A Novel Technique for Improving Cyclic Behavior of Steel Connections Equipped with Smart Memory Alloys

Abstract

:1. Introduction

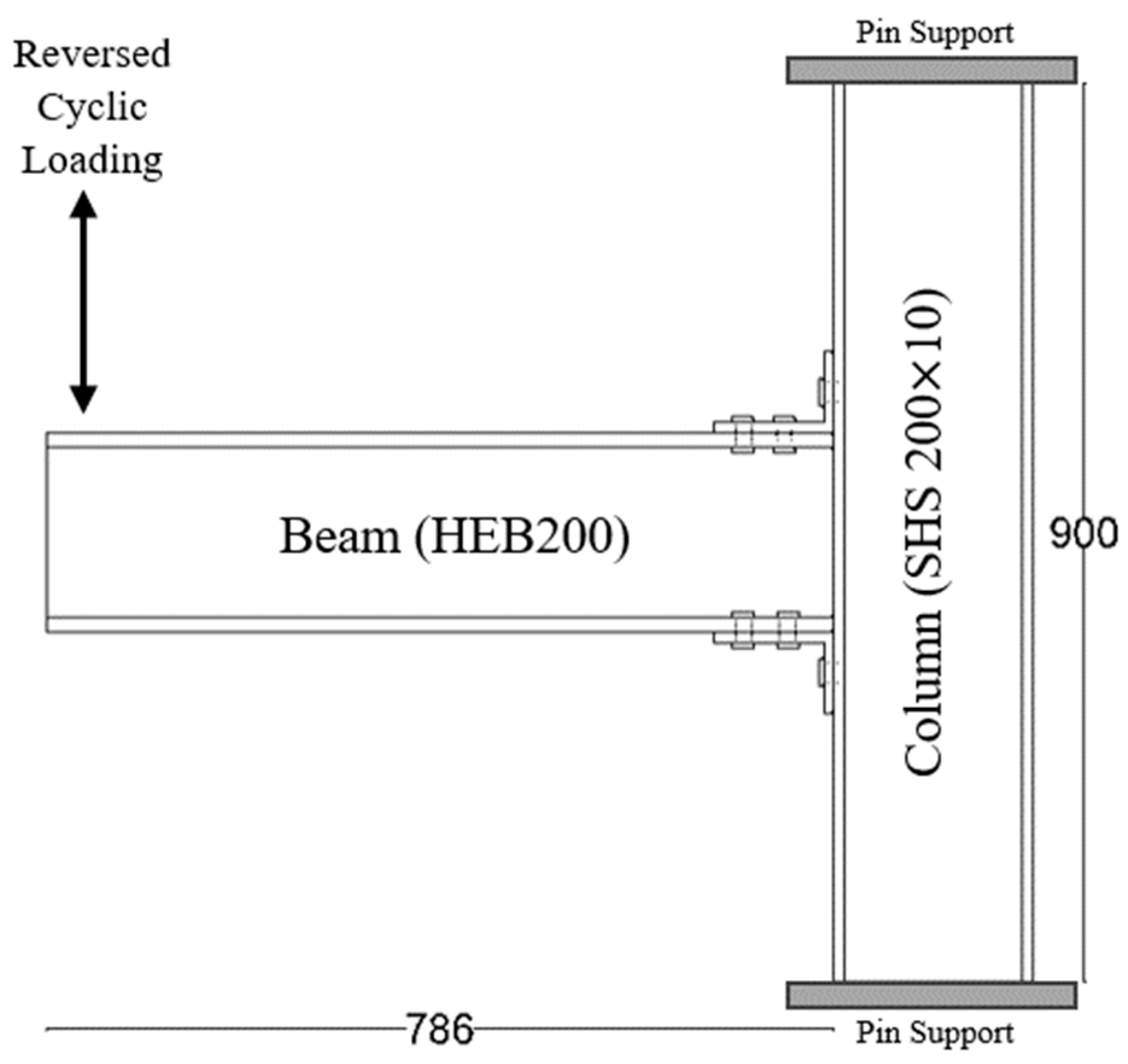

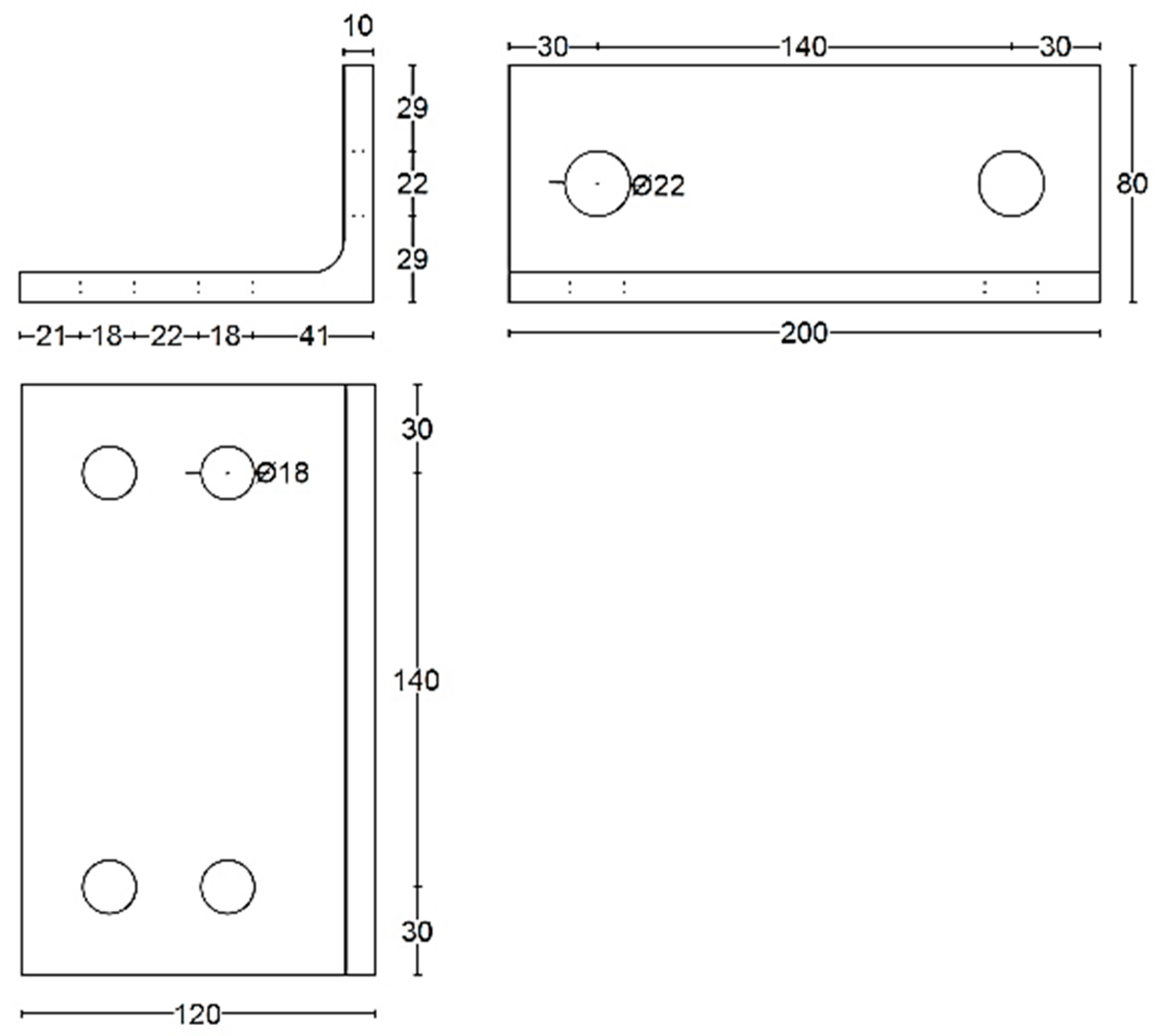

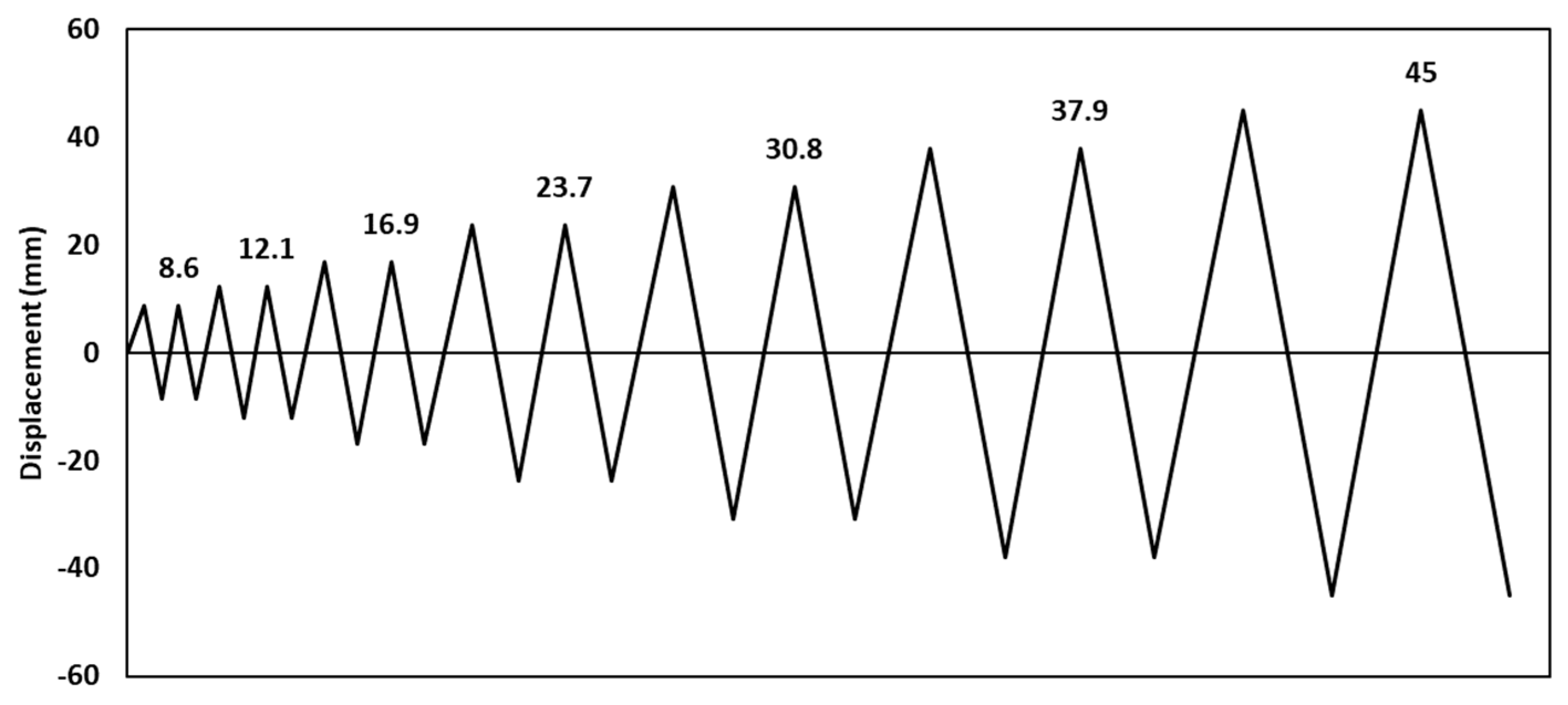

2. Experimental Reference

