Resistance of External Thermal Insulation Systems with Fire Barriers to Long-Lasting Weathering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

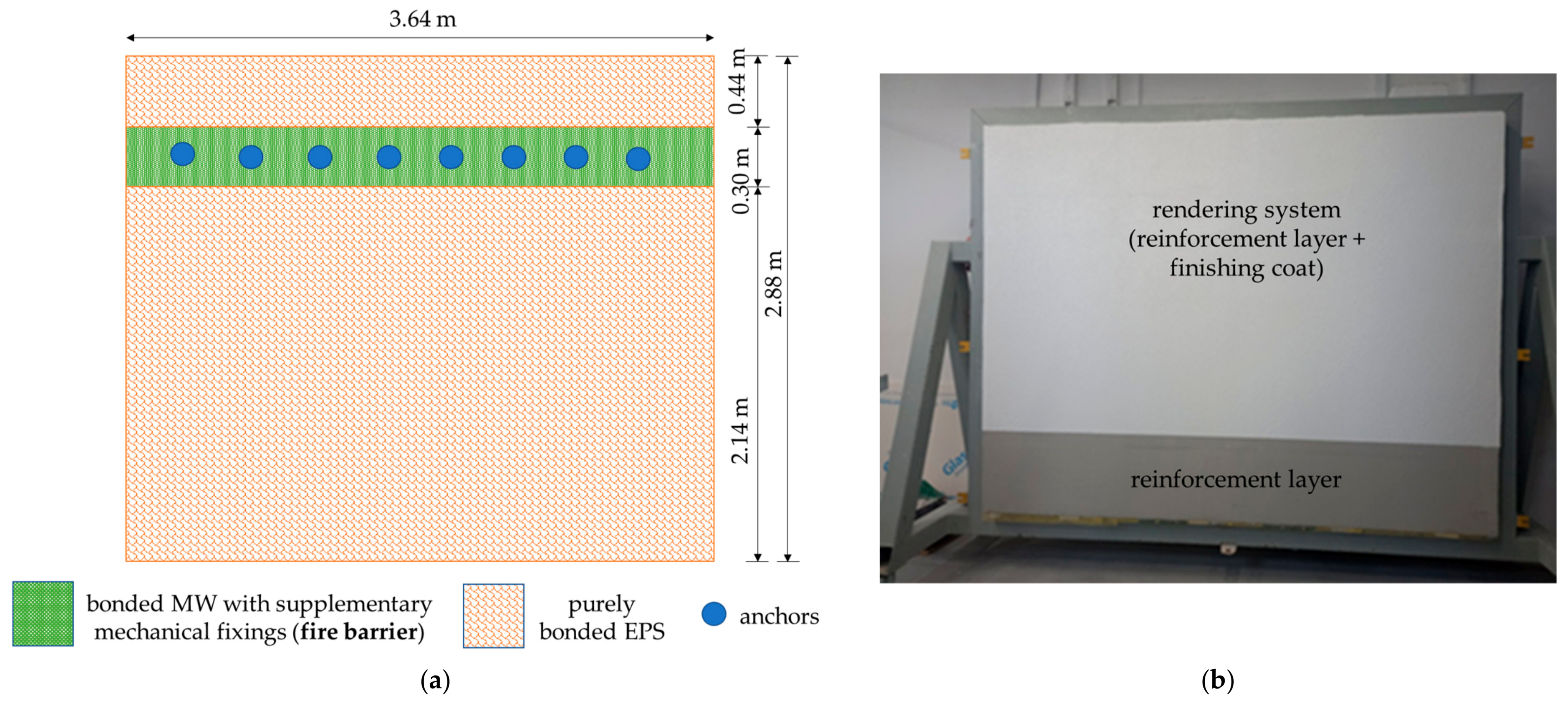

2.2. Test Objects

- 3.6 m-ide and 2.8 m-high one-test model representing the thermal insulation system,

- 1.0 m × 0.5 m mock-ups representing fragments of the test model, that is, a thermal insulation system on an EPS layer (two mock-ups) and strips between the storeys on an MW layer (two mock-ups).

2.3. Weathering

- 29-day-long hydrothermal cycles involving:

- –

- 80 cycles of heating and wetting (HW), 6 h each, including:

- ·

- heating to T 70 ± 2 °C for 1 h,

- ·

- maintaining T 70 ± 5 °C, RH ≤ 30% for 2 h,

- ·

- wetting by sprinkling water at 15 ± 5 °C for 1 h,

- ·

- drying for 2 h at 20 ± 5 °C,

- –

- conditioning for 48 h at T 20 ± 5 °C, RH ≥ 50%;

- –

- 5 cycles of heating and cooling (HC), 24 h each, were performed as follows:

- ·

- heating to T 50 ± 2 °C for 1 h,

- ·

- maintaining T 50 ± 5 °C and RH ≤ 30% for 7 h,

- ·

- cooling down to T −20 ± 3 °C for 2 h,

- ·

- freezing for 14 h at T −20 ± 3 °C,

- –

- conditioning for 48 h at T 20 ± 5 °C and RH ≥ 50%.

- 17-day-long wetting, freezing, and thawing (WFT), including:

- –

- water sprinkling at 15 ± 5 °C for 8 h;

- –

- 30 cycles, 8 h, including:

- ·

- cooling down to T −20 ± 3 °C for 2 h,

- ·

- freezing for 4 h at T −20 ± 3 °C,

- ·

- thawing at T 20 ± 5 °C for 1 h,

- ·

- water sprinkling at T 15 ± 5 °C for 1 h;

- –

- conditioning for 7 d at T 20 ± 5 °C and RH ≥ 50%.

