A Split-Plot Experimentation Strategy for Making Causal Inferences in Advanced Materials: Auxetic Polyurethane Foam Manufacturing and Processing Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design and Analysis

2.2. Materials and Fabrication

2.3. Poisson’s Ratio Calculation

3. Results and Discussion

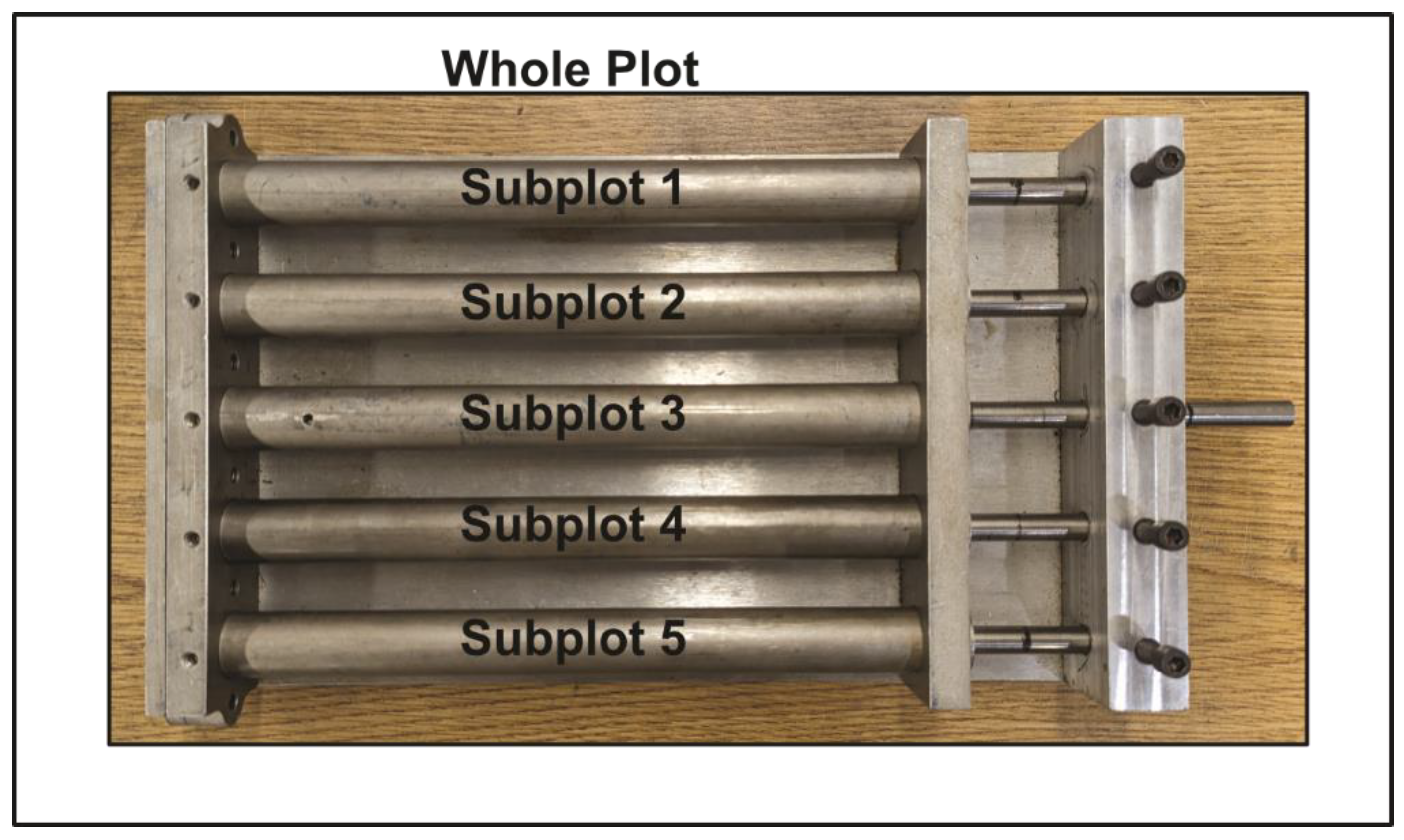

3.1. Fabrication of Auxetic PU Foams, Factor Selection, and Factor Levels

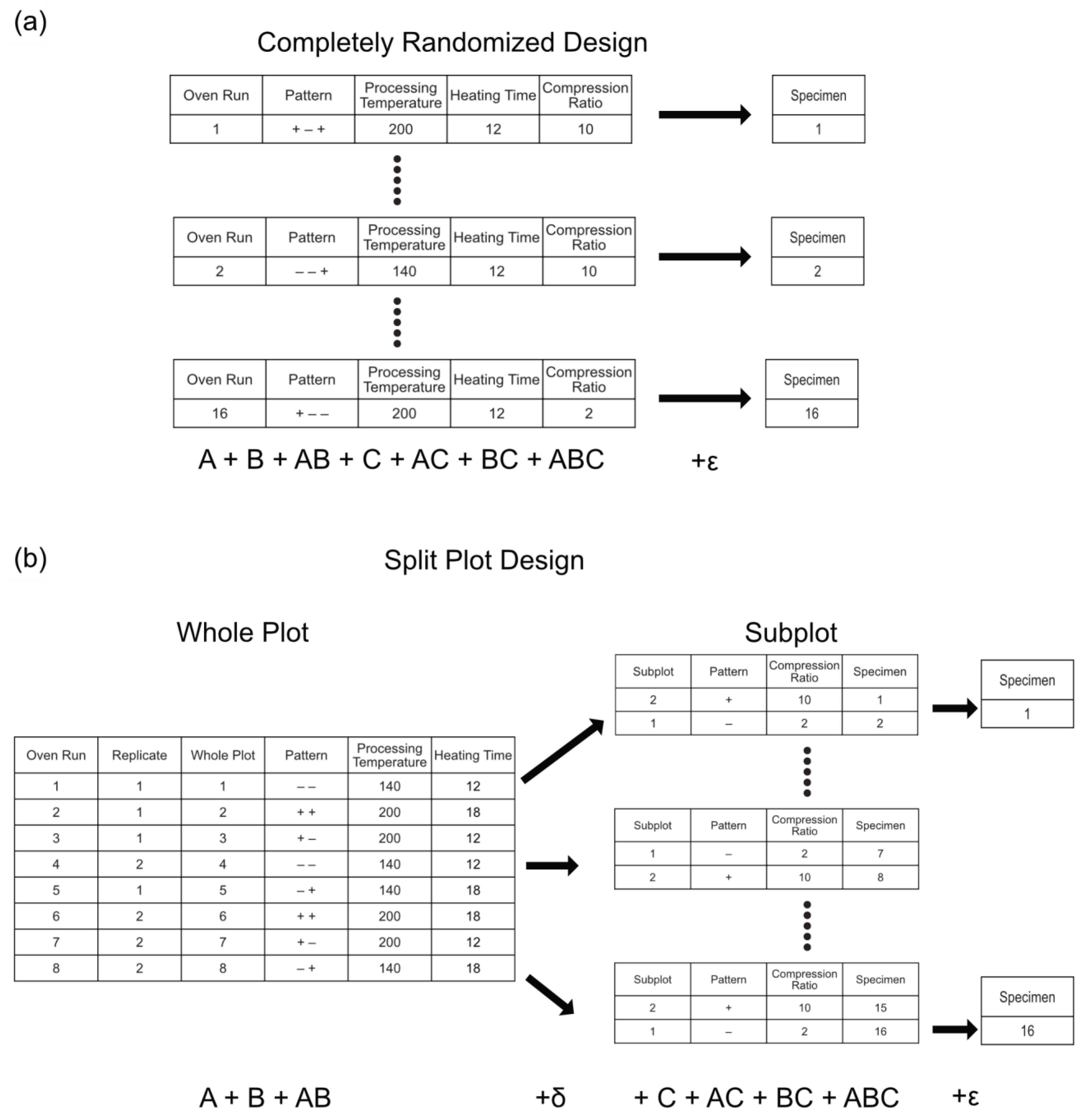

3.2. Experimental Design and Design Execution

3.3. Evaluation of Experimental Design