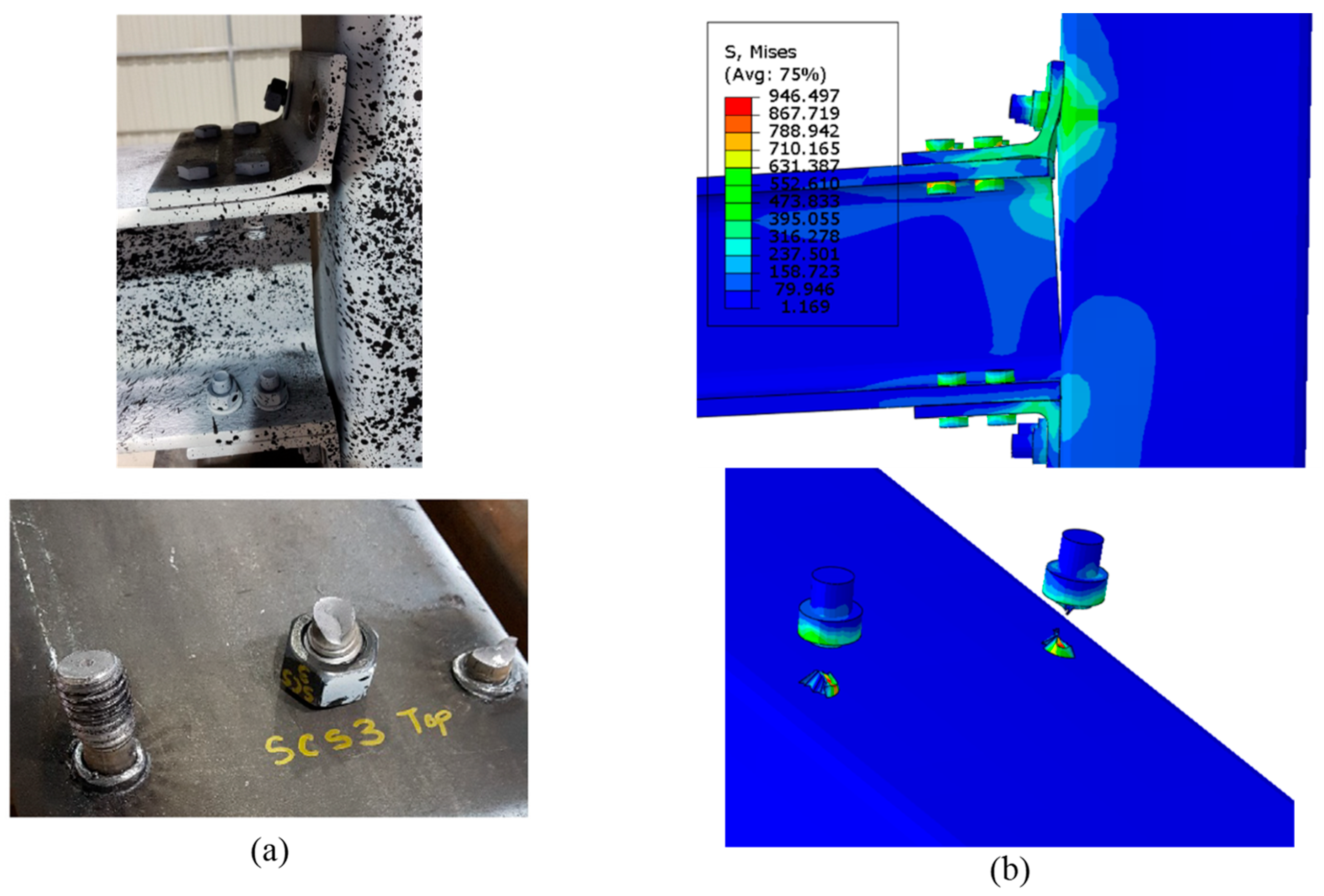

3. Finite Element Modelling

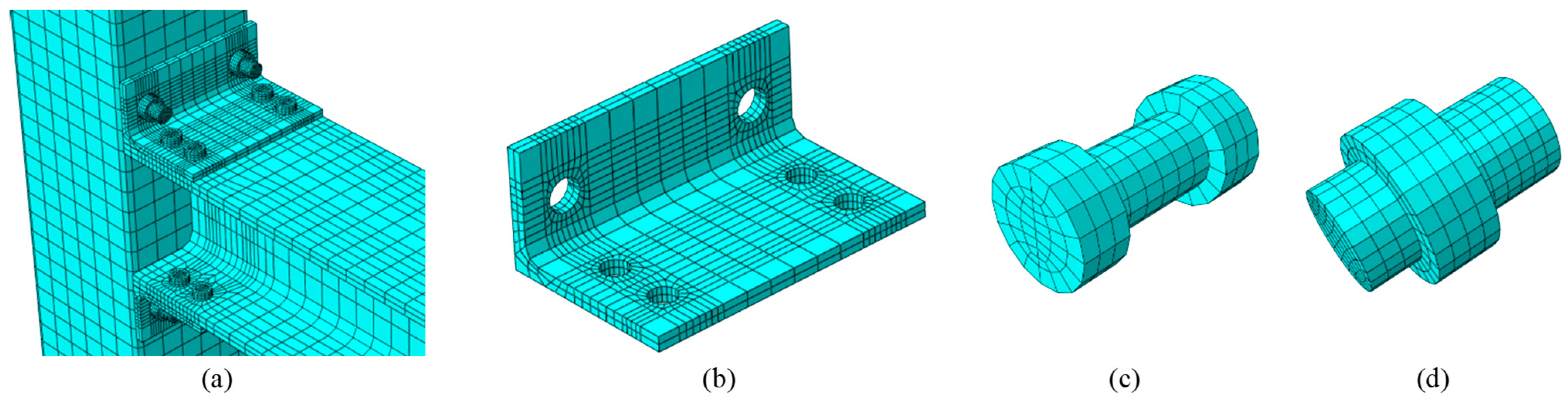

3.1. Elements, Interactions, and Boundary Conditions

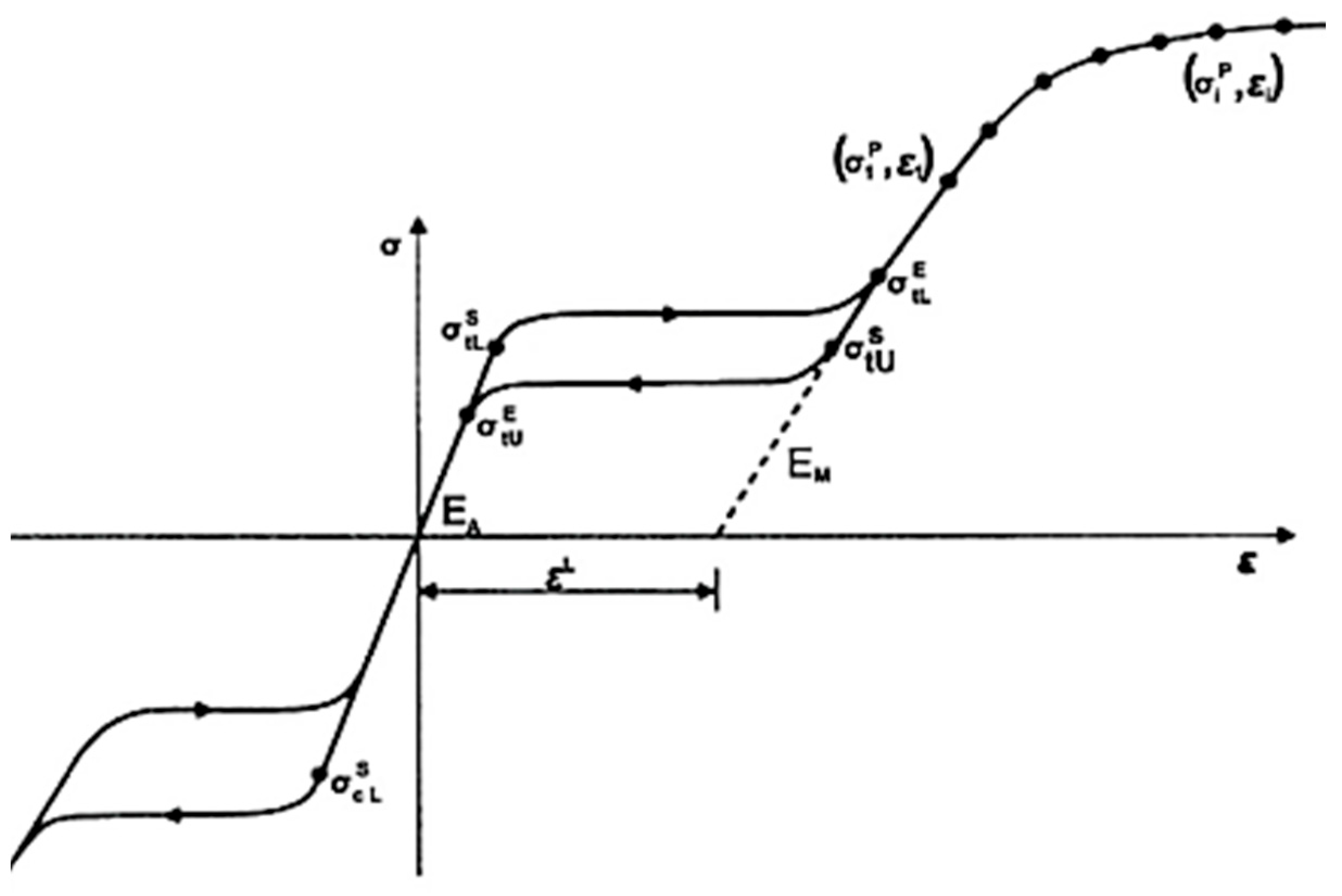

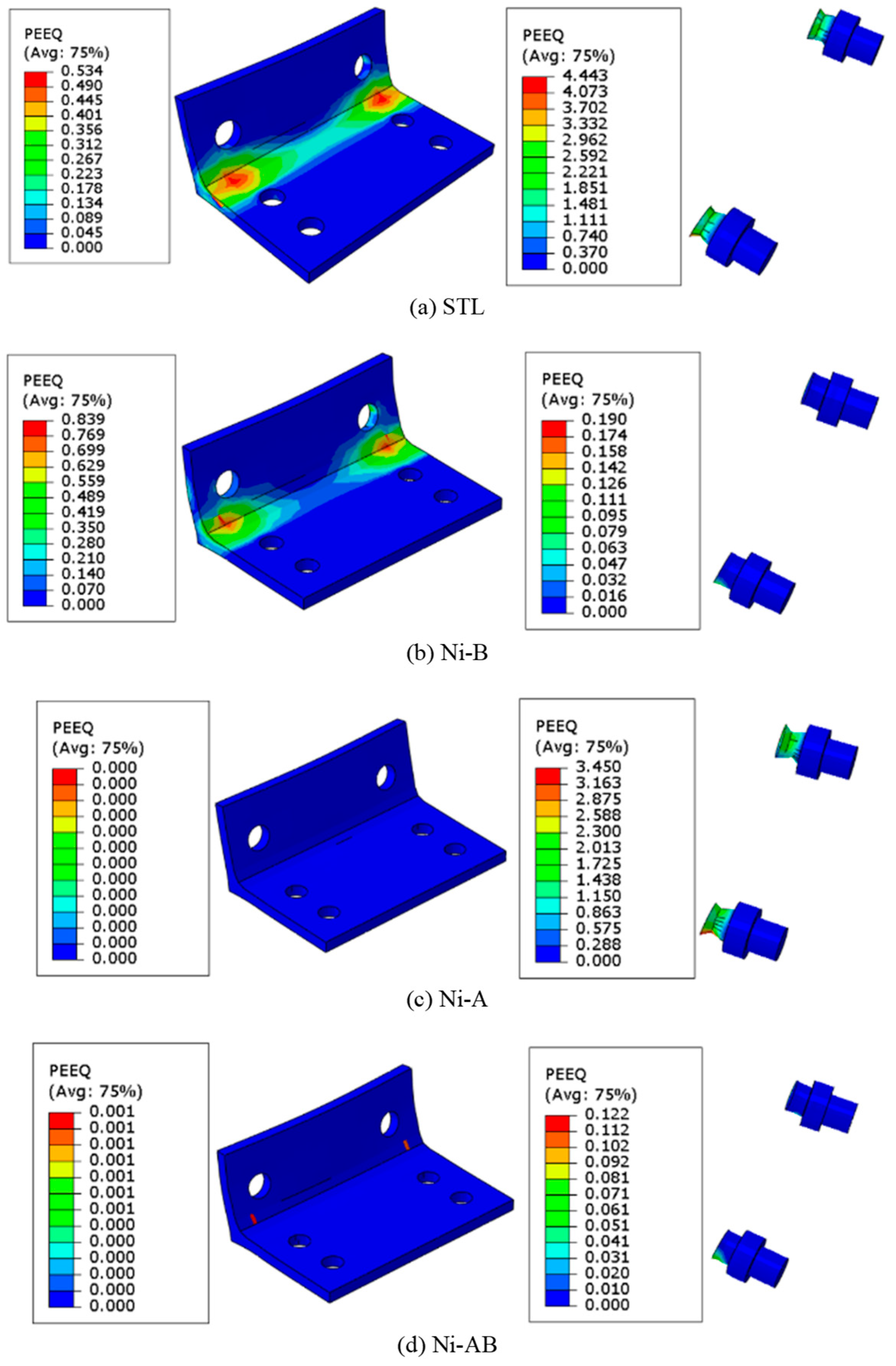

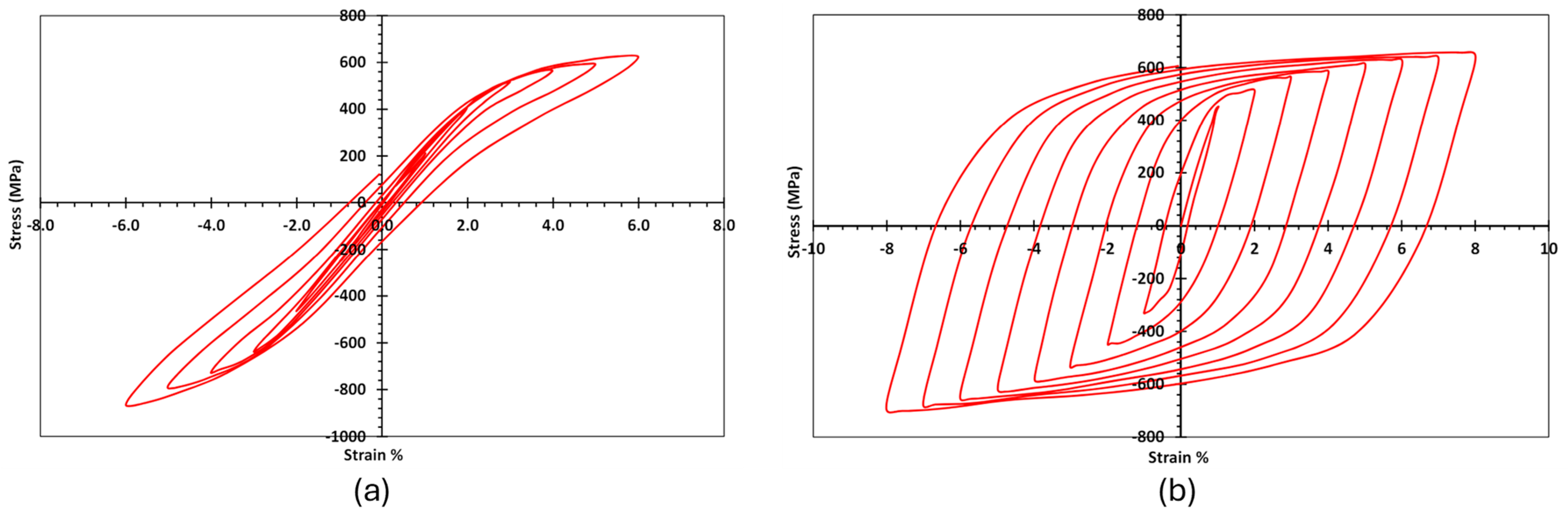

3.2. Material Models

