Effective Non-Radiative Interfacial Recombination Suppression Scenario Using Air Annealing for Antimony Triselenide Thin-Film Solar Cells

Abstract

1. Introduction

2. Experimental Details

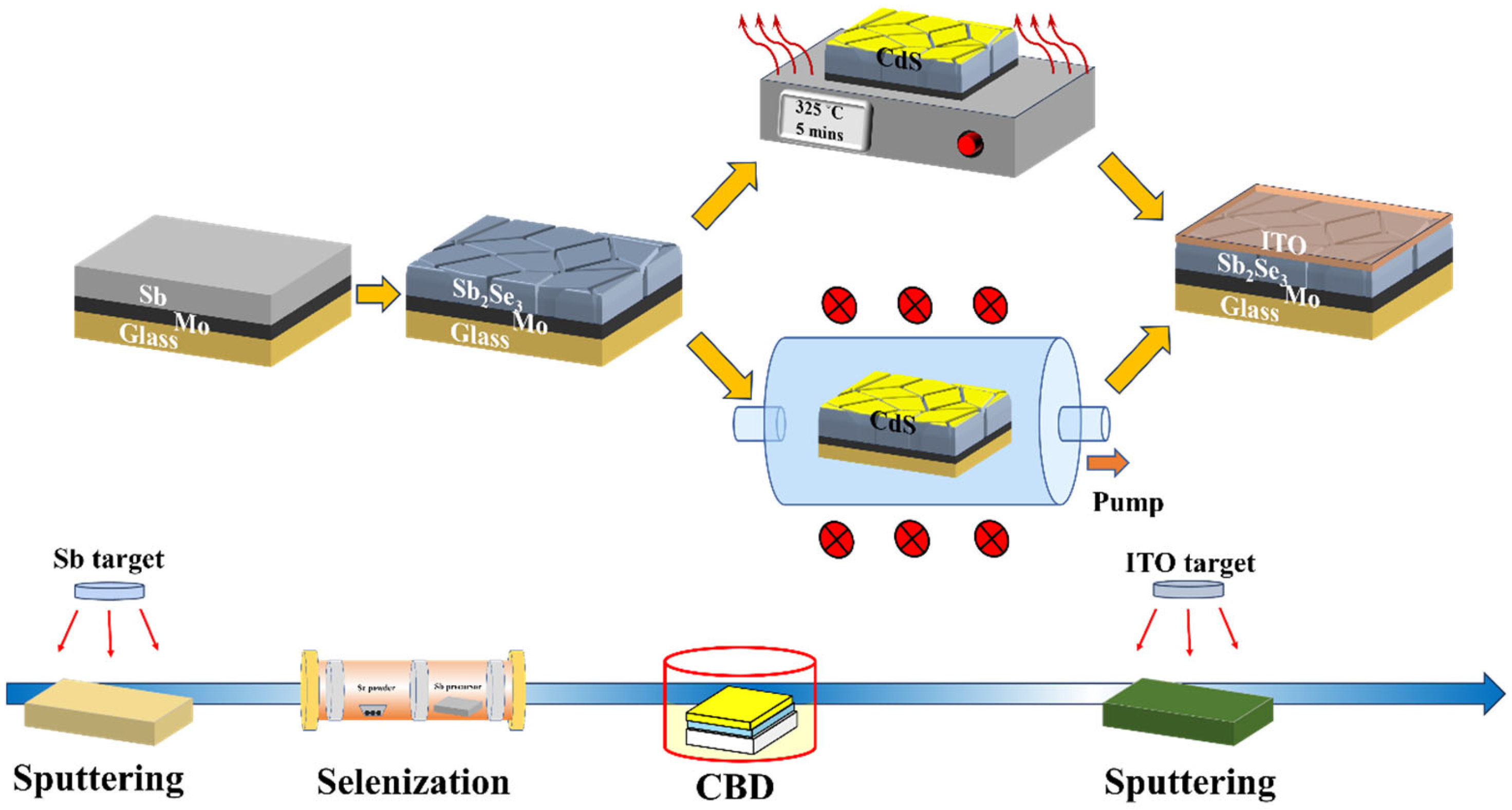

2.1. Preparation of Sb2Se3 Thin Film

2.2. Assemble of Sb2Se3 Thin-Film Solar Cells

2.3. Characterizations

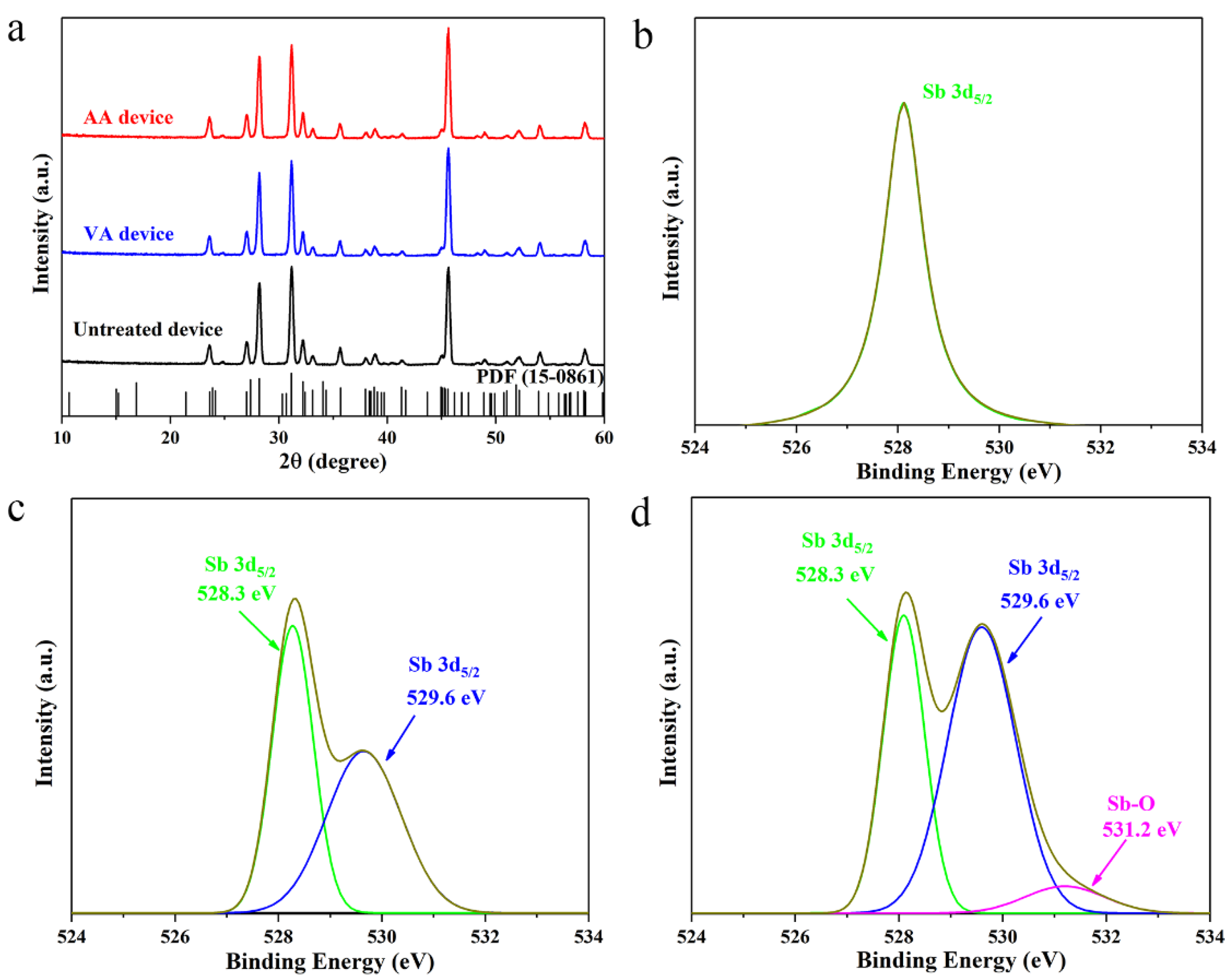

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pourasl, H.H.; Barenji, R.V.; Khojastehnezhad, V.M. Solar energy status in the world: A comprehensive review. Energy Rep. 2023, 10, 3474–3493. [Google Scholar] [CrossRef]

- Yu, Y.L.; Bai, X.J.; Li, S.Y.; Shi, J.H.; Wang, L.; Xi, F.S.; Ma, W.H.; Deng, R. Review of silicon recovery in the photovoltaic industry. Curr. Opin. Green Sust. 2023, 44, 100870. [Google Scholar] [CrossRef]

- Ranjan, S.; Balaji, S.; Panella, R.A.; Ydstie, B.E. Silicon solar cell production. Comput. Chem. Eng. 2011, 35, 1439–1453. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X. Solar cell efficiency tables (version 63). Prog. Photovolt. Res. Appl. 2023, 32, 3–13. [Google Scholar] [CrossRef]