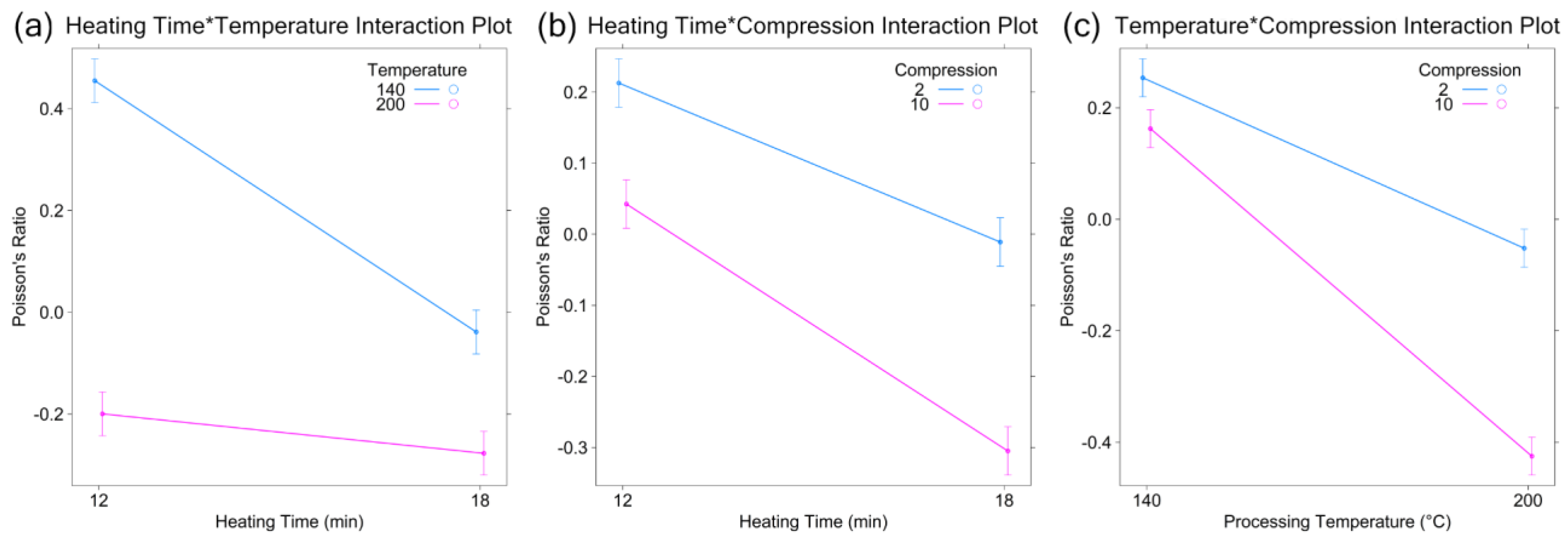

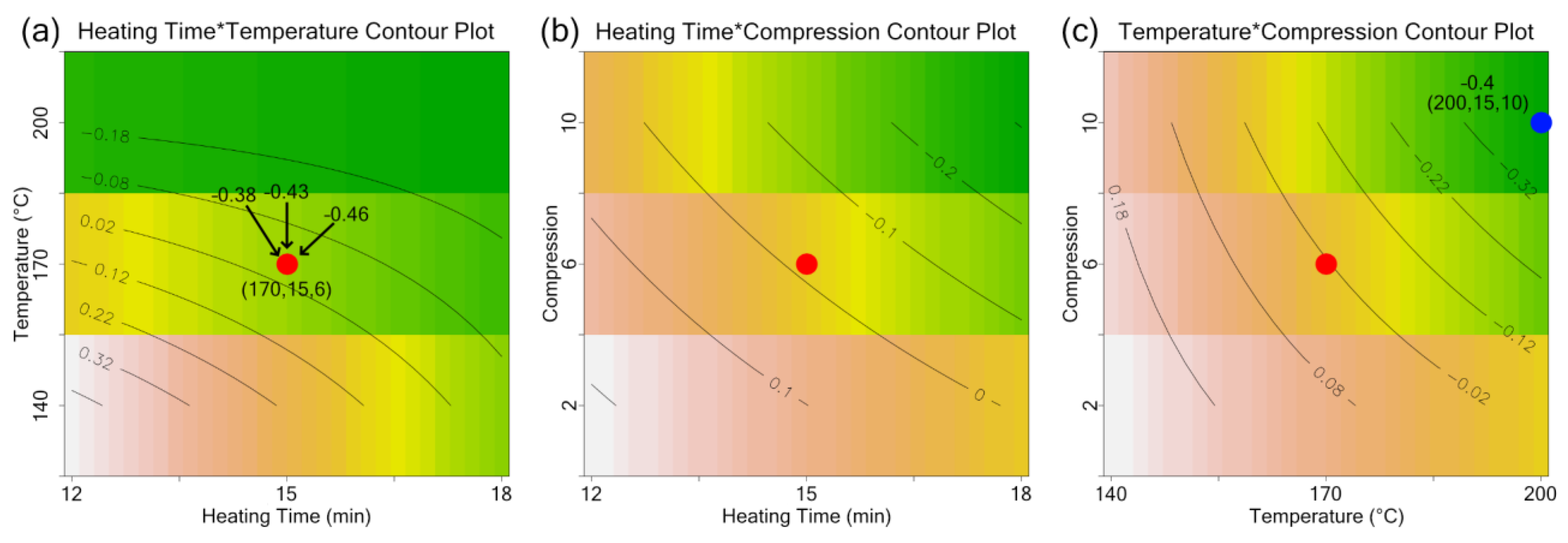

3.4. Model Construction and Validation

3.5. Advantage of Using Split-Plot Designs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pearl, J.; Glymour, M.; Jewell, N.P. Causal Inference in Statistics: A Primer; Reprinted with revisions; Wiley: Chichester, UK, 2021. [Google Scholar]

- Jones, B.; Nachtsheim, C.J. Split-Plot Designs: What, Why, and How. J. Qual. Technol. 2009, 41, 340–361. [Google Scholar] [CrossRef]