4. Validation of the FE Model

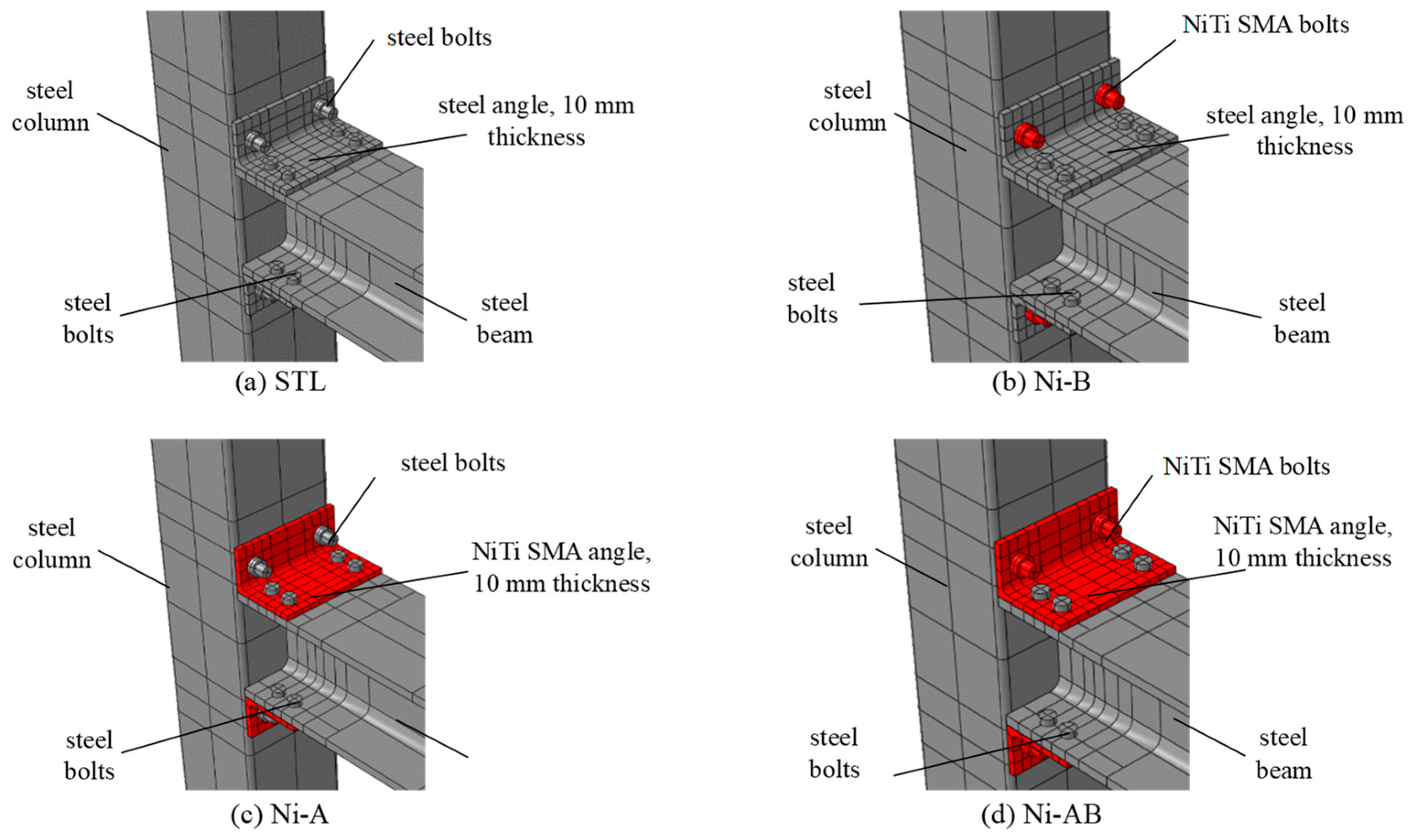

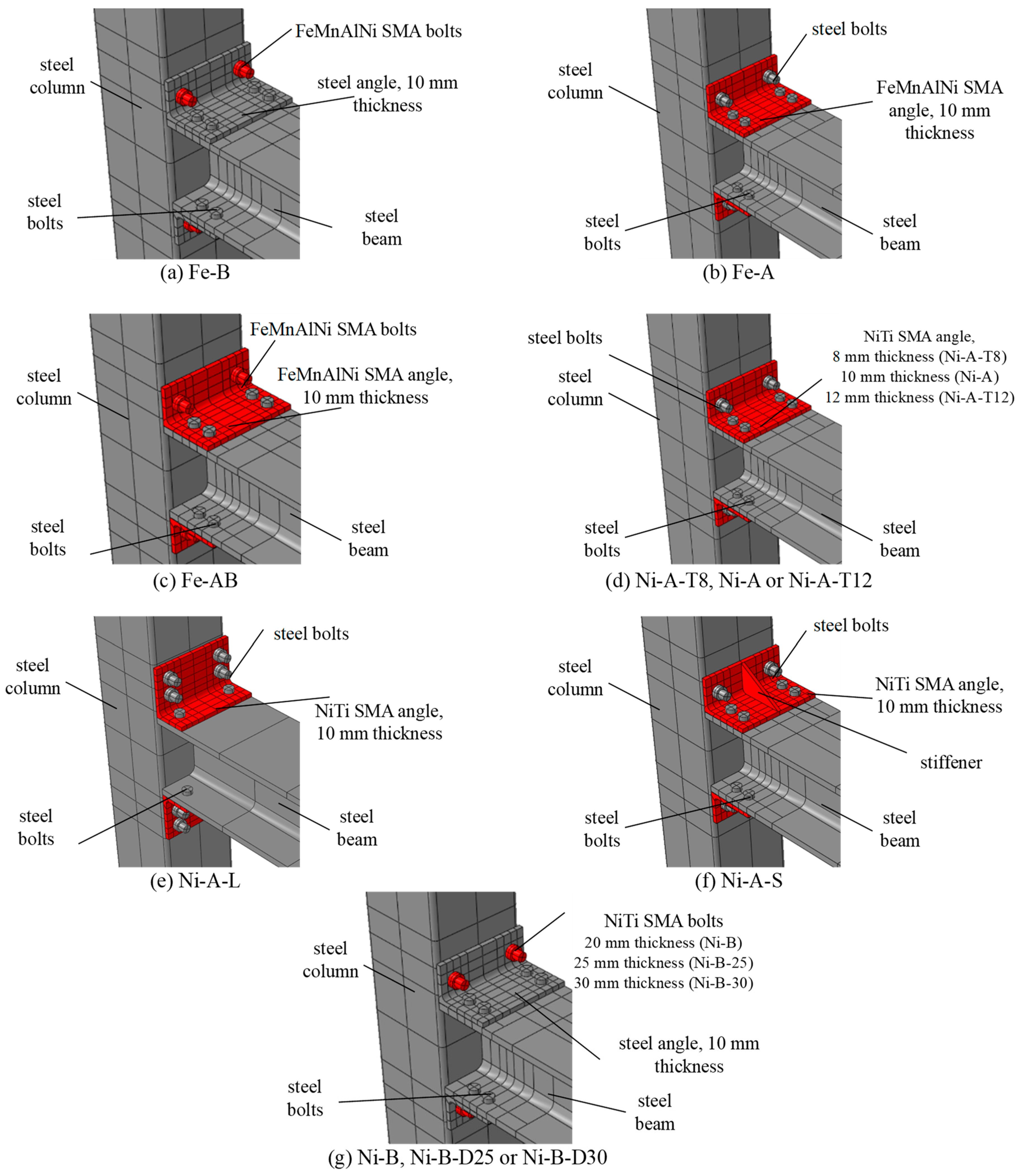

5. Numerical Study

6. Numerical Results

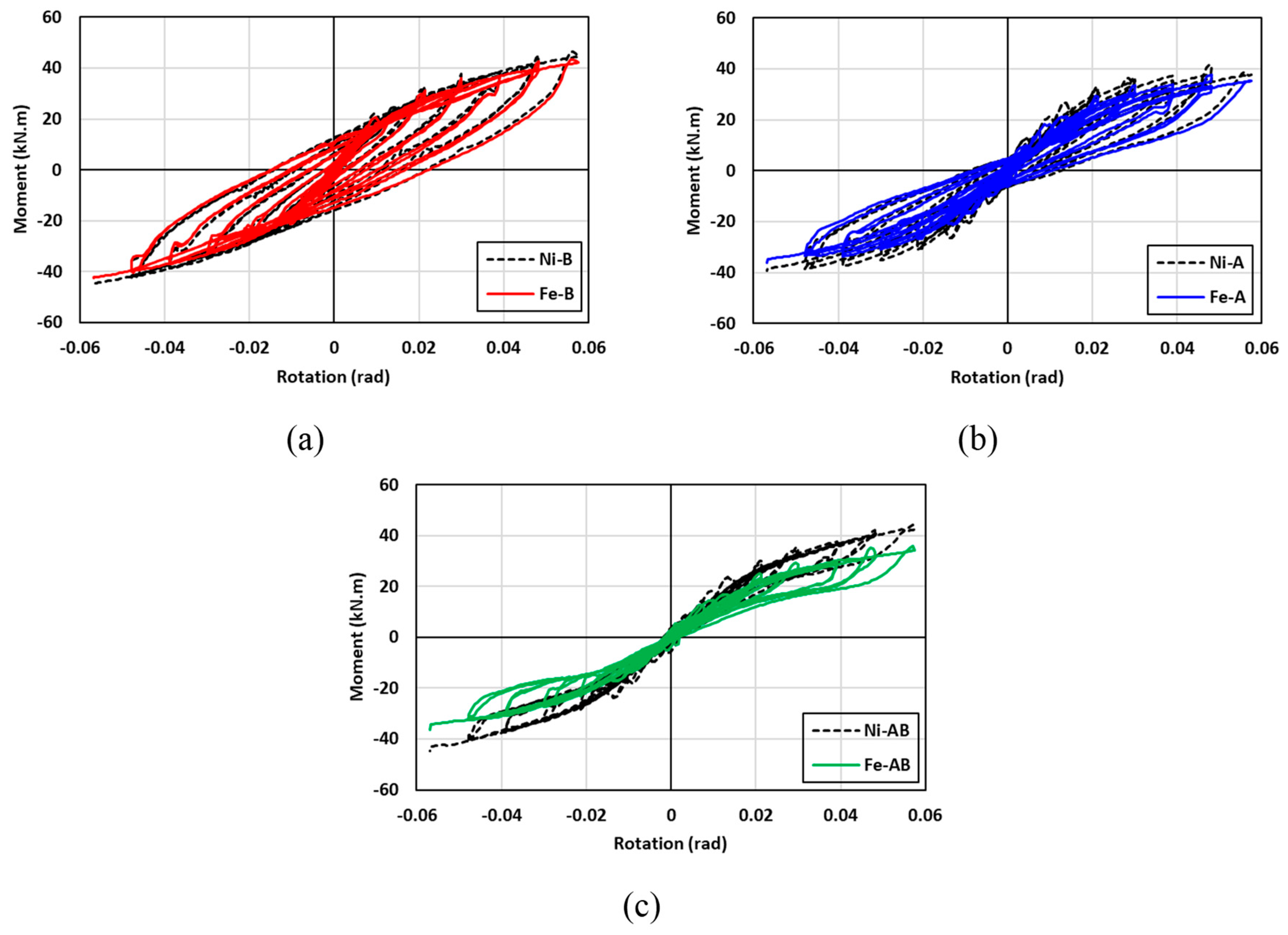

6.1. Hysteretic Response

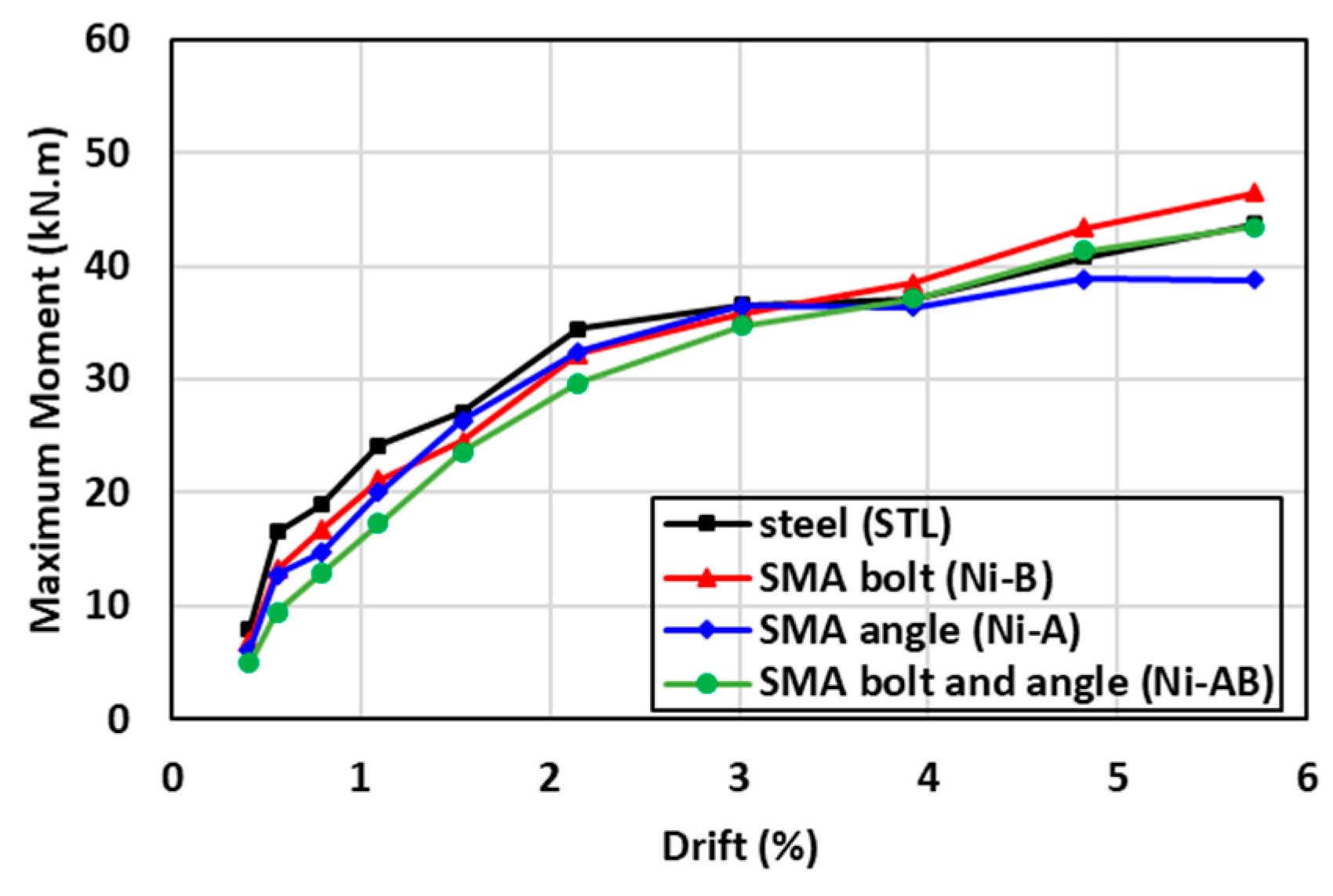

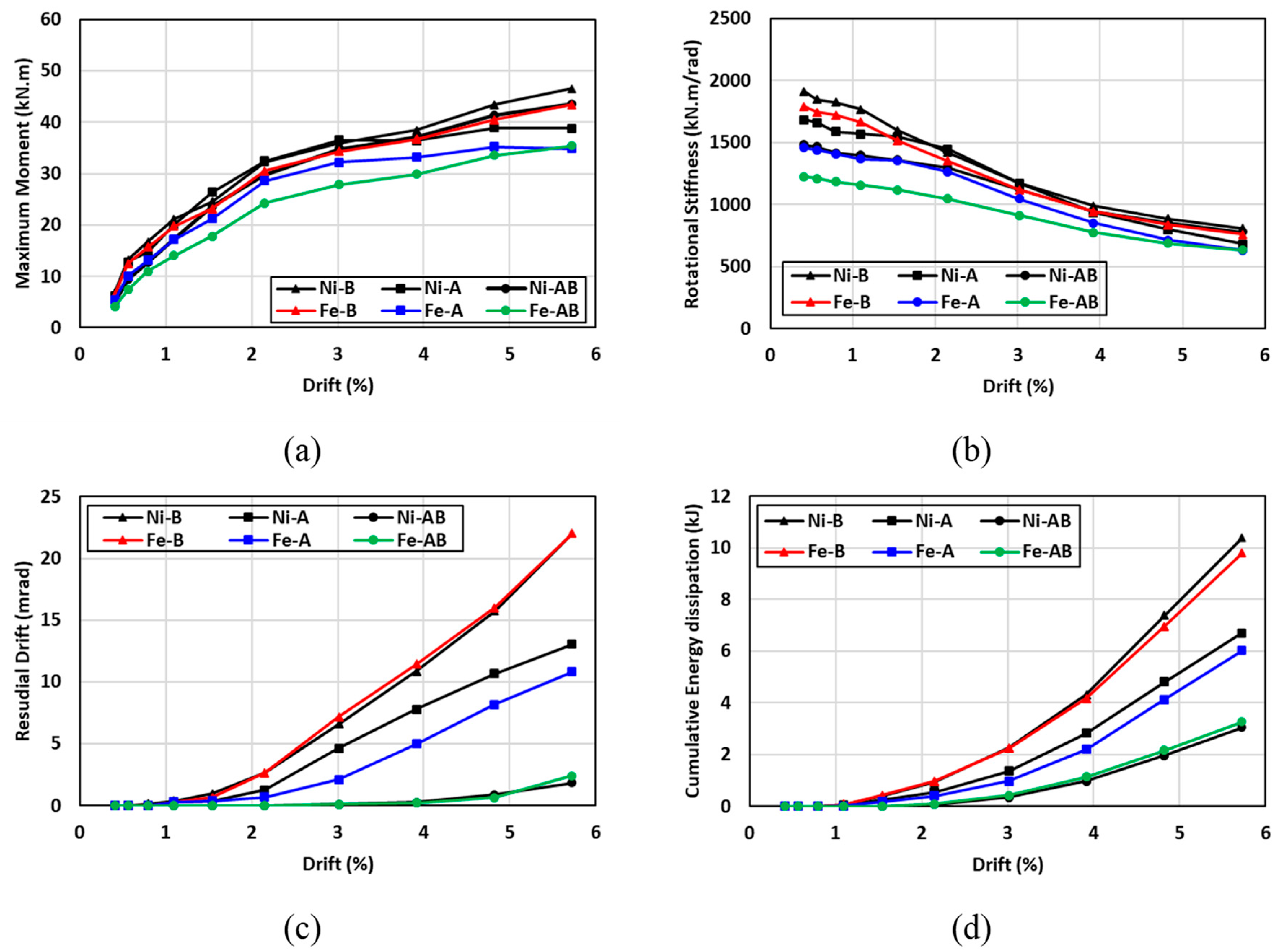

