Study on the Shear Strength of Loess Solidified by Guar Gum and Basalt Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

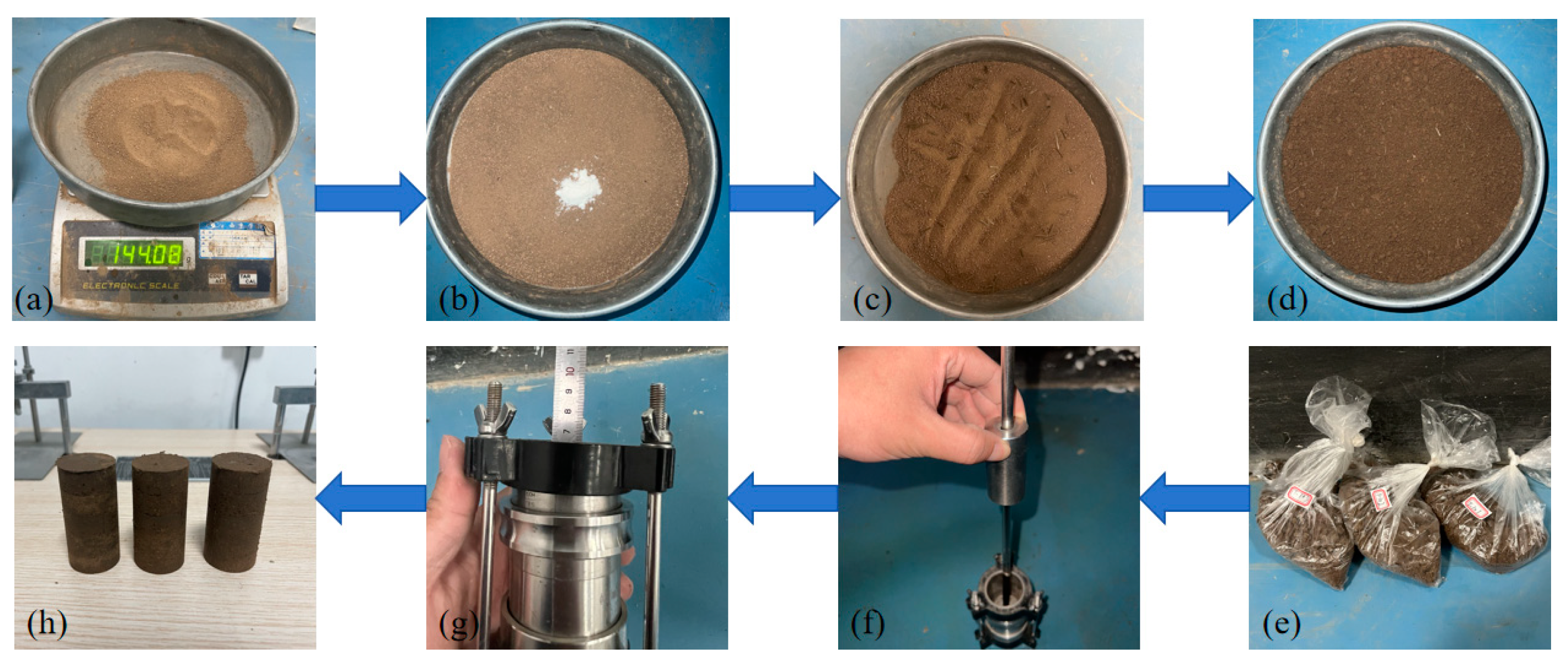

2.2. Sample Preparation

2.3. Test Method

3. Results and Analysis

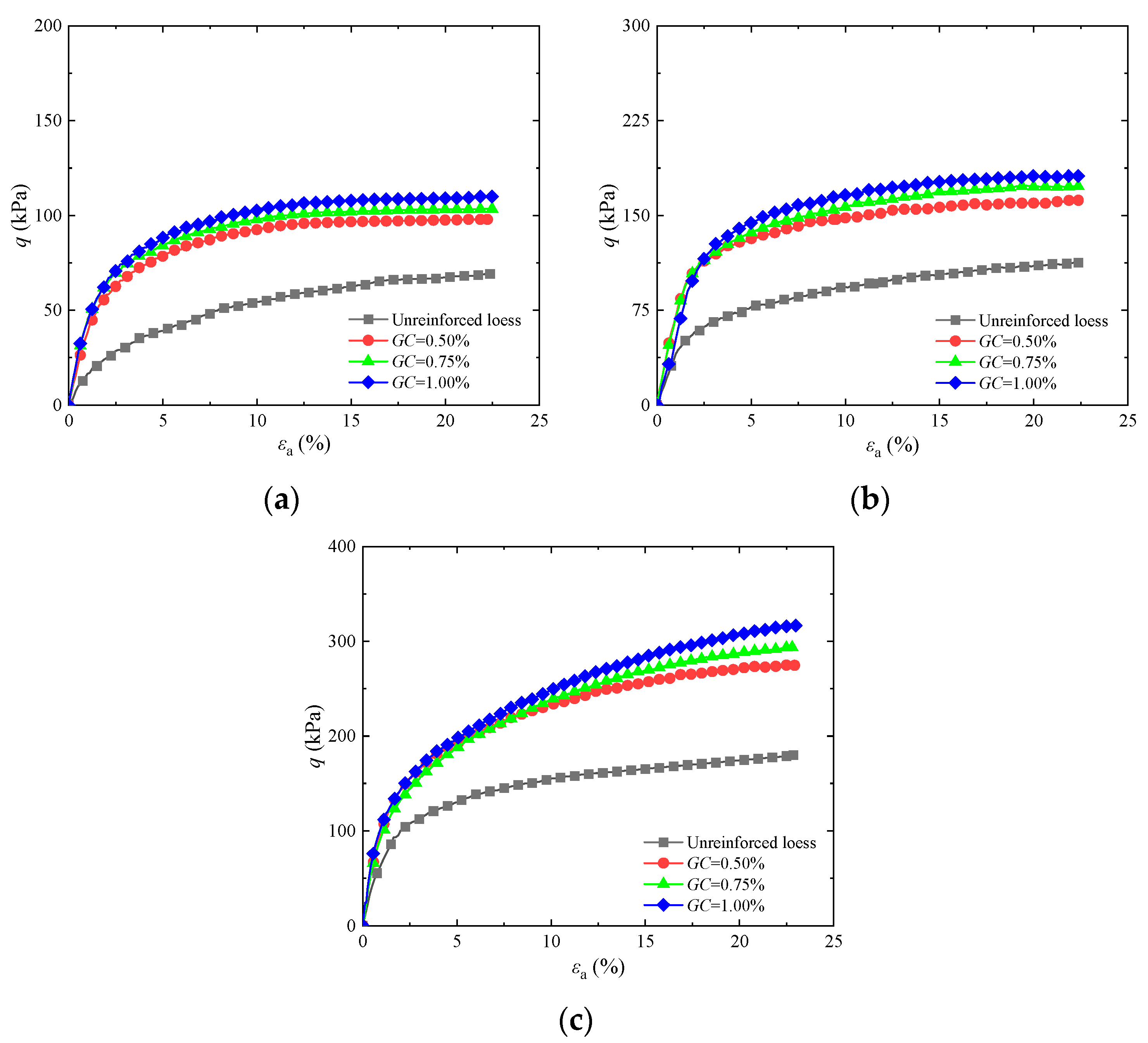

3.1. Analysis of Shear Strength Characteristics of Guar Gum-Solidified Loess

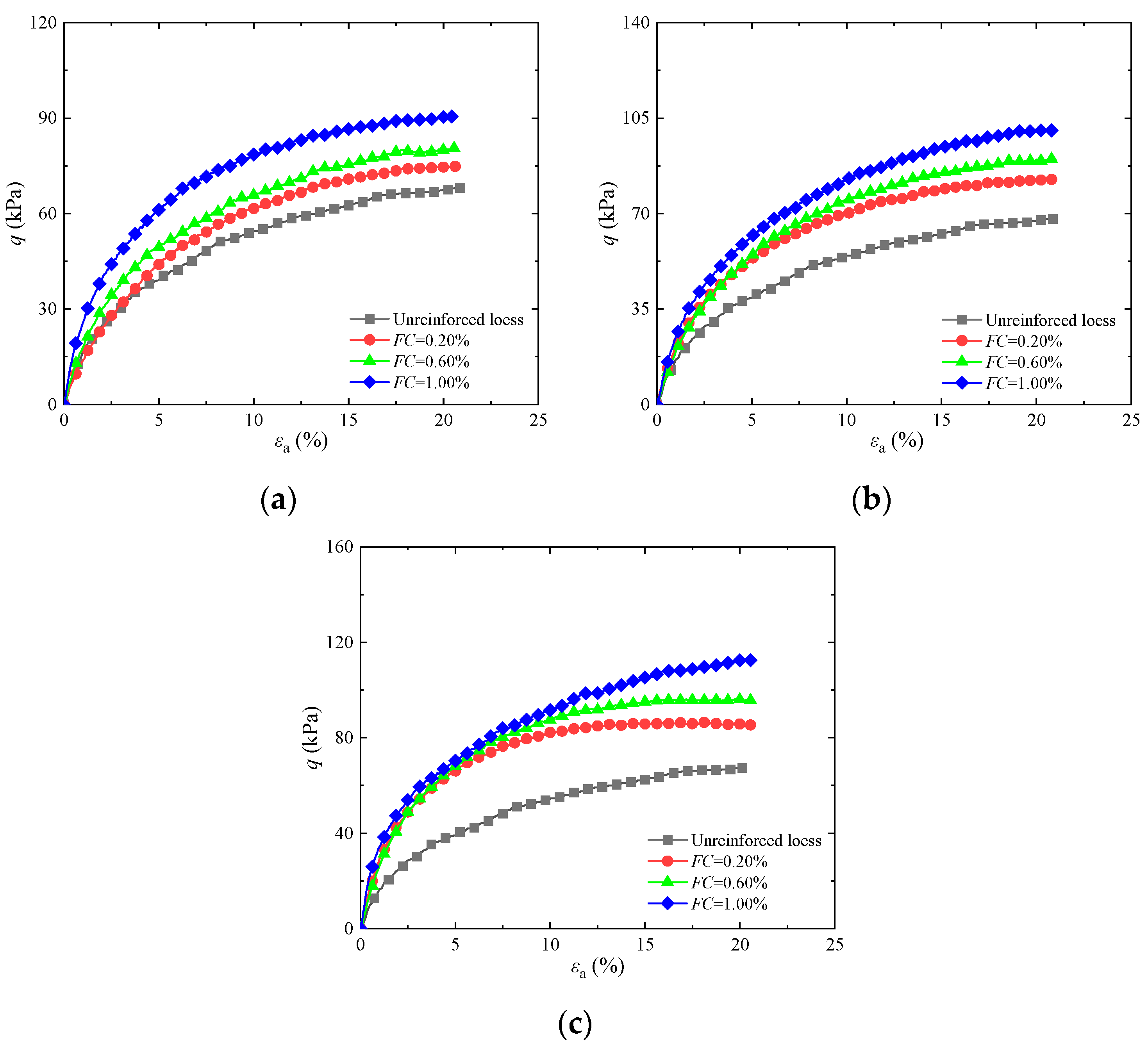

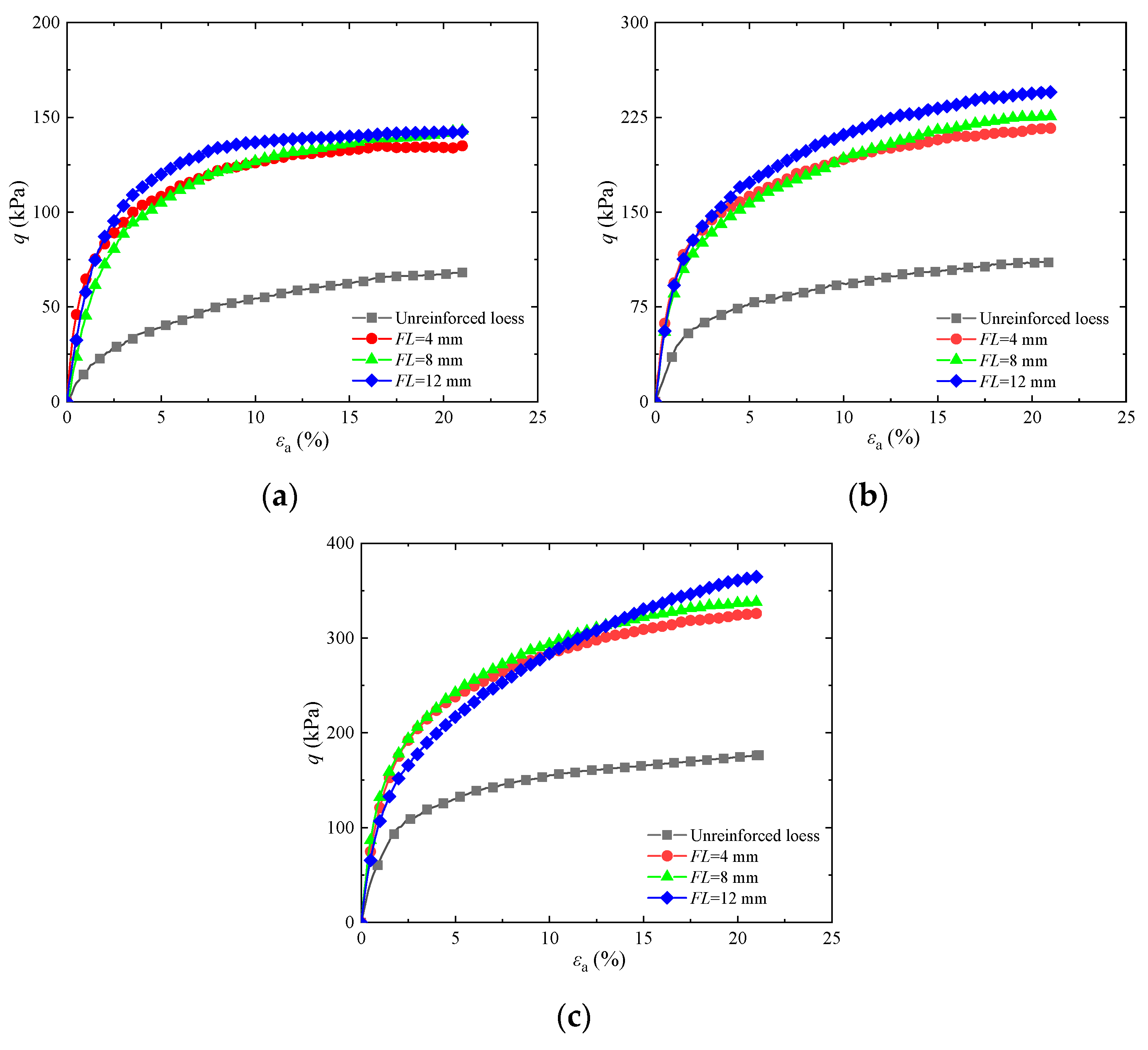

3.2. Analysis of Shear Strength Characteristics of Basalt Fiber-Solidified Loess

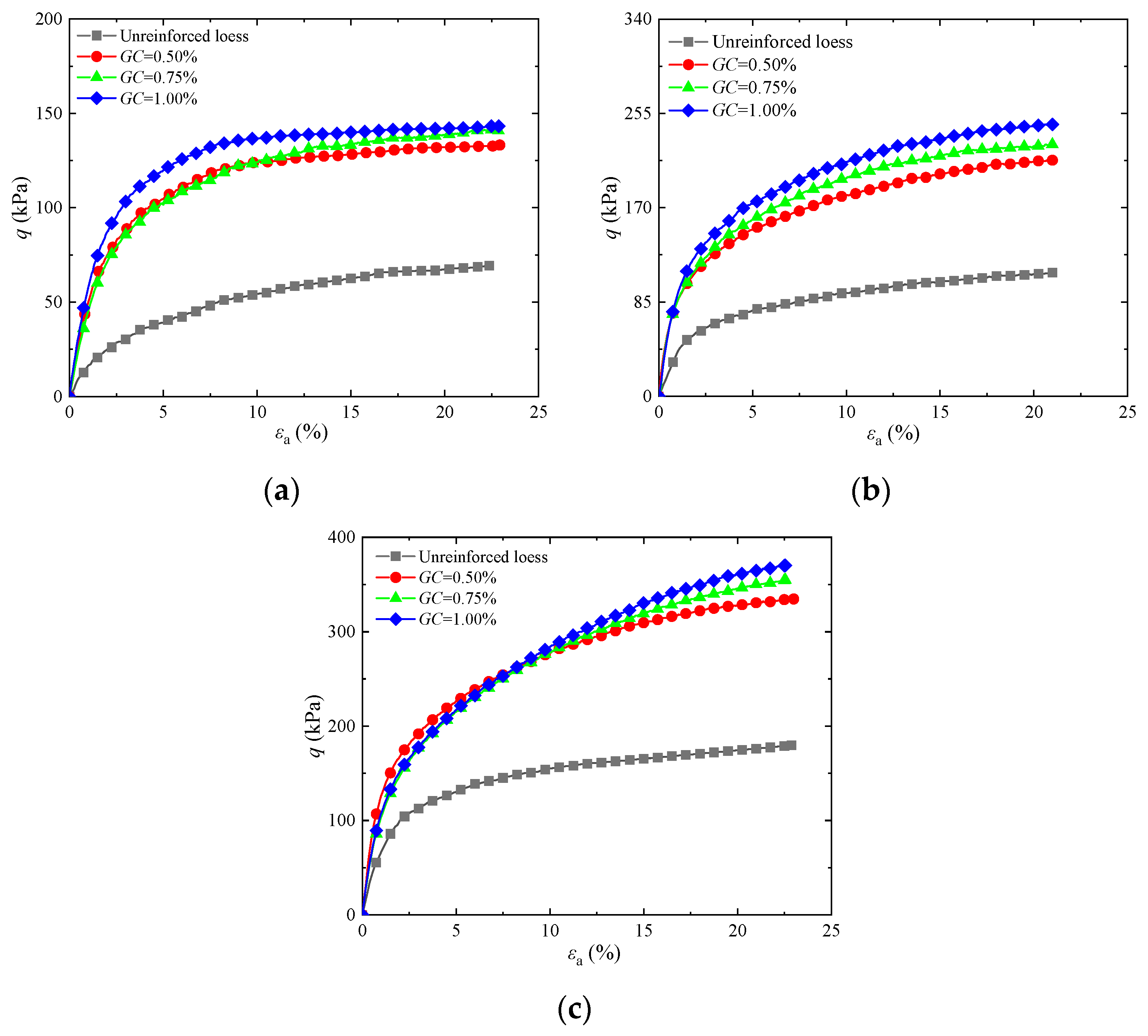

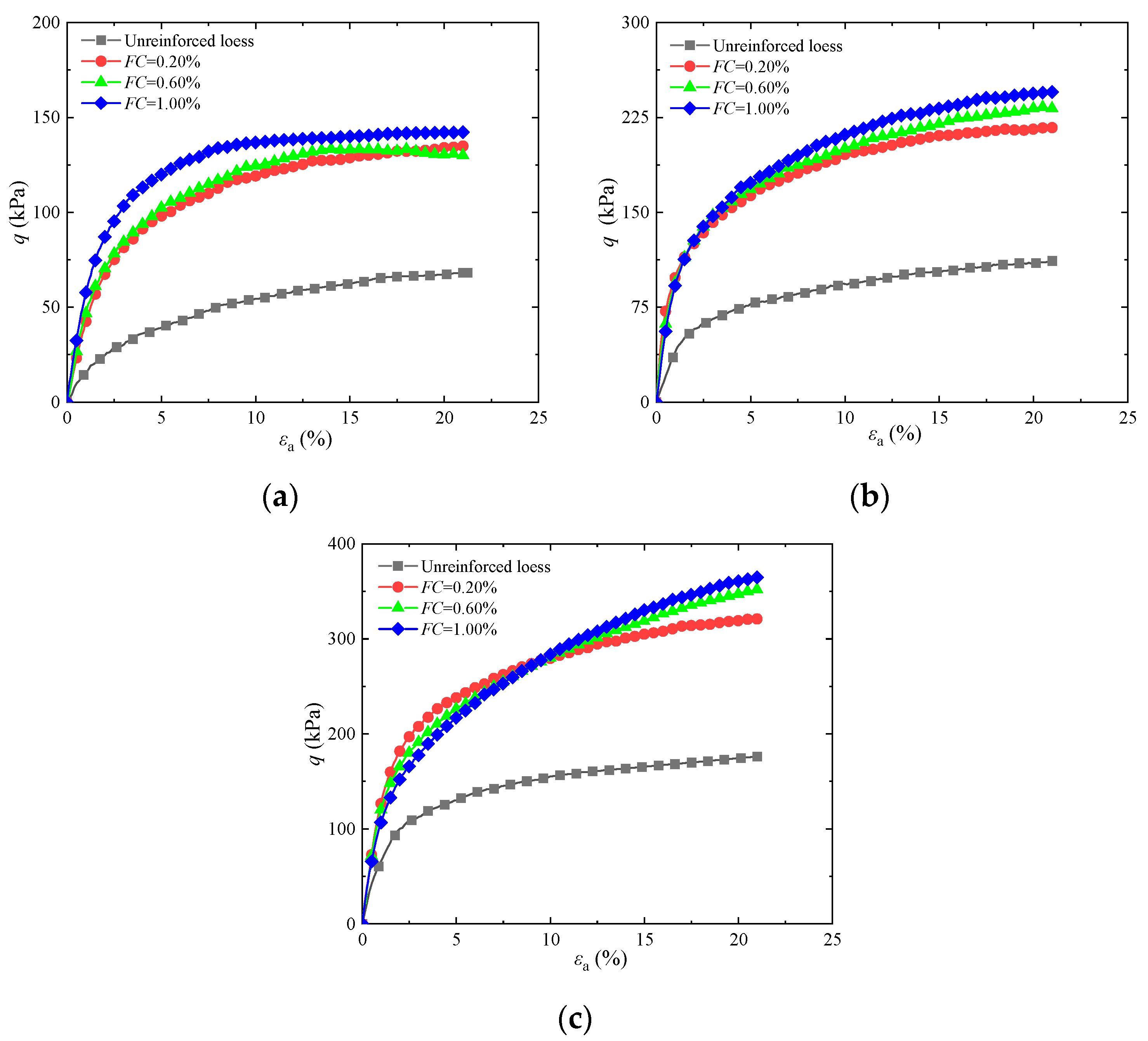

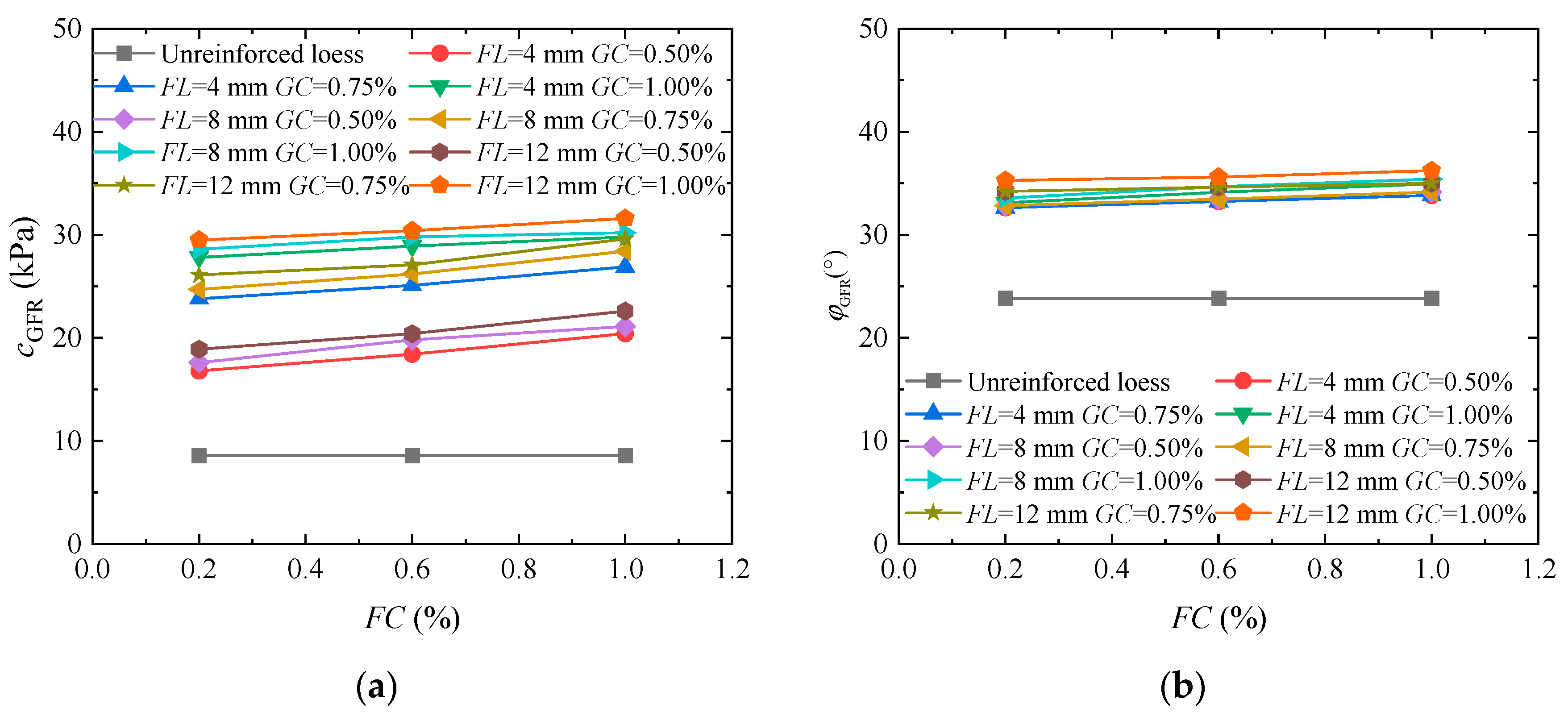

