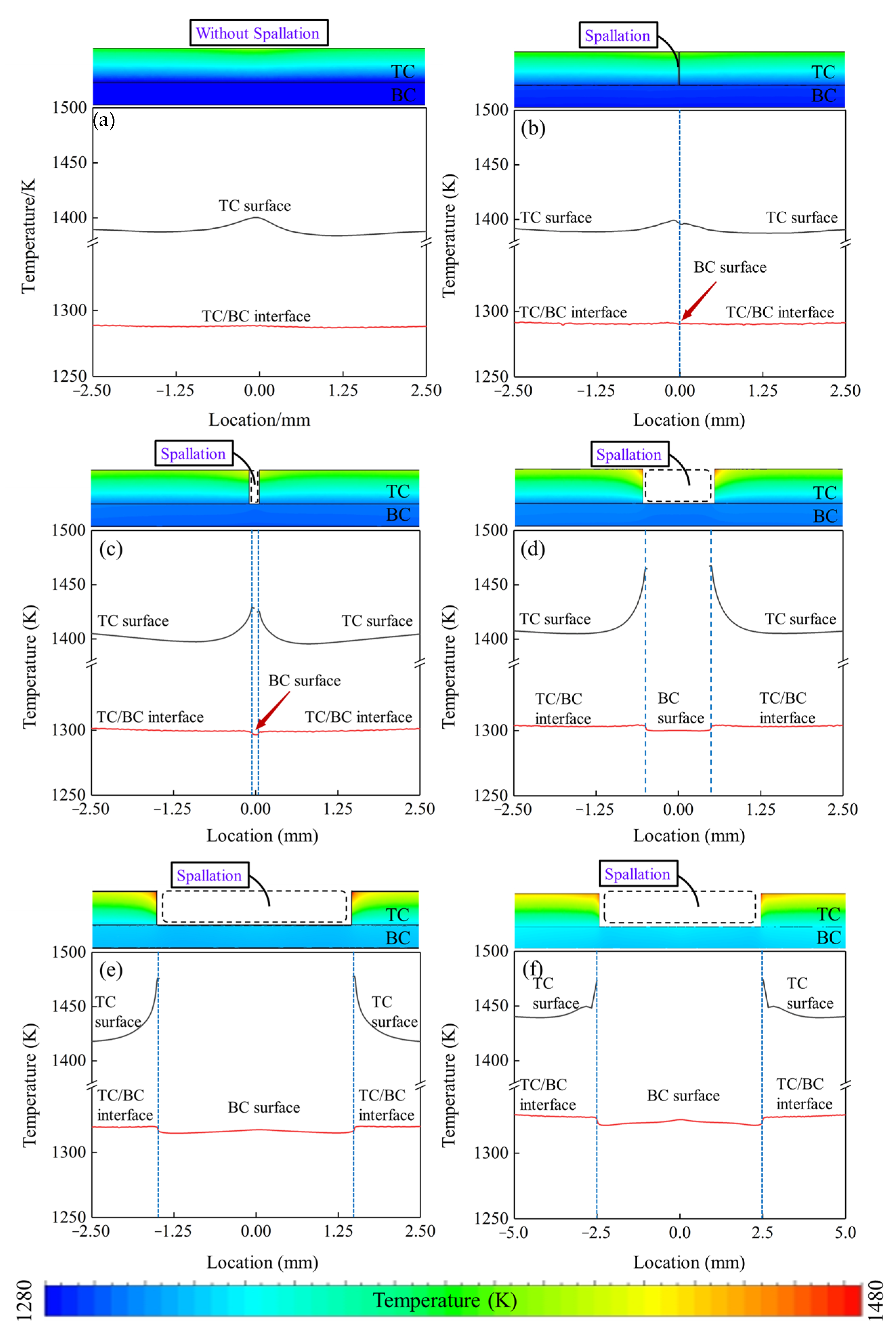

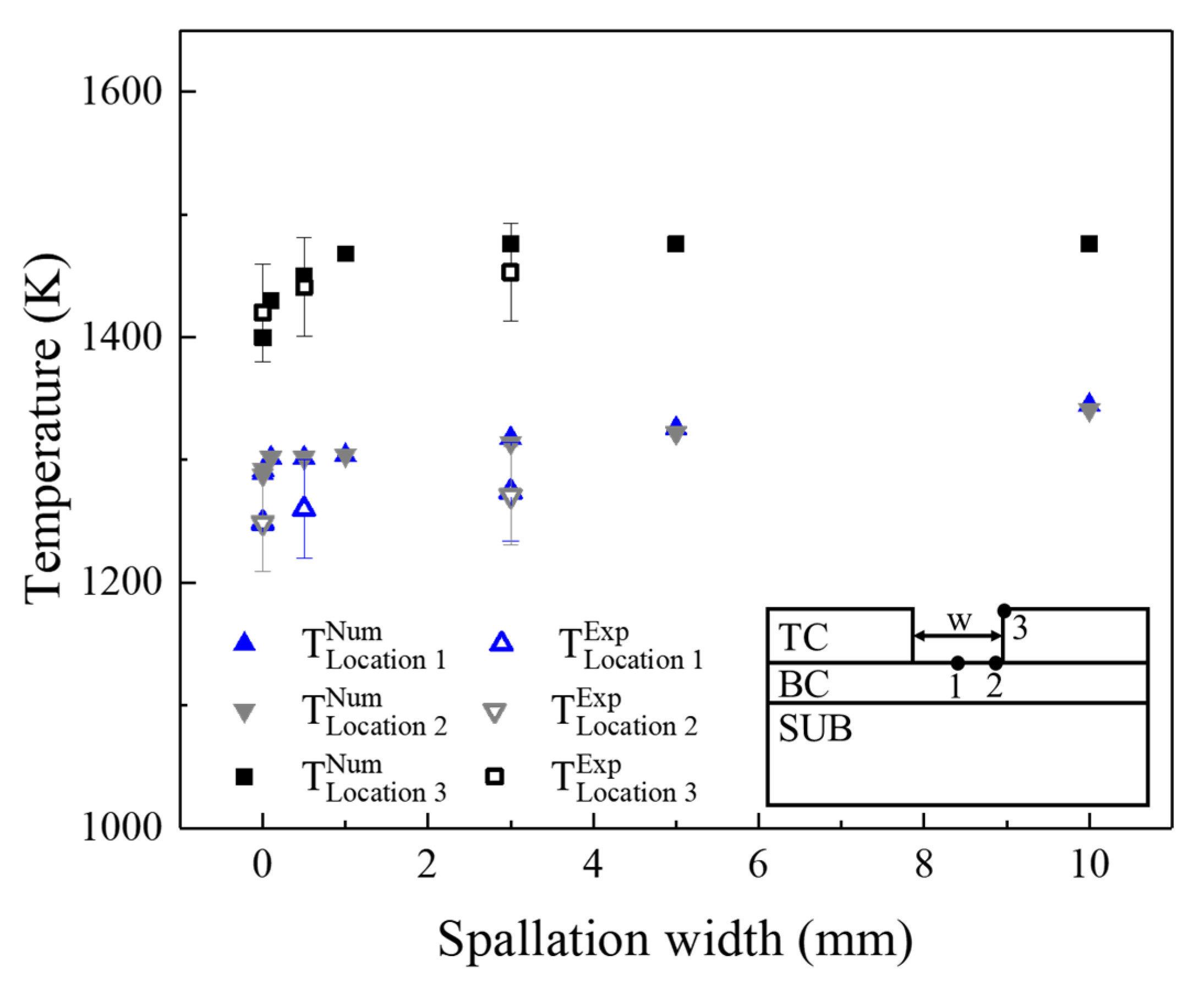

4.1. Temperature Distributions in the Localized Spallation Region

4.1.1. Experimental Results

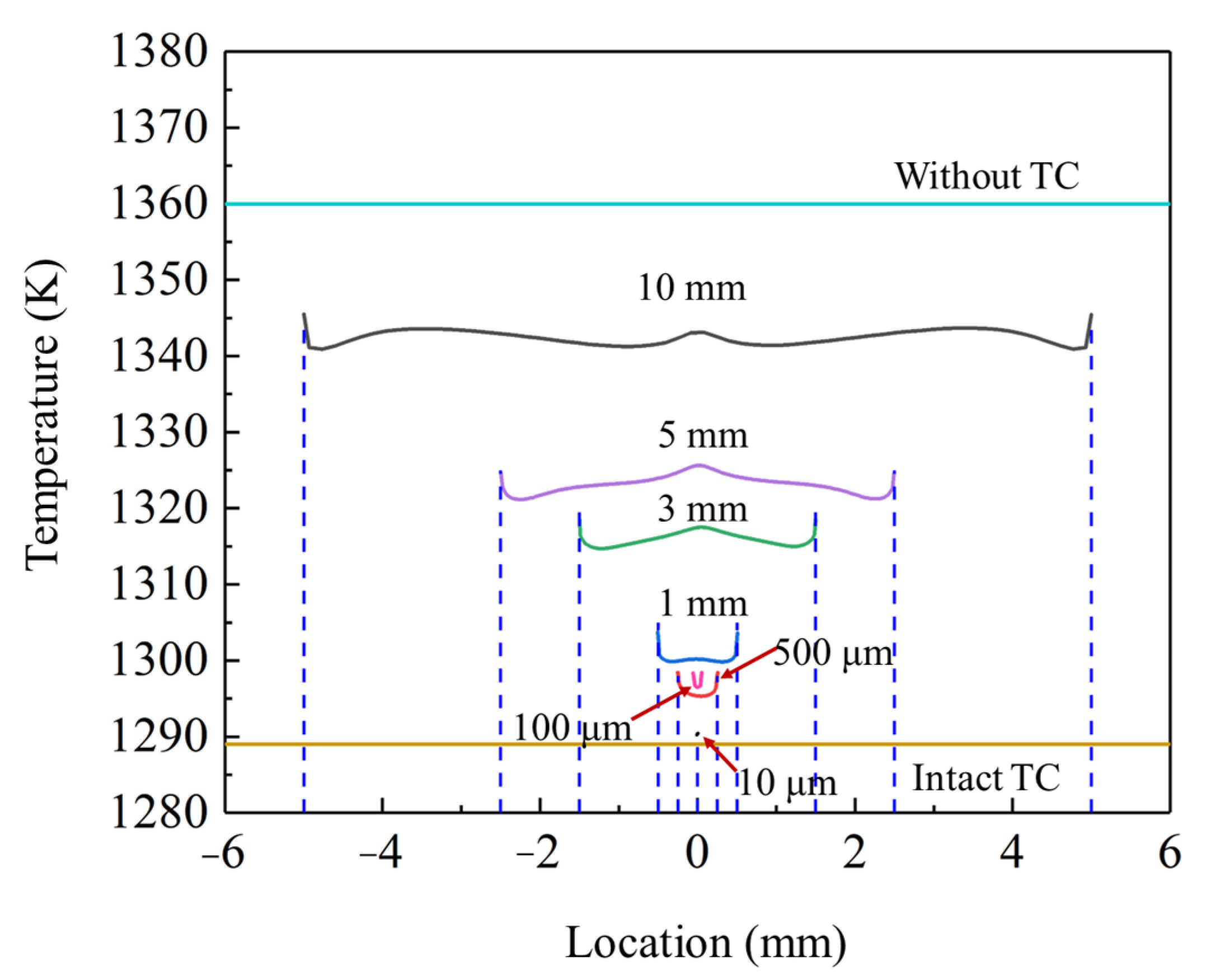

4.1.2. Numerical Results

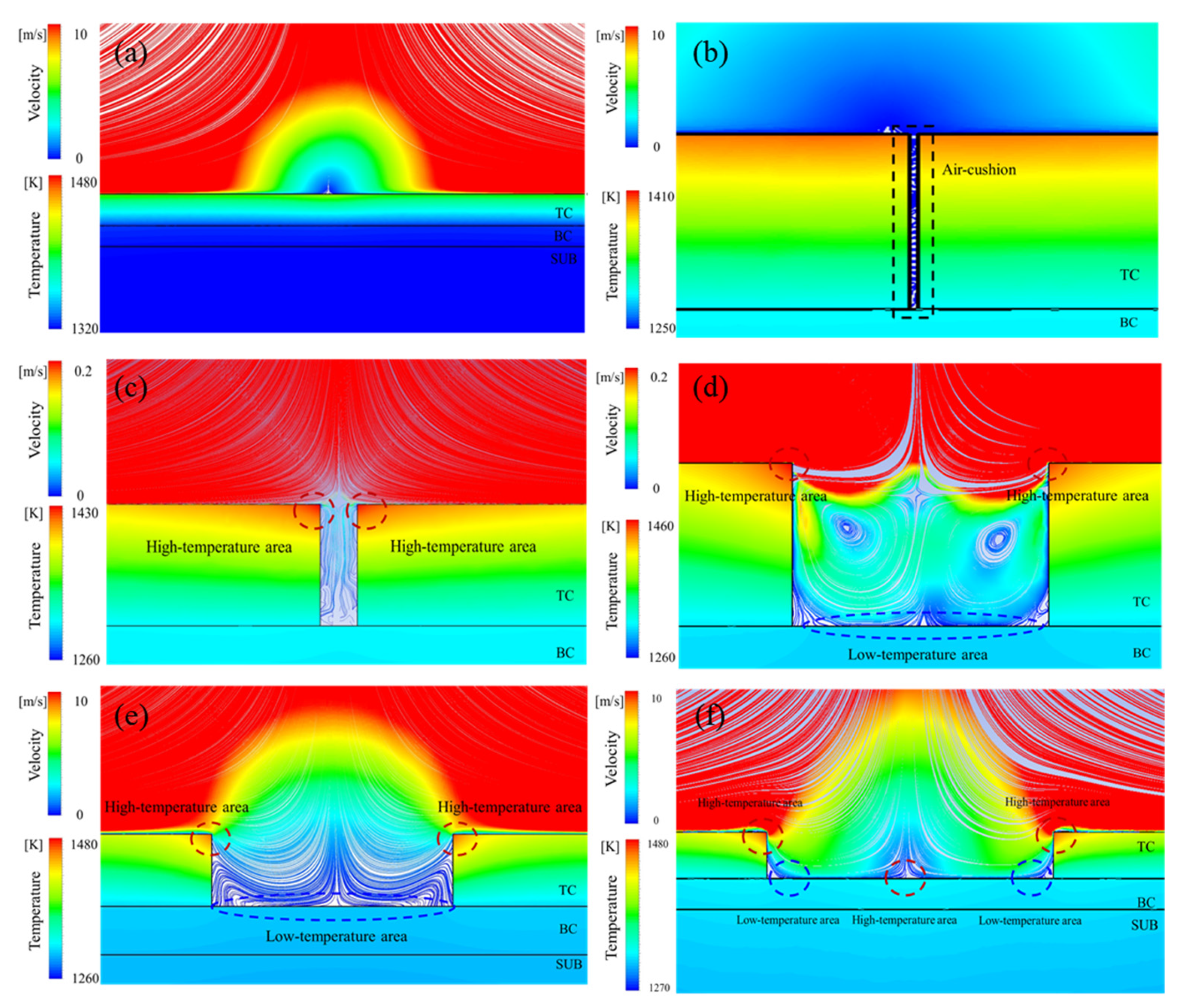

4.2. Flow Characteristics in the Localized Spallation Region

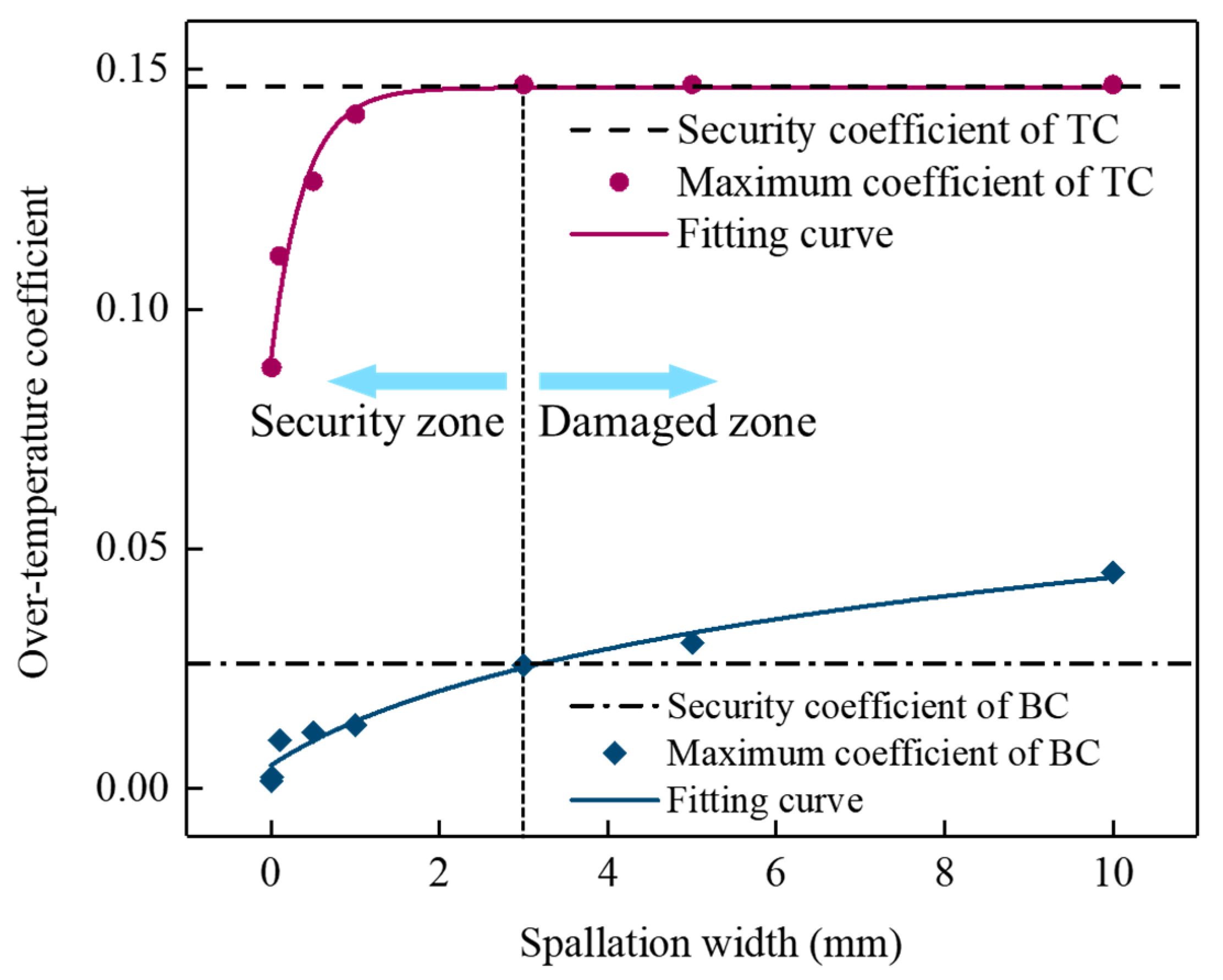

4.3. Over-Temperature Damage Induced by Localized Spallation

5. Conclusions

- (1)

- The temperature variations induced by localized spallation were given, which was validated by the numerical results. When the spallation width was less than 10 μm, the temperature in the TBCs did not change, and the