Optimizing Fatigue Performance in Gradient Structural Steels by Manipulating the Grain Size Gradient Rate

Abstract

:1. Introduction

2. Materials and Methods

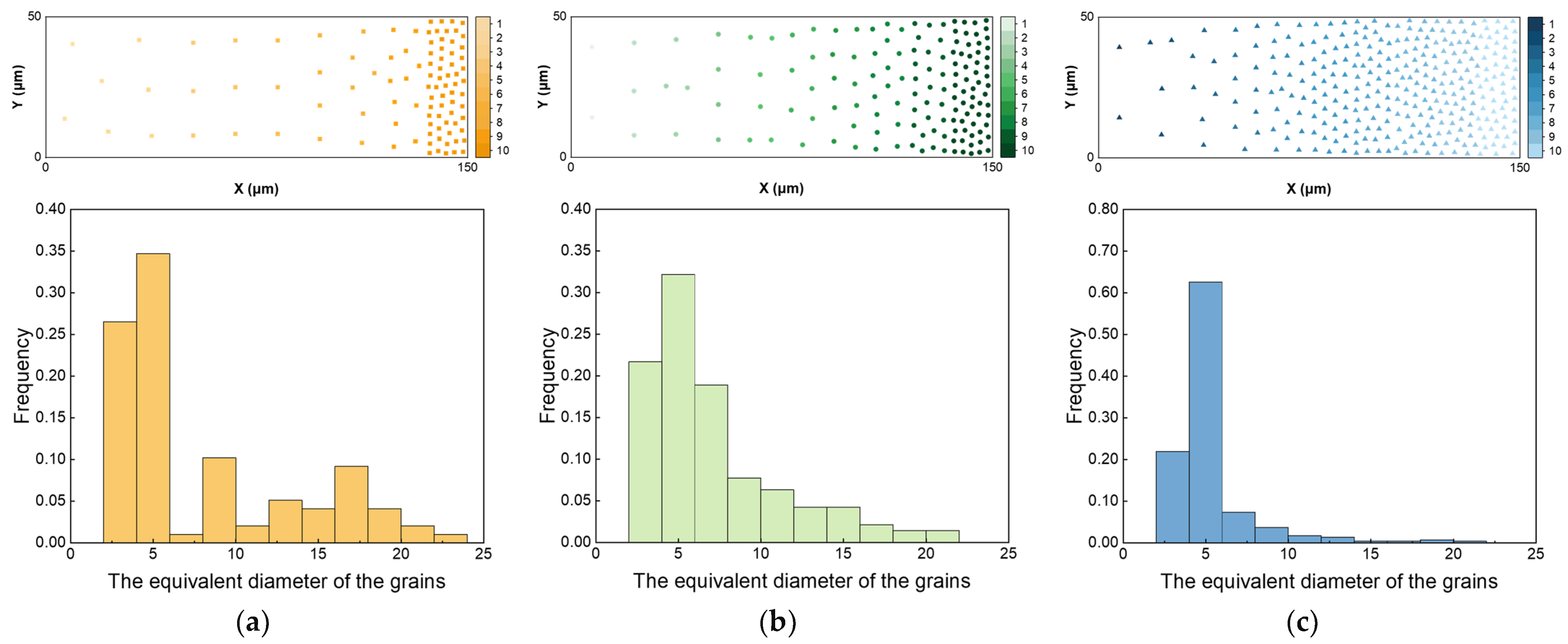

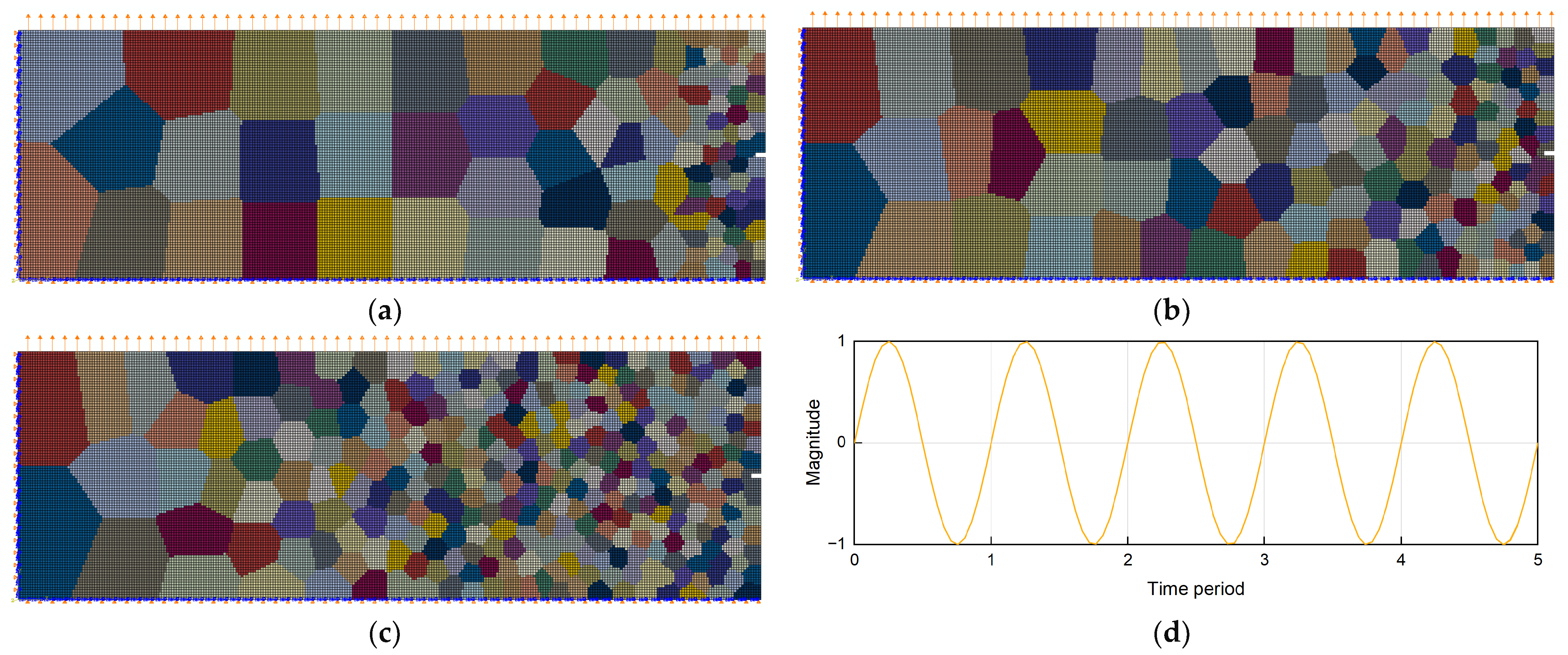

2.1. Three Types of Gradient Rate Polycrystalline Models

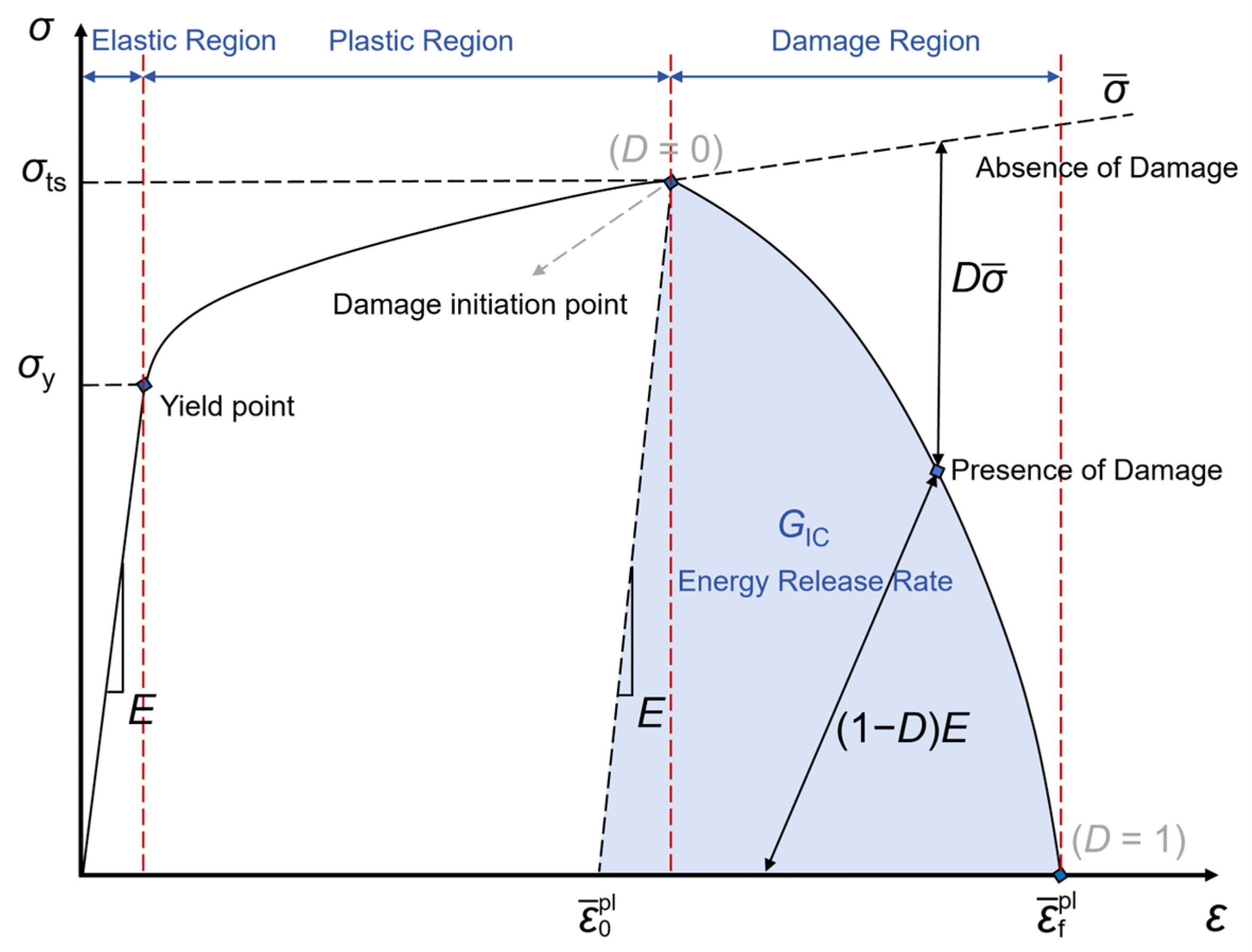

2.2. Elastoplastic and Damage Constitutive Equation

