Adapted Design Process for Continuous Fiber-Reinforced Additive Manufacturing—A Methodological Framework

Abstract

:1. Introduction

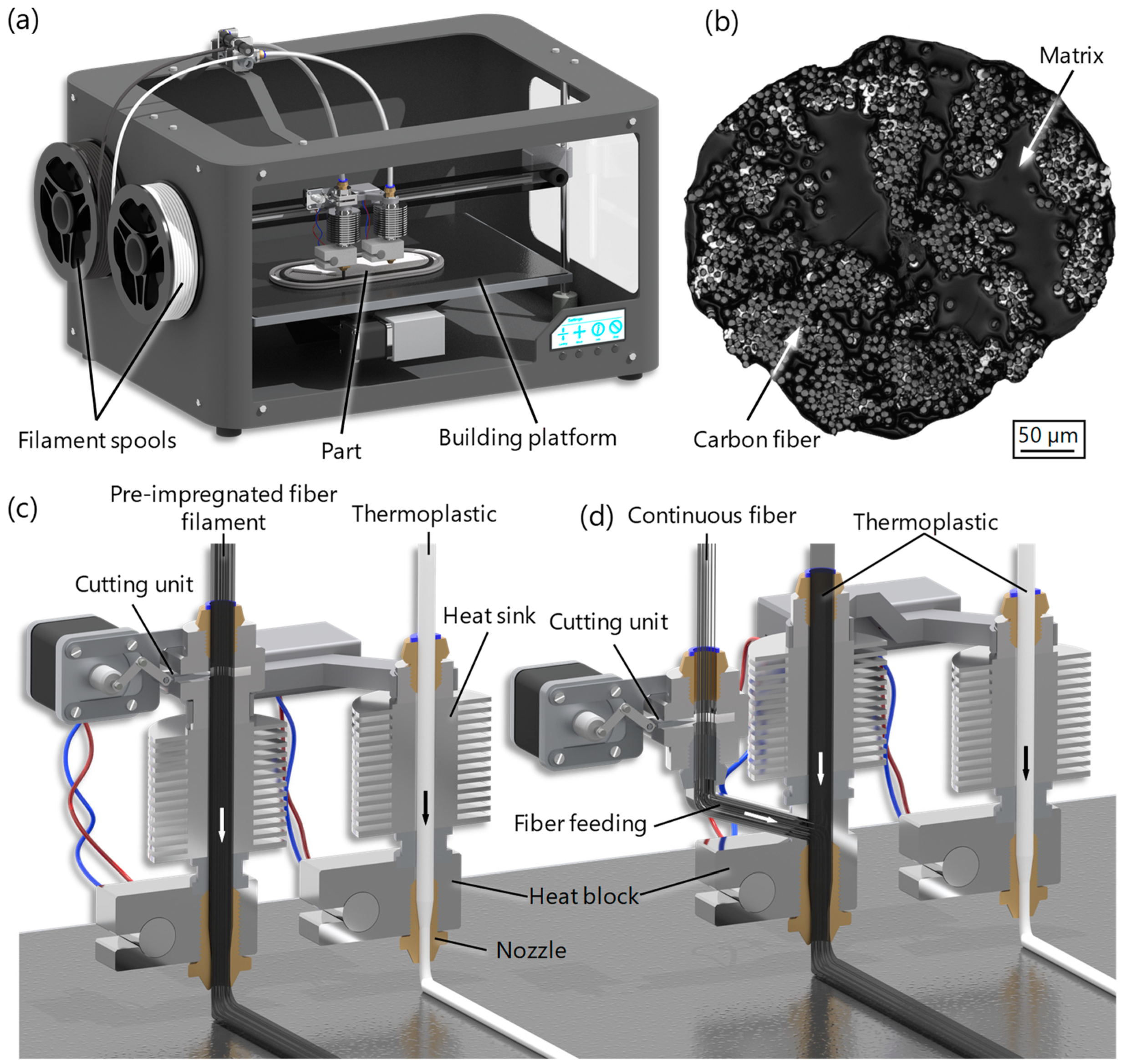

2. Continuous Fiber-Reinforced MEX

3. Design for Additive Manufacturing

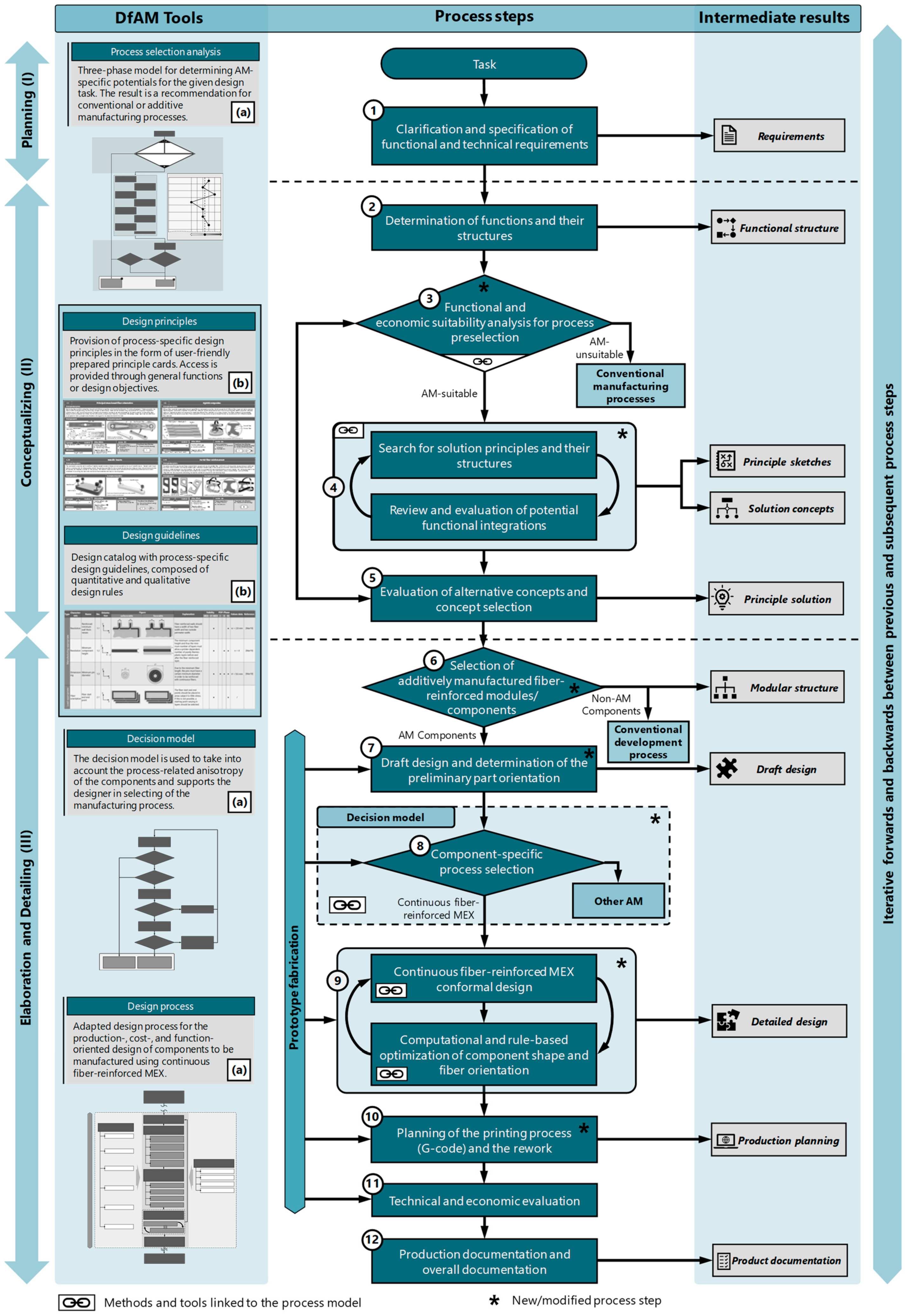

4. Research Gap and Objective

- The design of components and systems to be manufactured using CFR-MEX should be embedded in the development process and methodically supported.

- The focus of conventional process models and also AM-adapted methods is often on the mechanical properties or the realization of a specific AM potential; this leaves little room for the integration of additional functions and the exploitation of all process-specific potentials.

- To date, no process-specific decision support tools have been developed for process selection and evaluation to ensure process suitability for the product being developed.

- Due to the significant effects of fiber orientation, production planning has a considerable influence on the resulting properties. However, in existing development models, the filling pattern generation of the components to be additively manufactured is not part of the design process but is attributed to the manufacturing experts.

