Analysis of Carrier Transport at Zn1−xSnxOy/Absorber Interface in Sb2(S,Se)3 Solar Cells

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

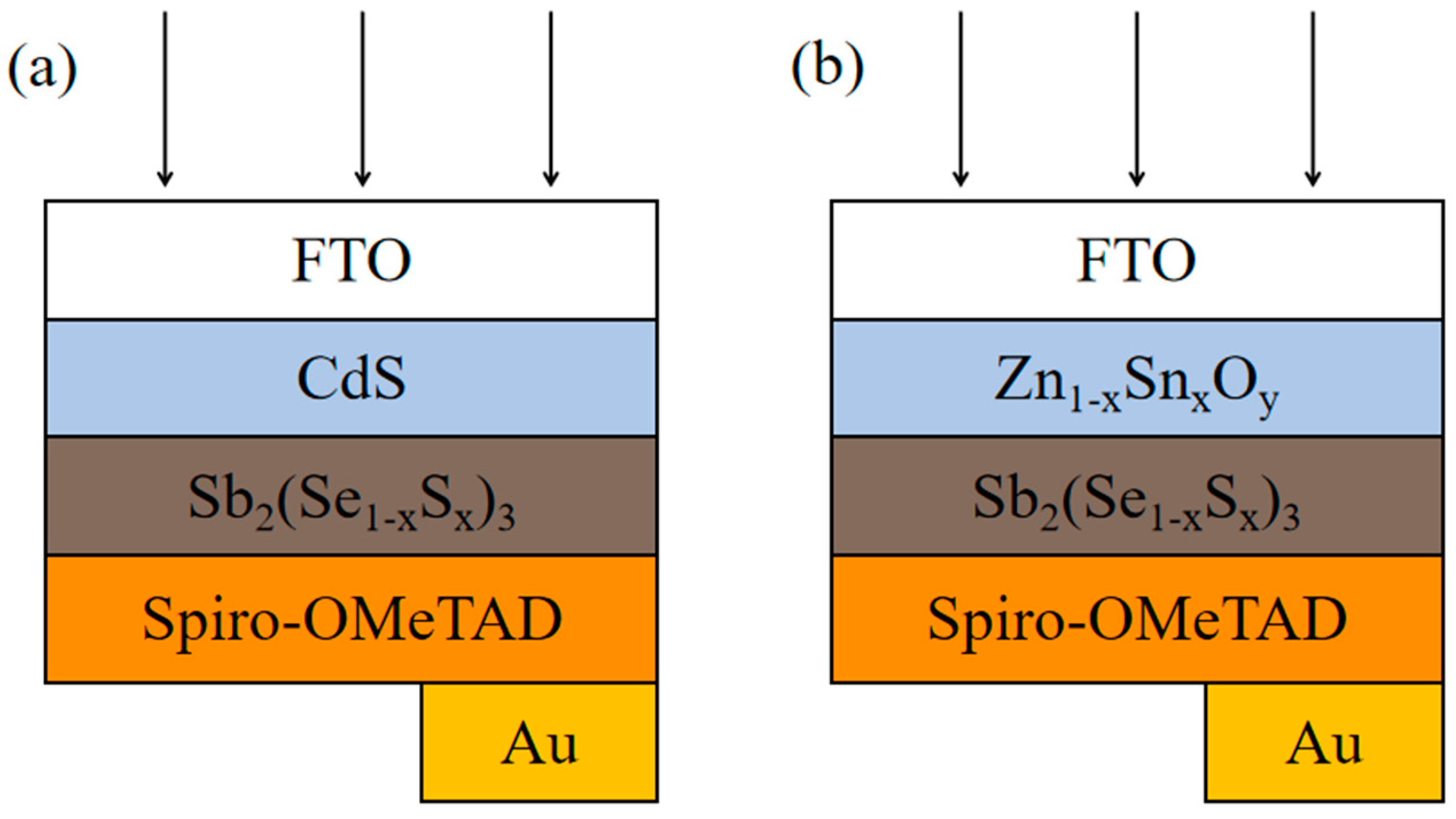

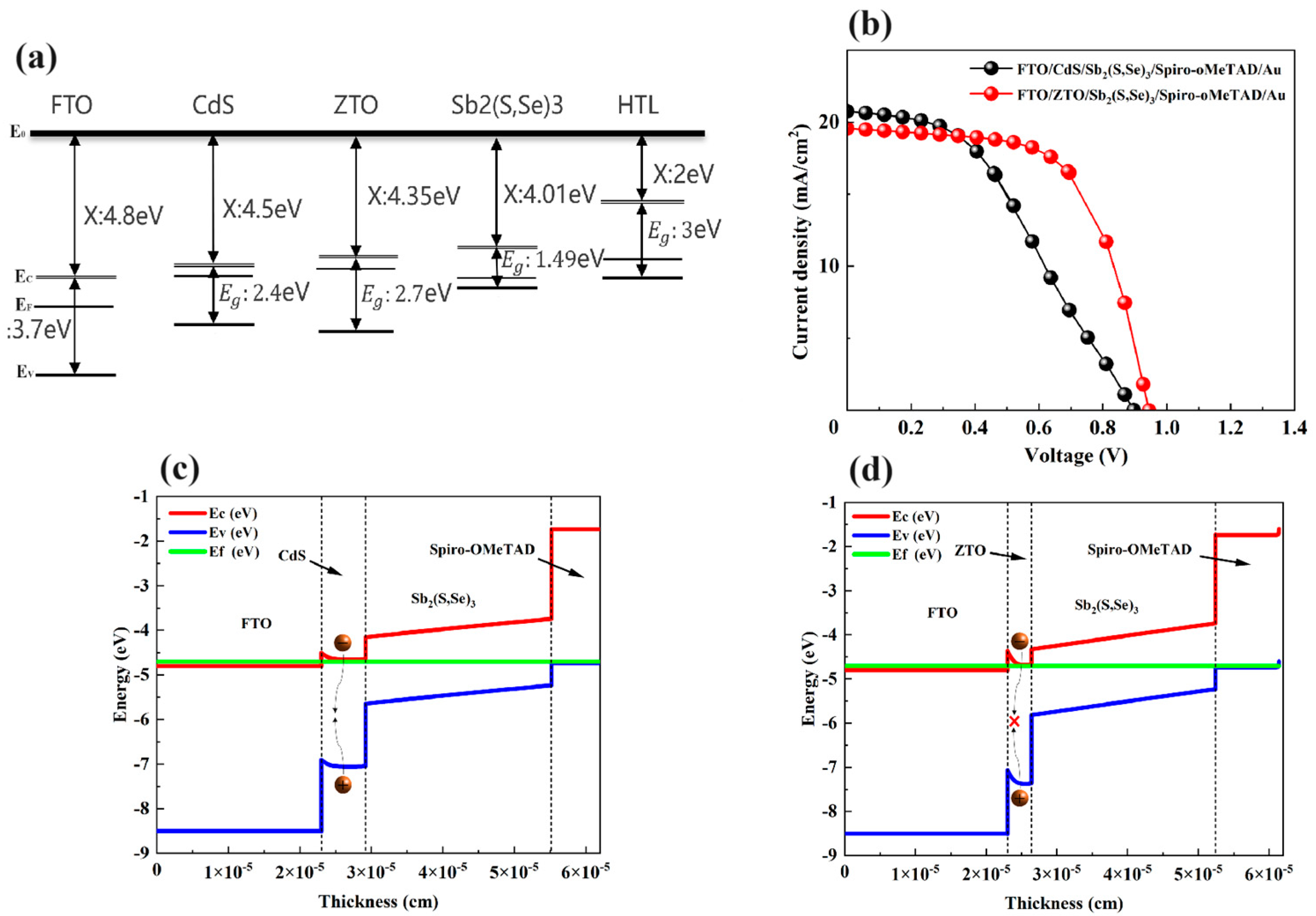

3.1. Impact of ZTO Layer