6.2. Moment Capacity

6.3. Rotational Stiffness

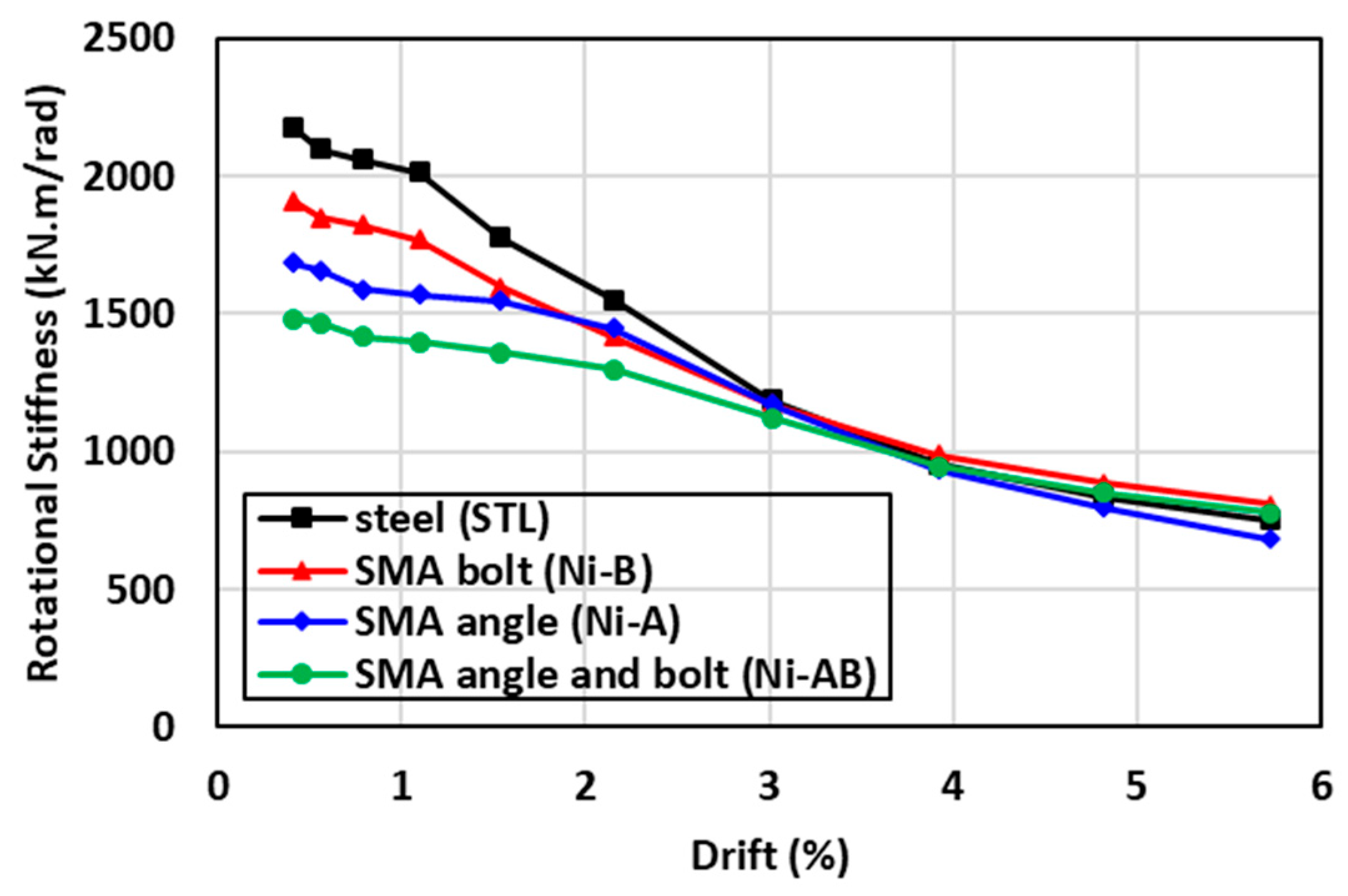

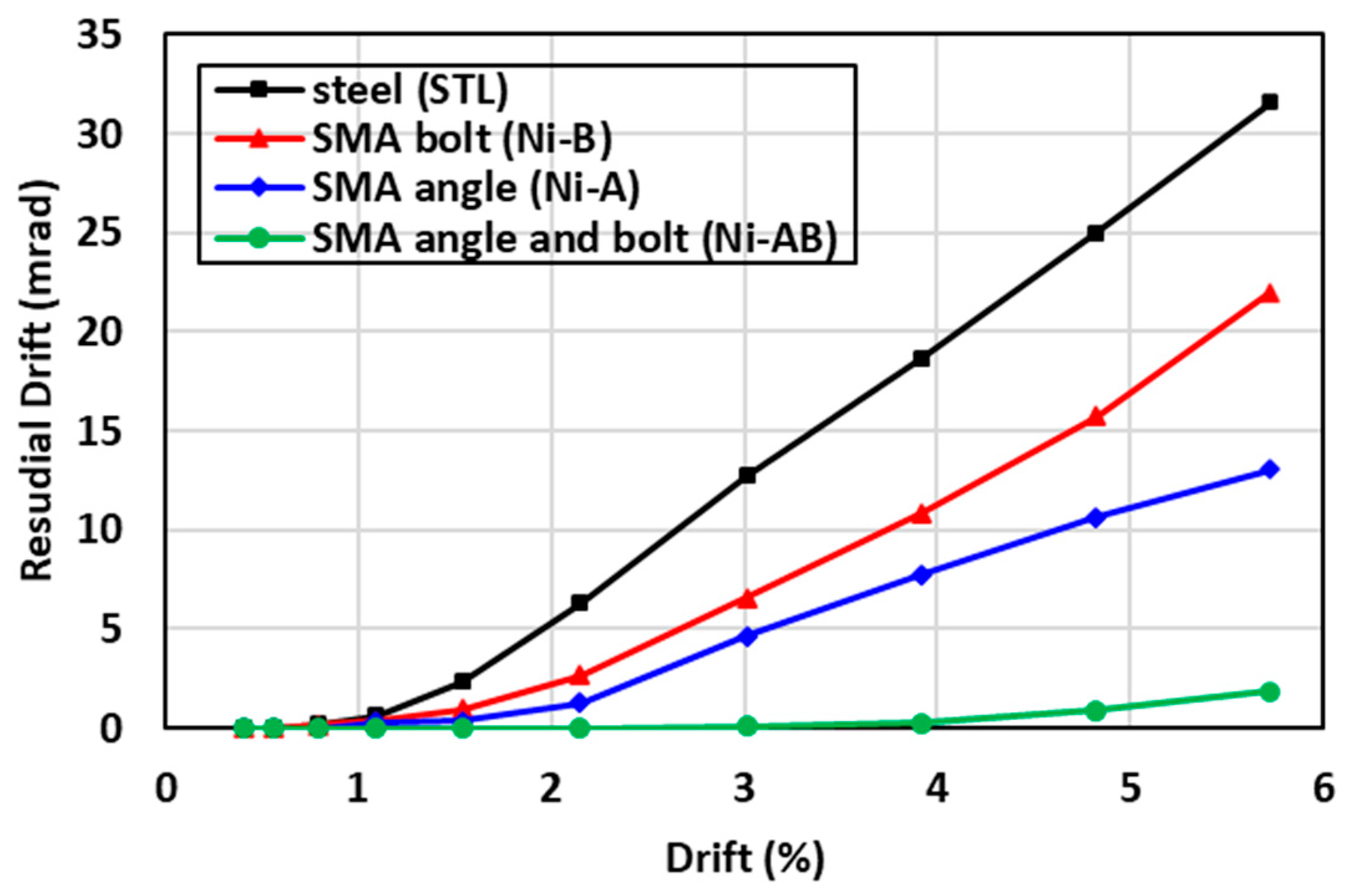

6.4. Residual Drift and Self-Centering Factor

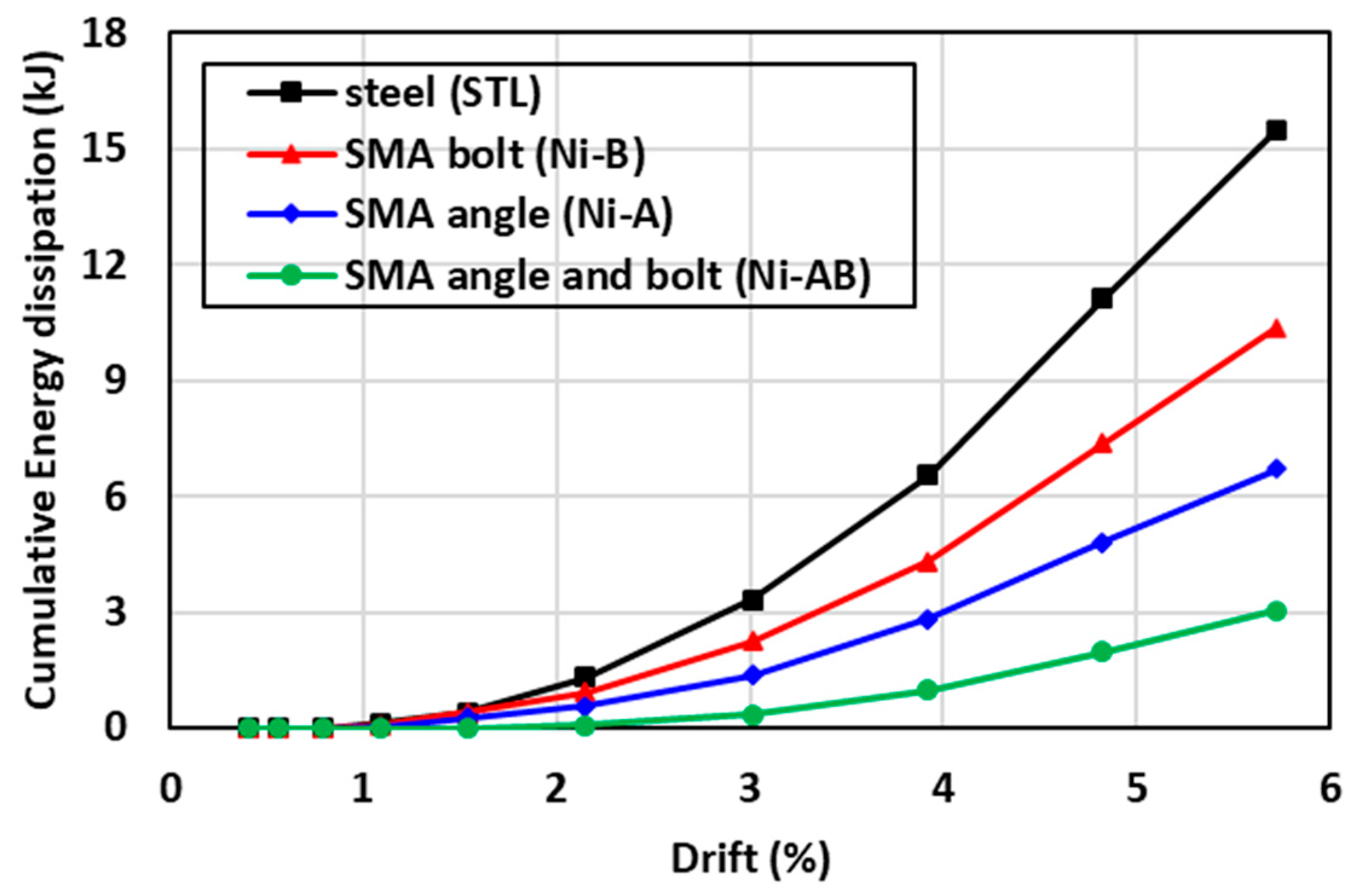

6.5. Energy Dissipation

7. Parametric Study

7.1. Effect of the SMA Type