5. Design Framework

5.1. Requirements for the Process Model

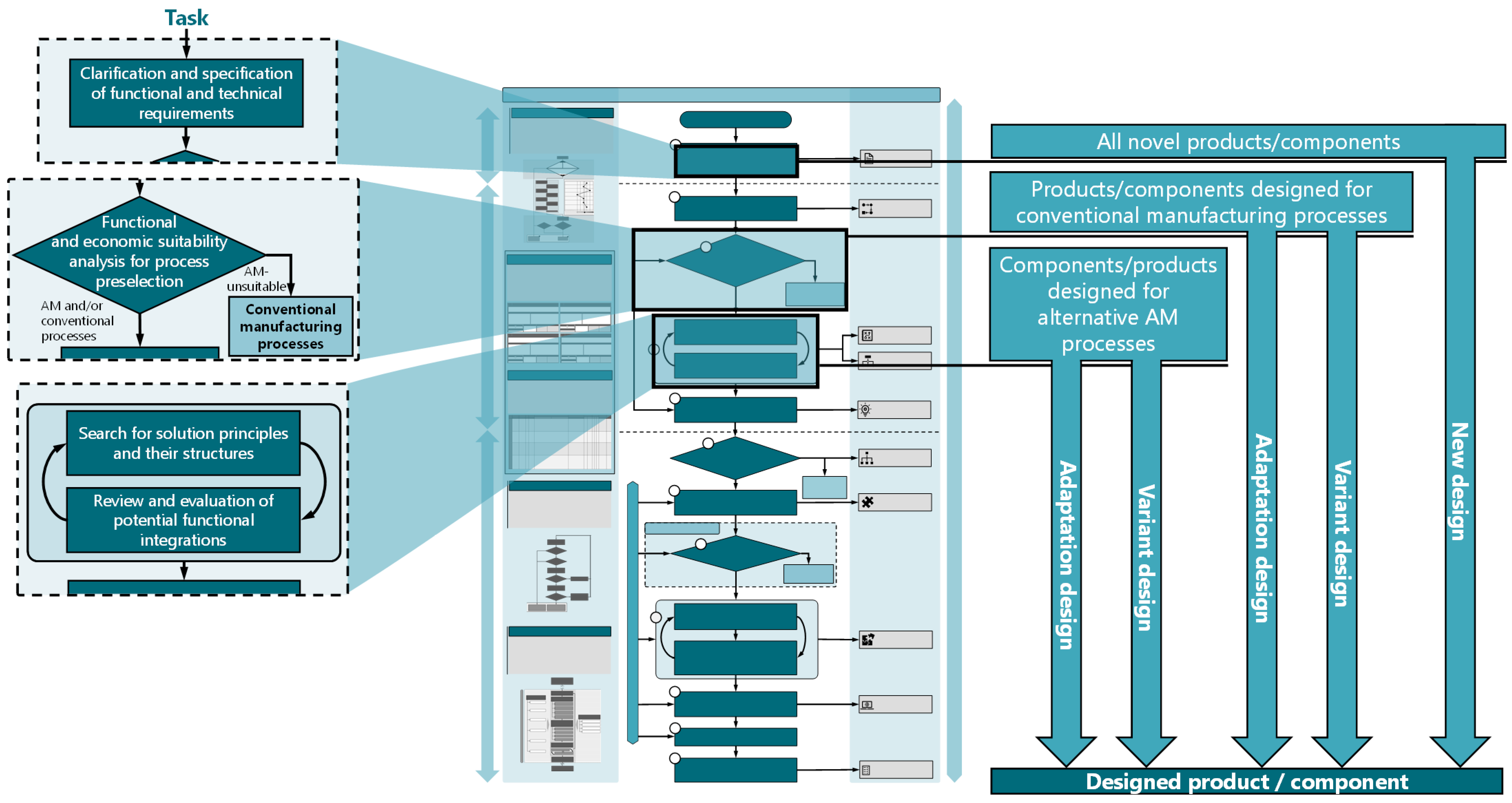

5.2. Adapted Process Model

5.2.1. Planning Phase

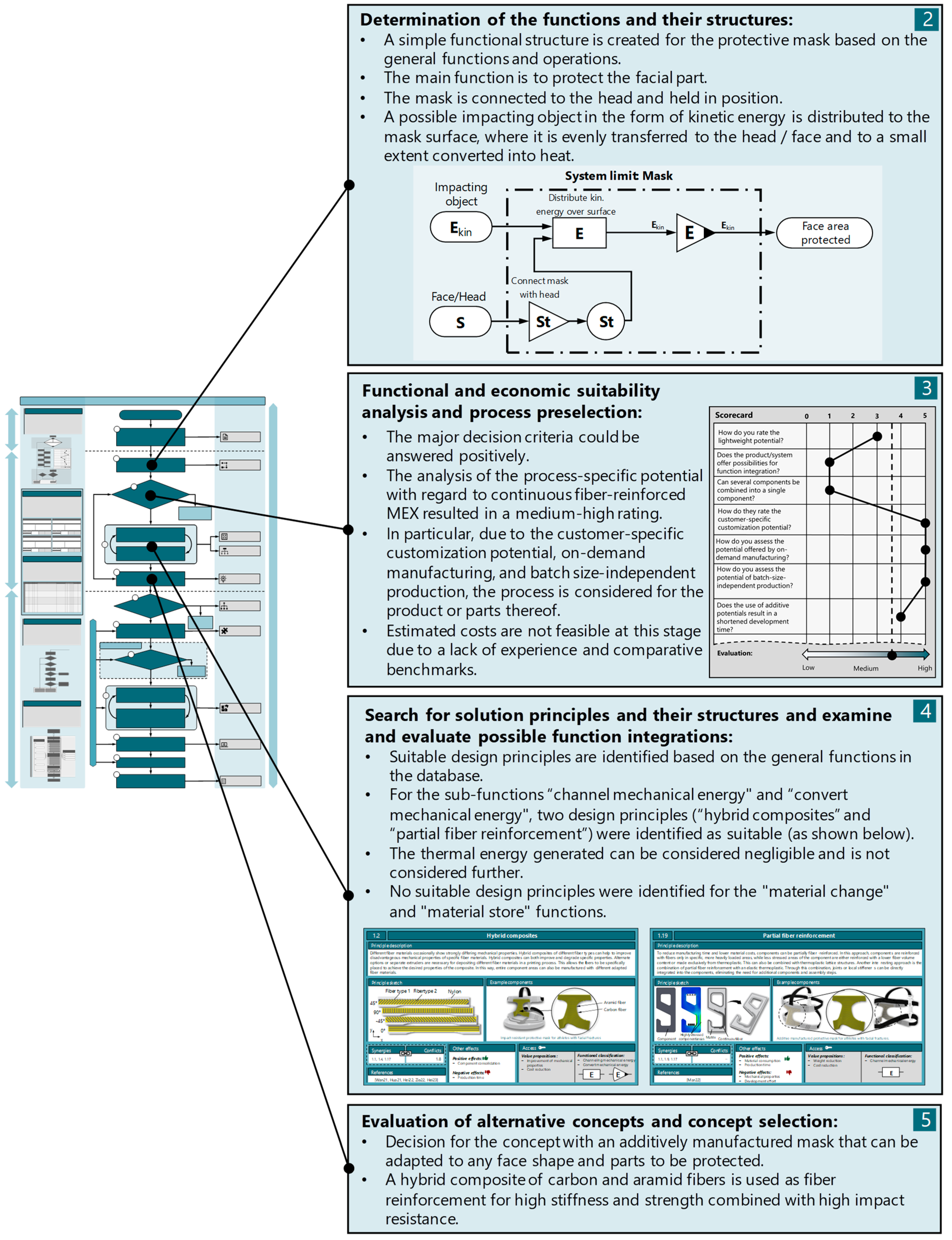

5.2.2. Conceptualization Phase

