Carbon Fiber-Based Vitrimer Composites: A Path toward Current Research That Is High-Performing, Useful, and Sustainable

Abstract

:1. Introduction

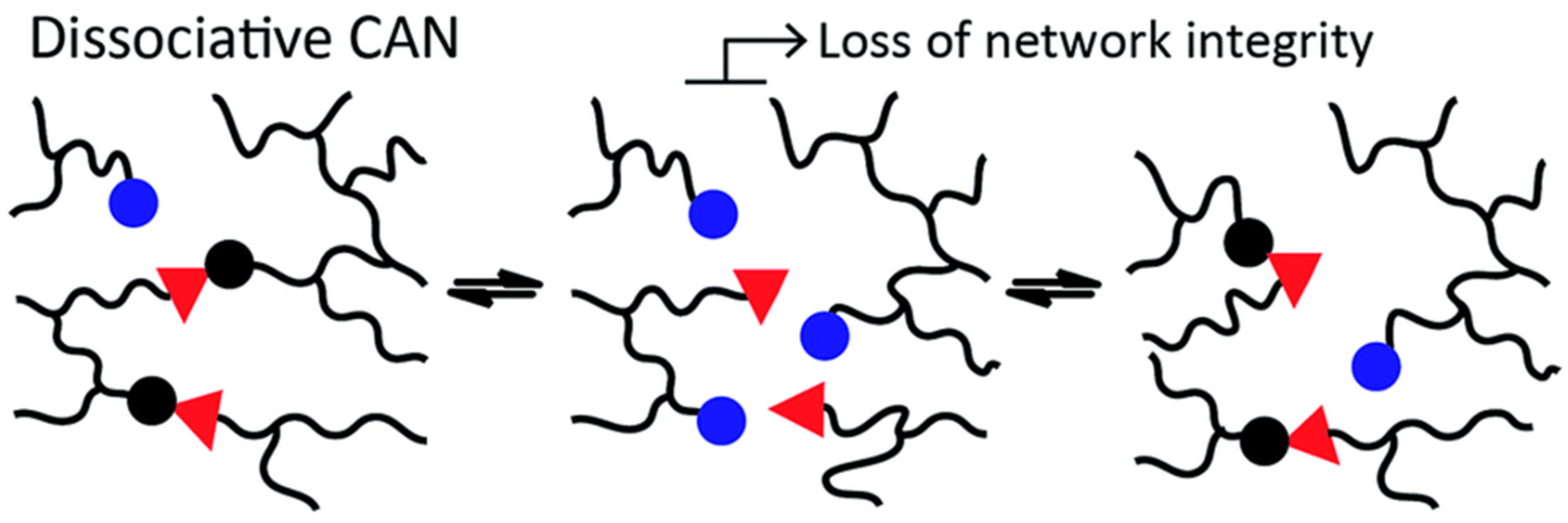

2. Vitrimers—General Introduction

3. Carbon Fiber-Based Vitrimer Composites and Their Preparation Strategies

3.1. Carbon Fiber-Based Vitrimer Composites

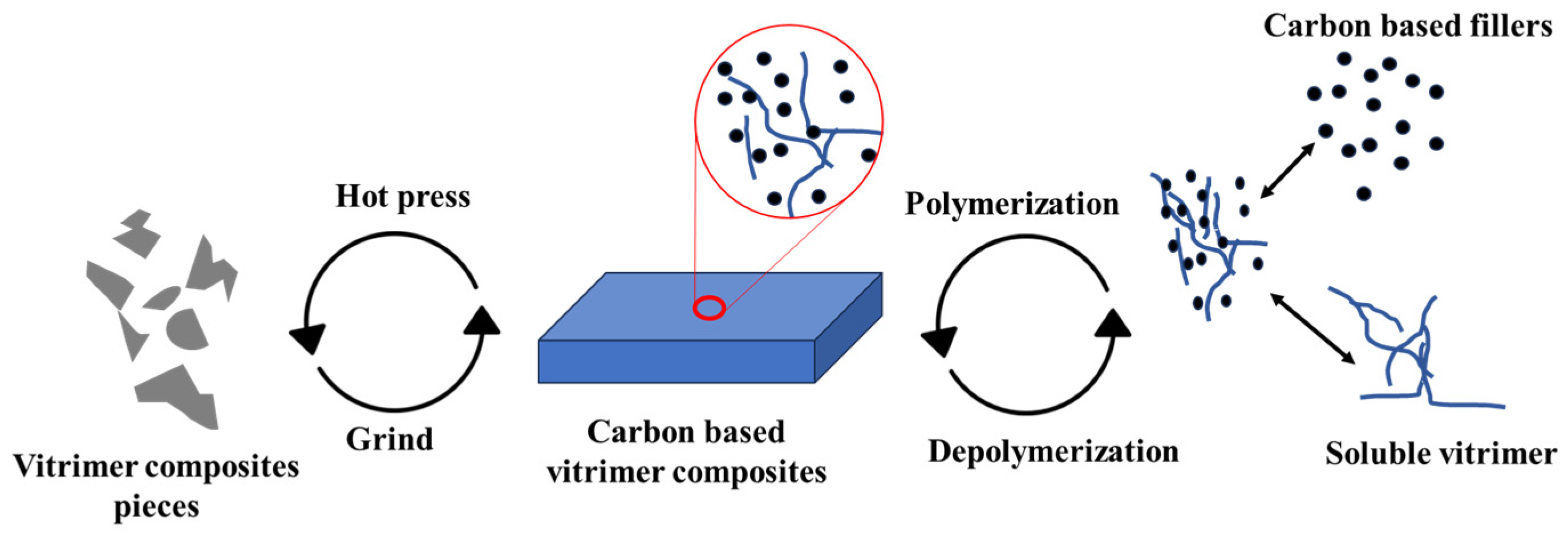

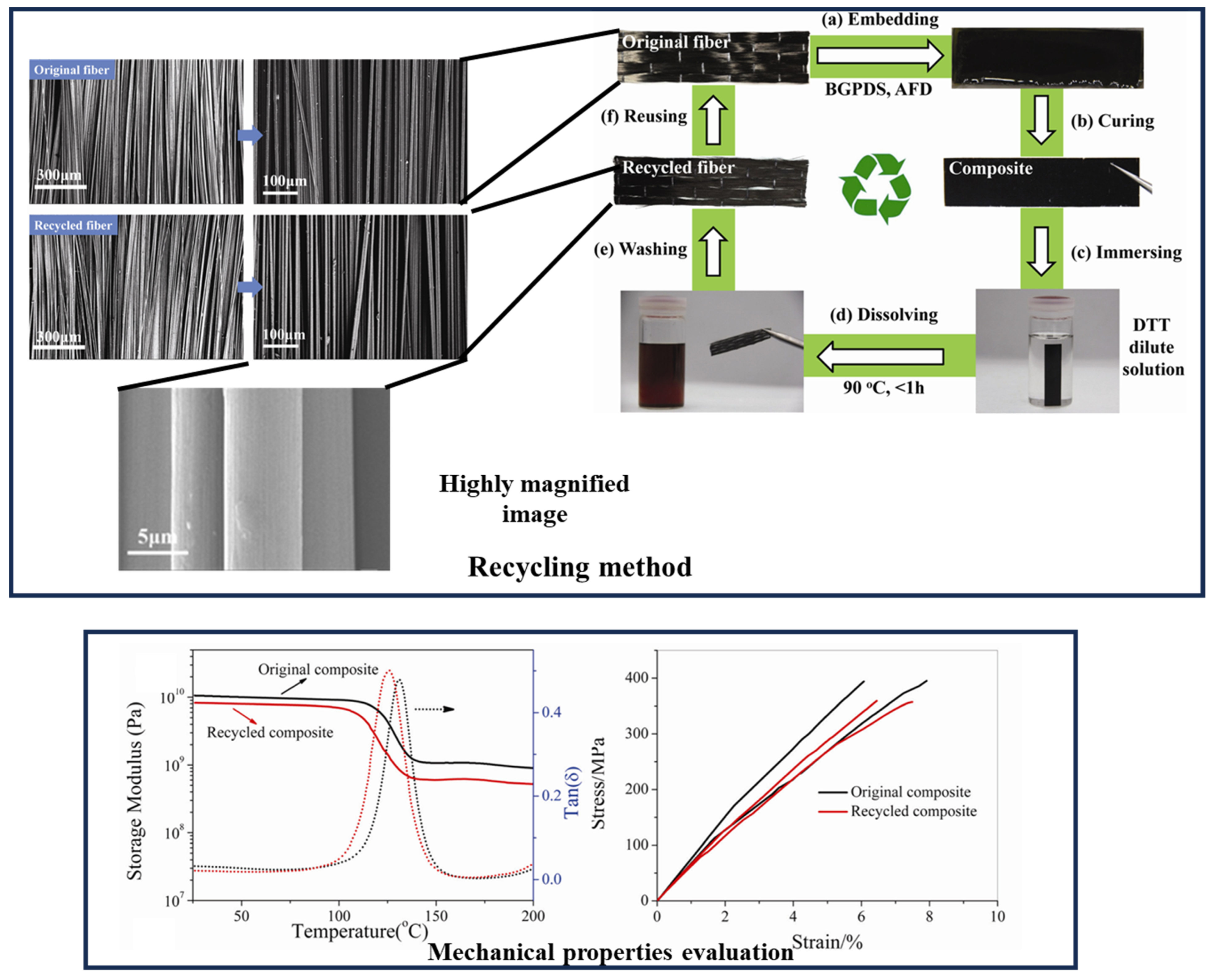

3.2. Recycling and Reuse of Carbon Fiber Vitrimer Composites: Strategies

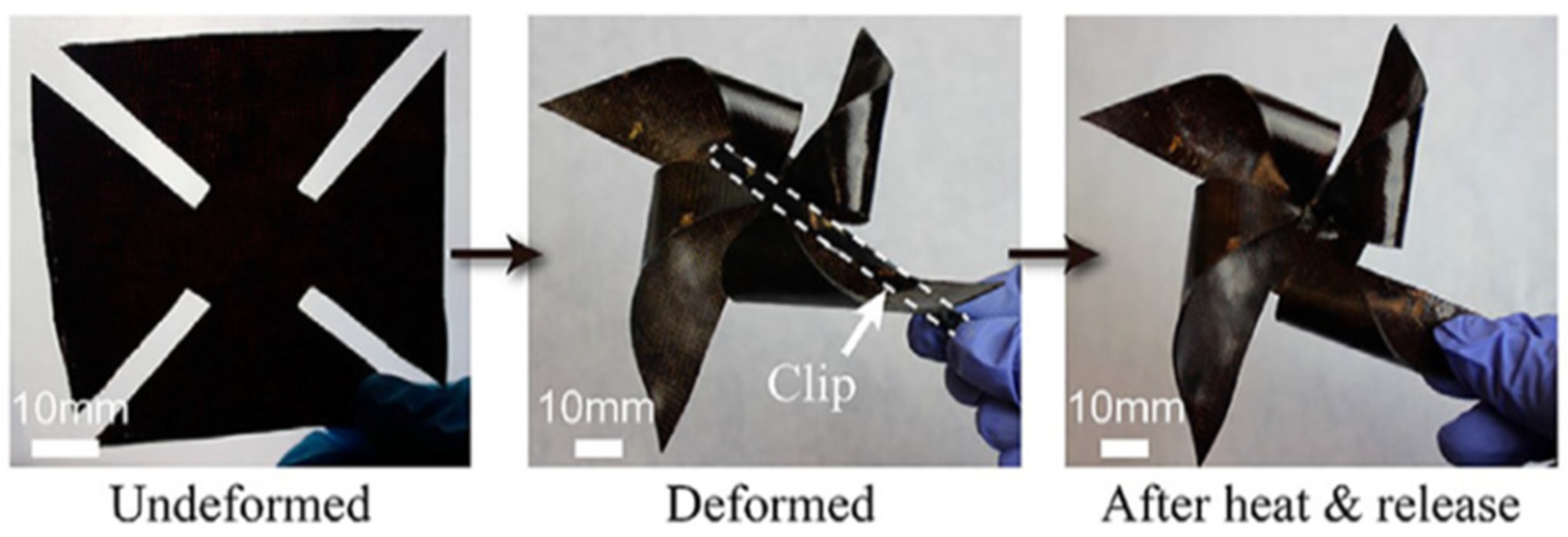

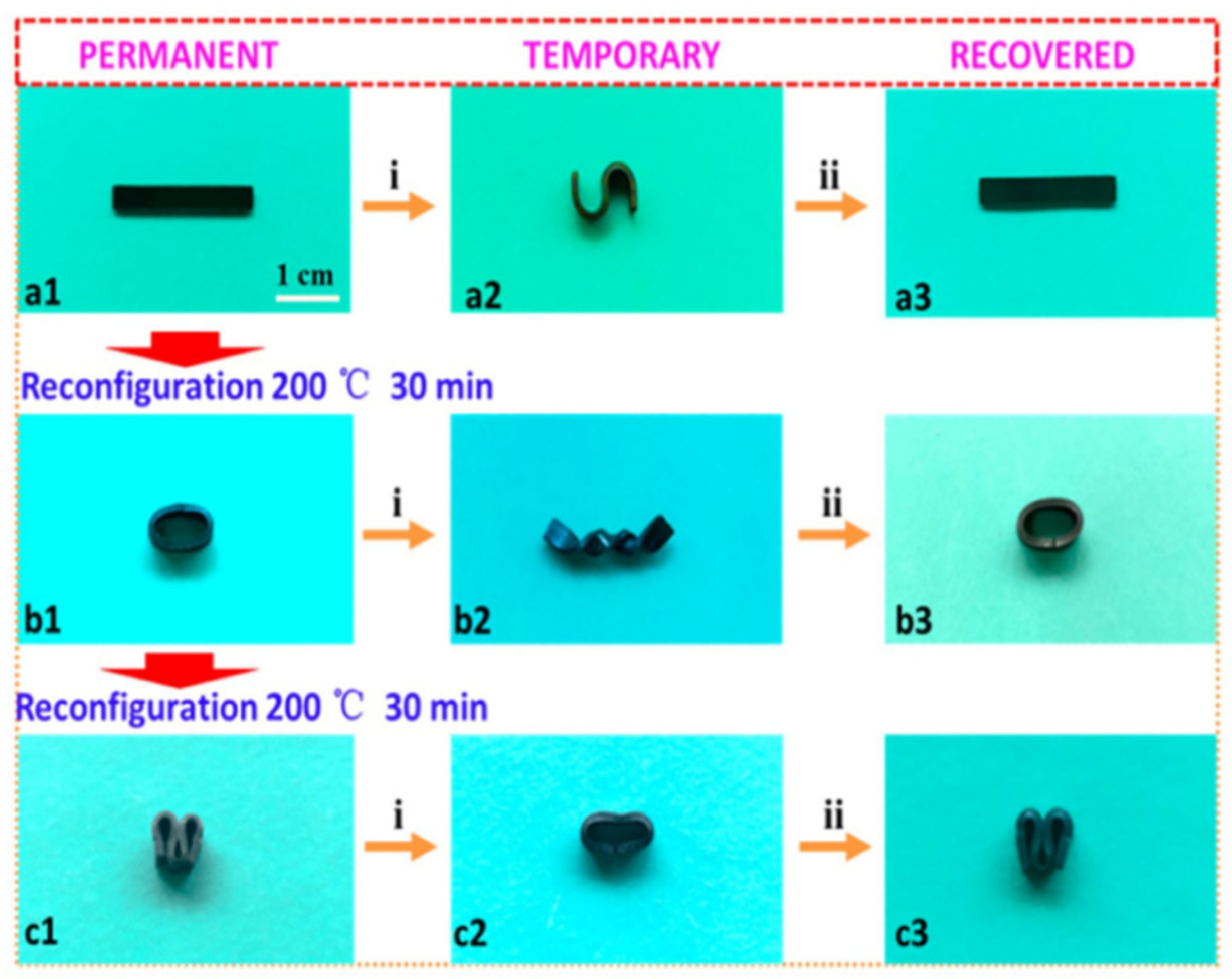

3.3. Reshaping of Composites

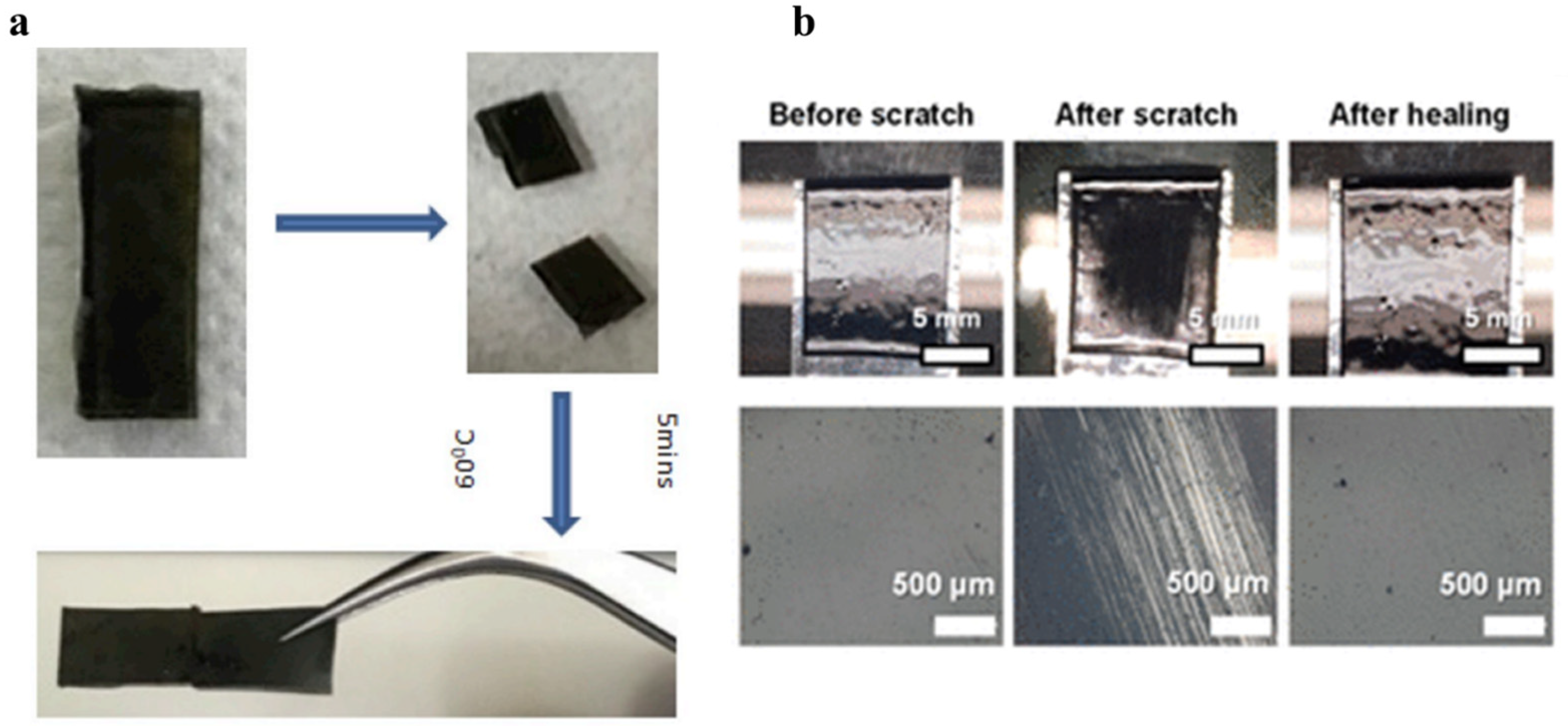

3.4. Repairing Vitrimer Based Composites

3.5. Recycling of Vitrimer Composites

4. Conclusions and Future Aspects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pickering, S. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2005, 37, 1206–1215. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Kalali, E.N.; Wan, J.-T.; Wang, D.-Y. Carbon-family materials for flame retardant polymeric materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Sun, H.; Li, H.; Peng, H. Developing polymer composite materials: Carbon nanotubes or graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef] [PubMed]

- Chung, D. Carbon Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Esawi, A.M.; Farag, M.M. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar] [CrossRef]

- Loos, M. Carbon Nanotube Reinforced Composites: CNT Polymer Science and Technology; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Sun, X.; Huang, C.; Wang, L.; Liang, L.; Cheng, Y.; Fei, W.; Li, Y. Recent progress in graphene/polymer nanocomposites. Adv. Mater. 2021, 33, e2001105. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef]

- Compton, O.C.; Nguyen, S.T. Graphene oxide, highly reduced graphene oxide, and graphene: Versatile building blocks for carbon-based materials. Small 2010, 6, 711–723. [Google Scholar] [CrossRef]

