Influence of the Addition of TiO2 Nanoparticles on the Self-Cleaning Capacity of Cementitious Composites

Abstract

1. Introduction

2. Materials and Methods

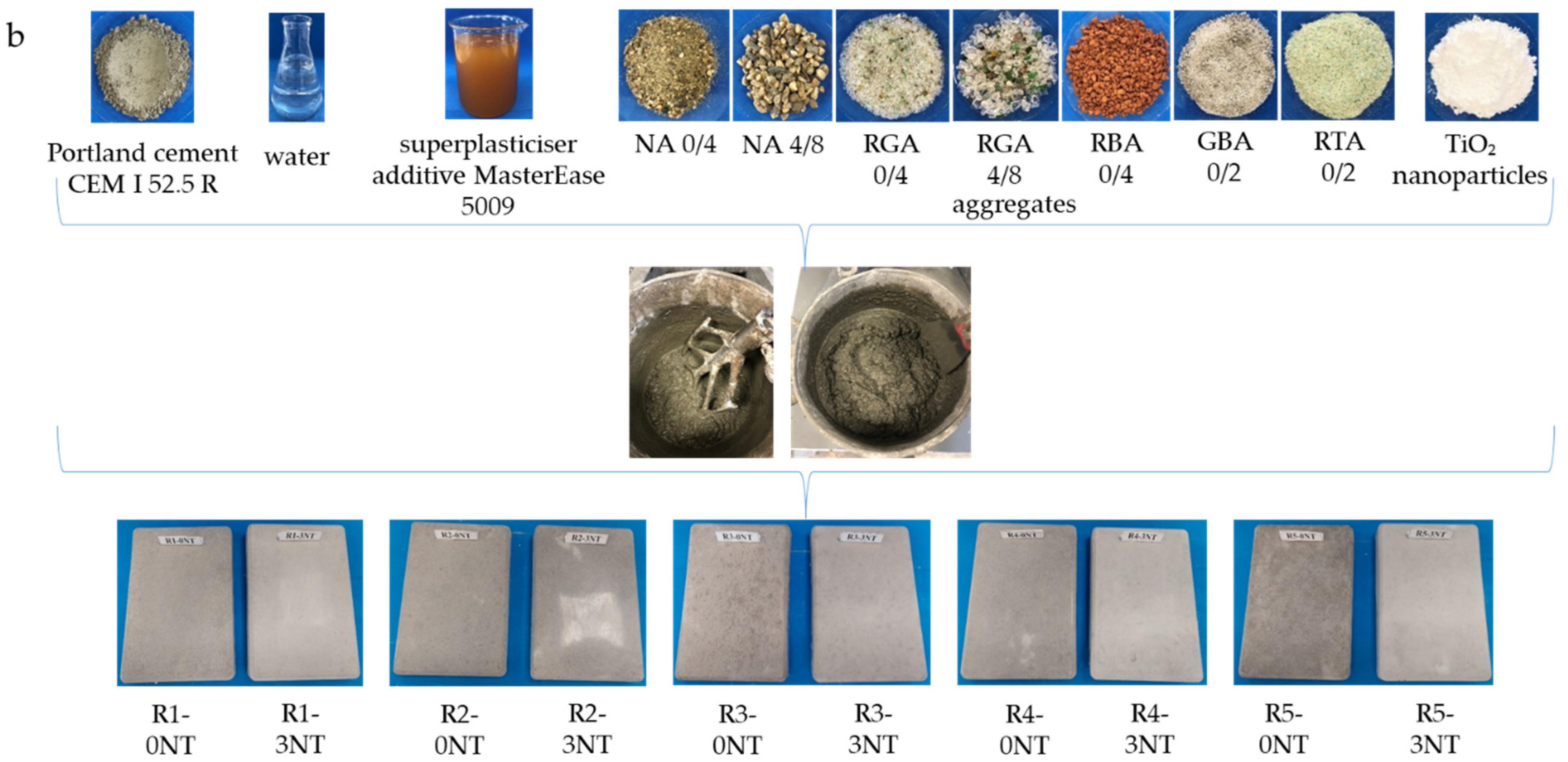

2.1. Raw Materials

- Portland cement CEM I 52.5 R, characterised by a minimum content of 95% Portland clinker (Table 1) and a compressive strength at 28 days of at least 52. 5 N/mm2, produced by HOLCIM Romania, Aleșd, Bihor County, Romania.

- Natural aggregates (NA) with grain size classes 0/4 mm and 4/8 mm; recycled glass aggregate (RGA) with grain size classes 0/4 mm and 4/8 mm; recycled ceramic brick aggregate (RBA) with grain size class 0/4 mm; blast furnace slag (GBA) with grain size class 0/2 mm, characterised in terms of chemical composition according to Table 2; recycled textolite waste aggregates (RTA) (characterised in Table 3), with particle size class 0/2 mm.

- Superplasticiser additive MasterEase 5009 (BASF, Ludwigshafen, Germany), a superplasticiser additive based on polymeric compounds with a water-soluble chloride content of maximum 0.1% (wt.) and an alkali content (Na2O equivalent) of maximum 2.5% (wt.), according to EN 934-1:2008 [48] and EN 934-2:2009 [49].

- TiO2 nanoparticles of the type AEROXIDE® TiO2 P25 (Evonik Degussa Industries AG, Hanau, Germany) characterised by an average particle size of 21 nm, with a specific surface area of 35–65 m2/g, a purity of 99.5%, containing more than 70% anatase crystalline phase, and containing water. The Portland cement and all recycled waste aggregates were of domestic origin.

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | P2O5 | TiO2 | Mn2O3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| w% | 15.02 | 3.17 | 3.01 | 55.12 | 3.13 | 3.74 | 0.23 | 1.15 | 0.12 | 0.28 | 0.04 |

| Portland clinker (%) EN 197-1 [50] | Minor component (%) EN 197-1 [50] | Sulphate content (as SO3%) EN 196-2 [51] | Chloride content (%) EN 196-2 [51] | Insoluble residues (%) EN 197-1 [50] | |||||||

| 95–100 | 0–5 | ≤4 | ≤0.1 | ≤5 | |||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | P2O5 | TiO2 | Cr2O3 | Mn2O3 | P.C | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| w% | 30.20 | 10.05 | 14.70 | 37.40 | 4.05 | - | 0.20 | 0.38 | - | <0.52 | <0.05 | 2.15 | - |

| As | Ba | Cd | Cr | Cu | Hg | Mo | Ni | Pb | Sb | Se | Zn | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/kg | 2.85 | 603.8 | <0.03 | 18.2 | 1064 | <0.003 | <3.0 | <0.20 | <0.30 | <0.5 | <0.015 | 12.59 |

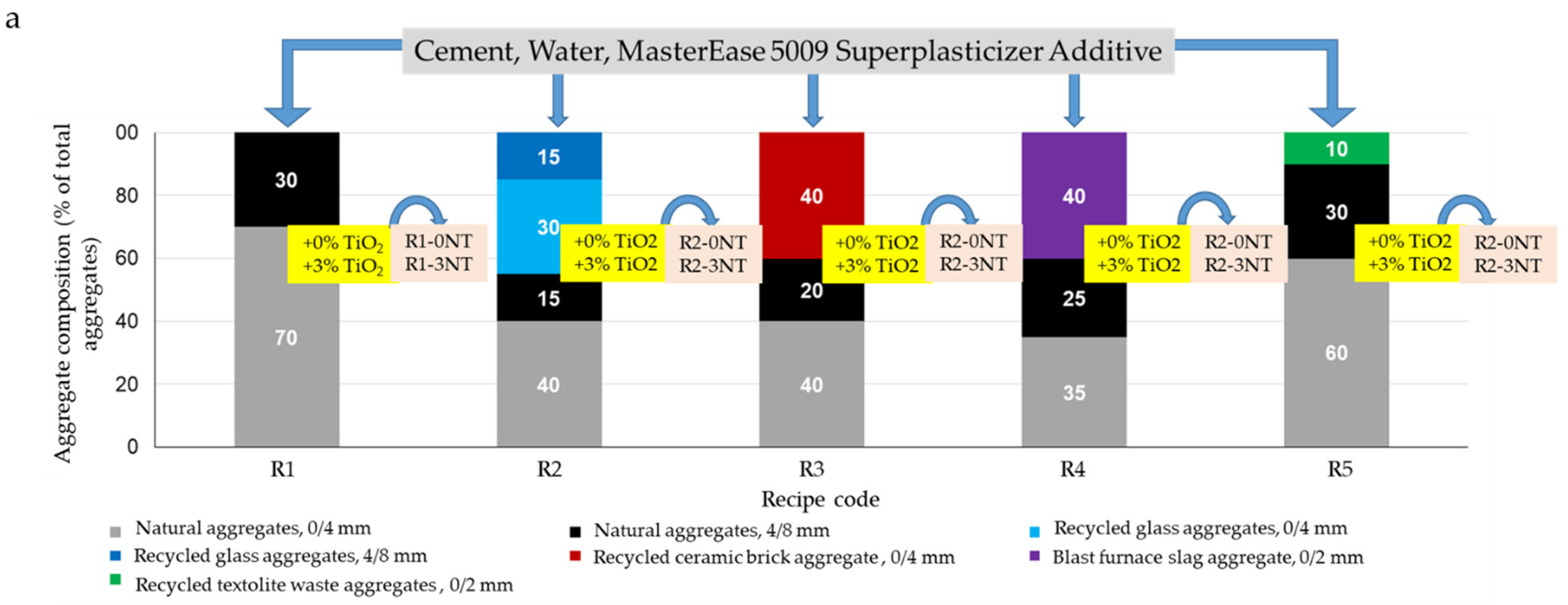

2.2. Manufacturing of Cementitious Composites and Specimens

- First set—Cementitious composite comprising cement, natural aggregates, superplasticiser additive, and water, as shown in Table 4, without the addition of TiO2 nanoparticles, referred to as the control group (R1-0NT), and with the addition of 3% TiO2 nanoparticles (by weight relative to the amount of cement) (R1-3NT).

- Second set—Cementitious composite consisting of cement, natural aggregates partially substituted by recycled glass waste aggregates, superplasticiser additive, and water, as shown in Figure 2, without the addition of TiO2 nanoparticles (R2-0NT) and with the addition of 3% TiO2 nanoparticles (weight relative to the amount of cement) (R2-3NT).

- Third set—Cementitious composite consisting of cement, natural aggregates partially substituted with recycled ceramic brick waste aggregates, superplasticiser additive, and water, as shown in Figure 2, without the addition of TiO2 nanoparticles (R3-0NT) and with the addition of 3% TiO2 nanoparticles (weight relative to the amount of cement) (R3-3NT).