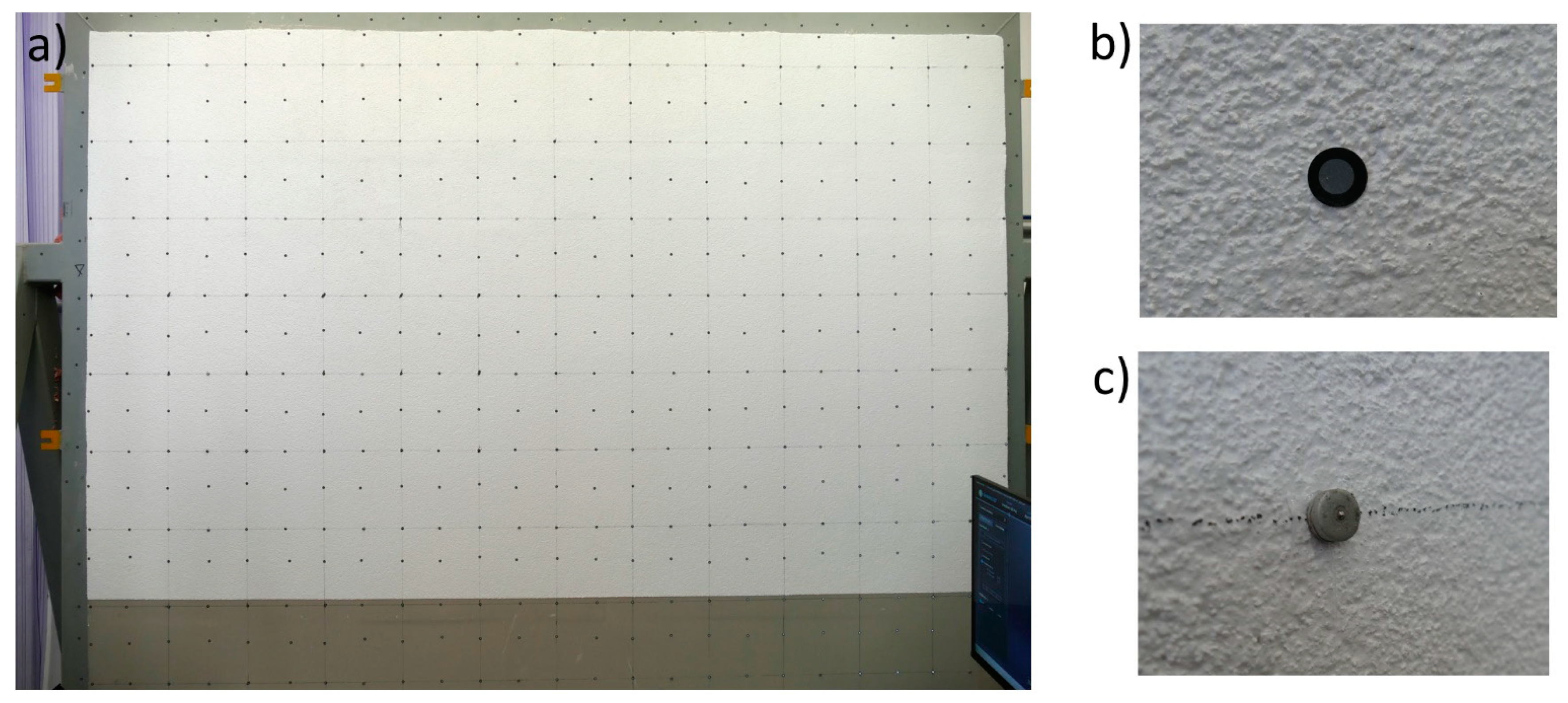

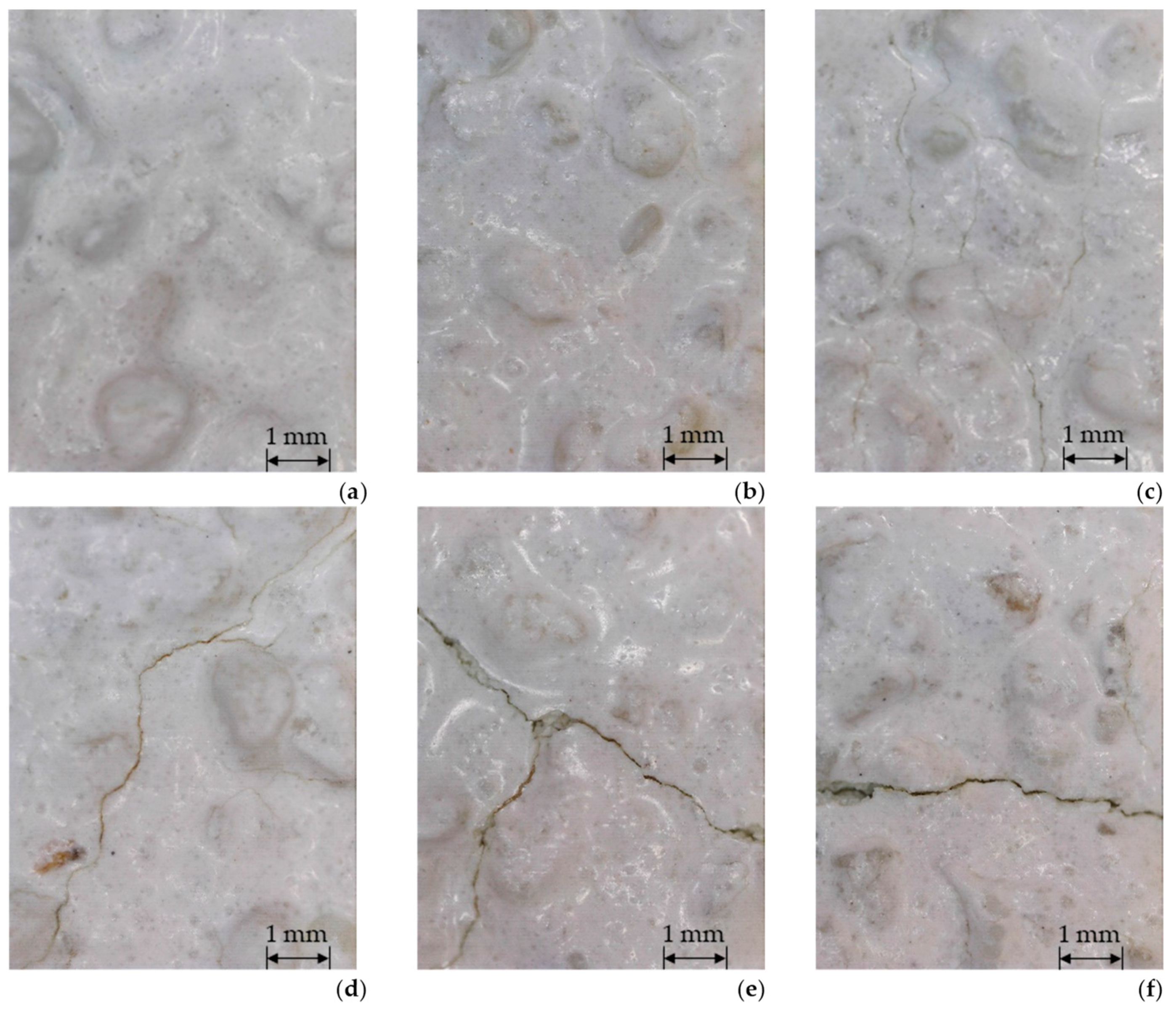

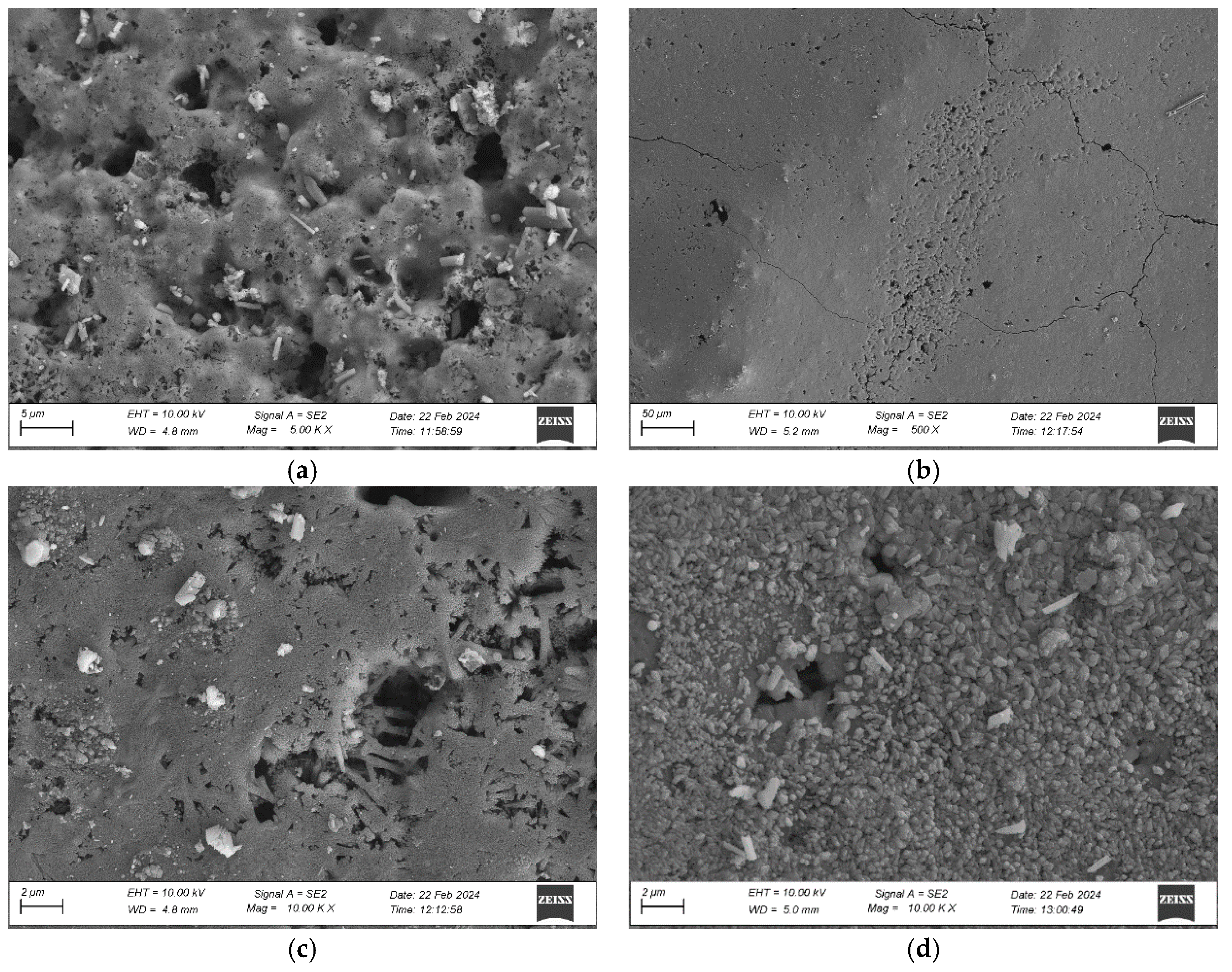

2.4. Macroscopic and Microscopic Inspection

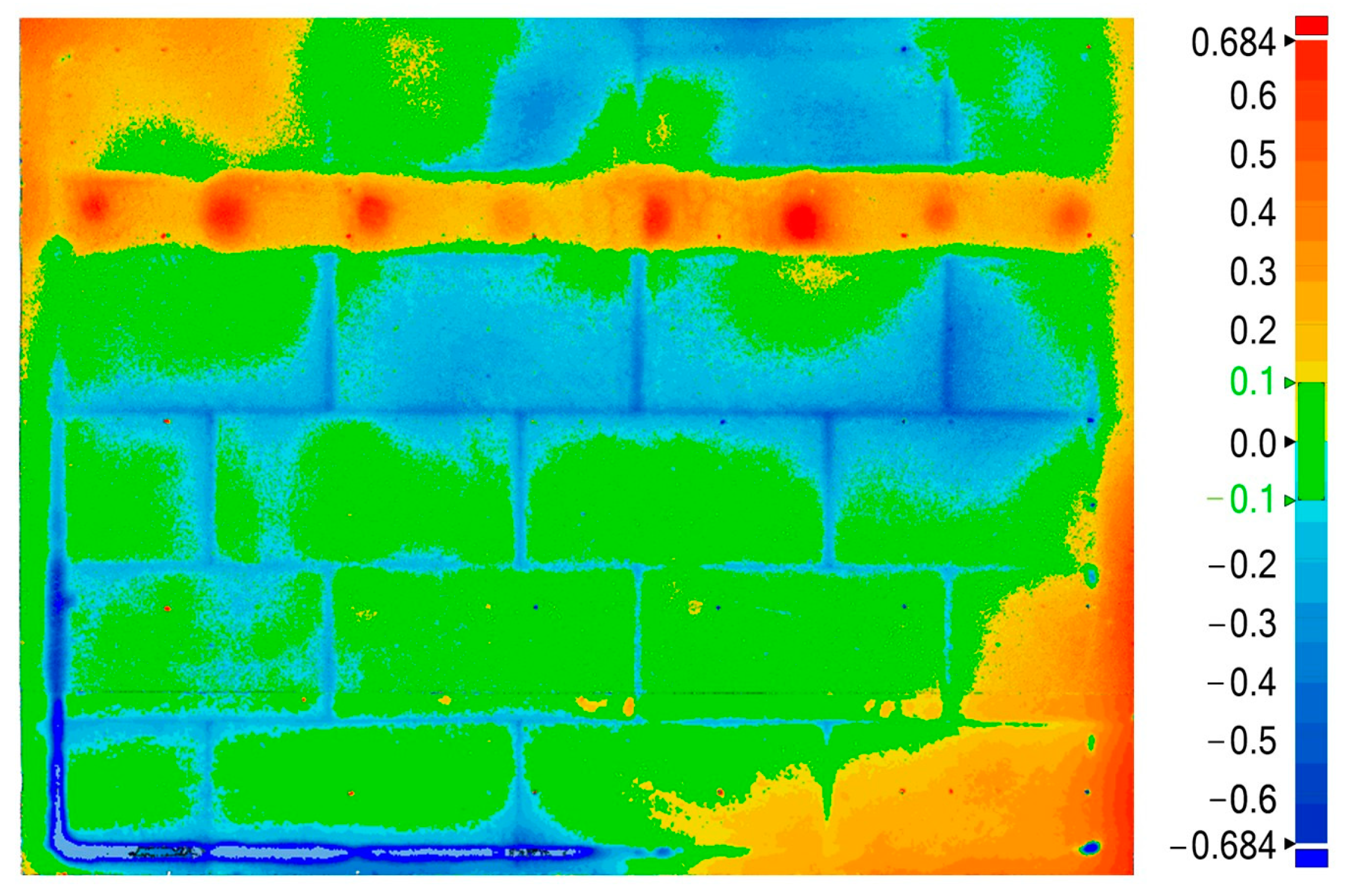

2.5. 3D Scanning with Inspection Analysis

2.6. Performance Tests

3. Results and Discussion

3.1. Macroscopic and Microscopic Assessment

3.2. Inspection Analysis

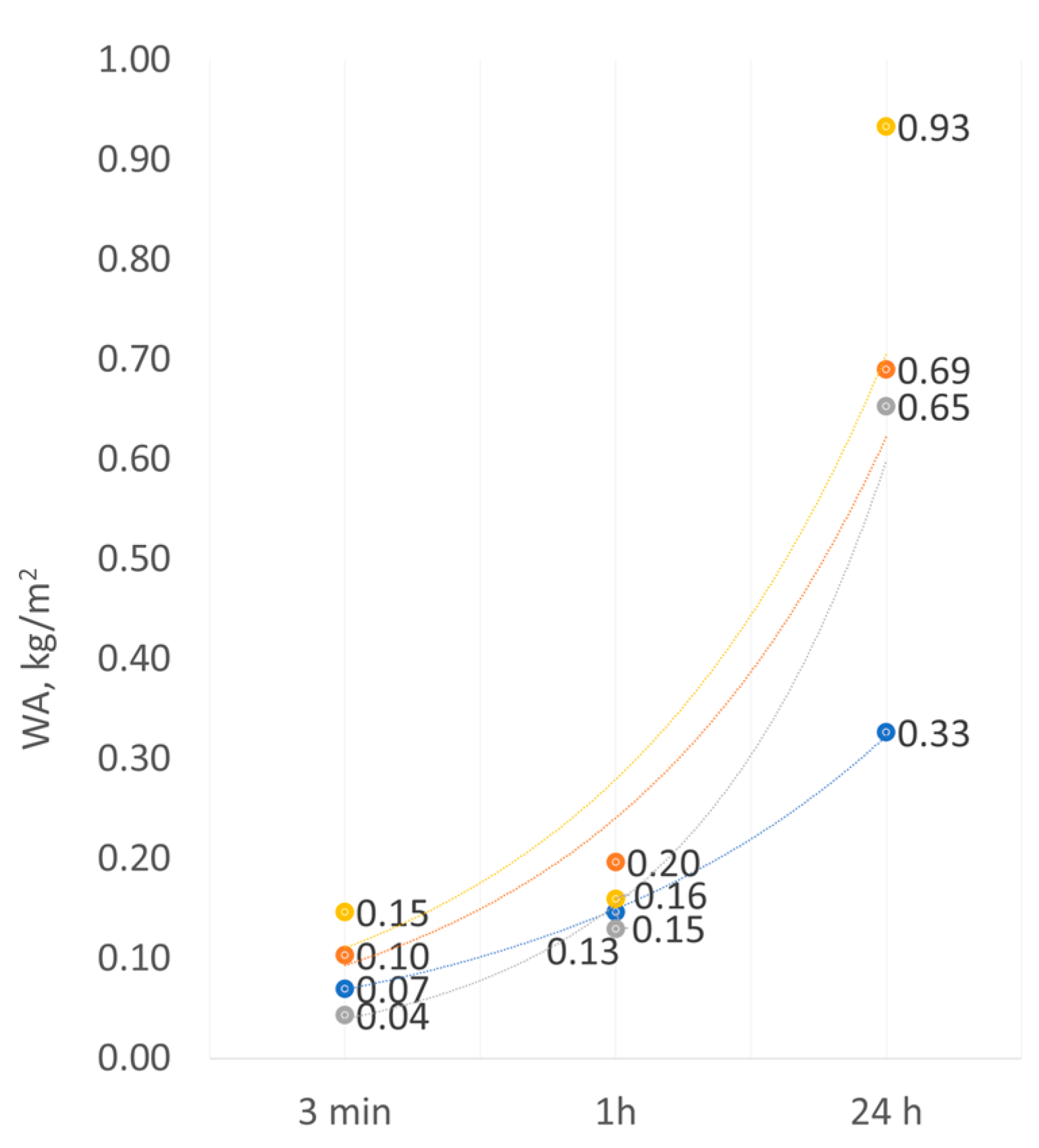

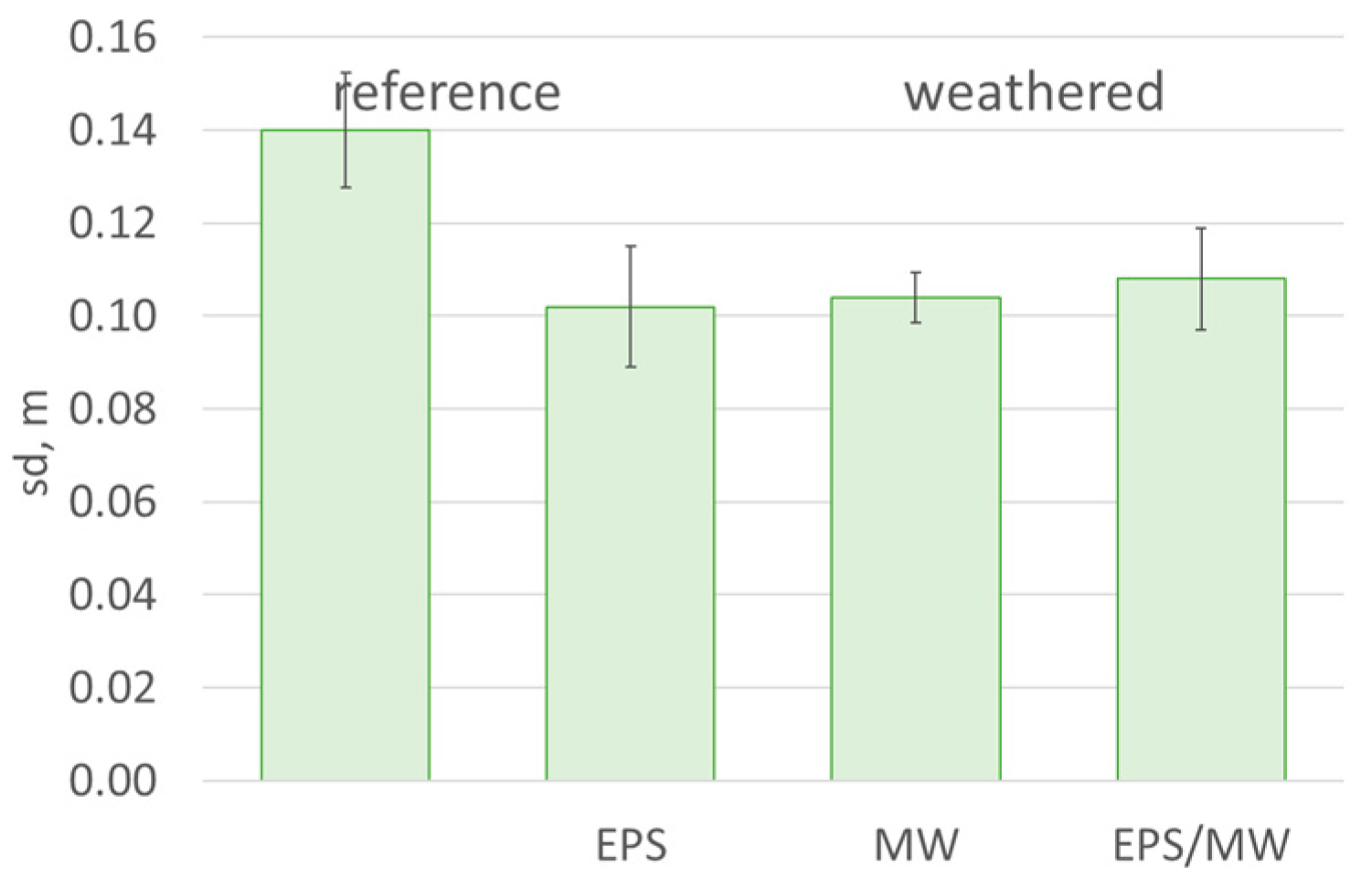

3.3. Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michałowski, B.; Marcinek, M.; Tomaszewska, J.; Czernik, S.; Piasecki, M.; Geryło, R.; Michalak, J. Influence of Rendering Type on the Environmental Characteristics of Expanded Polystyrene-Based External Thermal Insulation Composite System. Buildings 2020, 10, 47. [Google Scholar] [CrossRef]

- Pasker, R. The European ETICS market–Do ETICS sufficiently contribute to meet political objectives? In Proceedings of the 4th European ETICS Forum, Warsaw, Poland, 5 October 2017; European Association for External Thermal Insulation Composite Systems (EAE): Baden-Baden, Germany, 2017. [Google Scholar]

- Michalak, J. External thermal insulation composite systems (ETICS) from industry and academia perspective. Sustainability 2021, 13, 3705. [Google Scholar] [CrossRef]

- Sudoł, E.; Kozikowska, E. Mechanical Properties of Polyurethane Adhesive Bonds in a Mineral Wool-Based External Thermal Insulation Composite System for Timber Frame Buildings. Materials 2021, 14, 2527. [Google Scholar] [CrossRef] [PubMed]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of External Thermal