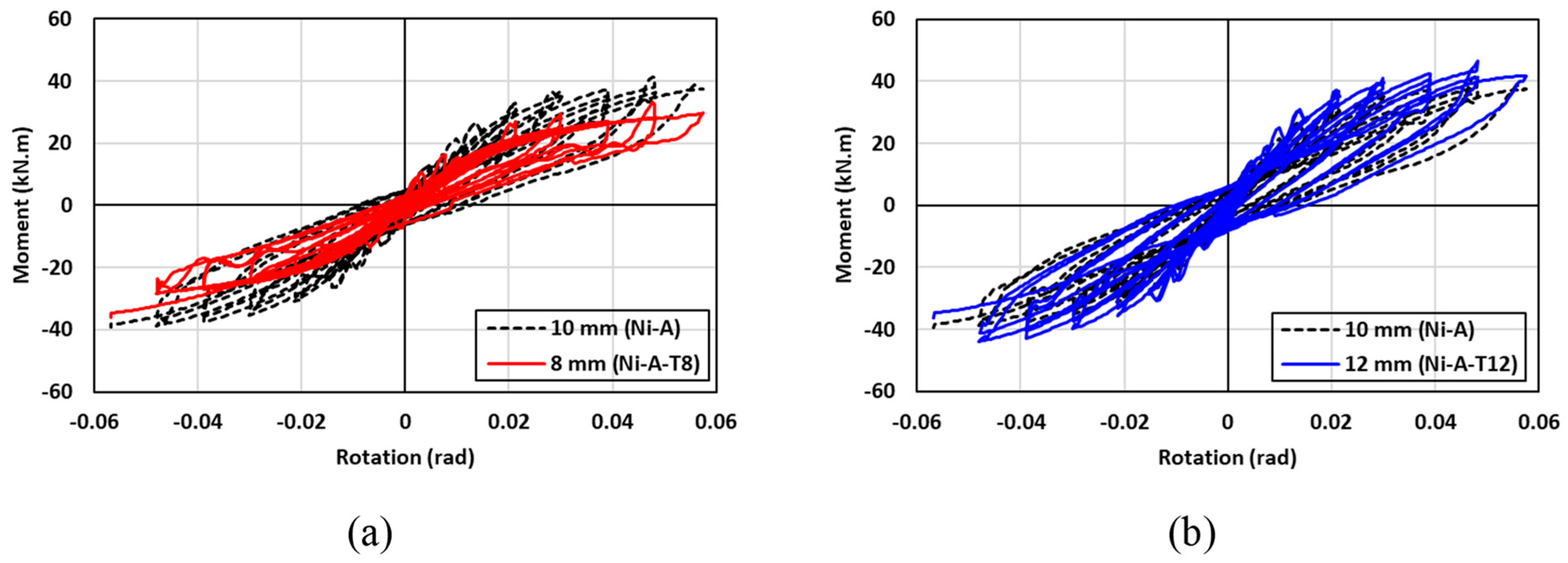

7.2. Effect of SMA Angle Thickness

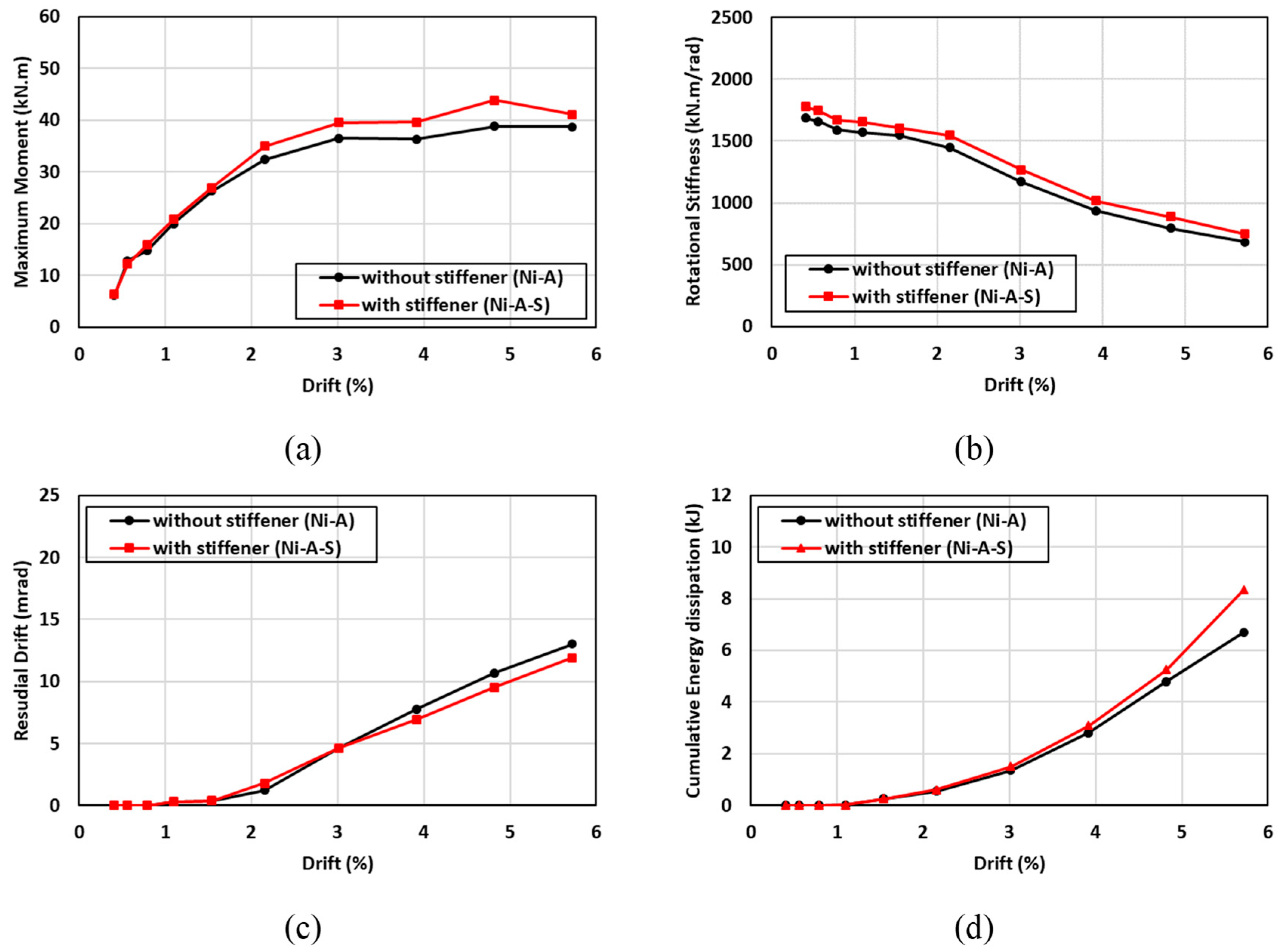

7.3. Effect of SMA Angle Stiffener

7.4. Effect of the SMA Angle Orientation

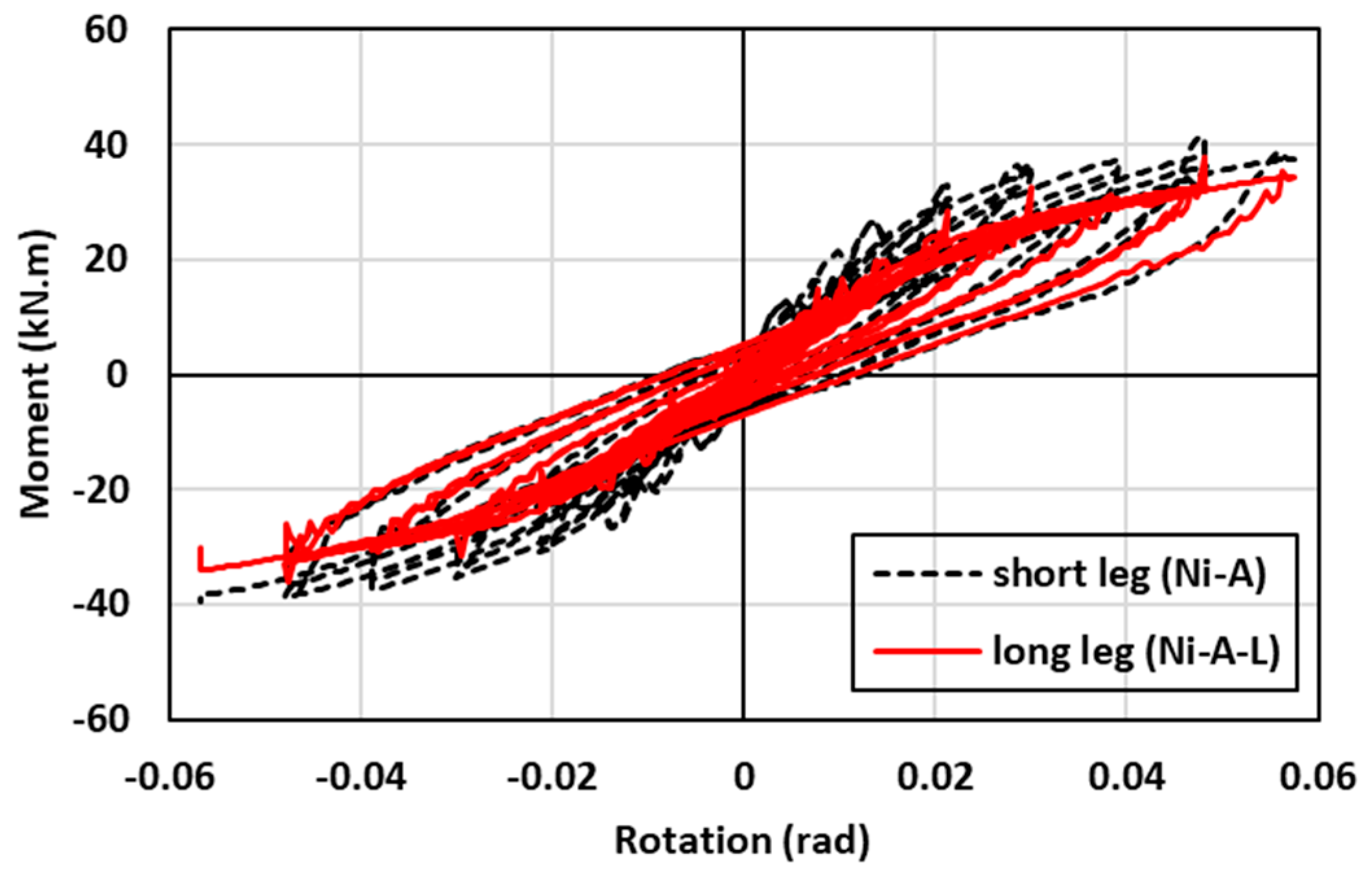

7.5. Effect of the SMA Bolt Diameter