- Fraser, S.; Barsotti, A.; Rogich, D. Sorting out materials issues. Resour. Policy 1988, 14, 3–20. [Google Scholar] [CrossRef]

- Curlee, T.R.; Das, S.; Lee, R.; Trumble, D. Advanced Materials: Information and Analysis Needs; ORNL: Oak Ridge, TN, USA, 1990; ORNL/TM-11593; p. 6567025. [Google Scholar] [CrossRef]

- Wood, D.L.; Li, J.; An, S.J. Formation Challenges of Lithium-Ion Battery Manufacturing. Joule 2019, 3, 2884–2888. [Google Scholar] [CrossRef]

- Mathieu, R.; Baghdadi, I.; Briat, O.; Gyan, P.; Vinassa, J.-M. D-optimal design of experiments applied to lithium battery for ageing model calibration. Energy 2017, 141, 2108–2119. [Google Scholar] [CrossRef]

- Li, J.; Fleetwood, J.; Hawley, W.B.; Kays, W. From Materials to Cell: State-of-the-Art and Prospective Technologies for Lithium-Ion Battery Electrode Processing. Chem. Rev. 2022, 122, 903–956. [Google Scholar] [CrossRef] [PubMed]

- Lucu, M.; Martinez-Laserna, E.; Gandiaga, I.; Camblong, H. A critical review on self-adaptive Li-ion battery ageing models. J. Power Sources 2018, 401, 85–101. [Google Scholar] [CrossRef]