Insulation Systems. Expanded Polystyrene vs. Mineral Wool: Case Study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- EAD 040083-01-0404; European Assessment Document External Thermal Insulation Composite Systems (ETICS) with Renderings. European Organization for Technical Assesment (EOTA): Brussels, Belgium, 2020.

- SITP WP-03:2018; Design Guidelines: Insulation of Building Facades due to Fire Safety. Association of Firefighting Engineers and Technicians: Warsaw, Poland, 2018. (In Polish)

- Niziurska, M.; Wieczorek, M.; Borkowicz, K. Fire Safety of External Thermal Insulation Systems (ETICS) in the Aspect of Sustainable Use of Natural Resources. Sustainability 2022, 14, 1224. [Google Scholar] [CrossRef]

- Čolić, A.; Pečur, I.B. Influence of Horizontal and Vertical Barriers on Fire Development for Ventilated Façades. Fire Technol. 2020, 56, 1725–1754. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- EN 13162+A1:2015; Thermal Insulation Products for Buildings. Factory Made Mineral Wool (MW) Products. Specification. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 13501-1:2019-02; Fire Classification of Construction Products and Building Elements. Part 1: Classification Using Data from Reaction to Fire Tests. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Regulation (EU) No 305/2011 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2011.088.01.0005.01.ENG&toc=OJ:L:2011:088:TOC (accessed on 1 April 2024).