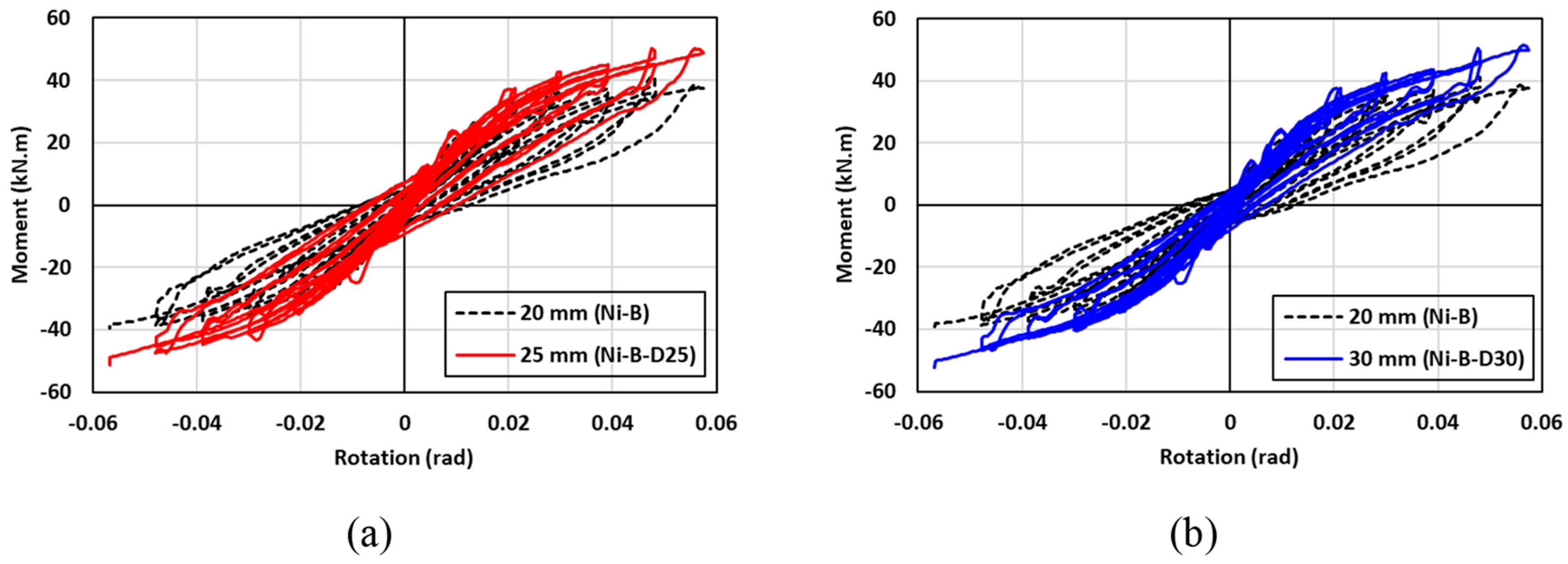

8. Conclusions

- The developed 3D finite element model was capable of simulating successfully the cyclic performance of the steel I beam-hollow column connection. The numerical results compared fairly well to those obtained from the experimental test results.