- Wu, N.; Hu, Q.; Wei, R.; Mai, X.; Naik, N.; Pan, D.; Guo, Z.; Shi, Z. Review on the electromagnetic interference shielding properties of carbon based materials and their novel composites: Recent progress, challenges and prospects. Carbon 2021, 176, 88–105. [Google Scholar] [CrossRef]

- Winne, J.M.; Leibler, L.; Du Prez, F.E. Dynamic covalent chemistry in polymer networks: A mechanistic perspective. Polym. Chem. 2019, 10, 6091–6108. [Google Scholar] [CrossRef]

- Chakma, P.; Konkolewicz, D. Dynamic covalent bonds in polymeric materials. Angew. Chem. Int. Ed. 2019, 58, 9682–9695. [Google Scholar] [CrossRef] [PubMed]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like malleable materials from permanent organic networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Denissen, W.; Winne, J.M.; Du Prez, F.E. Vitrimers: Permanent organic networks with glass-like fluidity. Chem. Sci. 2016, 7, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Imbernon, L.; Norvez, S. From landfilling to vitrimer chemistry in rubber life cycle. Eur. Polym. J. 2016, 82, 347–376. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities. Prog. Polym. Sci. 2018, 80, 39–93. [Google Scholar] [CrossRef]

- Christensen, P.R.; Scheuermann, A.M.; Loeffler, K.E.; Helms, B.A. Closed-loop recycling of plastics enabled by dynamic covalent diketoenamine bonds. Nat. Chem. 2019, 11, 442–448. [Google Scholar] [CrossRef] [PubMed]

- Röttger, M.; Domenech, T.; van der Weegen, R.; Breuillac, A.; Nicolaÿ, R.; Leibler, L. High-performance vitrimers from commodity thermoplastics through dioxaborolane metathesis. Science 2017, 356, 62–65. [Google Scholar] [CrossRef]

- Kissounko, D.A.; Taynton, P.; Kaffer, C. New material: Vitrimers promise to impact composites. Reinf. Plast. 2018, 62, 162–166. [Google Scholar] [CrossRef]

- Alabiso, W.; Schlögl, S. The Impact of vitrimers on the industry of the future: Chemistry, properties and sustainable forward-looking applications. Polymers 2020, 12, 1660. [Google Scholar] [CrossRef]

- Guerre, M.; Taplan, C.; Winne, J.M.; Du Prez, F.E. Vitrimers: Directing chemical reactivity to control material properties. Chem. Sci. 2020, 11, 4855–4870. [Google Scholar] [CrossRef]

- Van Zee, N.J.; Nicolaÿ, R. Vitrimers: Permanently crosslinked polymers with dynamic network topology. Prog. Polym. Sci. 2020, 104, 101233. [Google Scholar] [CrossRef]

- Oehlenschlaeger, K.K.; Mueller, J.O.; Brandt, J.; Hilf, S.; Lederer, A.; Wilhelm, M.; Graf, R.; Coote, M.L.; Schmidt, F.G.; Barner-Kowollik, C. Adaptable hetero Diels–Alder networks for fast self-healing under mild conditions. Adv. Mater. 2014, 26, 3561–3566. [Google Scholar] [CrossRef]

- Trovatti, E.; Lacerda, T.M.; Carvalho, A.J.F.; Gandini, A. Recycling tires? Reversible crosslinking of poly(butadiene). Adv. Mater. 2015, 27, 2242–2245. [Google Scholar] [CrossRef]

- Black, S.P.; Sanders, J.K.M.; Stefankiewicz, A.R. Disulfide exchange: Exposing supramolecular reactivity through dynamic covalent chemistry. Chem. Soc. Rev. 2013, 43, 1861–1872. [Google Scholar] [CrossRef]

- Liu, T.; Zhao, B.; Zhang, J. Recent development of repairable, malleable and recyclable thermosetting polymers through dynamic transesterification. Polymer 2020, 194, 122392. [Google Scholar] [CrossRef]

- Guerre, M.; Taplan, C.; Nicolaÿ, R.; Winne, J.M.; Du Prez, F.E. Fluorinated vitrimer elastomers with a dual temperature response. J. Am. Chem. Soc. 2018, 140, 13272–13284. [Google Scholar] [CrossRef]

- Denissen, W.; Rivero, G.; Nicolaÿ, R.; Leibler, L.; Winne, J.M.; Du Prez, F.E. Vinylogous urethane vitrimers. Adv. Funct. Mater. 2015, 25, 2451–2457. [Google Scholar] [CrossRef]

- Gandini, A. The furan/maleimide Diels–Alder reaction: A versatile click–unclick tool in macromolecular synthesis. Prog. Polym. Sci. 2013, 38, 1–29. [Google Scholar] [CrossRef]

- Krishnakumar, B.; Sanka, R.P.; Binder, W.H.; Parthasarthy, V.; Rana, S.; Karak, N. Vitrimers: Associative dynamic covalent adaptive networks in thermoset polymers. Chem. Eng. J. 2020, 385, 123820. [Google Scholar] [CrossRef]

- Van Lijsebetten, F.; Holloway, J.O.; Winne, J.M.; Du Prez, F.E. Internal catalysis for dynamic covalent chemistry applications and polymer science. Chem. Soc. Rev. 2020, 49, 8425–8438. [Google Scholar] [CrossRef]

- An, L.; Shi, Q.; Jin, C.; Zhao, W.; Wang, T. Chain diffusion based framework for modeling the welding of vitrimers. J. Mech. Phys. Solids 2022, 164, 104883. [Google Scholar] [CrossRef]

- Ricarte, R.G.; Shanbhag, S. Unentangled vitrimer melts: Interplay between Chain relaxation and cross-link exchange controls linear rheology. Macromolecules 2021, 54, 3304–3320. [Google Scholar] [CrossRef]

- Yang, Y.; Pei, Z.; Zhang, X.; Tao, L.; Wei, Y.; Ji, Y. Carbon nanotube–vitrimer composite for facile and efficient photo-welding of epoxy. Chem. Sci. 2014, 5, 3486–3492. [Google Scholar] [CrossRef]