- Parracha, J.L.; Borsoi, G.; Veiga, R.; Flores-Colen, I.; Nunes, L.; Garcia, A.R.; Ilharco, L.M.; Dionísio, A.; Faria, P. Effects of hygrothermal, UV and SO2 accelerated ageing on the durability of ETICS in urban environments. Build. Environ. 2021, 204, 108151. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- Tavares, J.; Silva, A.; de Brito, J. Computational models applied to the service life prediction of External Thermal Insulation Composite Systems (ETICS). J. Build. Eng. 2020, 27, 100944. [Google Scholar] [CrossRef]

- Landolfi, R.; Nicolella, M. Durability Assessment of ETICS: Comparative Evaluation of Different Insulating Materials. Sustainability 2022, 14, 980. [Google Scholar] [CrossRef]

- Gonçalves, M.; Simões, N.; Serra, C.; Almeida, J.; Flores-Colen, I.; Vieira de Castro, N.; Duarte, L. Onsite monitoring of ETICS comparing different exposure conditions and insulation materials. J. Build. Eng. 2021, 42, 103067. [Google Scholar] [CrossRef]

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J. Durability of ETICS with Rendering in Norway—Experimental and Field Investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef]

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L.; Dionísio, A.; Gomes, M.G.; Faria, P. Performance parameters of ETICS: Correlating water resistance, bio-susceptibility and surface properties. Constr. Build. Mater. 2021, 272, 121956. [Google Scholar] [CrossRef]

- Xu, H.; Wang, H.; Huo, Q.; Qin, Y.; Zhou, H. Comparative study of Chinese, European and ISO external thermal insulation composite system (ETICS) standards and technical recommendations. J. Build. Eng. 2023, 68, 105687. [Google Scholar] [CrossRef]