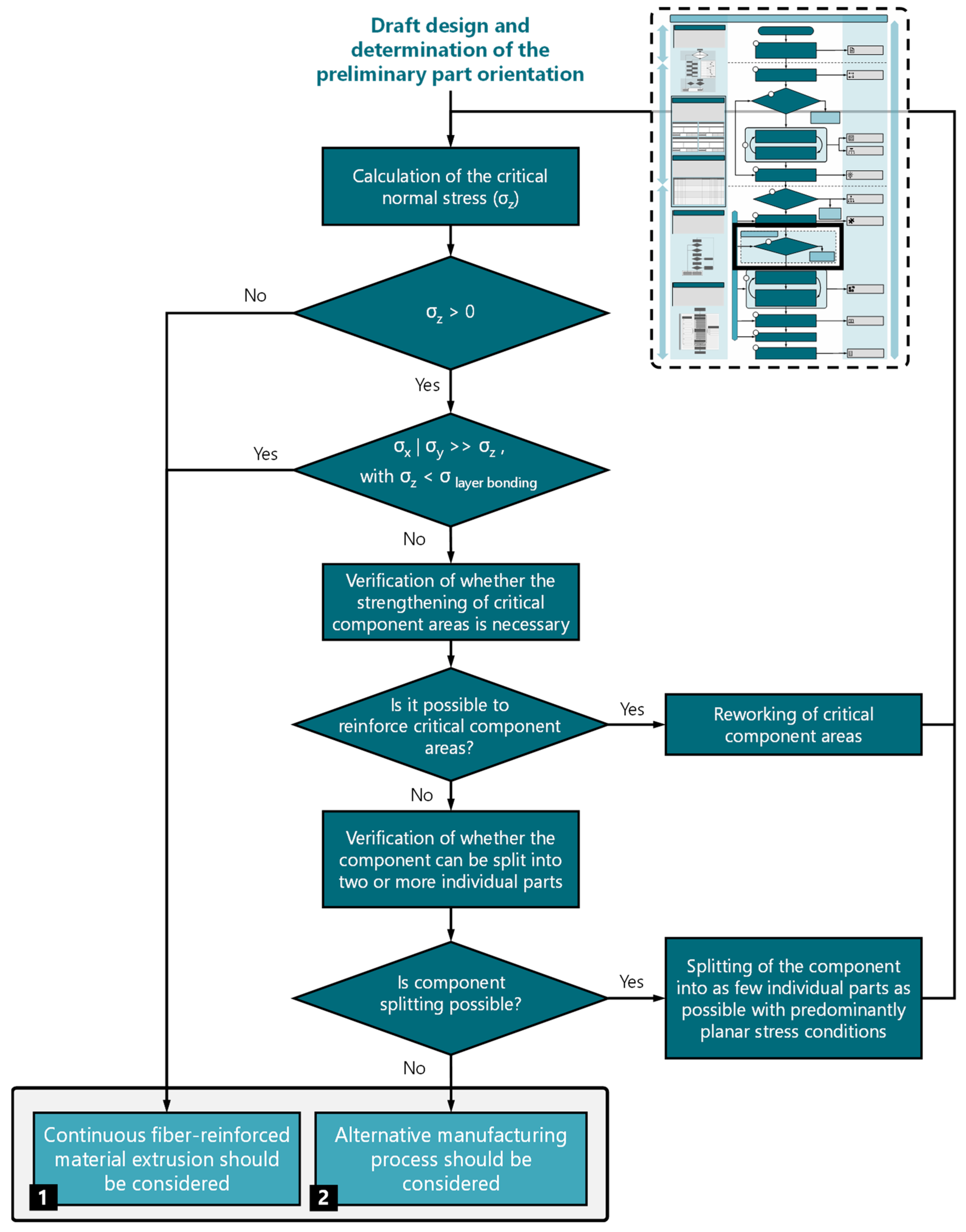

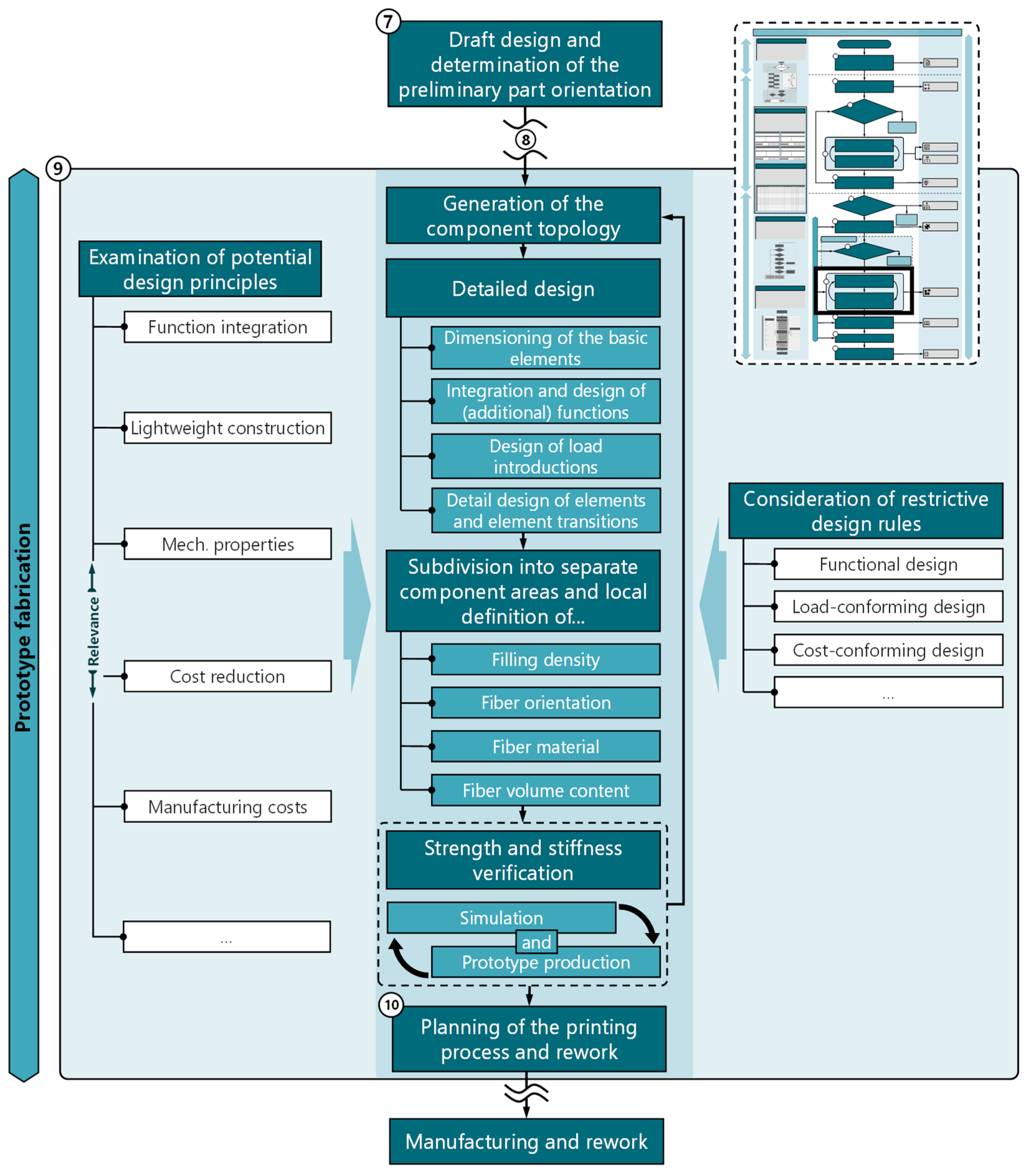

5.2.3. Elaboration and Detailing Phase

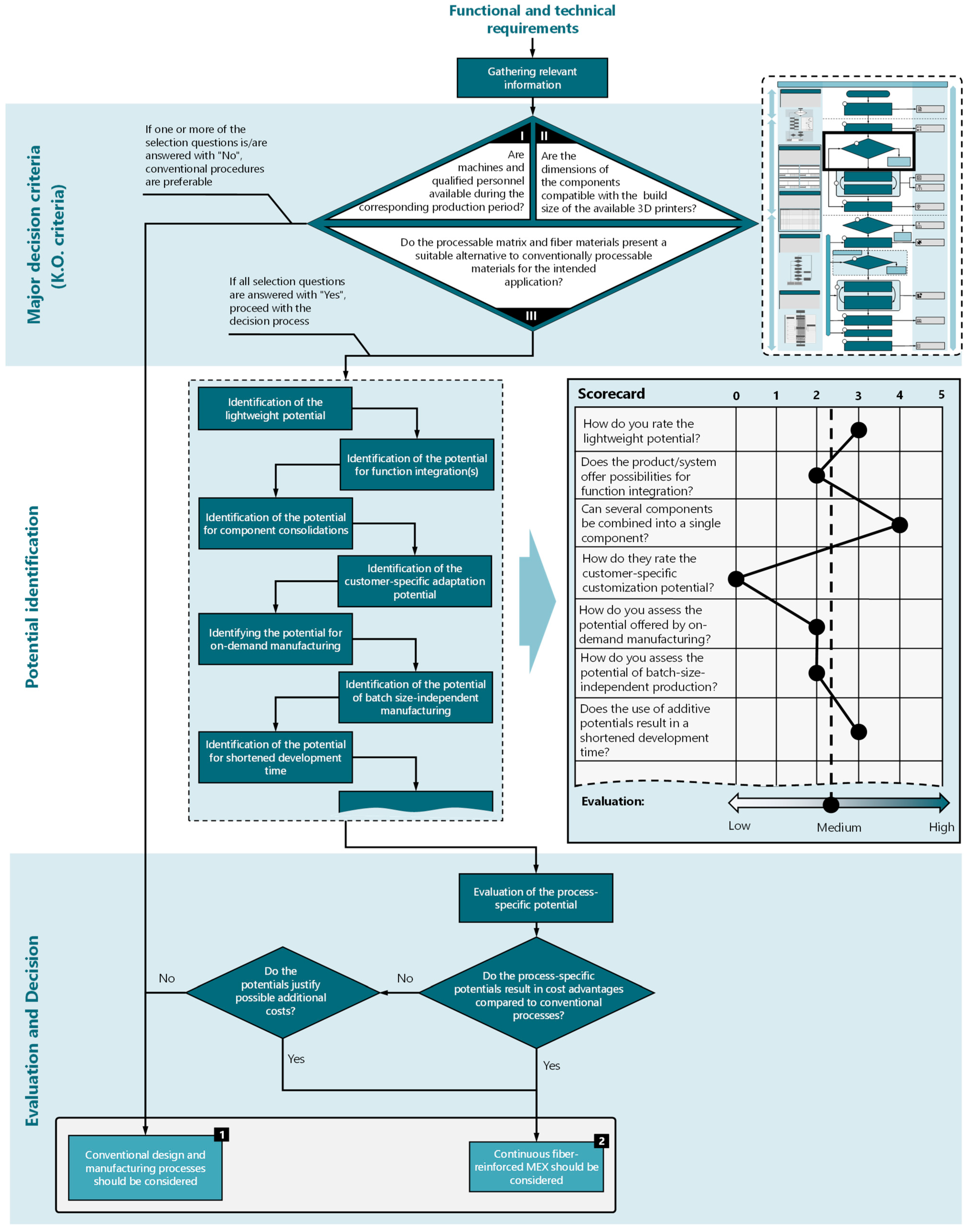

5.3. Process Selection Analysis

- Can the required quantities be realized using AM within the planned production period?

- Are the anticipated component dimensions manufacturable with the available equipment?

- Do the processable (matrix and fiber) materials represent an alternative to conventionally processable materials?