2.3. Pre-Processing and Abaqus/Explicit Calculation Method

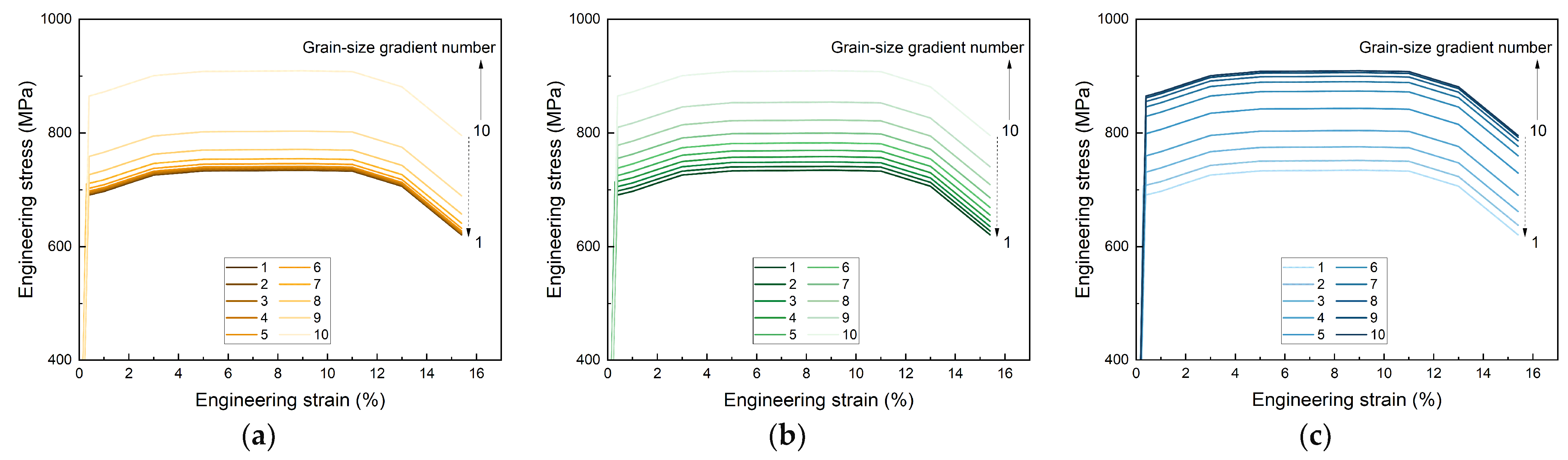

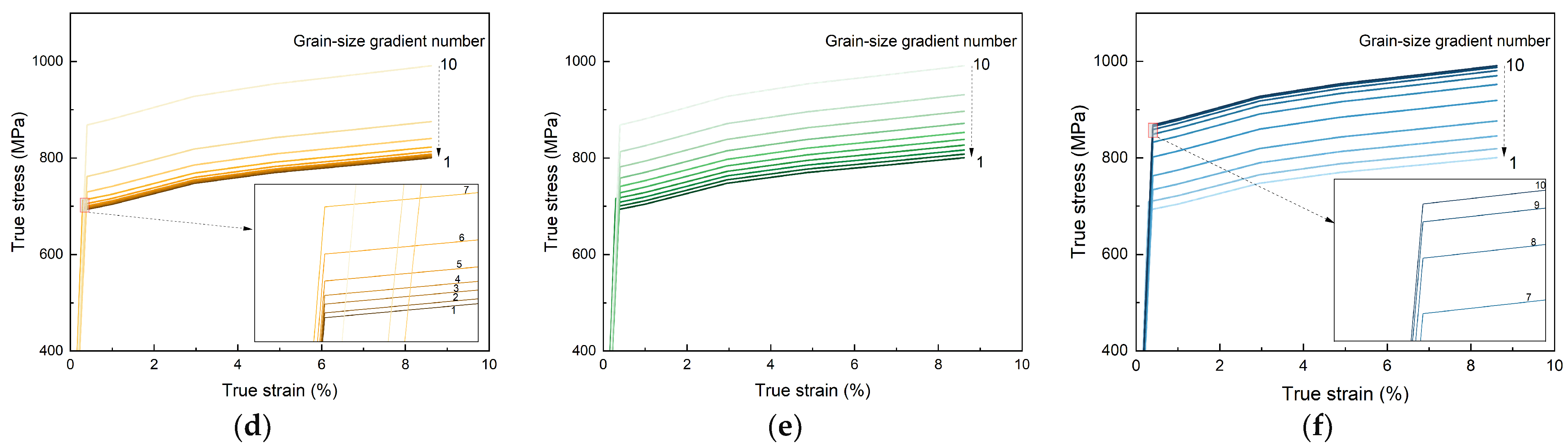

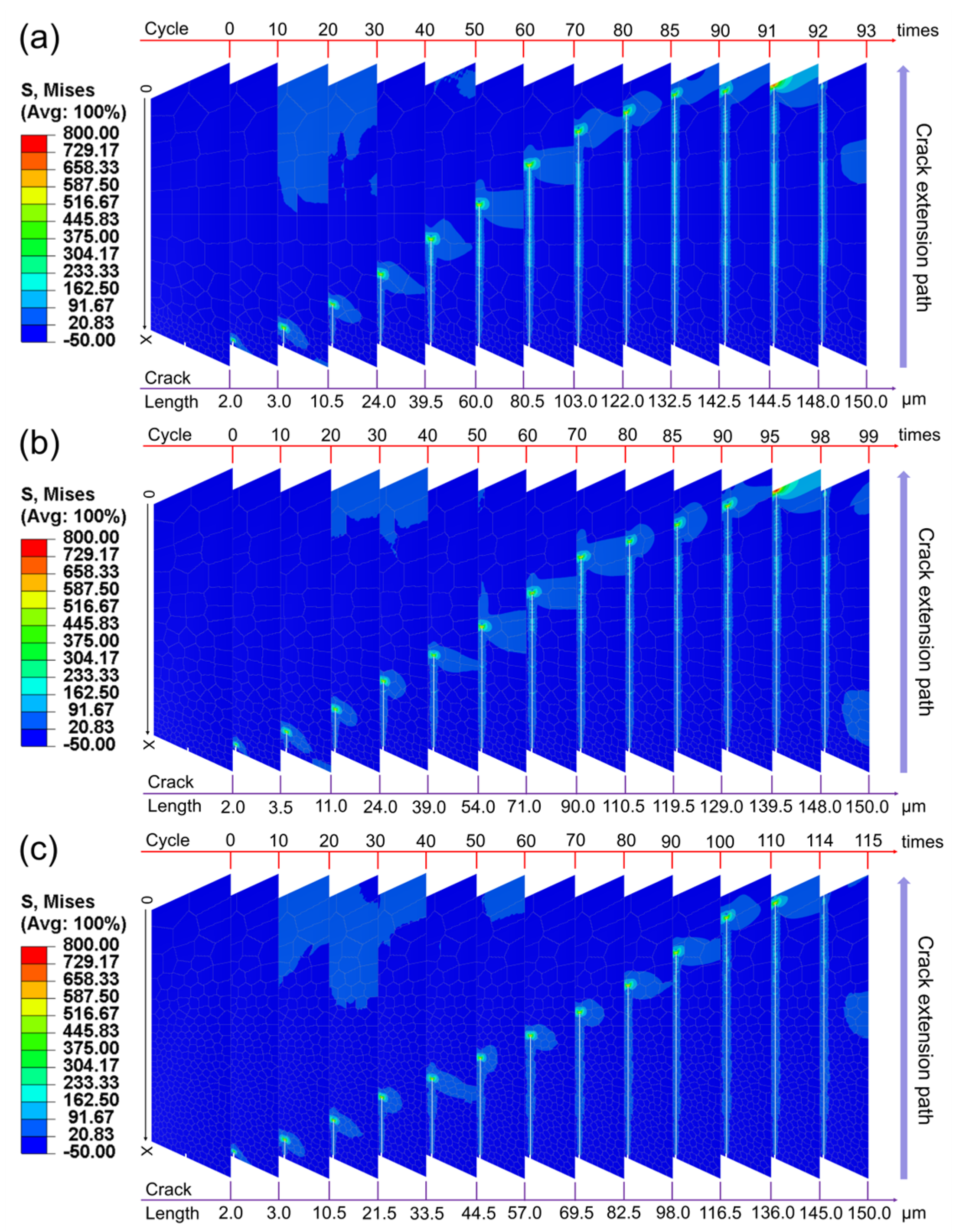

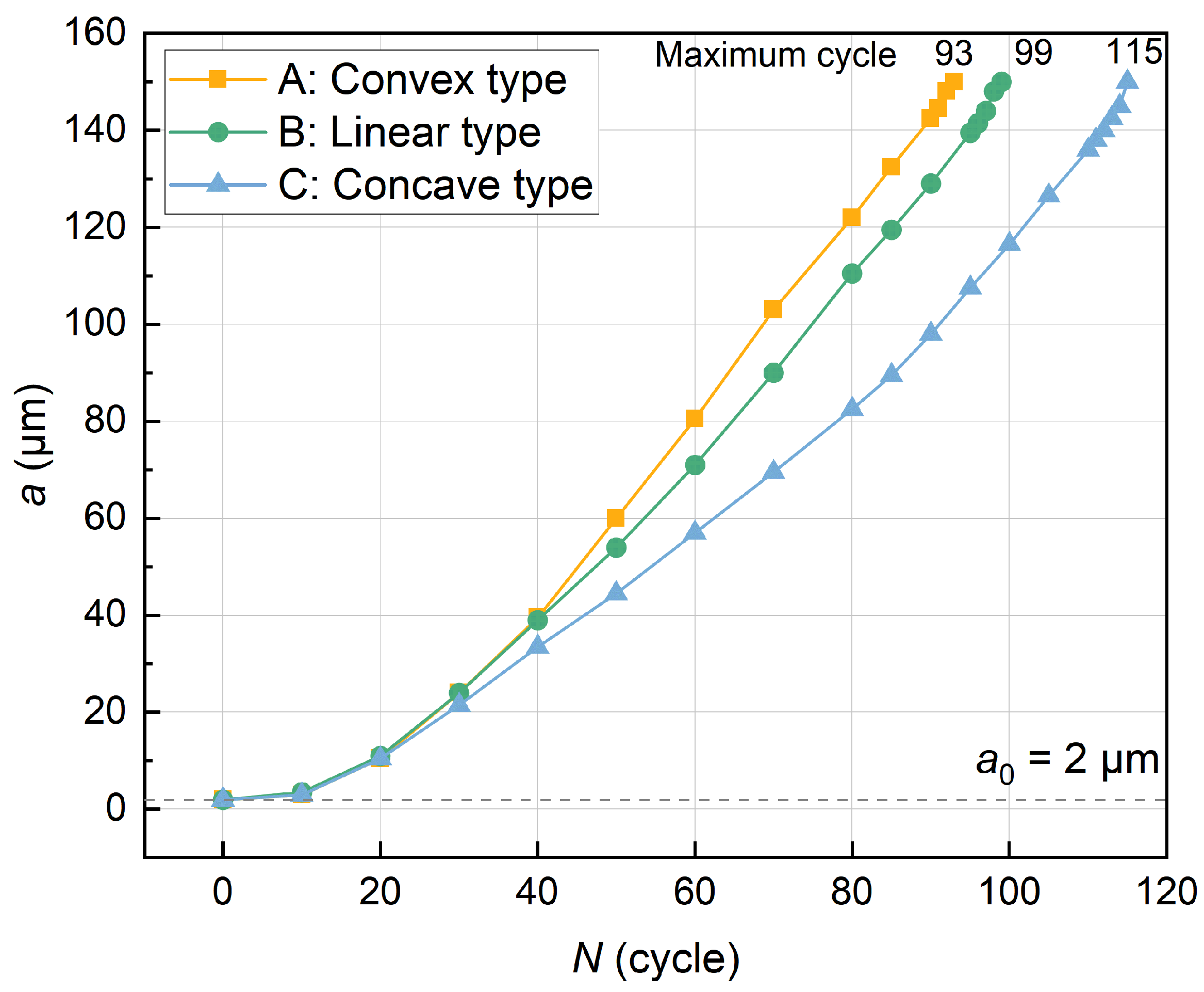

3. Results

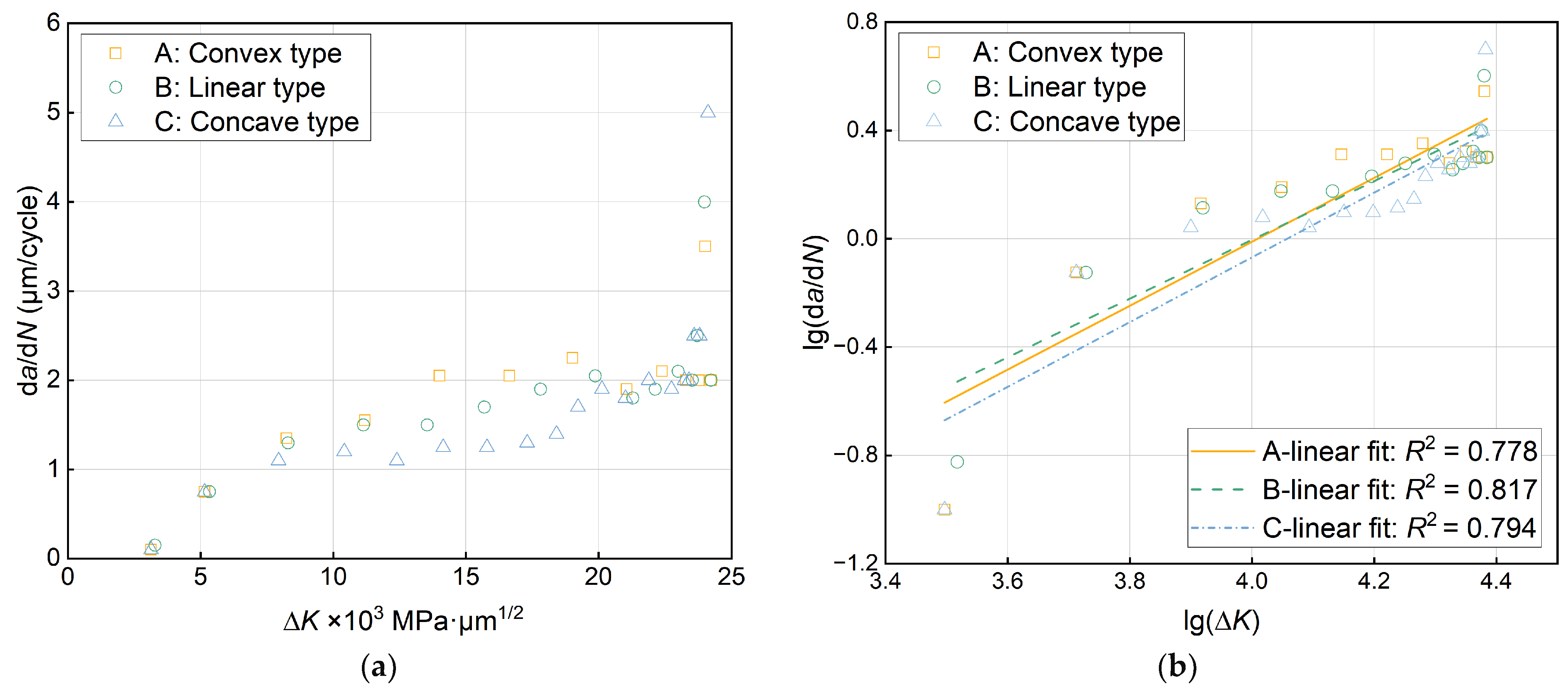

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Zhang, C.H.; Cui, X.; Zhang, S.; Chen, J.; Zhang, J.B. Novel