3.3. Analysis of Shear Strength Characteristics of the Guar Gum and Basalt Fiber-Solidified Loess

3.4. Analysis of the Mechanism of Action for Loess Solidified by Guar Gum and Basalt Fiber

4. Modeling of Shear Strength Model of Guar Gum and Basalt Fiber-Solidified Loess

4.1. Model Establishment

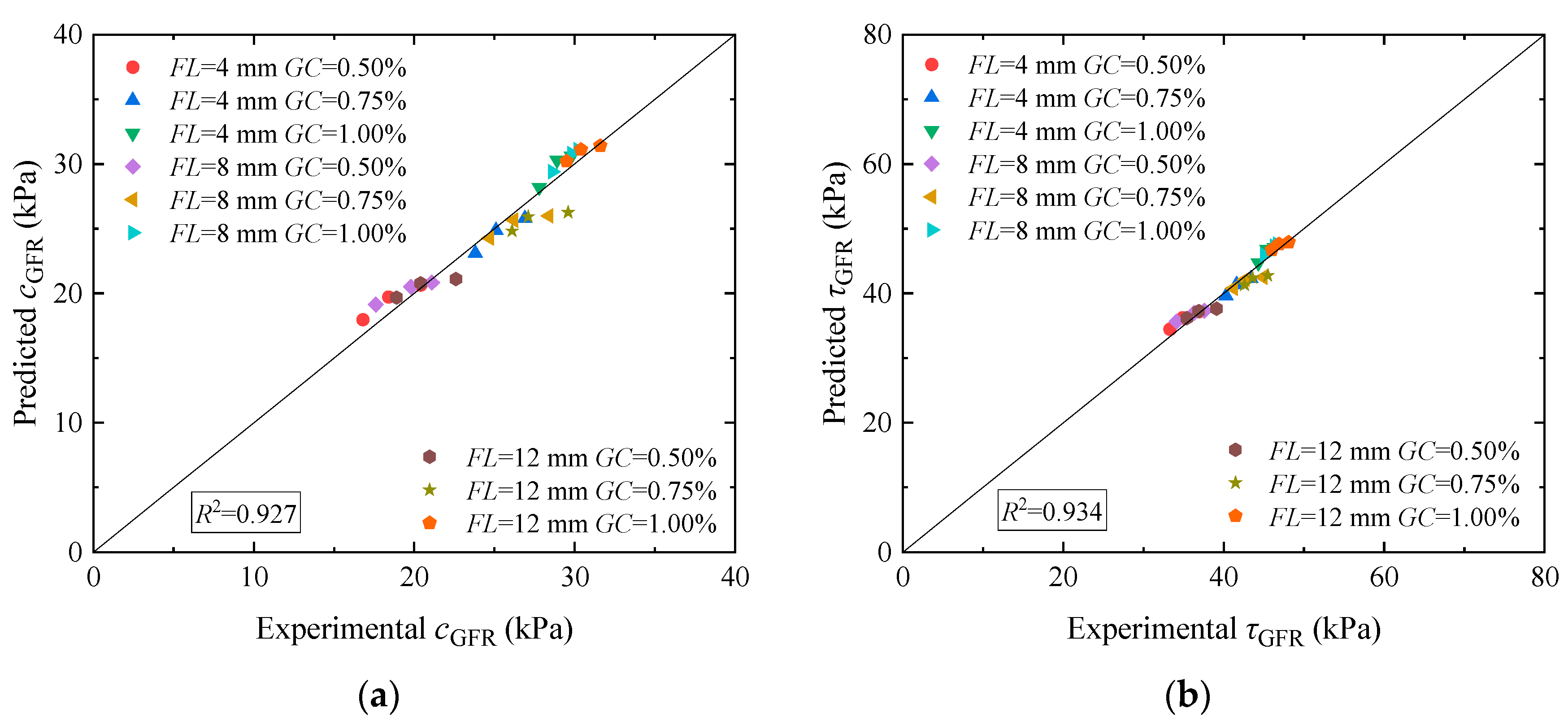

4.2. Model Parameter Fitting

4.3. Model Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, L.; Wang, X.; Xue, C.; Wang, D.; Lian, B. Laboratory experiments and numerical simulation study of composite-material-modified loess improving high-speed railway subgrade. Polymers 2022, 14, 3215. [Google Scholar] [CrossRef]