- Fung, Y. Foundations of Solid Mechanics, 1st ed.; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1965. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Dover Publications: New York, NY, USA, 1965. [Google Scholar]

- Evans, K.E.; Alderson, A. Auxetic Materials: Functional Materials and Structures from Lateral Thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Yeganeh-Haeri, A.; Weidner, D.J.; Parise, J.B. Elasticity of alpha-cristobalite: A silicon dioxide with a negative Poisson’s ratio. Science 1992, 257, 650–652. [Google Scholar] [CrossRef]

- Gunton, D.J.; Saunders, G.A. The Young’s modulus and Poisson’s ratio of arsenic, antimony and bismuth. J. Mater. Sci. 1972, 7, 1061–1068. [Google Scholar] [CrossRef]

- Mardling, P.; Alderson, A.; Jordan-Mahy, N.; Le Maitre, C.L. The use of auxetic materials in tissue engineering. Biomater. Sci. 2020, 8, 2074–2083. [Google Scholar] [CrossRef]

- Lakes, R. Foam Structures with a Negative Poisson’s Ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Li, Z.-M.; Shi, W.; Xie, B.-H.; Yang, M.-B. Review on auxetic materials. J. Mater. Sci. 2004, 39, 3269–3279. [Google Scholar] [CrossRef]

- Alderson, A. A triumph of lateral thought. Chem. Ind. 1999, 17, 384–391. [Google Scholar]

- Chen, X.; Liu, C.; Wadsworth, M.; Zeng, E.Z.; Driscoll, T.; Zeng, C.; Li, Y. Surface Engineering of Auxetic Scaffolds for Neural and Vascular Differentiation from Human Pluripotent Stem Cells. Adv. Healthc. Mater. 2023, 12, 2202511. [Google Scholar] [CrossRef] [PubMed]

- Bhullar, S.K. Characterization of auxetic polyurethanes foam for biomedical implants. e-Polymers 2014, 14, 441–447. [Google Scholar] [CrossRef]

- Lim, T.C.; Alderson, A.; Alderson, K.L. Experimental studies on the impact properties of auxetic materials: Experimental studies on the impact properties of auxetic materials. Phys. Status Solidi B 2014, 251, 307–313. [Google Scholar] [CrossRef]

- Foster, L.; Peketi, P.; Allen, T.; Senior, T.; Duncan, O.; Alderson, A. Application of Auxetic Foam in Sports Helmets. Appl. Sci. 2018, 8, 354. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing, version 4.4.0; R Foundation for Statistical Computing: Vienna, Austria, 2023. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using lme4. J. Stat. Soft. 2015, 67, 48. [Google Scholar] [CrossRef]

- Kuznetsova, A.; Brockhoff, P.B.; Christensen, R.H.B. lmerTest Package: Tests in Linear Mixed Effects Models. J. Stat. Soft. 2017, 82, 1–26. [Google Scholar] [CrossRef]

- Fox, J.; Weisberg, S. An R Companion to Applied Regression, 3rd ed.; SAGE: Los Angeles, CA, USA; London, UK; New Delhi, India; Singapore; Washington, DC, USA; Melbourne, VIC, Australia, 2019. [Google Scholar]

- Tremblay, A.; Canada, S.; Ransijn, J.; University of Copenhagen. LMERConvenienceFunctions: Model Selection and Post-Hoc Analysis for (G)LMER Models, version 3.0; 2020. Available online: https://CRAN.R-project.org/package=LMERConvenienceFunctions (accessed on 29 June 2024).