- Fourth set—Cementitious composite consisting of cement, natural aggregates partially substituted by waste slag aggregates, superplasticiser additive, and water, as shown in Figure 2, without the addition of TiO2 nanoparticles (R4-0NT) and with the addition of 3% TiO2 nanoparticles (weight relative to the amount of cement) (R4-3NT).

- Fifth set—Cementitious composite consisting of cement, natural aggregates partially substituted with aggregates from recycled textolite waste recovered from waste electrical and electronic equipment (WEEE), superplasticiser additive, and water, as shown in Figure 2, without the addition of TiO2 nanoparticles (R5-0NT) and with the addition of 3% TiO2 nanoparticles (wt. based on the amount of cement) (R5-3NT).

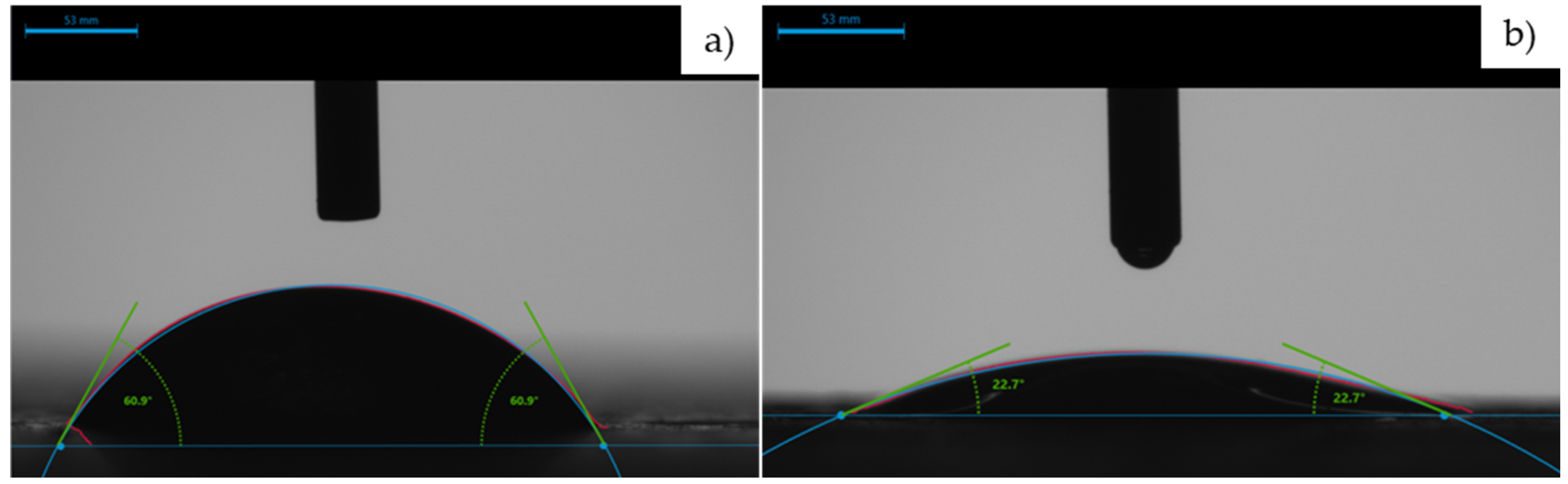

2.3. Contact Angle Measurement

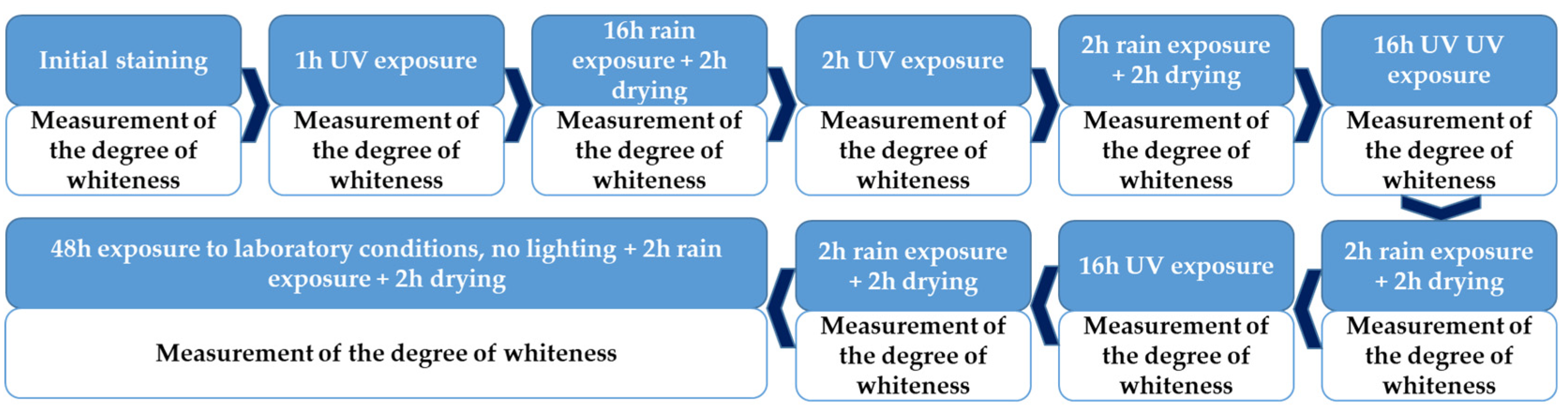

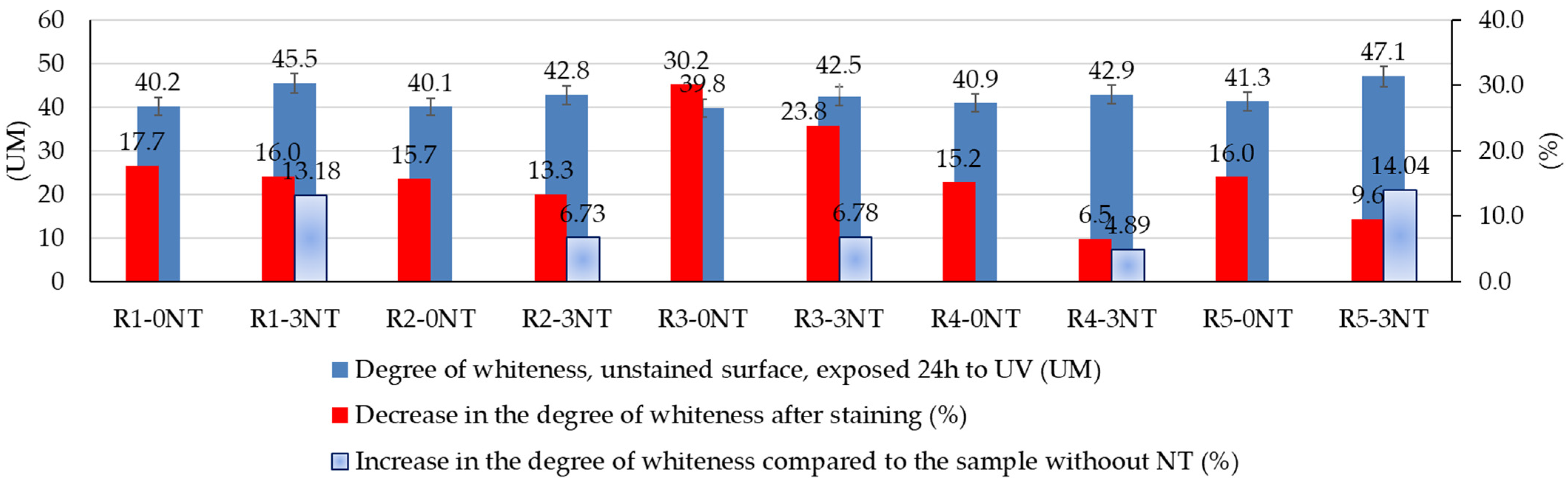

2.4. Analysis of the Surface Self-Cleaning Performance of Cementitious Composites

- The degree of whiteness of the sample—DW—in the stained area, at initial staining and after completion of one or more steps of the testing protocol;

- Recovery of degree of whiteness—represents the proportion of the initial degree of whiteness retained by the sample after one or more of the steps outlined in the testing procedure, expressed through Equation (1):

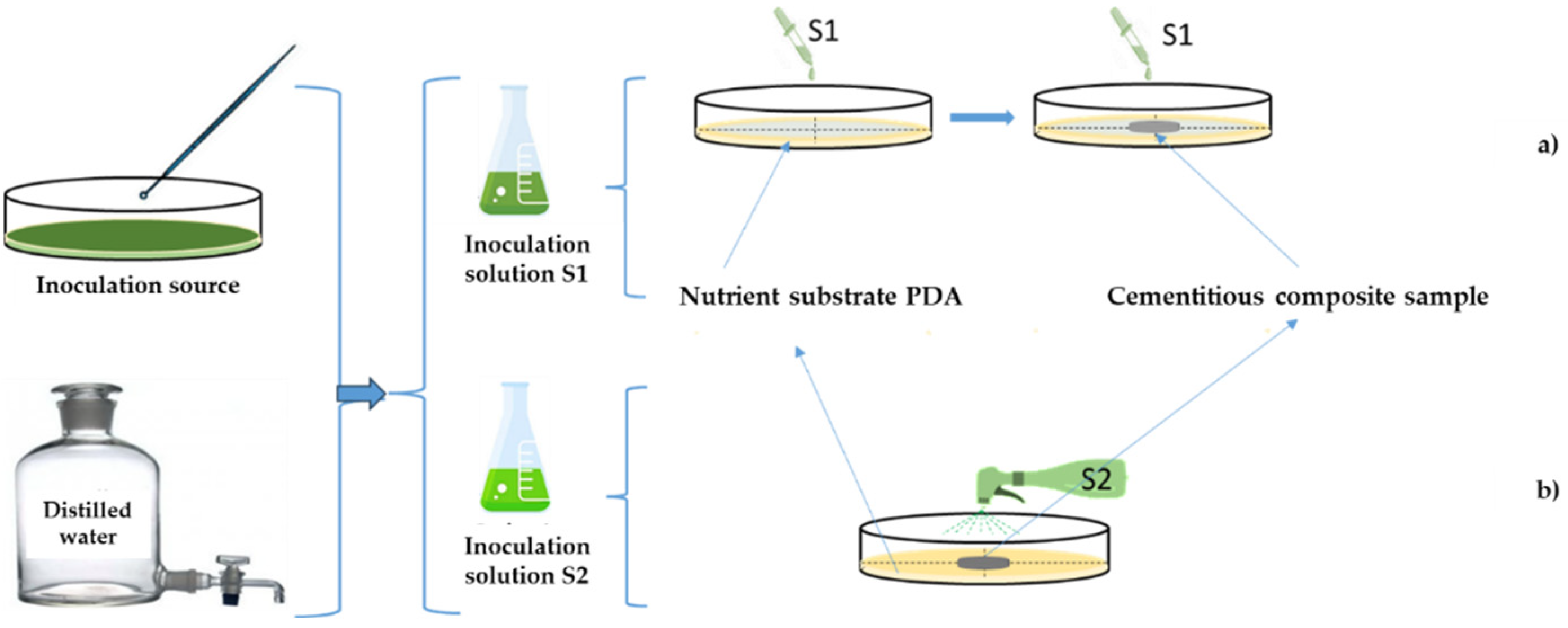

2.5. Analysis of the Mould Resistance of Cementitious Composite Surfaces

- For the S1 inoculation solution, a batch of Petri dishes was prepared by dripping 1.5 mL of the S1 mould spore suspension (Figure 5a), ensuring that the entire PDA surface was covered. A centrally located sample of photoactivated cement composite with nanoparticle additives was then placed in the Petri dish under conditions that prevented cross-contamination. A further 0.5 mL of the spore suspension was then applied to the cement composite sample. The Petri dish was covered with its lid, and the entire system was sealed around the edges with sealing tape to prevent cross-contamination.