- Parracha, J.L.; Veiga, R.; Flores-Colen, I.; Nunes, L. Toward the Sustainable and Efficient Use of External Thermal Insulation Composite Systems (ETICS): A Comprehensive Review of Anomalies, Performance Parameters, Requirements and Durability. Buildings 2023, 13, 1664. [Google Scholar] [CrossRef]

- Norvaišienė, R.; Buhagiar, V.; Burlingis, A.; Miškinis, K. Investigation of mechanical resistance of external thermal insulation composite systems (ETICS). J. Build. Eng. 2020, 32, 101682. [Google Scholar] [CrossRef]

- Xiong, H.; Yuan, K.; Wen, M.; Yu, A.; Xu, J. Influence of pore structure on the moisture transport property of external thermal insulation composite system as studied by NMR. Constr. Build. Mater. 2019, 228, 116815. [Google Scholar] [CrossRef]

- Garecki, M.; Bednarczyk, K.; Świercz, P.; Pogorzelec, P.; Kulesza, M.; Michałowski, B. Dylatacja 25-go metra. In Skutki—Przyczyny—Realne Wyzwania, Proceedings of the International Conference ETICS, Łochów, Poland, 11–13 May 2022; Polish Association for Insulation Systems: Warsaw, Poland, 2022. (In Polish) [Google Scholar]

- Norvaišienė, R.; Krause, P.; Buhagiar, V.; Burlingis, A. Resistance of ETICS with Fire Barriers to Cyclic Hygrothermal Impact. Sustainability 2021, 13, 9220. [Google Scholar] [CrossRef]

- Amaro, B.; Saraiva, D.; De Brito, J.; Flores-Colen, I. Inspection and diagnosis system of ETICS on walls. Constr. Build. Mater. 2013, 47, 1257–1267. [Google Scholar] [CrossRef]

- Asphaug, S.K.; Time, B.; Kvande, T. Moisture Accumulation in Building Façades Exposed to Accelerated Artificial Climatic Ageing—A Complementary Analysis to NT Build 495. Buildings 2021, 11, 568. [Google Scholar] [CrossRef]