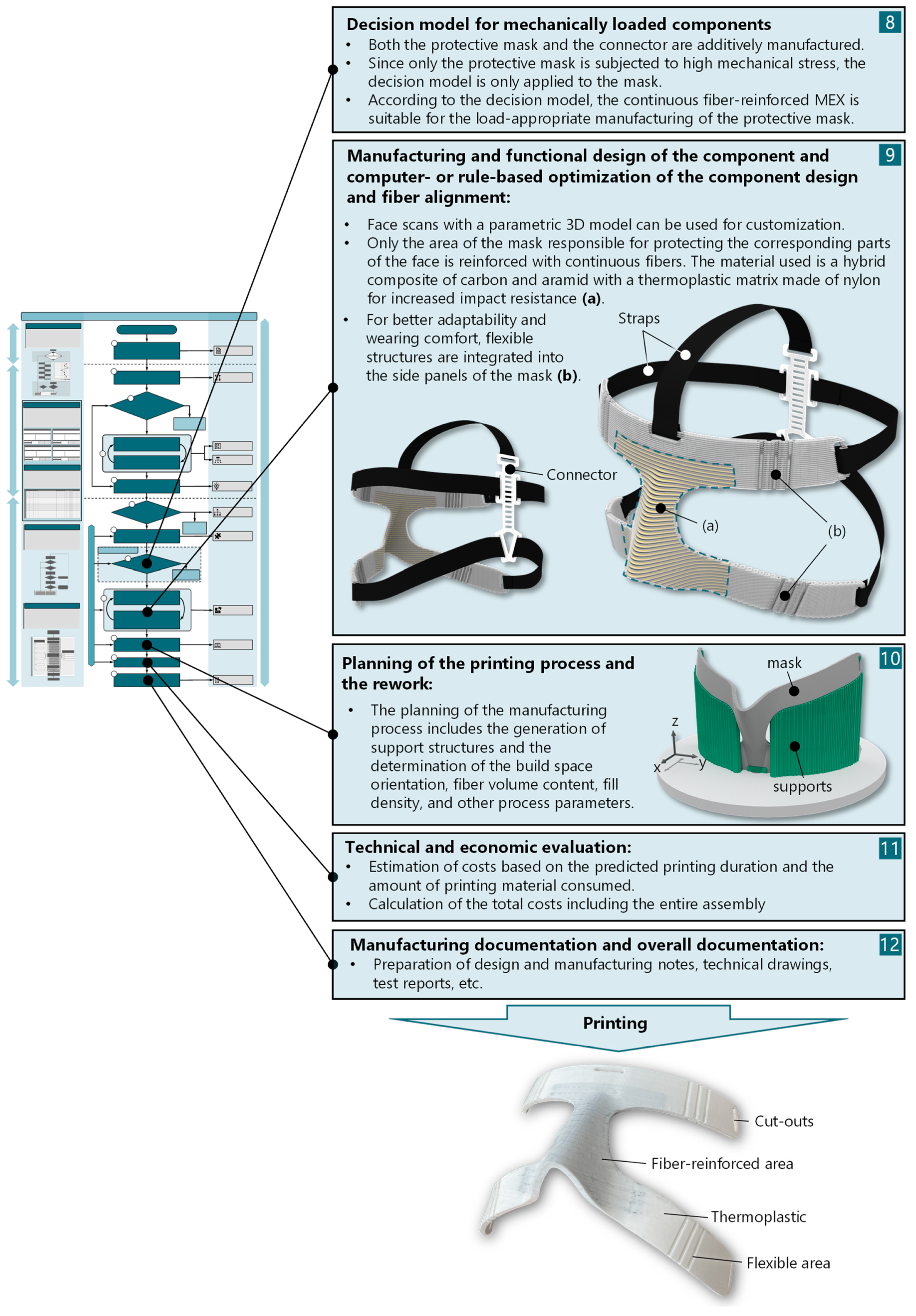

5.4. Decision Model

5.5. Adapted Design Process

5.6. Adaptation and Variant Designs

6. Case Study

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gebhardt, A. Additive Fertigungsverfahren: Additive Manufacturing und 3D-Drucken für Prototyping—Tooling—Produktion, 5th ed.; Hanser: Munich, Germany, 2016; ISBN 9783446444010. [Google Scholar]

- Verein Deutscher Ingenieure e. V. VDI-Richtlinie 3405, Additive Fertigungsverfahren—Grundlagen, Begriffe, Verfahrensbeschreibungen; Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; ISBN 1493921126. [Google Scholar]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Laverne, F.; Segonds, F.; Anwer, N.; Le Coq, M. DFAM in the design process: A proposal of classification to foster early design stages; In Proceedings of the CONFERE 2014, Šibenik, Croatia, 3–4 July 2014.

- Meisel, N.; Williams, C. An Investigation of Key Design for Additive Manufacturing Constraints in Multimaterial Three-Dimensional Printing. J. Mech. Des. 2015, 137, 111406. [Google Scholar] [CrossRef]

- Kumke, M.; Watschke, H.; Vietor, T. A new methodological framework for design for additive manufacturing. Virtual Phys. Prototyp. 2016, 11, 3–19. [Google Scholar] [CrossRef]

- Saleh, M.A.; Kempers, R.; Melenka, G.W. 3D printed continuous wire polymer composites strain sensors for structural health monitoring. Smart Mater. Struct. 2019, 28, 105041. [Google Scholar] [CrossRef]

- Yao, X.; Luan, C.; Zhang, D.; Lan, L.; Fu, J. Evaluation of carbon fiber-embedded 3D printed structures for strengthening and structural-health monitoring. Mater. Des. 2017, 114, 424–432. [Google Scholar] [CrossRef]

- Luan, C.; Yao, X.; Zhang, C.; Wang, B.; Fu, J. Large-scale deformation and damage detection of 3D printed continuous carbon fiber reinforced polymer-matrix composite structures. Compos. Struct. 2019, 212, 552–560. [Google Scholar] [CrossRef]

- Thakur, A.; Dong, X. Additive manufacturing of 3D structural battery composites with coextrusion deposition of continuous carbon fibers. Manuf. Lett. 2020, 26, 42–47. [Google Scholar] [CrossRef]

- Thakur, A.; Dong, X. Printing with 3D continuous carbon fiber multifunctional composites via UV-assisted coextrusion deposition. Manuf. Lett. 2020, 24, 1–5. [Google Scholar] [CrossRef]

- Heitkamp, T.; Hilbig, H.; Kuschmitz, S.; Girnth, S.; Waldt, N.; Klawitter, G.; Vietor, T. Design Principles and Restrictions for Continuous Fiber-Reinforced Additive Manufacturing. J. Mech. Eng. 2024, 146, 062002. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e. V. DIN EN ISO/ASTM 52900: Additive Fertigung—Grundlagen—Terminologie (Entwurf); Beuth Verlag GmbH: Berlin, Germany, 2018. [Google Scholar]