3.2. Analysis of Photo-Generated Carrier Collection at ZTO/Sb2(S,Se)3 Interface

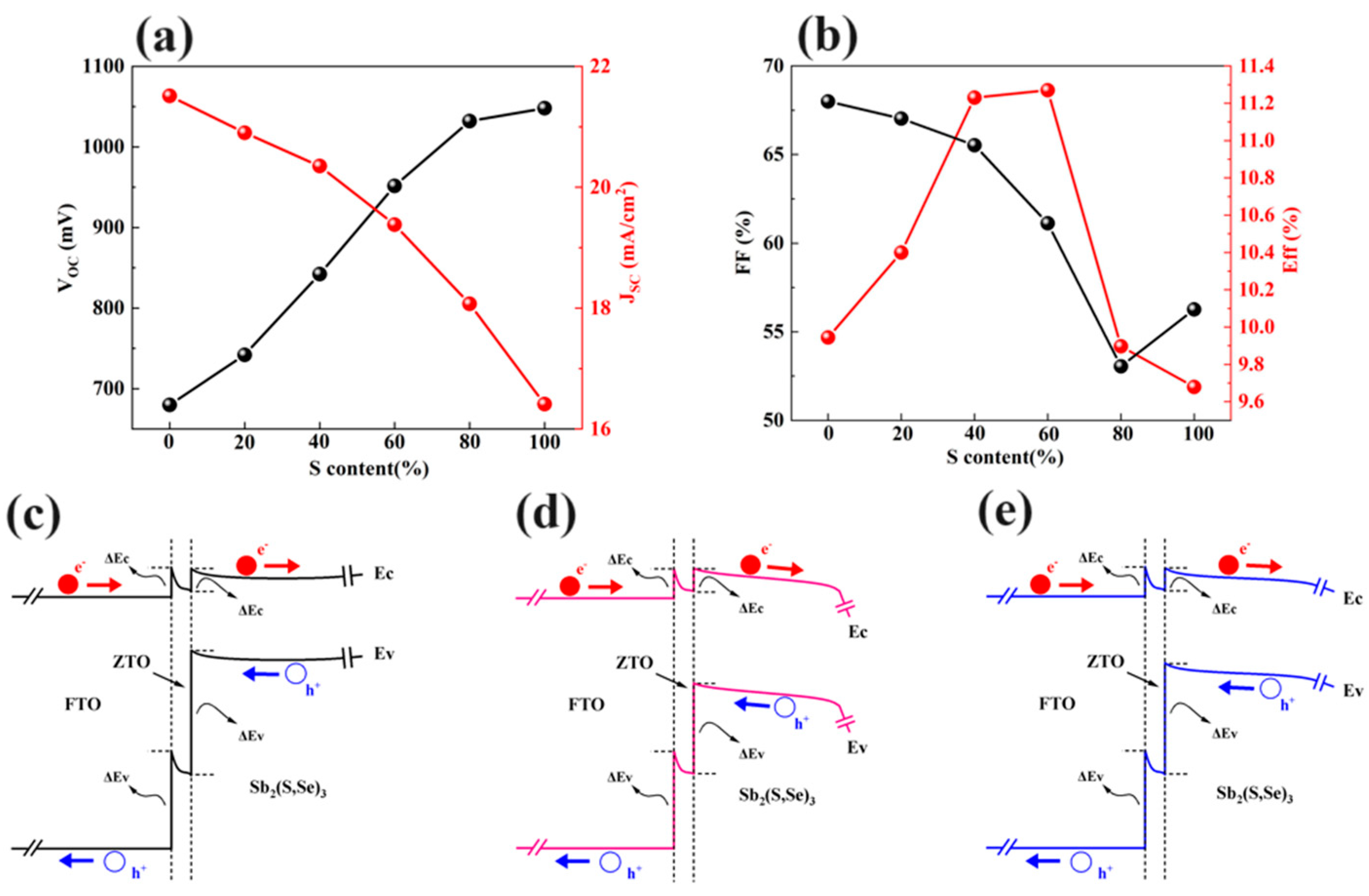

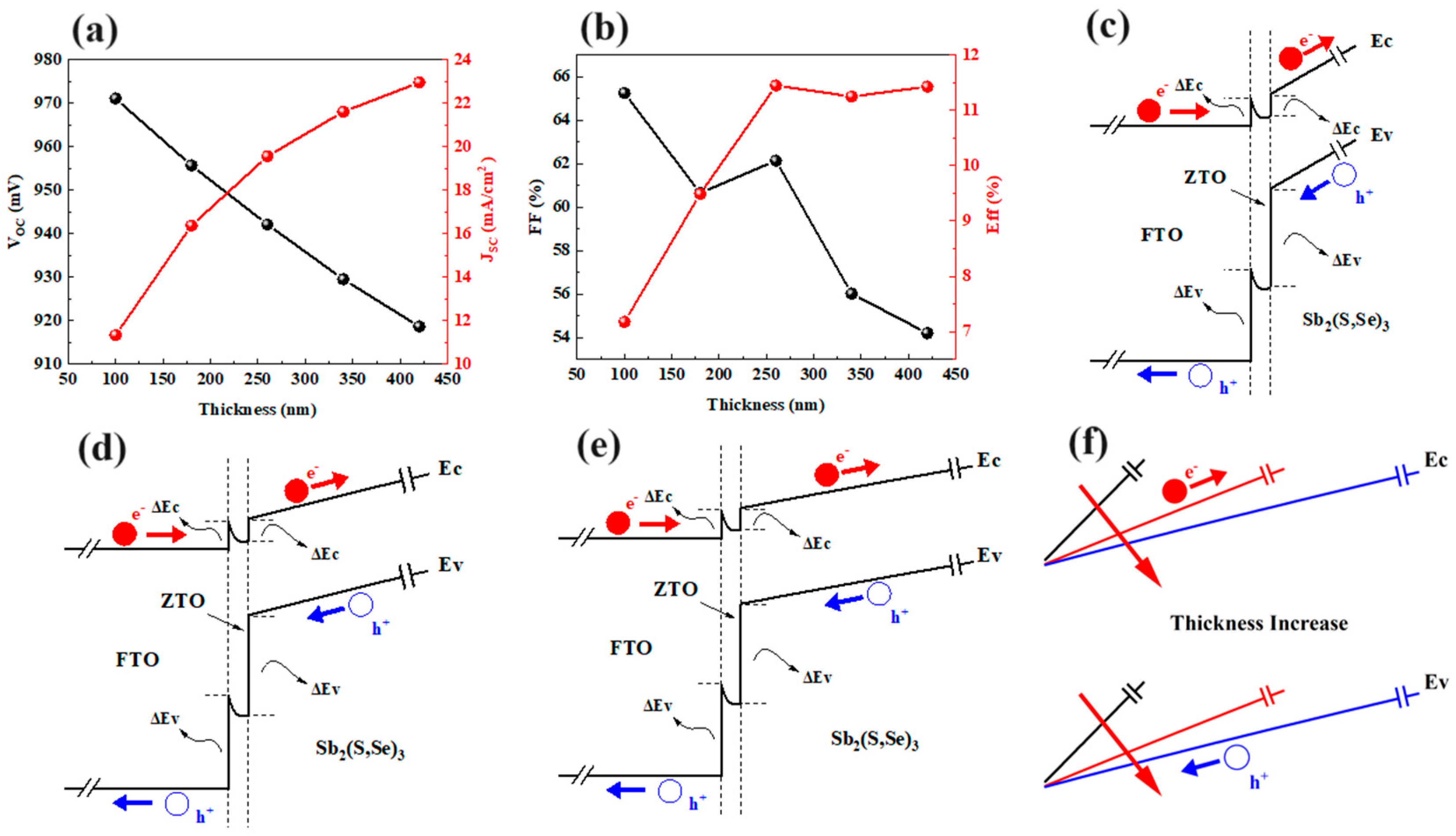

3.2.1. Effect of S Content and Thickness in Absorber Layer