gradient alloy steel with quasi-continuous ratios fabricated by SLM: Material microstructure and wear mechanism. Mater. Charact. 2021, 174, 111020. [Google Scholar] [CrossRef]

- Ji, W.M.; Zhou, R.H.; Vivegananthan, P.; Wu, M.S.; Gao, H.J.; Zhou, K. Recent progress in gradient-structured metals and alloys. Prog. Mater. Sci. 2023, 140, 101194. [Google Scholar] [CrossRef]

- Han, J.C.; Xu, L.; Wang, B.L.; Zhang, X.H. Progress and prospects of functional gradient materials. J. Solid Rocket Technol. 2004, 27, 207–215. [Google Scholar]

- Zhu, Y.T.; Wu, X.L. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, P.; Li, Y.; Wang, H.; Cai, Z.; Li, J.; Liang, Y.; Liang, Y. Effect of a gradient structure on the mechanical performance of Inconel 718 Ni-based superalloy at elevated temperatures. J. Mater. Res. Technol. 2023, 23, 2031–2042. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.W.; Liu, J.B.; Wang, G.; Wang, H.T.; Wei, Y.J.; Gao, H.J. Strength gradient enhances fatigue resistance of steels. Sci. Rep. 2016, 6, 22156. [Google Scholar] [CrossRef]