- Li, Y.; Shi, W.; Aydin, A.; Beroya-Eitner, M.A.; Gao, G. Loess genesis and worldwide distribution. Earth Sci. Rev. 2020, 201, 102947. [Google Scholar] [CrossRef]

- Tabarsa, A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Laboratory investigation and field evaluation of loess improvement using nanoclay—A sustainable material for construction. Constr. Build. Mater. 2018, 158, 454–463. [Google Scholar] [CrossRef]

- Zhao, M.; Guo, W.; Chen, L.Y.; Wang, S. Experiment on the frost resistance of Modified Phospho Gypsum: A case used to Improve Baozhong Railway Subgrade loess. J. Mt. Sci. 2019, 16, 2920–2930. [Google Scholar] [CrossRef]

- Smalley, I.J.; Jefferson, I.F.; Dijkstra, T.A.; Derbyshire, E. Some major events in the development of the scientific study of loess. Earth Sci. Rev. 2001, 54, 5–18. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, Y.; Zeng, R.; Yang, Z.; Chen, X.; Zhao, F.; Meng, X. Detection of land subsidence associated with land creation and rapid urbanization in the Chinese loess plateau using time series insar: A case study of Lanzhou new district. Remote Sens. 2018, 10, 270. [Google Scholar] [CrossRef]

- Lv, Y.; Deng, L.; Fan, W. Loess collapsibility characteristics of railway engineering sites using large-scale trial immersion pit experiments. Bull. Eng. Geol. Environ. 2021, 80, 3271–3291. [Google Scholar] [CrossRef]