- For the S2 inoculant, a batch was prepared by spraying 0.5 mL of the S2 inoculant directly onto the surface of the cement composite sample already placed on the nutrient substrate (Figure 5b). The spraying was performed centrally, perpendicular to the surface and from a constant height of 50 mm, ensuring that the inoculation solutions were distributed both on the surface of the sample and on the uncovered surface of the nutrient substrate. Consequently, in comparison to the concentrated solution (S1), the degree of contamination in this case would theoretically be reduced by a factor of 60 (1/6 of the amount used in the droplet application multiplied by a factor of 10 dilution).

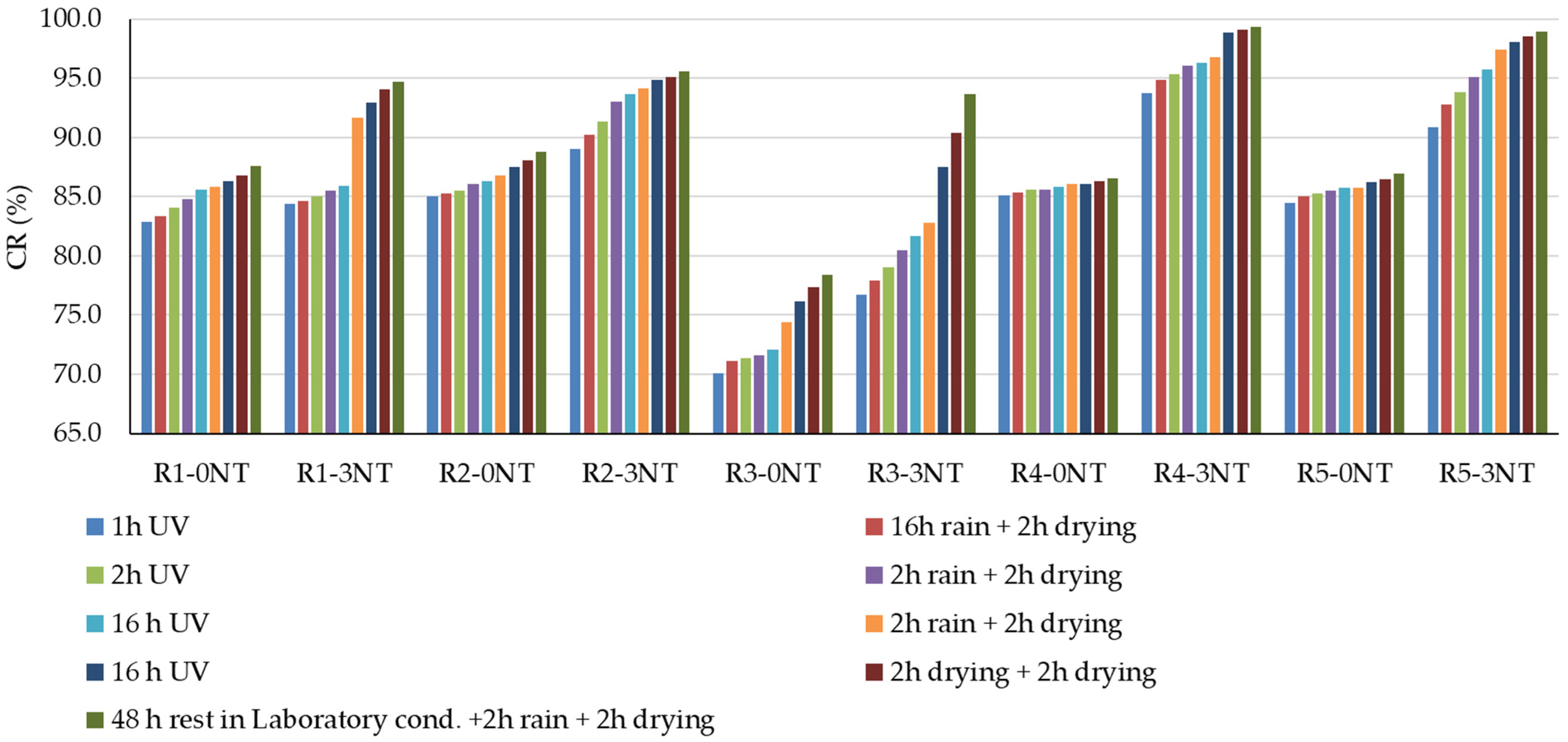

3. Results and Discussions

3.1. Surface Hydrophilicity Analysis of Cementitious Composites

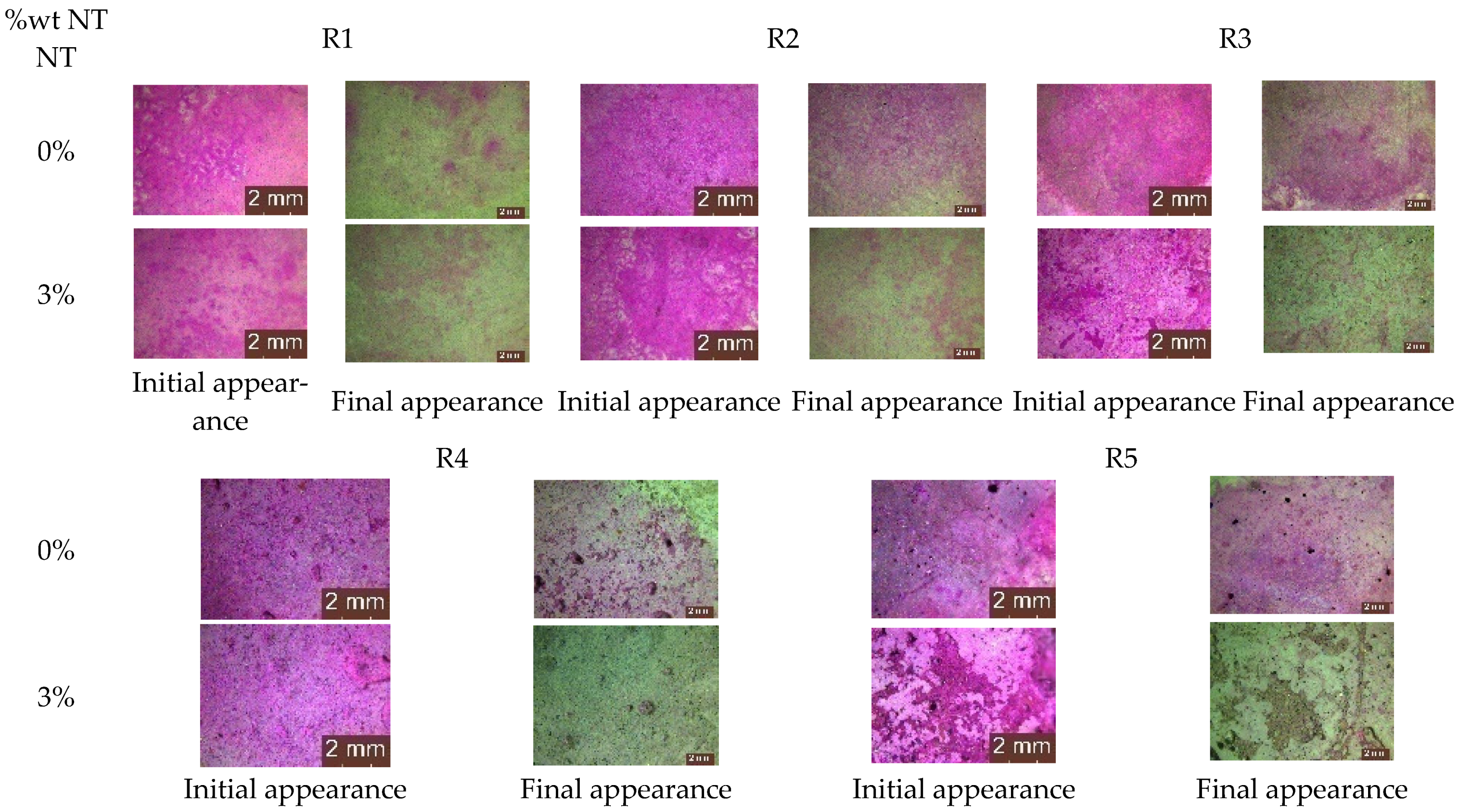

3.2. Analysis of the Self-Cleaning Properties of Cementitious Composite Surfaces

3.3. Analysis of the Mould Resistance of Cementitious Composite Surfaces

3.3.1. Cementitious Samples Exposed 720 h to an Environment Contaminated with Aspergillus niger Showed the following Developments