- Mazurchevici, A.; Nedelcu, D.; Popa, R. Additive manufacturing of composite materials by FDM technology: A review. Indian J. Eng. Mater. Sci. 2020, 27, 179–192. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D printing of continuous carbon fiber prepreg filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Prüß, H.; Vietor, T. Design for Fiber-Reinforced Additive Manufacturing. J. Mech. Des. 2015, 137, 111409. [Google Scholar] [CrossRef]

- Kuschmitz, S.; Schirp, A.; Busse, J.; Watschke, H.; Schirp, C.; Vietor, T. Development and Processing of Continuous Flax and Carbon Fiber-Reinforced Thermoplastic Composites by a Modified Material Extrusion Process. Materials 2021, 14, 2332. [Google Scholar] [CrossRef] [PubMed]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbé, A.; Guillou, E.; Castro, M. 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Rijckaert, S.; Daelemans, L.; Cardon, L.; Boone, M.; van Paepegem, W.; de Clerck, K. Continuous Fiber-Reinforced Aramid/PETG 3D-Printed Composites with High Fiber Loading through Fused Filament Fabrication. Polymers 2022, 14, 298. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Kim, S.G.; Kim, H.J.; Ahn, S.H. Measurement of anisotropic compressive strength of rapid prototyping parts. J. Mater. Process. Technol. 2007, 187–188, 627–630. [Google Scholar] [CrossRef]

- Bagsik, A.; Schöppner, V.; Klemp, E. Extensive Analysis of the mechanical strength properties of Fused Deposition Modeling Parts manufactured with ULTEM 9085. In Proceedings of the 5th International Conference on Polymer and Mould Innovations, Centre for Polymer and Material Technology, Ghent, Belgium, 12–14 September 2012. [Google Scholar]

- Zhang, H.; Yang, D.; Sheng, Y. Performance-driven 3D printing of continuous curved carbon fibre reinforced polymer composites: A preliminary numerical study. Compos. Part B Eng. 2018, 151, 256–264. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Malakhov, A.V.; Polilov, A.N.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of optimized composites with variable fiber volume fraction and stiffness using continuous fiber. Compos. Sci. Technol. 2020, 186, 107905. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Wang, T.; Ramopoulos, V.; Neumaier, D.; Hofele, J.; Walter, M.; Jelonnek, J. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures. Compos. Part B Eng. 2020, 182, 107612. [Google Scholar] [CrossRef]

- Hou, Z.; Tian, X.; Zhang, J.; Zheng, Z.; Zhe, L.; Li, D.; Malakhov, A.V.; Polilov, A.N. Optimization design and 3D printing of curvilinear fiber reinforced variable stiffness composites. Compos. Sci. Technol. 2021, 201, 108502. [Google Scholar] [CrossRef]