TBCs were in a safe state during service. Once the spallation exceeded about 10 μm, the over-temperature phenomenon occurred in TBCs, and the temperature rose significantly. It may bring significant thermal mismatch stress in the TC layer and accelerate the non-uniform sintering and premature failure of TBCs. As the spallation increased to more than 3 mm, the maximum temperature in the TBCs became almost constant and gradually approached the security temperature, and the spallation width of 3 mm could be used as the critical spallation size for safety service, above which the TBCs fails and below which it is regarded as sustainable;

- (2)

- The flow characteristics of the high-temperature gas were significantly affected by the localized spallation, which brought different temperature changes in the TBCs. When the spallation was less than 10 μm, the gas flow velocity in the spallation region was close to zero, which slowed down the external gas flow into the spallation region, and resulted in a weak impression on the temperature field. With the further increase in spallation width, the gas velocity in the spallation region gradually increased and brought significant temperature changes in TBCs. Once the spallation increased to more than 3 mm, the flow distributions near the spallation region gradually stabilized, and the maximum temperature value in the TBCs became almost constant;

- (3)

- A concept of the over-temperature coefficient was proposed to identify the over-temperature damage induced by the localized spallation. The nonlinear fitting equation was obtained to reveal and predict the evolution of the over-temperature coefficient. The over-temperature coefficient may serve as a valuable metric for evaluating the performance limits of TBCs, and the results provide a foundation for the development of effective evaluation methods for surface-damaged TBCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, P.; Fan, X.; Sun, Y.; Li, D.; Wang, T. Bending-driven failure mechanism and modelling of double-ceramic-layer thermal barrier coating system. Int. J. Solids Struct. 2018, 130–131, 11–20. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, D.; Wang, W.; Zhao, X.; Ma, X.; Wang, B.; Shi, H.J. Fracture behavior of TBCs with cooling hole structure under cyclic thermal loadings. Ceram. Int. 2020, 46, 3644–3654. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, X.; Wang, B. Stress analysis of the thermal barrier coating system near a cooling hole considering the free-edge effect. Ceram. Int. 2020, 46, 331–342. [Google Scholar] [CrossRef]

- Jude, S.; Jappes, J.; Adamkhan, M. Thermal barrier coatings for high-temperature application on superalloy substrates-A review. Mater. Today Proc. 2022, 60, 1670–1675. [Google Scholar] [CrossRef]