- The connection equipped with a smart actuating system, consisting of the SMA bolts and SMA angles, reduced the residual drift by up to 94%, and doubled the self-centering capability, compared to conventional steel connections.

- The connections equipped with SMA elements exhibited a slower reduction in stiffness degradation and initial rotational stiffness, compared to conventional steel connections.

- The numerical results showed that utilizing SMA angles and SMA bolts provided a significant enhancement in self-centering, and caused a reduction in the other design parameters. However, the use of SMA bolts and steel angles resulted in enhanced energy dissipation, moment capacity, and initial rotational stiffness, and reduced self-centering. The behavior of the I beam-hollow column connection equipped with SMA angles and steel bolts was in between the performance of the previous two cases.

- Among the types of smart materials investigated, Fe-based SMA members could be a good alternative to NiTi based SMA members for improving the self-centering capability and reducing the residual drifts of conventional steel connections.

- Among the parameters investigated, increasing the SMA bolt diameter, and SMA plate thickness, caused a significant increase in self-centering capability of steel connections, without compromising their moment capacity.

- Generally, the advantages of connecting the short leg of SMA angle to hollow section steel column outperformed the connection of long leg of SMA angle to the same column.

- The numerical results of the parametric study reported herein, could serve as a valuable reference for optimizing the performance of the steel I beam-hollow column connections equipped with smart actuating systems, subjected to reversed cyclic loading.

- Additionally, minimizing the permanent deformations through the use of SMAs, would reduce the maintenance requirements of structures built in active seismic zones, and thus boost their applications in various types of structures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, D.K. Lessons learned from the Northridge earthquake. Eng. Struct. 1998, 20, 249–260. [Google Scholar] [CrossRef]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Omori, T.; Ishida, K. Ferrous Polycrystalline Shape-Memory Alloy Showing Huge Superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef] [PubMed]

- Muntasir Billah, A.; Rahman, J.; Zhang, Q. Shape memory alloys (SMA) for resilient bridges: A state-of-the-art review. Structures 2022, 37, 514–527. [Google Scholar] [CrossRef]

- Zareie, S.; Issa, A.S.; Seethaler, R.J.; Zabihollah, A. Recent advances in the applications of shape memory alloys in civil infrastructures: A Review. Structures 2020, 27, 1535–1550. [Google Scholar] [CrossRef]

- Higazey, M.; Alshannag, M.; Alqarni, A. Numerical Investigation on the Performance of Exterior Beam–Column Joints Reinforced with Shape Memory Alloys. Buildings 2023, 13, 1801. [Google Scholar] [CrossRef]

- Alshannag, M.J.; Alqarni, A.S.; Higazey, M.M. Superelastic Nickel–Titanium (NiTi)-Based Smart Alloys for Enhancing the Performance of Concrete Structures. Materials 2023, 16, 4333. [Google Scholar] [CrossRef]

- Dezfuli, F.; Hedayati, J.Q.W.; Alam, M.S. Longitudinal seismic response control of long-span cable-stayed bridges using shape memory alloy wire-based lead rubber bearings under near-fault records. J. Intell. Mater. Syst. Struct. 2018, 29, 703–728. [Google Scholar]

- Dezfuli, F.H.; Alam, M.S. Performance-based assessment and design of FRP-based high damping rubber bearing incorporated with shape memory alloy wires. Eng. Struct. 2014, 61, 166–183. [Google Scholar] [CrossRef]

- Billah, A.H.M.M.; Alam, M.S. Probabilistic seismic risk assessment of concrete bridge piers reinforced with different types of shape memory alloys. Eng. Struct. 2018, 162, 97–108. [Google Scholar] [CrossRef]

- Dezfuli, F.H.; Alam, M.S. Shape memory alloy wire-based smart natural rubber bearing. Smart. Mater. Struct. 2013, 22, 045013. [Google Scholar] [CrossRef]

- Leon, R.T.; DesRoches, R.; Ocel, J.; Hess, G. Innovative beam column connections using shape memory alloys. In Proceedings of the SPIE’s 8th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 4–8 March 2001; pp. 227–237. [Google Scholar]

- Ocel, J.; DesRoches, R.; Leon, R.T.; Hess, W.G.; Krumme, R.; Hayes, J.R.; Sweeney, S. Steel beam-column connections using shape memory alloys. J. Struct. Eng. 2004, 130, 732–740. [Google Scholar] [CrossRef]

- McGavin, G.L.; Guerin, G. Real-time seismic damping and frequency control of steel structures using Nitinol wire. In Proceedings of the SPIE’s 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 9 July 2002; pp. 176–185. [Google Scholar]

- Qian, H.; Li, H.; Song, G. Experimental investigations of building structure with a superelastic shape memory alloy friction damper subject to seismic loads. Smart. Mater. Struct. 2016, 25, 125026. [Google Scholar] [CrossRef]

- Li, H.; Liu, M.; Ou, J. Vibration mitigation of a stay cable with one shape memory alloy damper. Struct. Contr. Health Monit. 2004, 11, 21–36. [Google Scholar] [CrossRef]

- DesRoches, R.; Delemont, M. Seismic retrofit of simply supported bridges using shape memory alloys. Eng. Struct. 2002, 24, 325–332. [Google Scholar] [CrossRef]

- Zuo, X.B.; Li, A.Q.; Sun, W.; Sun, X.H. Optimal design of shape memory alloy damper for cable vibration control. J. Vib. Contr. 2009, 15, 897–921. [Google Scholar] [CrossRef]

- Vafaei, D.; Eskandari, R. Seismic performance of steel mega braced frames equipped with shape-memory alloy braces under near-fault earthquakes. Struct. Des. Tall. Build. 2016, 25, 3–21. [Google Scholar] [CrossRef]

- Moradi, S.; Alam, M.S.; Asgarian, B. Incremental dynamic analysis of steel frames equipped with NiTi shape memory alloy braces. Struct. Des. Tall. Build. 2014, 23, 1406–1425. [Google Scholar] [CrossRef]

- Hu, J.W. Seismic analysis and parametric study of SDOF lead-rubber bearing (LRB) isolation systems with recentering shape memory alloy (SMA) bending bars. J. Mech. Sci. Technol. 2016, 30, 2987–2999. [Google Scholar] [CrossRef]

- Gur, S.; Mishra, S.K.; Chakraborty, S. Performance assessment of buildings isolated by shape-memory-alloy rubber bearing: Comparison with elastomeric bearing under near-fault earthquakes. Struct. Contr. Health Monit. 2014, 21, 449–465. [Google Scholar] [CrossRef]

- Dolce, M.; Cardone, D.; Marnetto, R. SMA Recentering Devices for Seismic Isolation of Civil Structures. In Proceedings of the SPIE’s 8th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 4–8 March 2001; pp. 238–249. [Google Scholar]

- Khan, M.; Pequegnat, A.; Zhou, Y. Multiple Memory Shape Memory Alloys. Adv. Eng. Mater. 2013, 15, 386–393. [Google Scholar] [CrossRef]

- ASTM F2516-22; Standard Test Method for Tension Testing of Nickel-Titanium Superelastic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Ozbulut, O.E.; Hurlebaus, S.; Desroches, R. Seismic response control using Shape memory alloys: A review. J. Intell. Mater. Syst. Struct. 2011, 22, 1531–1549. [Google Scholar] [CrossRef]

- Lin, H.C.; Lin, K.M.; Chuang, Y.C.; Chou, T.S. The welding characteristics of Fe–30Mn–6Si and Fe–30Mn–6Si–5Cr shape memory alloys. J. Alloys Compd. 2000, 306, 186–192. [Google Scholar] [CrossRef]

- Zhou, C.; Lin, C.; Liu, L. Study on CO2 laser weldability of Fe-Mn-Si shape memory alloy. In Proceedings of the Third International Conference on Smart Materials and Nanotechnology in Engineering, Shenzhen, China, 5–8 December 2011; SPIE: Bellingham, WA, USA, 2011. article no. 84092G, 6p. [Google Scholar]

- Zhao, X.; Lan, L.; Sun, H.; Huang, J.; Zhang, H. Mechanical properties of additive laser-welded NiTi alloy. Mater. Lett. 2010, 64, 628–631. [Google Scholar] [CrossRef]

- Santos, T.G.; Fernandes, F.B.; Bernardo, G.; Miranda, R.M. Analyzing mechanical properties and nondestructive characteristics of brazed joints of NiTi shape memory alloys to carbon steel rods. Int. J. Adv. Manuf. Technol. 2013, 66, 787–793. [Google Scholar] [CrossRef]

- Alam, M.S.; Youssef, M.A.; Nehdi, M. Utilizing shape memory alloys to enhance the performance and safety of civil infrastructure: A review. Can. J. Civ. Eng. 2007, 34, 1075–1086. [Google Scholar] [CrossRef]

- Elghazouli, A.Y.; Málaga-Chuquitaype, C.; Castro, J.M.; Orton, A.H. Experimental Monotonic and Cyclic Behaviour of Blind-Bolted Angle Connections. Eng. Struct. 2009, 31, 2540–2553. [Google Scholar] [CrossRef]

- Serrano-López, M.A.; López-Colina, C.; Wang, Y.C.; Lozano, M.; Gayarre, F.L. Comparative Behaviour of ‘I Beam-RHS Column’ Joints with and without Web Weld. J. Constr. Steel Res. 2019, 159, 330–340. [Google Scholar] [CrossRef]

- Serrano-López, M.A.; López-Colina, C.; Wang, Y.C.; Lozano, M.; García, I.; Gayarre, F.L. An Experimental Study of I Beam-RHS Column Demountable Joints with Welded Studs. J. Constr. Steel Res. 2021, 182, 106651. [Google Scholar] [CrossRef]

- Nakashima, M.; Inoue, K.; Tada, M. Classification of Damage to Steel Buildings Observed in the 1995 Hyogoken-Nanbu Earthquake. Eng. Struct. 1998, 20, 271–281. [Google Scholar] [CrossRef]

- Kawashima, K.; MacRae, G.; Hoshikuma, J.; Nagaya, K. Residual Displacement Response Spectrum. J. Struct. Eng. 1998, 124, 523–530. [Google Scholar] [CrossRef]