- Malakhov, A.V.; Polilov, A.N. Design of composite structures reinforced curvilinear fibres using FEM. Compos. Part A Appl. Sci. Manuf. 2016, 87, 23–28. [Google Scholar] [CrossRef]

- Heitkamp, T.; Kuschmitz, S.; Girnth, S.; Marx, J.-D.; Klawitter, G.; Waldt, N.; Vietor, T. Stress-adapted fiber orientation along the principal stress directions for continuous fiber-reinforced material extrusion. Prog. Addit. Manuf. 2022, 8, 541–559. [Google Scholar] [CrossRef]

- Swaminathan, S.; Ozutemiz, K.B.; Majidi, C.; Hudson, S.E. FiberWire: Embedding Electronic Function into 3D Printed Mechanically Strong, Lightweight Carbon Fiber Composite Objects. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems, Glasgow Scotland, UK, 4–9 May 2019; Brewster, S., Ed.; Association for Computing Machinery: New York, NY, USA, 2019; pp. 1–11. ISBN 9781450359702. [Google Scholar]

- Gardner, J.M.; Sauti, G.; Kim, J.-W.; Cano, R.J.; Wincheski, R.A.; Stelter, C.J.; Grimsley, B.W.; Working, D.C.; Siochi, E.J. 3-D printing of multifunctional carbon nanotube yarn reinforced components. Addit. Manuf. 2016, 12, 38–44. [Google Scholar] [CrossRef]

- Galos, J.; Hu, Y.; Ravindran, A.R.; Ladani, R.B.; Mouritz, A.P. Electrical properties of 3D printed continuous carbon fibre composites made using the FDM process. Compos. Part A Appl. Sci. Manuf. 2021, 151, 106661. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, T.; Zhang, M.; Liang, R.; Wang, B. Fabrication and characterization of aerosol-jet printed strain sensors for multifunctional composite structures. Smart Mater. Struct. 2012, 21, 115008. [Google Scholar] [CrossRef]

- Heitkamp, T.; Goutier, M.; Hilbig, K.; Girnth, S.; Waldt, N.; Klawitter, G.; Vietor, T. Parametric study of piezoresistive structures in continuous fiber reinforced additive manufacturing. Compos. Part C Open Access 2024, 13, 100431. [Google Scholar] [CrossRef]

- Yin, L.; Tian, X.; Shang, Z.; Wang, X.; Hou, Z. Characterizations of continuous carbon fiber-reinforced composites for electromagnetic interference shielding fabricated by 3D printing. Appl. Phys. A 2019, 125, 266. [Google Scholar] [CrossRef]

- Heitkamp, T.; Hilbig, K.; Goutier, M.; Girnth, S.; Waldt, N.; Klawitter, G.; Vietor, T. Characterization of mechanical properties, efficiency, and design considerations for the additive manufacturing of hybrid composites with continuous fibers. Hybrid Adv. 2024, 5, 100146. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Rosen, D.W. Design for Additive Manufacturing: A Method to Explore Unexplored Regions of the Design Space; The University of Texas: Austin, TX, USA, 2007. [Google Scholar]

- Laverne, F.; Segonds, F.; Anwer, N.; Le Coq, M. Assembly Based Methods to Support Product Innovation in Design for Additive Manufacturing: An Exploratory Case Study. J. Mech. Des. 2015, 137, 121701. [Google Scholar] [CrossRef]

- Pradel, P.; Zhu, Z.; Bibb, R.; Moultrie, J. Investigation of design for additive manufacturing in professional design practice. J. Eng. Des. 2018, 29, 165–200. [Google Scholar] [CrossRef]

- Ponche, R.; Kerbrat, O.; Mognol, P.; Hascoet, J.-Y. A novel methodology of design for Additive Manufacturing applied to Additive Laser Manufacturing process. Robot. Comput.-Integr. Manuf. 2014, 30, 389–398. [Google Scholar] [CrossRef]

- Ponche, R.; Hascoet, J.Y.; Kerbrat, O.; Mognol, P. A new global approach to design for additive manufacturing. Virtual Phys. Prototyp. 2012, 7, 93–105. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: A critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure e. V. VDI-Richtlinie 2221 Blatt 1, Entwicklung Technischer Produkte und Systeme—Gestaltung Individueller Produktentwicklungsprozesse; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- Zhu, Z.; Pradel, P.; Bibb, R.; Moultrie, J. A framework for designing end use products for direct manufacturing using additive manufacturing technologies. In Proceedings of the 21st International Conference on Engineering Design (ICED17), Vancouver, ON, Canada, 21–25 August 2017; Volume 5. [Google Scholar]

- Kranz, J. Methodik und Richtlinien für die Konstruktion von Laseradditiv Gefertigten Leichtbaustrukturen; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783662553398. [Google Scholar]

- Verein Deutscher Ingenieure e. V. VDI/VDE-Richtlinie 2206—Entwicklung Mechatronischer und Cyber-Physischer Systeme; Beuth Verlag GmbH: Berlin, Germany, 2021. [Google Scholar]

- Beyer, C. Strategic Implications of Current Trends in Additive Manufacturing. J. Manuf. Sci. Eng. 2014, 136, 064701. [Google Scholar] [CrossRef]

- Eddy, D.C.; Krishnamurty, S.; Grosse, I.R.; Steudel, M. Early design stage selection of best manufacturing process. J. Eng. Des. 2020, 31, 1–36. [Google Scholar] [CrossRef]

- Valjak, F.; Bojčetić, N. Conception of Design Principles for Additive Manufacturing. Proc. Int. Conf. Eng. Des. 2019, 1, 689–698. [Google Scholar] [CrossRef]

- Kuschmitz, S.; Watschke, H.; Schumacher, F.; Vietor, T. Bereitstellung von Lösungsprinzipien für die additive Fertigung zur Unterstützung der Bauteilkonzeption in der industriellen Praxis. In Proceedings of the RapidTech + FabCon 3.D: International Hub for Additive Manufacturing: Exhibition + Conference + Networking: Proceedings of the 16th Rapid.Tech Conference Erfurt, Germany, 25–27 June 2019; Kynast, M., Eichmann, M., Witt, G., Eds.; Hanser: München, Germany, 2019; pp. 75–88. ISBN 978-3-446-46223-6. [Google Scholar]