- Khattak, M.J.; Alrashidi, M. Durability and mechanistic characteristics of fiber reinforced soil–cement mixtures. Int. J. Pavement Eng. Int. 2006, 7, 53–62. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Shear strength and mesoscopic characteristics of basalt fiber–reinforced loess after dry–wet cycles. J. Mater. Civ. Eng. 2022, 34, 04022083. [Google Scholar] [CrossRef]

- Bao, H.; Liu, C.; Lan, H.; Yan, C.; Li, L.; Zheng, H.; Dong, Z. Time-dependency deterioration of polypropylene fiber reinforced soil and guar gum mixed soil in loess cut-slope protecting. Eng. Geol. 2022, 311, 106895. [Google Scholar] [CrossRef]

- Jia, Z.; Yan, C.; Li, B.; Shi, Y.; Lan, H.; Xu, J.; Bao, H. Experimental study on erosion resistance and ecological slope protection of guar gum-treated fiber-reinforcement loess. Chin. J. Geotech. Eng. 2022, 44, 1881–1889. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, J.; Wang, X.; Ding, Y.; Chen, X.; Liu, T. Experimental study on mechanical properties of basalt fiber-reinforced silty clay. J. Cent. South Univ. 2022, 29, 1945–1956. [Google Scholar] [CrossRef]

- Wang, W.; Cao, G.; Li, Y.; Zhou, Y.; Lu, T.; Zheng, B.; Geng, W. Effects of freeze–thaw cycles on strength and wave velocity of lime-stabilized basalt fiber-reinforced loess. Polymers 2022, 14, 1465. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability 2023, 15, 4411. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Study on strength behavior of basalt fiber-reinforced loess by digital image technology (DIT) and scanning electron microscope (SEM). Arab. J. Sci. Eng. 2021, 46, 11319–11338. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Samakoosh, M.A.; Kutanaei, S.S. Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr. Build. Mater. 2019, 211, 1094–1104. [Google Scholar] [CrossRef]

- Yang, B.; Weng, X.; Liu, J.; Kou, Y.; Jiang, L.; Li, H.; Yan, X. Strength characteristics of modified polypropylene fiber and cement-reinforced loess. J. Cent. South Univ. 2017, 24, 560–568. [Google Scholar] [CrossRef]