- Li, X.; Lu, L.; Li, J.; Zhang, X.; Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706–723. [Google Scholar] [CrossRef]

- Wang, Y. Numerical Investigations on Strengthening-Toughening and Failure Mechanisms of Metallic Materials with Gradient Structure. Ph.D. Dissertation, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Shuai, L.; Yinlei, G.; Dongdong, L.; Ziyue, L.; Yunli, F.; Fucheng, Z. Unusual grain-size effects on tensile deformation behavior of twinning-induced plasticity steel with low Mn content. J. Mater. Res. Technol. 2023, 24, 586–594. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Fujii, T.; Muhamad Azmi, M.S.B.; Tohgo, K.; Shimamura, Y. Influence of strain gradient on fatigue life of carbon steel for pressure vessels in low-cycle and high-cycle fatigue regimes. Materials 2022, 15, 445. [Google Scholar] [CrossRef]

- Zerbst, U.; Klinger, C.; Klingbeil, D. Structural assessment of railway axles–A critical review. Eng. Fail. Anal. 2013, 35, 54–65. [Google Scholar] [CrossRef]

- Liu, Z.P.; Zhang, H.X.; Yan, Z.F.; Dong, P. Enhanced fatigue performance of aluminum alloy through surface strengthening treatment. Mater. Lett. 2022, 306, 130864. [Google Scholar] [CrossRef]

- Bagheri, S.; Guagliano, M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf. Eng. 2009, 25, 3–14. [Google Scholar] [CrossRef]

- Liu, W.; Wu, G.; Zhai, C.; Ding, W.; Korsunsky, A.M. Grain refinement and fatigue strengthening mechanisms in as-extruded Mg–6Zn–0.5Zr and Mg–10Gd–3Y–0.5Zr magnesium alloys by shot peening. Int. J. Plast. 2013, 49, 16–35. [Google Scholar] [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Low cycle fatigue behavior of AA7075 with surface gradient structure produced by ultrasonic shot peening. Procedia Struct. Integr. 2016, 2, 3288–3295. [Google Scholar] [CrossRef]

- Li, W.; Tao, N.R.; Lu, K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr. Mater. 2008, 59, 546–549. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. J. Mater. Sci. Technol. 1999, 15, 193–197. [Google Scholar]

- Wei, Y.J.; Li, Y.Q.; Zhu, L.C.; Liu, Y.; Lei, X.Q.; Wang, G.; Wu, Y.X.; Mi, Z.L.; Liu, J.B.; Wang, H.T.; et al. Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 3580. [Google Scholar] [CrossRef]

- Lu, K. Gradient nanostructured materials. Acta Metall. Sin. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, X.Y.; Xu, D.S.; Lu, L.; Gao, H.J.; Zhu, T. Gradient plasticity in gradient nano-grained metals. Extrem. Mech. Lett. 2016, 8, 213–219. [Google Scholar] [CrossRef]

- Yang, M.X.; Li, R.G.; Jiang, P.; Yuan, F.P.; Wang, Y.D.; Zhu, Y.T.; Wu, X.L. Residual stress provides significant strengthening and ductility in gradient structured materials. Mater. Res. Lett. 2019, 7, 433–438. [Google Scholar] [CrossRef]

- Luo, X.K.; Wang, Y.M.; Dang, N.; Tian, K.; Wang, K.; Zhao, C.L.; Zha, X.H.; Wang, X.; Yu, Y. Gradient microstructure and foreign-object-damaged fatigue properties of Ti6Al4V titanium alloy processed by the laser shock peening and subsequent shot peening. Mater. Sci. Eng. A 2022, 849, 143398. [Google Scholar] [CrossRef]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef]

- Ding, J.; Xue, S.; Shang, Z.; Li, J.; Zhang, Y.; Su, R.; Niu, T.; Wang, H.; Zhang, X. Characterization of precipitation in gradient Inconel 718 superalloy. Mater. Sci. Eng. A 2021, 804, 140718. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, X.Q.; Zhao, S.; Zhu, Y.K.; Yang, H.J.; Tian, Y.Z.; Zhang, Z.Z.; Zhang, P.; An, X.H.; Zhang, Z.F. Fatigue-resistant design in low-cycle regime by regulating the micro-structural gradient in a TWIP steel: Modelling and experiment. Int. J. Plast. 2022, 159, 103471. [Google Scholar] [CrossRef]

- Tilbrook, M.T.; Moon, R.J.; Hoffman, M. Finite element simulations of crack propagation in functionally graded materials under flexural loading. Eng. Fract. Mech. 2005, 72, 2444–2467. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, G.; Wang, W.; Wang, X.; Li, Q.; Wei, Y. Optimal stress and deformation partition in gradient materials for better strength and tensile ductility: A numerical investigation. Sci. Rep. 2017, 7, 10954. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Soh, A.K. Modeling of the plastic deformation of nanostructured materials with grain size gradient. Int. J. Plast. 2012, 39, 88–102. [Google Scholar] [CrossRef]

- Li, J.J.; Weng, G.J.; Chen, S.H.; Wu, X.L. On strain hardening mechanism in gradient nanostructures. Int. J. Plast. 2017, 88, 89–107. [Google Scholar] [CrossRef]