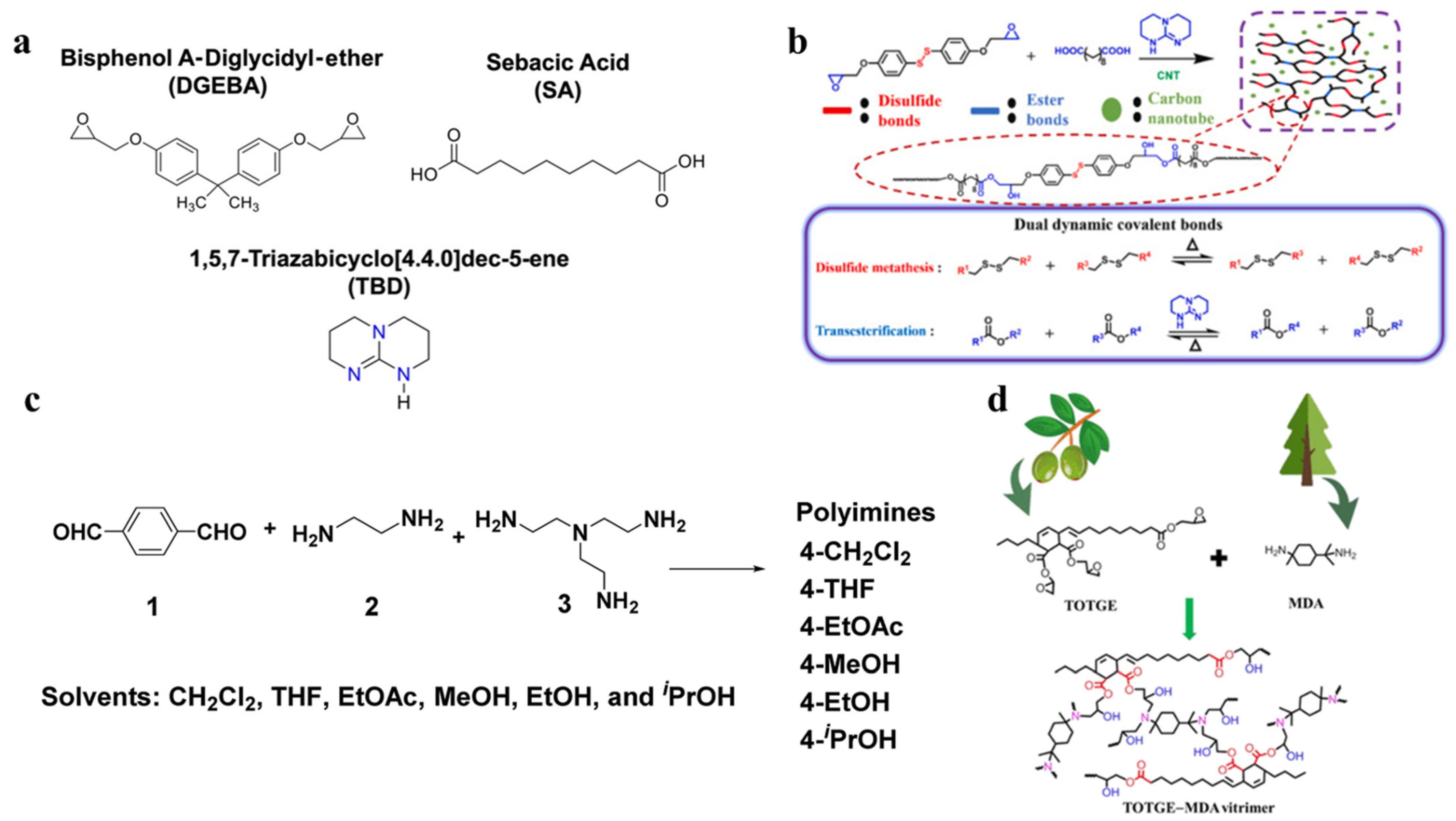

- Guo, Z.; Wang, W.; Liu, Z.; Xue, Y.; Zheng, H.; Majeed, K.; Zhang, B.; Zhou, F.; Zhang, Q. Preparation of carbon nanotube-vitrimer composites based on double dynamic covalent bonds: Electrical conductivity, reprocessability, degradability and photo-welding. Polymer 2021, 235, 124280. [Google Scholar] [CrossRef]

- Zhu, C.; Xi, C.; Doro, W.; Wang, T.; Zhang, X.; Jin, Y.; Zhang, W. Tuning the physical properties of malleable and recyclable polyimine thermosets: The effect of solvent and monomer concentration. RSC Adv. 2019, 7, 48303–48307. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; He, J.; Li, Y.-D.; Zhao, X.-L.; Zeng, J.-B. Biobased epoxy vitrimer from epoxidized soybean oil for reprocessable and recyclable carbon fiber reinforced composite. Compos. Commun. 2020, 22, 100445. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional epoxy vitrimers and composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Hubbard, A.M.; Ren, Y.; Papaioannou, P.; Sarvestani, A.; Picu, C.R.; Konkolewicz, D.; Roy, A.K.; Varshney, V.; Nepal, D. Vitrimer composites: Understanding the role of filler in vitrimer applicability. ACS Appl. Polym. Mater. 2022, 4, 6374–6385. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, X.; Liang, K.; Guo, B.; Li, X.; Wang, Z.; Zhang, L. Mechanically robust and recyclable EPDM rubber composites by a green cross-linking strategy. ACS Sustain. Chem. Eng. 2019, 7, 11712–11720. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, Z.; Chen, Y.; Wu, S.; Guo, B. Programming dynamic imine bond into elastomer/graphene composite toward mechanically strong, malleable, and multi-stimuli responsive vitrimer. Compos. Sci. Technol. 2018, 168, 214–223. [Google Scholar] [CrossRef]

- Huang, Q.; Tang, Z.; Wang, D.; Wu, S.; Guo, B. Engineering segregated structures in a cross-linked elastomeric network enabled by dynamic cross-link reshuffling. ACS Macro Lett. 2021, 10, 231–236. [Google Scholar] [CrossRef] [PubMed]

- Qiu, M.; Wu, S.; Tang, Z.; Guo, B. Exchangeable interfacial crosslinks towards mechanically robust elastomer/carbon nanotubes vitrimers. Compos. Sci. Technol. 2018, 165, 24–30. [Google Scholar] [CrossRef]

- Yan, P.; Zhao, W.; Jiang, L.; Wu, B.; Hu, K.; Yuan, Y.; Lei, J. Reconfiguration and shape memory triggered by heat and light of carbon nanotube–polyurethane vitrimer composites. J. Appl. Polym. Sci. 2017, 135, 45784. [Google Scholar] [CrossRef]

- Lucherelli, M.A.; Duval, A.; Avérous, L. Biobased vitrimers: Towards sustainable and adaptable performing polymer materials. Prog. Polym. Sci. 2022, 127, 101515. [Google Scholar] [CrossRef]

- Li, W.; Xiao, L.; Huang, J.; Wang, Y.; Nie, X.; Chen, J. Bio-based epoxy vitrimer for recyclable and carbon fiber reinforced materials: Synthesis and structure-property relationship. Compos. Sci. Technol. 2022, 227, 109575. [Google Scholar] [CrossRef]