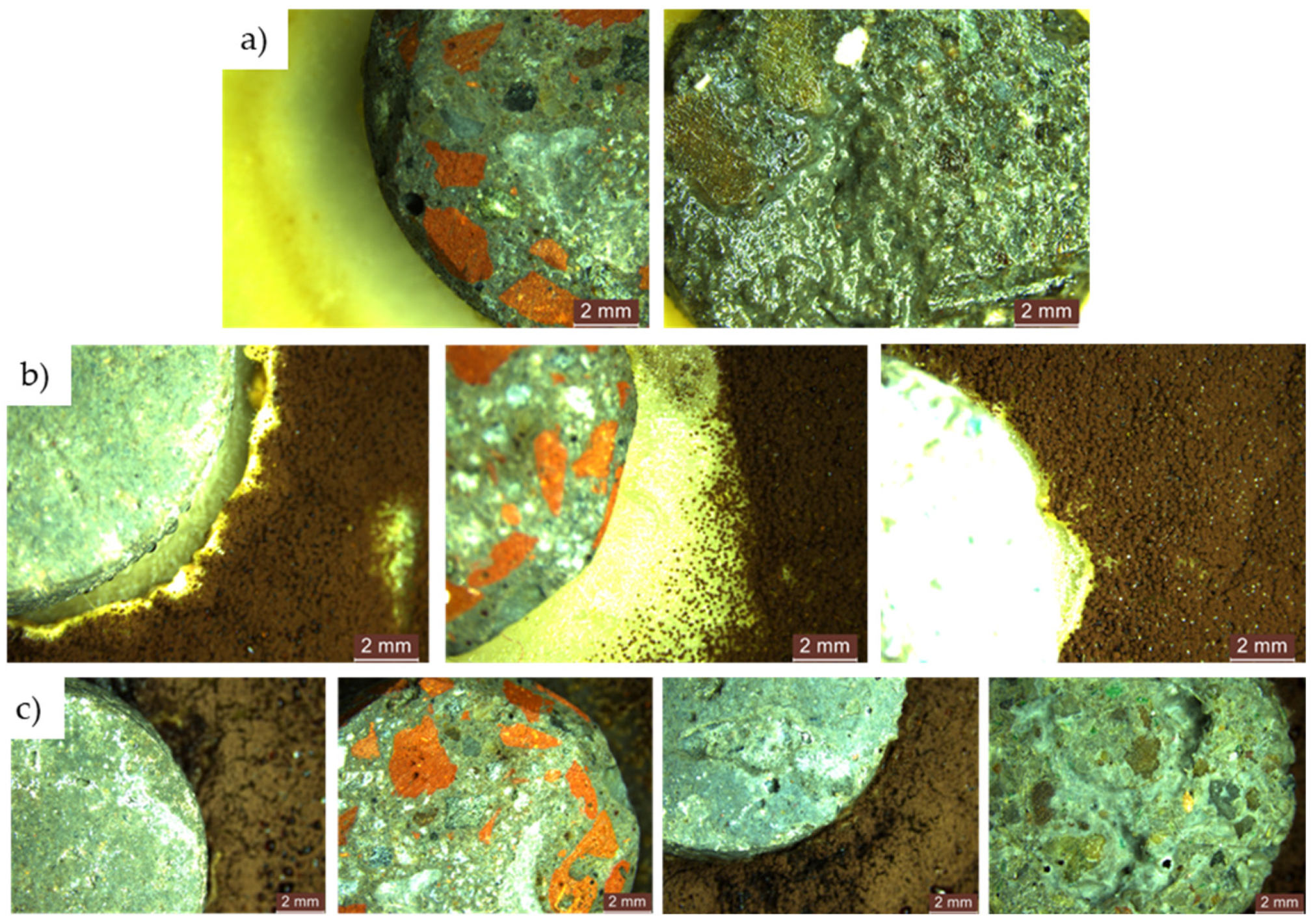

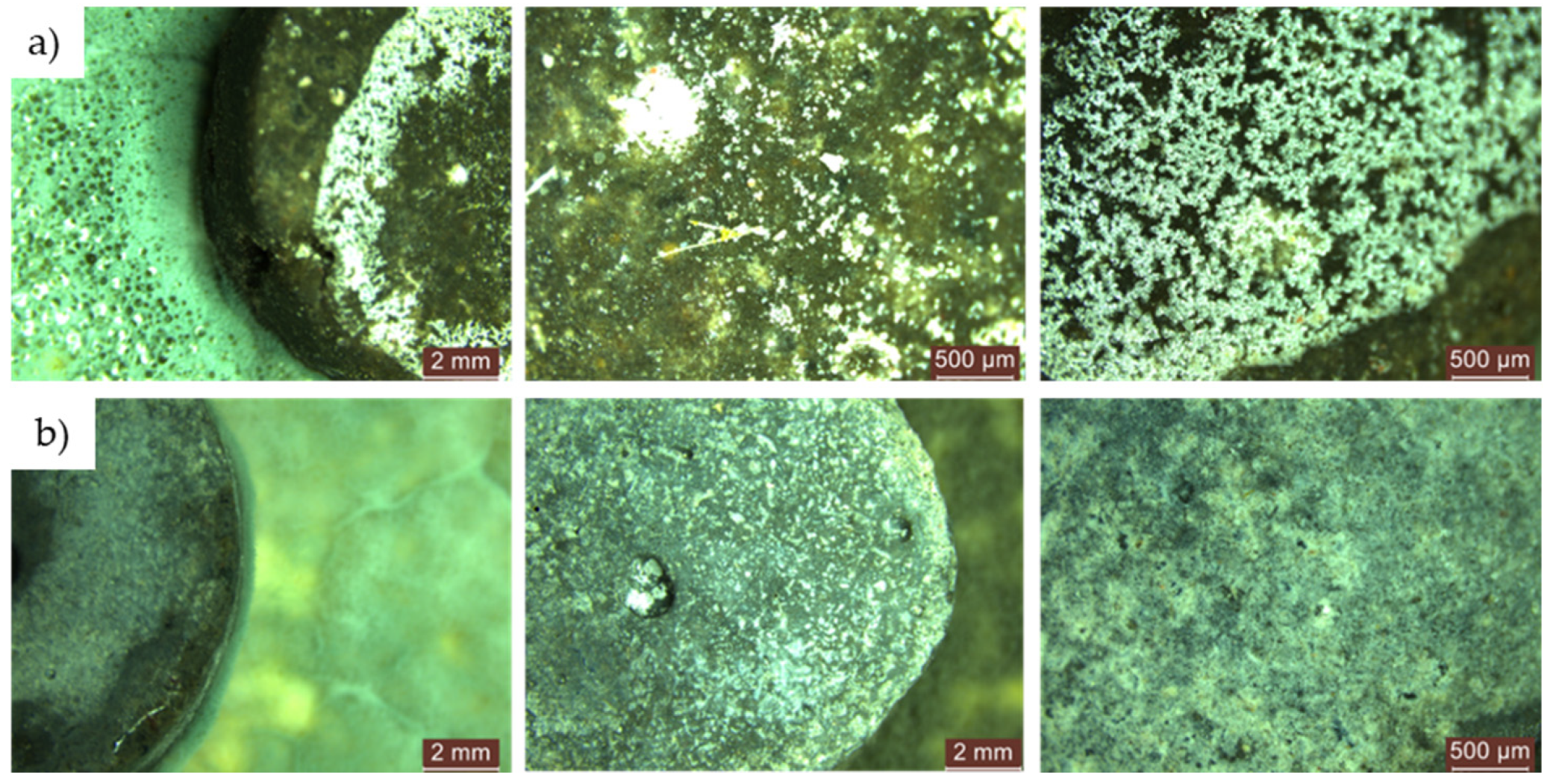

- After 24 h of exposure, the control sample (R1-0NT) already showed uniform mould growth along its periphery, accompanied by a clear point of mould growth on its surface (Figure 11a). Conversely, in the case of the mixture containing natural aggregates and a 3% NT additive (R1-3NT), there was no evidence of mould growth along the edges or on the surface of the specimen within the first 24 h of exposure to the contaminated environment. In addition, a subtle inhibition halo with an average size of 1.50–2.50 mm was observed peripherally around the cementitious specimen, coinciding with the absence of mould growth in this region (Figure 11b).

- During the 48 to 72 to 720 h exposure period in the contaminated environment, the control sample (R1-0NT) showed continued mould growth on both the cementitious surface and the edges of the specimen, facilitating spore formation (Figure 11c). Conversely, the R1-3NT sample maintained an inhibition halo that gradually diminished over time, maintaining a clean surface with no traces of mould (Figure 11d).

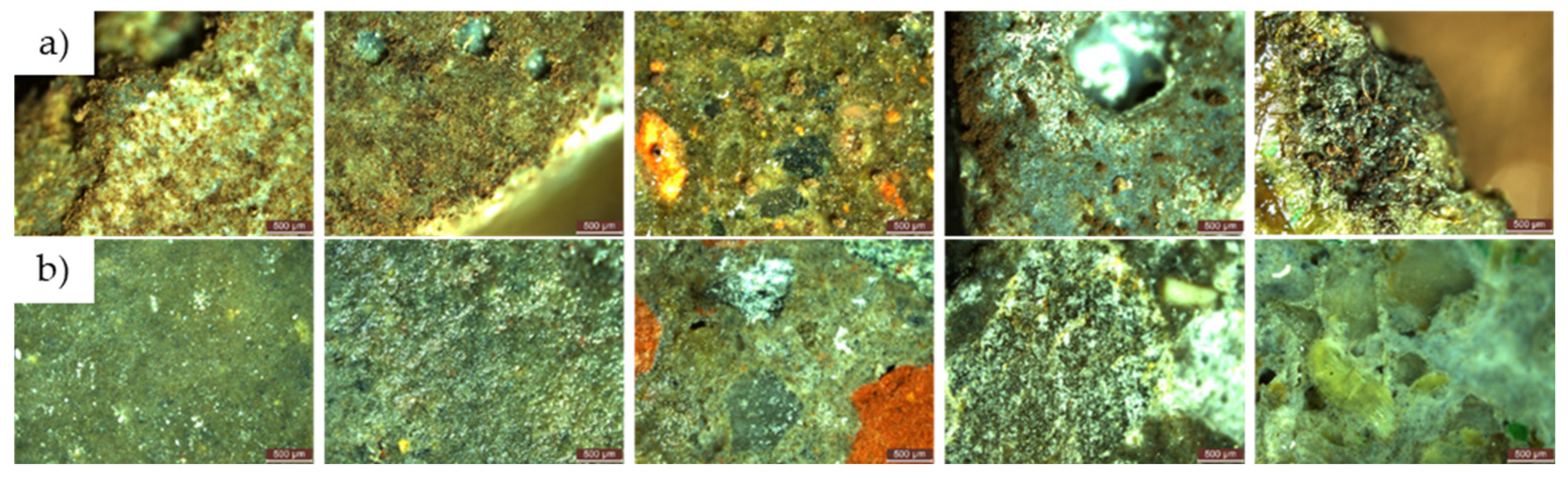

- Similarly, exposure of the NT-free specimens, derived from cementitious compositions with partial replacement of NA with recycled waste aggregates (R2-0NT… R5-0NT), showed mould proliferation along the edges and evidence of mould presence on the surfaces of the specimens after 24 h exposure to an environment contaminated with Aspergillus niger. This trend continued up to 720 h, as illustrated in Figure 12. Notably, an anomaly to this pattern was observed in samples where NA has been partially replaced with GBA (R4), as no evidence of mould presence was detected on either the edges or surfaces of the samples.