- McCormick, J.; Aburano, H.; Ikenaga, M.; Nakashima, M. Permissible Residual Deformation Levels for Building Structures Considering Both Safety and Human Elements. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Moradi, S.; Alam, M.S. Feasibility Study of Utilizing Superelastic Shape Memory Alloy Plates in Steel Beam–Column Connections for Improved Seismic Performance. J. Intell. Mater. Syst. Struct. 2014, 26, 463–475. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Rahmzadeh, A.; Moradi, S.; Alam, M.S. Feasibility of Using Reduced Length Superelastic Shape Memory Alloy Strands in Post-Tensioned Steel Beam–Column Connections. J. Intell. Mater. Syst. Struct. 2018, 30, 283–307. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Rahmzadeh, A.; Alam, M.S. Improving the Seismic Performance of Post-Tensioned Self-Centering Connections Using SMA Angles or End Plates with SMA Bolts. Smart Mater. Struct. 2019, 28, 075044. [Google Scholar] [CrossRef]

- Torabipour, A.; Asghari, N.; Haghighi, H.; Yaghoubi, S.; Urgessa, G. Assessing Effectiveness of Shape Memory Alloys on the Response of Bolted T-Stub Connections Subjected to Cyclic Loading. CivilEng 2023, 4, 105–133. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, S.; Chen, K.; Huang, J. Development of superelastic SMA angles as seismic-resistant self-centering devices. Eng. Struct. 2020, 218, 110836. [Google Scholar] [CrossRef]

- ABAQUS. ABAQUS Analysis User’s Manual Version 2020; Dassault Systems Simulation Corp.: Providence, RI, USA, 2020. [Google Scholar]

- FEMA. 461: Interim Testing Protocols for Determining the Seismic Performance Characteristics of Structural and Nonstructural Components; Federal Emergency Management Agency: Washington, DC, USA, 2007.

- Yam, M.C.H.; Fang, C.; Lam, A.C.C.; Zhang, Y. Numerical Study and Practical Design of Beam-to-Column Connections with Shape Memory Alloys. J. Constr. Steel Res. 2015, 104, 177–192. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; He, C.; Chen, Y. Self-Centring Behaviour of Steel and Steel-Concrete Composite Connections Equipped with NiTi SMA Bolts. Eng. Struct. 2017, 150, 390–408. [Google Scholar] [CrossRef]

- Shu, Y.; Qiang, X.H.; Jiang, X.; Zhang, Q.L.; Wu, H.L. Numerical Study on the Mechanical Behavior of Fe-SMA/Steel Hybrid Joints Based on Cohesive Zone Modeling. In Life-Cycle of Structures and Infrastructure Systems; CRC Press: Boca Raton, FL, USA, 2023; pp. 2170–2177. [Google Scholar]

- Farmani, M.A.; Ghassemieh, M. Steel Beam-to-Column Connections Equipped with SMA Tendons and Energy Dissipating Devices Including Shear Tabs or Web Hourglass Pins. J. Constr. Steel Res. 2017, 135, 30–48. [Google Scholar] [CrossRef]

- Wang, J.-X.; Yang, Y.; Xian, W.; Li, Q.-Y. Progressive Collapse Mechanism Analysis of Concrete-Filled Square Steel Tubular Column to Steel Beam Joint with Bolted–Welded Hybrid Connection. Int. J. Steel Struct. 2020, 20, 1618–1635. [Google Scholar] [CrossRef]

- Auricchio, F.; Taylor, R.L. Shape-memory alloys: Modelling and numerical simulations of the finite-strain superelastic behavior. Comput. Methods Appl. Mech. Eng. 1996, 143, 175–194. [Google Scholar] [CrossRef]

- Auricchio, F.; Lubliner, J. Shape-memory alloys: Macromodelling and numerical simulations of the superelastic behavior. Comput. Methods Appl. Mech. Eng. 1997, 146, 281–312. [Google Scholar] [CrossRef]

- Shrestha, B.; Hao, H. Parametric study of seismic performance of super-elastic shape memory alloy-reinforced bridge piers. Struct. Infrastruct. Eng. 2015, 12, 1076–1089. [Google Scholar] [CrossRef]

- Fugazza, D. Shape Memory Alloy Devices for Earthquake Engineering: Mechanical Properties, Constitutive Modelling and Numerical Simulations. Master’s Thesis, University of Pavia, Pavia, Italy, 2003. [Google Scholar]

- Ghassemieh, M.; Mostafazadeh, M.; Sadeh, M.S. Seismic control of concrete shear wall using shape memory alloys. J. Intell. Mater. Syst. Struct. 2012, 23, 535–543. [Google Scholar] [CrossRef]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic effect in polycrystalline ferrous alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef]

- Shannag, M.J.; Alhassan, M.A. Seismic Upgrade of Interior Beam-Column Subassemblages with High-Performance Fiber-Reinforced Concrete Jackets. ACI Struct. J. 2005, 102, 131–138. [Google Scholar]

- Basim, M.C.; Pourreza, F.; Mousazadeh, M.; Akbari Hamed, A. The effects of modeling uncertainties on the residual drift of steel structures under mainshock-aftershock sequences. Structures 2022, 36, 912–926. [Google Scholar] [CrossRef]

- Shajil, N.; Srinivasan, S.M.; Santhanam, M. Self-centering of shape memory alloy fiber reinforced cement mortar members subjected to strong cyclic loading. Mater. Struct. 2012, 46, 651–661. [Google Scholar] [CrossRef]

- Shannag, M.; Abu-Dyya, N.; Abu-Farsakh, G. Lateral Load Response of High Performance Fiber Reinforced Concrete Beam-Column Joints. Constr. Build. Mater. 2005, 19, 500–509. [Google Scholar] [CrossRef]

- Jalaeefar, A.; Asgarian, B. Experimental investigation of mechanical properties of nitinol, structural steel, and their hybrid component. J. Mater. Civ. Eng. 2013, 25, 1498–1505. [Google Scholar] [CrossRef]

| Element | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (GPa) | |

|---|---|---|---|---|

| Column (SHS200 × 10) | 417.0 | 520.1 | 215.3 | |

| Beam (HEB 200) | Flange | 325.2 | 492.7 | 195.7 |

| Web | 334.9 | 482.0 | 192.3 | |

| Angle (L120 × 80 × 10) | Long leg | 316.6 | 468.8 | 176.4 |

| Short leg | 322.5 | 469.6 | 201.5 | |

| Alloy | Start of Transformation (Loading) | End of Transformation (Loading) | Start of Transformation (Unloading) | End of Transformation (Unloading) | Young’s Modulus | Transformation Strain |

|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (MPa) | EA (GPa) | ||

| NiTi [53] | 435 | 535 | 335 | 170 | 68 | 0.08 |

| FeMnAlNi [54] | 320 | 443 | 211 | 122 | 98 | 0.06 |

| Experimental Study [33] | Current Study | Variation, % | |

|---|---|---|---|

| Maximum Moment (kN-m) | 41.67 | 43.77 | 5.04 |

| Energy dissipation (kJ) | 15.02 | 15.50 | 3.21 |

| Sample ID | Material of Angles | Material of Column’s Bolts | Material of Beam’s Bolts | Material of the Beam | Material of the Column |

|---|---|---|---|---|---|

| STL | Steel | Steel | Steel | Steel | Steel |

| Ni-B | Steel | NiTi SMA | Steel | Steel | Steel |

| Ni-A | NiTi SMA | Steel | Steel | Steel | Steel |

| Ni-AB | NiTi SMA | NiTi SMA | Steel | Steel | Steel |

| Sample ID | Residual Drift (mrad) | Self-Centering Factor | Maximum Moment (kN-m) | Initial Rotational Stiffness (kN-m/rad) | Total Energy Dissipation (kJ) | Failure Mode |

|---|---|---|---|---|---|---|

| STL | 31.6 | 0.45 | 43.8 | 2177.4 | 15.50 | Bolt failure in tension |

| Ni-B | 22.0 | 0.62 | 46.5 | 1911.6 | 10.39 | Bolt failure in tension |

| Ni-A | 13.0 | 0.77 | 41.4 | 1683.5 | 6.70 | Bolt failure in tension |

| Ni-AB | 1.8 | 0.97 | 44.2 | 1481.4 | 3.03 | Bolt failure in tension |

| # | Parameter | Variables | Related Specimens |

|---|---|---|---|

| 1 | SMA type | (a) NiTi | Ni-B, Ni-A and Ni-AB |

| (b) FeMnAlNi | Fe-B, Fe-A and Fe-AB | ||

| 2 | Thickness of SMA angle | (a) 8 mm | Ni-A-T8 |

| (b) 10 mm | Ni-A | ||

| (c) 12 mm | Ni-A-T12 | ||

| 3 | Direction of SMA angle | (a) short leg connected to the column | Ni-A |

| (b) long leg connected to the column | Ni-A-L | ||

| 4 | Stiffener of SMA angle | (a) without stiffener | Ni-A |

| (b) with stiffener | Ni-A-S | ||

| 5 | Diameter of SMA bolt | (a) 20 mm | Ni-B |

| (b) 25 mm | Ni-B-D25 | ||

| (c) 30 mm | Ni-B-D30 |

| # | Sample ID | Angle Material | Angle Thickness | Angle Direction (Connected Leg to the Column) | Material Of Column’s Bolt | Diameter of Column’s Bolt |

|---|---|---|---|---|---|---|

| 1 | STL | Steel | 10 mm | Short leg | Steel | 20 mm |

| 2 | Ni-B | Steel | 10 mm | Short leg | NiTi | 20 mm |

| 3 | Ni-A | NiTi | 10 mm | Short leg | Steel | 20 mm |

| 4 | Ni-AB | NiTi | 10 mm | Short leg | NiTi | 20 mm |

| 5 | Fe-B | Steel | 10 mm | Short leg | FeMnAlNi | 20 mm |

| 6 | Fe-A | FeMnAlNi | 10 mm | Short leg | Steel | 20 mm |

| 7 | Fe-AB | FeMnAlNi | 10 mm | Short leg | FeMnAlNi | 20 mm |

| 8 | Ni-A-T8 | NiTi | 8 mm | Short leg | Steel | 20 mm |

| 9 | Ni-A-T12 | NiTi | 12 mm | Short leg | Steel | 20 mm |

| 10 | Ni-A-S * | NiTi | 10 mm | Short leg | Steel | 20 mm |

| 11 | Ni-A-L | NiTi | 10 mm | Long leg | Steel | 20 mm |

| 12 | Ni-B-D25 | Steel | 10 mm | Short leg | NiTi | 25 mm |

| 13 | Ni-B-D30 | Steel | 10 mm | Short leg | NiTi | 30 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqarni, A.S.; Alshannag, M.J.; Higazey, M.M. A Novel Technique for Improving Cyclic Behavior of Steel Connections Equipped with Smart Memory Alloys. Materials 2024, 17, 3226. https://doi.org/10.3390/ma17133226

Alqarni AS, Alshannag MJ, Higazey MM. A Novel Technique for Improving Cyclic Behavior of Steel Connections Equipped with Smart Memory Alloys. Materials. 2024; 17(13):3226. https://doi.org/10.3390/ma17133226

Chicago/Turabian StyleAlqarni, Ali S., Mohammad J. Alshannag, and Mahmoud M. Higazey. 2024. "A Novel Technique for Improving Cyclic Behavior of Steel Connections Equipped with Smart Memory Alloys" Materials 17, no. 13: 3226. https://doi.org/10.3390/ma17133226

APA StyleAlqarni, A. S., Alshannag, M. J., & Higazey, M. M. (2024). A Novel Technique for Improving Cyclic Behavior of Steel Connections Equipped with Smart Memory Alloys. Materials, 17(13), 3226. https://doi.org/10.3390/ma17133226