- Metaferia, W.; Schulte, K.L.; Simon, J.; Johnston, S.; Ptak, A.J. Gallium arsenide solar cells grown at rates exceeding 300 µm h−1 by hydride vapor phase epitaxy. Nat. Commun. 2019, 10, 3361. [Google Scholar] [CrossRef] [PubMed]

- Radziemska, E. Thermal performance of Si and GaAs based solar cells and modules: A review. Prog. Energy Combust. Sci. 2003, 29, 407–424. [Google Scholar] [CrossRef]

- Chowdhury, T.A.; Zafar, M.B.; Islam, M.; Shahinuzzaman, M.; Islam, M.A.; Khandaker, M.U. Stability of perovskite solar cells: Issues and prospects. RSC Adv. 2023, 13, 1787–1810. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.X.; Niu, X.X.; Chen, Q.; Zhou, H.P. Towards commercialization: The operational stability of perovskite solar cells. Chem. Soc. Rev. 2020, 49, 8235–8286. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, J.W.; Jung, H.S.; Shin, H.; Park, N.G. High-efficiency perovskite solar cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef]

- Tian, J.J.; Xue, Q.F.; Yao, Q.; Li, N.; Brabec, C.J.; Yip, H.L. Inorganic halide perovskite solar cells: Progress and challenges. Adv. Energy Mater. 2020, 10, 2000183. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, S.Y.; Qin, S.K.; Liu, X.S.; Chen, J.; Xue, D.J.; Luo, M.; Cao, Y.Z.; Cheng, Y.B. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat. Photon. 2015, 9, 409. [Google Scholar] [CrossRef]

- Tang, R.; Zheng, Z.H.; Su, Z.H.; Li, X.J.; Wei, Y.D.; Zhang, X.H.; Fu, Y.Q.; Luo, J.T.; Fan, P.; Liang, G.X. Highly efficient and stable planar heterojunction solar cell based on sputtered and post-selenized Sb2Se3 thin film. Nano Energy 2019, 64, 103929. [Google Scholar] [CrossRef]

- Wen, X.X.; Chen, C.; Lu, S.C.; Li, K.H.; Kondrotas, R.; Zhao, Y.; Chen, W.H.; Gao, L.; Wang, C.; Zhang, J. Vapor transport deposition of antimony selenide thin film solar cells with 7.6% efficiency. Nat. Commun. 2018, 9, 2179. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Q.; Liang, X.Y.; Li, G.; Liu, H.X.; Zhang, H.Y.; Guo, J.X.; Chen, J.W.; Shen, K.; San, X.Y.; Yu, W. 9.2%-efficient core-shell structured antimony selenide nanorod array solar cells. Nat. Commun. 2019, 10, 125. [Google Scholar] [CrossRef] [PubMed]

- Li, K.H.; Chen, C.; Lu, S.C.; Wang, C.; Wang, S.Y.; Lu, Y.; Tang, J. Orientation engineering in low-dimensional crystal-structural materials via seed screening. Adv. Mater. 2019, 31, 1903914. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Liang, X.; Liu, T.; Liu, Y.; Yang, L.; Lai, W.; Schropp, R.E.I.; Song, D.; Mai, Y.; Li, Z. 1D/3D Alloying Induced Phase Transition in Light Absorbers for Highly Efficient Sb2Se3 Solar Cells. Sol. RRL 2020, 4, 2000054. [Google Scholar] [CrossRef]

- Tang, R.; Chen, S.; Zheng, Z.H.; Su, Z.H.; Luo, J.T.; Fan, P.; Zhang, X.H.; Tang, J.; Liang, G.X. Heterojunction annealing enabling record open-circuit voltage in antimony triselenide solar cells. Adv. Mater. 2022, 34, 2109078. [Google Scholar] [CrossRef] [PubMed]

- Cong, L.; Shen, K.; Lin, D.X.; Cao, Y.; Qiu, S.D.; Zheng, J.Z.; Bao, F.X.; Gao, Y.Y.; Zhu, H.B.; Li, Z.Q. Back Contact Interfacial Modification in Highly-Efficient All Inorganic Planar n-i-p Sb2Se3 Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 38397–38405. [Google Scholar]