- After 24 h exposure, specimens made from cementitious compositions with partial substitution of NA with recycled waste aggregates and the addition of 3% NT (R2-3NT… R5-3NT) showed clean edges and surfaces, free from mould. In addition, inhibition halos were present, the size of which varied between compositions, probably influenced by the nature of the recycled aggregates replacing NA, as shown in Figure 13a.

- Prolonged exposure of these composites (R2-3NT… R5-3NT) containing recycled aggregates and NT to the contaminated environment, as shown in Figure 13b,c, demonstrated the continued resistance of the surfaces to mould activity, with the surfaces remaining clean. However, a reduction in the inhibition halo was observed over time, indicating a decrease in antimicrobial activity within the substrate.

- A proliferation of moulds with a much wider and more uniform spatial distribution was observed on the PDA medium. However, in contrast to the samples contaminated using droplets of the concentrated solution (S1), the population density was much lower.

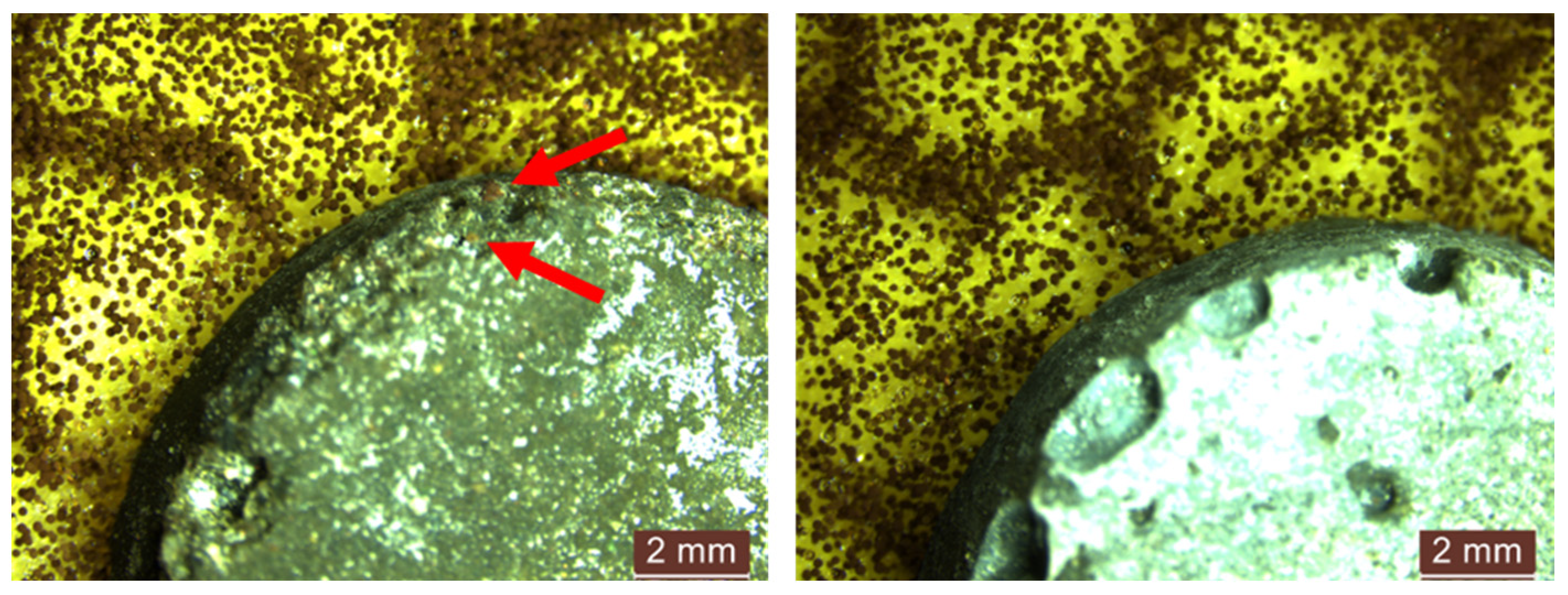

- Within the first 24 h of exposure, there was no evidence of the presence of mould, except within the open area of the test apparatus, specifically on the surface of the PDA medium.

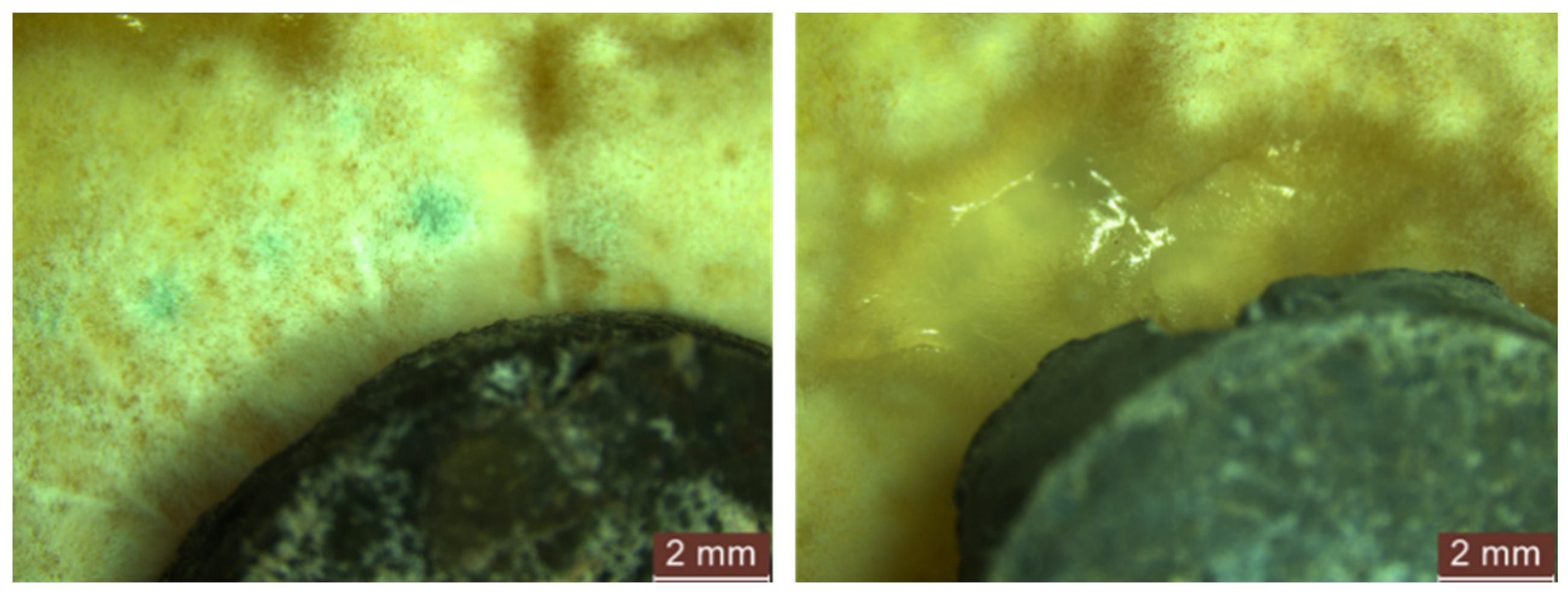

- After 48 h, the R1-0NT composition (with natural aggregates, no NT) showed initial signs of mould development on both the edges and surface of the specimen, as shown in Figure 14 (left). In contrast, the similar composition with 3% NT (R1-3NT) maintains clean edges and surface without the formation of an inhibition halo, as shown in Figure 14 (right). This condition persists up to the evaluation at 720 h of exposure, with continued mould growth observed in the NT-free sample (R1-0NT).

- Throughout the evaluation period, both in composites with recycled aggregates without NT (R2-0NT… R5-0NT) and those with a 3% NT addition (R2-3NT… R5-3NT), the edges and surfaces of the specimens remained free of mould growth, as shown in Figure 15. However, the presence of a clearly defined inhibition halo was not observed.

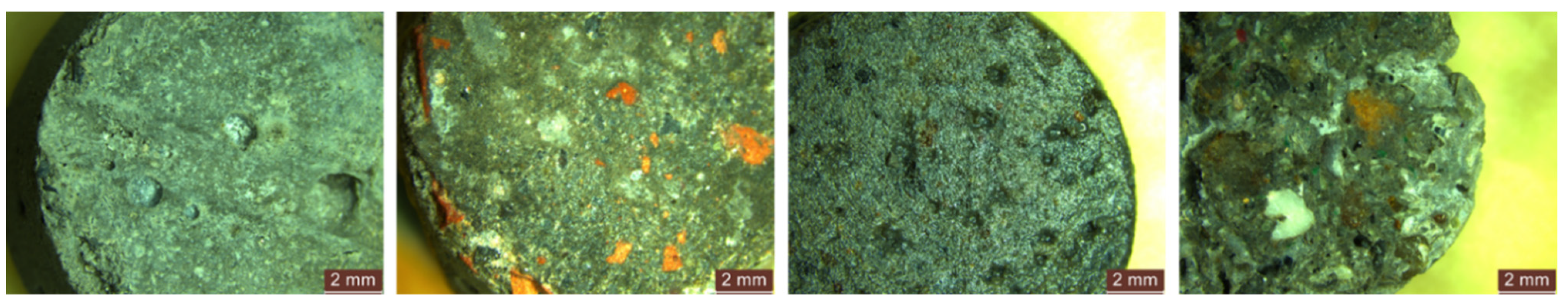

3.3.2. The Cementitious Samples Exposed for 720 h in an Environment Contaminated with Penicillium chrysogenum

- The cementitious composites containing natural aggregates (R1) showed an inability to induce the formation of an inhibition halo, despite the inclusion of NT in the composition. In cases where NT was absent from the composition (R1-0NT), mould colonies proliferated rapidly on both the surface and edges of the specimens within the first 48 h of exposure to the contaminated environment, as shown in Figure 16. These colonies progressively increased in size with prolonged exposure, as observed in Figure 16a. Conversely, there was no discernible evidence of mould development on the cementitious surface in compositions containing NT throughout the 720 h evaluation period, as shown in Figure 16b.