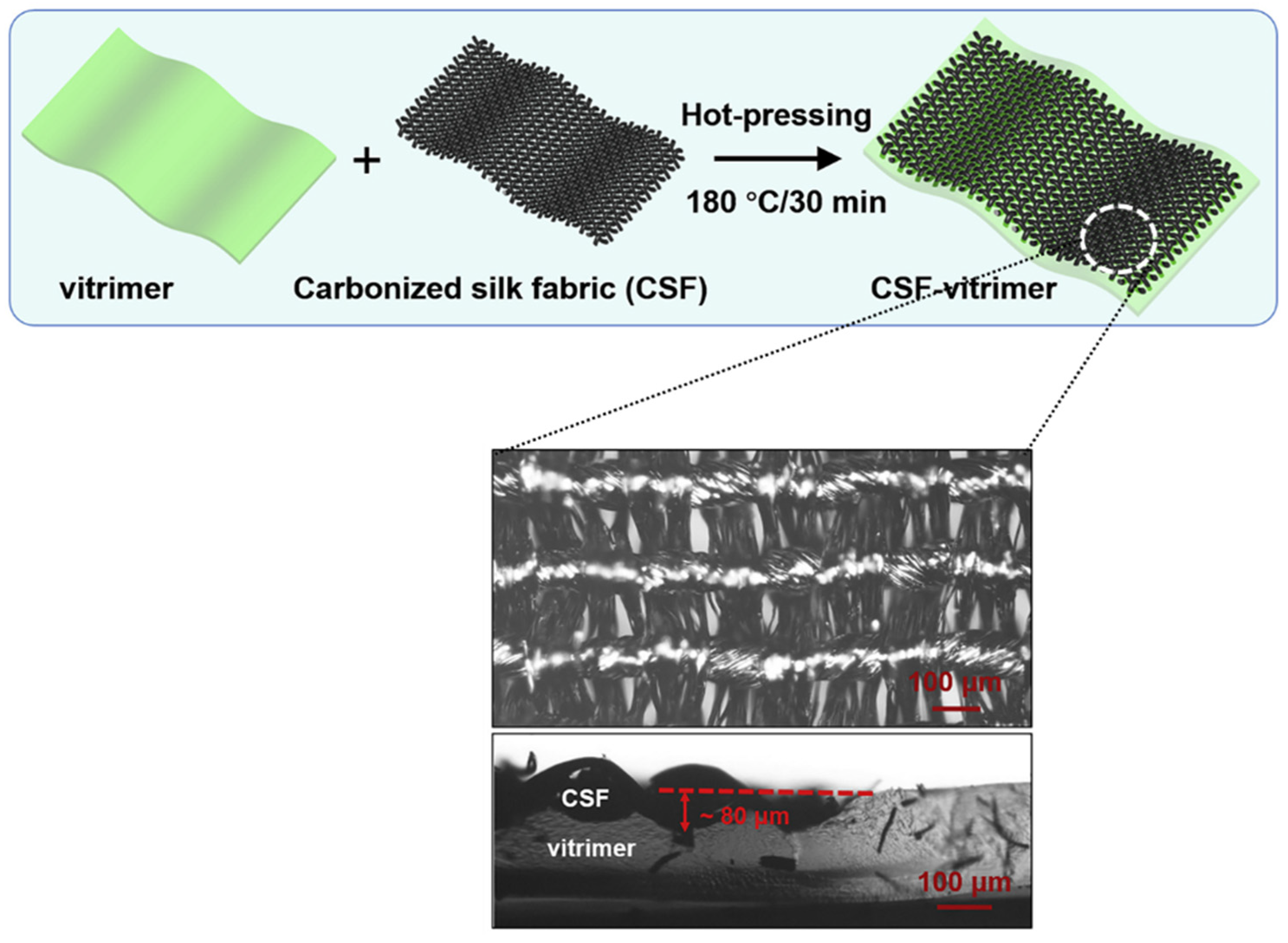

- Xu, Y.; Dai, S.; Bi, L.; Jiang, J.; Zhang, H.; Chen, Y. Catalyst-free self-healing bio-based vitrimer for a recyclable, reprocessable, and self-adhered carbon fiber reinforced composite. Chem. Eng. J. 2022, 429, 132518. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, S.; Zhang, H.; Bi, L.; Jiang, J.; Chen, Y. Reprocessable, self-adhesive, and recyclable carbon fiber-reinforced composites using a catalyst-free self-healing bio-based vitrimer matrix. ACS Sustain. Chem. Eng. 2021, 9, 16281–16290. [Google Scholar] [CrossRef]

- Chen, J.-H.; Liu, B.-W.; Lu, J.-H.; Lu, P.; Tang, Y.-L.; Chen, L.; Wang, Y.-Z. Catalyst-free dynamic transesterification towards a high-performance and fire-safe epoxy vitrimer and its carbon fiber composite. Green Chem. 2022, 24, 6980–6988. [Google Scholar] [CrossRef]

- Yang, W.; Ding, H.; Zhou, W.; Liu, T.; Xu, P.; Puglia, D.; Kenny, J.M.; Ma, P. Design of inherent fire retarding and degradable bio-based epoxy vitrimer with excellent self-healing and mechanical reprocessability. Compos. Sci. Technol. 2022, 230, 109776. [Google Scholar] [CrossRef]

- Ruland, W. Carbon fibers. Adv. Mater. 1990, 2, 528–536. [Google Scholar] [CrossRef]

- Perret, R.; Ruland, W. The microstructure of PAN-base carbon fibres. J. Appl. Crystallogr. 1970, 3, 525–532. [Google Scholar] [CrossRef]

- Chand, S. Review Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, D.-C.J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef] [PubMed]