- Luo, Y.D.; Tang, R.; Chen, S.; Hu, J.G.; Liu, Y.K.; Li, Y.F.; Liu, X.S.; Zheng, Z.H.; Su, Z.H.; Ma, X.F. An effective combination reaction involved with sputtered and selenized Sb precursors for efficient Sb2Se3 thin film solar cells. Chem. Eng. J. 2020, 393, 124599. [Google Scholar] [CrossRef]

- Liang, X.Y.; Guo, C.S.; Liu, T.; Liu, Y.F.; Yang, L.; Song, D.Y.; Shen, K.; Schropp, R.E.I.; Li, Z.Q.; Mai, Y.H. Crystallographic Orientation Control of 1D Sb2Se3 Nanorod Arrays for Photovoltaic Application by In Situ Back-Contact Engineering. Sol. RRL 2020, 4, 2000294. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.B.; Li, K.H.; Chen, C.; Deng, H.X.; Gao, L.; Zhao, Y.; Jiang, F.; Li, L.Y.; Huang, F. Stable 6%-efficient Sb2Se3 solar cells with a ZnO buffer layer. Nat. Energy 2017, 2, 17046. [Google Scholar] [CrossRef]

- Liu, T.; Liang, X.Y.; Liu, Y.F.; Li, X.L.; Wang, S.F.; Mai, Y.H.; Li, Z.Q. Conduction Band Energy-Level Engineering for Improving Open-Circuit Voltage in Antimony Selenide Nanorod Array Solar Cells. Adv. Sci. 2021, 8, 2100868. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhang, X.T.; Chen, H.B.; Tang, Z.Q.; Meng, D.; Chi, K.L.; Cai, Y.M.; Song, G.X.; Cao, Y.; Hu, Z.Y. Dual-function of CdCl2 treated SnO2 in Sb2Se3 solar cells. Appl. Surf. Sci. 2020, 534, 147632. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Wang, S.Y.; Li, C.A.; Che, B.; Chen, X.L.; Chen, H.Y.; Tang, R.F.; Wang, X.M.; Chen, G.L.; Wang, T. Regulating deposition kinetics via a novel additive-assisted chemical bath deposition technology enables fabrication of 10.57%-efficiency Sb2Se3 solar cells. Energy Environ. Sci. 2022, 15, 5118–5128. [Google Scholar] [CrossRef]

- Xue, D.J.; Shi, H.J.; Tang, J. Recent progress in material study and photovoltaic device of Sb2Se3. Acta Phys. Sin. 2015, 64, 038406. [Google Scholar]

- Yan, C.; Huang, J.L.; Sun, K.W.; Johnston, S.; Zhang, Y.F.; Sun, H.; Pu, A.B.; He, M.R.; Liu, F.Y.; Eder, K. Cu2ZnSnS4 solar cells with over 10% power conversion efficiency enabled by heterojunction heat treatment. Nat. Energy 2018, 3, 764. [Google Scholar] [CrossRef]

- Su, Z.H.; Liang, G.X.; Fan, P.; Luo, J.T.; Zheng, Z.H.; Xie, Z.G.; Wang, W.; Chen, S.; Hu, J.G.; Wei, Y.D. Device postannealing enabling over 12% efficient solution-processed Cu2ZnSnS4 solar cells with Cd2+ substitution. Adv. Mater. 2020, 32, 2000121. [Google Scholar] [CrossRef] [PubMed]

- Niu, X.; Zhu, H.; Liang, X.; Guo, Y.; Li, Z.; Mai, Y. Air-annealing of Cu(In, Ga)Se2/CdS and performances of CIGS solar cells. Appl. Surf. Sci. 2017, 426, 1213–1220. [Google Scholar] [CrossRef]

- Gao, S.S.; Zhang, Y.; Ao, J.P.; Li, X.L.; Qiao, S.A.; Wang, Y.; Lin, S.P.; Zhang, Z.J.; Wang, D.X.; Zhou, Z.Q. Insight into the role of post-annealing in air for high efficient Cu2ZnSn(S, Se)4 solar cells. Sol. Energy Mater. Sol. Cells. 2018, 182, 228–236. [Google Scholar] [CrossRef]

- Liu, X.S.; Chen, C.; Wang, L.; Zhong, J.; Luo, M.; Chen, J.; Xue, D.J.; Li, D.B.; Zhou, Y.; Tang, J. Improving the performance of Sb2Se3 thin film solar cells over 4% by controlled addition of oxygen during film deposition. Prog. Photovolt. Res. Appl. 2015, 23, 1828–1836. [Google Scholar] [CrossRef]