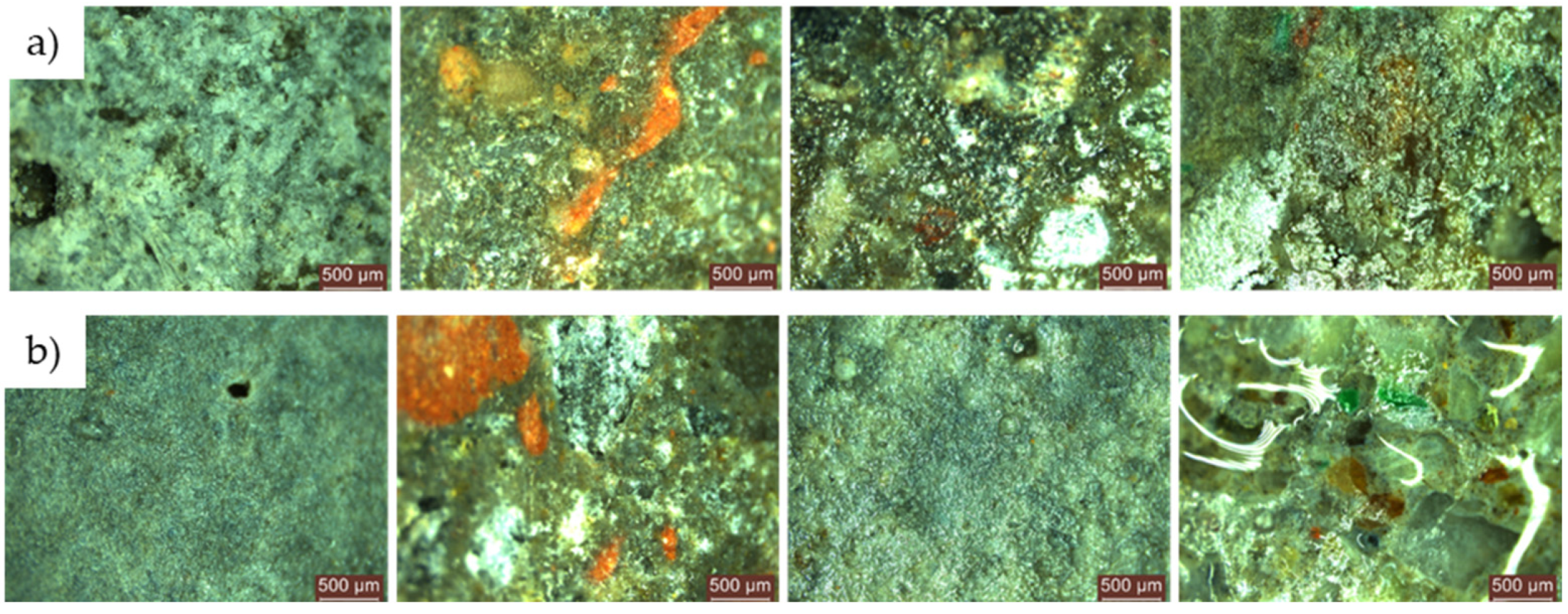

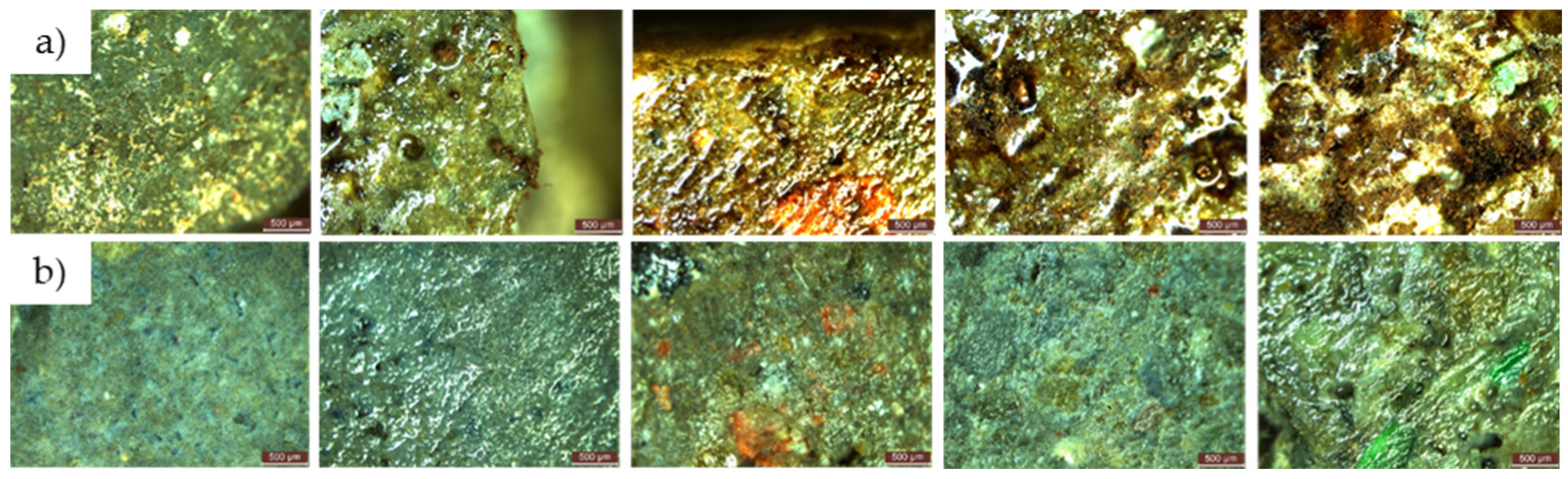

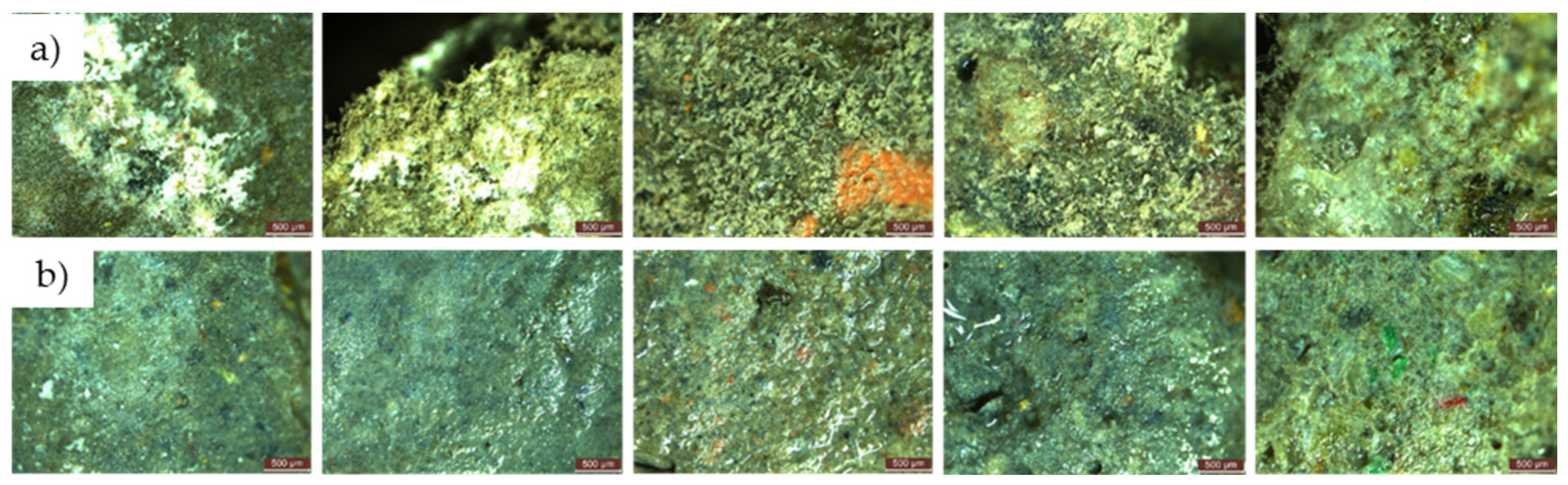

- Within the initial 48 h exposure period in a contaminated environment, cementitious composites containing recycled aggregates showed no evidence of mould growth, irrespective of the presence or absence of NT in the composite matrix. This remained consistent throughout the 720 h observation period, as shown in Figure 17.Figure 17. Microscopic analysis of cementitious composite samples with recycled aggregates (R2-R5) exposed for 720 h to a concentrated solution (S1) of Penicillium chrysogenum in a contaminated environment—from left to right: composition with RGA (R2), composition with RBA (R3), composition with GBA (R4), composition with RTA (R5). (a) Compositions without NT; (b) compositions with 3% NT.Figure 17. Microscopic analysis of cementitious composite samples with recycled aggregates (R2-R5) exposed for 720 h to a concentrated solution (S1) of Penicillium chrysogenum in a contaminated environment—from left to right: composition with RGA (R2), composition with RBA (R3), composition with GBA (R4), composition with RTA (R5). (a) Compositions without NT; (b) compositions with 3% NT.

- The cementitious composite containing natural aggregates without NT (R1-0NT) did not show the formation of an inhibition halo, as illustrated in Figure 18 (left). In contrast, the inclusion of 3% NT led to the observation of an inhibition halo with an average size of 1–1.5 mm after 48 h exposure to the contaminated environment, as shown in Figure 18 (right). There was no evidence of mould growth on the surface of the samples, and these states held throughout the 720 h period.

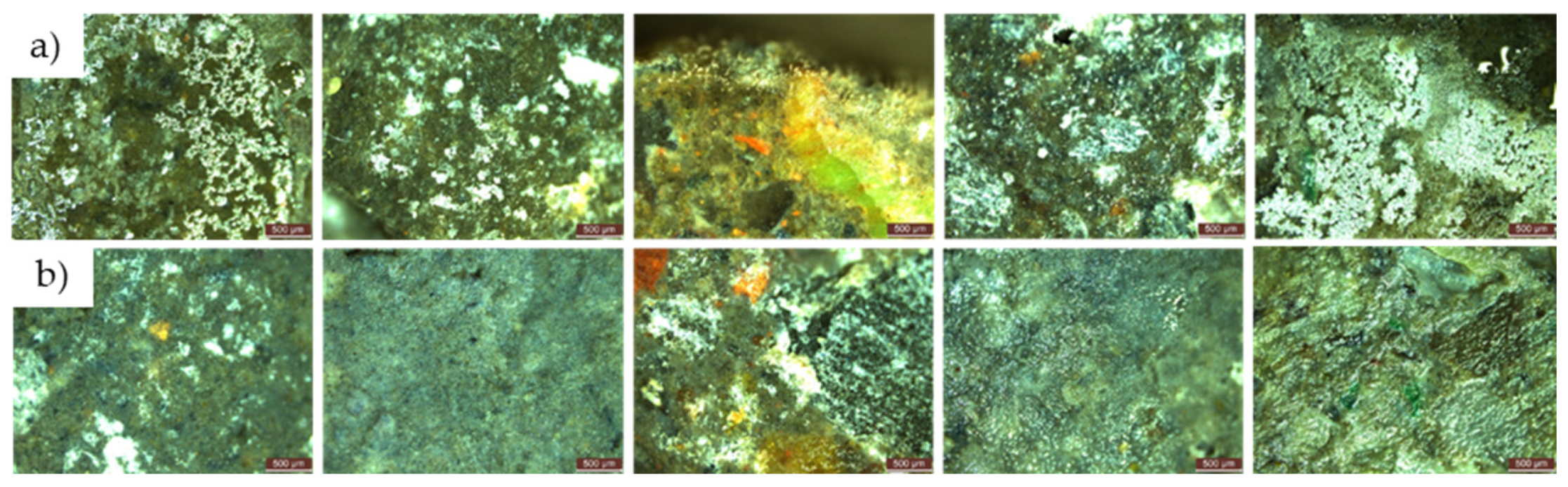

- For cementitious composites with recycled aggregates and without NT (R2-0NT… R5-0NT), no inhibition halo was observed around the specimens, as shown in Figure 19a. However, for composites containing NT (R2-3NT… R5-3NT), an inhibition halo was present, especially when natural aggregates were replaced by brick waste aggregates (R3-3NT), with an average size of 0.8–1.5 mm, as shown in Figure 19b.