- Li, D.; Jiang, P.; Gao, R.; Sun, F.; Jin, X.; Fan, X. Experimental and numerical investigation on the thermal and mechanical behaviours of thermal barrier coatings exposed to CMAS corrosion. J. Adv. Ceram. 2021, 10, 551–564. [Google Scholar] [CrossRef]

- Ji, X.; Xiao, G.; Lu, P.; Hao, X.; Fan, X. Characterization of power-law constitutive relationship of nickel-based single crystal superalloys under different loading rates by nanoindentation with different types of indenters. Int. J. Solids Struct. 2022, 259, 112025. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Jiang, P.; Fan, X.; Sun, Y.; Wang, H.; Su, L.; Wang, T. Thermal-cycle dependent residual stress within the crack-susceptible zone in thermal barrier coating system. J. Am. Ceram. Soc. 2018, 101, 4256–4261. [Google Scholar] [CrossRef]

- Lv, B.; Xie, H.; Xu, R.; Fan, X.; Zhang, W.; Wang, T.J. Effects of sintering and mixed oxide growth on the interface cracking of air-plasma-sprayed thermal barrier coating system at high temperature. Appl. Surf. Sci. 2016, 360, 461–469. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, T.; Sun, B.; Wang, B.; Zhang, X.; Song, L. Isothermal oxidation and TGO growth behavior of NiCoCrAlY-YSZ thermal barrier coatings on a Ni-based superalloy. J. Alloys Compd. 2020, 844, 156093. [Google Scholar] [CrossRef]

- Jonnalagadda, K.P.; Eriksson, R.; Yuan, K.; Li, X.H.; Ji, X.; Yu, Y.; Peng, R.L. A study of damage evolution in high purity nano TBCs during thermal cycling: A fracture mechanics based modelling approach. J. Eur. Ceram. Soc. 2017, 3, 2889–2899. [Google Scholar] [CrossRef]

- Cen, L.; Qin, W.Y.; Yu, Q.M. The sintering and creep and cracking of thermal barrier coatings under thermal cycling. Eng. Fail. Anal. 2022, 133, 105947. [Google Scholar] [CrossRef]

- Sun, F.; Fan, X.; Zhang, T.; Jiang, P.; Yang, J. Numerical analysis of the influence of pore microstructure on thermal conductivity and Young’s modulus of thermal barrier coating. Ceram. Int. 2020, 46, 24326–24332. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, F.; Jiang, P.; Sun, Y. Effects of Roughness on Stresses in an Oxide Scale Formed on a Superalloy Substrate. Coatings 2021, 11, 479. [Google Scholar] [CrossRef]

- Jiang, P.; Yang, L.; Sun, Y.; Li, D.; Wang, T. Local residual stress evolution of highly irregular thermally grown oxide layer in thermal barrier coatings. Ceram. Int. 2021, 47, 10990–10995. [Google Scholar] [CrossRef]

- Li, P.; Jin, X.C.; Lu, P.; Liu, D.; Mou, R.; Fan, X. Comparative study on microstructure evolution and failure mechanisms of ordinary and refurbished EB-PVD TBC under cyclic oxidation. J. Adv. Ceram. 2023, 12, 1805–1820. [Google Scholar] [CrossRef]

- Yanar, N.; Pettit, F.; Meier, G. Failure characteristics during cyclic oxidation of yttria stabilized zirconia thermal barrier coatings deposited via electron beam physical vapor deposition on platinum aluminide and on nicocraly bond coats with processing modifications for improved performances. Metall. Mater. Trans. 2006, 37, 1563–1580. [Google Scholar]

- Mahfouz, L.; Maurel, V.; Guipont, V.; Marchand, B.; El Hourany, R.; Coudon, F.; Mack, D.E.; Vaßen, R. Thermal Barrier Coatings in burner rig experiment analyzed through LAser Shock for DAmage Monitoring (LASDAM) method. J. Eur. Ceram. Soc. 2024, 44, 7867–7882. [Google Scholar] [CrossRef]

- Zhou, D.; Mack, D.E.; Gerald, P.; Guillon, O.; Vaßen, R. Architecture designs for extending thermal cycling lifetime of suspension plasma sprayed thermal barrier coatings. Ceram. Int. 2019, 45, 18471–18479. [Google Scholar] [CrossRef]