- Scarpa, F.; Pastorino, P.; Garelli, A.; Patsias, S.; Ruzzene, M. Auxetic compliant flexible PU foams: Static and dynamic properties. Phys. Stat. Sol. (B) 2005, 242, 681–694. [Google Scholar] [CrossRef]

- Chan, N.; Evans, K.E. Fabrication methods for auxetic foams. J. Mater. Sci. 1997, 32, 5945–5953. [Google Scholar] [CrossRef]

- Friis, E.A.; Lakes, R.S.; Park, J.B. Negative Poisson’s ratio polymeric and metallic foams. J. Mater. Sci. 1988, 23, 4406–4414. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Lakes, R.; Butenhoff, A. Influence of Cell Size on Re-Entrant Transformation of Negative Poisson’s Ratio Reticulated Polyurethane Foams. Cell. Polym. 2001, 20, 373–385. [Google Scholar] [CrossRef]

- Bianchi, M.; Frontoni, S.; Scarpa, F.; Smith, C.W. Density change during the manufacturing process of PU-PE open cell auxetic foams. Phys. Stat. Sol. (B) 2011, 248, 30–38. [Google Scholar] [CrossRef]

- Bianchi, M.; Scarpa, F.; Smith, C.W.; Whittell, G.R. Physical and thermal effects on the shape memory behaviour of auxetic open cell foams. J. Mater. Sci. 2010, 45, 341–347. [Google Scholar] [CrossRef]

- Bianchi, M.; Scarpa, F.L.; Smith, C.W. Stiffness and energy dissipation in polyurethane auxetic foams. J. Mater. Sci. 2008, 43, 5851–5860. [Google Scholar] [CrossRef]

- Critchley, R.; Smy, V.; Corni, I.; Wharton, J.A.; Walsh, F.C.; Wood, R.J.K.; Stokes, K.R. Experimental and computation assessment of thermomechanical effects during auxetic foam fabrication. Sci. Rep. 2020, 10, 18301. [Google Scholar] [CrossRef]

- Duncan, O.; Allen, T.; Foster, L.; Gatt, R.; Grima, J.N.; Alderson, A. Controlling Density and Modulus in Auxetic Foam Fabrications—Implications for Impact and Indentation Testing. Proceedings 2018, 2, 250. [Google Scholar] [CrossRef]

- Duncan, O.; Clegg, F.; Essa, A.; Bell, A.M.T.; Foster, L.; Allen, T.; Alderson, A. Effects of Heat Exposure and Volumetric Compression on Poisson’s Ratios, Young’s Moduli, and Polymeric Composition During Thermo-Mechanical Conversion of Auxetic Open Cell Polyurethane Foam. Phys. Stat. Sol. (B) 2019, 256, 1800393. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, C. On the successful fabrication of auxetic polyurethane foams: Materials requirement, processing strategy and conversion mechanism. Polymer 2016, 87, 98–107. [Google Scholar] [CrossRef]

- Bianchi, M.; Scarpa, F.; Smith, C.W. Shape memory behaviour in auxetic foams: Mechanical properties. Acta Mater. 2010, 58, 858–865. [Google Scholar] [CrossRef]

- Lisiecki, J.; Kłysz, S.; Błażejewicz, T.; Gmurczyk, G.; Reymer, P. Tomographic examination of auxetic polyurethane foam structures: Tomographic examination of auxetic polyurethane foam structures. Phys. Stat. Sol. (B) 2014, 251, 314–320. [Google Scholar] [CrossRef]

- Yates, F. Complex Experiments. Suppl. J. R. Stat. Soc. 1935, 2, 181. [Google Scholar] [CrossRef]

- Yates, F. The Design and Analysis of Factorial Experiments; Imperial Bureau of Soil Science: Harpenden, UK, 1937. [Google Scholar]

- Box, G.; Jones, S. Split-plot designs for robust product experimentation. J. Appl. Stat. 1992, 19, 3–26. [Google Scholar] [CrossRef]

- Bisgaard, S. The Design and Analysis of 2k–p × 2q–r Split Plot Experiments. J. Qual. Technol. 2000, 32, 39–56. [Google Scholar] [CrossRef]

- Hinkelmann, K.; Kempthorne, O.; Hinkelmann, K. (Eds.) Design and Analysis of Experiments, 2nd ed.; Wiley series in probability and statistics; Wiley-Interscience: Hoboken, NJ, USA, 2008. [Google Scholar]