- When natural aggregates were replaced with glass waste (R2-3NT), slag (R4-3NT), or textolite (R5-3NT), no continuous inhibition halo was observed around the specimens. Instead, irregular zones of inhibition were observed adjacent to the samples. This condition persisted up to the evaluation carried out after 720 h of exposure to an aggressive environment, with no sign of mould growth on the specimen surfaces. Thus, for this type of mould, the tested materials exhibited an irregular inhibitory effect in the environment that could persist for long periods.

3.3.3. Microscopic Analysis of the Specimen Surfaces after 120 Days (4 Months) of Exposure to the Contaminated Environment

- For both types of mould, Aspergillus niger and Penicillium chrysogenum, evidence of mould colony development was observed on the surface of the R1–R5 cementitious composite specimens that did not contain NT, regardless of whether the concentrated inoculation solution (S1) (Figure 20 and Figure 21) or the diluted solution (S2) was used (Figure 22 and Figure 23).

- No evidence of colonisation was observed on the surfaces of cementitious composite samples R1–R5 containing 3% NT (3% by weight relative to the amount of cement) when using either concentrated (S1) or dilute (S2) inoculants. However, it is noteworthy that even in cases where an inhibition halo or inhibition zones were initially observed around the specimens, these phenomena largely dissipated over time, with the mould film extending to the interface region between the cementitious specimen and the PDA nutrient substrate.

- compete biocide effect—the sample does not present any fungal contamination; a halo is clear and visible around the cementitious samples;

- partial biocide effect—the sample present mould marks or weak contamination; the halo is partial visible around the cementitious samples, and they have an irregular shape;

- no biocide effect—the samples are completely covered by moulds; no halo (partial or complete) is visible around the cementitious samples.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Albsoul, H.; Doan, D.T.; Aigwi, I.E.; GhaffarianHoseini, A. A review of extant literature and recent trends in residential construction waste reduction. Waste Manag. Res. 2024, 0734242X241241607. [Google Scholar] [CrossRef] [PubMed]

- Abhilash, P.P.; Nayak, D.K.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of nano-silica in concrete; a review. Constr. Build. Mater. 2021, 278, 122347. [Google Scholar]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar] [CrossRef]

- Bunea, G.; Toma, I.O.; Alexa-Stratulat, S.M.; Mihai, P.; Cimpoeşu, N.; Istrate, B.; Stoian, G. Assessing the effect of adding TiO2 and calcined montmorillonite clay nanoparticles on the mechanical properties of cement mortar. Constr. Build. Mater. 2024, 413, 134910. [Google Scholar] [CrossRef]

- Vavouraki, A.I.; Gounaki, I.; Venieri, D. Properties of inorganic polymers based on ground waste concrete containing CuO and ZnO nanoparticles. Polymers 2021, 13, 2871. [Google Scholar] [CrossRef] [PubMed]

- Hosan, A.; Shaikh, F.U.A. Compressive strength development and durability properties of high volume slag and slag-fly ash blended concretes containing nano-CaCO3. J. Mater. Res. Technol. 2021, 10, 1310–1322. [Google Scholar] [CrossRef]

- Golewski, G.L. Enhancement fracture behavior of sustainable cementitious composites using synergy between fly ash (FA) and nanosilica (NS) in the assessment based on digital image processing procedure. Theor. Appl. Fract. Mech. 2024, 131, 104442. [Google Scholar] [CrossRef]

- AlTawaiha, H.; Alhomaidat, F.; Eljufout, T. A Review of the Effect of Nano-Silica on the Mechanical and Durability Properties of Cementitious Composites. Infrastructures 2023, 8, 132. [Google Scholar] [CrossRef]

- Amin, M.; Abu el-Hassan, K. Effect of using different types of nano materials on mechanical properties of high strength concrete. Constr. Build. Mater. 2015, 80, 116–124. [Google Scholar] [CrossRef]

- Zhao, Z.R.; Kong, J.; Yang, H.X. Study on Frost Resistance of Nano SiO2 Cement Concrete. Appl. Mech. Mater. 2012, 198–199, 48–51. [Google Scholar] [CrossRef]

- Shaikh, F.U.; Supit, S.W. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Build. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef]

- Ren, J.; Lai, Y.; Gao, J. Exploring the influence of SiO2 and TiO2 nanoparticles on the mechanical properties of concrete. Constr. Build. Mater. 2018, 175, 277–285. [Google Scholar] [CrossRef]

- Hamdany, A.H.; Satyanaga, A.; Zhang, D.; Kim, Y.; Kim, J.R. Photocatalytic cementitious material for eco-efficient construction—A systematic literature review. Appl. Sci. 2022, 12, 8741. [Google Scholar] [CrossRef]

- Fujishima, A.; Zhang, X. Titanium dioxide photocatalysis: Present situation and future approaches. Comptes Rendus Chim. 2006, 9, 750–760. [Google Scholar] [CrossRef]

- Ohama, Y.; Van Gemert, D. (Eds.) Application of Titanium Dioxide Photocatalysis to Construction Materials: State-of-the-Art Report of the RILEM Technical Committee 194-TDP; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; Volume 5. [Google Scholar]

- Dharma, H.N.C.; Jaafar, J.; Widiastuti, N.; Matsuyama, H.; Rajabsadeh, S.; Othman, M.H.D.; Rahman, M.A.; Jafri, N.N.M.; Suhaimin, N.S.; Nasir, A.M.; et al. A review of titanium dioxide (TiO2)-based photocatalyst for oilfield-produced water treatment. Membranes 2022, 12, 345. [Google Scholar] [CrossRef] [PubMed]

- Anucha, C.B.; Altin, I.; Bacaksiz, E.; Stathopoulos, V.N. Titanium dioxide (TiO2)-based photocatalyst materials activity enhancement for contaminants of emerging concern (CECs) degradation: In the light of modification strategies. Chem. Eng. J. Adv. 2022, 10, 100262. [Google Scholar] [CrossRef]

- Sharifi, T.; Crmaric, D.; Kovacic, M.; Popovic, M.; Rokovic, M.K.; Kusic, H.; Jozić, D.; Ambrožić, G.; Kralj, D.; Kontrec, J.; et al. Tailored BiVO4 for enhanced visible-light photocatalytic performance. J. Environ. Chem. Eng. 2021, 9, 106025. [Google Scholar] [CrossRef]

- Baxter, D.M.; Perkins, J.L.; McGhee, C.R.; Seltzer, J.M. A regional comparison of mold spore concentrations outdoors and inside “clean” and “mold contaminated” Southern California buildings. J. Occup. Environ. Hyg. 2005, 2, 8–18. [Google Scholar] [CrossRef]

- Chen, H.; Deng, S.; Bruner, H.; Garcia, J. Roots of Mold Problems and Humidity Control Measures in Institutional Buildings with Pre-Existing Mold Condition; Energy Systems Laboratory: Bryan, TX, USA, 2004. [Google Scholar]

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227–1249. [Google Scholar] [CrossRef]

- Mills, A.; Hill, C.; Robertson, P.K. Overview of the current ISO tests for photocatalytic materials. J. Photochem. Photobiol. A Chem. 2012, 237, 7–23. [Google Scholar] [CrossRef]

- Kühn, K.P.; Chaberny, I.F.; Massholder, K.; Stickler, M.; Benz, V.W.; Sonntag, H.G.; Erdinger, L. Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere 2003, 53, 71–77. [Google Scholar] [CrossRef]

- Irie, H.; Hashimoto, K. Photocatalytic active surfaces and photo-induced high hydrophilicity/high hydrophobicity. In Environmental Photochemistry Part II; Springer: Berlin/Heidelberg, Germany, 2005; pp. 425–450. [Google Scholar]

- Yadav, H.M.; Kim, J.S.; Pawar, S.H. Developments in photocatalytic antibacterial activity of nano TiO2: A review. Korean J. Chem. Eng. 2016, 33, 1989–1998. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, C.; Li, Q.; Zhang, W.; Cao, L.; Ye, J. Preparation of titanium dioxide nano particle modified photocatalytic self-cleaning concrete. J. Clean. Prod. 2015, 87, 762–765. [Google Scholar] [CrossRef]

- Machida, M.; Norimoto, K.; Kimura, T. Antibacterial activity of photocatalytic titanium dioxide thin films with photodeposited silver on the surface of sanitary ware. J. Am. Ceram. Soc. 2005, 88, 95–100. [Google Scholar] [CrossRef]

- Watts, R.J.; Kong, S.; Orr, M.P.; Miller, G.C.; Henry, B.E. Photocatalytic inactivation of coliform bacteria and viruses in secondary wastewater effluent. Water Res. 1995, 29, 95–100. [Google Scholar] [CrossRef]

- Vohra, A.; Goswami, D.Y.; Deshpande, D.A.; Block, S.S. Enhanced photocatalytic inactivation of bacterial spores on surfaces in air. J. Ind. Microbiol. Biotechnol. 2005, 32, 364. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.H.; Karuppayil, S.M. Fungal pollution of indoor environments and its management. Saudi J. Biol. Sci. 2012, 19, 405–426. [Google Scholar] [CrossRef] [PubMed]

- Giannantonio, D.J.; Kurth, J.C.; Kurtis, K.E.; Sobecky, P.A. Effects of concrete properties and nutrients on fungal colonization and fouling. Int. Biodeterior. Biodegrad. 2009, 63, 252–259. [Google Scholar] [CrossRef]