- Beck, T.; Herzog, R.; Trunova, O.; Offermann, M.; Steinbrech, R.W.; Singheiser, L. Damage mechanisms and lifetime behavior of plasma-sprayed thermal barrier coating systems for gas turbines—Part II: Modeling. Surf. Coat. Technol. 2008, 202, 5901–5908. [Google Scholar] [CrossRef]

- Trunova, O.; Beck, T.; Herzog, R.; Steinbrech, R.W.; Singheiser, L. Damage mechanisms and lifetime behavior of plasma sprayed thermal barrier coating systems for gas turbines—Part I: Experiments. Surf. Coat. Technol. 2008, 202, 5027–5032. [Google Scholar] [CrossRef]

- Liu, Y.; Persson, C.; Wigren, J. Experimental and numerical life prediction of thermally cycled thermal barrier coatings. J. Therm. Spray Technol. 2004, 13, 415–424. [Google Scholar] [CrossRef]

- Nordhorn, C.; Mücke, R.; Mack, D.E.; Vaßen, R. Probabilistic lifetime model for atmospherically plasma sprayed thermal barrier coating systems. Mech. Mater. 2016, 93, 199–208. [Google Scholar] [CrossRef]

- Han, M.; Zhou, G.; Huang, J.; Chen, S. A parametric study of the double-ceramic-layer thermal barrier coatings part I: Optimization design of the ceramic layer thickness ratio based on the finite element analysis of thermal insulation (take LZ7C3/8YSZ/NiCoAlY DCL-TBC for an example). Surf. Coat. Technol. 2016, 236, 500–509. [Google Scholar] [CrossRef]

- Li, B.; Shu, Y.; Li, Y. Interface cracking behavior in high-temperature coatings with non-uniformly distributed segmentation cracks. Eur. J. Mech. A-Solid. 2022, 96, 104674. [Google Scholar] [CrossRef]

- Cai, Z.; Hong, H.; Peng, D.; Zhao, X.; Wang, W.; Liu, Y.; Cao, Z. A numerical study of the influence of interface morphology on the stress behavior in thermal barrier coatings near an inclined film-cooling hole. Ceram. Int. 2020, 46, 18142–18150. [Google Scholar] [CrossRef]

- Zhou, D.; Guillon, O.; Vaßen, R. Development of YSZ Thermal barrier coatings using axial suspension plasma spraying. Coatings 2017, 7, 120. [Google Scholar] [CrossRef]

- Colón, S.; Ricklick, M.; Nagy, D.; Lafleur, A. Geometric effects of thermal barrier coating damage on turbine blade temperatures. Am. Soc. Mech. Eng. 2019, 58585, V02DT47A009. [Google Scholar]

- Hu, Z.-C.; Liu, B.; Wang, L.; Cui, Y.-H.; Wang, Y.-W.; Ma, Y.-D.; Sun, W.-W.; Yang, Y. Research Progress of Failure Mechanism of Thermal Barrier Coatings at High Temperature via Finite Element Method. Coatings 2020, 10, 732. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Zhu, W.; Yang, L.; Zhou, Y.C. Numerical prediction of thermal insulation performance and stress distribution of thermal barrier coatings coated on a turbine vane. Int. J. Therm. Sci. 2020, 158, 106552. [Google Scholar] [CrossRef]

- Ganvir, A.; Kumara, C.; Gupta, M.; Nylen, P. Thermal conductivity in suspension sprayed thermal barrier coatings: Modeling and experiments. J. Therm. Spray Technol. 2016, 26, 71–82. [Google Scholar] [CrossRef]

- Qu, Y.; Pan, E.; Zhu, F.; Jin, F.; Roy, A.K. Modeling thermoelectric effects in piezoelectric semiconductors: New fully coupled mechanisms for mechanically manipulated heat flux and refrigeration. Int. J. Eng. Sci. 2023, 182, 103775. [Google Scholar] [CrossRef]

- Wang, H.; Cai, Z.; Zhang, Z.; Liu, Y.; Zhao, X.; Wang, W. Dynamic evolution of nonuniform temperature-stress distributions in continuously eroding thermal barrier coatings. Surf. Coat. Technol. 2021, 410, 126946. [Google Scholar] [CrossRef]

- Tang, W.Z.; Yang, L.; Zhu, W.; Zhou, Y.C.; Guo, J.W.; Lu, C. Numerical simulation of temperature distribution and thermal-stress field in a turbine blade with multilayer-structure tbcs by a fluid–solid coupling method. J. Mater. Sci. Technol. 2016, 32, 452–458. [Google Scholar] [CrossRef]