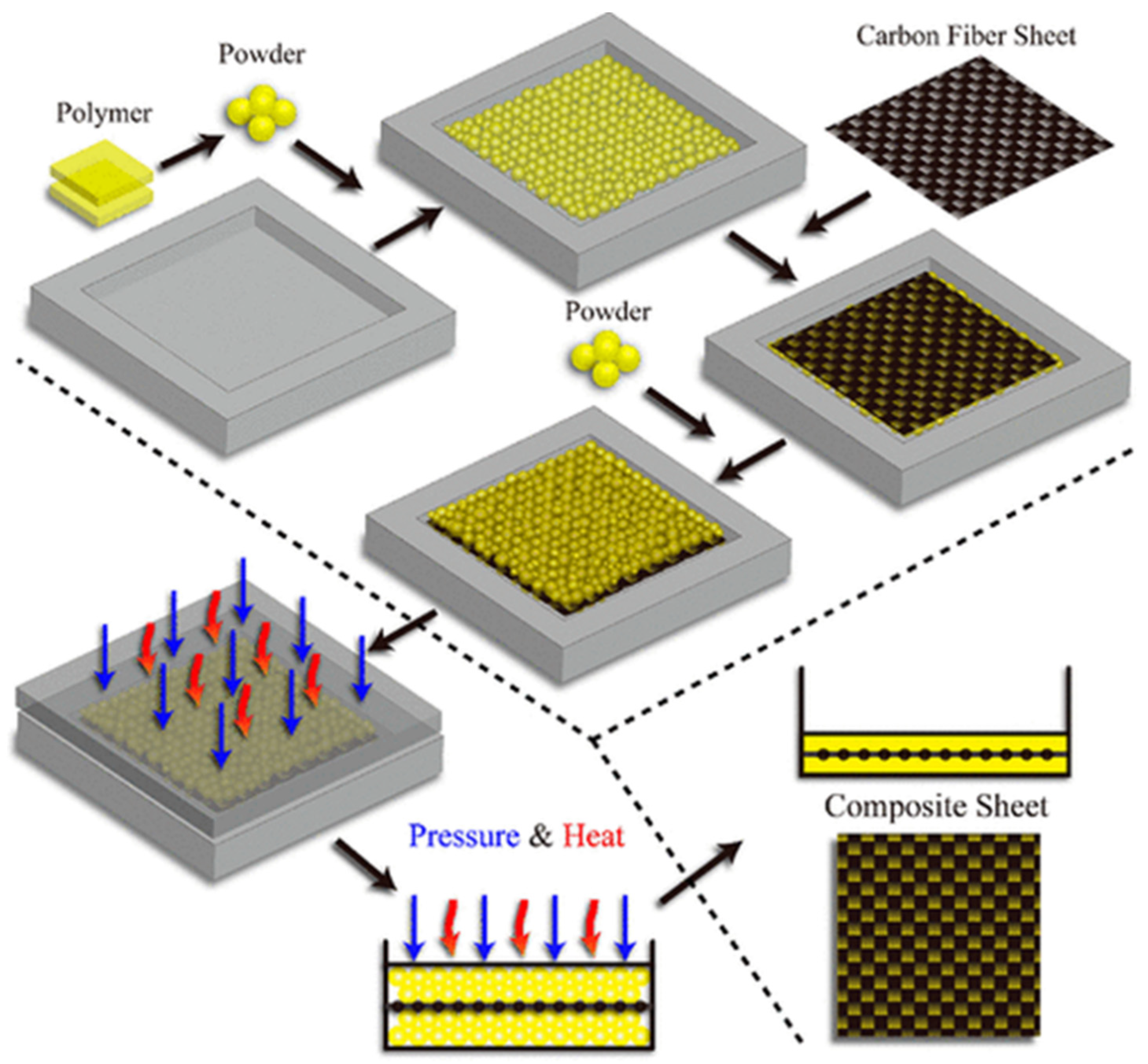

- Yu, L.; Lei, Z.; Sun, X.; Ding, P.; Wesche, A.; Jin, Y.; Zhang, W.; Long, R. Rapid fabrication of fiber-reinforced polyimine composites with reprocessability, repairability, and recyclability. ACS Appl. Polym. Mater. 2021, 3, 5808–5817. [Google Scholar] [CrossRef]

- Tangthana-Umrung, K.; Gresil, M. Interlaminar fracture toughness behaviour of carbon fibre reinforced polymer with epoxy-dicarboxylic acid vitrimer matrix. Compos. Commun. 2022, 32, 101182. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, S. Recent progress in fabrication, structure, and properties of carbon fibers. Polym. Rev. 2012, 52, 234–258. [Google Scholar] [CrossRef]

- Cárdenas, C.B.; Gayraud, V.; Rodriguez, M.E.; Costa, J.; Salaberria, A.M.; de Luzuriaga, A.R.; Markaide, N.; Keeryadath, P.D.; Zapatería, D.C. Study into the mechanical properties of a new aeronautic-grade epoxy-based carbon-fiber-reinforced vitrimer. Polymers 2022, 14, 1223. [Google Scholar] [CrossRef]

- Wang, H.; Liu, H.-C.; Zhang, Y.; Xu, H.; Jin, B.-Q.; Cao, Z.-X.; Wu, H.-T.; Huang, G.-S.; Wu, J.-R. A Triple crosslinking design toward epoxy vitrimers and carbon fiber composites of high performance and multi-shape memory. Chin. J. Polym. Sci. 2021, 39, 736–744. [Google Scholar] [CrossRef]

- Si, H.; Zhou, L.; Wu, Y.; Song, L.; Kang, M.; Zhao, X.; Chen, M. Rapidly reprocessable, degradable epoxy vitrimer and recyclable carbon fiber reinforced thermoset composites relied on high contents of exchangeable aromatic disulfide crosslinks. Compos. Part B Eng. 2020, 199, 108278. [Google Scholar] [CrossRef]

- Yu, L.; Zhu, C.; Sun, X.; Salter, J.; Wu, H.; Jin, Y.; Zhang, W.; Long, R. Rapid fabrication of malleable fiber reinforced composites with vitrimer powder. ACS Appl. Polym. Mater. 2019, 1, 2535–2542. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Zhang, S.; Wei, Y.; He, X.; Wang, J.; Zhang, Y.; Ji, Y. Vitrimer-based soft actuators with multiple responsiveness and self-healing ability triggered by multiple stimuli. Matter 2021, 4, 3354–3365. [Google Scholar] [CrossRef]

- Liu, T.; Hao, C.; Shao, L.; Kuang, W.; Cosimbescu, L.; Simmons, K.L.; Zhang, J. Carbon fiber reinforced epoxy vitrimer: Robust mechanical performance and facile hydrothermal decomposition in pure water. Macromol. Rapid Commun. 2021, 42, e2000458. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Sun, X.; Jin, Y.; Zhang, W.; Long, R. Mechanics of vitrimer particle compression and fusion under heat press. Int. J. Mech. Sci. 2021, 201, 106466. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Ashori, A. Mechanical performance of epoxy/carbon fiber laminated composites. J. Reinf. Plast. Compos. 2014, 33, 733–740. [Google Scholar] [CrossRef]

- Kamble, M.; Vashisth, A.; Yang, H.; Pranompont, S.; Picu, C.R.; Wang, D.; Koratkar, N. Reversing fatigue in carbon-fiber reinforced vitrimer composites. Carbon 2022, 187, 108–114. [Google Scholar] [CrossRef]

- Lorwanishpaisarn, N.; Kasemsiri, P.; Srikhao, N.; Son, C.; Kim, S.; Theerakulpisut, S.; Chindaprasirt, P. Carbon fiber/epoxy vitrimer composite patch cured with bio-based curing agents for one-step repair metallic sheet and its recyclability. J. Appl. Polym. Sci. 2021, 138, 51406. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, A.; Zhang, L.; Chen, Z.; Qin, R.; Liu, Y.; Jiang, X.; Ye, D.; Liu, Z. Recyclable carbon fiber reinforced vanillin-based polyimine vitrimers: Degradation and mechanical properties study. Macromol. Mater. Eng. 2022, 307, 202100893. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhang, L.; Jiang, Q.; Liu, W. An imine-containing epoxy vitrimer with versatile recyclability and its application in fully recyclable carbon fiber reinforced composites. Compos. Sci. Technol. 2020, 199, 108314. [Google Scholar] [CrossRef]

- Zhou, Z.; Kim, S.; Bowland, C.C.; Li, B.; Ghezawi, N.; Lara-Curzio, E.; Hassen, A.; Naskar, A.K.; Rahman, A.; Saito, T. Unraveling a path for multi-cycle recycling of tailored fiber-reinforced vitrimer composites. Cell Rep. Phys. Sci. 2022, 3, 101036. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Hao, C.; Liu, T.; Liu, W.; Fei, M.E.; Shao, L.; Kuang, W.; Simmons, K.L.; Zhang, J. Recyclable CFRPs with extremely high T g: Hydrothermal recyclability in pure water and upcycling of the recyclates for new composite preparation. J. Mater. Chem. 2022, 10, 15623–15633. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Q.; Wang, T. Dual-triggered and thermally reconfigurable shape memory graphene-vitrimer composites. ACS Appl. Mater. Interfaces 2016, 8, 21691–21699. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Pei, Z.; Li, Z.; Wei, Y.; Ji, Y. Making and remaking dynamic 3d structures by shining light on flat liquid crystalline vitrimer films without a mold. J. Am. Chem. Soc. 2016, 138, 2118–2121. [Google Scholar] [CrossRef] [PubMed]