- Ple, O.; Lê, T.N.H. Effect of polypropylene fiber-reinforcement on the mechanical behavior of silty clay. Geotext. Geomembr. 2012, 32, 111–116. [Google Scholar] [CrossRef]

- Tang, C.; Li, J.; Wang, D.; Shi, B. Investigation on the interfacial mechanical behavior of wave-shaped fiber reinforced soil by pullout test. Geotext. Geomembr. 2016, 44, 872–883. [Google Scholar] [CrossRef]

- Lian, B.; Peng, J.; Zhan, H.; Cui, X. Effect of randomly distributed fibre on triaxial shear behavior of loess. Bull. Eng. Geol. Environ. 2020, 79, 1555–1563. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, B. Strength and deformation behavior of fiber-reinforced cohesive soil under varying moisture and compaction states. Geotech. Geol. Eng. 2017, 35, 1767–1781. [Google Scholar] [CrossRef]

- Wang, X.; Liu, K.; Lian, B. Experimental study on ring shear properties of fiber-reinforced loess. Bull. Eng. Geol. Environ. 2021, 80, 5021–5029. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Influence of dry-wet cycles on the strength behavior of basalt-fiber reinforced loess. Eng. Geol. 2022, 302, 106645. [Google Scholar] [CrossRef]

- Xue, Z.; Cheng, W.; Wang, L.; Song, G. Improvement of the shearing behaviour of loess using recycled straw fiber reinforcement. KSCE J. Civ. Eng. 2021, 25, 3319–3335. [Google Scholar] [CrossRef]

- Chen, C.; Li, G.; Liu, J.; Xi, Y.; Nan, J. Shear strength characteristics of basalt fiber-reinforced loess. Sci. Rep. 2023, 13, 15923. [Google Scholar] [CrossRef] [PubMed]

- G/BT 50123-2019; Standard for Geotechnical Testing Method. Construction Ministry of PRC: Beijing, China, 2019.

- Jia, Z.; Yan, C.; Li, B.; Bao, H.; Lan, H.; Liang, Z.; Ren, J. Performance test and effect evaluation of guar gum-stabilized loess as a sustainable slope protection material. J. Clean. Prod. 2023, 408, 137085. [Google Scholar] [CrossRef]

- Ma, Y.; Bao, H.; Yan, C.; Lan, H.; Peng, J.; Zheng, H.; Liu, C. Mechanical properties and microstructure evolution of two ecological slope-protection materials under dry-wet cycles. J. Clean. Prod. 2023, 416, 137833. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical behaviour of guar gum-treated soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, T.; Meng, Q.; Wang, X.; He, J. Experimental evaluation of the shear behavior of fiber-reinforced calcareous sands. Int. J. Geomech. 2018, 18, 04018175. [Google Scholar] [CrossRef]

| Water Content (%) | Dry Density (g·cm−3) | Specific Gravity Gs | Initial Porosity Ratio | Plasticity Limit (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|---|---|---|

| 14.50 | 1.24 | 2.67 | 0.73 | 18.60 | 33.80 | 15.20 |

| Density/ (g·cm−3) | Diameter (μm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Acid and Alkali Resistance |

|---|---|---|---|---|---|

| 2.65 | 10 | 3500~4500 | 100 | 2.20 | Strong |

| Confining Pressure σ3 (kPa) | Water Content ω (%) | Fiber Length FL (mm) | Fiber Content FC (%) | Guar Gum Dosage GC (%) |

|---|---|---|---|---|

| 25 | 20 | 0 | 0 | 0, 0.50, 0.75, 1.00 |

| 4 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 8 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 12 | 0.20,0.60,1.00 | 0, 0.50, 0.75, 1.00 | ||

| 50 | 20 | 0 | 0 | 0, 0.50, 0.75, 1.00 |

| 4 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 8 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 12 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 100 | 20 | 0 | 0 | 0, 0.50, 0.75, 1.00 |

| 4 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 8 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 | ||

| 12 | 0.20, 0.60, 1.00 | 0, 0.50, 0.75, 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.; Sun, M.; Li, H.; Li, G.; Wang, P.; Li, L. Study on the Shear Strength of Loess Solidified by Guar Gum and Basalt Fiber. Materials 2024, 17, 3116. https://doi.org/10.3390/ma17133116

Xi Y, Sun M, Li H, Li G, Wang P, Li L. Study on the Shear Strength of Loess Solidified by Guar Gum and Basalt Fiber. Materials. 2024; 17(13):3116. https://doi.org/10.3390/ma17133116

Chicago/Turabian StyleXi, Yu, Mingming Sun, Huanhuan Li, Gang Li, Pengzhou Wang, and Li Li. 2024. "Study on the Shear Strength of Loess Solidified by Guar Gum and Basalt Fiber" Materials 17, no. 13: 3116. https://doi.org/10.3390/ma17133116

APA StyleXi, Y., Sun, M., Li, H., Li, G., Wang, P., & Li, L. (2024). Study on the Shear Strength of Loess Solidified by Guar Gum and Basalt Fiber. Materials, 17(13), 3116. https://doi.org/10.3390/ma17133116