- Xu, P.W.; Luo, H.Y.; Li, S.J.; Lv, Y.; Tang, J.; Ma, Y. Enhancing the ductility in the age-hardened aluminum alloy using a gradient nanostructured structure. Mater. Sci. Eng. A 2017, 682, 704–713. [Google Scholar] [CrossRef]

- Lin, Y.; Yu, Q.; Pan, J.; Duan, F.H.; Ritchie, R.O.; Li, Y. On the impact toughness of gradient-structured metals. Acta Mater. 2020, 193, 125–137. [Google Scholar] [CrossRef]

- Lin, Y.; Pan, J.; Zhou, H.F.; Gao, H.J.; Li, Y. Mechanical properties and optimal grain size distribution profile of gradient grained nickel. Acta Mater. 2018, 153, 279–289. [Google Scholar] [CrossRef]

- Jing, L.; Pan, Q.; Long, J.; Tao, N.; Lu, L. Effect of volume fraction of gradient nanograined layer on high-cycle fatigue behavior of Cu. Scr. Mater. 2019, 161, 74–77. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, S.; Ao, N.; Zhang, J.; Li, H.; Zhou, L.; Xu, P.; Su, Y. Fatigue crack non-propagation behavior of a gradient steel structure from induction hardened railway axles. Int. J. Fatigue 2023, 166, 107296. [Google Scholar] [CrossRef]

- Zhang, S.J.; Xie, J.J.; Jiang, Q.Q.; Zhang, X.L.; Sun, C.Q.; Hong, Y.S. Fatigue crack growth behavior in gradient microstructure of hardened surface layer for an axle steel. Mater. Sci. Eng. A 2017, 700, 66–74. [Google Scholar] [CrossRef]

- Du, Y.; Schmid-Fetzer, R.; Wang, J.C.; Liu, S.H.; Wang, J.C.; Jin, Z.P. Computational Design of Engineering Materials: Fundamentals and Case Studies; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar] [CrossRef]

- Wang, X.; Xiang, Y.X.; Zhu, W.J.; Ding, T.T.; Li, H.Y. Damage assessment in Q690 high strength structural steel using nonlinear Lamb waves. Constr. Build. Mater. 2020, 234, 117384. [Google Scholar] [CrossRef]

- Quey, R.; Kasemer, M. The Neper/FEPX Project: Free/Open-source Polycrystal Generation, Deformation Simulation, and Post-processing. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1249, 012021. [Google Scholar] [CrossRef]

- Seok, M.Y.; Choi, I.C.; Moon, J.; Kim, S.; Ramamurty, U.; Jang, J.-I. Estimation of the Hall–Petch strengthening coefficient of steels through nanoindentation. Scr. Mater. 2014, 87, 49–52. [Google Scholar] [CrossRef]

- Faridmehr, I.; Osman, M.H.; Adnan, A.B.; Nejad, A.F.; Hodjati, R.; Azimi, M. Correlation between engineering stress-strain and true stress-strain curve. Am. J. Civil Eng. Archit. 2014, 2, 53–59. [Google Scholar] [CrossRef]

- Wagner, R. ABAQUS Tutorial: Damage for Ductile Metals–Material Model Explained–Ductile Damage. Available online: https://www.researchgate.net/publication/350124892 (accessed on 17 March 2021).

- Hanlon, T.; Kwon, Y.N.; Suresh, S. Grain size effects on the fatigue response of nanocrystalline metals. Scr. Mater. 2003, 49, 675–680. [Google Scholar] [CrossRef]

- Paris, P.C.; Marines-Garcia, I.; Hertzberg, R.; Donald, J.K. The relationship of effective stress intensity, elastic modulus and Burgers-vector on fatigue crack growth as associated with “fish eye” gigacycle fatigue phenomena. In Proceedings of the VHCF-3, Kyoto, Japan, 16–19 September 2004; pp. 1–13. [Google Scholar]

- Bedford, A.; Liechti, K.M. Mechanics of Materials; Springer Nature: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Li, Y. Research Progress on Gradient Metallic Materials. Mater. China 2016, 35, 658–665. [Google Scholar]

- Huang, H.W.; Wang, Z.B.; Lu, J.; Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, L.C.; Zhang, S.J.; Sun, C.Q.; Wang, W.J.; Yang, G.X.; Li, Q.; Wei, Y.J. The influence of combined gradient structure with residual stress on crack-growth behavior in medium carbon steel. Eng. Fract. Mech. 2019, 209, 369–381. [Google Scholar] [CrossRef]

- Zou, J.; Liang, Y.; Jiang, Y.; Yin, C.; Huang, C.; Liu, D.; Zhu, Z.; Wu, Y. Fretting fatigue mechanism of 40CrNiMoA steel subjected to the ultrasonic surface rolling process: The role of the gradient structure. Int. J. Fatigue 2023, 167, 107383. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, S.; Ao, N.; Zhou, L.; Wang, L.; Liu, D. The effect of gradient order on impact toughness of carbon S38C axle steels with induction hardening. Eng. Fail. Anal. 2023, 149, 107254. [Google Scholar] [CrossRef]

- Yang, X.J.; Zhou, J.X.; Ling, X. Influences of surface grain size and gradient variation along depth on fatigue life of metallic materials. Mater. Des. 2013, 43, 454–459. [Google Scholar] [CrossRef]

| Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Strain | 0.000 | 0.003 | 0.010 | 0.020 | 0.030 | 0.049 | 0.068 | 0.086 |

| Stress (MPa) | 0.000 | 692.070 | 704.324 | 726.046 | 747.687 | 770.007 | 785.220 | 800.551 |