- Jiang, J.; Cai, Z.; Wang, W.; Liu, Y. Finite element analysis of thermal-mechanical behavior in the thermal barrier coatings with cooling hole structure. ASME Turbo. Expo. 2017, 50916, V006T24A011. [Google Scholar]

- Ekkad, S.V.; Han, J.C. Heat transfer inside and downstream of cavities using transient liquid crystal method. J. Thermophys. Heat. Tr. 2015, 10, 511–516. [Google Scholar] [CrossRef]

- Long, Y.; Chen, X.; Wang, Y.; Weng, Y. Conjugate flow and heat transfer analysis between segmented thermal barrier coatings and cooling film. Int. J. Therm. Sci. 2021, 167, 107003. [Google Scholar] [CrossRef]

- Ekkad, S.V.; Han, J.C. Heat Transfer Distributions on a Cylinder with Simulated Thermal Barrier Coating Spallation. J. Thermophys. Heat Transf. 1999, 13, 76–81. [Google Scholar] [CrossRef]

- Musalek, R.; Tesar, T.; Medricky, J.; Lukac, F.; Lim, S. High-temperature cycling of plasma sprayed multilayered NiCrAlY/YSZ/GZO/YAG thermal barrier coatings prepared from liquid feedstocks. J. Therm. Spray Technol. 2021, 30, 81–96. [Google Scholar] [CrossRef]

- Ekkad, S.V.; Han, J.C. Film cooling measurements on cylindrical models with simulated thermal barrier coating spallation. J. Thermophys. Heat Transf. 2000, 14, 194–200. [Google Scholar] [CrossRef]

- Schulz, U.; Fritscher, K.; Peters, M. Thermocyclic behavior of variously stabilized EB-PVD thermal barrier coatings. J. Eng. Gas Turb. Power 1997, 119, 917. [Google Scholar] [CrossRef]

| Parameters | APS for BC | APS for TC |

|---|---|---|

| Gun | F4MB | F4MB |

| Distance of gun to SUB (mm) | 120 | 120 |

| Current (A) | 600 | 550 |

| Power (kW) | 42.7 | 42.7 |

| Feeding rate (%) | 30 | 25 |

| Thickness (mm) | 0.2 | 0.3 |

| Gas transport (Ar) (L/min) | 2.5 | 2.5 |

| Primary plasma gas (Ar) (L/min) | 65 | 35 |

| Secondary plasma gas (H2) (L/min) | 6.5 | 8 |

| T (°C) | K (W/m/K) | C (J/kg/K) | ρ (kg/m3) | |

|---|---|---|---|---|

| TC | - | 1.05 | 483 | 5650 |

| BC | 25 | 4.3 | 501 | 7320 |

| 400 | 6.4 | 592 | ||

| 800 | 10.2 | 781 | ||

| 1000 | 11.1 | 764 | ||

| SUB | 100 | 11.4 | 544 | 8110 |

| 300 | 14.9 | |||

| 500 | 18.3 | |||

| 700 | 21.8 | |||

| 900 | 25.2 | |||

| 1100 | 28.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, F.; Jiang, P.; Zhang, J.; Chen, Y.; Li, D. Evaluation of Localized Spallation of TBCs via a Combination of Conjugate Heat Transfer Numerical and Experimental Analysis. Materials 2024, 17, 3102. https://doi.org/10.3390/ma17133102

Sun F, Jiang P, Zhang J, Chen Y, Li D. Evaluation of Localized Spallation of TBCs via a Combination of Conjugate Heat Transfer Numerical and Experimental Analysis. Materials. 2024; 17(13):3102. https://doi.org/10.3390/ma17133102

Chicago/Turabian StyleSun, Fan, Peng Jiang, Jianpu Zhang, Yiwen Chen, and Dingjun Li. 2024. "Evaluation of Localized Spallation of TBCs via a Combination of Conjugate Heat Transfer Numerical and Experimental Analysis" Materials 17, no. 13: 3102. https://doi.org/10.3390/ma17133102

APA StyleSun, F., Jiang, P., Zhang, J., Chen, Y., & Li, D. (2024). Evaluation of Localized Spallation of TBCs via a Combination of Conjugate Heat Transfer Numerical and Experimental Analysis. Materials, 17(13), 3102. https://doi.org/10.3390/ma17133102