- Gu, J.D.; Ford, T.E.; Berke, N.S.; Mitchell, R. Biodeterioration of concrete by the fungus Fusariu. Int. Biodeterior. Biodegrad. 1998, 41, 101–109. [Google Scholar] [CrossRef]

- Fonseca, A.J.; Pina, F.; Macedo, M.F.; Leal, N.; Romanowska-Deskins, A.; Laiz, L.; Gómez-Bolea, A.; Saiz-Jimenez, C. Anatase as an alternative application for preventing biodeterioration of mortars: Evaluation and comparison with other biocides. Int. Biodeterior. Biodegrad. 2010, 64, 388–396. [Google Scholar] [CrossRef]

- Liu, J.; Yi, Y.; Wang, X. Exploring factors influencing construction waste reduction: A structural equation modeling approach. J. Clean. Prod. 2020, 276, 123185. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef] [PubMed]

- Nematzadeh, M.; Dashti, J.; Ganjavi, B. Optimizing compressive behavior of concrete containing fine recycled refractory brick aggregate together with calcium aluminate cement and polyvinyl alcohol fibers exposed to acidic environment. Constr. Build. Mater. 2018, 164, 837–849. [Google Scholar] [CrossRef]

- Chen, Y.Z. Comparison of policy about construction waste resource utilization in China & abroad. Archit. Technol. 2019, 50, 342–345. [Google Scholar]

- Pavlu, T.; Fortova, K.; Divis, J.; Hajek, P. The utilization of recycled masonry aggregate and recycled EPS for concrete blocks for mortarless masonry. Materials 2019, 12, 1923. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of recycled fine glass aggregates on the properties of dry–mixed concrete blocks. Constr. Build. Mater. 2013, 38, 638–643. [Google Scholar] [CrossRef]

- Pizoń, J.; Gołaszewski, J.; Alwaeli, M.; Szwan, P. Properties of concrete with recycled concrete aggregate containing metallurgical sludge waste. Materials 2020, 13, 1448. [Google Scholar] [CrossRef] [PubMed]

- Premur, V.; Anić Vučinić, A.; Vujević, D.; Bedeković, G. The possibility for environmental friendly recycling of printed circuit boards. J. Sustain. Dev. Energy Water Environ. Syst. 2016, 4, 14–22. [Google Scholar] [CrossRef]

- Santhanam, N.; Ramesh, B.; Pohsnem, F.K. Concrete blend with E-waste plastic for sustainable future. Mater. Today Proc. 2020, 22, 959–965. [Google Scholar] [CrossRef]

- Sikora, P.; Augustyniak, A.; Cendrowski, K.; Horszczaruk, E.; Rucinska, T.; Nawrotek, P.; Mijowska, E. Characterization of mechanical and bactericidal properties of cement mortars containing waste glass aggregate and nanomaterials. Materials 2016, 9, 701. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, M.; Kohail, M.; Abadel, A.A.; Alharbi, Y.R.; Soliman, A.M.; Mohsen, A. Exploration of mechanical performance, porous structure, and self-cleaning behavior for hydrothermally cured sustainable cementitious composites containing de-aluminated metakaolin waste and TiO2 nanoparticles. J. Mater. Res. Technol. 2023, 25, 3998–4019. [Google Scholar] [CrossRef]

- Hamead, A.A. The effect of recycled waste medicine materials on the properties of cement mortar coatis. J. Eng. Sci. Technol. 2020, 15, 4182–4199. [Google Scholar]

- Snoeck, D.; Roigé, N.; Manso, S.; Segura, I.; De Belie, N. The effect of (and the potential of recycled) superabsorbent polymers on the water retention capability and bio-receptivity of cementitious materials. Resour. Conserv. Recycl. 2022, 177, 106016. [Google Scholar] [CrossRef]

- EN 934-1:2008; Admixtures for Concrete, Mortar and Grout. Common Requirements-Part 1: Common Requirements. 2008. Available online: https://standards.iteh.ai/catalog/standards/cen/cbbb6eaf-9456-4291-b1dc-58892224ee57/en-934-1-2008 (accessed on 30 May 2024).

- EN 934-2:2009; Admixtures for Concrete, Mortar and Grout. Concrete Admixtures. Definitions, Requirements, Conformity, Marking and Labelling. 2012. Available online: https://standards.iteh.ai/catalog/standards/cen/16790a91-c169-477d-beec-09ff83c9a0a4/en-934-2-2009 (accessed on 17 June 2024).

- SR EN 191-1:2011; Methods of Testing Cement—Part 1: Determination of Strength. ASRO: Bucharest, Romania, 2011. (In Romanian)

- SR EN 196-2:2013; Methods of Testing Cements—Part 2: Chemical Analysis of Cement. ASRO: Bucharest, Romania, 2013. (In Romanian)

- Florean, C.T.; Vermeșan, H.; Gabor, T.; Neamțu, B.V.; Thalmaier, G.; Hegyi, A.; Csapai, A.; Lăzărescu, A.V. Influence of TiO2 Nanoparticles on the Physical, Mechanical, and Structural Characteristics of Cementitious Composites with Recycled Aggregates. Materials 2024, 17, 2014. [Google Scholar] [CrossRef] [PubMed]

- Florean, C.T.; Vermeșan, H.; Gabor, T.; Neamțu, B.V.; Thalmaier, G.; Corbu, O.; Lazarescu, A.V.; Hegyi, A.; Csapai, A. Possibilities for Conserving Natural Resources and the Environment Through the use of Recycled Waste Aggregates as a Substitute for Natural Aggregates in Cementitious Composites. Int. J. Conserv. Sci. 2024, 15, 527–546. [Google Scholar] [CrossRef]

- Florean, C.T.; Vermesan, H.; Thalmaier, G.; Neamtu, B.V.; Gabor, T.; Campian, C.; Hegyi, A.; Csapai, A. The Influence of TiO2 Nanoparticles on the Physico–Mechanical and Structural Characteristics of Cementitious Materials. Coatings 2024, 14, 218. [Google Scholar] [CrossRef]

- SR EN 1015-2:2001; Test Methods for Masonry Mortars. Part 2: Global Sampling of Mortars and Preparation of Mortars for Testing. ASRO: Bucharest, Romania, 2001. (In Romanian)

- Andersen, B.; Frisvad, J.C.; Søndergaard, I.; Rasmussen, I.S.; Larsen, L.S. Associations between fungal species and water-damaged building materials. Appl. Environ. Microbiol. 2011, 77, 4180–4188. [Google Scholar] [CrossRef] [PubMed]

- Zukiewicz-Sobczak, W.; Sobczak, P.; Krasowska, E.; Zwolinski, J.; Chmielewska-Badora, J.; Galinska, E.M. Allergenic potential of moulds isolated from buildings. Ann. Agric. Environ. Med. 2013, 20, 500–503. [Google Scholar]

- Haverinen-Shaughnessy, U. Prevalence of dampness and mold in European housing stock. J. Expo. Sci. Environ. Epidemiol. 2012, 22, 461–467. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Yu, X.; Han, B.; Ou, J. Multifunctional cementitious composites modified with nano titanium dioxide: A review. Compos. Part A Appl. Sci. Manuf. 2018, 111, 115–137. [Google Scholar] [CrossRef]

- Nyong, A.; Nsi, E.; Awaka-Ama, J.; Udo, G. Comparative evaluation of the photodegradation of stearic acid by TiO2-modified cement under UV irradiation through water contact angle and absorbance studies. Adv. Mater. 2020, 9, 1–7. [Google Scholar] [CrossRef]

- Thakur, N.; Thakur, N.; Kumar, A.; Thakur, V.K.; Kalia, S.; Arya, V.; Kumar, A.; Kumar, S.; Kyzas, G.Z. A critical review on the recent trends of photocatalytic, antibacterial, antioxidant and nanohybrid applications of anatase and rutile TiO2 nanoparticles. Sci. Total Environ. 2024, 914, 169815. [Google Scholar] [CrossRef]

- Rajaram, P.; Jeice, A.R.; Jayakumar, K. Review of green synthesized TiO2 nanoparticles for diverse applications. Surf. Interfaces 2023, 39, 102912. [Google Scholar] [CrossRef]

| Recipe Code | Design Class | Water/ Cement Ratio | Cement (kg/m3) | Natural Aggregates, Cumulative (kg/m3) | Natural Aggregates, Sort 0/4 mm (% of Total Aggregates) | Natural Aggregates, Sort 4/8 mm (% of Total Aggregates) | MasterEase 5009 Superplasticiser Additive (% Mass Ratio to Cement Quantity) |

|---|---|---|---|---|---|---|---|

| R1 | C 20/25 | 0.6 | 366 | 1577 | 70 | 30 | 0.5 |

| Sample Code | Average Contact Angle at the t0 Moment (°) | Average Contact Angle at the t100 Moment (°) | STF at the t0 Moment (mN/m) | STF at the t100 Moment (mN/m) |

|---|---|---|---|---|

| R1-0NT | 60.87 | 47.83 | 47.67 | 54.99 |

| R1-3NT | 22.77 | 18.15 | 67.74 | 69.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florean, C.T.; Csapai, A.; Vermesan, H.; Gabor, T.; Hegyi, A.; Stoian, V.; Uriciuc, W.A.; Petcu, C.; Cîmpan, M. Influence of the Addition of TiO2 Nanoparticles on the Self-Cleaning Capacity of Cementitious Composites. Materials 2024, 17, 3098. https://doi.org/10.3390/ma17133098

Florean CT, Csapai A, Vermesan H, Gabor T, Hegyi A, Stoian V, Uriciuc WA, Petcu C, Cîmpan M. Influence of the Addition of TiO2 Nanoparticles on the Self-Cleaning Capacity of Cementitious Composites. Materials. 2024; 17(13):3098. https://doi.org/10.3390/ma17133098

Chicago/Turabian StyleFlorean, Carmen Teodora, Alexandra Csapai, Horatiu Vermesan, Timea Gabor, Andreea Hegyi, Vlad Stoian, Willi Andrei Uriciuc, Cristian Petcu, and Marius Cîmpan. 2024. "Influence of the Addition of TiO2 Nanoparticles on the Self-Cleaning Capacity of Cementitious Composites" Materials 17, no. 13: 3098. https://doi.org/10.3390/ma17133098

APA StyleFlorean, C. T., Csapai, A., Vermesan, H., Gabor, T., Hegyi, A., Stoian, V., Uriciuc, W. A., Petcu, C., & Cîmpan, M. (2024). Influence of the Addition of TiO2 Nanoparticles on the Self-Cleaning Capacity of Cementitious Composites. Materials, 17(13), 3098. https://doi.org/10.3390/ma17133098