- Jakomin, R.; Rampino, S.; Spaggiari, G.; Casappa, M.; Trevisi, G.; Canale, E.D.; Gombia, E.; Bronzoni, M.; Sossoe, K.K.; Mezzadri, F. Cu-Doped Sb2Se3 Thin-Film Solar Cells Based on Hybrid Pulsed Electron Deposition/Radio Frequency Magnetron Sputtering Growth Techniques. Solar 2024, 4, 83–98. [Google Scholar] [CrossRef]

- Liu, D.; Tang, R.F.; Ma, Y.Y.; Jiang, C.H.; Lian, W.T.; Li, G.; Han, W.H.; Zhu, C.F.; Chen, T. Direct hydrothermal deposition of antimony triselenide films for efficient planar heterojunction solar cells. ACS Appl. Mater. Interfaces 2021, 13, 18856–18864. [Google Scholar] [CrossRef] [PubMed]

- Lian, W.T.; Jiang, C.H.; Yin, Y.W.; Tang, R.F.; Li, G.; Zhang, L.J.; Che, B.; Chen, T. Revealing composition and structure dependent deep-level defect in antimony trisulfide photovoltaics. Nat. Commun. 2021, 12, 3260. [Google Scholar] [CrossRef] [PubMed]

- Liang, G.X.; Luo, Y.D.; Chen, S.; Tang, R.; Zheng, Z.H.; Li, X.J.; Liu, X.S.; Liu, Y.K.; Li, Y.F.; Chen, X.Y. Sputtered and selenized Sb2Se3 thin-film solar cells with open-circuit voltage exceeding 500 mV. Nano Energy 2020, 73, 104806. [Google Scholar] [CrossRef]

- Gong, Y.C.; Qiu, R.C.; Niu, C.Y.; Fu, J.J.; Jedlicka, E.; Giridharagopal, R.; Zhu, Q.; Zhou, Y.G.; Yan, W.B.; Yu, S.T. Ag incorporation with controlled grain growth enables 12.5% efficient kesterite solar cell with open circuit voltage reached 64.2% Shockley–Queisser limit. Adv. Funct. Mater. 2021, 31, 2101927. [Google Scholar] [CrossRef]

- Weiss, T.P.; Bacho, I.M.; Zuccalà, E.; Melchiorre, M.; Valle, N.; Adib, B.E.; Yokosawa, T.; Spiecker, E.; Bachmann, J.; Dale, P.J. Post-deposition annealing and interfacial atomic layer deposition buffer layers of Sb2Se3/CdS stacks for reduced interface recombination and increased open-circuit voltages. Prog. Photovolt. Res. Appl. 2023, 31, 203–219. [Google Scholar] [CrossRef]