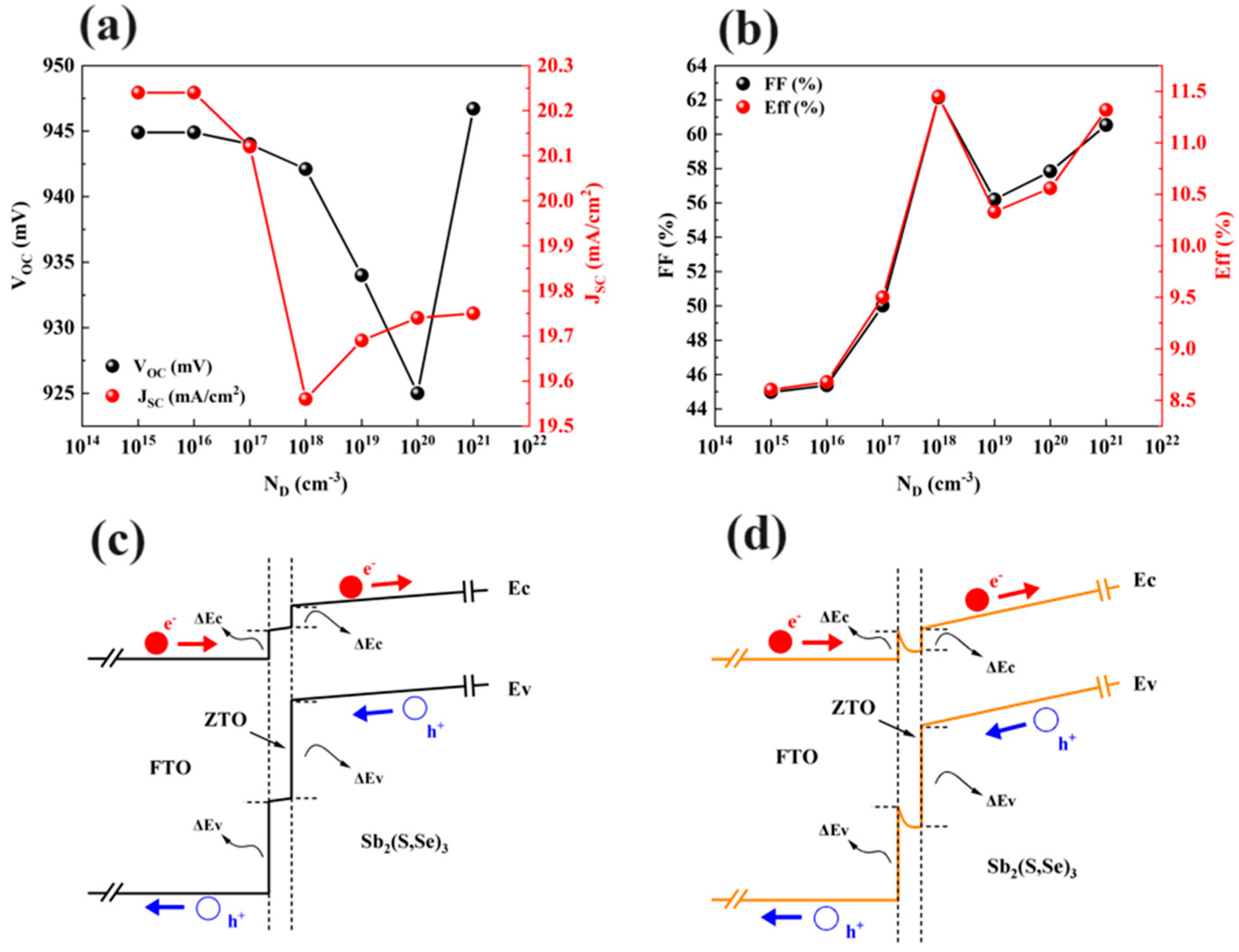

3.2.2. Impact of Carrier Concentration of ZTO Layer

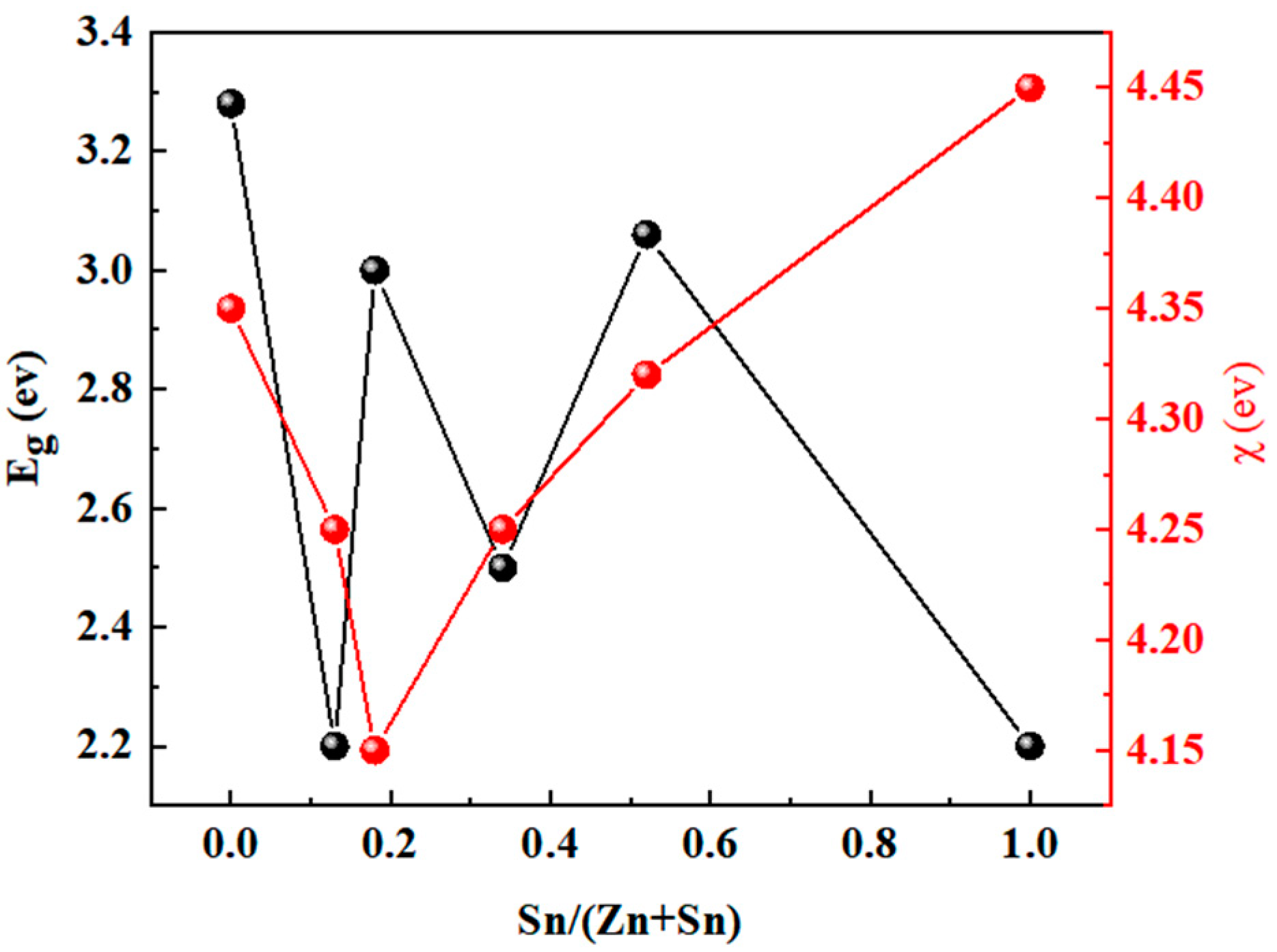

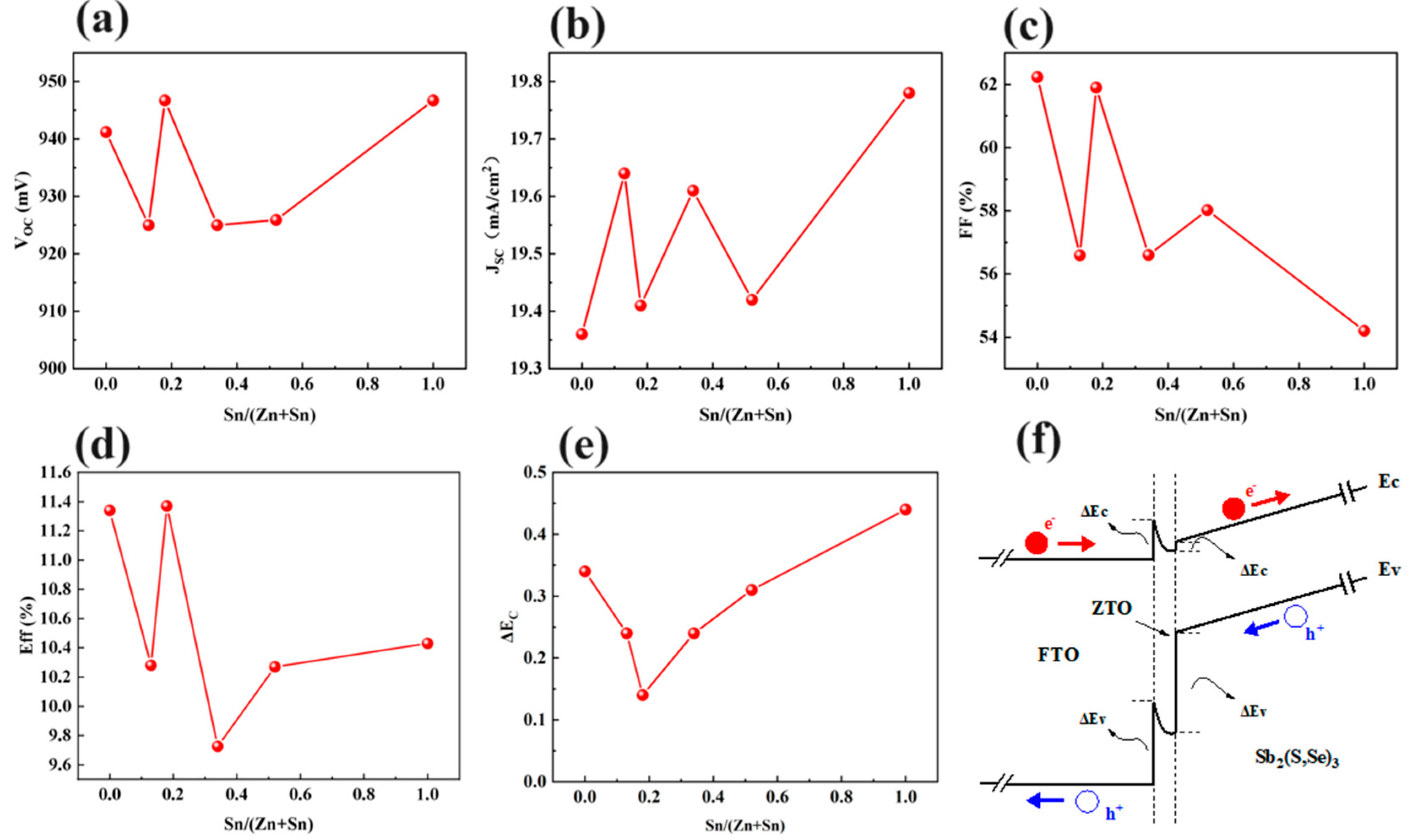

3.2.3. Effect of Sn/(Zn+Sn) Ratio in ZTO

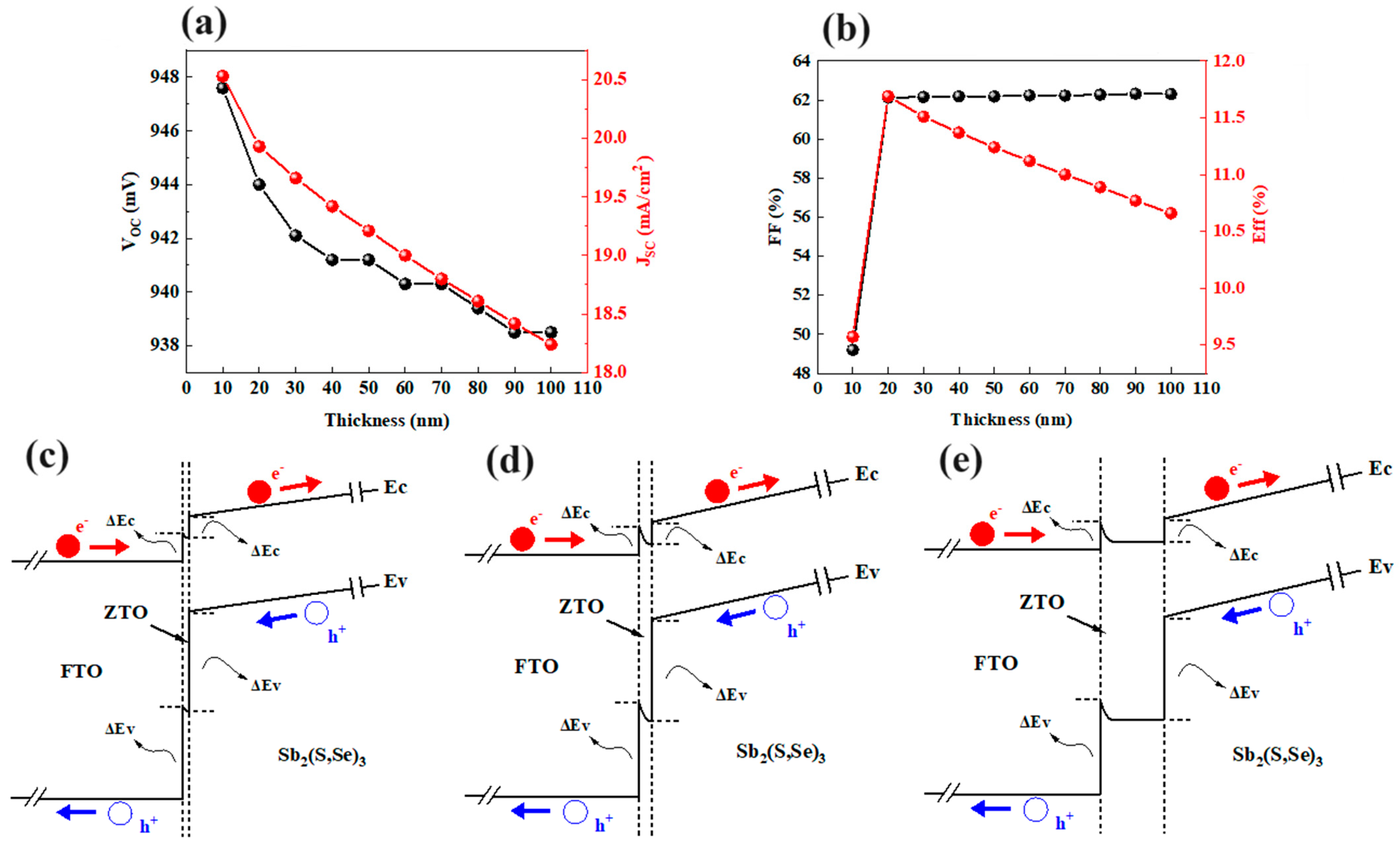

3.2.4. Effect of ZTO Thickness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, G.X.; Li, C.H.; Zhao, J.; Fu, Y.; Yu, Z.X.; Zheng, Z.H.; Su, Z.H.; Fan, P.; Zhang, X.H.; Luo, J.T.; et al. Self-powered broadband kesterite photodetector with ultrahigh specific detectivity for weak light applications. SusMat 2023, 3, 682–696. [Google Scholar] [CrossRef]

- Lei, H.; Chen, J.; Tan, Z.; Fang, G. Review of recent progress in antimony chalcogenide-based solar cells: Materials and devices. Sol. RRL 2019, 3, 1900026. [Google Scholar] [CrossRef]

- Wang, X.; Tang, R.; Wu, C.; Zhu, C.; Chen, T. Development of antimony sulfide-selenide Sb2(S,Se)3-based solar cells. J. Energy Chem. 2018, 27, 713–721. [Google Scholar] [CrossRef]