- Freitas, S.; de Freitas, V.P. Cracks on ETICS along thermal insulation joints: Case study and a pathology catalogue. Struct. Surv. 2016, 34, 57–72. [Google Scholar] [CrossRef]

- European Organization for Technical Assesment. Guideline for European Technical Approval ETAG 004 External Thermal Insulation Composite Systems (ETICS); European Organization for Technical Assesment: Brussels, Belgium, 2013. [Google Scholar]

- Krause, P.; Norvaišienė, R. Temperature and humidity tests of the ETICS system with a fire barrier. Mater. Bud. 2020, 5, 16–18. [Google Scholar] [CrossRef]

- Maia, J.; Ramos, N.M.M.; Veiga, R. A new durability assessment methodology of thermal mortars applied in multilayer rendering systems. Constr. Build. Mater. 2019, 222, 654–663. [Google Scholar] [CrossRef]

- European Severe Weather Database. Available online: https://eswd.eu/ (accessed on 1 April 2024).

- Bochen, J. Weathering effects on physical–chemical properties of external plaster mortars exposed to different environments. Constr. Build. Mater. 2015, 79, 192–206. [Google Scholar] [CrossRef]

- Ślusarek, J.; Orlik-Kożdoń, B.; Bochen, J.; Muzyczuk, T. Impact of the imperfection of thermal insulation on structural changes of thin-layer façade claddings in ETICS. J. Build. Eng. 2020, 32, 101487. [Google Scholar] [CrossRef]

- Griciutė, G.; Bliūdžius, R. Study on the microstructure and water absorption rate changes of exterior thin-layer polymer renders during natural and artificial ageing. Medziagotyra 2015, 21, 149–154. [Google Scholar] [CrossRef]

- EN 13163:2012+A1:2015; Thermal Insulation Products for Buildings—Factory Made Expanded Polystyrene (EPS) Products—Specificatio. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- Sulakatko, V.; Vogdt, F. Construction Process Technical Impact Factors on Degradation of the External Thermal Insulation Composite System. Sustainability 2018, 10, 3900. [Google Scholar] [CrossRef]

- Piekarczuk, A.; Sudoł, E.; Mazurek, A. Measurement analysis of Large-Area elements of external thermal insulation Composite Systems using 3D scanning techniques. Meas. J. Int. Meas. Confed. 2024, 233. [Google Scholar] [CrossRef]

- ISO 7783:2018; Paints and Varnishes Determination of Water-Vapour Transmission Properties. Cup Method. International Organization for Standardization (ISO): Switzerland, Geneva, 2018.

- ISO 7892:1988; Vertical Building Elements. Impact Resistance Tests. Impact Bodies and General Test Procedures. International Organization for Standardization (ISO): Geneva, Switzerland, 1988.

- Bochen, J. Study on the microstructure of thin-layer facade plasters of thermal insulating system during artificial weathering. Constr. Build. Mater. 2009, 23, 2559–2566. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Özgüven, S.; Çalış, M. Effect of plaster thickness on performance of external thermal insulation cladding systems (ETICS) in buildings. Constr. Build. Mater. 2016, 122, 496–504. [Google Scholar] [CrossRef]

- Malanho, S.; Veiga, M. do R. Bond strength between layers of ETICS—Influence of the characteristics of mortars and insulation materials. J. Build. Eng. 2020, 28, 101021. [Google Scholar] [CrossRef]

- Yuan, K.; Xiong, H.; Wen, M.; Xu, J. Visualization of localized deformation of external thermal insulation composite systems during aging. Appl. Therm. Eng. 2022, 206, 118108. [Google Scholar] [CrossRef]

- Sudoł, E.; Dębski, D.; Zamorowska, R.; Francke, B. Impact resistance of external thermal insulation systems. MATEC Web Conf. 2018, 163, 08004. [Google Scholar] [CrossRef]

original condition,

original condition,  after weathering; MW-based system:

after weathering; MW-based system:  original condition,

original condition,  after weathering.

after weathering.

original condition,

original condition,  after weathering; MW-based system:

after weathering; MW-based system:  original condition,

original condition,  after weathering.

after weathering.