- Najarian, F.; Alipour, R.; Shokri Rad, M.; Nejad, A.F.; Razavykia, A. Multi-objective optimization of converting process of auxetic foam using three different statistical methods. Measurement 2018, 119, 108–116. [Google Scholar] [CrossRef]

- Abedini, N.H.Z.; Nourani, A.; Mohseni, M.; Hosseini, N.; Norouzi, S.; Bakhshayesh, P.R. Effects of geometrical and processing parameters on mechanical properties of auxetic polyurethane foams. SN Appl. Sci. 2022, 4, 162. [Google Scholar] [CrossRef]

- Vining, G.G.; Kowalski, S.M.; Montgomery, D.C. Response Surface Designs within a Split-Plot Structure. J. Qual. Technol. 2005, 37, 115–129. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Pignatiello, J.J.; Ramberg, J.S. Top ten triumphs and tragedies of genichi taguchi. Qual. Eng. 1991, 4, 211–225. [Google Scholar] [CrossRef]

- Taguchi, G.; Chowdhury, S.; Wu, Y. Taguchi’s Quality Engineering Handbook, 1st ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar] [CrossRef]

- Pignatiello, J.J. An Overview of the Strategy and Tactics of Taguchi. IIE Trans. 1988, 20, 247–254. [Google Scholar] [CrossRef]

| Observational Unit | Oven Run | Pattern | Processing Temperature | Heating Time | Compression Ratio |

|---|---|---|---|---|---|

| 1 | 1 | + − + | 200 | 12 | 10 |

| 2 | 2 | − − + | 140 | 12 | 10 |

| 3 | 3 | − + − | 140 | 18 | 2 |

| 4 | 4 | − + + | 140 | 18 | 10 |

| 5 | 5 | + − + | 200 | 12 | 10 |

| 6 | 6 | + + − | 200 | 18 | 2 |

| 7 | 7 | + − − | 200 | 12 | 2 |

| 8 | 8 | − − − | 140 | 12 | 2 |

| 9 | 9 | + + − | 200 | 18 | 2 |

| 10 | 10 | + + + | 200 | 18 | 10 |

| 11 | 11 | − − + | 140 | 12 | 10 |

| 12 | 12 | − + − | 140 | 18 | 2 |

| 13 | 13 | + + + | 200 | 18 | 10 |

| 14 | 14 | − + + | 140 | 18 | 10 |

| 15 | 15 | − − − | 140 | 12 | 2 |

| 16 | 16 | + − − | 200 | 12 | 2 |

| Observational Unit | Oven Run | Whole Plot | Pattern | Processing Temperature | Heating Time | Compression Ratio |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | − − + | 140 | 12 | 10 |

| 2 | 1 | 1 | − − − | 140 | 12 | 2 |

| 3 | 2 | 2 | + + + | 200 | 18 | 10 |

| 4 | 2 | 2 | + + − | 200 | 18 | 2 |

| 5 | 3 | 3 | + − − | 200 | 12 | 2 |

| 6 | 3 | 3 | + − + | 200 | 12 | 10 |

| 7 | 4 | 4 | − − − | 140 | 12 | 2 |

| 8 | 4 | 4 | − − + | 140 | 12 | 10 |

| 9 | 5 | 5 | − + − | 140 | 18 | 2 |

| 10 | 5 | 5 | − + + | 140 | 18 | 10 |

| 11 | 6 | 6 | + + + | 200 | 18 | 10 |

| 12 | 6 | 6 | + + − | 200 | 18 | 2 |

| 13 | 7 | 7 | + − + | 200 | 12 | 10 |

| 14 | 7 | 7 | + − − | 200 | 12 | 2 |

| 15 | 8 | 8 | − + + | 140 | 18 | 10 |

| 16 | 8 | 8 | − + − | 140 | 18 | 2 |

| Source of Variation | Degrees of Freedom (DF) | Expected Mean Square (EMS) | Sum of Squares (SS) | Mean Squares (MS) | F-Statistic (F0) |