- Fu, K.K.; Yang, M.C.; Wood, K.L. Design Principles: Literature Review, Analysis, and Future Directions. J. Mech. Des. 2016, 138, 101103. [Google Scholar] [CrossRef]

- Quan, Z.; Wu, A.; Keefe, M.; Qin, X.; Yu, J.; Suhr, J.; Byun, J.-H.; Kim, B.-S.; Chou, T.-W. Additive manufacturing of multi-directional preforms for composites: Opportunities and challenges. Mater. Today 2015, 18, 503–512. [Google Scholar] [CrossRef]

- Diegel, O.; Nordin, A.; Motte, D. (Eds.) A Practical Guide to Design for Additive Manufacturing; Springer: Singapore, 2019; ISBN 978-981-13-8280-2. [Google Scholar]

- Deutsches Institut für Normung e. V. DIN 66025-1: Programmaufbau für Numerisch Gesteuerte Arbeitsmaschinen; Beuth Verlag GmbH: Berlin, Germany, 1983. [Google Scholar]

- Prüß, H. Gestaltung und generative Fertigung von Faser-Kunststoff-Verbunden. Ph.D. Thesis, Technische Universität Braunschweig, Dr. Hut Verlag, München, Germany, 2017. [Google Scholar]

- Schürmann, H. Konstruieren mit Faser-Kunststoff-Verbunden, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 9783540721901. [Google Scholar]

- Ehrlenspiel, K.; Meerkamm, H. Integrierte Produktentwicklung: Denkabläufe, Methodeneinsatz, Zusammenarbeit; 6., überarbeitete und erweiterte Auflage; Carl Hanser Verlag: München, Germany, 2017; ISBN 9783446449084. [Google Scholar]

- Pahl, G.; Feldhusen, J.; Grote, K.-H. Konstruktionslehre: Methoden und Anwendung erfolgreicher Produktentwicklung; Springer Vieweg: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-29568-3. [Google Scholar]

- Verein Deutscher Ingenieure e. V. VDI-Richtlinie 2223, Methodisches Entwerfen Technischer Produkte; Beuth Verlag GmbH: Berlin, Germany, 2004. [Google Scholar]

- Zäh, M. Wirtschaftliche Fertigung mit Rapid-Technologien: Anwender-Leitfaden zur Auswahl Geeigneter Verfahren; Hanser: München, Germany, 2013; ISBN 3446439161. [Google Scholar]

- Marston, A.P.; O’Brien, E.K.; Hamilton, G.S. Nasal Injuries in Sports. Clin. Sports Med. 2017, 36, 337–353. [Google Scholar] [CrossRef] [PubMed]

- Krutsch, V.; Gesslein, M.; Loose, O.; Weber, J.; Nerlich, M.; Gaensslen, A.; Bonkowsky, V.; Krutsch, W. Injury mechanism of midfacial fractures in football causes in over 40% typical neurological symptoms of minor brain injuries. Knee Surg. Sports Traumatol. Arthrosc. Off. J. ESSKA 2018, 26, 1295–1302. [Google Scholar] [CrossRef] [PubMed]

- Markforged Inc. Eiger 3D Printing Software|Markforged. Available online: https://markforged.com/software (accessed on 16 March 2022).

| No. | Requirement | Type |

|---|---|---|

| 1.1 | The process model should encompass all phases of the product development process, from clarifying requirements to creating the concept, on to detailing and designing the component. | General |

| 1.2 | The process model should be applicable to all types of design (novel, adaptation, and variant designs). | General |

| 2.1 | In line with a holistic approach, process-specific opportunistic and restrictive design knowledge for additive manufacturing processes should be linked with the phases/process steps. | AM-specific |

| 2.2 | The development process must be suitable for conventional methods as well as for additive manufacturing/CFR-MEX until the final decision for using AM is made and should be designed as neutrally as possible. This allows individual modules/components to be manufactured conventionally, avoiding elaborate iterations. | AM-specific |

| 2.3 | To narrow down the design freedoms and potentials of the additive manufacturing process, an early selection of the process should be performed. | AM-specific |

| 3.1 | The build-space orientation should be determined early on, taking into account the extreme anisotropy in mechanically heavily loaded components, and critically assessed in conjunction with a suitability test of the manufacturing process. | CFR-MEX-specific |

| 3.2 | The generation and planning of machine code (fill patterns, build-space orientation, cutting positions, etc.) must be part of the design phase, as the resulting mechanical properties are particularly dependent on the fiber orientation, which should be adapted to the respective load case. | CFR-MEX-specific |

| Product Data/Manufacturing Data | Value/Description |

|---|---|

| Fiber material | Carbon fiber |

| Matrix material | PA6 (Nylon) |

| Weight of continuous- fiber-reinforced filament | 9.2 g |

| Weight of thermoplastic filament | 83.8 g |

| Material and production costs per piece | 33.80 € |

| Printing time | ~23 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heitkamp, T.; Hilbig, K.; Girnth, S.; Kuschmitz, S.; Waldt, N.; Klawitter, G.; Vietor, T. Adapted Design Process for Continuous Fiber-Reinforced Additive Manufacturing—A Methodological Framework. Materials 2024, 17, 3194. https://doi.org/10.3390/ma17133194

Heitkamp T, Hilbig K, Girnth S, Kuschmitz S, Waldt N, Klawitter G, Vietor T. Adapted Design Process for Continuous Fiber-Reinforced Additive Manufacturing—A Methodological Framework. Materials. 2024; 17(13):3194. https://doi.org/10.3390/ma17133194

Chicago/Turabian StyleHeitkamp, Tim, Karl Hilbig, Simon Girnth, Sebastian Kuschmitz, Nils Waldt, Günter Klawitter, and Thomas Vietor. 2024. "Adapted Design Process for Continuous Fiber-Reinforced Additive Manufacturing—A Methodological Framework" Materials 17, no. 13: 3194. https://doi.org/10.3390/ma17133194

APA StyleHeitkamp, T., Hilbig, K., Girnth, S., Kuschmitz, S., Waldt, N., Klawitter, G., & Vietor, T. (2024). Adapted Design Process for Continuous Fiber-Reinforced Additive Manufacturing—A Methodological Framework. Materials, 17(13), 3194. https://doi.org/10.3390/ma17133194