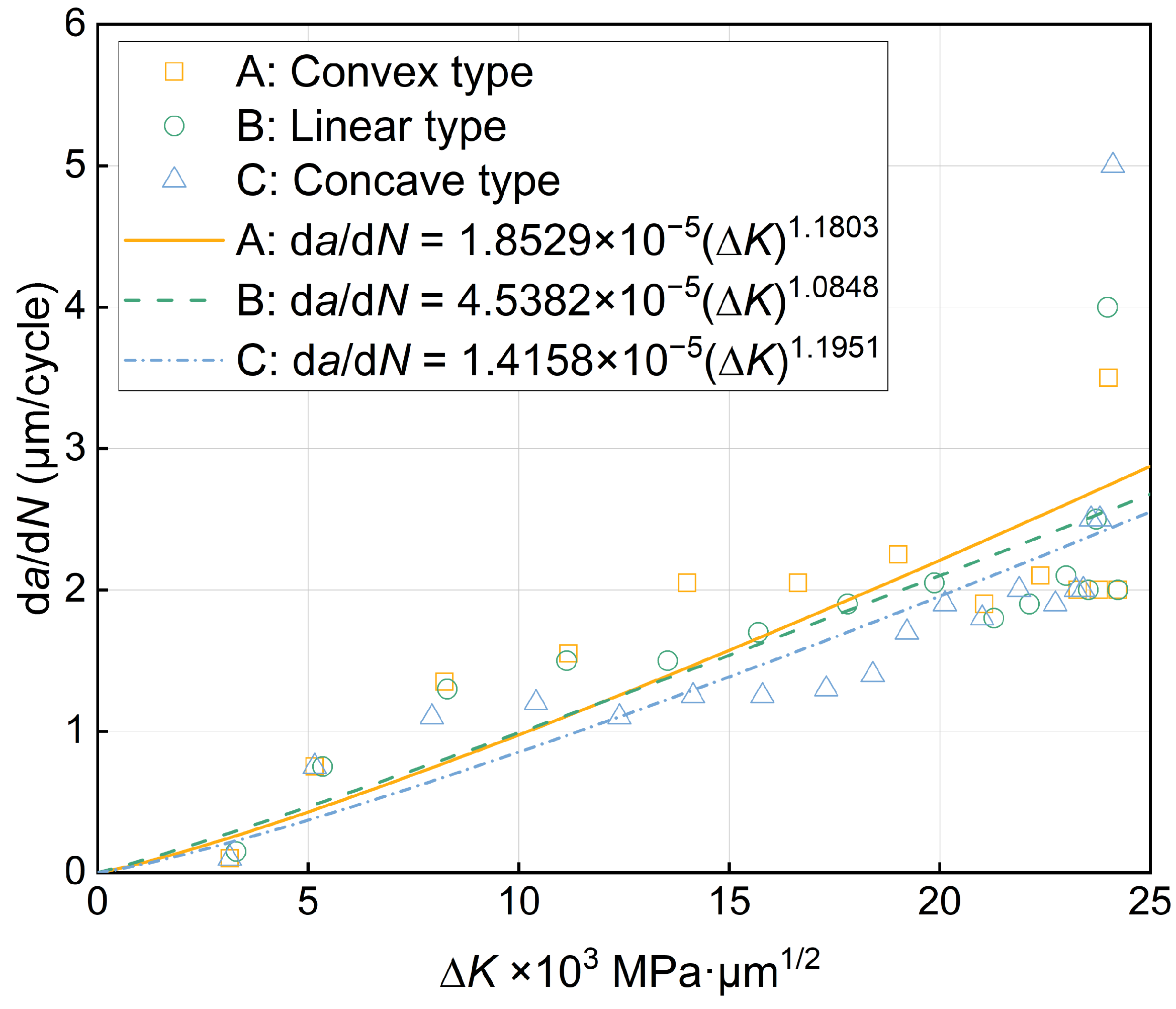

| Model | m | lgC | C | R2 |

|---|---|---|---|---|

| A | 1.1803 | −4.7322 | 1.8529 × 10−5 | 0.778 |

| B | 1.0848 | −4.3431 | 4.5382 × 10−5 | 0.817 |

| C | 1.1951 | −4.8490 | 1.4158 × 10−5 | 0.794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, M.; Chen, X.; He, M.; Kong, Y.; Du, Y.; Hartmaier, A.; Zheng, X.; Liu, Y. Optimizing Fatigue Performance in Gradient Structural Steels by Manipulating the Grain Size Gradient Rate. Materials 2024, 17, 3210. https://doi.org/10.3390/ma17133210

Pan M, Chen X, He M, Kong Y, Du Y, Hartmaier A, Zheng X, Liu Y. Optimizing Fatigue Performance in Gradient Structural Steels by Manipulating the Grain Size Gradient Rate. Materials. 2024; 17(13):3210. https://doi.org/10.3390/ma17133210

Chicago/Turabian StylePan, Meichen, Xin Chen, Meiling He, Yi Kong, Yong Du, Alexander Hartmaier, Xiaoyu Zheng, and Yuling Liu. 2024. "Optimizing Fatigue Performance in Gradient Structural Steels by Manipulating the Grain Size Gradient Rate" Materials 17, no. 13: 3210. https://doi.org/10.3390/ma17133210

APA StylePan, M., Chen, X., He, M., Kong, Y., Du, Y., Hartmaier, A., Zheng, X., & Liu, Y. (2024). Optimizing Fatigue Performance in Gradient Structural Steels by Manipulating the Grain Size Gradient Rate. Materials, 17(13), 3210. https://doi.org/10.3390/ma17133210