- Jiang, C.; Zhou, J.; Tang, R.; Lian, W.; Wang, X.; Lei, X.; Zeng, H.; Zhu, C.; Tang, W.; Chen, T. 9.7%-efficient Sb2(S,Se)3 solar cells with a dithieno[3,2-b:2’,3’-d] pyrrolecored hole transporting material. Energy Environ. Sci. 2021, 14, 359–364. [Google Scholar] [CrossRef]

- Yang, B.; Qin, S.K.; Xue, D.J.; Chen, C.; He, Y.S.; Niu, D.M.; Huang, H.; Tang, J. In situ sulfurization to generate Sb2(Se1−xSx)3 alloyed films and their application for photovoltaics. Prog. Photovolt. 2017, 25, 113–122. [Google Scholar] [CrossRef]

- Pan, Y.L.; Hu, X.B.; Guo, Y.X.; Pan, X.Y.; Zhao, F.; Weng, G.E.; Tao, J.H.; Zhao, C.H.; Jiang, J.C.; Chen, S.Q.; et al. Vapor transport deposition of highly efficient Sb2(S,Se)3 solar cells via controllable orientation growth. Adv. Funct. Mater. 2012, 31, 2101476. [Google Scholar] [CrossRef]

- Chen, C.; Yin, Y.W.; Lian, W.T.; Jiang, L.F.; Tang, R.F.; Jiang, C.H.; Wu, C.Y.; Gao, D.; Wang, X.M.; Fang, F.; et al. Pulsed laser deposition of antimony selenosulfide thin film for the efficient solar cells. Appl. Phys. Lett. 2020, 116, 133901. [Google Scholar] [CrossRef]

- Wu, C.Y.; Lian, W.T.; Zhang, L.J.; Ding, H.H.; Jiang, C.H.; Ma, Y.Y.; Han, W.H.; Li, Y.M.; Zhu, J.F.; Chen, T.; et al. Water additive enhanced solution processing of alloy Sb2(S1−xSex)3-based solar cells. Sol. RRL 2020, 4, 1900582. [Google Scholar] [CrossRef]

- Wang, X.M.; Tang, R.F.; Jiang, C.H.; Lian, W.T.; Ju, H.X.; Jiang, G.S.; Li, Z.Q.; Zhu, C.F.; Chen, T. Manipulating the electrical properties of Sb2(S,Se)3 film for high-efficiency solar cell. Adv. Energy Mater. 2020, 10, 2002341. [Google Scholar] [CrossRef]

- Li, S.; Lu, S.C.; Lu, Y.; Xue, J.Y.; Li, K.H.; Chen, C.; Tang, J. Efficient Sb2(S,Se)3 solar cells via monitorable chemical bath deposition. J. Mater. Chem. A 2022, 10, 11625–11635. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Wang, S.Y.; Jiang, C.H.; Li, C.; Xiao, P.; Tang, R.F.; Gong, J.B.; Chen, G.L.; Chen, T.; Li, J.M.; et al. Regulating energy band alignment via alkaline metal fluoride assisted solution post-treatment enabling Sb2(S,Se)3 solar cells with 10.7% efficiency. Adv. Energy Mater. 2021, 12, 2103015. [Google Scholar] [CrossRef]

- Huang, M.L.; Xu, P.; Han, D.; Tang, J.; Chen, S.Y. Complicated and unconventional defect properties of the quasi-one-dimensional photovoltaic semiconductor Sb2Se3. ACS Appl. Mater. Interfaces 2019, 11, 15564–15572. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.S.; Chen, J.; Luo, M.; Leng, M.Y.; Xia, Z.; Zhou, Y.; Qin, S.K.; Xue, D.J.; Lv, L.; Huang, H.; et al. Thermal evaporation and characterization of Sb2Se3 thin film for substrate Sb2Se3/CdS solar cells. ACS Appl. Mater. Interfaces 2014, 6, 10687–10695. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.K.; Sun, X.X.; Li, C.; Xu, R.; Xu, J.; Du, Y.Y.; Wu, Y.X.; Ni, J.; Cai, H.K.; Li, J.; et al. Electron transport layer-free planar perovskite solar cells: Further performance enhancement perspective from device simulation. Sol. Energy Mater. Sol. Cells 2016, 157, 1038–1047. [Google Scholar] [CrossRef]

- Dabbabi, S.; Nasr, T.B.; Kamoun-Turki, N. Parameters optimization of CIGS solar cell using 2D physical modeling. Results Phys. 2017, 7, 4020–4024. [Google Scholar] [CrossRef]

- Gobbo, C.; Di Palma, V.; Trifiletti, V.; Malerba, C.; Valentini, M.; Matacena, L.; Daliento, S.; Binetti, S.; Acciarri, M.; Tseberlidis, G. Effect of the ZnSnO/AZO interface on the charge extraction in Cd-free kesterite solar cells. Energies 2023, 16, 4137. [Google Scholar] [CrossRef]

- Anwar, F.; Mahbub, R.; Satter, S.S.; Ullah, S.M. Effect of different HTM layers and electrical parameters on ZnO nanorod-based lead-free perovskite solar cell for high-efficiency performance. Int. J. Photoenergy 2017, 2017, 9846310. [Google Scholar] [CrossRef]

- Azri, F.; Meftah, A.; Sengouga, N.; Meftah, A. Electron and hole transport layers optimization by numerical simulation of a perovskite solar cell. Sol. Energy 2019, 181, 372–378. [Google Scholar] [CrossRef]