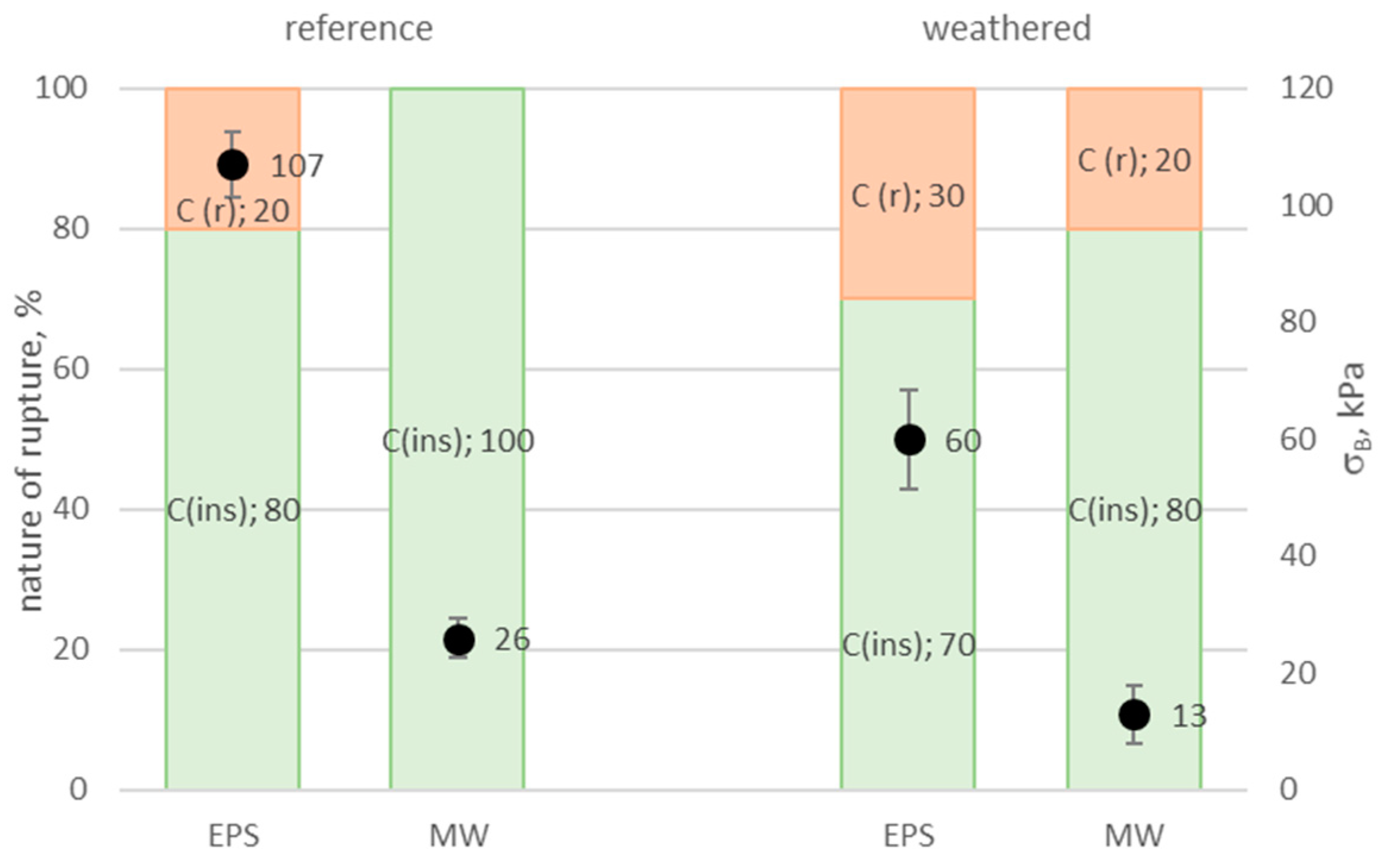

insulation product (ins),

insulation product (ins),  render (r); the error bars represent the standard deviation of the bond strength.

render (r); the error bars represent the standard deviation of the bond strength.

insulation product (ins),

insulation product (ins),  render (r); the error bars represent the standard deviation of the bond strength.

render (r); the error bars represent the standard deviation of the bond strength.

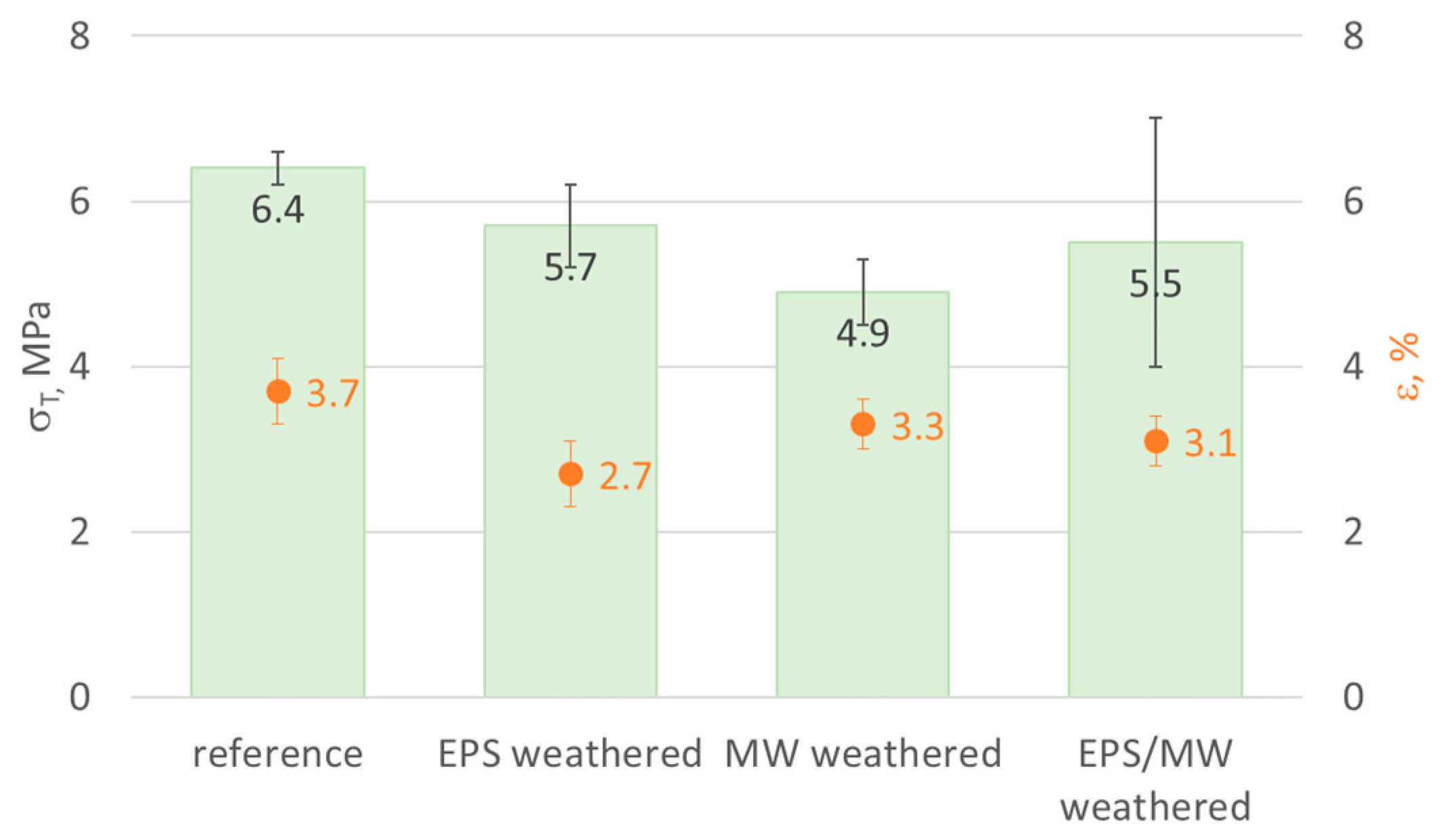

tensile strength σT,

tensile strength σT,  elongation at break ε; identified for the EPS- and MW-based rendering system and in the EPS/MW contact area; error bars represent standard deviation.

elongation at break ε; identified for the EPS- and MW-based rendering system and in the EPS/MW contact area; error bars represent standard deviation.

tensile strength σT,

tensile strength σT,  elongation at break ε; identified for the EPS- and MW-based rendering system and in the EPS/MW contact area; error bars represent standard deviation.

elongation at break ε; identified for the EPS- and MW-based rendering system and in the EPS/MW contact area; error bars represent standard deviation.