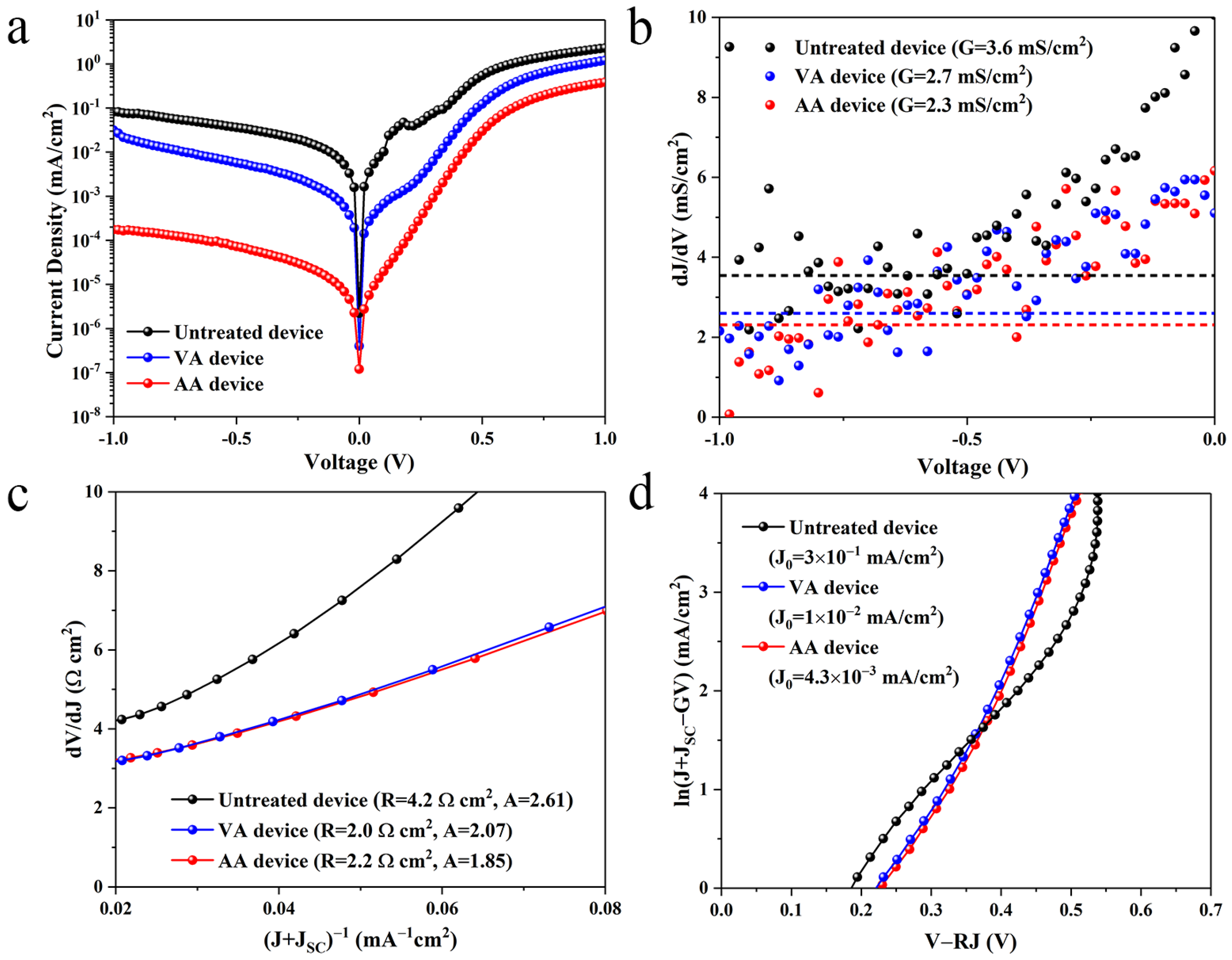

| Device | VOC (V) | JSC (mA/cm2) | FF (%) | PCE (%) | RS (Ω·cm2) | A | J0 (A/cm2) |

|---|---|---|---|---|---|---|---|

| Untreated device | 0.450 | 18.99 | 51.49 | 4.40 | 4.2 | 2.61 | 3 × 10−1 |

| VA device | 0.481 | 23.93 | 60.12 | 6.92 | 2.0 | 2.07 | 1 × 10−2 |

| AA device | 0.517 | 24.80 | 59.44 | 7.62 | 2.2 | 1.85 | 4.3 × 10−3 |

| Device | NCV (cm−3) | NDLCP (cm−3) | Ni (cm−3) | Wd (nm) |

|---|---|---|---|---|

| Untreated device | 3.44 × 1015 | 1.32 × 1014 | 3.31 × 1015 | 231 |

| VA device | 3.87 × 1015 | 2.93 × 1015 | 9.40 × 1014 | 238 |

| AA device | 1.17 × 1015 | 7.10 × 1014 | 4.60 × 1014 | 294 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, R.; Hu, W.; Hu, C.; Duan, C.; Hu, J.; Liang, G. Effective Non-Radiative Interfacial Recombination Suppression Scenario Using Air Annealing for Antimony Triselenide Thin-Film Solar Cells. Materials 2024, 17, 3222. https://doi.org/10.3390/ma17133222

Tang R, Hu W, Hu C, Duan C, Hu J, Liang G. Effective Non-Radiative Interfacial Recombination Suppression Scenario Using Air Annealing for Antimony Triselenide Thin-Film Solar Cells. Materials. 2024; 17(13):3222. https://doi.org/10.3390/ma17133222

Chicago/Turabian StyleTang, Rong, Wenyong Hu, Changji Hu, Chunyan Duan, Juguang Hu, and Guangxing Liang. 2024. "Effective Non-Radiative Interfacial Recombination Suppression Scenario Using Air Annealing for Antimony Triselenide Thin-Film Solar Cells" Materials 17, no. 13: 3222. https://doi.org/10.3390/ma17133222

APA StyleTang, R., Hu, W., Hu, C., Duan, C., Hu, J., & Liang, G. (2024). Effective Non-Radiative Interfacial Recombination Suppression Scenario Using Air Annealing for Antimony Triselenide Thin-Film Solar Cells. Materials, 17(13), 3222. https://doi.org/10.3390/ma17133222