- Nicolas-Marin, M.M.; Ayala-Mato, F.; Vigil-Galan, O.; Courel, M. Simulation analysis of Cd1−xZnXS/Sb2(Se1−xSX)3 solar cells with n-i-p structure. Sol. Energy 2021, 224, 245–252. [Google Scholar] [CrossRef]

- Saadat, M.; Amiri, O. Fine adjusting of charge carriers transport in absorber/HTL interface in Sb2(S,Se)3 solar cells. Sol. Energy 2022, 243, 163–173. [Google Scholar] [CrossRef]

- Jimenez, T.; Seuret-Jimenez, D.; Vigil-Galan, O.; Basurto-Pensado, M.A.; Courel, M. Sb2(S1−xSeX)3 solar cells: The impact of radiative and non-radiative loss mechanisms. J. Phys. D Appl. Phys. 2018, 51, 435501. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Shin, S.; Jin, Z.; Min, Y.S. Band structure of amorphous zinc tin oxide thin films deposited by atomic layer deposition. J. Ind. Eng. Chem. 2018, 58, 328–333. [Google Scholar] [CrossRef]

- Shaker, A.; Salem, M.S.; Jayan, K.D. Analysis and design of p-n homojunction Sb2Se3 solar cells by numerical simulation. Sol. Energy 2022, 242, 276–286. [Google Scholar] [CrossRef]

- Wang, W.H.; Yao, L.Q.; Dong, J.B.; Wu, L.; Cao, Z.X.; Hui, L.; Chen, G.L.; Luo, J.S.; Zhang, Y. Interface modification uncovers the potential application of SnO2/TiO2 double electron transport layer in efficient cadmium-free Sb2Se3 devices. Adv. Mater. Interfaces 2022, 9, 2102464. [Google Scholar] [CrossRef]

| Parameters | FTO | Sb2(S,Se)3 | Spiro-oMeTAD | CdS | ZTO |

|---|---|---|---|---|---|

| Thickness (nm) | 230 | 260 | 90 | 62 | 34 |

| εr | 9 | 14.38 | 3 | 10 | 9 |

| χ (eV) | 4.8 | 4.01 | 2 | 4.5 | 4.35 |

| Eg (eV) | 3.7 | 1.49 | 3 | 2.4 | 2.7 |

| NC (cm−3) | 2.2 × 1018 | 2.2 × 1018 | 2.5 × 1018 | 2.2 × 1018 | 2.2 × 1018 |

| NV (cm−3) | 1.8 × 1019 | 1.8 × 1020 | 1.8 × 1019 | 1.8 × 1019 | 1.8 × 1019 |

| µe (cm2/V.s) | 20 | 14 | 1.0 × 10−4 | 100 | 30 |

| µh (cm2/V.s) | 10 | 2.6 | 2.0 × 10−4 | 25 | 5 |

| NA (cm−3) | – | 1.0 × 1014 | 5.0 × 1018 | – | 10 |

| ND (cm−3) | 1.0 × 1020 | – | – | 4.0 × 1017 | 1015–1021 |

| Vth,e (cm/s) | 1.0 × 107 | 1.0 × 107 | 1.0 × 1018 | 1.0 × 107 | 1.0 × 107 |

| Vth,p (cm/s) | 1.0 × 107 | 1.0 × 107 | 1.0 × 1018 | 1.0 × 107 | 1.0 × 107 |

| FTO | Sb2(S,Se)3 | Spiro-oMeTAD | CdS | ZTO | ||

|---|---|---|---|---|---|---|

| Defect 1 | Defect 2 | |||||

| Defect Type | Single Acceptor | Single Acceptor | Single Acceptor | Single Acceptor | Single Donor | Single Neutral |

| Nt | 1.0 × 1015 | 1.3 × 1014 | 1.0 × 1015 | 1.0 × 1018 | 1.0 × 1014 | 3.0 × 1017 |

| σe(cm2) | 1.0 × 10−15 | 1.99 × 10−14 | 1.99 × 10−14 | 1.0 × 10−15 | 3.0 × 10−15 | 1.0 × 10−14 |

| σh(cm2) | 1.0 × 10−15 | 1.99 × 10−14 | 1.99 × 10−14 | 1.0 × 10−15 | 2.0 × 10−14 | 1.0 × 10−15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Xu, Z.; Guo, Y.; Chen, C.; Zhao, X.; Chen, X.; Hu, J.; Liang, G. Analysis of Carrier Transport at Zn1−xSnxOy/Absorber Interface in Sb2(S,Se)3 Solar Cells. Materials 2024, 17, 3214. https://doi.org/10.3390/ma17133214

Lin J, Xu Z, Guo Y, Chen C, Zhao X, Chen X, Hu J, Liang G. Analysis of Carrier Transport at Zn1−xSnxOy/Absorber Interface in Sb2(S,Se)3 Solar Cells. Materials. 2024; 17(13):3214. https://doi.org/10.3390/ma17133214

Chicago/Turabian StyleLin, Junhui, Zhijie Xu, Yingying Guo, Chong Chen, Xiaofang Zhao, Xuefang Chen, Juguang Hu, and Guangxing Liang. 2024. "Analysis of Carrier Transport at Zn1−xSnxOy/Absorber Interface in Sb2(S,Se)3 Solar Cells" Materials 17, no. 13: 3214. https://doi.org/10.3390/ma17133214