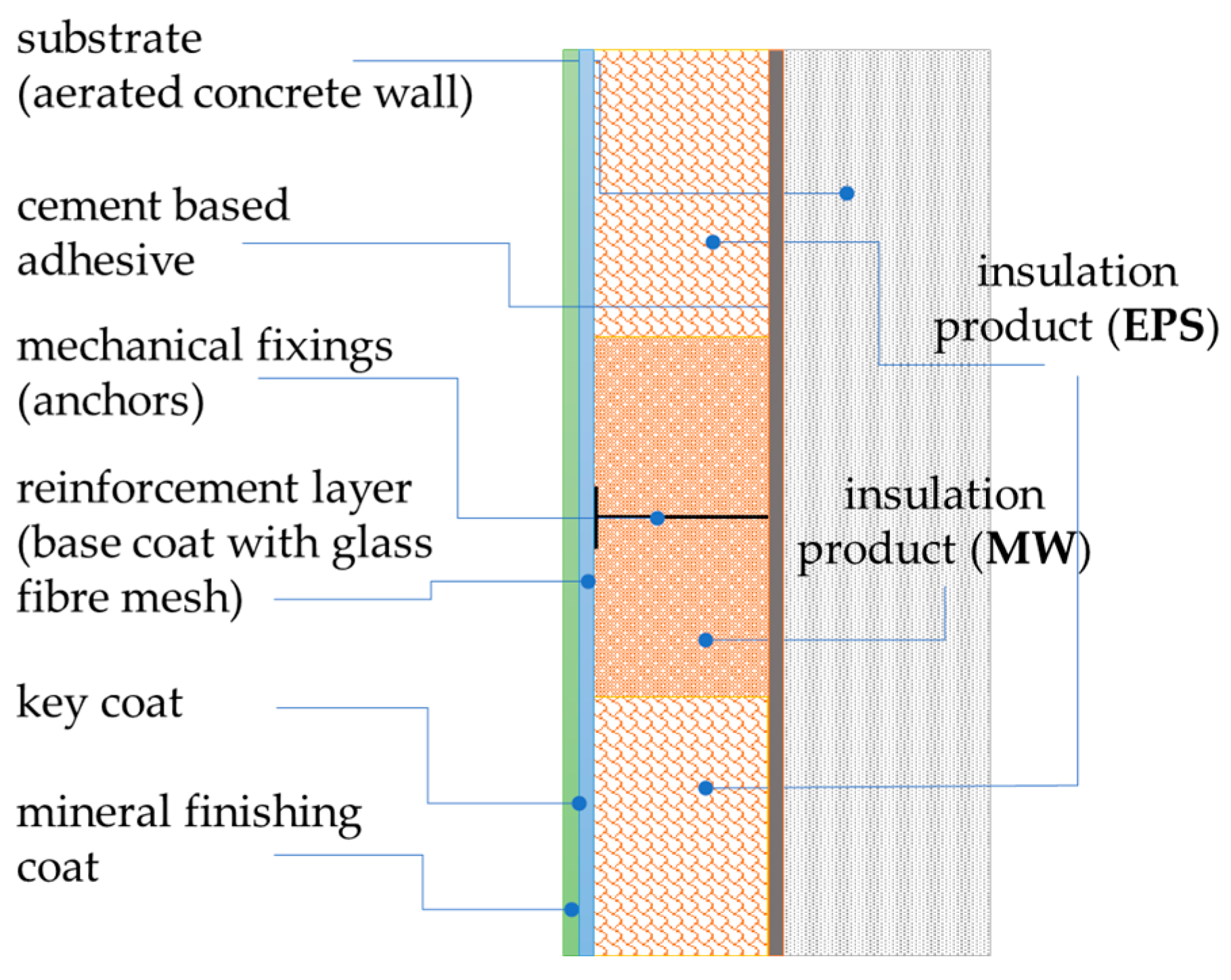

| Thermal Insulation System Layer | Material Characteristics |

|---|---|

| Adhesive for fixing thermal insulation to the substrate | Dry mix of cement-based binder, aggregates and modifiers; grain size distribution <0.8 mm, bulk density 1520÷1860 kg/m3, less than 98.4% ash content at 450 °C, mixed with water |

| Insulation product: | |

| base (systemic solution) | Expanded polystyrene (EPS), according to EN 13163 [38], 150 mm thick, λD = 0.038 W/mK, EPS-EN 13163-T1-L2-W2-S2-P5-BS115-CS(10)70-TR100-DS(N)2-DS(70,-)2-R100 code, perpendicular tensile strength ≥ 110 kPa and tensile strength ≥ 39 kPa determined in tests |

| fire barrier | Mineral rock wool (MW) according to EN 13162 [12], 150 mm thick, λD = 0.035 W/mK, MW-EN 13162-T5-DS(70,90)-CS(10)20-TR20-PL(5)200-WS-WL(P)-MU1 code, perpendicular tensile strength ≥ 22 kPa and tensile strength ≥ 9 kPa determined in tests |

| Reinforcement layer: | |

| base coat | The same product as that used for fixing thermal insulation to the substrate |

| reinforcement | 1000 mm-wide fibreglass mesh, mesh size 4.5 mm × 5.0 mm; surface mass 150 g/m2, characterised by residual resistance after alkali ageing ≥ 20 N/mm and relative residual resistance after alkali ageing ≥ 50% |

| Key coat | Universal primer for thin-coat mineral rendering (liquid), volumetric density 1368 ÷ 1672 kg/m3 and dry matter content 55.6 ÷ 64.4% |

| Finishing coat | Dry mix based on the microfibre-reinforced composition of mineral binder (high-alkaline potassium water glass), inorganic binders, coarse marble aggregates, silicate flour, modifiers and preserving agents, 1.5 grain size distribution bulk density 1320 ÷ 1800 kg/m3, less than 99.8% ash content at 450 °C, mixed with water. |

| Defects | Exposure Stage (1) | |||||

|---|---|---|---|---|---|---|

| Sequence I | Sequence II | |||||

| HW | HC | WFT | HW | HC | WFT | |

| not found | not found | not found | not found | not found | not found |

| not found | not found | not found | not found | not found | found |

| not found | not found | not found | not found | not found | not found |

| not found | not found | found (2) | found (3) | found (3) | found (3) |

| not found | not found | not found | found (4) | found (4) | found (4) |

| Insulation Product | Impact Energy | Defects/Diameter of Damage, mm/ Wide of Cracks, mm | Impact Resistance Category |

|---|---|---|---|

| Reference samples | |||

| EPS | 3 J (1) | not penetrated (3)/25 ÷ 33/<0.2 | III |

| MW | 3 J | no deterioration (4) | II |

| 10 J (2) | not penetrated/28 ÷ 36/<0.2 | ||

| Weathered samples | |||

| EPS | 3 J | not penetrated/25 ÷ 33/<0.2 | III |

| MW | 3 J | not penetrated/24 ÷ 34/<0.2 | III |

| EPS/MW | 3 J | not penetrated/25 ÷ 34/<0.2 | III |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudoł, E.; Piekarczuk, A.; Kozikowska, E.; Mazurek, A. Resistance of External Thermal Insulation Systems with Fire Barriers to Long-Lasting Weathering. Materials 2024, 17, 3113. https://doi.org/10.3390/ma17133113

Sudoł E, Piekarczuk A, Kozikowska E, Mazurek A. Resistance of External Thermal Insulation Systems with Fire Barriers to Long-Lasting Weathering. Materials. 2024; 17(13):3113. https://doi.org/10.3390/ma17133113

Chicago/Turabian StyleSudoł, Ewa, Artur Piekarczuk, Ewelina Kozikowska, and Aleksandra Mazurek. 2024. "Resistance of External Thermal Insulation Systems with Fire Barriers to Long-Lasting Weathering" Materials 17, no. 13: 3113. https://doi.org/10.3390/ma17133113

APA StyleSudoł, E., Piekarczuk, A., Kozikowska, E., & Mazurek, A. (2024). Resistance of External Thermal Insulation Systems with Fire Barriers to Long-Lasting Weathering. Materials, 17(13), 3113. https://doi.org/10.3390/ma17133113