|---|---|---|---|---|---|

| Temperature (A) | a − 1 | ||||

| Heating Time (B) | b − 1 | ||||

| AB | (a − 1)(b − 1) | ||||

| ErrorWP | ab(r − 1) | ||||

| Compression Ratio (C) | c − 1 | ||||

| AC | (a − 1)(c − 1) | ||||

| BC | (b − 1)(c − 1) | ||||

| ABC | (a − 1)(b − 1)(c − 1) | ||||

| ErrorSP | ab(c − 1)(r − 1) |

| Effect | DF | SS | MS | F0 | p-Value |

|---|---|---|---|---|---|

| Temperature (A) | 1 | 0.7979 | 0.7979 | 550.7 | 1.95 × 10−5 * |

| Heating Time (B) | 1 | 0.3263 | 0.3263 | 225.3 | 1.15 × 10−4 * |

| AB | 1 | 0.1733 | 0.1733 | 119.6 | 3.97 × 10−4 * |

| WPError | 4 | 0.0058 | 0.0015 | ||

| Compression Ratio (C) | 1 | 0.2155 | 0.2155 | 627.1 | 1.51 × 10−5 * |

| AC | 1 | 0.0794 | 0.0794 | 230.9 | 1.09 × 10−4 * |

| BC | 1 | 0.0153 | 0.0153 | 44.56 | 2.62 × 10−3 * |

| ABC | 1 | 0.0005 | 0.0005 | 1.314 | 0.3156 |

| SPError | 4 | 0.0014 | 0.0003 | ||

| Total | 15 | 1.615 |

| Term | Coefficient | 95% CI |

|---|---|---|

| Intercept | −0.015 | −0.030, 0 |

| Temperature (A) | −0.223 | −0.238, −0.208 |

| Time (B) | −0.143 | −0.158, −0.128 |

| AB | 0.104 | 0.089, 0.119 |

| Compression (C) | −0.116 | −0.124, −0.108 |

| AC | −0.070 | −0.079, −0.062 |

| BC | −0.031 | −0.039, −0.022 |

| Observational Unit | Whole Plot | Temperature | Time | Cooling | Radial Compression | Axial Compression |

|---|---|---|---|---|---|---|

| 1 | 1 | 135 | 15 | Water | 1.58 | 1.17 |

| 2 | 1 | 135 | 15 | Water | 2.53 | 1.17 |

| 3 | 1 | 135 | 15 | Water | 1.58 | 3 |

| 4 | 1 | 135 | 15 | Water | 2.53 | 3 |

| … | … | … | … | … | … | … |

| 32 | 8 | 135 | 12 | Water | 1.58 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wadsworth, M.S.; Deloyer, M.J.; Vanli, O.A.; Zeng, C. A Split-Plot Experimentation Strategy for Making Causal Inferences in Advanced Materials: Auxetic Polyurethane Foam Manufacturing and Processing Analysis. Materials 2024, 17, 3280. https://doi.org/10.3390/ma17133280

Wadsworth MS, Deloyer MJ, Vanli OA, Zeng C. A Split-Plot Experimentation Strategy for Making Causal Inferences in Advanced Materials: Auxetic Polyurethane Foam Manufacturing and Processing Analysis. Materials. 2024; 17(13):3280. https://doi.org/10.3390/ma17133280

Chicago/Turabian StyleWadsworth, Matthew S., Md Jahan Deloyer, Omer Arda Vanli, and Changchun Zeng. 2024. "A Split-Plot Experimentation Strategy for Making Causal Inferences in Advanced Materials: Auxetic Polyurethane Foam Manufacturing and Processing Analysis" Materials 17, no. 13: 3280. https://doi.org/10.3390/ma17133280

APA StyleWadsworth, M. S., Deloyer, M. J., Vanli, O. A., & Zeng, C. (2024). A Split-Plot Experimentation Strategy for Making Causal Inferences in Advanced Materials: Auxetic Polyurethane Foam Manufacturing and Processing Analysis. Materials, 17(13), 3280. https://doi.org/10.3390/ma17133280