- Weidmann, S.; Volk, P.; Mitschang, P.; Markaide, N. Investigations on thermoforming of carbon fiber reinforced epoxy vitrimer composites. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106791. [Google Scholar] [CrossRef]

- Son, D.; Kang, J.; Vardoulis, O.; Kim, Y.; Matsuhisa, N.; Oh, J.Y.; To, J.W.; Mun, J.; Katsumata, T.; Liu, Y.; et al. An integrated self-healable electronic skin system fabricated via dynamic reconstruction of a nanostructured conducting network. Nat. Nanotechnol. 2018, 13, 1057–1065. [Google Scholar] [CrossRef]

- Zheng, N.; Xu, Y.; Zhao, Q.; Xie, T. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self-healing. Chem. Rev. 2021, 121, 1716–1745. [Google Scholar] [CrossRef]

- Capelot, M.; Montarnal, D.; Tournilhac, F.; Leibler, L. Metal-catalyzed transesterification for healing and assembling of thermosets. J. Am. Chem. Soc. 2012, 134, 7664–7667. [Google Scholar] [CrossRef]

- Hillewaere, X.K.; Du Prez, F.E. Fifteen chemistries for autonomous external self-healing polymers and composites. Prog. Polym. Sci. 2015, 49, 121–153. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, X.; Urban, M.W. Chemical and physical aspects of self-healing materials. Prog. Polym. Sci. 2015, 49–50, 34–59. [Google Scholar] [CrossRef]

- Wu, P.; Liu, L.; Wu, Z. A transesterification-based epoxy vitrimer synthesis enabled high crack self-healing efficiency to fibrous composites. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107170. [Google Scholar] [CrossRef]

- Krishnakumar, B.; Sanka, R.P.; Binder, W.H.; Park, C.; Jung, J.; Parthasarthy, V.; Rana, S.; Yun, G.J. Catalyst free self-healable vitrimer/graphene oxide nanocomposites. Compos. Part B Eng. 2020, 184, 107647. [Google Scholar] [CrossRef]

- Patel, T.; Kim, M.P.; Park, J.; Lee, T.H.; Nellepalli, P.; Noh, S.M.; Jung, H.W.; Ko, H.; Oh, J.K. Self-healable reprocessable triboelectric nanogenerators fabricated with vitrimeric poly(hindered urea) networks. ACS Nano 2020, 14, 11442–11451. [Google Scholar] [CrossRef] [PubMed]

- An, L.; Jin, C.; Li, X.; Zhao, W. Surface degradation assisted welding for vitrimer composites. Mater. Lett. 2022, 328, 133051. [Google Scholar] [CrossRef]

- Titirici, M.-M.; White, R.J.; Brun, N.; Budarin, V.L.; Su, D.S.; del Monte, F.; Clark, J.H.; MacLachlan, M.J. Sustainable carbon materials. Chem. Soc. Rev. 2014, 44, 250–290. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Cui, J.; Hu, G.; Zhang, B. Recycling strategies for vitrimers. Int. J. Smart Nano Mater. 2022, 13, 367–390. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and recyclable CFRP pultruded profile manufactured from an epoxy vitrimer. Polym. Test. 2020, 93, 106931. [Google Scholar] [CrossRef]

- Qiao, Z.; Wang, M.; Jiang, J.; Liu, H.; Wang, M.; Zhao, W.; Wang, Z. High-Performance and Degradable Polybenzoxazine/VU Vitrimer and Its Application for Carbon Fiber Recycling. ACS Sustain. Chem. Eng. 2022, 10, 9113–9122. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Ma, S.; Yu, T.; Xu, X.; Li, Q.; Wang, S.; Han, Y.; Yu, Z.; Zhu, J. Catalyst-free malleable, degradable, bio-based epoxy thermosets and its application in recyclable carbon fiber composites. Compos. Part B Eng. 2021, 211, 108654. [Google Scholar] [CrossRef]

- Wang, S.; Ma, S.; Li, Q.; Xu, X.; Wang, B.; Yuan, W.; Zhou, S.; You, S.; Zhu, J. Facile in situ preparation of high-performance epoxy vitrimer from renewable resources and its application in nondestructive recyclable carbon fiber composite. Green Chem. 2019, 21, 1484–1497. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, B.; Ye, D.; Liu, Z. Fully recyclable carbon fiber reinforced vanillin-based epoxy vitrimers. Eur. Polym. J. 2022, 162, 110927. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, E.; Feng, Z.; Liu, J.; Chen, B.; Liang, L. Degradable bio-based epoxy vitrimers based on imine chemistry and their application in recyclable carbon fiber composites. J. Mater. Sci. 2021, 56, 15733–15751. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, X. Improving the transesterification and electrical conductivity of vitrimers by doping with conductive polymer wrapped carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2017, 99, 15–22. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; Liu, G.-L.; Li, Y.-D.; Weng, Y.; Zeng, J.-B. Biobased high-performance epoxy vitrimer with UV shielding for recyclable carbon fiber reinforced composites. ACS Sustain. Chem. Eng. 2021, 9, 4638–4647. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, Y.; Qian, X.; Chen, Q.; Wei, Y.; Ji, Y. Liquid-crystalline soft actuators with switchable thermal reprogrammability. Angew. Chem. 2020, 132, 4808–4814. [Google Scholar] [CrossRef]

- Kathan, M.; Kovaříček, P.; Jurissek, C.; Senf, A.; Dallmann, A.; Thünemann, A.F.; Hecht, S. Control of imine exchange kinetics with photoswitches to modulate self-healing in polysiloxane networks by light illumination. Angew. Chem. Int. Ed. 2016, 55, 13882–13886. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, V.; Kuang, W.; Fifield, L.S. Carbon Fiber-Based Vitrimer Composites: A Path toward Current Research That Is High-Performing, Useful, and Sustainable. Materials 2024, 17, 3265. https://doi.org/10.3390/ma17133265

Kumar V, Kuang W, Fifield LS. Carbon Fiber-Based Vitrimer Composites: A Path toward Current Research That Is High-Performing, Useful, and Sustainable. Materials. 2024; 17(13):3265. https://doi.org/10.3390/ma17133265

Chicago/Turabian StyleKumar, Vishal, Wenbin Kuang, and Leonard S. Fifield. 2024. "Carbon Fiber-Based Vitrimer Composites: A Path toward Current Research That Is High-Performing, Useful, and Sustainable" Materials 17, no. 13: 3265. https://doi.org/10.3390/ma17133265

APA StyleKumar, V., Kuang, W., & Fifield, L. S. (2024). Carbon Fiber-Based Vitrimer Composites: A Path toward Current Research That Is High-Performing, Useful, and Sustainable. Materials, 17(13), 3265. https://doi.org/10.3390/ma17133265